See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/260596286

Glutaraldehyde-tanned leather treated with tocopherol.

Article in Journal- American Leather Chemists Association · March 2005

CITATION

1

1 author:

Cheng-Kung Liu

United States Department of Agriculture

223 PUBLICATIONS 2,401 CITATIONS

SEE PROFILE

READS

594

Some of the authors of this publication are also working on these related projects:

Developing value-added products from wool View project

All content following this page was uploaded by Cheng-Kung Liu on 23 June 2015.

The user has requested enhancement of the downloaded file.

102

G

LUTARALDEHYDE

-

TANNED

L

EATHER

T

REATED

WITH

T

OCOPHEROL

a by

C HENG -K UNG L IU ,* N ICHOLAS P. L ATONA , AND J OSEPH L EE

United States Department of Agriculture,** Agricultural Research Service

Eastern Regional Research Center

600 E AST M ERMAID L ANE

W YNDMOOR , PA 19038-8598

Non-chrome-tanned (chrome-free) leather has gradually gained commercial importance, particularly for automobile upholstery applications. UV and heat resistance are very important qualities for automobile applications. We developed an environmentally friendly finishing process that will improve the UV- and heat resistance of automobile upholstery leather. Tocopherol (Vitamin E) is a potent free radical scavenger and highly protective agent for collagen fibers against UV damage. We previously reported that the application of tocopherol to the grain layer of chrome-tanned leather improved its durability. The current study focuses on non-chrome-tanned leather made with a glutaraldehyde tanning process. We applied tocopherol to the grain layer of that leather and also studied the addition of tocopherol to the fatliquoring drums. Following exposure in a Fade-Ometer, the treated samples were evaluated by colorimetry and mechanical testing for the efficacy of UV- and heat resistance. A polarizing microscope equipped with a Berek compensator was employed to determine the birefringence of the untreated and treated leather collagen fibers to determine the treatment effects on the degree of orientation. Data showed that leather coated with tocopherol exhibited significant improvement in tensile strength retention and color fading resistance against UV radiation and heat. Leather fatliquored with tocopherol, however, did not show a similar improvement.

I

A

BSTRACT

NTRODUCTION the early 1960's.

1-5 It has become the most common alternative tanning agent to chrome salts, because it is less expensive, is readily available, and is highly soluble in aqueous solution. In recent years, it has been the dominant tanning agent for preparation of chrome-free leather. The chemistry of fixation of glutaraldehyde to collagen is not fully understood. Presumably, it involves crossslinking by the reaction of an aldehyde group with an amino group of lysine or hydroxylysine or an aldol condensation between two adjacent aldehydes.

6 Although the majority of leather is tanned using Cr(III) salts, environmental concerns over the use and disposal of chrome-tanned leather encourage the use of chrome-free leather, particularly in the European automotive leather markets.

7 Presently there is an increasing demand for the domestic production of automotive leather.

8 The quality of chrome-free leather such as glutaraldehyde-tanned leather in some respects is inferior to that of chrome-tanned leather, for example in colorfastness and thermal stability.

9,10 Leather for car interiors is required to meet exceptionally high quality standards. Consumers expect leather to be able to withstand exposure to extreme and varying temperatures, light, moisture and mechanical loading conditions over time. Most automobile leather is colored to improve its appearance and aesthetic value.

Sunlight on the other hand is a powerful form of energy that can break up colored molecules into smaller pieces and can cause a yellowing or bleaching effect. If chrome-free leather is used for instrument panels and consoles, the problem of shrinkage due to poor heat resistance is especially acute, as temperatures well over 100°C can be reached. The poor lightfastness of crust leathers prevents the use of light pigments or dyes and, therefore, more natural looking or aniline finishes for leather. When using such leather in automotive applications, these inadequacies are of paramount importance, and they need to be studied to find ways of producing lightfast leather with improved thermostability.

Glutaraldehyde tanning was developed by Filachione et al .

in the Eastern Regional Research Center (ARS, ERRC) in

*Corresponding Author. (e-mail address: cliu@errc.ars.usda.gov).

