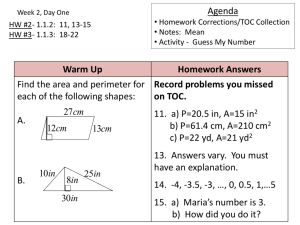

John Deere Agriculture 6820, 6920 and 6920S Tractors Repair REPAIR MANUAL 6820, 6920, 6920S TM4756, August 2010 TM4756-REPAIR MANUAL (g) by Belgreen Table of contents FOREWORD VERSION DATE Section 05 - SAFETY Group 05 - Safety Information Section 10 - GENERAL INFORMATION Group 05 - Specifications Group 10 - Tune-Up Group 15 - Predelivery Inspection Section 20 - ENGINE Group 00 - Removal and Installation of Components Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 05 - Speed Control Group 10 - Fuel System Group 15 - Air Intake System Group 20 - Cooling System Group 25 - Cold-Weather Starting Aids Group 30 - Exhaust System Section 40 - ELECTRICAL SYSTEM Group 05 - Electrical Connectors Group 10 - Wiring Harnesses Group 15 - Charging Circuit Group 20 - Starter Motor Circuit Group 25 - Fuses, Relays and Switches Group 30 - Monitoring Systems Group 40 - Electrical Components Section 53 - AUTOPOWR/IVT TRANSMISSION Group 00 - Removal and Installation of AutoPowr/IVT Transmission Group 05 - Transmission Shift Controls Group 10 - Input Housing Group 15 - Output Housing Group 20 - Differential Drive Shaft Assembly Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 00 - Removal and Installation of Components Group 05 - Transmission Shift Controls Group 10 - PowrQuad Module Group 15 - Creeper Transmission Group 20 - Range Transmission Section 56 - DRIVE SYSTEMS Group 00 - Removal and Installation of Components Group 05 - U-Jointed Shafts and Torsion Damper Group 10 - Front-Wheel Drive Clutch Group 15 - Differential Group 20 - Hydraulic Pump Drive Group 25 - Final Drives Group 30 - Rear PTO Group 35 - Front PTO Group 40 - Front Implement Drive Section 60 - STEERING AND BRAKES <- Go to Global Table of contents TM4756-REPAIR MANUAL TM4756-REPAIR MANUAL (g) by Belgreen Group 05 - Hydrostatic Steering Group 10 - Brake Valve Group 15 - Rear Wheel Brakes Group 20 - Handbrake Group 25 - Hydraulic Trailer Brake Group 30 - Air Brakes up to Serial No. 398655 Group 31 - Air Brakes from Serial No. 398656 Group 40 - AutoTrac Section 70 - HYDRAULIC SYSTEM Group 05 - Controls Group 10 - Hydraulic Pump and Charge Oil Pump Group 15 - Valves Group 20 - Hitch Group 25 - Selective Control Valves and Couplers Group 30 - Independent Selective Control Valve Section 80 - MISCELLANEOUS Group 00 - Removal and Installation of Components Group 05 - Main Frame Group 10 - Front Wheels, Rear Wheels and Fenders Group 15 - Trailer Mounting and Swinging Drawbar Group 20 - Triple Link Suspension (TLS) of Front-Wheel Drive Axle Group 25 - Pick-Up Hitch Section 90 - OPERATOR′S CAB Group 00 - Removal and Installation of Components Group 05 - Controls and Instruments Group 10 - Air-Conditioning System Group 11 - ClimaTrak Group 15 - Heating System Group 20 - Seats Group 25 - Operator′s Cab Group 30 - Cab Suspension Section 99 - SPECIAL TOOLS (DEALER-FABRICATED) Group 05 - Special Tools (Dealer-Fabricated) Group 10 - Special Tools (Available from the Dealer) <- Go to Global Table of contents TM4756-REPAIR MANUAL <- Go to Global Table of contents TM4756-REPAIR MANUAL TM4756-REPAIR MANUAL (g) by Belgreen Foreword This repair manual is valid for the following tractor types: 6820, 6920 and 6920S. The manual is written for experienced customer service personnel. Essential tools required in performing certain service work are identified in this manual and are recommended for use. Live with safety: Read the safety messages in the introduction of this manual and the cautions presented throughout the text of the manual. CAUTION: This is the safety-alert symbol. It indicates that there is danger of injury. Technical Manuals are concise service guides for specific machines. They are on-the-job guides containing only the vital information needed for diagnosis, analysis, testing, and repair. Fundamental service information is available from other sources covering basic theory of operation, fundamentals of troubleshooting, general maintenance, and basic type of failures and their causes. <- Go to Global Table of contents TM4756-REPAIR MANUAL SAFETY (g) by Belgreen Version Date 01 December 2005 <- Go to Global Table of contents TM4756-REPAIR MANUAL TM4756-REPAIR MANUAL (g) by Belgreen Section 05 - SAFETY Table of contents Group 05 - Safety Information ................................................................................................. 1 Recognize Safety Information ................................................................................................ 1 ”Important” Information ......................................................................................................... 1 ”Note” Information ................................................................................................................. 1 Prevent Machine Runaway ..................................................................................................... 1 Handle Fluids Safely—Avoid Fires .......................................................................................... 2 Prevent Battery Explosions .................................................................................................... 3 Prepare for Emergencies ........................................................................................................ 3 Prevent Acid Burns ................................................................................................................. 5 Avoid High-Pressure Fluids ..................................................................................................... 6 Service Cooling System Safely ............................................................................................... 6 Remove Paint Before Welding or Heating .............................................................................. 7 Avoid Heating Near Pressurized Fluid Lines ........................................................................... 8 Work In Ventilated Area ......................................................................................................... 8 Wear Protective Clothing ....................................................................................................... 9 Practice Safe Maintenance ................................................................................................... 10 Park Machine Safely ............................................................................................................. 11 Use Proper Lifting Equipment ............................................................................................... 11 Construct Dealer-Made Tools Safely .................................................................................... 12 Support Machine Properly .................................................................................................... 12 Work in Clean Area .............................................................................................................. 13 Illuminate Work Area Safely ................................................................................................. 14 Service Machines Safely ....................................................................................................... 14 Use Proper Tools .................................................................................................................. 15 Service Tires Safely .............................................................................................................. 15 Service Front-Wheel Drive Tractor Safely ............................................................................ 17 Safety Information - Air Brake System ................................................................................. 17 Avoid Eye Contact With Radar ............................................................................................. 18 Keep ROPS Installed Properly ............................................................................................... 19 Replace Safety Signs ............................................................................................................ 19 Dispose of Waste Properly ................................................................................................... 20 Live With Safety ................................................................................................................... 21 Safety Measures on Electronic Control Units ........................................................................ 21 <- Go to Global Table of contents TM4756-REPAIR MANUAL Section 05 - SAFETY Group 05: Safety Information Group 05 - Safety Information Recognize Safety Information This is a safety-alert symbol. When you see this symbol on your machine or in this manual, be alert to the potential for personal injury. Follow recommended precautions and safe operating practices. ”Important” Information Information marked as IMPORTANT points out problems that may lead to machine damage. By following the directions given, these problems can be avoided. ”Note” Information When marked with NOTE the information given is more detailed or contains restrictions to directions given previously. On the other hand useful information may be given belonging to certain instructions without being directly connected to them. Prevent Machine Runaway <- Go to Section TOC Section 05 page 1 TM4756-REPAIR MANUAL Section 05 - SAFETY Group 05: Safety Information Avoid possible injury or death from machinery runaway. Do not start engine by shorting across starter terminals. Machine will start in gear if normal circuitry is bypassed. NEVER start engine while standing on ground. Start engine only from operator’s seat, with transmission in neutral or park. Handle Fluids Safely—Avoid Fires When you work around fuel, do not smoke or work near heaters or other fire hazards. Store flammable fluids away from fire hazards. Do not incinerate or puncture pressurized containers. Make sure machine is clean of trash, grease, and debris. <- Go to Section TOC Section 05 page 2 TM4756-REPAIR MANUAL Section 05 - SAFETY Group 05: Safety Information Do not store oily rags; they can ignite and burn spontaneously. Prevent Battery Explosions Keep sparks, lighted matches, and open flame away from the top of battery. Battery gas can explode. Never check battery charge by placing a metal object across the posts. Use a volt-meter or hydrometer. Do not charge a frozen battery; it may explode. Warm battery to 16°C (60°F). Prepare for Emergencies Be prepared if a fire starts. <- Go to Section TOC Section 05 page 3 TM4756-REPAIR MANUAL Section 05 - SAFETY Group 05: Safety Information Keep a first aid kit and fire extinguisher handy. Keep emergency numbers for doctors, ambulance service, hospital, and fire department near your telephone. <- Go to Section TOC Section 05 page 4 TM4756-REPAIR MANUAL Section 05 - SAFETY Group 05: Safety Information Prevent Acid Burns Sulfuric acid in battery electrolyte is poisonous. It is strong enough to burn skin, eat holes in clothing, and cause blindness if splashed into eyes. Avoid the hazard by: 1. 2. 3. 4. 5. Filling batteries in a well-ventilated area. Wearing eye protection and rubber gloves. Avoiding breathing fumes when electrolyte is added. Avoiding spilling or dripping electrolyte. Use proper jump start procedure. If you spill acid on yourself: <- Go to Section TOC Section 05 page 5 TM4756-REPAIR MANUAL Section 05 - SAFETY Group 05: Safety Information 1. Flush your skin with water. 2. Apply baking soda or lime to help neutralize the acid. 3. Flush your eyes with water for 15—30 minutes. Get medical attention immediately. If acid is swallowed: 1. Do not induce vomiting. 2. Drink large amounts of water or milk, but do not exceed 2 L (2 quarts). 3. Get medical attention immediately. Avoid High-Pressure Fluids Escaping fluid under pressure can penetrate the skin causing serious injury. Avoid the hazard by relieving pressure before disconnecting hydraulic or other lines. Tighten all connections before applying pressure. Search for leaks with a piece of cardboard. Protect hands and body from high-pressure fluids. If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be surgically removed within a few hours or gangrene may result. Doctors unfamiliar with this type of injury should reference a knowledgeable medical source. Such information is available in English from Deere & Company Medical Department in Moline, Illinois, U.S.A., by calling 1-800-822-8262 or +1 309-748-5636. Service Cooling System Safely <- Go to Section TOC Section 05 page 6 TM4756-REPAIR MANUAL Section 05 - SAFETY Group 05: Safety Information Explosive release of fluids from pressurized cooling system can cause serious burns. Shut off engine. Only remove filler cap when cool enough to touch with bare hands. Slowly loosen cap to first stop to relieve pressure before removing completely. Remove Paint Before Welding or Heating Avoid potentially toxic fumes and dust. Hazardous fumes can be generated when paint is heated by welding, soldering, or using a torch. Remove paint before heating: Remove paint a minimum of 100 mm (4 in.) from area to be affected by heating. If paint cannot be removed, wear an approved respirator before heating or welding. <- Go to Section TOC Section 05 page 7 TM4756-REPAIR MANUAL Section 05 - SAFETY Group 05: Safety Information If you sand or grind paint, avoid breathing the dust. Wear an approved respirator. If you use solvent or paint stripper, remove stripper with soap and water before welding. Remove solvent or paint stripper containers and other flammable material from area. Allow fumes to disperse at least 15 minutes before welding or heating. Do not use a chlorinated solvent in areas where welding will take place. Do all work in an area that is well ventilated to carry toxic fumes and dust away. Dispose of paint and solvent properly. Avoid Heating Near Pressurized Fluid Lines Flammable spray can be generated by heating near pressurized fluid lines, resulting in severe burns to yourself and bystanders. Do not heat by welding, soldering, or using a torch near pressurized fluid lines or other flammable materials. Pressurized lines can accidentally burst when heat goes beyond the immediate flame area. Work In Ventilated Area <- Go to Section TOC Section 05 page 8 TM4756-REPAIR MANUAL Section 05 - SAFETY Group 05: Safety Information Engine exhaust fumes can cause sickness or death. If it is necessary to run an engine in an enclosed area, remove the exhaust fumes from the area with an exhaust pipe extension. If you do not have an exhaust pipe extension, open the doors and get outside air into the area. Wear Protective Clothing Wear close fitting clothing and safety equipment appropriate to the job. <- Go to Section TOC Section 05 page 9 TM4756-REPAIR MANUAL Section 05 - SAFETY Group 05: Safety Information Prolonged exposure to loud noise can cause impairment or loss of hearing. Wear a suitable hearing protective device such as earmuffs or earplugs to protect against objectionable or uncomfortable loud noises. Operating equipment safely requires the full attention of the operator. Do not wear radio or music headphones while operating machine. Practice Safe Maintenance Understand service procedure before doing work. Keep area clean and dry. Never lubricate, service, or adjust machine while it is moving. Keep hands, feet , and clothing from power-driven parts. Disengage all power and operate controls to relieve pressure. Lower <- Go to Section TOC Section 05 page 10 TM4756-REPAIR MANUAL Section 05 - SAFETY Group 05: Safety Information equipment to the ground. Stop the engine. Remove the key. Allow machine to cool. Securely support any machine elements that must be raised for service work. Keep all parts in good condition and properly installed. Fix damage immediately. Replace worn or broken parts. Remove any buildup of grease, oil, or debris. On self-propelled equipment, disconnect battery ground cable (-) before making adjustments on electrical systems or welding on machine. On towed implements, disconnect wiring harnesses from tractor before servicing electrical system components or welding on machine. Park Machine Safely Before working on the machine: Lower all equipment to the ground. Stop the engine and remove the key. Disconnect the battery ground strap. Hang a "DO NOT OPERATE" tag in operator station. Use Proper Lifting Equipment <- Go to Section TOC Section 05 page 11 TM4756-REPAIR MANUAL Section 05 - SAFETY Group 05: Safety Information Lifting heavy components incorrectly can cause severe injury or machine damage. Follow recommended procedure for removal and installation of components in the manual. Construct Dealer-Made Tools Safely Faulty or broken tools can result in serious injury. When constructing tools, use proper, quality materials, and good workmanship. Do not weld tools unless you have the proper equipment and experience to perform the job. Support Machine Properly <- Go to Section TOC Section 05 page 12 TM4756-REPAIR MANUAL Section 05 - SAFETY Group 05: Safety Information Always lower the attachment or implement to the ground before you work on the machine. If the work requires that the machine or attachment be lifted, provide secure support for them. If left in a raised position, hydraulically supported devices can settle or leak down. Do not support the machine on cinder blocks, hollow tiles, or props that may crumble under continuous load. Do not work under a machine that is supported solely by a jack. Follow recommended procedures in this manual. When implements or attachments are used with a machine, always follow safety precautions listed in the implement or attachment operator′s manual. Work in Clean Area Before starting a job: Clean work area and machine. <- Go to Section TOC Section 05 page 13 TM4756-REPAIR MANUAL Section 05 - SAFETY Group 05: Safety Information Make sure you have all necessary tools to do your job. Have the right parts on hand. Read all instructions thoroughly; do not attempt shortcuts. Illuminate Work Area Safely Illuminate your work area adequately but safely. Use a portable safety light for working inside or under the machine. Make sure the bulb is enclosed by a wire cage. The hot filament of an accidentally broken bulb can ignite spilled fuel or oil. Service Machines Safely Tie long hair behind your head. Do not wear a necktie, scarf, loose clothing, or necklace when you work near machine tools or moving parts. If these items were to get caught, severe injury could result. <- Go to Section TOC Section 05 page 14 TM4756-REPAIR MANUAL Section 05 - SAFETY Group 05: Safety Information Remove rings and other jewelry to prevent electrical shorts and entanglement in moving parts. Use Proper Tools Use tools appropriate to the work. Makeshift tools and procedures can create safety hazards. Use power tools only to loosen threaded parts and fasteners. For loosening and tightening hardware, use the correct size tools. DO NOT use U.S. measurement tools on metric fasteners. Avoid bodily injury caused by slipping wrenches. Use only service parts meeting John Deere specifications. Service Tires Safely <- Go to Section TOC Section 05 page 15 TM4756-REPAIR MANUAL Section 05 - SAFETY Group 05: Safety Information Explosive separation of a tire and rim parts can cause serious injury or death. Do not attempt to mount a tire unless you have the proper equipment and experience to perform the job. Always maintain the correct tire pressure. Do not inflate the tires above the recommended pressure. Never weld or heat a wheel and tire assembly. The heat can cause an increase in air pressure resulting in a tire explosion. Welding can structurally weaken or deform the wheel. When inflating tires, use a clip-on chuck and extension hose long enough to allow you to stand to one side and NOT in front of or over the tire assembly. Use a safety cage if available. Check wheels for low pressure, cuts, bubbles, damaged rims or missing lug bolts and nuts. <- Go to Section TOC Section 05 page 16 TM4756-REPAIR MANUAL Section 05 - SAFETY Group 05: Safety Information Service Front-Wheel Drive Tractor Safely When servicing front-wheel drive tractor with the rear wheels supported off the ground and rotating wheels by engine power, always support front wheels in a similar manner. Loss of electrical power or transmission/ hydraulic system pressure will engage the front driving wheels, pulling the rear wheels off the support if front wheels are not raised. Under these conditions, front drive wheels can engage even with switch in disengaged position. Safety Information - Air Brake System <- Go to Section TOC Section 05 page 17 TM4756-REPAIR MANUAL Section 05 - SAFETY Group 05: Safety Information CAUTION: Compressed air tank is pressurized! Always relieve pressure before working on the air brake system. Do not carry out any welding jobs on the air brake system. Avoid Eye Contact With Radar <- Go to Section TOC Section 05 page 18 TM4756-REPAIR MANUAL Section 05 - SAFETY Group 05: Safety Information Radar ground speed sensor emits a very low intensity microwave signal. It will not cause any ill effects during normal use. Although intensity is low, DO NOT look directly into face of sensor while in operation, to avoid any possible eye damage. Keep ROPS Installed Properly Make certain all parts are reinstalled correctly if the roll-over protective structure (ROPS) is loosened or removed for any reason. Tighten mounting bolts to proper torque. The protection offered by ROPS will be impaired if ROPS is subjected to structural damage, is involved in an overturn incident, or is in any way altered by welding, bending, drilling, or cutting. A damaged ROPS should be replaced, not reused. <- Go to Section TOC Section 05 page 19 TM4756-REPAIR MANUAL Section 05 - SAFETY Group 05: Safety Information Replace Safety Signs Replace missing or damaged safety signs. See the machine operator’s manual for correct safety sign placement. Dispose of Waste Properly Improperly disposing of waste can threaten the environment and ecology. Potentially harmful waste used with John Deere equipment include such items as oil, fuel, coolant, brake fluid, filters, and batteries. Use leakproof containers when draining fluids. Do not use food or beverage containers that may mislead someone into drinking from them. Do not pour waste onto the ground, down a drain, or into any water source. <- Go to Section TOC Section 05 page 20 TM4756-REPAIR MANUAL Section 05 - SAFETY Group 05: Safety Information Air conditioning refrigerants escaping into the air can damage the Earth’s atmosphere. Government regulations may require a certified air conditioning service center to recover and recycle used air conditioning refrigerants. Inquire on the proper way to recycle or dispose of waste from your local environmental or recycling center, or from your John Deere dealer. Live With Safety Before returning machine to customer, make sure machine is functioning properly, especially the safety systems. Install all guards and shields. Safety Measures on Electronic Control Units <- Go to Section TOC Section 05 page 21 TM4756-REPAIR MANUAL GENERAL INFORMATION (g) by Belgreen CAUTION: Before installing test equipment on tractor, always shut off the engine and turn off key switch. CAUTION: Always engage the park lock when performing tests with the engine running. CAUTION: When testing is performed with the engine running, there is a risk of injury from rotating parts. IMPORTANT: Do not use a test lamp on any control unit. Only use a multimeter (JT05791A/JDG1478). IMPORTANT: To protect electronic circuits, disconnect the battery and alternator before performing any welding on the tractor. <- Go to Section TOC Section 05 page 22 TM4756-REPAIR MANUAL TM4756-REPAIR MANUAL (g) by Belgreen Section 10 - GENERAL INFORMATION Table of contents Group 05 - Specifications ......................................................................................................... 1 Specifications (Summary of References) ............................................................................... 1 Engine Specifications ............................................................................................................. 3 Cooling System ...................................................................................................................... 3 Injection Pump (Bosch VP44) ................................................................................................. 4 Level 11 Electronic Fuel System with HPCR (Denso) .............................................................. 4 Air Intake System ................................................................................................................... 4 Electrical system .................................................................................................................... 4 Hydrostatic Steering System .................................................................................................. 4 AutoTrac ................................................................................................................................. 4 Clutch ..................................................................................................................................... 4 AutoPowr/IVT transmission ..................................................................................................... 4 PowrQuad Plus transmission .................................................................................................. 5 AutoQuad II transmission ....................................................................................................... 5 Creeper transmission ............................................................................................................. 5 Rear PTO ................................................................................................................................ 5 Front PTO ............................................................................................................................... 5 Differential assembly ............................................................................................................. 6 Differential lock ...................................................................................................................... 6 Final drives ............................................................................................................................. 6 Front-Wheel Drive .................................................................................................................. 6 FWD Axle with TLS ................................................................................................................. 6 Cab Suspension: ..................................................................................................................... 6 Hydraulic Brakes .................................................................................................................... 6 Handbrake ............................................................................................................................. 6 Parking Lock ........................................................................................................................... 6 Hydraulic System with Axial Piston Pump (PFC System) ........................................................ 6 Rockshaft ............................................................................................................................... 7 Front Hitch ............................................................................................................................. 7 Ground Speeds ....................................................................................................................... 7 Front and Rear Wheels ........................................................................................................... 7 Dimensions and Weights ........................................................................................................ 7 Capacities .............................................................................................................................. 8 Handling and Storing Diesel Fuel ........................................................................................... 9 Diesel Fuel ........................................................................................................................... 11 Lubricity of Diesel Fuel ......................................................................................................... 11 Diesel Engine Break-In Oil .................................................................................................... 13 Diesel Engine Oil (Engine Serial Number up to 799999) ...................................................... 15 Diesel Engine Oil (Engine Serial Number from 800000) ....................................................... 17 Transmission and Hydraulic Oil ............................................................................................ 19 Front-Wheel Drive Axle Oil ................................................................................................... 21 Diesel Engine Coolant .......................................................................................................... 23 Supplemental Coolant Additives .......................................................................................... 24 Grease .................................................................................................................................. 24 Oil Filters .............................................................................................................................. 25 Mixing of Lubricants ............................................................................................................. 26 <- Go to Global Table of contents TM4756-REPAIR MANUAL TM4756-REPAIR MANUAL (g) by Belgreen Lubricant Storage ................................................................................................................. 26 Operating in Warm Temperature Climates .......................................................................... 26 Alternative and Synthetic Lubricants ................................................................................... 27 Unified Inch Bolt and Screw Torque Values .......................................................................... 28 Metric Bolt and Screw Torque Values ................................................................................... 29 Hydraulic system inch fitting torques .................................................................................. 30 Hydraulic system metric fitting torques ............................................................................... 31 Product identification and component serial numbers ......................................................... 32 Engine Serial Number .......................................................................................................... 34 Transmission serial number ................................................................................................. 34 Front wheel drive axle serial number ................................................................................... 35 Operator′s cab serial number ............................................................................................... 35 Operator′s seat serial number .............................................................................................. 36 Sub-assembly serial numbers .............................................................................................. 37 Group 10 - Tune-Up ................................................................................................................. 38 Tune-Up (Summary of References) ...................................................................................... 38 Specifications ....................................................................................................................... 39 Using High-Pressure Washers .............................................................................................. 39 Preliminary Engine Test ....................................................................................................... 40 Tractor Tune-Up ................................................................................................................... 41 Removing and Cleaning the Primary Air Cleaner Element ................................................... 43 Checking the Air Cleaner Safety Element ............................................................................ 43 Installing the Primary Filter Element .................................................................................... 44 Checking the Air Intake System Connections for Leaks ....................................................... 44 Checking the Crankcase Vent Hose for Clogging ................................................................. 45 Cleaning Dirt from Radiator Screen ..................................................................................... 45 Keeping the Radiator Screen Clean ...................................................................................... 46 Checking the Caps on the Expansion Tank .......................................................................... 46 Checking the Radiator for Leaks .......................................................................................... 47 Checking the engine′s thermostat ....................................................................................... 47 Checking the Fuel Transfer Pump Operation ........................................................................ 47 Bleeding the fuel system (with Bosch VP44 injection pump) ............................................... 49 Checking the fuel filter (with Bosch VP44 injection pump) ................................................... 52 Cleaning the water trap ....................................................................................................... 52 Checking the Fuel Filter (with Denso/Stanadyne Injection Pump; Stage II Engines According to 97/68/EC) ...................................................................................................................... 54 Bleeding the Fuel System (with Stanadyne Injection Pump; Stage II Engines According to 97/68/EC) ...................................................................................................................... 55 Bleeding the Fuel System (with Denso Injection Pump; Stage II Engines According to 97/68/EC) ...................................................................................................................... 55 Run Engine until it is Warm and Check Engine Speeds ........................................................ 56 Checking Setting of Fuel Injection Pump .............................................................................. 56 Cleaning the Battery, Cables and Battery Box with a Clean Cloth ....................................... 56 Check the Neutral Start Circuit ............................................................................................ 58 Checking operation of starter motor .................................................................................... 60 Checking the lighting circuit ................................................................................................ 60 Final Engine Check ............................................................................................................... 61 Tractor Operation Check ...................................................................................................... 61 Group 15 - Predelivery Inspection ........................................................................................ 63 Predelivery Inspection .......................................................................................................... 63 <- Go to Global Table of contents TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications Group 05 - Specifications Specifications (Summary of References) ”Engine specifications” ”Cooling system” ”Bosch VP44 injection pump” ”Level 11 electronic fuel system with HPCR (Denso)” ”Air intake system” ”Electrical system” ”Hydrostatic steering” ”AutoTrac” ”Clutch” ”AutoPowr/IVT transmission” ”PowrQuad Plus transmission” ”AutoQuad II transmission” ”Creeper transmission” ”Rear PTO” ”Front PTO” ”Differential” ”Differential lock” ”Final drives” ”Front-wheel drive” ”Front-wheel drive axle with TLS” ”Cab suspension” ”Hydraulic brakes” ”Handbrake” ”Park lock” ”Hydraulic system with axial piston pump” ”Hitch” ”Front hitch” ”Ground speeds” ”Front and rear wheels” ”Dimensions and weights” ”Capacities” ”Handling and storing diesel fuel” ”Diesel fuel” ”Lubricity of diesel fuel” ”Diesel engine break-in oil” ”Diesel engine oil (engine serial number up to 799.999)” ”Diesel engine oil (engine serial number from 800.000)” ”Transmission and hydraulic oil” ”Front-wheel drive axle oil” ”Diesel engine coolant” ”Coolant additives” ”Grease” <- Go to Section TOC Section 10 page 1 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications ”Oil filter” ”Mixing of lubricants” ”Lubricant storage” ”Operating in warm temperature climates” ”Alternative and synthetic lubricants” ”Unified inch bolt and cap screw torque values” ”Metric bolt and cap screw torque values” ”Hydraulic system inch fitting torques” ”Hydraulic system metric fitting torques” ”Product identification and sub-assembly serial numbers” ”Engine serial number” ”Transmission serial number” ”Front-wheel drive axle serial number” ”Operator′s cab serial number” ”Operator′s seat serial number” ”Sub-assembly serial numbers” <- Go to Section TOC Section 10 page 2 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications Engine Specifications Type - 6820 with Bosch VP-44 injection pump .......... 6068HLA71 with Denso HPCR injection pump .......... 6068HL472 - 6920 with Bosch VP-44 injection pump .......... 6068HLA72 with Denso HPCR injection pump .......... 6068HL473 - 6920S with Bosch VP-44 injection pump .......... 6068HLA73 with Denso HPCR injection pump .......... 6068HL474 Engine power according to ECE-R24 at rated engine speed with viscous fan - 6820 .......... 99 kW (135 hp) - 6920 .......... 110 kW (150 hp) - 6920S .......... 118 kW (160 hp) Max. torque at 1500 rpm engine speed with Bosch VP44 injection pump (on Stage II engines according to 97/68/EC) - 6820 .......... 611 N˙m (450 lb-ft) - 6920 .......... 699 N˙m (515 lb-ft) - 6920S .......... 699 N˙m (515 lb-ft) Max. torque at 1400 rpm engine speed with Denso/Stanadyne injection pump (on Stage II engines according to 97/68/EC) - 6820 .......... 620 N˙m (457 lb-ft) - 6920 .......... 688 N˙m (507 lb-ft) - 6920S .......... 685N˙m (505 lb-ft) Max. PTO power at rated PTO speed (factory measured, with 1000 rpm at PTO) - 6820 .......... 90 kW (122 hp) - 6920 .......... 99 kW (134 hp) - 6920S when driving .......... 104 kW (141 hp) when stationary .......... 100 kW (136 hp) Bore .......... 106.5 mm (4.19 in.) Stroke .......... 127.0 mm (5.00 in.) Displacement .......... 6790 cm 3 (414 cu.in.) Firing order .......... 1-5-3-6-2-4 Compression ratio .......... 16.8:1 Valve clearance (engine hot or cold) - intake valves .......... 0.35 mm (0.014 in.) - exhaust valves .......... 0.45 mm (0.018 in.) Slow idle - electronic actuation at an ambient temperature above 20°C (68°F) .......... 850±10 rpm between 0°C (32°F) and 20°C (68°F) .......... 875±50 rpm below 0°C (32°F) .......... 1050±10 rpm Fast idle - electronic actuation .......... 2250-10/+20 rpm with AutoQuad activated .......... max. 2100 rpm Rated engine speed .......... 2100 rpm Operating speeds .......... 1300 - 2100 rpm <- Go to Section TOC Section 10 page 3 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications Cooling System Type .......... pressurized system with two cooling circuits (high- and low-temperature circuits) with centrifugal pump and expansion tank. Temperature control .......... thermostat and viscous fan drive Injection Pump (Bosch VP44) Pump type .......... solenoid valve-controlled radial piston distributor pump, regulated electronically and giving direct injection Number of pistons .......... four Injection pressure .......... approx. 700 bar (70000 kPa; 10150 psi) Automatic switching off .......... electrical Level 11 Electronic Fuel System with HPCR (Denso) Type .......... Common rail Injection pressure .......... up to approx. 1450 bar (120000 kPa; 17400 psi) Air Intake System Engine air cleaner .......... dry-type air cleaner, self-cleaned by pressure from the fan blade; with safety element Electrical system Battery .......... 12 V, 154 Ah or 12 V, 174 Ah Alternator with overvoltage protection .......... 14 V, 90 A or 14 V, 115 A Starter motor .......... 12 V, 3.0 kW (4.0 hp) Battery terminal grounded .......... negative Hydrostatic Steering System Type .......... fully hydraulic AutoTrac →NOTE: Applies only to 6430 - 6630 tractors with operator′s cab. Type .......... satellite-supported steering system Control .......... electro-hydraulic Clutch Type .......... hydraulically controlled wet disk clutch Operation .......... mechanical / hydraulic with pre-tensioned Belleville springs <- Go to Section TOC Section 10 page 4 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications AutoPowr/IVT transmission Type .......... infinitely variable mechanical/hydraulic transmission Forward/reverse speed range .......... 0.1 km/h (0.06 mph)—40 km/h (25 mph) Forward/reverse speed range .......... 0.1 km/h (0.06 mph)—50 km/h (31 mph) [ If equipped ] Shifting the reverse drive lever .......... electrical, under load, without operating clutch Shifting the speed control lever .......... increases and decreases in speed are infinitely variable and take place without interrupting the power flow or actuating the clutch PowrQuad Plus transmission Type .......... synchronized hydraulic transmission Range shifting .......... mechanically, synchronized -Tractors with 40 km/h (25 mph) transmission .......... 5 ranges Shifting of the 4 gears .......... mechanical/hydraulic, under load, without actuating the clutch Reverse gear shifting .......... mechanical/hydraulic, under load, without actuating the clutch Shifting the F-N-R lever .......... mechanical-hydraulic or electrical-hydraulic, under load, without operating clutch AutoQuad II transmission Type .......... synchronized hydraulic transmission Range shifting .......... mechanically, synchronized -Tractors with 40 km/h (25 mph) transmission .......... 5 ranges -Tracors with 50 km/h (31 mph) transmission .......... 5 ranges Shifting of the 4 gears .......... electrical-hydraulic, under load, without operating clutch Reverse gear shifting .......... electrical-hydraulic, under load, without operating clutch Shifting the F-N-R lever .......... mechanical-hydraulic or electrical-hydraulic, under load, without operating clutch Creeper transmission Type .......... non-synchronized reduction gear Reduction of ground speed in ranges A, B and C as well as in the reverse range .......... approx. 90 % Shifting the two creeper speeds .......... mechanically, non-synchronized Rear PTO Type .......... independent, engaging/disengaging under load Engine speed for PTO operation - 540 rpm rear PTO (reversible or shiftable) .......... 1995 rpm - 540E rpm rear PTO .......... 1743 rpm - 1000 rpm rear PTO .......... 1995 rpm Front PTO <- Go to Section TOC Section 10 page 5 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications Type .......... engaging/disengaging under load Engine speed for 1000 rpm front PTO (viewed in direction of travel) - clockwise rotating (6 splines) .......... 1995 rpm - counterclockwise rotating (21 splines) .......... 1995 rpm Differential assembly Type .......... helical bevel gear drive Differential lock Operation .......... electrical/hydraulic, pedal operated Disengaging .......... electrical/hydraulic, after traction has equalized Final drives Type .......... planetary reduction gear Front-Wheel Drive Type .......... operated under load, hydraulically controlled drive with wet disk clutch Control .......... solenoid valve, electrical-hydraulic Engagement .......... with pre-tensioned Belleville springs Disengagement .......... hydraulically FWD Axle with TLS Type .......... active spring system with levelling control Control .......... electro/hydro/pneumatic Cab Suspension: Type .......... active spring system with levelling control Control .......... electro/hydro/pneumatic Hydraulic Brakes Type .......... self-adjusting, hydraulically operated wet disk brakes, individually acting in field operation Handbrake Type .......... mechanically operated brake band acting on differential Parking Lock Type .......... mechanically operated locking pawl, acting on front wheel drive gear <- Go to Section TOC Section 10 page 6 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications Hydraulic System with Axial Piston Pump (PFC System) Type .......... closed-center system with load-sensing control Pump displacement .......... 28 cm 3 (1.7 cu.in.) or 45 cm 3 (2.7 cu.in.) System pressure: min. (stand-by) .......... 3000 kPa (30 bar; 435 psi) max. .......... 20000 kPa (200 bar; 2900 psi) Pump type .......... axial piston pump, pressure- and flow-compensated Rockshaft Type .......... three-point hitch with two lift cylinders, activated via stepper motor and valve Control types .......... load, depth, load-and depth control, float position Control .......... electronic/hydraulic draft link control, draft sensor or position sensor (actual value), .......... operation box (set-point values), .......... electronic control unit (processor) Front Hitch Front Hitch .......... controlled via selective control valve Ground Speeds Ground Speeds .......... see Operator′s Manual Front and Rear Wheels Tires, wheel treads, tire pressure and ballast .......... see Operator′s Manual Dimensions and Weights Dimensions and Weights .......... see Operator′s Manual <- Go to Section TOC Section 10 page 7 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications Capacities Fuel tank .......... 207 L (54.7 U.S. gal.), 250 L (66.0 US.gal) or 325 L (85.9 US.gal.) Cooling system - coolant change .......... 28 L (7.4 U.S. gal.) Engine crankcase - oil change with filter change .......... 19.5 L (5.2 US.gal.) - oil change without filter change .......... 18.5 L (4.9 US.gal.) Transmission/hydraulic system AutoQuad Plus and AutoQuad II transmissions - oil change with filter change .......... 56 L (14.8 US.gal.) AutoPowr/IVT transmission - oil change with filter change .......... 66 L (17.4 US.gal.) Extra on tractors with - creeper .......... 1 L (0.3 U.S. gal.) - front-wheel drive axle .......... 3 L (0.8 U.S. gal.) - front-wheel drive axle with TLS .......... 3 L (0.8 U.S. gal.) →NOTE: Due to different equipment and design, the capacities of the front-wheel drive axles are approximate; they vary considerably. As a basic rule: Always fill with oil up to the bottom of filler plug hole. <- Go to Section TOC Section 10 page 8 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications Front-wheel drive axle without TLS 6820 (AS 2045) - axle housing .......... 6.6 L (1.7 U.S. gal.) - final drive housing (each) .......... 0.8 L (0.2 U.S. gal.) 6920/6920S (AS 2060) - axle housing .......... 7.0 L (1.8 U.S. gal.) - final drive housing (each) .......... 1.7 L (0.4 U.S. gal.) 6920/6920S (045JD) - axle housing .......... 9.5 L (2.5 U.S. gal.) - final drive housing (each) .......... 2.0 L (0.53 U.S. gal.) Front-wheel drive axle with TLS 6820 (AS 2045) - axle housing .......... 8.0 L (2.11 U.S. gal.) - final drive housing (each) .......... 1.7 L (0.4 U.S. gal.) 6920/6920S (AS 2060) - axle housing .......... 9 L (2.4 U.S. gal.) - final drive housing (each) .......... 2.2 L (0.6 U.S. gal.) 6920/6920S (045JDS20) - axle housing .......... 10.6 L (2.8 U.S. gal.) - final drive housing (each) .......... 2.0 L (0.53 U.S. gal.) Front-wheel drive axle with TLS and disk brake 6820 (AS 2045) - axle housing .......... 8.0 L (2.11 U.S. gal.) - final drive housing (each) .......... 1.0 L (0.3 U.S. gal.) 6920/6920S (AS 2060) - axle housing .......... 9.0 L (2.4 U.S. gal.) - final drive housing (each) .......... 1.8 L (0.5 U.S. gal.) 6920/6920S (045JDS20) - axle housing .......... 10.6 L (2.8 U.S. gal.) - final drive housing (each) .......... 2.0 L (0.5 U.S. gal.) Front PTO .......... 3.5 L (0.9 U.S. gal.) Air-conditioning system R134a refrigerant .......... 1450 - 1500 g (2.20 - 3.30 lb) Oil volume (PAG oil) .......... 220 ml (7.44 fl. oz.) Handling and Storing Diesel Fuel CAUTION: Handle fuel carefully. Do not fill the fuel tank when engine is running. DO NOT smoke while you fill the fuel tank or service the fuel system. Fill the fuel tank at the end of each day′s operation to prevent water condensation and freezing during cold weather. <- Go to Section TOC Section 10 page 9 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications Keep all storage tanks as full as practicable to minimize condensation. Ensure that all fuel tank caps and covers are installed properly to prevent moisture from entering. Monitor water content of the fuel regularly. When using bio-diesel fuel, the fuel filter may require more frequent replacement due to premature plugging. Check engine oil level daily prior to starting engine. A rising oil level may indicate fuel dilution of the engine oil. IMPORTANT: The fuel tank is vented through the filler cap. If a new filler cap is required, always replace it with an original vented cap. When fuel is stored for an extended period or if there is a slow turnover of fuel, add a fuel conditioner to stabilize the fuel and prevent water condensation. Contact your fuel supplier for recommendations. <- Go to Section TOC Section 10 page 10 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications Diesel Fuel Consult your local fuel distributor for properties of the diesel fuel available in your area. In general, diesel fuels are blended to satisfy the low temperature requirements of the geographical area in which they are marketed. Diesel fuels specified to EN 590 or ASTM D975 are recommended. In all cases, the fuel shall meet the following properties: Cetane number of 40 minimum. Cetane number greater than 50 is preferred, especially for temperatures below -20°C (-4°F) or elevations above 1500 m (5000 ft). Cold Filter Plugging Point (CFPP) below the expected low temperature ORCloud Point at least 5°C (9°F) below the expected low temperature. Fuel lubricity should pass a minimum of 3100 gram load level as measured by the BOCLE scuffing test. Sulfur content: Sulfur content should not exceed 0.5%. Sulfur content less than 0.05% is preferred. If diesel fuel with sulfur content greater than 0.5% sulfur content is used, reduce the service interval for engine oil and filter by 50%. DO NOT use diesel fuel with sulfur content greater than 1.0% Bio-diesel fuels to DIN 51606 or an equivalent standard (RME) etc. should be used only after consultation with your John Deere dealer. →NOTE: If the injection pump has been adapted for bio-diesel fuel (RME), the tractor can be used in temperatures as low as -10°C. If the tractor is operated frequently at temperatures of around -10°C or lower and the fuel used is either bio-diesel or normal diesel, the engine oil level should be checked every day before the engine is started. If the oil level is 10 mm higher than the max. level, a change of oil is required. Oil change intervals should be reduced when operating in low temperatures under the conditions described above. Do NOT mix used engine oil or any other type of lubricant with diesel fuel. <- Go to Section TOC Section 10 page 11 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications Lubricity of Diesel Fuel Most diesel fuels manufactured in the United States, Canada, and the European Union have adequate lubricity to ensure proper operation and durability of fuel injection system components. However, diesel fuels manufactured in some areas of the world may lack the necessary lubricity. IMPORTANT: Make sure the diesel fuel used in your machine demonstrates good lubricity characteristics. Fuel lubricity should pass a maximum scar diameter of 0.45 mm as measured by ASTM D6079 or ISO 12156-1. If fuel of low or unknown lubricity is used, add John Deere PREMIUM DIESEL FUEL CONDITIONER (or equivalent) at the specified concentration. Lubricity of Biodiesel Fuel Significant improvement in lubricity can occur with biodiesel blends up to B20. The gain in lubricity above a 20% blend is limited. <- Go to Section TOC Section 10 page 12 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications Diesel Engine Break-In Oil New engines are filled at the factory with either John Deere Break-In ™ or Break-In™ Plus Engine Oil. During the break-in period, add John Deere Break-In™ or Break-In™ Plus Engine Oil, respectively, as needed to maintain the specified oil level. Operate the engine under various conditions, particularly heavy loads with minimal idling, to help seat engine components properly. Change the oil and filter at 100 hours maximum for Break-In™ Oil or 500 hours maximum for Break-In™ Plus Oil during the initial operation of a new or rebuilt engine. After engine overhaul, fill the engine with either John Deere Break-In™ or Break-In™ Plus Engine Oil. If John Deere Break-In™ or Break-In™ Plus Engine Oil is not available, use a 10W-30 diesel engine oil meeting one of the following during the first 100 hours of operation: API Service Classification CE API Service Classification CD API Service Classification CC ACEA Oil Sequence E2 ACEA Oil Sequence E1 IMPORTANT: Do not use Plus-50™ II, Plus-50 or engine oils meeting any of the following for the initial break-in of a new or rebuilt engine: API CJ-4 ACEA E9 API CI-4 PLUS ACEA E7 API CI-4 ACEA E6 API CH-4 ACEA E5 API CG-4 ACEA E4 API CF-4 ACEA E3 API CF-2 API CF These oils will not allow the engine to break in properly. John Deere Break-In™ Plus Engine Oil can be used for all John Deere diesel engines at all emission certification levels. After the break-in period, use John Deere Plus-50 ™ II, John Deere Plus-50, or other diesel <- Go to Section TOC Section 10 page 13 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications engine oil as recommended in this manual. <- Go to Section TOC Section 10 page 14 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications Diesel Engine Oil (Engine Serial Number up to 799999) Use oil with a viscosity based on the expected air temperature range during the period between oil changes. The following oil is preferred: John Deere PLUS-50 ™ The following oil is also recommended: John Deere TORQ-GARD SUPREME ™ Other oils may be used if they meet one or more of the following: API CG-4 API CF-4 ACEA E5 ACEA E4 <- Go to Section TOC Section 10 page 15 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications ACEA E3 ACEA E2 Multi-viscosity diesel engine oils are preferred. If diesel fuel with sulfur content greater than 0.5% is used, reduce the service interval by 50%. <- Go to Section TOC Section 10 page 16 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications Diesel Engine Oil (Engine Serial Number from 800000) Use oil viscosity based on the expected air temperature range during the period between oil changes. The following oil is recommended for 500-hour oil changes: John Deere PLUS-50 ™ Other oils may be used if they meet one or more of the following: ACEA E5 ACEA E4 If none of the available oil types meet these specifications, reduce the intervals at which oil is changed to 250 hours. In this case, John Deere TORQ-GARD SUPREME ™ is recommended. Other oils may be used if they meet one or more of the following: <- Go to Section TOC Section 10 page 17 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications API CG-4 API CF-4 ACEA E3 ACEA E2 Multi-viscosity diesel engine oils are preferred. If diesel fuel with sulfur content greater than 0.5% is used, reduce the service interval by 50% also. <- Go to Section TOC Section 10 page 18 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications Transmission and Hydraulic Oil Use oil with a viscosity based on the expected air temperature range during the period between oil changes. The following oils are preferred: John Deere HY-GARD ™ John Deere HY-GARD ™ with low viscosity Other oils may be used if they meet one or more of the following: John Deere Standard JDM J20C John Deere Standard JDM J20D Use John Deere BIO-HY-GARD II ™ [ BIO-HY-GARD II meets or exceeds the minimum biodegradability of 80 % within 21 days according to CEC L-33-A-93 test method. BIO-HY-GARD <- Go to Section TOC Section 10 page 19 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications meets or exceeds the minimum biodegradability of 80 % within 21 days according to CEC L-33-T-82 test method. These oils should not be mixed with mineral oils because this reduces the biodegradability and makes proper oil recycling impossible. ] or BIO-HY-GARD ™ [ BIO-HY-GARD II meets or exceeds the minimum biodegradability of 80 % within 21 days according to CEC L-33-A-93 test method. BIO-HY-GARD meets or exceeds the minimum biodegradability of 80 % within 21 days according to CEC L-33-T-82 test method. These oils should not be mixed with mineral oils because this reduces the biodegradability and makes proper oil recycling impossible. ] when a biodegradable fluid is required. IMPORTANT: On tractors with AutoPowr: Do NOT use HY-GARD with low viscosity. Do NOT use BIO-HY-GARD. On the other hand, BIO-HY-GARD II may be used. Other types of oil used must meet John Deere Standard JDM J20C. <- Go to Section TOC Section 10 page 20 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications Front-Wheel Drive Axle Oil Use oil with a viscosity based on the expected air temperature range during the period between oil changes. The following oil is preferred. John Deere HY-GARD ™ Other oils may be used if they meet the following: John Deere Standard JDM J20C Use one of the following oils when a biodegradable fluid is required: John Deere BIO-HY-GARD II ™ [ BIO-HY-GARD II meets or exceeds the minimum biodegradability of 80 % within 21 days according to CEC L-33-A-93 test method. BIO-HY-GARD meets or exceeds the minimum biodegradability of 80 % within 21 days according to CEC L-33-T-82 test method. These oils should not be mixed with <- Go to Section TOC Section 10 page 21 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications mineral oils because this reduces the biodegradability and makes proper oil recycling impossible. ] or BIO-HY-GARD ™ [ BIO-HY-GARD II meets or exceeds the minimum biodegradability of 80 % within 21 days according to CEC L-33-A-93 test method. BIO-HY-GARD meets or exceeds the minimum biodegradability of 80 % within 21 days according to CEC L-33-T-82 test method. These oils should not be mixed with mineral oils because this reduces the biodegradability and makes proper oil recycling impossible. ] →NOTE: Do NOT use BIO-HY-GARD on braked axles. <- Go to Section TOC Section 10 page 22 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications Diesel Engine Coolant The engine cooling system is filled to provide year-round protection against corrosion and cylinder liner pitting, and winter freeze protection to -37°C (-34°F). John Deere COOL-GARD is preferred for service. If John Deere COOL-GARD is not available, use a low silicate ethylene glycol or propylene glycol base coolant concentrate in a 50% mixture of concentrate with quality water. The coolant concentrate shall be of a quality that provides cavitation protection to cast iron and aluminum parts in the cooling system. John Deere COOL-GARD meets this requirement. Freeze protection A 50% mixture of ethylene glycol engine coolant in water provides freeze protection to -37°C (-34°F). A 50% mixture of propylene glycol engine coolant in water provides freeze protection to -33°C (-27°F). If protection at lower temperatures is required, consult your John Deere dealer for recommendations. Water quality Water quality is important to the performance of the cooling system. Distilled, deionized, or demineralized water is recommended for mixing with ethylene glycol and propylene glycol base engine coolant concentrate. IMPORTANT: Do not use cooling system sealing additives or antifreeze that contains sealing additives. IMPORTANT: Do not mix ethylene glycol and propylene glycol base coolants. <- Go to Section TOC Section 10 page 23 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications Supplemental Coolant Additives Some coolant additives will gradually deplete during engine operation. For John Deere COOLGARD ™ Premix, COOL-GARD Concentrate, or John Deere COOL-GARD PG Premix, replenish coolant additives between drain intervals by adding a supplemental coolant additive as determined necessary by coolant testing. John Deere LIQUID COOLANT CONDITIONER is recommended as a supplemental coolant additive for John Deere COOL-GARD Premix, COOL-GARD Concentrate, and COOL-GARD PG Premix. John Deere LIQUID COOLANT CONDITIONER is not designed for use with COOL-GARD II Premix or COOL-GARD II Concentrate. IMPORTANT: Do not add a supplemental coolant additive when the cooling system is drained and refilled with any of the following: John Deere COOL-GARD II John Deere COOL-GARD John Deere COOL-GARD PG If other coolants are used, consult the coolant supplier and follow the manufacturer′s recommendation for use of supplemental coolant additives. The use of non-recommended supplemental coolant additives may result in additive drop-out and gelation of the coolant. Add the manufacturer′s recommended concentration of supplemental coolant additive. DO NOT add more than the recommended amount. Grease <- Go to Section TOC Section 10 page 24 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications Use grease based on NLGI consistency numbers and the expected air temperature range during the service interval. John Deere SD POLYUREA GREASE is preferred. The following greases are also recommended John Deere HD LITHIUM COMPLEX GREASE John Deere HD WATER RESISTANT GREASE John Deere GREASE-GARD ™ Other greases may be used if they meet the following: NLGI Performance Classification GC-LB IMPORTANT: Some types of grease thickeners are not compatible with others. Consult your grease supplier before mixing different types of grease. Oil Filters Filtration of oils is critical to proper operation and lubrication. Always change filters regularly as specified in this manual. <- Go to Section TOC Section 10 page 25 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications Use filters meeting John Deere performance specifications. Mixing of Lubricants In general, avoid mixing different brands or types of oil. Oil manufacturers blend additives in their oils to meet certain specifications and performance requirements. Mixing different oils can interfere with the proper functioning of these additives and degrade lubricant performance. Consult your John Deere dealer to obtain specific information and recommendations. Lubricant Storage Your equipment can operate at top efficiency only when clean lubricants are used. Use clean containers to handle all lubricants. Whenever possible, store lubricants and containers in an area protected from dust, moisture, and other contamination. Store containers on their side to avoid water and dirt accumulation. Make certain that all containers are properly marked to identify their contents. Properly dispose of all old containers and any residual lubricant they may contain. Operating in Warm Temperature Climates John Deere engines are designed to operate using glycol base engine coolants. Always use a recommended glycol base engine coolant, even when operating in geographical areas where freeze protection is not required. John Deere COOL-GARD ™ II Premix is available in a concentration of 50% ethylene glycol. However, there are situations in warm temperature climates where a coolant with lower glycol concentration (approximately 20% ethylene glycol) has been approved. In these cases, the low glycol formulation has been modified to provide the same level of corrosion inhibitor as John Deere COOL-GARD II Premix (50/50). <- Go to Section TOC Section 10 page 26 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications IMPORTANT: Water may be used as coolantin emergency situations only. Foaming, hot surface aluminum and iron corrosion, scaling, and cavitation will occur when water is used as the coolant, even when coolant conditioners are added. Drain cooling system and refill with recommended glycol base engine coolant as soon as possible. Alternative and Synthetic Lubricants Conditions in certain geographical areas may require lubricant recommendations different from those printed in this manual. Some John Deere brand coolants and lubricants may not be available in your location. Synthetic lubricants may be used if they meet the performance requirements as shown in this manual. The temperature limits and service intervals shown in this manual apply to both conventional and synthetic oils. Re-refined base stock products may be used if the finished lubricant meets the performance requirements. Avoid mixing different brands or types of oils. Oil manufacturers blend base stock and additives to create their oils and to meet certain specifications and performance requirements. Mixing different oils can interfere with proper functioning of these formulations and degrade lubricant performance. Consult your authorized John Deere dealer to obtain specific information and recommendations. <- Go to Section TOC Section 10 page 27 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications Unified Inch Bolt and Screw Torque Values SAE Grade 2 Bolt or Screw [ Grade 2 applies for hex cap screws (not hex bolts) up to 6. in (152 mm) long. Grade 1 applies for hex cap screws over 6 in. (152 mm) long, and for all other types of bolts and screws of any length. ] SAE Grade 1 Lubricated Lubricated [ “Lubricated” means coated with a lubricant such as engine oil, fasteners with phosphate and oil coatings, or 7/8 in. and larger fasteners with JDM F13C zinc flake coating. ] [ “Dry” means plain or zinc plated without any lubrication, or 1/4 to 3/4 in. fasteners with JDM F13B zinc flake coating. ] [ “Lubricated” means coated with a lubricant such as engine oil, fasteners with phosphate and oil coatings, or 7/8 in. and larger fasteners with JDM F13C zinc flake coating. ] Dry SAE Grade 5, 5.1 or 5.2 SAE Grade 8 or 8.2 Lubricated Lubricated [ “Dry” means plain or zinc plated without any lubrication, or 1/4 to 3/4 in. fasteners with JDM F13B zinc flake coating. ] [ “Lubricated” means coated with a lubricant such as engine oil, fasteners with phosphate and oil coatings, or 7/8 in. and larger fasteners with JDM F13C zinc flake coating. ] Dry [ “Dry” means plain or zinc plated without any lubrication, or 1/4 to 3/4 in. fasteners with JDM F13B zinc flake coating. ] [ “Lubricated” means coated with a lubricant such as engine oil, fasteners with phosphate and oil coatings, or 7/8 in. and larger fasteners with JDM F13C zinc flake coating. ] Dry Dry [ “Dry” means plain or zinc plated without any lubrication, or 1/4 to 3/4 in. fasteners with JDM F13B zinc flake coating. ] Size N˙m lb.-in. N˙m lb.-in. N˙m lb.-in. N˙m lb.-in. N˙m lb.-in. N˙m lb.-in. N˙m lb.-in. N˙m lb.-in. 1/4 3.7 33 4.7 42 6 53 7.5 66 9.5 84 12 106 13.5 120 17 150 N˙m lb.-ft. N˙m lb.-ft. 28 20.5 35 26 5/16 3/8 7/16 7.7 13.5 68 120 9.8 86 12 106 15.5 137 19.5 172 25 221 N˙m lb.-ft. N˙m lb.-ft. 35 26 44 32.5 49 36 63 46 17.5 155 22 194 27 240 N˙m lb.-ft. N˙m lb.-ft. N˙m lb.-ft. 28 20.5 35 26 44 32.5 56 41 70 52 80 59 100 74 22 194 N˙m lb.