**Mention of trade names or commercial products in this article is solely for the purpose of providing specific information and does not imply recommendation or endorsement by the U.S. Department of Agriculture.

a A Technical Paper based on a presentation at the 100th annual meeting of the American Leather Chemists Association at the

Chase Park Plaza, St. Louis, Missouri on June 16 - 20, 2004

JALCA, VOL. 100, 2005

UV AND HEAT RESISTANCE 103

Many studies demonstrated physico-chemical changes of collagen induced by UV radiation.

11,12 Sionkowska reported that solar radiation induces photodegradation of collagen.

13

Fujimori revealed that a solution of collagen, after UV irradiation, loses the ability to form natural fibrils.

14 For synthetic polymers, UV absorbents such as hydroxybenzophenones have been widely used to improve the light stability of both plastics and their colorants.

15 UV absorbents are also commonly used in skin care products such as sunscreens.

16 They include benzophenones, cinnamates and salicylates. Contact sensitivity or allergic reactions have been reported with benzophenones.

17 Cinnamates are effective UV blockers but have poor waterproofness. They are generally used in combination with other agents; an example is octylmethyl cinnamate. Salicylates are also often used in sunscreens, and they are water-insoluble.

Antioxidants are often included in sunscreens as free-radical scavengers. Tocopherol (vitamin E) is a potent free radical scavenger and a highly protective agent against UV skin damage.

18,19 It is a light yellow colored oil and a fat-soluble vitamin. The principal role of tocopherol as an antioxidant must be to neutralize free radicals that could initiate a chain reaction, resulting in the formation of peroxides and products of their subsequent degradation.

20 Thermal stability of leather may be improved by using antioxidants such as toco-

TABLE I

Deliming and Pretanning

Dilution Process

1:5

1:10

1:10

1:5

% Product

Wash

Drain

Delime

300

150

1

0.8

0.15

Bate

Drain

Washed

Drain

Pickle

200

Pretannage

30

7

1

0.5

1.6

1.5

2

3

0.1

Basification 0.25

Water

Water

Decatal ES-Deliming Agent

Decatal ES-Deliming Agent

Rohapon 6000-Bating Agent

Water

Water

Sodium Chloride

Lipoderm Liq NB1C-Fatliquor

Formic Acid

Sulfuric Acid

Sellatan CF Liq

Sellatan RL-Synth. Replacement Tannin

Sellatan FL-Synth. Replacement Tannin

Busan 30 L-Biocide

Sodium Bicarbonate

0.15

0.15

Sodium Bicarbonate

Sodium Bisulfite

Next day check pH. Horse up overnight pherols to protect against thermal oxidation, thereby improving the stability of the triple helical structure of the collagen molecules. We recently experimented with the application of α -tocopherol to the grain layer of chrometanned leather. Results showed that chrome-tanned leather treated with α -tocopherol yielded a significant improvement in mechanical strength and softness and, more importantly, increased strength retention and color fading resistance against UV radiation and heat. However, how the α tocopherol treatments affect the fine structure of collagen fibers is unknown. Collagen fibers are the building blocks of leather. The need to study the fine structure of collagen fibers has led us to employ a polarizing microscope to measure the birefringence of fibers and thereby gain insights on the effects of UV and heat on the fine structure of fibers.

Birefringence is a physical quantity associated with the degree of orientation of the molecular chains in the fibers.

The current study focuses on the non-chrome-tanned leather made with a glutaraldehyde tanning process. We applied tocopherol to the grain layer of leather and also studied the addition of tocopherol to the fatliquoring process.

Following exposure in a Fade-Ometer, the treated samples were evaluated by colorimetry and mechanical testing for their UV and heat resistance. o C

27

27

18

18

Time (min.) pH RPM

15 6

15

30

120

10

10

15

30

90

60

60

20

Overnight

8.3-8.5

2.7-2.9

3.8-4.0

6

6

6

6

16

6

6

6

16

16

6

JALCA, VOL. 100, 2005

104 UV AND HEAT RESISTANCE

E

XPERIMENTAL

Materials And Procedures

Fresh hides were purchased from Moyer Packing Co.

(Souderton, PA ) and frozen at the ERRC. The hides were thawed and cut into specimens. The hides were unhaired using a sulfide-free unhairing process developed by Marmer et al . at ERRC.