-ft. 1/2 34 25 42 31 53 39 67 49 85 63 110 80 120 88 155 115 9/16 48 35.5 60 45 76 56 95 70 125 92 155 115 175 130 220 165 5/8 67 49 85 63 105 77 135 100 170 125 215 160 240 175 305 225 3/4 120 88 150 110 190 140 240 175 300 220 380 280 425 315 540 400 7/8 190 140 240 175 190 140 240 175 490 360 615 455 690 510 870 640 1 285 210 360 265 285 210 360 265 730 540 920 680 1030 760 1300 960 1-1/8 400 300 510 375 400 300 510 375 910 670 1150 850 1450 1075 1850 1350 1-1/4 570 420 725 535 570 420 725 535 1280 945 1630 1200 2050 1500 2600 1920 1-3/8 750 550 950 700 750 550 950 700 1700 1250 2140 1580 2700 2000 3400 2500 1-1/2 990 730 1250 930 990 730 1250 930 2250 1650 2850 2100 3600 2650 4550 3350 Torque values listed are for general use only, based on the strength of the bolt or screw. DO NOT use these values if a different torque value or tightening procedure is given for a specific application. For plastic insert or crimped steel type lock nuts, for stainless steel fasteners, or for nuts on U-bolts, see the tightening instructions for the specific application. Shear bolts are designed to fail under predetermined loads. Always replace shear bolts with identical grade. <- Go to Section TOC Replace fasteners with the same or higher grade. If higher grade fasteners are used, tighten these to the strength of the original. Make sure fastener threads are clean and that you properly start thread engagement. When possible, lubricate plain or zinc plated fasteners other than lock nuts, wheel bolts or wheel nuts, unless different instructions are given for the specific application. Section 10 page 28 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications Metric Bolt and Screw Torque Values Bolt or Screw Class 4.8 Class 8.8 or 9.8 Class 10.9 Class 12.9 Lubricated Lubricated Lubricated Lubricated [ “Lubricated” means coated with a lubricant such as engine oil, fasteners with phosphate and oil coatings, or M20 and larger fasteners with JDM F13C zinc flake coating. ] [ “Dry” means plain or zinc plated without any lubrication, or M6 to M18 fasteners with JDM F13B zinc flake coating. ] [ “Lubricated” means coated with a lubricant such as engine oil, fasteners with phosphate and oil coatings, or M20 and larger fasteners with JDM F13C zinc flake coating. ] [ “Dry” means plain or zinc plated without any lubrication, or M6 to M18 fasteners with JDM F13B zinc flake coating. ] [ “Lubricated” means coated with a lubricant such as engine oil, fasteners with phosphate and oil coatings, or M20 and larger fasteners with JDM F13C zinc flake coating. ] Dry Dry [ “Dry” means plain or zinc plated without any lubrication, or M6 to M18 fasteners with JDM F13B zinc flake coating. ] [ “Lubricated” means coated with a lubricant such as engine oil, fasteners with phosphate and oil coatings, or M20 and larger fasteners with JDM F13C zinc flake coating. ] Dry Dry [ “Dry” means plain or zinc plated without any lubrication, or M6 to M18 fasteners with JDM F13B zinc flake coating. ] Size N˙m lb.-in. N˙m lb.-in. N˙m lb.-in. N˙m lb.-in. N˙m lb.-in. N˙m lb.-in. N˙m lb.-in. N˙m lb.-in. M6 4.7 42 6 53 8.9 79 11.3 100 13 115 16.5 146 15.5 137 19.5 172 N˙m lb.-ft. N˙m lb.-ft. N˙m lb.-ft. N˙m lb.-ft. 32 23.5 40 29.5 37 27.5 47 35 M8 M10 11.5 102 14.5 128 22 194 27.5 243 N˙m lb.-ft. N˙m lb.-ft. N˙m lb.-ft. 29 21 43 32 55 40 63 46 80 59 75 55 95 70 23 204 N˙m lb.-ft. M12 40 29.5 50 37 75 55 95 70 110 80 140 105 130 95 165 120 M14 63 46 80 59 120 88 150 110 175 130 220 165 205 150 260 190 M16 100 74 125 92 190 140 240 175 275 200 350 255 320 235 400 300 M18 135 100 170 125 265 195 330 245 375 275 475 350 440 325 560 410 M20 190 140 245 180 375 275 475 350 530 390 675 500 625 460 790 580 M22 265 195 330 245 510 375 650 480 725 535 920 680 850 625 1080 800 M24 330 245 425 315 650 480 820 600 920 680 1150 850 1080 800 1350 1000 M27 490 360 625 460 950 700 1200 885 1350 1000 1700 1250 1580 1160 2000 1475 M30 660 490 850 625 1290 950 1630 1200 1850 1350 2300 1700 2140 1580 2700 2000 M33 900 665 1150 850 1750 1300 2200 1625 2500 1850 3150 2325 2900 2150 3700 2730 M36 1150 850 1450 1075 2250 1650 2850 2100 3200 2350 4050 3000 3750 2770 4750 3500 Torque values listed are for general use only, based on the strength of the bolt or screw. DO NOT use these values if a different torque value or tightening procedure is given for a specific application. For stainless steel fasteners or for nuts on U-bolts, see the tightening instructions for the specific application. Tighten plastic insert or crimped steel type lock nuts by turning the nut to the dry torque shown in the chart, unless different instructions are given for the specific application. <- Go to Section TOC Shear bolts are designed to fail under predetermined loads. Always replace shear bolts with identical property class. Replace fasteners with the same or higher property class. If higher property class fasteners are used, tighten these to the strength of the original. Make sure fastener threads are clean and that you properly start thread engagement. When possible, lubricate plain or zinc plated fasteners other than lock nuts, wheel bolts or wheel nuts, unless different instructions are given for the specific application. Section 10 page 29 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications Hydraulic system inch fitting torques LEGEND: A B C D Bulkhead fitting Lock nut Collar nut Collar nut Fittings with flat-faced ring seal Collar nut Lock nut for bulkhead fitting Thread size N˙m lb-ft N˙m lb-ft 9/16—18 16 12 5 3.5 11/16—16 24 18 9 6.5 13/16—16 50 37 17 12.5 1—14 69 51 17 12.5 1-3/16—12 102 75 17 12.5 1-7/16—12 142 105 17 12.5 1-11/16—12 190 140 17 12.5 2—12 217 160 17 12.5 The torques in the table above are intended only as approximate values, and do NOT apply if a different torque value is listed for specific fittings at other points in this manual. Check fittings regularly to make sure they are seated properly. When replacing fittings, be sure to use parts with an equal or higher grade to the parts you are replacing. Items of hardware (e.g. collar nuts) that are of a higher grade should be tightened to the same torque value as the parts they replace. It is vitally important to make sure that the sealing faces are clean and that the O-rings have been inserted properly. <- Go to Section TOC Section 10 page 30 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications Hydraulic system metric fitting torques LEGEND: A B C D Stud-end fitting Groove for metric spec. Lock nut Adjustable stud-end fitting Straight stud-end fitting and lock nut for adjustable stud-end fitting Steel or grey-cast iron Aluminium Thread size N˙m lb–ft N˙m lb–ft M12x1.5 21 15.5 9 6.6 M14x1.5 33 24 15 11 M16x1.5 41 30 18 13 M18x1.5 50 37 21 15 M22x1.5 69 51 28 21 M27x2 102 75 46 34 M33x2 158 116 71 52 M38x2 176 130 79 58 M42x2 190 140 85 63 M48x2 217 160 98 72 The torques in the table above are intended only as approximate values, and do NOT apply if a different torque value is listed for specific fittings at other points in this Manual. Check fittings regularly to make sure they are seated properly. When replacing fittings, be sure to use parts with an equal or higher grade to the parts you are replacing. Items of hardware (e.g. union nuts) that are of a higher grade should be tightened to the same torque value as the parts they replace. It is vitally important to make sure that the sealing faces are clean and that the O-rings have been inserted properly. <- Go to Section TOC Section 10 page 31 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications Product identification and component serial numbers <- Go to Section TOC Section 10 page 32 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION LEGEND: DT-1 <- Go to Section TOC Group 05: Specifications PowrQuad module Section 10 page 33 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION DT-2 EN-1 FA-1 FI-1 FI-2 FI-3 HY-1 OS-1 OS-2 OS-3 OS-4 OS-5 OS-6 RA-1 RA-3 RI-1 RI-2 RI-3 RI-4 RI-5 RI-6 Group 05: Specifications SyncroPlus module Motor Front axle Front PTO Front hitch Front loader Hydraulic pump Operator′s cab ROPS Seat Brake valve Steering valve Compressor, air conditioning Transmission assembly Transmission ratios, differential - FWD Inlet priority valve Hydraulic pick-up hitch Wagon hitch Swinging drawbar Holder for pick-up hitch Trailer brake valve Engine Serial Number →NOTE: Besides the engine serial number, the plate shows the engine type as well. When ordering spare parts for the engine, please quote all the numbers and letters on this type plate. The engine serial number plate is located on the right-hand side of engine block. <- Go to Section TOC Section 10 page 34 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications Transmission serial number →NOTE: Besides the transmission serial number and type this plate shows the transmission ratio of differential and front wheel drive as well. The transmission serial number plate is located on the right-hand side of differential housing. Front wheel drive axle serial number The front wheel drive axle serial number plate is located on the rear, right-hand side of the axle. Operator′s cab serial number <- Go to Section TOC Section 10 page 35 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 05: Specifications The operator′s cab serial number plate is located behind the operator′s seat on the hydraulic pump cover. Operator′s seat serial number LEGEND: A B Designation Part number (needed when ordering) <- Go to Section TOC Section 10 page 36 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION C Group 10: Tune-Up Date of manufacture (year/week) The serial number of the operator′s seat is located on the back of the seat. Explanation of serial number plate field C: The first two digits (XXxx xx) indicate the year of manufacture. Third and fourth digits (xxXX xx) indicate the week of manufacture. Sub-assembly serial numbers Fuel injection pump, fuel injection nozzles, alternator, starter motor, steering unit (hydrostatic steering system), air conditioning system compressor (if equipped) and the hydraulic pump also have serial numbers. These numbers help to distinguish between the different types of a sub-assembly. <- Go to Section TOC Section 10 page 37 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 10: Tune-Up Group 10 - Tune-Up Tune-Up (Summary of References) "Specifications" "Using high-pressure washers" “Preliminary engine tests” “Tractor tune-up” “Removing and cleaning the primary air cleaner element” “Checking the air cleaner safety element” “Installing the primary air cleaner element” “Checking air intake system connections for leaks” “Checking the crankcase vent hose for clogging” “Cleaning the radiator grille screen” “Cleaning radiator” “Checking the caps on the expansion tank” “Checking the radiator for leaks” “Checking the engine′s thermostat” “Checking the fuel transfer pump operation” “Bleeding the fuel system (with Bosch VP44 injection pump)” “Checking the fuel filter (with Bosch VP44 injection pump)” “Cleaning the water trap” “Checking the fuel filter (with Denso/Stanadyne injection pump; Stage II engines according to 97/68/EC)” ”Bleeding the fuel system (with Stanadyne injection pump; Stage II engines according to 97/68/EC)” ”Bleeding the fuel system (with Denso injection pump; Stage II engines according to 97/68/EC)” “Running the engine until it is warm and checking engine speeds” “Checking setting of fuel injection pump” “Cleaning the battery, cables and battery box with a clean cloth” “Checking the neutral start circuit” “Checking operation of starting motor” “Checking operation of lighting system” “Final engine check” “Tractor operation check” <- Go to Section TOC Section 10 page 38 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 10: Tune-Up Specifications Thermostat - opening temperature .......... 82°C (180°F) - operating temperature (fully open) .......... 94°C (202°F) Slow idle - speed .......... 845 - 855 rpm Fast idle - speed .......... 2455 - 2465 rpm Rated engine speed .......... 2300 rpm Air cleaner restriction warning switch closes at a vacuum of .......... 5.9 to 6.9 kPa (59 to 69 mbar; 0.85 to 1.0 psi) Radiator cap pressure valve - opens at a pressure of .......... 70 to 90 kPa (0.70 to 0.90 bar; 10 to 13 psi) - vacuum, max. .......... 10 kPa (100 mbar; 1.5 psi) Cooling system test pressure .......... 50 to 60 kPa (0.5 to 0.6 bar; 7 to 8.7 psi) Using High-Pressure Washers IMPORTANT: Directing pressurized water at electronic/electrical components or connectors, bearings and hydraulic seals, fuel injection pumps or other sensitive parts and components may cause product malfunctions. Reduce pressure, and spray at a 45 to 90° angle. <- Go to Section TOC Section 10 page 39 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 10: Tune-Up Preliminary Engine Test Before tuning up an engine, determine whether a tune-up will restore operating efficiency. If there is doubt, the following preliminary test will help to determine whether the engine can be tuned. Perform the following tests: [1] - After engine has been stopped for several hours, carefully loosen crankcase drain plug and watch for any water to seep out. A few drops could be due to condensation, but any more than this would indicate problems which require engine repairs rather than just a tuneup. Refer to the Technical Manual ”Engines” in the event of malfunctions. [2] - With engine stopped, inspect engine coolant for an oil film. With engine running, inspect coolant for air bubbles. Either condition would indicate problems which require engine repairs rather than just a tune-up. Refer to the Technical Manual ”Engines” in the event of malfunctions. [3] - Perform a dynamometer test as instructed below. See Technical Manual ”Operation and Tests”. Repeat dynamometer test after tune-up so that horsepower before and after tune-up can be compared. [4] - Measure compression as described in the Technical Manual ”Engines”. <- Go to Section TOC Section 10 page 40 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 10: Tune-Up Tractor Tune-Up Fuel system components (Bosch VP44) LEGEND: A B C D E F G H I Fuel tank Primary fuel filter Fuel filter Injection pump (Bosch VP-44) Cooling element with integrated fuel cooler Fuel injection nozzle Fuel gauge sending unit Fuel transfer pump Control unit (ECU) <- Go to Section TOC Section 10 page 41 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 10: Tune-Up Denso/Stanadyne fuel system (Stage II engines according to 97/68/EC) LEGEND: A B C D E F G H I <- Go to Section TOC Fuel tank Primary fuel filter Fuel filter Injection pump Fuel cooler Fuel transfer pump Fuel gauge sending unit Control unit Check valve Section 10 page 42 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 10: Tune-Up Inspect the entire fuel system for leaks, and put right anything that is wrong. Removing and Cleaning the Primary Air Cleaner Element Open the hood, pull lug (A) forward and swing catch (B) down. Fold cover (C) up. Pull primary filter element (D) out of the cleaner housing. IMPORTANT: Never run the engine without the primary filter element! IMPORTANT: The guide ring for the primary air cleaner element must not be damaged or deformed. <- Go to Section TOC Section 10 page 43 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 10: Tune-Up Checking the Air Cleaner Safety Element Check if safety element (see arrow) is properly installed. IMPORTANT: Always replace secondary (safety) element, do not attempt to clean it. Installing the Primary Filter Element With the rubber seal first (arrows on decal pointing into the filter housing), slide a serviced or new primary filter element as far as it will go into the filter housing. Fold down the cover and let the catch click into place. IMPORTANT: Never close the hood or start the engine unless the filter is locked securely. <- Go to Section TOC Section 10 page 44 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 10: Tune-Up Checking the Air Intake System Connections for Leaks Check restriction in air intake system by measuring vacuum, see " Testing the Air Intake System ", Section 230, Group 15. Checking the Crankcase Vent Hose for Clogging LEGEND: A Vent hose If necessary, remove vent hose and clean it in a suitable solvent. Cleaning Dirt from Radiator Screen <- Go to Section TOC Section 10 page 45 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 10: Tune-Up Keeping the Radiator Screen Clean For efficient cooling, the radiator screen must be kept clean. Pull the screen (if equipped) out to the side. Remove any dust or oil and carefully straighten any bent fins. Checking the Caps on the Expansion Tank Use special tester for cap check, see " Checking the Expansion Tank Caps ", Section 230, <- Go to Section TOC Section 10 page 46 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 10: Tune-Up Group 15. Checking the Radiator for Leaks Clean cooling system as described under “Changing Coolant” in the Operator′s Manual. Refer to " Checking the Cooling System for Leaks ", Section 230, Group 15 in the event of malfunctions. Checking the engine′s thermostat Refer to Technical Manual “Engines”. Checking the Fuel Transfer Pump Operation <- Go to Section TOC Section 10 page 47 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 10: Tune-Up With Bosch VP44 injection pump Stage II engines to 97/68/EC LEGEND: A Fuel transfer pump In the event of a malfunction, see " Checking the Fuel Transfer Pump Operation ", Section 230, Group 15. <- Go to Section TOC Section 10 page 48 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 10: Tune-Up Bleeding the fuel system (with Bosch VP44 injection pump) CAUTION: High-pressure fluid Escaping fluid under pressure can penetrate the skin causing serious injury. Avoid the hazard by relieving pressure before disconnecting hydraulic or other lines. Tighten all connections before applying pressure. Search for leaks with a piece of cardboard. Protect hands and body from high pressure fluids. If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be surgically removed within a few hours or gangrene may result. Doctors unfamiliar with this type of injury should reference to a knowledgeable medical source. Such information is available from Deere & Company Medical Department in Moline, Illinois, U.S.A. Whenever the fuel system has been opened up for service (lines disconnected or filters removed), it will be necessary to bleed air from the system. This fuel system can only be bled by the electronic transfer pump or at the injection nozzles. Bleeding should not be performed at any location on the Bosch VP44 injection pump. <- Go to Section TOC Section 10 page 49 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 10: Tune-Up Bleeding at the Fuel Transfer Pump LEGEND: A B C Bleed orifice in filter base Overflow valve Fuel return line The bleed is automatically performed by a small orifice (A) inside the filter base connected to the overflow valve (B) on injection pump. This system allows air to escape continually through the fuel return line (C) when ignition is ON. [1] - Turn key in main switch to the right as far as the first switch position so that the fuel transfer pump is operating. [2] - Allow 40 seconds for electric transfer pump to complete priming. [3] - If additional system bleeding is required, bleed the circuit by loosening fuel line connections at injection nozzles. See the next procedure, "Bleeding the Fuel System at the Fuel Injection Nozzles". Bleeding the Fuel System at the Fuel Injection Nozzles Injection Line <- Go to Section TOC Section 10 page 50 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 10: Tune-Up [1] - Place throttle lever in half-throttle position. On engines equipped with electronic fuel shut-off solenoid, energize solenoid. [2] IMPORTANT: Always use a backup wrench when loosening or tightening fuel lines at nozzles and/or injection pump to avoid damage. Using two open-end wrenches, loosen two fuel line connections at injection nozzles. [3] - Crank engine over with starting motor for 15 seconds (but do not start engine) until fuel free from bubbles flows out of loosened connection. Retighten connection to specifications. Item Measurement Specification Fuel injection lines Torque 27 N˙m (20 lb-ft) [4] - Repeat procedure for remaining injection nozzles (if necessary) until all air has been removed from fuel system. <- Go to Section TOC Section 10 page 51 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 10: Tune-Up Checking the fuel filter (with Bosch VP44 injection pump) LEGEND: A B C Drain screw Plastic ring Drain screw (fuel tank) Should water or sediment deposits have settled in filter, proceed as follows: Loosen drain screw (A) and plastic ring (B). Retighten the screw and plastic ring as soon as water and sediment deposits have drained out. If water was present in fuel filter, then also slacken off the drain screw (C) under the fuel tank by one turn. After draining off any water deposits, retighten the drain screws (see table). Item Measurement Specification Drain screw (fuel tank) Torque 12 N˙m 9 lb-ft <- Go to Section TOC Section 10 page 52 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 10: Tune-Up Cleaning the water trap LEGEND: A B <- Go to Section TOC Drain plug Breather hole Section 10 page 53 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 10: Tune-Up Checking the Fuel Filter (with Denso/Stanadyne Injection Pump; Stage II Engines According to 97/68/EC) LEGEND: A B C Drain screw Bleed screw Drain plug (fuel tank) Should water or sediment deposits have settled in filter, proceed as follows: Loosen drain screw (A) and bleed screw (B). Retighten drain screw (A) and bleed screw (B) as soon as water and sediment deposits have drained out. If water was present in fuel filter, then also slacken off the drain plug (C) under the fuel tank by one turn. After draining off any water deposits, retighten drain plug (see table). Item Measurement Specification Drain plug (fuel tank) Torque 12 N˙m 9 lb-ft <- Go to Section TOC Section 10 page 54 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 10: Tune-Up Bleeding the Fuel System (with Stanadyne Injection Pump; Stage II Engines According to 97/68/EC) The fuel system must be bled whenever the fuel tank has been run dry or the fuel filters have been replaced. Turn key in main switch to the right as far as the first switch position so that the fuel transfer pump is operating. Keep the pump running for approx. 40 seconds. Bleeding the Fuel System (with Denso Injection Pump; Stage II Engines According to 97/68/EC) CAUTION: Never loosen or disconnect the lines between injection pump and nozzles as the fuel pressure there is very high! <- Go to Section TOC Section 10 page 55 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 10: Tune-Up The fuel system must be bled whenever the fuel tank has been run dry or the fuel filters have been replaced. Turn key in main switch to the right as far as the first switch position so that the fuel transfer pump is operating. Keep the pump running for approx. 40 seconds. Run Engine until it is Warm and Check Engine Speeds Engine speeds: See reference " Engine Specifications ", Section 10, Group 05. Adjustment: See reference " Speed Control Linkage ", Section 30, Group 05. For more information about the injection pump, see the Component Technical manuals for Diesel engines. Checking Setting of Fuel Injection Pump Refer to the component technical manual (CTM). Cleaning the Battery, Cables and Battery Box with a Clean Cloth <- Go to Section TOC Section 10 page 56 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 10: Tune-Up If necessary, remove oxidation on connectors using a wire brush. Coat battery poles and connectors with petroleum jelly. Check electrolyte level in each battery cell. Remove caps (A). Level of electrolyte should be above the mark. Fill with distilled water only. →NOTE: If water must be added to battery more often than every 200 hours of operation, alternator may be overcharging. See reference ”Checking the Electrical Circuits” in Section 240, Group 15. <- Go to Section TOC Section 10 page 57 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 10: Tune-Up Check the Neutral Start Circuit Tractors with SyncroPlus transmission [1] - Depress the clutch pedal. [2] - Move range-shift lever (A) to neutral. [3] - Move gear-shift lever (B) to any gear. [4] - Turn key in main switch as far as it will go to the right. The starter motor must NOT turn over. If it does, seeReference 240-15-001, SE01 — Starting Motor and Charging Circuit. [5] - Repeat the test in all the other gears. Tractors with Power Reverser transmission [1] - Depress the clutch pedal. [2] - Move range-shift lever (A) to neutral. [3] - Move reverse drive lever (B) to any travel direction (forward or reverse). [4] - Turn key in main switch as far as it will go to the right. The starter motor must NOT turn over. If it does, seeReference 240-15-001, SE01 — Starting Motor and Charging Circuit. [5] - Repeat the test in the other direction of travel. <- Go to Section TOC Section 10 page 58 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 10: Tune-Up Tractors with PowrQuad transmission [1] - Depress the clutch pedal. [2] - Move range-shift lever (A) to neutral. [3] - Move reverse drive lever (B) to forward position. [4] - Turn key in main switch as far as it will go to the right. The starter motor must NOT turn over. If it does, seeReference 240-15-001, SE01 — Starting Motor and Charging Circuit. [5] - Repeat the test in the reverse position. Tractors with PowrQuad Plus or AutoQuad II transmissions [1] - Move range-shift lever (A) and reverse drive lever (B) to neutral. [2] - Start the engine and wait 6-7 seconds. [3] - Move the reverse drive lever to forward or reverse and release it there. If the reverse drive lever remains in the selected position without being held there manually, the neutral start circuit is operating correctly. If the reverse drive lever moves INSTANTLY by itself from forward or reverse to neutral without being moved by hand, seeReference 240-15-001, SE01 — Starting Motor and <- Go to Section TOC Section 10 page 59 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 10: Tune-Up Charging Circuit. Tractors with AutoPowr/IVT transmission [1] - Move reverse drive lever (A) to forward or reverse. [2] - Turn key in main switch as far as it will go to the right. The starter motor must NOT turn over. If it does, seeReference 240-15-001, SE01 — Starting Motor and Charging Circuit. Checking operation of starter motor IMPORTANT: Do not operate starter motor for more than 20 seconds at a time. Turn key in main switch to “zero”. Wait at least one minute before attempting to start again. Refer to Technical Manual “Operation and Tests” in the event of malfunctions. <- Go to Section TOC Section 10 page 60 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 10: Tune-Up Checking the lighting circuit Check setting of headlights, and adjust if necessary. When equipped, check lights on cab frame and adjust, if necessary. Refer to Technical Manual “Operation and Tests” in the event of malfunctions. Final Engine Check Use a dynamometer to check engine power. See Reference220-15-010, ”Dynamometer Test” in Section 220, Group 15. →NOTE: Compare performance with test carried out before tune-up. Tractor Operation Check Check power train, steering and brakes, hydraulic system and operator′s cab as described in <- Go to Section TOC Section 10 page 61 TM4756-REPAIR MANUAL Section 10 - GENERAL INFORMATION Group 15: Predelivery Inspection the Operator′s Manual. Refer to the relevant Group of the Technical Manual in the event of any malfunction. <- Go to Section TOC Section 10 page 62 TM4756-REPAIR MANUAL ENGINE (g) by Belgreen Group 15 - Predelivery Inspection Predelivery Inspection The first page in the Service Record, which is titled “Delivery Certificate”, when properly filled out and signed by the dealer and customer, verifies that predelivery and delivery services were satisfactorily performed. When delivering the tractor, give the customer a “Service Record” booklet with a copy of the plate that bears the product identification number and sub-assembly serial numbers, plus the relevant Operator′s Manual. Be sure to explain their purposes to him. Because of the shipping factors involved, plus extra finishing touches necessary to promote customer satisfaction, there are certain predelivery services that must be performed by the dealer. The page in the Service Record booklet titled “Predelivery Inspection” lists the checks, adjustments and service jobs already performed at the factory, which the dealer has to recheck. Perform all the checks and service jobs listed, and tick them off on the page titled “Delivery Check List”. When completely filled out and signed, this page certifies that the proper delivery service has been carried out. Make three copies of the plate that bears the product identification number and subassembly serial numbers. Thefirst copy is intended for the John Deere dealer, thesecond copy is for the servicing dealer and thethird copy should be attached to the “Service Record” booklet. The plate bearing the product identification number and sub-assembly serial numbers must be attached to the left-hand side (as viewed in direction of travel; see arrow). <- Go to Section TOC Section 10 page 63 TM4756-REPAIR MANUAL TM4756-REPAIR MANUAL (g) by Belgreen Section 20 - ENGINE Table of contents Group 00 - Removal and Installation of Components .......................................................... 1 Specifications ......................................................................................................................... 1 Removing the Engine ............................................................................................................. 2 Installing the Engine ............................................................................................................ 20 <- Go to Global Table of contents TM4756-REPAIR MANUAL Section 20 - ENGINE Group 00: Removal and Installation of Components Group 00 - Removal and Installation of Components Specifications Item Measurement Specification Engine mounting screws Torque 100 N˙m 74 lb-ft Front engine supports to main frame, cap screws Torque 95 N˙m 70 lb-ft U.j. shaft to input flange, cap screws Torque 135 N˙m 100 lb-ft Mounting at rear of front frame, nuts Torque 55 N˙m 40 lb-ft Mounting at side of front frame, screws Torque 55 N˙m 40 lb-ft Mounting at front of front frame, screws Torque 55 N˙m 40 lb-ft <- Go to Section TOC Section 20 page 1 TM4756-REPAIR MANUAL Section 20 - ENGINE Group 00: Removal and Installation of Components Removing the Engine IMPORTANT: Before disassembling the engine, mark where the cables and hoses are connected; this will make it easier to re-assemble them. [1] - LEGEND: A B C Battery terminal (polarity as indicated on the battery) Battery terminal (polarity as indicated on the battery) Retaining strap Open the hood and disconnect battery terminals (A) and (B). CAUTION: Disconnect the negative terminal first. Always reconnect the positive terminal first. Always pay close attention to battery terminals. Release retaining strap (C) and lift off the battery. [2] - <- Go to Section TOC Section 20 page 2 TM4756-REPAIR MANUAL Section 20 - ENGINE Group 00: Removal and Installation of Components LEGEND: A B C D Connector Hinge Damper connecting point Nuts Remove engine hood. This is done by pulling out connector (A) and disconnecting the two gas-filled damper struts from the frame at (C). Remove hinge (B) from the front frame, remove nuts (D) for this purpose. →NOTE: The hood is heavy and awkward to move; you will require the assistance of a second person. <- Go to Section TOC Section 20 page 3 TM4756-REPAIR MANUAL Section 20 - ENGINE Group 00: Removal and Installation of Components [3] - LEGEND: A Drain valve Put one end of a suitable hose on the drain neck and put the other end of the hose in a suitable container. Open drain valve (A) and drain the coolant. →NOTE: Opening the cap on the expansion tank helps the coolant to drain quicker. See also reference ”Removing the Radiator” in Section 30, Group 20. [4] - LEGEND: A Screws in floor-plate Remove the mat from the cab floor, take out screws (A) and lift off the floor-plate. <- Go to Section TOC Section 20 page 4 TM4756-REPAIR MANUAL Section 20 - ENGINE Group 00: Removal and Installation of Components [5] - LEGEND: A Input flange of transmission Disconnect the u.j. shaft at flange (A). [6] - LEGEND: A B C D E Clamps on muffler pipe Wiring harness Wiring harness Ground cable Retaining nuts at rear Unfasten the two clamps (A) and remove the flexible muffler pipe. Disconnect wiring harnesses (B) and (C) from the front frame. Disconnect ground cable (D) from the engine block. At the rear, take off the two retaining nuts (E). →NOTE: For information on removing the muffler, refer also to Section 30, Group 30. <- Go to Section TOC Section 20 page 5 TM4756-REPAIR MANUAL Section 20 - ENGINE Group 00: Removal and Installation of Components [7] - LEGEND: A B Fitting on compressed-air line Refrigerant hose If a compressed-air line is equipped, disconnect it at fitting (A). If refrigerant hose (B) is equipped, take its clamp off the engine block. CAUTION: Before disconnecting the compressed-air line, reduce the pressure in the system by operating the drain valve at the compressed-air tank. <- Go to Section TOC Section 20 page 6 TM4756-REPAIR MANUAL Section 20 - ENGINE Group 00: Removal and Installation of Components [8] - LEGEND: A B C D E F H J Connector Connector Bracket for fuel transfer pump Connector for water-in-fuel sensor Fuel hose All starting motor cables Fuel filter Ground cable Disconnect all connectors (A), (B) and (D), and disconnect ground cable (J). See also Section 40, Group 10. Take off fuel filter (H) and disconnect all the starting motor cables (F). Pull off fuel hose (E) and seal the open end. Take bracket (C) off the main frame, break the connection and let the fuel transfer pump hang on the hoses. CAUTION: Comply with relevant safety instructions when working on the fuel system. →NOTE: There may be differences depending on how the tractor is equipped. <- Go to Section TOC Section 20 page 7 TM4756-REPAIR MANUAL Section 20 - ENGINE Group 00: Removal and Installation of Components [9] - LEGEND: A B C Air-intake hose Coolant hose Screws Disconnect air-intake hose (A) from the turbocharger. Disconnect coolant hose (B) from the thermostat housing. At both sides, take out the two screws (C). IMPORTANT: Seal the turbocharger and air-intake hose so that no dust can penetrate. →NOTE: Trap the coolant as it emerges. [10] - Disconnect all remaining wiring harness connection points on the engine. See Section 40, Group 10. →NOTE: Before disconnecting the wiring harness, mark each individual connection. This will facilitate re-assembly. Remove any cable straps and brackets that may be present. <- Go to Section TOC Section 20 page 8 TM4756-REPAIR MANUAL Section 20 - ENGINE Group 00: Removal and Installation of Components [11] - LEGEND: A B C Air-intake hose Air-intake hose Air cleaner housing Disconnect hoses (A) and (B) and remove air cleaner housing (C). [12] - From above, lift the rear part of the front frame. <- Go to Section TOC Section 20 page 9 TM4756-REPAIR MANUAL Section 20 - ENGINE Group 00: Removal