23 The deliming and pretanning steps are listed in Table I. The sources of chemicals are: Decatal ES

(BASF, Charlotte, NC), Rohapon 6000 (TFL, Greensboro,

NC), Lipoderm NB1C (BASF, Charlotte, NC), Sellatan

CFL (TFL, Greensboro, NC), Irgatan RL (TFL, Greensboro,

NC), Irgatan FL (TFL, Greensboro, NC), Busan 30L

(Buckman Laboratories Inc., Memphis, TN). After unhairing the samples were lime-split to a thickness between 1.0

and 1.5 mm. The samples were then pretanned, retanned and horsed up overnight. Table II lists the sequential processes for tanning, retanning, dyeing and fatliquoring used for the preparation of the chrome-free tocopherol-coated samples. The source of chemicals are: Saform acid

(Sentury Custom Services, Allamuchy, NJ), Sellatan CFL

(TFL, Greensboro, NC), Sellatan RL (TFL, Greensboro,

NC), Lipsol SQ (Strucktol/Schill and Seilacher, Stow, OH), and Basyntan DLE (BASF, Charlotte, NC), Sellatan FL

(TFL, Greensboro, NC), Tara (Tannin Corp., Peabody, MA),

Eureka 950R (Atlas Refinery, Newark, NJ), Lipsol SQ,

Magnopol SOF-G (TFL, Greensboro, NC), Derma Red BG

(Clariant Corp., Fair Lawn, NJ). The leather was then drained, washed at 50 °C and then drained again. The leather was thereafter placed in plastic bags until it was toggle-dried at ambient temperature. The shrinkage temperature on the dried test pieces was found to be 85 °C. We achieved a very consistent and good shrink temperature that indicates uniform processing. The samples were then wet

TABLE II

Tanning, Retanning, and Fatliquoring Processes for Tocopherol Coatings

Dilution Process % Product o C Time (min.) pH

1:10

1:5

1:5

1:5

1:10

Wash

Drain

Float

Tannage

Basification

Retan

200

Retan

Fatliquoring

Dyeing

3.5

6

Next day check pH

Drain

Wash 200

1

22

6

3

3

2

Drain

Float

Fatliquoring

150

0.4

2

0.8

0.2

2

2

Retan

150

6

2.5

4

2

1

0.5

Add

Drain

Wash

Drain

200

Water

Water

Sentry-Saform Acid-Non Swelling Acid

Sellatan CF Liq

Sodium Formate

Sodium Bicarbonate

Sellatan RL-Synth. Replacement Tannin

Lipsol SQ-Lecithin Fatliquor

Basyntan DLE

Sellatan RL-Synth. Replacement Tannin

Sellatan FL-Synth. Replacement Tannin

Tara-Vegetable Extract

Eureka 950R-Fatliquor

Lipsol SQ-Lecithin Fatliquor

Magnapol SOF-G-Polymeric Softener

Derma Red BG-Dye

Water

Water 50

Eureka 950R-Fatliquor

Lipsol SQ-Lecithin Fatliquor

Magnapol SOF-G-Polymeric Softener

Sellatan RL-Synth. Replacement Tannin

Basyntan DLE-White Tanning Agent

Formic Acid

Water

20

20

50

50

15

10

60

20

20

90

60 overnight

15

60

30

40

10

3.2-3.4

3.7-4.0

4.0-4.2

3.2-3.5

JALCA, VOL. 100, 2005

RPM

16

16

16

16

16

16

16

16

16

16

16

6

16

UV AND HEAT RESISTANCE 105 back and passed through a Molissa staking machine at a medium setting (model 16370, Strojosuit, Czechoslovakia) twice at a rate of 1.6 meters/min (5.3 ft/min). Six approximately 21.6 x 26.6-cm rectangular pieces were cut out near the standard butt test area (ASTM D2813-97). We then applied the dl α -tocopherol (Sigma, St. Louis, MO) on the surface of the grain in the amount of 7 g/ft 2 . The coated leather samples were then conditioned in a conditioning room at 23°C and 50 percent RH.

Besides coating tocopherol directly on the grain layer, in another experiment, we added tocopherol to the fatliquoring drum, instead of coating. Table III lists the various processes for tanning, retanning, dyeing and fatliquoring used for the preparation of the chrome-free leather with tocopherol added in the main fatliquoring step.

Measurements

Before physical property testing, the samples were stored in a conditioned room at 23°C and 50% RH according to

ASTM D1610-96. Mechanical property measurements included tensile strength and elongation. Tensile strength is the maximum stress in tension that the leather may sustain without breaking. Elongation is defined as the maximum strain. Rectangular shaped leather samples (1 × 10 cm) were cut near the standard test area as described in ASTM

D2813-97 with the long dimension parallel to the backbone.

These properties were measured with a sample length of 5 cm between the two grips. The strain rate (crosshead speed) was set at 5 cm/min. An upgraded Instron mechanical prop-

TABLE III

Tanning, Retanning, and Fatliquoring Processes for Tocopherol added in Fatliquor

Dilution Process

1:10

1:5

1:5

1:5

1:10

% Product o

C

Wash

Drain

Float

Tannage

Basification

Retan

200

0.2

2

2

1

22

150

0.4

2

0.8

Water

Water

Sentry-Saform Acid-Non Swelling Acid

Sellatan CF Liq

Sodium Formate

Sodium Bicarbonate

Synth. Replacement Tannin

Lipsol SQ-Lecithin Fatliquor

Basyntan DLE-White Tanning Agent

Sellatan RL-Synth. Replacement Tannin

20

20

Retan

Fatliquoring

6

3

3

2

Dyeing

3.5

6

Next Day Check pH

Drain

Wash

Drain

Float

Fatliquoring

Retan

Add

Drain

Wash

Drain

200

150

6

2.5

4

Tocopherol Emulsified with surfactant SDS 2:1

0.5 to 10 Tocopherol, Samples

2

1

0.5

Sellatan RL-Synth. Replacement Tannin

Basyntan DLE

Formic Acid

200

Sellatan FL-Synth. Replacement Tannin

Tara-Vegetable Extract

Eureka 950R-Fatliquor

Lipsol SQ-Lecithin Fatliquor

Magnapol SOF-G-Polymeric Softener

Derma Red BG-Dye

Water

Water 50

Eureka 950R-Fatliquor

Lipsol SQ-Lecithin Fatliquor

Magnapol SOF-G-Polymeric Softener

Water

50

50

Time (min.)

15

10

60

20

20

90

60

Overnight

4.0-4.2

15

60

30

40

10 pH

3.2-3.4

3.7-4.0

3.2-3.5

RPM

16

16

16

16

16

16

16

6

16

16

16

16

JALCA, VOL. 100, 2005

106 UV AND HEAT RESISTANCE erty tester, model 1122, and Testworks 3.1 data acquisition software (MTS Systems Corp., Minneapolis, MN) were used throughout this work. Each test was conducted on four samples to obtain an average value.

We used an Atlas Ci3000F, Xenon Arc Fade-Ometer

(Oxford, PA), to evaluate the UV- and heat resistance of the leather samples. The samples were put inside the Fade-

Ometer that calibrated at 420nm, for total radiation dosage of 225.6 kJ/m 2 (about 72 h exposure). The settings for the

Fade-Ometer were as follows: black panel temperature100

± 2 o C, dry bulb temperature 65 ± 5 o C, radiation intensity

1.1 Watts/m 2 and RH 20 ± 10%. These settings have been commonly used in various industries for testing UV and heat resistances. The colorfastness to light of the specimen is evaluated by measuring the color change ( ∆ E) between the exposed samples and the unexposed original samples, using the color-insights® QC Manager System (BYK-

Gardner, Inc., Silver Spring, MD), which is an absorptiometric colorimeter often used for fabrics. We followed the

CIELAB colorimetric method; ∆ E was calculated using the following equation: 24

∆ E = ( ∆ L* 2 + ∆ a* 2 + ∆ b* 2 ) 1/2 (1)

L* represents the difference between light and dark. A* represents the difference between green (-a*) and red (+a*), and b* represents the difference between yellow (+b*) and blue (-b*). Measurements were conducted four times to obtain an average value.

Birefringence Measurement

We conducted birefringence (double refraction; n) measurements for the collagen fibers from various test specimens of leather.