and Installation of Components [13] - LEGEND: A to F Coolant hoses Disconnect coolant hoses (A), (B), (C), (D), (E) and (F). →NOTE: Trap the coolant as it emerges. <- Go to Section TOC Section 20 page 10 TM4756-REPAIR MANUAL Section 20 - ENGINE Group 00: Removal and Installation of Components [14] - LEGEND: A B C D Connector Connector Screw Nuts Unscrew connector (A) from the cross-member and pull out connector (B). Remove screw (C) and take off the two nuts (D). →NOTE: The illustration shows a tractor with a battery cut-off switch. [15] - <- Go to Section TOC Section 20 page 11 TM4756-REPAIR MANUAL Section 20 - ENGINE Group 00: Removal and Installation of Components LEGEND: A B C D E F G Screws on the cross-member (with battery cut-off switch only) Screws on the bracket for the air cleaner Screws on the bracket for the fuel cooler Bracket for the fuel cooler Cross-member (with battery cut-off switch only) Fuel cooler Refrigerant lines At both sides of the tractor, remove screws (A) to (C). Then lift off cross-member (E). In the case of tractors with fuel cooler, remove bracket (D) of cooler (F) without first disconnecting the hoses. The fuel cooler (F) must be placed on the left side of the tractor as soon as possible. CAUTION: Comply with relevant safety instructions when working on the fuel system. [16] - On tractors with air-conditioning, doNOT disconnect refrigerant lines (G); instead, disassemble as follows: <- Go to Section TOC Section 20 page 12 TM4756-REPAIR MANUAL Section 20 - ENGINE Group 00: Removal and Installation of Components a. LEGEND: A Retaining springs On both sides, unhook the retaining spring (A) of the condenser. b. Remove all the clamps on the refrigerant hoses. c. Relieve tension on drive belt (see Section 30, Group 20). d. LEGEND: A B Drive belt Compressor attaching screws Remove the air-conditioning compressor. Relieve tension on drive belt (A) and take it off the compressor′s V-belt pulley. Take out screws (B). The compressor remains in position until the front frame is removed. <- Go to Section TOC Section 20 page 13 TM4756-REPAIR MANUAL Section 20 - ENGINE Group 00: Removal and Installation of Components e. Remove the condenser and place it temporarily on top of the engine. Once the front frame has been removed, move the condenser together with the compressor to the right-hand side of the engine. IMPORTANT: Use suitably folded cardboard to protect the fins on the condenser from damage. Do not bend the refrigerant hoses or subject them to tension. CAUTION: If the air-conditioning sub-assemblies are not handled correctly, leaks will result. If leaks occur, pressurized refrigerant will escape, possibly leading to severe personal injury. Always wear appropriate safety gear when working on the air-conditioning system. <- Go to Section TOC Section 20 page 14 TM4756-REPAIR MANUAL Section 20 - ENGINE Group 00: Removal and Installation of Components [17] - LEGEND: A B C Screws for attaching the front frame at the side Plug Plug At both sides of the tractor, remove screws (A). Disconnect plugs (B) and (C). [18] - LEGEND: A Screws Take screws (A) off the front attaching point of the front frame. <- Go to Section TOC Section 20 page 15 TM4756-REPAIR MANUAL Section 20 - ENGINE Group 00: Removal and Installation of Components [19] - Suspend the front frame as shown, and remove it. →NOTE: One at a time, cut through all the cable straps (number varies depending on how tractor is equipped) before you raise the front frame. <- Go to Section TOC Section 20 page 16 TM4756-REPAIR MANUAL Section 20 - ENGINE Group 00: Removal and Installation of Components [20] - LEGEND: A B D01042AA JDG19 As shown, attach twoJDG19suspension eyes (A) to the cylinder head. Suspend the engine on theD01042AA(A) load-positioning sling. →NOTE: Depending on what further work is to be done on the engine, it may be necessary to remove the muffler. [21] - <- Go to Section TOC Section 20 page 17 TM4756-REPAIR MANUAL Section 20 - ENGINE Group 00: Removal and Installation of Components LEGEND: A B Attaching screws on front engine mounting Rear engine mounting screws On both sides of the tractor, separate the front engine mounting from the main frame. Do this by taking out screws (A). At both sides of the tractor, take screw (B) out of the rear engine mountings. CAUTION: Before removing the engine mountings, suspend the engine properly. <- Go to Section TOC Section 20 page 18 TM4756-REPAIR MANUAL Section 20 - ENGINE Group 00: Removal and Installation of Components [22] - Using load-positioning slingD01042AA, lift the engine out of the main frame. →NOTE: Use the load-positioning sling to alter the angle of the engine as appropriate. [23] - Before doing further work on the engine, place it on a suitable stand. <- Go to Section TOC Section 20 page 19 TM4756-REPAIR MANUAL Section 20 - ENGINE Group 00: Removal and Installation of Components Installing the Engine [1] - LEGEND: A JDG19 suspension eyes AttachJDG19suspension eyes (A) to the cylinder head. Attach the lifting tackle to the suspension eyes using load-positioning slingD01042AA. [2] - Use load-positioning slingD01042AAto install the engine in the main frame. →NOTE: Make sure the u.j. shaft is positioned correctly. Use the load-positioning sling to alter the angle of the engine as appropriate. <- Go to Section TOC Section 20 page 20 TM4756-REPAIR MANUAL Section 20 - ENGINE Group 00: Removal and Installation of Components LEGEND: A B C D E F G H Engine mounting screw (rear) Washer Rubber bearing Rubber bearing with bushing Supporting cup Engine mounting screw (front) Nut Engine mounting screw Locate the engine mountings as shown and tighten the engine mounting screws to the torque prescribed. <- Go to Section TOC Section 20 page 21 TM4756-REPAIR MANUAL Section 20 - ENGINE Group 00: Removal and Installation of Components Item Measurement Specification Engine mounting screws Torque 100 N˙m 74 lb-ft Item Measurement Specification Front engine supports to main frame, cap screws Torque 95 N˙m 70 lb-ft IMPORTANT: Do NOT use grease or oil to make assembly of these parts easier. If a lubricant is needed, use talcum powder or silicone spray. [3] - LEGEND: A Input flange Install u.j. shaft on input flange (A) and tighten the cap screws to the specified torque. Item Measurement Specification U.j. shaft to input flange, cap screws Torque 135 N˙m 100 lb-ft See also ”Installing the U.J. Shaft (Engine)”, Section 56, Group 05. IMPORTANT: Use screws that have not been used before. →NOTE: To bring the holes into alignment, it may help to use flywheel turning deviceJDG820to turn the flywheel. [4] - Install the floor-plate of the cab or open operator′s station. <- Go to Section TOC Section 20 page 22 TM4756-REPAIR MANUAL Section 20 - ENGINE Group 00: Removal and Installation of Components [5] - Install rubber damper (A) and spacer bushings (B) and (C). [6] - Suspend the front frame as shown, and install it. Connect all the hoses to the relevant hose fittings and lay out the engine wiring harness. CAUTION: Install the battery only when assembly is completed. See Section 40, Group 10. See also ”Installing the Radiator” in Section 30, Group 20. <- Go to Section TOC Section 20 page 23 TM4756-REPAIR MANUAL Section 20 - ENGINE Group 00: Removal and Installation of Components [7] - LEGEND: A Mounting at side of front frame Install and tighten attaching screws (A). Item Measurement Specification Mounting at side of front frame, screws Torque 55 N˙m 40 lb-ft [8] - LEGEND: A Front frame attachment (at front of frame) Install and tighten screws (A). Item Measurement Specification Mounting at front of front frame, screws Torque 55 N˙m 40 lb-ft <- Go to Section TOC Section 20 page 24 TM4756-REPAIR MANUAL Section 20 - ENGINE Group 00: Removal and Installation of Components [9] - LEGEND: A Front frame attachment (at rear of frame) Install the rear part of the front frame and tighten nuts (A) on both sides. Item Measurement Specification Mounting at rear of front frame, nuts Torque 55 N˙m 40 lb-ft [10] - Tractors with air-conditioning: CAUTION: If the air-conditioning sub-assemblies are not handled correctly, leaks will result. If leaks occur, pressurized refrigerant will escape, possibly leading to severe personal injury. Always wear appropriate safety gear when working on the air-conditioning system. a. Install the compressor bracket and compressor. b. Install the drive belt. c. Install the condenser. d. Install all the clamps on the refrigerant hoses, and secure all the lines/hoses. <- Go to Section TOC Section 20 page 25 TM4756-REPAIR MANUAL Section 20 - ENGINE Group 00: Removal and Installation of Components IMPORTANT: Lay out the hoses and lines so that they are not subject to any mechanical or thermal forces. [11] - LEGEND: A B C Air cleaner housing Strut attaching screws Fuel cooler Install the strut and tighten the screws (B). Tractors with fuel cooler: Install cooler (C) on the front frame. Install the air filter housing (A). CAUTION: Comply with relevant safety instructions when working on the fuel system. [12] - For further assembly, reverse disassembly procedure. See ”Removing the Engine” in this Group. <- Go to Section TOC Section 20 page 26 TM4756-REPAIR MANUAL FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS (g) by Belgreen [13] - Then: a. Add coolant. b. Check the engine oil level. c. Check the air intake and coolant hoses for leaks. d. Check all electrical functions. e. Check engine idle speed. f. Check that the fuel hoses are laid out and connected correctly. g. Check that the protective equipment (e.g. caps on electrical connections and heatshields on the exhaust) are all installed properly. <- Go to Section TOC Section 20 page 27 TM4756-REPAIR MANUAL TM4756-REPAIR MANUAL (g) by Belgreen Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Table of contents Group 05 - Speed Control ......................................................................................................... 1 Speed Control (Summary of References) ............................................................................... 1 General Information ............................................................................................................... 1 Specifications ......................................................................................................................... 1 Accelerator Pedal, with Mechanical Speed Control ................................................................ 2 Replacing the Accelerator Pedal Assembly (AutoPowr/IVT) .................................................... 4 Removing the Accelerator Pedal′s Potentiometer .................................................................. 5 Removing the Hand Throttle′s Potentiometer ........................................................................ 9 Group 10 - Fuel System .......................................................................................................... 11 Fuel System (Summary of References) ................................................................................ 11 General Information ............................................................................................................. 11 Removing the Fuel Tank ...................................................................................................... 12 Installing the Fuel Tank ........................................................................................................ 13 Replacing the fuel gauge sender ......................................................................................... 14 Replace the Fuel Transfer Pump .......................................................................................... 16 Changing the Fuel Filter ....................................................................................................... 19 Bleeding the Fuel System .................................................................................................... 20 Bleeding Air from the Fuel System (with Bosch VP44 Injection Pump and Denso/Stanadyne) ....................................................................................................................................... 20 Installing Check Valve in Fuel System .................................................................................. 21 Install the Check Valve in the Fuel System (with Denso/Stanadyne injection pump; Stage II engines to 97/68/EC) ..................................................................................................... 21 Group 15 - Air Intake System ................................................................................................ 24 Air Intake System (Summary of References) ....................................................................... 24 General Information ............................................................................................................. 24 Air filter - Exploded view ...................................................................................................... 24 Replacing the Sending Unit for Air Cleaner Restriction (B02) ............................................... 25 Group 20 - Cooling System .................................................................................................... 26 Cooling System (Summary of References) ........................................................................... 26 General Information ............................................................................................................. 26 Specifications ....................................................................................................................... 26 Removing and Installing the Ring-Shaped Cooler ................................................................ 26 Remove the Radiator ........................................................................................................... 28 Change the Fan or the Viscous Fan Drive ............................................................................ 36 Remove and Install the Intercooler ...................................................................................... 38 Remove and Install the Intercooler (Stage II engines to 97/68/EC) ...................................... 40 Removing and Installing the Expansion Tank ....................................................................... 41 Removing and Installing the Thermostat Valve .................................................................... 43 Installing the Radiator .......................................................................................................... 45 Filling the Cooling System with Coolant ............................................................................... 46 Relieve the Tension on the Drive Belt .................................................................................. 50 Replacing the Drive Belt ...................................................................................................... 52 Replacing the Drive Belt Tensioner ...................................................................................... 53 Repairing the Fan Console ................................................................................................... 55 Remove and Install Fan Console (with Mechanical Coolant Pump) ...................................... 56 <- Go to Global Table of contents TM4756-REPAIR MANUAL TM4756-REPAIR MANUAL (g) by Belgreen Group 25 - Cold-Weather Starting Aids ............................................................................... 58 Fuel Preheater ...................................................................................................................... 58 Electrical Starting Aid ........................................................................................................... 59 Coolant Heater ..................................................................................................................... 60 Group 30 - Exhaust System .................................................................................................... 62 Exhaust System (Summary of References) .......................................................................... 62 General Information ............................................................................................................. 62 Specifications ....................................................................................................................... 62 Installing the Muffler ............................................................................................................ 63 Exhaust Pipe or Intermediate Exhaust Pipe ......................................................................... 66 Exhaust Pipe or Intermediate Exhaust Pipe —Upright .......................................................... 67 <- Go to Global Table of contents TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 05: Speed Control Group 05 - Speed Control Speed Control (Summary of References) “General information” “Specifications” “Accelerator pedal, with mechanical speed control” “Replacing the accelerator pedal assembly (AutoPowr/IVT)” “Removing the accelerator pedal′s potentiometer” “Removing the hand throttle′s potentiometer” General Information →NOTE: Replace the potentiometers as complete assemblies only. On tractors with electronic speed control ("cruise control"), calibration takes place automatically when the tractor is started. Specifications Item Measurement Specification Voltage output of hand throttle sensor and accelerator pedal sensor (electronic speed control) Voltage <- Go to Section TOC Section 30 page 1 0.5 to 4.5 volts (over entire range) TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 05: Speed Control Accelerator Pedal, with Mechanical Speed Control LEGEND: 1 2 3 4 5 6 7 8 9 10 11 12 <- Go to Section TOC Pedal plate Bushing Spring M6x16 self-tapping screw (3 used) Stop Lever Snap ring (5 used) Hex. nut (6 used) Spring pin (4 used) Ball socket Pivot (2 used) Retaining wire Section 30 page 2 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS 13 14 15 16 17 18 19 20 Group 05: Speed Control Threaded rod Bushing (4 used) Lever Lever Spring Lever Shaft Lever Checking the Linkage Dimension “a” must be 78 mm (3.07 in); check the dimension, and adjust if necessary. →NOTE: The ball sockets must be on the same side. <- Go to Section TOC Section 30 page 3 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 05: Speed Control Replacing the Accelerator Pedal Assembly (AutoPowr/IVT) LEGEND: A B C Accelerator pedal assembly Hex. socket screws (3 used) Plug connection [1] - Fold back the floor-mat. [2] - Take out hex. socket screws (B). [3] - Take off the accelerator pedal assembly and disconnect plug (C). [4] - For installation, follow removal procedure in reverse order. →NOTE: A new assembly does NOT require calibration. <- Go to Section TOC Section 30 page 4 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 05: Speed Control Removing the Accelerator Pedal′s Potentiometer [1] - Take out hex. socket screws (A). [2] - Remove potentiometer (B) together with holder (C) and the toothed segment. Installing the Accelerator Pedal′s Potentiometer [1] - Remove stopper (A) from the housing. <- Go to Section TOC Section 30 page 5 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 05: Speed Control [2] - Move the accelerator pedal far enough to allow a punch with a diameter of 5 mm (0.2 in.) to pass through the holes in housing (A) and toothed segment (B). <- Go to Section TOC Section 30 page 6 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 05: Speed Control [3] - LEGEND: A B C D E Potentiometer with holder Toothed segment with spring Accelerator pedal housing Punch Hole in toothed segment aligned with hole in potentiometer Use a punch to install potentiometer (A) with its holder and (pretensioned) toothed segment (B) on housing (C). <- Go to Section TOC Section 30 page 7 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 05: Speed Control [4] - Install hex. socket screws (A) on the housing. →NOTE: Install the stopper on the housing. <- Go to Section TOC Section 30 page 8 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 05: Speed Control Removing the Hand Throttle′s Potentiometer [1] - Take out hex. socket screws (A) and lift off operation unit (B). [2] - Mark the plug connections and then disconnect them. [3] - Disconnect plug connection (A) and remove potentiometer (B). Installing the hand throttle′s potentiometer <- Go to Section TOC Section 30 page 9 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 10: Fuel System [1] - When the segment is installed properly, the two arrows (A) are in perfect alignment. [2] - For installation, follow removal procedure in reverse order. <- Go to Section TOC Section 30 page 10 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 10: Fuel System Group 10 - Fuel System Fuel System (Summary of References) ”General information” ”Removing the fuel tank” ”Installing the fuel tank” ”Replacing the fuel gauge sender” ”Replacing the fuel transfer pump” ”Changing the fuel filter” ”Bleeding air from the fuel system (with Bosch VP44 injection pump and Denso/Stanadyne)” ”Installing the check valve in fuel system” ”Installing the check valve in the fuel system (with Denso/Stanadyne injection pump; Stage II engines to 97/68/EC)” General Information CAUTION: Do not smoke or permit live sparks or fire of any nature in the vicinity while repairing the fuel system. →NOTE: For instructions on how to repair the injection pump and nozzles, see the relevant Component Technical Manual for “Engines”. CAUTION: Never under any circumstances disconnect or open the lines between the injection pump and injection nozzles. Even with the engine shut off, the fuel pressure is still very high. Any work on the Common Rail fuel injection system (HPCR) must ONLY be carried out by trained personnel familiar with this type of systems. If an accident occurs, immediately see a doctor who is familiar with this type of injury. Any fluid injected into the skin must be surgically removed within a few hours or gangrene may result. <- Go to Section TOC Section 30 page 11 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 10: Fuel System Removing the Fuel Tank Remove drain plug (see arrow) and drain the fuel. For capacity of fuel tank, see “Capacities” in Section 10, Group 05. Tractors with Cab →NOTE: Mark the fuel hoses before disconnecting them. LEGEND: A B C D Cover Plug connection Fuel hoses Mounting plate Take off cover (A), disconnect fuel lines (C) and pull off plug (B). <- Go to Section TOC Section 30 page 12 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 10: Fuel System Support the tractor securely and remove the rear left wheel. Remove the step by taking out screws (A) and hex. socket screw (B). Take cap screws (C) out of the tensioning straps. Take fuel tank out of support. Installing the Fuel Tank Install fuel tank by following the removal procedure in reverse order. The tensioning straps must be hooked to the holders at the main frame. Make sure the fuel tank does not rub against other parts. Add fuel and bleed the fuel system. <- Go to Section TOC Section 30 page 13 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 10: Fuel System Replacing the fuel gauge sender Sender with retaining plate When exchanging the fuel level sender, take action to prevent dirt from getting into the tank. On tractors with cab, remove floor mat and cover (A). Disconnect cable (B) and fuel line connections (C) through opening in cab floor. Take out the four Phillips-head screws and lift off plate (D). Carefully pull the sender upwards and tilt it to avoid damaging the float system linkage. Install the fuel transfer pump on the new sender. See “Replacing the fuel transfer pump” , section 30, group 10. Correctly position the O-ring before installation. Insert the sender and fuel transfer pump in such a way that the pump fits into the recess in the base of the tank, and the connections face in the direction of forward travel. Connect the cables and install the fuel lines. <- Go to Section TOC Section 30 page 14 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 10: Fuel System IMPORTANT: Do not mix up connections! Install the retaining plate. Bleed fuel system. <- Go to Section TOC Section 30 page 15 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 10: Fuel System Replace the Fuel Transfer Pump LEGEND: A B C D E F Fuel transfer pump Screen Connecting hose Hose clip Fuel level sending unit and float system linkage Connector The fuel transfer pump is located inside the tank together with the fuel gauge sending unit, so proceed as instructed at Reference ”Replace the Fuel Gauge Sender” . Open hose clamp (D) and pull out fuel transfer pump (A), screen (B) and connecting hose (C). IMPORTANT: When repairing the fuel level sending unit or transfer pump, always use new hose clamps on the connecting hose. Make sure the connecting hose and fuel transfer pump are seated correctly. Clean screen (B). Tractors with Bosch VP44 injection pump <- Go to Section TOC Section 30 page 16 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS LEGEND: A Group 10: Fuel System Fuel transfer pump For information on how to replace the fuel transfer pump, refer to the Technical Manual for Stage 4 electronic fuel systems with Bosch VP44 pump, Section 02, Group 090,”Remove and Install the Electronic Fuel Transfer Pump - 12-Volt System”. Tractors with Denso/Stanadyne injection pump LEGEND: A B C <- Go to Section TOC Cap screw Retainer Fuel hose Section 30 page 17 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS D E F G Group 10: Fuel System Fuel hose Fuel transfer pump Connector Clamp Remove cap screws (A) and pull off retainer (B). Take off fuel hoses (C) and (D), and remove connector (F). Remove clamp (G) and lift off fuel transfer pump (E). For installation, follow removal procedure in reverse order. <- Go to Section TOC Section 30 page 18 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 10: Fuel System Changing the Fuel Filter LEGEND: A Retaining ring B Filter element C Second filter (tractors with Bosch VP44 injection pump only) [1] - Unfasten filter retaining ring (A) and remove filter (B). Seal old filter with cover of the new one. [2] - Remove water trap and install it on new filter. [3] - On tractors with Bosch VP44 injection pump, also replace second filter (C). [4] - Attach new filter. The marks on the filter must be aligned with those on the housing. [5] - Tighten retaining ring (A) until it can be heard to engage. [6] - Turn key in main switch to the right as far as the first switch position so that the fuel transfer pump is operating. Keep the pump running for approx. 20 seconds. <- Go to Section TOC Section 30 page 19 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 10: Fuel System Bleeding the Fuel System →NOTE: Before bleeding, check the system for leaks. In order to prevent the engine from starting, move gear lever or reverse drive lever to any position other than neutral. Turn ignition key fully to the right (to first position or as far as it will go) to make the fuel transfer pump operate. Keep the pump running for approx. 20 seconds. If fuel injection nozzles or lines have been replaced in the area behind fuel injection pump, bleed fuel system as described previously. If engine will not start, proceed as follows: [1] CAUTION: Escaping fuel under pressure can have sufficient force to penetrate the skin causing serious personal injury. If injured by escaping fuel see a doctor immediately as otherwise serious infections may be the result. Loosen lines at injection nozzles. [2] - Place throttle lever in full load position. [3] - Start engine until fuel flows free from bubbles out of loosened fuel nozzle connections. [4] - Retighten connections. Bleeding Air from the Fuel System (with Bosch VP44 Injection Pump and Denso/Stanadyne) Before bleeding, check the system for leaks. Turn ignition key to the right (to first position) to make the fuel transfer pump operate. Keep the pump running for approx. 40 seconds. <- Go to Section TOC Section 30 page 20 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 10: Fuel System CAUTION: With Denso injection pumps, never under any circumstances disconnect or open the lines between the pump and the injector nozzles. Pressure is very high! Any work on the Common Rail fuel injection system (HPCR) must ONLY be carried out by trained personnel familiar with this type of system. Refer to the relevant Technical Manuals. If an accident occurs, immediately see a doctor who is familiar with this type of injury. Any fluid injected into the skin must be surgically removed within a few hours or gangrene may result. Installing Check Valve in Fuel System Use two clips (B) to install the check valve (A) approx. 100 mm (4 in.) in front of the fuel filter. IMPORTANT: The arrow on the valve must point towards the fuel filter! Install the Check Valve in the Fuel System (with Denso/Stanadyne injection pump; Stage II engines <- Go to Section TOC Section 30 page 21 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 10: Fuel System to 97/68/EC) LEGEND: A B C D E F G H I Fuel tank Primary fuel filter Fuel filter Injection pump Fuel cooler Fuel transfer pump Fuel gauge sender Control unit Check valve Use two clips (B) to install the check valve (I) approx. 100 mm (4 in.) in front of the fuel filter. <- Go to Section TOC Section 30 page 22 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 15: Air Intake System IMPORTANT: The arrow on the valve must point towards the fuel filter! <- Go to Section TOC Section 30 page 23 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 15: Air Intake System Group 15 - Air Intake System Air Intake System (Summary of References) Air filter - Exploded view Replacing the Sending Unit for Air Cleaner Restriction (B02) General Information IMPORTANT: Never run the engine without the primary filter element, secondary (safety) filter element and the dust unloading valve all in place. →NOTE: For instructions on how to repair the turbocharger, see relevant Component Technical Manual for “Engines”. Air filter - Exploded view LEGEND: <- Go to Section TOC Section 30 page 24 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS A B C D E F G Group 20: Cooling System Air intake openings Air filter housing Outlet Primary filter element Secondary (safety) filter element Outlet support Sender for air filter restriction Replacing the Sending Unit for Air Cleaner Restriction (B02) LEGEND: A Sending unit for air cleaner restriction indicator (B02) B Plug The sending unit for the air cleaner restriction indicator is located between the air cleaner housing and expansion tank. Open the hood. Disconnect plug (B). Unscrew the sending unit for air cleaner restriction (A) and replace it with a new one. Assemble in reverse order. IMPORTANT: If you replace the sending unit for air cleaner restriction, you should check the basic informator (BIF) for diagnostic trouble codes. See reference “245-05-002 , Calling up Addresses and Diagnostic Trouble Codes”. <- Go to Section TOC Section 30 page 25 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System Group 20 - Cooling System Cooling System (Summary of References) ”Removing and installing the ring-shaped cooler” ”Removing the radiator” ”Changing the fan or the viscous fan drive” ”Remove and install the intercooler” ”Remove and install the intercooler (Stage II engines to 97/68/EC)” ”Removing and installing the expansion tank” ”Removing and installing the thermostat valve” ”Installing the radiator” ”Filling the cooling system with coolant” ”Relieving tension on the drive belt” ”Replacing the drive belt” ”Replacing the drive belt tensioner” ”Reconditioning the fan console” ”Remove and install fan console (with mechanical coolant pump)” General Information →NOTE: For information about repairing the coolant pump and thermostat, refer to relevant Component Technical Manual for “Engines”. Specifications Item Measurement Specification Drive belt tensioner to engine front plate, cap screw Torque 50 N˙m (37 lb-ft) Deflection roll to plate, cap screw Torque 75 N˙m (55 lb-ft) M10 cap screw Torque 50 N˙m (37 lb-ft) M12 cap screw Torque 90 N˙m (65 lb-ft) Fan to viscous fan drive, M10 hex. nut Torque 50 N˙m (37 lb-ft) Viscous fan drive to hub, M10 hex. nut Torque 50 N˙m (37 lb-ft) Cap screws at fan console with integrated coolant pump Torque 70 N˙m Fan console to engine 52 lb-ft Coolant drain plug Torque 4 – 5 N˙m 3 – 3.7 lb-ft <- Go to Section TOC Section 30 page 26 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System Removing and Installing the Ring-Shaped Cooler See reference ”Removing and Installing the Ring-Shaped Cooler” in Section 56, Group 05. <- Go to Section TOC Section 30 page 27 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System Remove the Radiator [1] - Draining the coolant ontractors up to serial no. 425328 . Illustration shows a tractor up to serial no. 425328 LEGEND: A B C <- Go to Section TOC Drain plug Filler cap Connect/disconnect control Section 30 page 28 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System IMPORTANT: Radiator repairs should be carried out only by experienced mechanics or in specialist workshops. Drain the coolant and trap it in a suitable container. Slacken off drain plug (A) half-way and open the filler cap (B) on the expansion tank. Item Measurement Specification Coolant drain plug Torque 4 – 5 N˙m 3 – 3.7 lb-ft Turn the connect/disconnect control (C) as far as it will go in direction ”b” (open). →NOTE: Connect/disconnect control (C) is used to connect or disconnect chambers within the radiator. On tractors with cab, fully open heater control. [2] - <- Go to Section TOC Section 30 page 29 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System LEGEND: A B C Drain plug Filler cap Connect/disconnect control Draining the coolant ontractors from serial no. 425329 . IMPORTANT: Radiator repairs should be carried out only by experienced mechanics or in specialist workshops. Drain the coolant and trap it in a suitable container. Slacken off drain plug (A) half-way and open the filler cap (B) on the expansion tank. Item Measurement Specification Coolant drain plug Torque 4 – 5 N˙m 3 – 3.7 lb-ft Turn the connect/disconnect control (C) as far as it will go in direction ”b” (open). →NOTE: The connect/disconnect control is used to connect or disconnect chambers within the radiator. On tractors with cab, fully open heater control. <- Go to Section TOC Section 30 page 30 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System [3] - Remove the air cleaner. Take off clamps (A) and (B) and disconnect plug (C). Tilt air cleaner housing (D) up in the direction indicated by the arrow. Pull the air cleaner housing out from the front. <- Go to Section TOC Section 30 page 31 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System [4] - Remove engine hood. IMPORTANT: The hood is heavy and awkward to move; you will require the assistance of a second person. Disconnect safety cable (A) at the screw. Disconnect plug (B). Disconnect the gas-filled cylinder (C) at the bottom. Take off hex. nuts (D) and lift off the engine hood assembly. [5] - Disconnect ground cable (A) from the radiator. <- Go to Section TOC Section 30 page 32 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System [6] - Take out cap screws (A) and lift off the mounting for the main fuse and horn. [7] - Take off rubber seal (A), feed cables (B) through the slits and slacken off clamp (C). [8] - Disconnect hoses (A), (B) and (C). [9] - <- Go to Section TOC Section 30 page 33 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System Take out attaching screws (A), (B) and (E). Take off retainer (C) and pull out dust screen (D). <- Go to Section TOC Section 30 page 34 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System Take off the two frame parts and use a cable binder to secure condenser (A) to the side of the engine. <- Go to Section TOC Section 30 page 35 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System Change the Fan or the Viscous Fan Drive →NOTE: If equipped Remove the radiator; see ”Remove the Radiator” in Section 30, Group 20. To remove the fan, take out the four hex. nuts (A). To remove the viscous fan drive, take out the four cap screws (B). IMPORTANT: Thermal coil on viscous fan drive can be easily damaged. Handle assembly carefully. Inspect drive for damage. Make sure thermal coil (D) is not bent or damaged. <- Go to Section TOC Section 30 page 36 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System →NOTE: Viscous fan drive is factory balanced and is not repairable. Small nicks or chips in fins are permissible. Inspect fins (E) for damage. IMPORTANT: Replace viscous drive if more than one complete fin has been lost. Improper balance could cause viscous drive or fan failure. When installing, tighten the hex. nuts to the appropriate torque (see below). Item Measurement Specification Securing the drive to the pulley Torque 50 N˙m 37 lb-ft Item Measurement Specification Securing the drive to the fan Torque 50 N˙m 37 lb-ft <- Go to Section TOC Section 30 page 37 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System Remove and Install the Intercooler LEGEND: A B C D E F G H I J K L M <- Go to Section TOC Hose clamp Air intake hose Intercooler Hose clamp Air intake hose Flanged screw Console Gasket Retainer Cap screw, 45—55 N˙m (33—41 lb-ft) Flanged screw, 13—17 N˙m (10—12 lb-ft) Ground strap Flange nut Section 30 page 38 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS N Group 20: Cooling System Rubber buffer Disconnect the inlet and return hoses (see arrows) from the intercooler. →NOTE: Before disconnecting coolant hoses, always put a suitable container underneath to trap coolant as it emerges. Loosen hose clamps (A) and (D) and remove air intake hoses (B) and (E). Take out flanged screw (K) and remove intercooler (C). For installation, follow removal procedure in reverse order. When installing, tighten to the appropriate torque (see below): Item Measurement Specification Ground strap to intercooler Torque 13—17 N˙m 10—12 lb-ft <- Go to Section TOC Section 30 page 39 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System Remove and Install the Intercooler (Stage II engines to 97/68/EC) <- Go to Section TOC Section 30 page 40 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS LEGEND: A B C D E F G H I Group 20: Cooling System Hose clamp Air-intake hose Cap screw (3 used) Bushing Intercooler Insulating pad Seal Contact plate Plug for injection valves Disconnect the inlet and return hoses (see arrows) from the intercooler. →NOTE: Before disconnecting coolant hoses, always put a suitable container underneath to trap coolant as it emerges. Remove air intake hose (B) and cap screws (C). →NOTE: Be careful when taking off the intercooler, as you may damage the injection valve plug (I; to the right of the cylinder head). Take off intercooler (E). For installation, follow removal procedure in reverse order. When installing, tighten to the appropriate torque (see below): Item Measurement Specification Intercooler to engine block attaching screw Torque 16 - 20 N˙m 11.5 - 14.5 lb-ft Removing and Installing the Expansion Tank <- Go to Section TOC Section 30 page 41 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System Carefully press the two plastic lugs (A) and slide expansion tank (B) in the direction indicated by the arrow. Installation Make sure that O-ring (A) is seated correctly. →NOTE: Carefully slide the expansion tank onto the radiator, making sure that it is straight and that O-ring (A) does not become damaged. Slide the expansion tank onto the radiator in reverse order to the procedure described above. <- Go to Section TOC Section 30 page 42 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System Removing and Installing the Thermostat Valve →NOTE: Applies only to tractors without AutoPowr On tractors up to serial no. 425328 Removal: Carefully lift up both lugs on the thermostat valve (A) and completely remove the thermostat valve from its seat. Installation: →NOTE: Make sure the valve seat is clean. To install the thermostat valve (A), reverse the removal procedure. <- Go to Section TOC Section 30 page 43 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System On tractors from serial no. 425329 Removal: LEGEND: A B C Hose (inlet from radiator) Hose clamp Hose (return to radiator) Take off clamps (B) and remove hose (C). LEGEND: A Thermostat valve Unscrew the low-temperature thermostat (A). Installation: →NOTE: Make sure the valve seat is clean. To install the thermostat valve (A), reverse the removal procedure and comply with the <- Go to Section TOC Section 30 page 44 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System following specification. Item Measurement Specification Thermostat Torque 27 N˙m 20 lb-ft Installing the Radiator Install the radiator in reverse order (with regard to the procedure described under "Removing the Radiator"). See reference “Removing the Radiator” . <- Go to Section TOC Section 30 page 45 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System Filling the Cooling System with Coolant On tractors up to serial no. 425328 LEGEND: A B C D <- Go to Section TOC Drain plug Connect/disconnect control Filler cap Relief valve cap Section 30 page 46 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System IMPORTANT: Radiator repairs should be carried out only by experienced mechanics or in specialist workshops. [1] - Tighten coolant drain plug (A) to the torque value quoted below, and remove filler cap (C) from the expansion tank. Item Measurement Specification Coolant drain plug Torque 4—5 N˙m 3—3.7 lb-ft Turn the connect/disconnect control (B) as far as it will go in direction ”b” (open). →NOTE: Connect/disconnect control (B) is used to connect or disconnect chambers within the radiator. [2] - On tractors withAutoPowr/IVT , the upper hose must also be removed from the intercooler. [3] - Add coolant up to the "max." mark. [4] - On tractors withAutoPowr/IVT : As soon as coolant emerges from the intercooler hose, connect the hose to the intercooler and secure it with a clamp. [5] - Start the engine and run it for 5 minutes. [6] - Shut down the engine and add coolant up to the "max." mark. [7] - Start the engine and bring it up to operating temperature. [8] - Shut down the engine and add coolant up to the "max." mark. [9] - Turn the connect/disconnect control (B) to the right to position ”a” (closed). [10] - Re-install and close the filler cap and relief valve cap. Check the cooling system for leaks; seeReference 230-15-070, Check Cooling System for Leaks. On tractors from serial no. 425329 <- Go to Section TOC Section 30 page 47 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS LEGEND: A B C Group 20: Cooling System Drain plug Filler cap Connect/disconnect control IMPORTANT: Radiator repairs should be carried out only by experienced mechanics or in specialist workshops. <- Go to Section TOC Section 30 page 48 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System [1] - Tighten coolant drain plug (A) to the torque value quoted below, and remove filler cap (b) from the expansion tank. Item Measurement Specification Coolant drain plug Torque 4—5 N˙m 3—3.7 lb-ft Turn the connect/disconnect control (C) as far as it will go in direction ”b” (open). →NOTE: Connect/disconnect control (C) is used to connect or disconnect chambers within the radiator. [2] - On tractors withAutoPowr/IVT , the upper hose must also be removed from the intercooler. [3] - Add coolant up to the "max." mark. [4] - On tractors withAutoPowr/IVT : As soon as coolant emerges from the intercooler hose, connect the hose to the intercooler and secure it with a clamp. [5] - Start the engine and run it for 5 minutes. [6] - Shut down the engine and add coolant up to the "max." mark. [7] - Start the engine and bring it up to operating temperature. [8] - Shut down the engine and add coolant up to the "max." mark. [9] - Turn the connect/disconnect control (C) to the right to position ”a” (closed). [10] - Re-install and close the fill cap. Check the cooling system for leaks; seeReference 230-15-070, Check Cooling System for Leaks. <- Go to Section TOC Section 30 page 49 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System Relieve the Tension on the Drive Belt LEGEND: A B C Bore (cam) Bore (base plate) Tensioner roll CAUTION: Disconnect negative (—) cable from battery. Remove cover on tensioner roll (C). Turn tensioner roll cap screw using a 15 mm (19/32 in.) wrench (see arrow). Once released, the drive belt tensioner automatically goes back to the tensioning position. The drive belt tensioner can be kept in relieved position as follows: Turn tensioner roll cap screw (see arrow) until bores (A) and (B) are aligned. Insert a 5 mm (0.2 in.) dia. pin into the two holes that are in alignment. <- Go to Section TOC Section 30 page 50 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System For tensioning, turn tensioner roll slightly to release metal pin and pull it from the bores. The drive belt tensioner returns to its tensioning position automatically. <- Go to Section TOC Section 30 page 51 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System Replacing the Drive Belt CAUTION: Disconnect negative (—) cable from battery. Before relieving the tension on the old drive belt, see reference ”Relieving Tension on the Drive Belt” . Tractors with front-wheel drive shaft: Before detaching the drive shaft between the clutch and the torsion damper, see reference”Installing and Removing the Drive Shaft”. LEGEND: A B C Corrugated-head screws Drive belt Fan Take the six screws (A) out of the fan. Take drive belt (B) off over fan (C) and put on a new drive belt (see below for routing of belt). IMPORTANT: When installing, always use new corrugated-head screws. Tighten corrugated-head screws to the following specification. <- Go to Section TOC Section 30 page 52 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System Item Measurement Specification Attachment to fan Torque 22 – 28 N˙m 16 – 21 lb-ft LEGEND: A B C D E F G H Crankshaft Coolant pump Tensioner roll Fan pulley Alternator Deflector roll Compressor (air conditioning system) Compressor (air brakes) Install the drive belt correctly and slacken drive belt tensioner again. If equipped: Before re-attaching the drive shaft (front-wheel drive), see reference”Installing and Removing the Drive Shaft”. Replacing the Drive Belt Tensioner <- Go to Section TOC Section 30 page 53 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System Slacken drive belt and remove the three cap screws (A). When installing, tighten the three cap screws (A) to the following torque: Item Measurement Specification Torque 50 N˙m 37 lb-ft Re-install drive belt. The tensioner roll is kept in released position by means of a metal pin with a dia. of 5 mm (0.2 in.). For tensioning, turn tensioner roll slightly to release metal pin and pull it from the bores. The drive belt tensioner returns to its tensioning position automatically. <- Go to Section TOC Section 30 page 54 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System Repairing the Fan Console LEGEND: A B C D Hub Snap ring Bearing Console Relieve and remove drive belt. Remove fan and viscous fan drive. Remove fan console. Using a puller, remove hub (A). Remove snap ring (B). Press out bearing (C) making sure not to break the console (D). <- Go to Section TOC Section 30 page 55 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 20: Cooling System When pressing in the bearing, use disks that match exactly. →NOTE: The bearing can be pressed in easier when it has been cooled beforehand. Slightly grease the bearing bore. Locate the bearing and press it in using a bushing until the snap ring can be installed. When pressing in, apply force only to the bearing cup! Place a pressure disk under bearing shaft (C). Apply force only to the shaft! Install hub by means of a bushing making sure to keep to dimension ”a”. Dimension ”a”: 110.76 to 110,96 mm (4.36063 to 4.3685 in.) IMPORTANT: Make absolutely sure that dimension ”a” is kept. Remove and Install Fan Console (with Mechanical <- Go to Section TOC Section 30 page 56 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 25: Cold-Weather Starting Aids Coolant Pump) LEGEND: A B C Cap screws Fan console Coolant pump (integrated in fan console) On tractors with AutoPowr/IVT transmission (from serial no. 446370) Relieve tension on drive belt and remove belt. Remove fan and viscous fan drive. Remove fan console. For installation, follow removal procedure in reverse order. When installing, tighten to the appropriate torque (see below): Item Measurement Specification Cap screws at fan console with integrated coolant pump Torque 70 N˙m 52 lb-ft <- Go to Section TOC Section 30 page 57 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 25: Cold-Weather Starting Aids Group 25 - Cold-Weather Starting Aids Fuel Preheater LEGEND: A B C D <- Go to Section TOC Cap Heating element Seal Fuel filter head Section 30 page 58 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 25: Cold-Weather Starting Aids With Bosch VP44 injection pump and Denso/Stanadyne LEGEND: A B Heater coil O-rings Electrical Starting Aid <- Go to Section TOC Section 30 page 59 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS LEGEND: A B C D E F Group 25: Cold-Weather Starting Aids Air intake pipe Cap screw Seal Heating element Seal Hex. nut Coolant Heater <- Go to Section TOC Section 30 page 60 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS LEGEND: A B C D E F G H <- Go to Section TOC Group 30: Exhaust System Heating element Seal ring O-ring Adapter Collar nut Connecting cable Cable binder Clamp Section 30 page 61 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 30: Exhaust System Group 30 - Exhaust System Exhaust System (Summary of References) ”Installing the muffler” ”Exhaust pipe or intermediate exhaust pipe” ”Exhaust pipe or intermediate exhaust pipe —upright” General Information →NOTE: For instructions on how to repair the turbocharger, see relevant Component Technical Manual for “Engines”. When assembling parts of the exhaust system that need to be joined together, use paste L102219. Specifications Item Measurement Specification Clamp, muffler Torque 10 to 14 N˙m 8 to 10 lb-ft Pipe clamp (25) Torque 48—60 N˙m 32—44 lb-ft Pipe clamp (20; spherical) Distance ”a” when tightened 4 mm 0.15 inch Exhaust pipe or intermediate exhaust pipe —upright Item Measurement Specification Pipe clamp (items 3 and 7) Torque 48—60 N˙m 32—44 lb-ft <- Go to Section TOC Section 30 page 62 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 30: Exhaust System Installing the Muffler LEGEND: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Muffler Retaining strap M8x70 hex. socket screw Bracket Washer Cap screw Bracket Hex. nut Heat shield Washer Cap screw Cap screw Clamp M8x35 hex. socket screw Stage I engines to 97/68/EC Secure bracket (7) to the engine block. Secure bracket (4) to bracket (7), but leave it slack enough to turn. Install retaining strap (2) on the muffler and on bracket (4). Install the muffler on the turbocharger. Turn clamp (13) several times while tightening. Tighten hex. socket screw (14) to the torque value given in the table. <- Go to Section TOC Section 30 page 63 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 30: Exhaust System Item Measurement Specification Clamp, muffler Torque 10 to 14 N˙m 8 to 10 lb-ft Stage II engines to 97/68/EC LEGEND: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Muffler Retaining strap M8x70 hex. socket screw Bracket Washer Cap screw Bracket Washer Hex. nut Cap screw Heat shield Cap screw Clamp M8x35 hex. socket screw Secure bracket (7) to the engine block. Secure bracket (4) to bracket (7), but leave it slack enough to turn. Install retaining strap (2) on the muffler and on bracket (4). Install the muffler on the turbocharger. Turn clamp (13) several times while tightening. Tighten hex. socket screw (14) to the torque <- Go to Section TOC Section 30 page 64 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 30: Exhaust System value given in the table. Item Measurement Specification Clamp, muffler Torque 10 to 14 N˙m 8 to 10 lb-ft <- Go to Section TOC Section 30 page 65 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS Group 30: Exhaust System Exhaust Pipe or Intermediate Exhaust Pipe LEGEND: 1 2 3 4 5 <- Go to Section TOC Exhaust pipe Clamp Clamp Hex. nut (2 used) Washer (2 used) Section 30 page 66 TM4756-REPAIR MANUAL Section 30 - FUEL, AIR INTAKE, COOLING AND EXHAUST SYSTEMS 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 Group 30: Exhaust System Sheet-metal nut (8 used) Cap screw (2 used) Hex. nut (4 used) Washer (2 used) Washer (2 used) Washer (4 used) Rubber bearing (2 used) Console Bushing (2 used) Cap screw (2 used) Console Washer (3 used) Hex. socket screw (3 used) Pan-head screw (3 used) Pipe clamp (2 used) Flexible pipe Heat shield (assembly) Spring Hex. nut Pipe clamp (2 used) Intermediate exhaust pipe Heat shield Tighten pipe clamps (20) and (25) as specified. Pipe clamp (spherical) . Item Measurement Specification Pipe clamp (25) Torque 48—60 N˙m 32—44 lb-ft Pipe clamp (20; spherical) Distance ”a” when tightened 4 mm 0.15 inch <- Go to Section TOC Section 30 page 67 TM4756-REPAIR MANUAL ELECTRICAL SYSTEM (g) by Belgreen Exhaust Pipe or Intermediate Exhaust Pipe —Upright LEGEND: 1 2 3 4 5 6 7 8 9 Exhaust pipe Clamp Clamp Intermediate exhaust pipe Flanged screw Console Clamp Pan-head screw Protective panel Items 3 and 7 (pipe clamps) must be tightened to the torque values given in the table below. Item Measurement Specification Pipe clamps (3) and (7) Torque 48—60 N˙m 32—44 lb-ft <- Go to Section TOC Section 30 page 68 TM4756-REPAIR MANUAL TM4756-REPAIR MANUAL (g) by Belgreen Section 40 - ELECTRICAL SYSTEM Table of contents Group 05 - Electrical Connectors ............................................................................................ 1 Connectors - Summary of References .................................................................................... 1 Special or Essential Tools ....................................................................................................... 2 General .................................................................................................................................. 6 Using high-pressure washers ................................................................................................. 6 Disconnecting electrical circuits ............................................................................................. 7 Strip Wire Ends ...................................................................................................................... 7 Install a Terminal ................................................................................................................... 8 WEATHER PACK Connectors ................................................................................................. 10 METRI PACK Connectors with Terminal Lock at the Rear ..................................................... 13 METRI PACK Connectors with Terminal Lock at the Front .................................................... 17 METRI PACK Connectors ....................................................................................................... 20 Connector at CAN Bus Terminating Resistor ........................................................................ 25 Connectors for Electronic Control Units ............................................................................... 28 Connectors ........................................................................................................................... 34 CRIMP SNAP IN Connectors .................................................................................................. 41 KOSTAL Connectors ............................................................................................................. 44 DEUTSCH Connectors ........................................................................................................... 47 Individual Terminals ............................................................................................................. 52 Connector for Bosch VP44 Injection Pump ........................................................................... 54 Fuse and Relay Boxes on Tractors with Operator′s Cab ....................................................... 57 Group 10 - Wiring Harnesses ................................................................................................. 61 Wiring Harnesses for Tractors with PowrQuad Plus or AutoQuad Transmissions and Stage I Engine to 97/68/EC — Recondition (Summary of References) ...................................... 61 Wiring Harnesses for Tractors with PowrQuad Plus or AutoQuad Transmissions and Stage II Engine to 97/68/EC — Recondition (Summary of References) ...................................... 63 Wiring Harnesses for Tractors with PowrQuad Plus or AutoQuad Plus Transmission from Serial No. 398656 — Recondition (Summary of References) .................................................. 65 Wiring Harnesses for Tractors with AutoPowr/IVT Transmission and Stage I Engine to 97/68/EC — Recondition (Summary of References) ...................................................... 67 Wiring Harnesses for Tractors with AutoPowr/IVT Transmission and Stage II Engine to 97/68/EC — Recondition (Summary of References) ...................................................... 69 Wiring Harnesses for Tractors with AutoPowr/IVT transmission from Serial No. 398656 — Recondition (Summary of References) .......................................................................... 71 Disconnecting electrical circuits ........................................................................................... 72 Ground Point Locations ........................................................................................................ 74 Removing and Installing Harness W01 — Power Supply ...................................................... 75 Removing and Installing Harness W02 — Engine Wiring Harness for Stage I Engine to 97/68/EC (ECU Level 4) ................................................................................................. 77 Removing and Installing Harness W02 — Engine Wiring Harness for Stage II Engine to 97/68/EC (ECU Level 11) ............................................................................................... 79 Removing and Installing Harness W02 — Engine (Level 11 ECU) from Serial No. 398656 ....................................................................................................................................... 81 Removing and Installing Harness W03 — Starting Aid for Stage I and II engines to 97/68/EC (Level 4 or 11 ECUs) ...................................................................................................... 82 Removing and Installing Harness W03 — Starting Aid (Level 11 ECU) from Serial No. 398656 <- Go to Global Table of contents TM4756-REPAIR MANUAL TM4756-REPAIR MANUAL (g) by Belgreen ....................................................................................................................................... 84 Removing and Installing Harness W03 — Starting Aid for Stage I and II engines to 97/68/EC (Level 4 or 11 ECUs) (AutoPowr/IVT transmission) ........................................................ 86 Removing and Installing Harness W03 — Starting Aid (Level 11 ECU) (AutoPowr/IVT transmission) from Serial No. 398656 ........................................................................... 87 Removing and Installing Harness W04 — Headlights ........................................................... 88 Removing and Installing Harness W06 — Front-Wheel Drive Axle with TLS ......................... 90 Removing and Installing Harness W07 — Front PTO ............................................................ 90 Removing and Installing Harness W08 — Cab, with Stage I Engine to 97/68/EC .................. 92 Removing and Installing Harness W08 — Cab, with Stage II Engine to 97/68/EC ................. 95 Removing and Installing Harness W08 — Cab from Serial No. 398656 ................................ 98 Removing and Installing Harness W08 — Cab, with Stage I engine to 97/68/EC (AutoPowr/IVT transmission) .............................................................................................................. 101 Removing and Installing Harness W08 — Cab, with Stage II engine to 97/68/EC (AutoPowr/IVT transmission) .............................................................................................................. 104 Removing and Installing Harness W08 — Cab (AutoPowr/IVT Transmission) from Serial No. 398656 ........................................................................................................................ 107 Removing and Installing Harness W09 — Cowl, with Stage I Engine to 97/68/EC .............. 110 Removing and Installing Harness W09 — Cowl, with Stage II Engine to 97/68/EC ............. 112 Removing and Installing Harness W09 — Cowl from Serial No. 398656 ............................ 114 Removing and Installing Harness W09 — Cowl, with Stage I engine to 97/68/EC (AutoPowr/IVT transmission) .............................................................................................................. 116 Removing and Installing Harness W09 — Cowl, with Stage II engine to 97/68/EC (AutoPowr/IVT transmission) ....................................................................................... 118 Removing and Installing Harness W09 — Cowl (AutoPowr/IVT Transmission) from Serial No. 398656 ........................................................................................................................ 120 Removing and Installing Harness W10 — Shift Console ..................................................... 121 Removing and Installing Harness W11 — Transmission Shift and Hand Throttle ............... 121 Removing and Installing Harness W11 — Speed Control Lever and Hand Throttle (AutoPowr/IVT transmission) ....................................................................................... 122 Removing and Installing Harness W12 — Command Arm (AutoPowr/IVT transmission) .... 124 Removing and Installing Harness W13 — Clutch Sending Unit .......................................... 125 Removing and Installing Harness W14 — 3-Terminal Power Outlet Socket ........................ 125 Removing and Installing Harness W15 — ECU for Stage I engines to 97/68/EC (Level 4 ECU) ..................................................................................................................................... 126 Removing and Installing Harness W15 — ECU for Stage II engines to 97/68/EC (Level 11 ECU) ..................................................................................................................................... 127 Removing and Installing Harness W15 — Engine Control Unit (Level 11 ECU) from Serial No. 398656 ........................................................................................................................ 128 Removing and Installing Harness W16 — SIC with Stage I engine to 97/68/EC .................. 129 Removing and Installing Harness W16 — SIC with Stage II engine to 97/68/EC ................. 131 Removing and Installing Harness W17 — Multi-function Unit ............................................ 132 Removing and Installing Harness W18 — Windshield Wiper Switch (Without Intermittent Wipe) ........................................................................................................................... 133 Removing and Installing Harness W18 — Windshield Wiper Switch (with Intermittent Wipe) ..................................................................................................................................... 134 Removing and Installing Harness W19 — Cab Roof, with Stage I Engine to 97/68/EC ....... 136 Removing and Installing Harness W19 — Cab Roof, with Stage II Engine to 97/68/EC ...... 138 Removing and Installing Harness W20 — Turn Signal and Clearance Lights ..................... 140 Removing and Installing Harness W21 — Worklights on Front of Cab Roof ....................... 144 <- Go to Global Table of contents TM4756-REPAIR MANUAL TM4756-REPAIR MANUAL (g) by Belgreen Removing and Installing Harness W22 — Worklights on Rear of Cab Roof ........................ 144 Removing and Installing Harness W22 — Xenon (HID) Worklights on Rear of Cab Roof .... 145 Removing and Installing Harness W23 — Windshield Wiper Switch (Without Switch for Windshield) ................................................................................................................. 146 Removing and Installing Harness W23 — Windshield Wiper (With Switch for Windshield) ..................................................................................................................................... 148 Removing and Installing Harness W24 — Rear Window Wiper ........................................... 150 Removing and Installing Harness W25 — Rear Window Wiper Switch ............................... 150 Removing and Installing Harness W26 — Fan and Air-Conditioner .................................... 151 Removing and Installing Harness W26 — Fan and Air-conditioner from Serial No. 398656 ..................................................................................................................................... 152 Removing and Installing Harness W26 — ClimaTrak (Cab) ................................................ 153 Removing and Installing Harness W28 — Front End of Transmission ................................. 156 Removing and Installing Harness W28 — Front End of Transmission (AutoPowr/IVT transmission) .............................................................................................................. 158 Removing and Installing Harness W29 — Valve Block (AutoPowr/IVT transmission) .......... 159 Removing and Installing Harness W30 — Rear End of Transmission ................................. 161 Removing and Installing Harness W31 — 7-Terminal Power Outlet Socket ........................ 163 Removing and Installing Harness W32 — Stepper Motors, with Stage I engine to 97/68/EC ..................................................................................................................................... 164 Removing and Installing Harness W32 — Stepper Motors, with Stage II engine to 97/68/EC ..................................................................................................................................... 166 Removing and Installing Harness W33 — Service .............................................................. 168 Removing and Installing Harness W34 — Electric Rear-View Mirrors ................................. 169 Removing and Installing Harness W35 — Access Step Lighting and Battery Cut-off Switch (Version 1) .................................................................................................................. 170 Removing and Installing Harness W35 — Access Step Lighting and Battery Cut-off Switch (Version 2) .................................................................................................................. 171 Removing and Installing Harness W36 — 60-amp GreenStar Socket for Stage I Engine to 97/68/EC ..................................................................................................................... 173 Removing and Installing Harness W36 — 60-amp GreenStar Implement Socket ............... 174 Removing and Installing Harness W37 — GreenStar Port .................................................. 176 Removing and Installing Harness W39 — GreenStar (Cab), for Stage I Engine to 97/68/EC ..................................................................................................................................... 176 Removing and Installing Harness W39 — GreenStar (Cab) ................................................ 178 Removing and Installing Harness W39 — GreenStar with TEC (Cab), for Stage I Engine to 97/68/EC ..................................................................................................................... 179 Removing and Installing Harness W39 — GreenStar with Tractor Equipment interface Controller (Cab) ........................................................................................................... 182 Removing and Installing Harness W40 — GreenStar (Cab Roof), for Stage I Engine to 97/68/EC ..................................................................................................................... 