25 The apparatus was a Nikon polarizing microscope (model E600 POL) equipped with a Berek compensator. The birefringence of a fiber was determined by measuring the two principal refractive indices, n

II and n

⊥

(measured parallel and perpendicular to fiber axis, respectively) and subtracting one from the other:

∆ n = n

II

- n

⊥

(2)

When a fiber is viewed between crossed polars, interference phenomena are observed. In the absence of a specimen, the field of view with crossed polars is dark because the polarizer will pass only light polarized in one direction, and the analyzer will pass only light polarized in a perpendicular direction. The Berek compensator is capable of quantitatively determining the wavelength retardation of a crystal, fiber, plastic film or other birefringent material. Provided that the thickness of the material can be measured, a Berek

JALCA, VOL. 100, 2005 compensator can be utilized to ascertain the birefringence value.

Tocopherol Quantification

Lipids were extracted from leather samples with hexane using a Dionex ASE 200 Accelerated Solvent Extractor using a previously described method.

26 Duplicate 1-gram samples were ground to 20 mesh using a Wiley Mill

(Thomas Scientific, Philadelphia). The extraction cells (11 ml) were loaded with the sample and the cell was topped off with Ottawa sand to fill the void space. The extractions were performed at a pressure of 1000 PSI and a temperature of 100°C. Each extraction consisted of three 10-min static cycles and a total volume of 22 ml hexane was used to extract each sample. One ml of extract was removed for

HPLC, the remaining extract was dried under N

2 and heat, and the total mass was measured (correcting for the amount removed). HPLC analysis was performed with an Agilent

1100 system, a LiChrsorb Diol column (3 x 100 mm), eluted isocratically with hexane/methyl t-butyl ether, 980/20, v/v, and flow rate of 0.5 ml/min. Under these conditions

α -tocoopherol eluted at a retention time of 6 minutes and was measured with an HP1100 Fluorescence detector operated at 294 nm excitation and 326 nm emission.

R

ESULTS AND

D

ISCUSSION

Color Lightfastness and Tensile Strength Retention

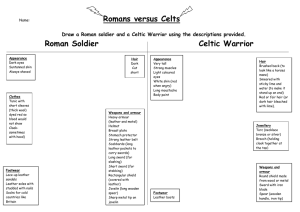

Figure 1a demonstrates the effect of UV radiation on reddyed leather samples. It shows the samples coated with tocopherol have much less color change than the samples without the protective coating. Good resistance to color fading in sunlight or artificial light is important for all upholstery leather, but is particularly critical in automotive leather, where the seats can be exposed to intense sunlight at high temperatures for very long periods of time.

Adequate tensile strength is very important in manufacturing leather goods, where the leather is often subjected to a tensile force during mechanical stretching or elongation.

Moreover, in a variety of end uses, leather goods must be capable of resisting considerable stress without fracture.

Tensile strength determines the maximum tensile stress the leather can sustain without fracture. Figure 1b shows the resultant tensile strength retention (ratio of tensile strength of samples before and after Fade-Ometer testing). For the control samples, the tensile strength suffers a significant loss. In contrast, tocopherol treatments yield greater tensile strength retention. It is interesting to note that the value is greater than 1, indicating tensile strength increased after

Fade-Ometer testing. This is probably due to the high temperature in the Fade-Ometer, which helps the penetration of

UV AND HEAT RESISTANCE 107

12

8

4

0

20

16

32

28

24 a.

1.2

1.0

0.8

0.6

0.4

b.

Control Tocopherol Control Tocopherol

TREATMENTS

Figure 1. - Color change (a) and tensile strength retention (b).

tocopherol, thereby increasing the lubrication of leather fibers. As reported previously, besides its function as a free radical scavenger, tocopherol may have a lubrication effect toward the leather fibrous structure, which would result in better tensile strength. Leather is made of bundles of interwoven collagen fibers. When leather is stretched, as done in a tensile test, the fibers are aligned in the direction of stretching. If the leather is not well lubricated, the fibers do not slip over each other and some fibers will start to break, which will break prematurely due to high friction resistance.

On the other hand, if the samples are well lubricated, then the leather will bypass this premature breakage and have more fibers to contribute to the resistance of deformation until final fracture, resulting in better tensile strength retention.