183 Removing and Installing Harness W40 — GreenStar (Cab Roof) ........................................ 184 Removing and Installing Harness W41 — JDLink ................................................................ 184 Removing and Installing Harness W42 — Battery Cut-Off Switch, Version 1 ...................... 185 Removing and Installing Harness W42 — Battery Cut-Off Switch, Version 2 ...................... 186 Removing and Installing Harness W47 — ClimaTrak (Cab Roof) ........................................ 188 Removing and Installing Harness W48 — ClimaTrak (Cowl) ............................................... 189 Removing and Installing Harness W49 — ClimaTrak (Evaporator Housing) ....................... 190 Removing and Installing Harness W50 — GreenStar (CAN BUS Terminator) ..................... 192 Removing and Installing Harness W51 — AutoTrac (Cab) .................................................. 192 <- Go to Global Table of contents TM4756-REPAIR MANUAL TM4756-REPAIR MANUAL (g) by Belgreen Removing and Installing Harness W52 — AutoTrac (Steering Angle Sensor) ..................... 194 Removing and Installing Harness W53 — AutoTrac (Command Arm) ................................ 195 Removing and Installing Harness W55 — Display .............................................................. 195 Removing and Installing Harness W56 — Serial Interface, Adapter ................................... 196 Removing and Installing Harness W57 — Electro-hydraulic Pick-up Hitch (Cab) ................ 197 Removing and Installing Harness W58 — Electro-hydraulic Pick-up Hitch (Valves) ........... 198 Group 15 - Charging Circuit ................................................................................................. 200 Charging Circuit - Summary of References ........................................................................ 200 Special Tools ...................................................................................................................... 200 Specifications ..................................................................................................................... 200 Repairing the Alternator ..................................................................................................... 200 Disconnecting Electrical Circuits ........................................................................................ 201 Relieving Drive Belt Tension .............................................................................................. 201 Remove/Install the Alternator ............................................................................................ 203 Remove and Install the Pulley ............................................................................................ 205 Group 20 - Starter Motor Circuit ......................................................................................... 207 Starter Motor Circuit - Summary of References ................................................................. 207 Special tools ....................................................................................................................... 207 Specifications ..................................................................................................................... 207 Repairing the Starter Motor ............................................................................................... 207 Disconnecting Electrical Circuits ........................................................................................ 208 Removing and installing the starter motor ......................................................................... 209 Group 25 - Fuses, Relays and Switches ............................................................................. 211 Fuses, Relays and Switches — Recondition (Summary of References) .............................. 211 General Information ........................................................................................................... 212 Special Tools ...................................................................................................................... 212 Specifications ..................................................................................................................... 214 Removing Trim Panels from Cowl ....................................................................................... 214 Disconnecting Electrical Circuits ........................................................................................ 215 Fuse and Relay Boxes on Tractors with Operator′s Cab up to Serial No. 398655 ............... 217 Fuse and Relay Boxes on Tractors with Operator′s Cab from Serial No. 398656 ............... 233 Fuse and Relay Boxes on Tractors with Operator′s Cab and AutoPowr/IVT Transmission up to Serial No. 398655 ........................................................................................................ 249 Fuse and Relay Boxes on Tractors with Operator′s Cab and AutoPowr/IVT Transmission from Serial No. 398656 ........................................................................................................ 265 Replacing the Main Fuses .................................................................................................. 280 Replacing Fuses of Electrical Starting Aid for Stage I and II Engines to 97/68/EC (Level 4 or 11 ECUs) .......................................................................................................................... 283 Replacing Fuses of Electrical Starting Aid for Stage I and II Engines to 97/68/EC (Level 4 or 11 ECUs) (AutoPowr/IVT Transmission) ............................................................................ 285 Replacing Fuse for Fuel Injection Pump (with Stage I Engines to 97/68/EC (Level 4 ECU) ..................................................................................................................................... 287 Replacing Fuse for Fuel Injection Pump (with Stage I Engines to 97/68/EC (Level 4 ECU) (AutoPowr/IVT Transmission) ...................................................................................... 289 Replacing the LTC Coolant Pump Fuse (AutoPowr/IVT Transmission) ................................ 291 Replace the Fuse for the Implement BUS (60-amp Implement Socket) ............................. 293 Replacing Starting Motor Relay for Stage I and II Engines to 97/68/EC (Level 4 or 11 ECUs) ..................................................................................................................................... 295 Replacing Starting Motor Relay for Stage I and II Engines to 97/68/EC (Level 4 or 11 ECUs) (AutoPowr/IVT Transmission) ...................................................................................... 297 <- Go to Global Table of contents TM4756-REPAIR MANUAL TM4756-REPAIR MANUAL (g) by Belgreen Replacing Relay of Electrical Starting Aid for Stage I and II Engines to 97/68/EC (Level 4 or 11 ECUs) .......................................................................................................................... 299 Replacing Relay of Electrical Starting Aid for Stage I and II Engines to 97/68/EC (Level 4 or 11 ECUs) (AutoPowr/IVT Transmission) ............................................................................ 301 Replacing Relay for Fuel Injection Pump (with Stage I Engines to 97/68/EC only (Level 4 ECU)) ..................................................................................................................................... 302 Replace the Power Supply Relay for the Implement BUS ................................................... 303 Replacing Battery Cut-off Switch Relay .............................................................................. 304 Replacing Battery Cut-off Switch Relay .............................................................................. 307 Replacing the Main Switch ................................................................................................. 308 Replacing the Brake Switches ............................................................................................ 310 Replacing the Light Switch ................................................................................................. 310 Replacing the Worklight Switches ...................................................................................... 312 Replacing the Switch for Lights on Cab Frame ................................................................... 314 Replacing the Beacon Light Switch .................................................................................... 316 Replacing the Hazard Warning Light Switch ...................................................................... 317 Replacing Switches on Multi-Function Unit ......................................................................... 319 Replacing the Rear Window Wiper and Washer Switch ...................................................... 327 Replacing the Windshield/Rear Window Switch ................................................................. 329 Replacing the Dome Light Door Switch .............................................................................. 331 Replacing the Handbrake Switch ....................................................................................... 333 Replacing the Front Wheel Drive Switch ............................................................................ 335 Replacing the Headland Management (HMS) Switch ......................................................... 336 Replacing the Record/Save Switch ..................................................................................... 337 Replacing the Program Switch ........................................................................................... 338 Replacing the Rear PTO Preselector Switch ....................................................................... 341 Replacing the Switch for AutoQuad Transmission .............................................................. 342 Replace the Switch for Gear Selector and Auto-mode ....................................................... 343 Replacing the Park Lock Switch on Tractors with PowrQuad Plus, AutoQuad or AutoQuad Plus Transmissions ............................................................................................................. 348 Replacing the Fan Switch ................................................................................................... 350 Replacing the Switch of the Air-Conditioning System Compressor .................................... 352 Replacing the Differential Lock Switch. .............................................................................. 353 Replacing the PTO Switches ............................................................................................... 354 Replacing the External Control Switch for the Rear PTO .................................................... 358 Replacing the Rockshaft′s Remote Control Switch ............................................................. 360 Replacing the Switches for the Electrical Rear-View Mirrors .............................................. 361 Replacing the Switch for the Heated Rear-View Mirrors ..................................................... 361 Replacing the Switch for the Heated Rear Window ............................................................ 362 Replacing Switch of Battery Cut-off Switch ........................................................................ 364 Replace the AutoTrac Switch ............................................................................................. 366 Replacing the Switch for the Electro-hydraulic Pick-up Hitch ............................................. 369 Replacing the Cruise Control Potentiometer on Tractors with AutoQuad Transmission ..... 371 Replacing the Cruise Control Potentiometer on Tractors with AutoPowr/IVT Transmission ..................................................................................................................................... 373 Replace the Auto-mode Potentiometer on Tractors with AutoQuad Plus Transmission ...... 375 Rockshaft Control ............................................................................................................... 377 Electrical Activators for Selective Control Valves (E-SCV) .................................................. 388 Electrical Activators for Independent Control Valves (E-ICV) ............................................. 392 Group 30 - Monitoring Systems .......................................................................................... 396 <- Go to Global Table of contents TM4756-REPAIR MANUAL TM4756-REPAIR MANUAL (g) by Belgreen Monitoring Systems - Recondition (Summary of References) ............................................ 396 General Information ........................................................................................................... 396 Information for Tractors with Stage I Engine to 97/68/EC (Level 4 ECU) ............................ 396 Information for Tractors with Stage II Engine to 97/68/EC (Level 11 ECU) ......................... 396 Information for Tractors with AutoTrac (SSU Control Unit) ................................................. 397 Disconnecting electrical circuits ......................................................................................... 397 Replacing the sender for the coolant temperature gauge (B08) ........................................ 398 Replacing Acoustic Warning Signal Sending Unit ............................................................... 399 Replace the Acoustic Alarm (Park Lock) on Tractors with AutoPowr/IVT Transmission ...... 401 Group 40 - Electrical Components ...................................................................................... 403 Electrical Components - Recondition (Summary of References) ........................................ 403 General Information ........................................................................................................... 403 Special or Essential Tools ................................................................................................... 403 Specifications ..................................................................................................................... 404 Disconnecting electrical circuits ......................................................................................... 404 Replacing the 7-Terminal Power Outlet Socket .................................................................. 405 Replacing the 3-Terminal Power Outlet Socket .................................................................. 407 Replacing the Multiple Power-Outlet Socket Strip .............................................................. 409 Replacing the Service Socket ............................................................................................. 411 Removing the Wiper Motor ................................................................................................ 413 Adjusting the Headlights .................................................................................................... 416 Adjusting the Lights on the Cab Frame .............................................................................. 417 Safety Instructions for Replacing a Halogen Bulb .............................................................. 419 Safety Instructions for Replacing Xenon (HID) Bulbs and Ballast Units .............................. 421 Replacing Xenon (HID) Worklights and Ballast Units .......................................................... 424 <- Go to Global Table of contents TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors Group 05 - Electrical Connectors Connectors - Summary of References ”Special tools” ”General information” ”Using high-pressure washers” ”Disconnecting electrical circuits” ”Stripping wire ends” ”Installing electrical connectors” ”WEATHER PACK connectors” ”METRI PACK connectors with terminal lock at the rear” ”METRI PACK connectors with terminal lock at the front” ”METRI PACK connectors” ”Connector at CAN Bus terminating resistor” ”Connectors for electronic control units” ”Connectors” ”CRIMP SNAP IN connector” ”KOSTAL connectors” ”DEUTSCH connectors” ”Individual terminals” ”Connector for Bosch VP44 injection pump” ”Fuse and relay boxes on tractors with operator′s cab” <- Go to Section TOC Section 40 page 1 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors Special or Essential Tools →NOTE: Order tools according to information given in the U.S. SERVICEGARD ™ Catalog or European Microfiche Tool Catalog (MTC). Wiring harness repair kit FKM10461 Repairing wiring harnesses Connector set AL70932 Repairing wiring harnesses Extraction tool JDG364 <- Go to Section TOC Section 40 page 2 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors Removing electrical connectors Extraction tool JDG776 Removing electrical connectors Extraction tool JDG777 Removing electrical connectors Crimping pliers FKM10427 Installing a terminal Crimping pliers <- Go to Section TOC Section 40 page 3 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors FKM10469 Installing a terminal Wiring harness repair kit JDG359 Repairing DEUTSCH connectors Terminal puller JDG1369 JDG1369 For pulling terminals off the injection pump connector. AMP crimping pliers JDG708 <- Go to Section TOC Section 40 page 4 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors JDG708 Installing a terminal <- Go to Section TOC Section 40 page 5 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors General Electrical connectors must not be forcibly mated or unmated. All are designed to be mated easily. If you have to use tools, you may be doing something wrong. Prying or forcing connectors may cause permanent damage to the locking mechanism, contacts, or both. When working on connectors, make sure you are working on the correct terminal. Remember that male and female halves are mirror images of each other. Look for the terminal number on the connector body. The connection of improper electrical circuits can cause unusual electrical symptoms. When an electrical connector is repaired, it is important that the proper terminals are used. In some of these connectors, different terminals are used to carry different currents. If contacts of different materials are mated, corrosion may develop that could affect performance. When removing terminals from connectors, it is very important to use the correct extraction tool and gently remove the terminal. The connector body can be damaged if terminals are just "jerked" out of it. The damage caused will prevent the new terminal from staying in the connector, making replacement of the connector body necessary. When installing a new terminal on a wire, make sure the insulation crimp and wire crimp are both made properly. Each part of the terminal crimps is designed for a specific purpose. Failure to properly crimp the wire contact area can result in poor or no electrical contact. Failure to crimp the insulation support properly can result in problems getting the terminal into the connector body, thus causing premature failure. Using high-pressure washers <- Go to Section TOC Section 40 page 6 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors IMPORTANT: Directing pressurized water at electronic/electrical components or connectors, bearings and hydraulic seals, fuel injection pumps or other sensitive parts and components may cause product malfunctions. Reduce pressure, and spray at a 45 to 90° angle. Disconnecting electrical circuits Before working on the electrical system, always disconnect battery ground strap (-). Strip Wire Ends Use special pliersKLM10019-1(A) to strip wire ends. <- Go to Section TOC Section 40 page 7 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors →NOTE: Special pliersKLM10019-1are included in electrical repair tool kitFKM10461 Electrical repair tool kit FKM10461 Repairing wiring harnesses . Place the wire in the matching recess of crimping pliers, with the portion to be stripped sticking out. Squeeze the pliers until they engage. To open the pliers, pull the release lever. Take the wire out of the recess and pull the insulation off the end of the wire. Install a Terminal <- Go to Section TOC Section 40 page 8 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors Use special pliersKLM10019-1(A) to install male and female terminals of the following types: WEATHER PACK connectors METRI PACK connectors CAN bus terminating resistor connectors Connectors KOSTAL connectors Individual terminals Fuse box →NOTE: Special pliersKLM10019-1are included in harness repair tool kitFKM10461. Strip insulation from wire to expose 6 mm (0.24 in.) length of wire. Place male or female terminal in matching recess of the crimping pliers. Place the stripped portion of the wire in the recess in the male or female terminal, and squeeze the pliers until they engage. To open the pliers, pull the release lever. <- Go to Section TOC Section 40 page 9 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors WEATHER PACK Connectors →NOTE: WEATHER PACK ™ connector →NOTE: 1- to 6-pin connectors are used on the tractor. LEGEND: A B Male Terminal Body Female Terminal Body [1] - Remove terminal →NOTE: The terminals and wire seals are held in place on the terminal body by a lock. This must be lifted up before removing the terminal. JDG364extraction tool (A) for WEATHER PACK connectors. <- Go to Section TOC Section 40 page 10 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors [2] - Install wire seal →NOTE: Wire seals are color-coded to indicate different wire sizes and connector types. Green - wire size 1 mm 2 (17 AWG) Gray - wire size 2.5 mm 2 (13 AWG) Blue - wire size 4 mm 2 (11 AWG) Slip the correct size seal onto the wire. IMPORTANT: The seal must fit snugly against the lead insulation, without a gap between the seal and the insulation. Furthermore, the outer lips of the seal must fit snugly against the wall of the terminal body. Strip insulation from wire to expose 6 mm (0.24 in.) length of wire. Move the seal all the way to the edge of the insulation. <- Go to Section TOC Section 40 page 11 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors [3] - Replace terminal Place male or female terminal in matching recess of crimping pliersKLM10019-1(JDG783). →NOTE: Special pliersKLM10019-1are included in harness repair tool kitFKM10461. Place the stripped portion of the wire and wire seal in the recess in the male or female terminal, and squeeze the pliers until they engage. →NOTE: The wire seal is crimped to the terminal together with the wire in one single process. [4] - Install terminal Before installing a male or female terminal, bend locking tang (A or B) back to its original position. From the back, insert the male terminal into the terminal body. Close the locking cap. <- Go to Section TOC Section 40 page 12 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors METRI PACK Connectors with Terminal Lock at the Rear →NOTE: METRI PACK [ METRI PACK is a trademark of Packard Electric ] connector →NOTE: 1- to 10-pin connectors are used on the tractor. LEGEND: A B <- Go to Section TOC Male Terminal Body Female Terminal Body Section 40 page 13 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors [1] - Remove terminal →NOTE: The terminals and wire seals are held in place on the terminal body by a locking cap. This must be removed before removing the terminal. Extraction toolJDG776(A) for METRI PACK connectors, Series 280 and 630. [2] - Remove terminal →NOTE: The terminals and wire seals are held in place on the terminal body by a locking cap. This must be removed before removing the terminal. Extraction toolJDG777(A) for METRI PACK connectors, Series 150. <- Go to Section TOC Section 40 page 14 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors [3] - Install wire seal →NOTE: Wire seals are color-coded to indicate different wire sizes and connector types. Red - wire size 1 mm 2 (17 AWG) Gray - wire size 2.5 mm 2 (13 AWG) Blue - wire size 4 mm 2 (11 AWG) Slip the correct size seal onto the wire. IMPORTANT: The seal must fit snugly against the lead insulation, without a gap between the seal and the insulation. Furthermore, the outer lips of the seal must fit snugly against the wall of the terminal body. Strip insulation from wire to expose 6 mm (0.24 in.) length of wire. Move the seal all the way to the edge of the insulation. <- Go to Section TOC Section 40 page 15 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors [4] - Replace terminal Place male or female terminal in matching recess of crimping pliersKLM10019-1. →NOTE: Special pliersKLM10019-1are included in harness repair tool kitFKM10461. Place the stripped portion of the wire and wire seal in the recess in the male or female terminal, and squeeze the pliers until they engage. →NOTE: The wire seal is crimped to the terminal together with the wire in one single process. [5] - Install terminal Before installing a male or female terminal, bend locking tang (A) back to its original position. From the back, insert the male terminal into the terminal body. Put on the locking cap. <- Go to Section TOC Section 40 page 16 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors METRI PACK Connectors with Terminal Lock at the Front →NOTE: METRI PACK [ METRI PACK is a trademark of Packard Electric ] connector →NOTE: 2- to 4-pin connectors are used on the tractor. [1] - Remove terminal lock Use a small screwdriver to disengage terminal lock (A) at the points indicated, and pull it out. [2] - Remove terminal JDG777extraction tool (A) for METRI PACK connectors. <- Go to Section TOC Section 40 page 17 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors [3] - Install wire seal Slip the correct size seal onto the wire. IMPORTANT: The seal must fit snugly against the lead insulation, without a gap between the seal and the insulation. Furthermore, the outer lips of the seal must fit snugly against the wall of the terminal body. Strip insulation from wire to expose 6 mm (0.24 in.) length of wire. Move the seal all the way to the edge of the insulation. [4] - Replace terminal Place male or female terminal in matching recess of crimping pliersKLM10019-1(JDG783). →NOTE: Special pliersKLM10019-1are included in harness repair tool kitFKM10461. Place the stripped portion of the wire and wire seal in the recess in the male or female terminal, and squeeze the pliers until they engage. →NOTE: The wire seal is crimped to the terminal together with the wire in one single process. <- Go to Section TOC Section 40 page 18 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors From the back, insert the male terminal into the terminal body. Put on the locking cap. <- Go to Section TOC Section 40 page 19 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors METRI PACK Connectors →NOTE: METRI PACK [ METRI PACK is a trademark of Packard Electric ] connector 2-pin or 3-pin connectors [1] - Extract female terminal Use a pointed tool (A) to press in the locking tang. Press the female terminal forward and out of the terminal body. [2] - Strip wire From the back, feed the wire through the rubber seal and through the terminal body. Strip insulation from wire to expose 4 mm (0.16 in.) length of wire. <- Go to Section TOC Section 40 page 20 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors [3] - Replace female terminal Place the female terminal in the matching recess in crimping pliersKLM10019-1. →NOTE: Special pliersKLM10019-1are included in harness repair tool kitFKM10461. Place the stripped portion of the wire in the recess in the female terminal, and squeeze the pliers until they engage. To open the pliers, pull the release lever. Before installing a female terminal, bend the locking tang back to its original position. Pull the female terminal back into the terminal body. 6-pin connector <- Go to Section TOC Section 40 page 21 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors [1] - Remove connector body Use a small screwdriver (C) to disengage the lock at the points indicated, and pull connector (A) out of terminal body (B). [2] - Remove terminal lock Use a small screwdriver (E) to disengage terminal lock (D), then push it out and take it off. [3] - Extract female terminal Using a pointed tool (F), depress the locking tang and pull the female terminal out of the body. <- Go to Section TOC Section 40 page 22 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors [4] - Install wire seal Slip the correct size seal onto the wire. IMPORTANT: The seal must fit snugly against the lead insulation, without a gap between the seal and the insulation. Furthermore, the outer lips of the seal must fit snugly against the wall of the terminal body. Strip insulation from wire to expose 4 mm (0.16 in.) length of wire. Move the seal all the way to the edge of the insulation. [5] - Replace terminal Place male or female terminal in matching recess of crimping pliersJDG1727(JDG783). →NOTE: Special pliersJDG1727are included in harness repair tool kitJDG1744. Place the stripped portion of the wire and wire seal in the recess in the male or female terminal, and squeeze the pliers until they engage. →NOTE: The wire seal is crimped to the terminal together with the wire in one single process. <- Go to Section TOC Section 40 page 23 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors From the back, insert the female or male terminal into the terminal body. Put the terminal lock back on. <- Go to Section TOC Section 40 page 24 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors Connector at CAN Bus Terminating Resistor [1] - Removing terminal lock Press the catches (B) to release the terminal locks (A). Pull the lock out of the terminal body. [2] - Extracting a female terminal Use extraction tool JD777 (C) Extraction tool JDG777 Removing electrical connectors to press in the locking tang, and pull the female terminal out from the rear. <- Go to Section TOC Section 40 page 25 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors [3] - Installing a wire seal Slip the correct size seal onto the wire. IMPORTANT: The seal must fit snugly against the wire insulation, without a gap between the seal and the insulation. Furthermore, the outer lips of the seal must fit snugly against the wall of the terminal body. Strip insulation from wire to expose 6 mm (0.24 in.) length of wire. Align seal with edge of insulation. <- Go to Section TOC Section 40 page 26 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors [4] - Replacing a female terminal Place female terminals in the matching recess in crimping pliers KLM10019-1. →NOTE: Special pliers KLM10019-1 are included in wiring harness repair kit FKM10461. Wiring harness repair kit FKM10461 Repairing wiring harnesses Place the stripped portion of the wire and wire seal in the recess in the female terminal, and squeeze the pliers until they engage. →NOTE: The wire seal is crimped to the female terminal together with the wire in one single process. To open the pliers, pull the release lever. Before installing a female terminal, bend the locking tang back to its original position. From the back, insert the female terminal into the terminal body. Insert the terminal lock. <- Go to Section TOC Section 40 page 27 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors Connectors for Electronic Control Units 45-pin or 68-pin connectors [1] - Remove cover Remove the cable binder. Press up locking tang and slide cover (A) to the left. [2] - Extract female terminal Use extraction toolFKM10457(B) to press in the locking tang and extract the female terminal from the rear. →NOTE: Extraction toolFKM10457is included in wiring harness repair kitFKM10461 <- Go to Section TOC Section 40 page 28 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors [3] - Install wire seal Slip the correct size seal onto the wire. IMPORTANT: The seal must fit snugly against the lead insulation, without a gap between the seal and the insulation. Furthermore, the outer lips of the seal must fit snugly against the wall of the terminal body. Strip insulation from wire to expose 4 mm (0.16 in.) length of wire. Move the seal all the way to the edge of the insulation. [4] - Replace terminal Place male or female terminal in matching recess of crimping pliersKLM10019-1(JDG783). →NOTE: Special pliersKLM10019-1are included in harness repair tool kitFKM10461. Place the stripped portion of the wire and wire seal in the recess in the male or female terminal, and squeeze the pliers until they engage. →NOTE: The wire seal is crimped to the terminal together with the wire in one single process. <- Go to Section TOC Section 40 page 29 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors From the back, insert the male terminal into the terminal body. Slide on the cover and install the cable binder. 30-pin connector [1] - Extract Female Terminal Use a pointed tool (A) to press in the locking tang. Press the female terminal forward and out of the terminal body. [2] - Strip Wire From the back, feed the wire through the rubber seal and through the terminal body. Strip insulation from wire to expose 4 mm (0.16 in.) length of wire. <- Go to Section TOC Section 40 page 30 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors [3] - Replace Female Terminal Place female terminals in the matching recess in crimping pliersKLM10019-1. →NOTE: Special pliersKLM10019-1are included in harness repair tool kitFKM10461. Place the stripped portion of the wire in the recess in the female terminal, and squeeze the pliers until they engage. To open the pliers, pull the release lever. Before installing a female terminal, bend the locking tang back to its original position. Pull the female terminal back into the terminal body. 32-pin or 48-pin connectors [1] - Remove cover Press the two locking tangs (A) outward and slide cover (B) away to the front. <- Go to Section TOC Section 40 page 31 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors [2] - Remove terminal lock Pull terminal lock (A) out of terminal body. [3] - Extract Female Terminal LEGEND: A B Chamber Openings Use extraction toolJDG1725to press in the locking tangs in openings (B) and extract the female terminal from the rear of the chamber. →NOTE: Special pliersJDG1725are included in harness repair tool kitJDG1744. <- Go to Section TOC Section 40 page 32 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors [4] - Replace terminal Place male or female terminal in matching recess of the crimping pliersJDG1727. →NOTE: Special pliersJDG1727are included in harness repair tool kitJDG1744. Place the stripped portion of the wire and wire seal in the recess in the male or female terminal, and squeeze the pliers until they engage. →NOTE: The wire seal is crimped to the terminal together with the wire in one single process. From the back, insert the female or male terminal into the terminal body. Insert the terminal lock. Slide on the cover and install the cable binder. <- Go to Section TOC Section 40 page 33 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors Connectors 10-, 16- and 24-pin connectors [1] - Remove terminal lock Pull terminal locks (A) out of terminal body. [2] - Extract terminal Use extraction toolFKM10456(A) to press in the locking tang and extract the male or female terminal from the rear. →NOTE: Extraction toolFKM10456is included in electrical repair tool kitFKM10461. <- Go to Section TOC Section 40 page 34 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors [3] - Install Wire Seal Slip the correct size seal onto the wire. IMPORTANT: The seal must fit snugly against the lead insulation, without a gap between the seal and the insulation. Furthermore, the outer lips of the seal must fit snugly against the wall of the terminal body. Strip insulation from wire to expose 4 mm (0.16 in.) length of wire. Move the seal all the way to the edge of the insulation. [4] - Replace terminal Place male or female terminal in matching recess of crimping pliersKLM10019-1(JDG783). →NOTE: Special pliersKLM10019-1are included in harness repair tool kitFKM10461. Place the stripped portion of the wire and wire seal in the recess in the male or female terminal, and squeeze the pliers until they engage. →NOTE: The wire seal is crimped to the terminal together with the wire in one single process. <- Go to Section TOC Section 40 page 35 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors From the back, insert the male terminal into the terminal body. Insert the terminal lock. 42-pin connector [1] - Remove terminal lock Pull terminal locks (A) out of terminal body. [2] - Extract Terminal Use extraction toolFKM10456orFKM10457(A) to press in the locking tang and extract the male or female terminal from the rear. →NOTE: Extraction toolFKM10456orFKM10457is included in electrical repair tool kitFKM10461. <- Go to Section TOC Section 40 page 36 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors [3] - Install Wire Seal Slip the correct size seal onto the wire. IMPORTANT: The seal must fit snugly against the lead insulation, without a gap between the seal and the insulation. Furthermore, the outer lips of the seal must fit snugly against the wall of the terminal body. Strip insulation from wire to expose 4 mm (0.16 in.) length of wire. Move the seal all the way to the edge of the insulation. [4] - Replace terminal Place male or female terminal in matching recess of crimping pliersKLM10019-1(JDG783). →NOTE: Special pliersKLM10019-1are included in harness repair tool kitFKM10461. Place the stripped portion of the wire and wire seal in the recess in the male or female terminal, and squeeze the pliers until they engage. →NOTE: The wire seal is crimped to the terminal together with the wire in one single process. <- Go to Section TOC Section 40 page 37 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors From the back, insert the male terminal into the terminal body. Insert the terminal lock. 62-pin connector [1] - Release terminal lock Release terminal locks (A) as shown (see arrow). [2] - Extract Terminal Use extraction toolFKM10456orFKM10457(A) to press in the locking tang and extract the male or female terminal from the rear. →NOTE: Extraction toolFKM10456orFKM10457is included in electrical repair tool kitFKM10461. <- Go to Section TOC Section 40 page 38 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors [3] - Install wire seal Slip the correct size seal onto the wire. IMPORTANT: The seal must fit snugly against the lead insulation, without a gap between the seal and the insulation. Furthermore, the outer lips of the seal must fit snugly against the wall of the terminal body. Strip insulation from wire to expose 4 mm (0.16 in.) length of wire. Move the seal all the way to the edge of the insulation. [4] - Replace terminal Place male or female terminal in matching recess of crimping pliersKLM10019-1(JDG783). →NOTE: Special pliersKLM10019-1are included in harness repair tool kitFKM10461. Place the stripped portion of the wire and wire seal in the recess in the male or female terminal, and squeeze the pliers until they engage. →NOTE: The wire seal is crimped to the terminal together with the wire in one single process. <- Go to Section TOC Section 40 page 39 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors From the back, insert the male terminal into the terminal body. Insert the terminal lock. <- Go to Section TOC Section 40 page 40 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors CRIMP SNAP IN Connectors →NOTE: CRIMP SNAP IN [ CRIMP SNAP IN is a trademark of the AMP company ] connectors LEGEND: A Connector assembly Remove the cap Remove the cable binder. Pull body (A) out of cap (B). Remove terminal lock <- Go to Section TOC Section 40 page 41 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors Pull terminal lock (C) out of the body. Extract female terminal Use a pointed tool to press in locking tang (D) and pull the female terminal out of the body. Install a female terminal Strip insulation from wire to expose 4 mm (0.16 in.) length of wire. <- Go to Section TOC Section 40 page 42 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors Place female terminals in the matching recess in crimping pliers “FKM10427” Crimping pliers FKM10427 Installing a terminal . Insert the stripped portion of the wire into the female terminal. Squeeze the pliers together. Before installing a female terminal, bend the locking tang back to its original position. From the back, insert the female terminal into the terminal body. Insert the terminal lock. Put on the cap and install the cable binder. <- Go to Section TOC Section 40 page 43 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors KOSTAL Connectors →NOTE: KOSTAL connector [ KOSTAL is a trademark of KOSTAL Kontakt-Systeme ] [1] - Disengage terminal lock Use a small screwdriver (B) to press terminal lock (A) out at the point indicated. [2] - Extract female terminal Use extraction toolKLM10019-4(A) to extract the female terminal. →NOTE: Extraction toolKLM10019-4is included in harness repair tool kitFKM10461. <- Go to Section TOC Section 40 page 44 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors [3] - Install wire seal Slip the correct size seal onto the wire. IMPORTANT: The seal must fit snugly against the lead insulation, without a gap between the seal and the insulation. Furthermore, the outer lips of the seal must fit snugly against the wall of the terminal body. Strip insulation from wire to expose 4 mm (0.16 in.) length of wire. Move the seal all the way to the edge of the insulation. [4] - Replace terminal Place male or female terminal in matching recess of crimping pliersKLM10019-1. →NOTE: Special pliersKLM10019-1are included in harness repair tool kitFKM10461. Place the stripped portion of the wire and wire seal in the recess in the male or female terminal, and squeeze the pliers until they engage. →NOTE: The wire seal is crimped to the terminal together with the wire in one single process. <- Go to Section TOC Section 40 page 45 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors From the back, insert the male terminal into the terminal body. <- Go to Section TOC Section 40 page 46 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors DEUTSCH Connectors →NOTE: DEUTSCH ™ connectors [1] - Extract male or female terminals Position extraction toolJDG362against wire as shown in the illustration. <- Go to Section TOC Section 40 page 47 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors →NOTE: Extraction toolJDG362is included in wiring harness repair tool kitJDG359 Wiring harness repair kit JDG359 Repairing DEUTSCH connectors . Slide extraction tool to the rear along the wire until the tip of the tool engages in the wire. IMPORTANT: When inserting the tool into the terminal body, take care NOT to twist the tool. Slide the extraction tool along the wire into the terminal body until it is located over the terminal. Remove the wire from the terminal body using the extraction tool. <- Go to Section TOC Section 40 page 48 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors [2] - Install a terminal Strip insulation from the end of the wire to a length of 6 mm (1/4 in.). Adjust crimping pliersJDG360for correct wire size at selector (A). →NOTE: Crimping pliersJDG360are included in wiring harness repair tool kitJDG359 Wiring harness repair kit JDG359 Repairing DEUTSCH connectors . Loosen lock nut (B) and turn adjusting screw (C) in until it stops. IMPORTANT: Select proper size of male or female terminal. <- Go to Section TOC Section 40 page 49 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors Insert terminal (A) and turn adjusting screw (D) until the terminal is flush with cover (B). Tighten locknut (C). IMPORTANT: The terminal must remain centered between the indenters on the pliers while it is being crimped onto the wire. Insert wire into terminal and squeeze the handles of the crimping pliers until they touch. Release the handle and remove the terminal. IMPORTANT: If all wire strands are not crimped into the terminal, cut off wire at terminal and repeat the installation procedures. →NOTE: Re-adjust crimping tool before each crimping procedure. <- Go to Section TOC Section 40 page 50 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors [3] - Install terminal IMPORTANT: Use a grommet of the appropriate size to insert the terminal at the correct location. Slide the terminal into the terminal body until resistance is encountered. Check that the terminal is seated firmly in the terminal body by pulling gently on the wire. <- Go to Section TOC Section 40 page 51 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors Individual Terminals [1] - Extract individual terminals Use a small screwdriver to press in the locking tang (A). Pull the terminal out of the terminal body. <- Go to Section TOC Section 40 page 52 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors [2] - Change a terminal Strip insulation from wire to expose 6 mm (0.24 in.) length of wire. Place terminals in the matching recess in crimping pliersKLM10019-1. →NOTE: Special pliersKLM10019-1are included in electrical repair tool kitFKM10461 Electrical repair tool kit FKM10461 Repairing wiring harnesses . Place the stripped portion of the wire in the recess in the terminal, and squeeze the pliers until they engage. To open the pliers, pull the release lever. Bend the locking tang back to its original position before re-installing the terminal in the terminal body. From the back, insert the terminal into the terminal body. <- Go to Section TOC Section 40 page 53 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors Connector for Bosch VP44 Injection Pump How to use AMP crimping pliers LEGEND: A B C D E F G H Locator assembly Locator Wire Crimping slot Crimping slot Terminal Insulation barrel Wire barrel [1] - Press the JDG1369 terminal extraction tool into the face of the connector and remove the wire and terminal from the back of the connector. Terminal extraction tool JDG1369 JDG1369 For pulling terminals off the injection pump connector. [2] →NOTE: Verify length of stripped wire and crimp height before using the AMP crimping tool. See instructions provided with the tool. Strip new wire to the length indicated in tool instructions. Do not nick or cut wire strands. <- Go to Section TOC Section 40 page 54 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors [3] - Hold the JDG708 AMP crimping tool so that the back (wire side) is facing you. Squeeze tool handles together and allow them to open fully. AMP crimping pliers JDG708 JDG708 For crimping terminal wire ends onto the injection pump connector. [4] →NOTE: See instructions provided with tool to determine which crimping slot (D or E) to use. Holding the terminal (F) by the mating end, insert the insulation barrel (G) first, through the front of the tool and into the appropriate crimp slot (D or E). [5] IMPORTANT: Make sure that both sides of the insulation barrel (G) are inserted evenly into the crimping section. Do NOT attempt to crimp an improperly positioned contact. Position the terminals so that the open “U” of the wire and insulation barrels (H and G) faces the top of the tool. Place the terminal up into the nest so that the movable locator (B) drops into the slot in the terminal as shown. Butt the front end of the wire barrel (H) against the movable locator. [6] - Hold the terminal (F) in position and squeeze the tool handles together until the ratchet engages sufficiently to hold the terminal in position. Do NOT deform the insulation barrel or wire barrel. [7] - Insert stripped wire (C) into terminal insulation and wire barrels until it is butted against the wire stop. <- Go to Section TOC Section 40 page 55 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors [8] - Crimping a terminal LEGEND: A Wire and terminal Hold the wire and terminal (A) in place. Squeeze tool handles together until the ratchet releases. Allow tool handles to open, and remove crimped terminal. →NOTE: The crimped terminal may stick in the crimping area. It can be easily removed by pushing downward on the top of the locator. [9] - Install wire in connector. <- Go to Section TOC Section 40 page 56 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors Fuse and Relay Boxes on Tractors with Operator′s Cab Opening the fuse and relay boxes Open fuse and relay boxes towards the front. Extracting a female terminal from relay boxes (K01 and K10) [1] - Removing a terminal lock Pull terminal lock (A) out at the rear. [2] - Extracting a female terminal Use a small screwdriver to press in the locking tang and extract the female terminal from the rear. Before installing a female terminal, bend the locking tang back to its original position. Extracting a female terminal from relay boxes (K02, K08 and K09) <- Go to Section TOC Section 40 page 57 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors [1] - Removing a terminal lock Pull terminal lock (A) out at the front. [2] - Extracting a female terminal Use a small screwdriver to press in the locking tang and extract the female terminal from the rear. Before installing a female terminal, bend the locking tang back to its original position. Extracting female terminals from fuse boxes (F03, F04, F05, F06 and F07) <- Go to Section TOC Section 40 page 58 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 05: Electrical Connectors [1] - Removing a terminal lock Pull terminal lock (A) out from underneath. [2] - Extracting a female terminal Use a small screwdriver to press in the locking tang and extract the female terminal from the rear. Before installing a female terminal, bend the locking tang back to its original position. Replacing a female terminal Strip insulation from wire to expose 6 mm (0.24 in.) length of wire. <- Go to Section TOC Section 40 page 59 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Place terminals in the matching recess in crimping pliers KLM10019-1. →NOTE: Special pliers KLM10019-1 are included in wiring harness repair kit FKM10461 Wiring harness repair kit FKM10461 Repairing wiring harnesses . Place the stripped portion of the wire in the recess in the terminal, and squeeze the pliers until they engage. To open the pliers, pull the release lever. Bend the locking tang back to its original position before re-installing the terminal in the terminal body. From the back, insert the terminal into the fuse and relay boxes. Close fuse and relay boxes towards the rear. <- Go to Section TOC Section 40 page 60 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Group 10 - Wiring Harnesses Wiring Harnesses for Tractors with PowrQuad Plus or AutoQuad Transmissions and Stage I Engine to 97/68/EC — Recondition (Summary of References) ”Disconnecting electrical circuits” . ”Ground point locations” . ”Removing and installing harness W01 — Power supply” . ”Removing and installing harness W02 — Engine wiring harness for Stage I engine to 97/68/EC (Level 4 ECU)” . ”Removing and installing harness W03 — Starting aid for Stage I and II engines to 97/68/EC (Level 4 or 11 ECUs)” . ”Removing and installing harness W04 — Headlights”. ”Removing and installing harness W06 — Front-wheel drive axle with TLS” . ”Removing and installing harness W07 — Front PTO” . ”Removing and installing harness W08 — Cab, for Stage I engine to 97/68/EC” . ”Removing and installing harness W09 — Cowl, for Stage I engine to 97/68/EC” . ”Removing and installing harness W10 — Shift console” . ”Removing and installing harness W11 — Transmission shift and hand throttle” . ”Removing and installing harness W13 — Clutch sending unit” . ”Removing and installing harness W14 — 3-terminal power outlet socket” . ”Removing and installing harness W15 — ECU for Stage I engines to 97/68/EC (Level 4 ECU)” . ”Removing and installing harness W16 — SIC with Stage I engine to 97/68/EC” . ”Removing and installing harness W17 — Multi-function unit” . ”Removing and installing harness W18 — Windshield wiper switch (without intermittent wipe)” . ”Removing and installing harness W18 — Windshield wiper switch (with intermittent wipe)” . ”Removing and installing harness W19 — Cab roof, for Stage I engine to 97/68/EC” . ”Removing and installing harness W20 — Turn signal and clearance lights”. ”Removing and installing harness W21 — Worklights on front of cab roof” . ”Removing and installing harness W22 — Worklights on rear of cab roof” . ”Removing and installing harness W22 — Xenon (HID) worklights on rear of cab roof”. ”Removing and installing harness W23 — Windshield wiper (without switch for windshield)” . ”Removing and installing harness W23 — Windshield wiper (with switch for windshield)” . ”Removing and installing harness W24 — Rear window wiper” . ”Removing and installing harness W25 — Rear window wiper switch” . ”Removing and installing harness W26 — Fan and air-conditioner” . ”Removing and installing harness W28 — Front end of transmission” . ”Removing and installing harness W30 — Rear end of transmission”. ”Removing and installing harness W31 — 7-terminal power outlet socket” . <- Go to Section TOC Section 40 page 61 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses ”Removing and installing harness W32 — Stepper motors for Stage I engine to 97/68/EC” . ”Removing and installing harness W33 — Service” . ”Removing and installing harness W34 — Electric rear-view mirrors”. ”Removing and installing harness W35 — Access step lighting and battery cut-off switch (version 1)”. ”Removing and installing harness W35 — Access step lighting and battery cut-off switch (version 2)”. ”Removing and installing harness W36 — 60-amp GreenStar socket for Stage I engine to 97/68/EC”. ”Removing and installing harness W37 — GreenStar port”. ”Removing and installing harness W39 — GreenStar (cab), for Stage I engine to 97/68/EC”. ”Removing and installing harness W39 — GreenStar with TEC (cab), for Stage I engine to 97/68/EC”. ”Removing and installing harness W40 — GreenStar (cab roof), for Stage I engine to 97/68/EC”. ”Removing and installing harness W41 — JDLink”. ”Removing and installing harness W42 — Battery cut-off switch, version 1”. ”Removing and installing harness W42 — Battery cut-off switch, version 2”. <- Go to Section TOC Section 40 page 62 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Wiring Harnesses for Tractors with PowrQuad Plus or AutoQuad Transmissions and Stage II Engine to 97/68/EC — Recondition (Summary of References) ”Disconnecting electrical circuits” . ”Ground point locations” . ”Removing and installing harness W01 — Power supply” . ”Removing and installing harness W02 — Engine wiring harness for Stage II engine to 97/68/EC (Level 11 ECU)”. ”Removing and installing harness W03 — Starting aid for Stage I and II engines to 97/68/EC (Level 4 or 11 ECUs)” . ”Removing and installing harness W04 — Headlights”. ”Removing and installing harness W06 — Front-wheel drive axle with TLS” . ”Removing and installing harness W07 — Front PTO” . ”Removing and installing harness W08 — Cab, for Stage II engine to 97/68/EC”. ”Removing and installing harness W09 — Cowl, for Stage II engine to 97/68/EC”. ”Removing and installing harness W10 — Shift console” . ”Removing and installing harness W11 — Transmission shift and hand throttle” . ”Removing and installing harness W13 — Clutch sending unit” . ”Removing and installing harness W14 — 3-terminal power outlet socket” . ”Removing and installing harness W15 — ECU for Stage II engines to 97/68/EC (Level 11 ECU)”. ”Removing and installing harness W16 — SIC with Stage II engine to 97/68/EC”. ”Removing and installing harness W17 — Multi-function unit” . ”Removing and installing harness W18 — Windshield wiper switch (without intermittent wipe)” . ”Removing and installing harness W18 — Windshield wiper switch (with intermittent wipe)” . ”Removing and installing harness W19 — Cab roof, for Stage II engine to 97/68/EC”. ”Removing and installing harness W20 — Turn signal and clearance lights”. ”Removing and installing harness W21 — Worklights on front of cab roof” . ”Removing and installing harness W22 — Worklights on rear of cab roof” . ”Removing and installing harness W22 — Xenon (HID) worklights on rear of cab roof”. ”Removing and installing harness W23 — Windshield wiper (without switch for windshield)” . ”Removing and installing harness W23 — Windshield wiper (with switch for windshield)” . ”Removing and installing harness W24 — Rear window wiper” . ”Removing and installing harness W25 — Rear window wiper switch” . ”Removing and installing harness W26 — Fan and air-conditioner” . ”Removing and installing harness W28 — Front end of transmission” . ”Removing and installing harness W30 — Rear end of transmission”. ”Removing and installing harness W31 — 7-terminal power outlet socket” . ”Removing and installing harness W32 — Stepper motors for Stage II engine to 97/68/EC”. <- Go to Section TOC Section 40 page 63 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses ”Removing and installing harness W33 — Service” . ”Removing and installing harness W34 — Electric rear-view mirrors”. ”Removing and installing harness W35 — Access step lighting and battery cut-off switch (version 1)”. ”Removing and installing harness W35 — Access step lighting and battery cut-off switch (version 2)”. ”Removing and installing harness W36 — 60-amp GreenStar socket for Stage I engine to 97/68/EC”. ”Removing and installing harness W37 — GreenStar port”. ”Removing and installing harness W39 — GreenStar (cab)”. ”Removing and installing harness W39 — GreenStar with tractor equipment interface controller (cab)”. ”Removing and installing harness W40 — GreenStar (cab roof)”. ”Removing and installing harness W41 — JDLink”. ”Removing and installing harness W42 — Battery cut-off switch, version 1”. ”Removing and installing harness W42 — Battery cut-off switch, version 2”. <- Go to Section TOC Section 40 page 64 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Wiring Harnesses for Tractors with PowrQuad Plus or AutoQuad Plus Transmission from Serial No. 398656 — Recondition (Summary of References) ”Disconnecting electrical circuits” . ”Ground point locations” . ”Removing and installing harness W01 — Power supply” . ”Removing and installing harness W02 — Engine (Level 11 ECU) from serial no. 398656”. ”Removing and installing harness W03 — Starting aid (Level 11 ECU) from serial no. 398656”. ”Removing and installing harness W04 — Headlights”. ”Removing and installing harness W06 — Front-wheel drive axle with TLS” . ”Removing and installing harness W07 — Front PTO” . ”Removing and installing harness W08 — Cab from serial no. 398656”. ”Removing and installing harness W09 — Cowl from serial no. 398656”. ”Removing and installing harness W10 — Shift console” . ”Removing and installing harness W11 — Transmission shift and hand throttle” . ”Removing and installing harness W13 — Clutch sending unit” . ”Removing and installing harness W14 — 3-terminal power outlet socket” . ”Removing and installing harness W15 — Engine control unit (Level 11 ECU) from serial no. 398656”. ”Removing and installing harness W16 — SIC with Stage II engine to 97/68/EC”. ”Removing and installing harness W17 — Multi-function unit” . ”Removing and installing harness W18 — Windshield wiper switch (without intermittent wipe)” . ”Removing and installing harness W18 — Windshield wiper switch (with intermittent wipe)” . ”Removing and installing harness W19 — Cab roof, for Stage II engine to 97/68/EC”. ”Removing and installing harness W20 — Turn signal and clearance lights”. ”Removing and installing harness W21 — Worklights on front of cab roof” . ”Removing and installing harness W22 — Worklights on rear of cab roof” . ”Removing and installing harness W22 — Xenon (HID) worklights on rear of cab roof”. ”Removing and installing harness W23 — Windshield wiper (without switch for windshield)” . ”Removing and installing harness W23 — Windshield wiper (with switch for windshield)” . ”Removing and installing harness W24 — Rear window wiper” . ”Removing and installing harness W25 — Rear window wiper switch” . ”Removing and installing harness W26 — Fan and air-conditioner from serial no. 398656”. ”Removing and installing harness W26 — ClimaTrak (cab)”. ”Removing and installing harness W28 — Front end of transmission” . ”Removing and installing harness W30 — Rear end of transmission”. ”Removing and installing harness W31 — 7-terminal power outlet socket” . <- Go to Section TOC Section 40 page 65 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses ”Removing and installing harness W32 — Stepper motors for Stage II engine to 97/68/EC”. ”Removing and installing harness W33 — Service” . ”Removing and installing harness W34 — Electric rear-view mirrors”. ”Removing and installing harness W35 — Access step lighting and battery cut-off switch (version 1)”. ”Removing and installing harness W35 — Access step lighting and battery cut-off switch (version 2)”. ”Removing and installing harness W36 — 60-amp GreenStar socket for Stage I engine to 97/68/EC”. ”Removing and installing harness W37 — GreenStar port”. ”Removing and installing harness W39 — GreenStar (cab)”. ”Removing and installing harness W39 — GreenStar with tractor equipment interface controller (cab)”. ”Removing and installing harness W40 — GreenStar (cab roof)”. ”Removing and installing harness W41 — JDLink”. ”Removing and installing harness W42 — Battery cut-off switch, version 1”. ”Removing and installing harness W42 — Battery cut-off switch, version 2”. ”Removing and installing harness W47 — ClimaTrak (cab roof)”. ”Removing and installing harness W48 — ClimaTrak (cowl)”. ”Removing and installing harness W49 — ClimaTrak (evaporator housing)”. ”Removing and installing harness W50 — GreenStar (CAN BUS terminator)”. ”Removing and installing harness W51 — AutoTrac (cab)”. ”Removing and installing harness W52 — AutoTrac (steering angle sensor)”. ”Removing and installing harness W53 — AutoTrac (Command Arm)”. <- Go to Section TOC Section 40 page 66 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Wiring Harnesses for Tractors with AutoPowr/IVT Transmission and Stage I Engine to 97/68/EC — Recondition (Summary of References) ”Disconnecting electrical circuits” . ”Ground point locations” . ”Removing and installing harness W01 — Power supply” . ”Removing and installing harness W02 — Engine wiring harness for Stage I engine to 97/68/EC (Level 4 ECU)” . ”Removing and installing harness W03 — Starting aid for Stage I and II engines to 97/68/EC (Level 4 or 11 ECUs) (AutoPowr/IVT transmission)”. ”Removing and installing harness W04 — Headlights”. ”Removing and installing harness W06 — Front-wheel drive axle with TLS” . ”Removing and installing harness W07 — Front PTO” . ”Removing and installing harness W08 — Cab, with Stage I engine to 97/68/EC (AutoPowr/IVT transmission)” . ”Removing and installing harness W09 — Cowl, with Stage I engine to 97/68/EC (AutoPowr/IVT transmission)” . ”Removing and installing harness W10 — Shift console” . ”Removing and installing harness W11 — Speed control lever and hand throttle (AutoPowr/IVT transmission)” . ”Removing and installing harness W12 — Command Arm (AutoPowr/IVT transmission)” . ”Removing and installing harness W13 — Clutch sending unit” . ”Removing and installing harness W14 — 3-terminal power outlet socket” . ”Removing and installing harness W15 — ECU for Stage I engines to 97/68/EC (Level 4 ECU)” . ”Removing and installing harness W16 — SIC with Stage I engine to 97/68/EC” . ”Removing and installing harness W17 — Multi-function unit” . ”Removing and installing harness W18 — Windshield wiper switch (without intermittent wipe)” . ”Removing and installing harness W18 — Windshield wiper switch (with intermittent wipe)” . ”Removing and installing harness W19 — Cab roof, for Stage I engine to 97/68/EC” . ”Removing and installing harness W20 — Turn signal and clearance lights”. ”Removing and installing harness W21 — Worklights on front of cab roof” . ”Removing and installing harness W22 — Worklights on rear of cab roof” . ”Removing and installing harness W22 — Xenon (HID) worklights on rear of cab roof”. ”Removing and installing harness W23 — Windshield wiper (without switch for windshield)” . ”Removing and installing harness W23 — Windshield wiper (with switch for windshield)” . ”Removing and installing harness W24 — Rear window wiper” . ”Removing and installing harness W25 — Rear window wiper switch” . ”Removing and installing harness W26 — Fan and air-conditioner” . ”Removing and installing harness W28 — Front end of transmission (AutoPowr/IVT <- Go to Section TOC Section 40 page 67 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses transmission)” . ”Removing and installing harness W29 — Valve block (AutoPowr/IVT transmission)” . ”Removing and installing harness W30 — Rear end of transmission”. ”Removing and installing harness W31 — 7-terminal power outlet socket” . ”Removing and installing harness W32 — Stepper motors for Stage I engine to 97/68/EC” . ”Removing and installing harness W33 — Service” . ”Removing and installing harness W34 — Electric rear-view mirrors”. ”Removing and installing harness W35 — Access step lighting and battery cut-off switch (version 1)”. ”Removing and installing harness W35 — Access step lighting and battery cut-off switch (version 2)”. ”Removing and installing harness W36 — 60-amp GreenStar socket for Stage I engine to 97/68/EC”. ”Removing and installing harness W37 — GreenStar port”. ”Removing and installing harness W39 — GreenStar (cab), for Stage I engine to 97/68/EC”. ”Removing and installing harness W39 — GreenStar with TEC (cab), for Stage I engine to 97/68/EC”. ”Removing and installing harness W40 — GreenStar (cab roof), for Stage I engine to 97/68/EC”. ”Removing and installing harness W41 — JDLink”. ”Removing and installing harness W42 — Battery cut-off switch, version 1”. ”Removing and installing harness W42 — Battery cut-off switch, version 2”. <- Go to Section TOC Section 40 page 68 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Wiring Harnesses for Tractors with AutoPowr/IVT Transmission and Stage II Engine to 97/68/EC — Recondition (Summary of References) ”Disconnecting electrical circuits” . ”Ground point locations” . ”Removing and installing harness W01 — Power supply” . ”Removing and installing harness W02 — Engine wiring harness for Stage II engine to 97/68/EC (Level 11 ECU)”. ”Removing and installing harness W03 — Starting aid for Stage I and II engines to 97/68/EC (Level 4 or 11 ECUs) (AutoPowr/IVT transmission)”. ”Removing and installing harness W04 — Headlights”. ”Removing and installing harness W06 — Front-wheel drive axle with TLS” . ”Removing and installing harness W07 — Front PTO” . ”Removing and installing harness W08 — Cab, with Stage II engine to 97/68/EC (AutoPowr/IVT transmission)”. ”Removing and installing harness W09 — Cowl, with Stage II engine to 97/68/EC (AutoPowr/IVT transmission)”. ”Removing and installing harness W10 — Shift console” . ”Removing and installing harness W11 — Speed control lever and hand throttle (AutoPowr/IVT transmission)” . ”Removing and installing harness W12 — Command Arm (AutoPowr/IVT transmission)” . ”Removing and installing harness W13 — Clutch sending unit” . ”Removing and installing harness W14 — 3-terminal power outlet socket” . ”Removing and installing harness W15 — ECU for Stage II engines to 97/68/EC (Level 11 ECU)”. ”Removing and installing harness W16 — SIC with Stage II engine to 97/68/EC”. ”Removing and installing harness W17 — Multi-function unit” . ”Removing and installing harness W18 — Windshield wiper switch (without intermittent wipe)” . ”Removing and installing harness W18 — Windshield wiper switch (with intermittent wipe)” . ”Removing and installing harness W19 — Cab roof, for Stage II engine to 97/68/EC”. ”Removing and installing harness W20 — Turn signal and clearance lights”. ”Removing and installing harness W21 — Worklights on front of cab roof” . ”Removing and installing harness W22 — Worklights on rear of cab roof” . ”Removing and installing harness W22 — Xenon (HID) worklights on rear of cab roof”. ”Removing and installing harness W23 — Windshield wiper (without switch for windshield)” . ”Removing and installing harness W23 — Windshield wiper (with switch for windshield)” . ”Removing and installing harness W24 — Rear window wiper” . ”Removing and installing harness W25 — Rear window wiper switch” . ”Removing and installing harness W26 — Fan and air-conditioner” . ”Removing and installing harness W28 — Front end of transmission (AutoPowr/IVT <- Go to Section TOC Section 40 page 69 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses transmission)” . ”Removing and installing harness W29 — Valve