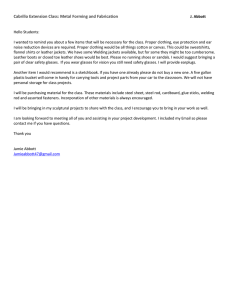

Birefringence and Fiber Strength

Figure 2 shows the birefringence of the fibers from the different leather samples. It demonstrates that the UV and heated samples after being run in the Fade-Ometer have a

0.04

0.03

0.02

0.01

0.00

CONTROL UV/Heat Toco Coat Toco Coat, UV/Heat

SAMPLES

Figure 2. - Birefringence of leather fibers.

significant lower birefringence than the original non-irradiated samples. The difference in the refractive indices depends on the relation between the direction of polarization of the light and the direction of alignment of the molecular chain. It is therefore to be expected that the birefringence will be greatest when the molecules are all lined up parallel to the fiber axis and that will be zero when they are randomly directed, as illustrated in Figure 3. This result indicates that the UV-irradiated leather fibers lost a significant degree of orientation in their molecular chains.

Presumably, the UV radiation and heat caused disorientation in the collagen molecular chains, thereby resulting in a lower birefringence. On the other hand, the sample coated with tocopherol did not lose the degree of orientation as drastically as the untreated samples after UV radiation in a

Fade-Ometer. Apparently, the tocopherol coating creates a protective shield that minimizes the UV and heat damage.

It is well known that fibers are highly anisotropic and their tenacity (the terminology used in textile industry for tensile strength of fibers) is very sensitive to the change of biren z n

II

∆∆ n = 0

∆∆ n = n

II

–n z

Figure 3. - Relationship between orientation and birefringence of fibers.

fringence. This is not surprising, because tensile strength is a vector quantity. It only quantifies breaking stress in the one direction that it is being stretched. Therefore, the resistance is given only by the vector components parallel to the applied force direction. Obviously, the more molecular chains that line up in this direction, the higher the tensile strength that is attained. As illustrated in Figure 4, the birefringence data has a strong link to the tenacity of fibers.

27

The higher birefringence values mean a greater degree of orientation of the molecular chains in the fibers, consequently the more molecular chains to share the tensile force, thus resulting in a better tensile strength.

Wet Treatments

Besides coating the leather samples with tocopherol, a set of

JALCA, VOL. 100, 2005

108 UV AND HEAT RESISTANCE

5

4

3

Polyethylene

Cotton

Nylon

Silk

2

Rayon

Wool

1

0.01

0.02

0.03

0.04

0.05

0.06

BIREFRINGENCE

Figure 4. - The correlation between fiber tenacity and birefringence.

15

10

5

0

0 2 4 6 8

TOCOPHEROL OFFERED (%)

10

Figure 5. - Tocopherol absorption as a function of tocopherol offered in the fatliquoring.

experiments was also conducted by adding tocopherol to the fatliquoring drum; the procedures are listed in Table III.

As demonstrated in Figure 5, the absorbed tocopherol increases as the tocopherol offered (denoted as X) in the drum increases. Regression analysis gave the following equation (Equation 3) with a coefficient of multiple determination (R 2 ) of 0.98.

Tocopherol content (mg/g) = 3.96 X - 0.24 X 2 (3)

Variance analysis showed that the p-value is less than 0.001, confirming that this nonlinear model is highly justifiable.

P-value indicates the probability that effects originated from experimental error (instead of factor itself); therefore a smaller value of p indicates a greater significance of effects.

The value of 0.1 (or 10%) is a commonly used cutoff of pvalue for significance.

The colorfastness test results from those wet-treatments are not as good as offered by the coated samples. As illustrated

JALCA, VOL. 100, 2005

32

30

28

26

24

0 5 10 15

TOCOPHEROL CONTENT (mg/g)

Figure 6. - Color change as a function of tocopherol content in the fatliquoring process.

1.1

0.8

0.5

1.7

1.4

0.2

0 5 10 15

TOCOPHEROL CONTENT (mg/g)

Figure 7. - Tensile strength retention as a function of tocopherol content in the fatliquoring process.

2.0

1.7

1.4

1.1

0.8

0.5

0.2

0 5 10 15

TOCOPHEROL CONTENT (mg/g)

Figure 8. - Elongation a function of tocopherol content in the fatliquoring process.

in Figure 6, the colorfastness shows some degree of improvement, but the beneficial effects of tocopherol are not as obvious as the coated samples. On the other hand, the increase in the strength retention ratio is rather evident as

UV AND HEAT RESISTANCE 109 with the percent tocopherol offered in the drum increases, as shown in Figure 7. Tests also indicated that the samples fatliquored with tocopherols have greater elongation retention, as demonstrated in Figure 8. This is largely due to the lubrication function of tocopherol, with which the leather fibers readily slip over one another, thereby increasing the extensibility of leather.

C

ONCLUSIONS

This on-going research aims to develop a process treatment that is environmentally friendly and yet significantly increases the UV and heat resistance of chrome-free leather.

Data showed that coating leather with α -tocopherol significantly improves the color fading resistance and strength retention against UV radiation and high temperature. We also studied the addition of tocopherol to the fatliquoring drums, but this treated leather did not show a similar improvement. Our future work will explore the mixed α -,

β -, and γ -tocopherol for UV and heat resistance treatments, the mixed isomers are less costly than α -tocopherol alone.

On the other hand, we will also investigate the fine structure of treated leather fibers to gain a better understanding of the structure/properties relationship. Moreover, we will explore effectiveness of tocotrienols, which are believed to be stronger antioxidants than tocopherols. The tocotrienols differ from the tocopherols in the chemical nature of the side chain (tail). Tocopherols have a saturated phytyl side chain, whereas tocotrienols have an unsaturated isoprenoid or farnesyl side chain possessing three double bonds.

A

CKNOWLEDGMENTS

We thank Dr. Robert Moreau and Mr. Michael Powell of

ERRC for tocopherol quantitative measurements. We also thank Mr. Jurgen Kuhnert of Cudahy Tanning Co., Dr.

David Coffin of ERRC, and Mr. James Haworth of Cargill

Nutriproducts for their invaluable information and comments.

R

EFERENCES

1. Fein, M. L., Harris, E. H., Jr., Naghski, J., and Filachione,

E. M.; Tanning with glutaraldehyde. I. Rate studies. JALCA

54 , 488-502, 1959.

2. Filachione, E. M., Fein, M. L., Harris, E. H., Jr., Luvisi,

F. P., Korn, A. H., Windus, W., and Naghski, J.; Tanning with glutaraldehyde. II. Properties of the leathers. JALCA

54 , 668-679, 1959.

3. Fein, M. L., Filachione, E. M., Naghski, J., and Harris, E.

H., Jr.; Tanning with glutaraldehyde III. Combination tannages with chrome. JALCA 58 , 202-221, 1963.

4. Filachione, E. M., Fein, M. L., and Harris, E. H., Jr.;

Tanning with glutaraldehyde. IV. Use in side leather.

JALCA 59 , 378-402, 1964.

5. Filachione, E. M., Fein, M. L., and Harris, E. H., Jr.;

Tanning with glutaraldehyde. JALCA 59 , 281-292, 1964

6. Jayakrishnan, A., and Jameela, S. R.; Glutaraldehyde as a fixative in bioprostheses and drug delivery matrices.

Biomaterials 17 , 471-484. 1996.

7. Wolf, G., Breth, M., and Igl, G.; New developments in wet-white tanning technology. JALCA 96 , 111-119, 2001.

8. Marmer, W. N.; Overview of the USDA hides and leather research program. JALCA 96 , 88 93, 2001.

9. Schwaiger, W.; Ageing properties of automotive leather.

Leather International July, 28-30, 2001.

10. Fennen, J.; Wet white technology a status report. 99th

ALCA Annual Meeting, June 19-22, 2003.

11. Mezghani, S., Lamure, A., Bader, D., and Lacabanne,

C.; Thermally stimulated current changes of irradiated skin.

J. Materials Science: Materials in Medicine 7 , 285-289,

1996.

12. Weadock, K. S., Miller, E. J., Bellincampi, L. D.,

Zawadsky, J. P., and Dunn, M. G.; Physical crosslinking of collagen fibers; comparison of ultraviolet irradiation and dehydrothermal treatment. J. Biomedical Materials Res.

29 ,

1373-1379, 1995.

13. Sionkowska, A.; Photochemical transformations in collagen in the presence of melanin. J. Photochemistry and

Photobiology A: Chemistry 124 , 91-94, 1999.

14. Fujimori E.; Ultraviolet light-induced change in collagen macromolecules. Biopolymers 3 , 115, 1965.

15. Billmeyer, F. W.; Textbook of polymer science, 3rd Ed.,

John Wiley & Sons, New York, p. 369, 1984.

16. Shaath, N. A.; Evolution of modern sunscreen chemicals. In Lowe, N. J., Shaath, N. A., and Pathak, M. A., eds.,;Sunscreens development, evaluation, and regulatory aspects. New York, Marcel Dekker, 3-33, 1997.

17. Bissonnette, R.; Update on sunscreens. Skin Therapy

Letter 2 , 5, 1997.

18. Ames, B. N., Shigenaga, M. K., and Hagen, T. M.;

Oxidants, antioxidants, and the degenerative diseases of aging. Proc. Natl. Acad. Sci.

90 , 7915-7922, 1993.

19. Eberlein, K. B.; Placzek, M. and Przybilla, B.;

Protective effect against sunburn of combined systemic ascorbic acid (vitamin C) and dα -tocopherol (vitamin E).

J. Am. Acad. Dermatol.

38 , 45-48, 1998.

20. Machlin, L. J.; Vitamin E: A comprehensive Treatise.

Marcel Dekker, New York, p. 291, 1980.

21. Liu, C.-K. and Latona, N. P.; Physical property studies for a collagen material: leather treated with tocopherol.

Polym. Mater. Sci. Eng., Am. Chem. Soc. Div. Polym. Mater.

Sci. Eng . 89 , 226-227. 2003.

22. Liu, C.-K. and Latona, N. P.; The application of toco-

JALCA, VOL. 100, 2005

110 pherol to improve durability of leather. JALCA 98 , 389-

399, 2003.

23. Marmer, W. N., Dudley, R. L., DiMaio, G. L., and

Gehring, A. G.; Rapid oxidative unhairing with alkaline hydrogen peroxide. JALCA 98 , 351-358, 2003.

24. Giles, C. H.; A laboratory course in dyeing. The Society of Dyers and Colorists, Bradford, Yorkshire, UK, p 20,

1971.

25. Liu, C.-K., Cuculo, J. A., Allen, T. C., and DeGroot, A.

W.; Fiber formation via solution spinning of the cellulose/ammonia/ammonium thiocyanate system. J. Polym.

Sci., Polym. Phys. Ed.

29 , 181-196, 1991.

26. Moreau, R. A., Powell, M. J., and Singh, V.; Pressurized liquid extraction of polar and nonpolar lipids in corn and oats with hexane, methylene chloride, isopropanol, and ethanol. J. Am. Oil Chem. Soc.

80 , 1063-1067, 2003.

27. Morton, W. E. and Hearle, J. W. S.; Physical properties of textile fibres. The Textile Institute, Manchester and

London, p 577, 1978.

C

ONVENTION

D

ISCUSSION

Stephen Yanek, Eagle Ottawa - Thank you very much C.-K., very nice. Two questions. Does the tocopherol have one or more functional groups that could be used to help retain it to the leather? In the one chart that you showed where it peaked at about 8%, what method did you use to quantify that?

We used hexane extraction and HPLC of the hexane extract to quantify the level of tocopherol. I do not know which functional groups in tocopherol react with the leather.

Stephen Yanek, Eagle Ottawa - Was the concept that you were relying on to have the tocopherol dissolve in the oil to stay on the leather?

Yes.

Stephen Yanek, Eagle Ottawa - Was it a powder or a gel?

Tocopherol is an oil. We used a surfactant to help emulsification of the tocopherol in the fatliquor.

Rodney Hammond, Seton Co. - C.-K. have you looked at whether the improved UV performance of the leather that is treated with tocopherol continues if you put the leather through climate testing where you go with high humidity cycles, high humidity low temperature and then low humidity high temperature?

No we did not do that. We will do that in the future. Right now we are testing with the humidity constant at 20%.

Rodney Hammond, Seton Co. - The reason I ask you that is because you did not get the same results when you applied the tocopherol in the fatliquor which suggests that it is the surface coating itself that is giving the improved performance. Therefore, I would wonder if you do something that would affect the surface coating whether you would continue to have the improved performance over time.

I intend to look at that in the next series of experiments.

JALCA, VOL. 100, 2005