block (AutoPowr/IVT transmission)” . ”Removing and installing harness W30 — Rear end of transmission”. ”Removing and installing harness W31 — 7-terminal power outlet socket” . ”Removing and installing harness W32 — Stepper motors for Stage II engine to 97/68/EC”. ”Removing and installing harness W33 — Service” . ”Removing and installing harness W34 — Electric rear-view mirrors”. ”Removing and installing harness W35 — Access step lighting and battery cut-off switch (version 1)”. ”Removing and installing harness W35 — Access step lighting and battery cut-off switch (version 2)”. ”Removing and installing harness W36 — 60-amp GreenStar socket for Stage I engine to 97/68/EC”. ”Removing and installing harness W37 — GreenStar port”. ”Removing and installing harness W39 — GreenStar (cab)”. ”Removing and installing harness W39 — GreenStar with tractor equipment interface controller (cab)”. ”Removing and installing harness W40 — GreenStar (cab roof)”. ”Removing and installing harness W41 — JDLink”. ”Removing and installing harness W42 — Battery cut-off switch, version 1”. ”Removing and installing harness W42 — Battery cut-off switch, version 2”. <- Go to Section TOC Section 40 page 70 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Wiring Harnesses for Tractors with AutoPowr/IVT transmission from Serial No. 398656 — Recondition (Summary of References) ”Disconnecting electrical circuits” . ”Ground point locations” . ”Removing and installing harness W01 — Power supply” . ”Removing and installing harness W02 — Engine (Level 11 ECU) from serial no. 398656”. ”Removing and installing harness W03 — Starting aid (Level 11 ECU) (AutoPowr/IVT transmission) from serial no. 398656”. ”Removing and installing harness W04 — Headlights”. ”Removing and installing harness W06 — Front-wheel drive axle with TLS” . ”Removing and installing harness W07 — Front PTO” . ”Removing and installing harness W08 — Cab, with Stage I engine to 97/68/EC (AutoPowr/IVT transmission)”. ”Removing and installing harness W09 — Cowl (AutoPowr/IVT transmission) from serial no. 398656”. ”Removing and installing harness W10 — Shift console” . ”Removing and installing harness W11 — Speed control lever and hand throttle (AutoPowr/IVT transmission)” . ”Removing and installing harness W12 — Command Arm (AutoPowr/IVT transmission)” . ”Removing and installing harness W13 — Clutch sending unit” . ”Removing and installing harness W14 — 3-terminal power outlet socket” . ”Removing and installing harness W15 — Engine control unit (Level 11 ECU) from serial no. 398656”. ”Removing and installing harness W16 — SIC with Stage II engine to 97/68/EC”. ”Removing and installing harness W17 — Multi-function unit” . ”Removing and installing harness W18 — Windshield wiper switch (without intermittent wipe)” . ”Removing and installing harness W18 — Windshield wiper switch (with intermittent wipe)” . ”Removing and installing harness W19 — Cab roof, for Stage II engine to 97/68/EC”. ”Removing and installing harness W20 — Turn signal and clearance lights”. ”Removing and installing harness W21 — Worklights on front of cab roof” . ”Removing and installing harness W22 — Worklights on rear of cab roof”. ”Removing and installing harness W22 — Xenon (HID) worklights on rear of cab roof”. ”Removing and installing harness W23 — Windshield wiper (without switch for windshield)” . ”Removing and installing harness W23 — Windshield wiper (with switch for windshield)” . ”Removing and installing harness W24 — Rear window wiper” . ”Removing and installing harness W25 — Rear window wiper switch” . ”Removing and installing harness W26 — Fan and air-conditioner from serial no. 398656”. <- Go to Section TOC Section 40 page 71 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses ”Removing and installing harness W26 — ClimaTrak (cab)”. ”Removing and installing harness W28 — Front end of transmission (AutoPowr/IVT transmission)” . ”Removing and installing harness W29 — Valve block (AutoPowr/IVT transmission)” . ”Removing and installing harness W30 — Rear end of transmission”. ”Removing and installing harness W31 — 7-terminal power outlet socket” . ”Removing and installing harness W32 — Stepper motors for Stage II engine to 97/68/EC”. ”Removing and installing harness W33 — Service” . ”Removing and installing harness W34 — Electric rear-view mirrors”. ”Removing and installing harness W35 — Access step lighting and battery cut-off switch (version 1)”. ”Removing and installing harness W35 — Access step lighting and battery cut-off switch (version 2)”. ”Removing and installing harness W36 — 60-amp GreenStar socket for Stage I engine to 97/68/EC”. ”Removing and installing harness W37 — GreenStar port”. ”Removing and installing harness W39 — GreenStar (cab)”. ”Removing and installing harness W39 — GreenStar with tractor equipment interface controller (cab)”. ”Removing and installing harness W40 — GreenStar (cab roof)”. ”Removing and installing harness W41 — JDLink”. ”Removing and installing harness W42 — Battery cut-off switch, version 1”. ”Removing and installing harness W42 — Battery cut-off switch, version 2”. ”Removing and installing harness W47 — ClimaTrak (cab roof)”. ”Removing and installing harness W48 — ClimaTrak (cowl)”. ”Removing and installing harness W49 — ClimaTrak (evaporator housing)”. ”Removing and installing harness W50 — GreenStar (CAN BUS terminator)”. ”Removing and installing harness W51 — AutoTrac (cab)”. ”Removing and installing harness W52 — AutoTrac (steering angle sensor)”. ”Removing and installing harness W53 — AutoTrac (Command Arm)”. ”Removing and installing harness W55 — Display”. ”Removing and installing harness W56 — Serial interface, adapter”. ”Removing and installing harness W57 — Electro-hydraulic pick-up hitch (cab)”. ”Removing and installing harness W58 — Electro-hydraulic pick-up hitch (valves)”. Disconnecting electrical circuits <- Go to Section TOC Section 40 page 72 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Before working on the electrical system, always disconnect battery ground strap (-). <- Go to Section TOC Section 40 page 73 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Ground Point Locations <- Go to Section TOC Section 40 page 74 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses There are 17 ground point locations (XGND1 - XGND57), see pictures on the following pages) Battery Battery-to-engine ground (A) Engine-to-cab frame ground (B) Cab frame ground (C) Electronic component ground (D). This is located on the cab frame to the left of the fuse box. Removing and Installing Harness W01 — Power Supply <- Go to Section TOC Section 40 page 75 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: G01 F13 F14 X473 <- Go to Section TOC Group 10: Wiring Harnesses Terminal with ring, for positive terminal of battery Main fuse Main fuse Connecting point — power supply harness (W08) Section 40 page 76 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W02 — Engine Wiring Harness for Stage I Engine to 97/68/EC (ECU Level 4) LEGEND: G02 K40 M01 <- Go to Section TOC Alternator Injection pump relay Starting motor Section 40 page 77 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X02 X66/1 X66/2 X70 X79 X130 X205 X261 X262 X305 X351 X356 X357 X358 X359 X364 X411 X450 X451 X547 XGND9 <- Go to Section TOC Group 10: Wiring Harnesses Connecting point — front PTO harness (W07) Horn plug Horn plug Plug for sending unit (air cleaner restriction warning light) Plug for fuel preheater element Plug for compressor clutch (air conditioning) Connecting point — wiring harness W06 (FWD axle with TLS) Plug for sending unit (coolant temperature) Plug for sending unit (coolant temperature gauge) Plug for voltage-to-ground on radiator Plug for injection pump Plug for sending unit (crankshaft speed) Plug for fuel transfer pump Plug for sending unit (engine oil pressure) Plug for sending unit (camshaft speed) Plug for sending unit (fuel pressure) Connecting point — headlight harness (W04) Connecting point — engine harness (W08) Connecting point — engine harness (W15) Connecting point — starting aid harness (W03) Ground point Section 40 page 78 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W02 — Engine Wiring Harness for Stage II Engine to 97/68/EC (ECU Level 11) LEGEND: G02 M01 X02 <- Go to Section TOC Alternator Starting motor Connecting point — front PTO harness (W07) Section 40 page 79 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X66/1 X66/2 X70 X79 X130 X205 X261 X262 X301 X305 X356 X358 X359 X411 X450 X451 X547 X550 X566 X567 X568 X569 X575 X610 X625 XGND9 <- Go to Section TOC Group 10: Wiring Harnesses Horn plug Horn plug Plug for sending unit (air cleaner restriction warning light) Plug for fuel preheater element Plug for compressor clutch (air conditioning) Connecting point — wiring harness W06 (FWD axle with TLS) Plug for sending unit (coolant temperature) Plug for sending unit (coolant temperature gauge) Plug for sending unit (intake air temperature) Plug for voltage-to-ground on radiator Plug for sending unit (crankshaft speed) Plug for sending unit (engine oil pressure) Plug for sending unit (camshaft speed) Connecting point — headlight harness (W04) Connecting point — engine harness (W08) Connecting point — engine harness (W15) Connecting point — starting aid harness (W03) Plug for sending unit (fuel temperature) Plug for fuel valve Plug for water separator sender in fuel filter Plug for injection valves Plug for fan valve Plug for fuel transfer pump Ground connection for screening of wires Plug for sending unit (injection pressure) Ground point Section 40 page 80 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W02 — Engine (Level 11 ECU) from Serial No. 398656 LEGEND: G02 M01 X02 X66/1 X66/2 <- Go to Section TOC Alternator Starting motor 4-pin plug — Connection point for front PTO wiring harness (W07) 1-pin plug, horn 1-pin plug, horn Section 40 page 81 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X70 X79 X130 X205 X261 X301 X305 X356 X358 X359 X411 X450 X451 X547 X550 X566 X567 X568 X575 X604 X610 X625 XGND9 Group 10: Wiring Harnesses 2-pin plug, sender for restricted air cleaner warning light 2-pin plug, fuel preheater element 1-pin plug for air-conditioner compressor clutch 8-pin plug — Connection point of harness for front-wheel drive axle with TLS (W06) 2-pin plug, coolant temperature sender 2-pin plug, manifold air temperature sender 1-pin plug, voltage-to-ground on radiator 2-pin plug, crankshaft speed sender 3-pin plug for engine oil pressure sender 2-pin plug for camshaft speed sender 8-pin plug — Connection point for headlight wiring harness (W04) 42-pin plug — Connection point for engine wiring harness (W08) 42-pin plug — Connection point for engine wiring harness (W08) 10-pin plug — Connection point for starting aid wiring harness (W03) 2-pin plug for fuel temperature sender 2-pin plug for fuel valve 2-pin plug for sender of water separator in fuel filter 12-pin plug for injection valves 2-pin plug for fuel transfer pump 2-pin plug for front ambient air temperature sensor (ClimaTrak) Ground connection for screening of wires 3-pin plug for injection pressure sender Ground point Removing and Installing Harness W03 — Starting Aid for Stage I and II engines to 97/68/EC (Level 4 or 11 ECUs) <- Go to Section TOC Section 40 page 82 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: D31 F09 F10 F11 G02 Group 10: Wiring Harnesses Diode for electrical starting aid Fuse for heater element (electrical starting aid) Fuse for fuel injection pump (with Stage I engines to 97/68/EC only (Level 4 ECU)) Fuse for electrical starting aid Terminal with ring, for alternator <- Go to Section TOC Section 40 page 83 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM K01 K36 R15 X547 Group 10: Wiring Harnesses Starting motor relay Relay for electrical starting aid Terminal with ring, for heater element (electrical starting aid) Connecting point — starting aid harness (W02) Removing and Installing Harness W03 — Starting Aid (Level 11 ECU) from Serial No. 398656 LEGEND: F09 F11 G02 K01 K36 Glow plug fuse Fuse for electrical starting aid Terminal with ring, for alternator Starting motor relay Relay for electrical starting aid <- Go to Section TOC Section 40 page 84 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X547 X630 Group 10: Wiring Harnesses 10-pin plug — Connection point for starting aid wiring harness (W02) 1-pin plug — Connection point for glow plug wiring harness <- Go to Section TOC Section 40 page 85 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W03 — Starting Aid for Stage I and II engines to 97/68/EC (Level 4 or 11 ECUs) (AutoPowr/IVT transmission) LEGEND: D31 Diode for electrical starting aid <- Go to Section TOC Section 40 page 86 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM F09 F10 F11 F22 G02 K01 K36 R15 X528 X547 Group 10: Wiring Harnesses Fuse for heater element (electrical starting aid) Fuse for fuel injection pump (with Stage I engines to 97/68/EC only (Level 4 ECU)) Fuse for electrical starting aid Fuse for LTC coolant pump Terminal with ring, for alternator Starting motor relay Relay for electrical starting aid Terminal with ring, for heater element (electrical starting aid) Plug for LTC coolant pump Connecting point — starting aid harness (W02) Removing and Installing Harness W03 — Starting Aid (Level 11 ECU) (AutoPowr/IVT transmission) from Serial No. 398656 <- Go to Section TOC Section 40 page 87 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: F09 F11 F22 G02 K01 K36 X528 X547 X630 Group 10: Wiring Harnesses Glow plug fuse Fuse for electrical starting aid Fuse for LTC coolant pump Terminal with ring, for alternator Starting motor relay Relay for electrical starting aid 3-pin plug for LTC coolant pump 10-pin plug — Connection point for starting aid wiring harness (W02) 1-pin plug — Connection point for glow plug wiring harness Removing and Installing Harness W04 — Headlights <- Go to Section TOC Section 40 page 88 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses W04 - Harness for headlights, with worklights on front corner <- Go to Section TOC Section 40 page 89 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses W04 - Headlight wiring harness LEGEND: X67 X68 X69/1 X69/2 X411 Plug for r.h. headlight Plug for l.h. headlight Plug for front corner worklight, r.h. Plug for front corner worklight, l.h. Connecting point — Headlight harness (W02) Removing and Installing Harness W06 — FrontWheel Drive Axle with TLS LEGEND: X205 X206 X207 X209 Connecting point — Wiring harness W02 (front-wheel drive axle with TLS) Plug for solenoid valve on front-wheel drive axle with TLS Plug for solenoid valve on front-wheel drive axle with TLS Plug for position sensor on front-wheel drive axle with TLS Removing and Installing Harness W07 — Front PTO <- Go to Section TOC Section 40 page 90 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: X02 X166 X167 <- Go to Section TOC Group 10: Wiring Harnesses Connecting point — front PTO harness (W02) Plug for front PTO solenoid valve Plug for sending unit (front PTO speed) Section 40 page 91 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W08 — Cab, with Stage I Engine to 97/68/EC LEGEND: X34 X35 X37 X40 X44 X50 X106 X107 X113/1 X113/2 <- Go to Section TOC Plug for the remote-control switch of the rockshaft control, left Plug for the remote-control switch of the rockshaft control, right Plug for front loader Connecting point — rear window wiper harness (W24) Plug for rear window washer pump Connecting point — harness for air-conditioning and fan (W26) Plug for tail, brake and turn signal lights (right) Plug for tail, brake and turn signal lights (left) Plug for license plate or worklight on left fender Plug for license plate or worklight on right fender Section 40 page 92 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X122 X128 X132 X171/1F X171/1M X171/2F X171/2M X174 X230 X235 X236 X239 X242 X243 X245 X247 X248 X260 X285 X371 X400 X403 X404 X409 X409/1 X422 X423 X430 X440 X441 X450 X472/1 X472/2 X473 X483/1 X483/2 X485 X488 X489 X489/1 X500 X501 X503 X522 X540 <- Go to Section TOC Group 10: Wiring Harnesses Plug for differential lock switch Plug for cigarette lighter Signal socket Connecting point — worklights on fender Connecting point — license plate or worklight on right fender Connecting point — license plate light Connecting point — license plate or worklight on left fender Plug for remote-control switch of rear PTO, left Plug for seat switch Plug for handbrake switch Plug for cruise control potentiometer Connecting point — harness for 3-terminal power outlet socket (W14) Plug for HMS switch Plug for rear PTO preselector switch Plug for front-wheel drive switch Plug for monitor unit Plug for lighting system monitor unit Plug for worklight switch Plug for windshield washer pump Plug for accelerator pedal potentiometer Connecting point — cab roof harness (W19) Connecting point — cowl harness (W09) Connecting point — cowl harness (W09) Connecting point — ECU harness (W15) Connecting point — ECU harness (W15) Connecting point — shift console harness (W10) or Command Arm harness (W12) Connecting point — E-SCV / E-ICV controller (SIC) harness (W16) Connecting point — harness at rear end of transmission (W30) Plug for record/save switch Connecting point — transmission shift and hand throttle harness (W11) or Command Arm harness (W12) Connecting point — engine harness (W02) Plug for switch that operates the worklights at the rear of the cab roof Plug for switch that operates the worklights at the front of the cab roof Connecting point — power supply harness (W01) Plug for basic control unit (BCU) Plug for basic control unit (BCU) Plug for SFA control unit Plug for operator′s seat Plug for electronic PowrQuad controller (EPC) Prewiring for electrical range shift Connecting point — harness at front end of transmission (W28) Connecting point — wiring harness of GreenStar port (W37) Plug for park lock switch Connecting point — service harness (W33) Connecting point — wiring harness, GreenStar (cab) (W39) Section 40 page 93 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X544 X545 X551 XGND 1 XGND 5 XGND43 XGND47 XGND48 XGND49 XGND50 XGND52 <- Go to Section TOC Group 10: Wiring Harnesses Connecting point — wiring harness, access-step light and battery cut-off switch (W35) Plug for implement switch Plug for creeper switch Ground point Ground point Ground point for electronics Ground point Ground point Ground point Ground point Ground point Section 40 page 94 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W08 — Cab, with Stage II Engine to 97/68/EC LEGEND: X14/1 X14/2 X34 X35 X37 X40 X44 X50 X106 X107 <- Go to Section TOC Plug for position feedback unit Plug for sensitivity potentiometer Plug for the remote-control switch of the rockshaft control, left Plug for the remote-control switch of the rockshaft control, right Plug for front loader Connecting point — rear window wiper harness (W24) Plug for rear window washer pump Connecting point — harness for air-conditioning and fan (W26) Plug for tail, brake and turn signal lights (right) Plug for tail, brake and turn signal lights (left) Section 40 page 95 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X113/1 X113/2 X122 X125 X127 X128 X132 X171/1F X171/1M X171/2F X171/2M X174 X230 X235 X236 X239 X242 X243 X244 X245 X247 X248 X249 X260 X285 X371 X400 X403 X404 X409 X409/1 X409/2 X423 X430 X440 X450 X460/1 X471 X472/1 X472/2 X473 X483/1 X483/2 X485 X488 X489 X500 X503 <- Go to Section TOC Group 10: Wiring Harnesses Plug for license plate or worklight on left fender Plug for license plate or worklight on right fender Plug for differential lock switch Plug for rear PTO switch Plug for front PTO switch Plug for cigarette lighter Signal socket Connecting point — worklights on fender Connecting point — license plate or worklight on right fender Connecting point — license plate light Connecting point — license plate or worklight on left fender Plug for remote-control switch of rear PTO, left Plug for seat switch Plug for handbrake switch Plug for cruise control potentiometer Connecting point — harness for 3-terminal power outlet socket (W14) Plug for HMS switch Plug for rear PTO preselector switch Plug for ECO/power mode switch Plug for front-wheel drive switch Plug for monitor unit Plug for lighting system monitor unit Plug for gear selector switch Plug for worklight switch Plug for windshield washer pump Plug for accelerator pedal potentiometer Connecting point — cab roof harness (W19) Connecting point — cowl harness (W09) Connecting point — cowl harness (W09) Connecting point — ECU harness (W15) Connecting point — ECU harness (W15) Connecting point — ECU harness (W15) Connecting point — E-SCV / E-ICV controller (SIC) harness Connecting point — harness at rear end of transmission (W30) Plug for record/save switch Connecting point — engine harness (W02) Plug for hand throttle potentiometer Plug for program selector switch Plug for switch that operates the worklights at the rear of the cab roof Plug for switch that operates the worklights at the front of the cab roof Connecting point — power supply harness (W01) Plug for basic control unit (BCU) Plug for basic control unit (BCU) Plug for SFA control unit Plug for operator′s seat Plug for electronic PowrQuad controller (EPC) Connecting point — harness at front end of transmission (W28) Plug for park lock switch Section 40 page 96 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X522 X544 X545 X571 XGND1 XGND5 XGND43 XGND47 XGND48 XGND49 XGND50 XGND52 <- Go to Section TOC Group 10: Wiring Harnesses Connecting point — GreenStar harness (W39) Connecting point — wiring harness, access-step light and battery cut-off switch Plug for implement switch Service socket (CAN BUS) Ground point Ground point Ground point for electronics Ground point Ground point Ground point Ground point Ground point Section 40 page 97 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W08 — Cab from Serial No. 398656 LEGEND: F03 F04 F05 F06 F07 K01 K02 K08 K09 K10 <- Go to Section TOC Fuses (fuse and relay boxes) Fuses (fuse and relay boxes) Fuses (fuse and relay boxes) Fuses (fuse and relay boxes) Fuses (fuse and relay boxes) Relays (fuse and relay boxes) Relays (fuse and relay boxes) Relays (fuse and relay boxes) Relays and diodes (fuse and relay boxes) Relays (fuse and relay boxes) Section 40 page 98 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X14/1 X14/2 X34 X35 X37 X37/3 X40 X44 X106 X107 X113/1 X113/2 X122 X125 X127 X128 X132 X171/1F X171/1M X171/2F X171/2M X174 X230 X235 X236 X239 X242 X243 X245 X247 X248 X260 X285 X371 X400 X403 X404 X409 X409/1 X409/2 X423 X430 X440 X450 X460/1 X471 X472/1 <- Go to Section TOC Group 10: Wiring Harnesses 8-pin plug for feedback unit 3-pin plug for sensitivity potentiometer 6-pin plug for remote-control switch of rockshaft control, right 6-pin plug for remote-control switch of rockshaft control, left 2-pin plug for front loader 2-pin plug for accessories 6-pin plug — Connection point for rear window wiper harness (W24) 2-pin plug for rear window washer pump 4-pin plug for right tail, brake and turn signal lights 4-pin plug for left tail, brake and turn signal lights 2-pin plug for license plate/fender worklight, left 2-pin plug for license plate/fender worklight, right 2-pin plug for differential lock switch 3-pin plug for rear PTO switch 3-pin plug for front PTO switch 2-pin plug for cigarette lighter 7-pin signal socket 1-pin plug — Connection point, fender-mounted worklights 1-pin plug — Connection point for license plate/fender worklight, right 1-pin plug — Connection point for license plate light 1-pin plug — Connection point for license plate/fender worklight, left 3-pin plug for the remote-control switch of the rear PTO (switch on l.h. side) 2-pin plug for seat switch 2-pin plug for handbrake switch 4-pin plug for cruise control potentiometer 3-pin plug — Connection point of harness for 3-terminal power outlet socket (W14) 3-pin plug for HMS switch 3-pin plug for rear PTO preselector switch 3-pin plug for front wheel drive switch 26-pin plug for monitor unit 26-pin plug for lighting monitor unit 10-pin plug for worklight switch 2-pin plug for windshield washer pump 6-pin plug for accelerator pedal potentiometer 42-pin plug — Connection point for cab roof wiring harness (W19) 42-pin plug — Connection point for cowl wiring harness (W09) 42-pin plug — Connection point for cowl wiring harness (W09) 24-pin plug — ECU wiring harness connection point (W15) 1-pin plug — ECU wiring harness connection point (W15) 6-pin plug — ECU wiring harness connection point (W15) 16-pin plug — SIC harness connection point (W16) 42-pin plug — Connection point for harness at rear of transmission (W30) 3-pin plug for record/save switch 42-pin plug — Connection point for engine wiring harness (W02) 3-pin plug for hand throttle potentiometer 4-pin plug for program selector switch 4-pin plug, switch for worklights on rear of cab roof Section 40 page 99 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X472/2 X473 X483/1 X483/2 X485 X488 X500 X503 X522 X544 X545 X571 X577 X577/1 X623 X651 X653 X657 X660 XGND1 XGND4 XGND5 XGND6 XGND43 XGND44 XGND45 XGND47 XGND48 XGND49 XGND50 XGND52 <- Go to Section TOC Group 10: Wiring Harnesses 4-pin plug, switch for worklights on front of cab roof 2-pin plug — Connecting point for power supply wiring harness (W01) 68-pin plug for BCU 45-pin plug for BCU 45-pin plug for the SFA controller 2-pin plug for operator′s seat 42-pin plug, connection point for harness at front end of transmission (W28) 2-pin plug for park lock switch 10-pin plug — Connection point for GreenStar wiring harness (cab); W39 2-pin plug — Connection point for harness of access-step light and battery cut-off switch (W35) 2-pin plug for implement switch 9-pin service socket (CAN BUS) 7-pin plug — Connection point for fan and air-conditioning harness (W26) 2-pin plug — Connection point for ClimaTrak harness (cab), W26 3-pin plug for the remote-control switch of the rear PTO (switch on r.h. side) 4-pin plug for switches on shift lever 3-pin plug for Auto-mode potentiometer 68-pin plug for Electronic PowrQuad Controller (EPC) 3-pin plug for gear selector switch Ground point Collective ground point for XGND43 Ground point Collective ground point for XGND43 Ground point for electronics Collective ground point for XGND5 Collective ground point for XGND1 Ground point Ground point Ground point Ground point Ground point Section 40 page 100 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W08 — Cab, with Stage I engine to 97/68/EC (AutoPowr/IVT transmission) LEGEND: R18 X34 X35 X37 X40 X44 X50 X106 X107 <- Go to Section TOC Resistor for brake sensors Plug for the remote-control switch of the rockshaft control, left Plug for the remote-control switch of the rockshaft control, right Plug for front loader Connecting point — rear window wiper harness (W24) Plug for rear window washer pump Connecting point — harness for air-conditioning and fan (W26) Plug for tail, brake and turn signal lights (right) Plug for tail, brake and turn signal lights (left) Section 40 page 101 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X113/1 X113/2 X122 X128 X132 X133 X171/1F X171/1M X171/2F X171/2M X174 X230 X235 X236 X239 X242 X243 X245 X247 X248 X260 X285 X332 X367 X371 X382 X400 X403 X404 X409 X409/1 X422 X423 X430 X440 X450 X472/1 X472/2 X473 X481 X482 X483/1 X483/2 X484 X485 X488 <- Go to Section TOC Group 10: Wiring Harnesses Plug for license plate or worklight on left fender Plug for license plate or worklight on right fender Plug for differential lock switch Plug for cigarette lighter Signal socket Plug for UIC controller Connecting point — worklights on fender Connecting point — license plate or worklight on right fender Connecting point — license plate light Connecting point — license plate or worklight on left fender Plug for remote-control switch of rear PTO, left Plug for seat switch Plug for handbrake switch Plug for cruise control potentiometer Connecting point — harness for 3-terminal power outlet socket (W14) Plug for HMS switch Plug for rear PTO preselector switch Plug for front-wheel drive switch Plug for monitor unit Plug for lighting system monitor unit Plug for worklight switch Plug for windshield washer pump Plug for transmission control unit (TCU) Plug for AutoPowr selector Plug for accelerator pedal potentiometer Plug for park lock controller (PLC) Connecting point — cab roof harness (W19) Connecting point — cowl harness (W09) Connecting point — cowl harness (W09) Connecting point — ECU harness (W15) Connecting point — ECU harness (W15) Connecting point — shift console harness (W10) or Command Arm harness (W12) Connecting point — E-SCV / E-ICV controller (SIC) harness (W16) Connecting point — harness at rear end of transmission (W30) Plug for record/save switch Connecting point — engine harness (W02) Plug for switch that operates the worklights at the rear of the cab roof Plug for switch that operates the worklights at the front of the cab roof Connecting point — power supply harness (W01) Connecting point — harness at front end of transmission (W28) Connecting point — valve block harness (W29) Plug for basic control unit (BCU) Plug for basic control unit (BCU) Connecting point — speed control lever and hand throttle harness (W11) or Command Arm harness (W12) Plug for SFA control unit Plug for operator′s seat Section 40 page 102 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X522 X540 X544 X545 XGND1 XGND5 XGND43 XGND47 XGND48 XGND49 XGND50 XGND52 <- Go to Section TOC Group 10: Wiring Harnesses Connecting point — service harness (W33) Connecting point — wiring harness, GreenStar (cab) (W39) Connecting point — wiring harness, access-step light and battery cut-off switch (W35) Plug for implement switch Ground point Ground point Ground point for electronics Ground point Ground point Ground point Ground point Ground point Section 40 page 103 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W08 — Cab, with Stage II engine to 97/68/EC (AutoPowr/IVT transmission) LEGEND: R18 X34 X35 X37 X40 X44 X50 X106 X107 <- Go to Section TOC Resistor for brake sensors Plug for the remote-control switch of the rockshaft control, left Plug for the remote-control switch of the rockshaft control, right Plug for front loader Connecting point — rear window wiper harness (W24) Plug for rear window washer pump Connecting point — harness for air-conditioning and fan (W26) Plug for tail, brake and turn signal lights (right) Plug for tail, brake and turn signal lights (left) Section 40 page 104 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X113/1 X113/2 X122 X128 X132 X133 X171/1F X171/1M X171/2F X171/2M X174 X230 X235 X236 X239 X242 X243 X245 X247 X248 X260 X285 X332 X367 X371 X382 X400 X403 X404 X409 X409/1 X422 X423 X430 X440 X450 X472/1 X472/2 X473 X481 X482 X483/1 X483/2 X484 X485 X488 <- Go to Section TOC Group 10: Wiring Harnesses Plug for license plate or worklight on left fender Plug for license plate or worklight on right fender Plug for differential lock switch Plug for cigarette lighter Signal socket Plug for UIC controller Connecting point — worklights on fender Connecting point — license plate or worklight on right fender Connecting point — license plate light Connecting point — license plate or worklight on left fender Plug for remote-control switch of rear PTO, left Plug for seat switch Plug for handbrake switch Plug for cruise control potentiometer Connecting point — harness for 3-terminal power outlet socket (W14) Plug for HMS switch Plug for rear PTO preselector switch Plug for front-wheel drive switch Plug for monitor unit Plug for lighting system monitor unit Plug for worklight switch Plug for windshield washer pump Plug for transmission control unit (TCU) Plug for AutoPowr selector Plug for accelerator pedal potentiometer Plug for park lock controller (PLC) Connecting point — cab roof harness (W19) Connecting point — cowl harness (W09) Connecting point — cowl harness (W09) Connecting point — ECU harness (W15) Connecting point — ECU harness (W15) Connecting point — shift console harness (W10) or Command Arm harness (W12) Connecting point — E-SCV / E-ICV controller (SIC) harness Connecting point — harness at rear end of transmission (W30) Plug for record/save switch Connecting point — engine harness (W02) Plug for switch that operates the worklights at the rear of the cab roof Plug for switch that operates the worklights at the front of the cab roof Connecting point — power supply harness (W01) Connecting point — harness at front end of transmission (W28) Connecting point — valve block harness (W29) Plug for basic control unit (BCU) Plug for basic control unit (BCU) Connecting point — speed control lever and hand throttle harness (W11) or Command Arm harness (W12) Plug for SFA control unit Plug for operator′s seat Section 40 page 105 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X522 X544 X545 X571 XGND1 XGND5 XGND43 XGND47 XGND48 XGND49 XGND50 XGND52 <- Go to Section TOC Group 10: Wiring Harnesses Connecting point — GreenStar harness (W39) Connecting point — wiring harness, access-step light and battery cut-off switch Plug for implement switch Service socket (CAN BUS) Ground point Ground point Ground point for electronics Ground point Ground point Ground point Ground point Ground point Section 40 page 106 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W08 — Cab (AutoPowr/IVT Transmission) from Serial No. 398656 LEGEND: F03 F04 F05 F06 F07 K01 K02 K08 K09 <- Go to Section TOC Fuses (fuse and relay boxes) Fuses (fuse and relay boxes) Fuses (fuse and relay boxes) Fuses (fuse and relay boxes) Fuses (fuse and relay boxes) Relays (fuse and relay boxes) Relays (fuse and relay boxes) Relays (fuse and relay boxes) Relays and diodes (fuse and relay boxes) Section 40 page 107 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM K10 R18 X34 X35 X37 X37/3 X40 X44 X106 X107 X113/1 X113/2 X122 X128 X132 X133 X171/1F X171/1M X171/2F X171/2M X174 X230 X235 X236 X239 X242 X243 X245 X247 X248 X260 X285 X332 X367 X371 X382 X400 X403 X404 X409 X422 X423 X430 X440 X450 X472/1 <- Go to Section TOC Group 10: Wiring Harnesses Relays (fuse and relay boxes) Resistor for brake sensors 6-pin plug for remote-control switch of rockshaft control, left 6-pin plug for remote-control switch of rockshaft control, right 2-pin plug for front loader 2-pin plug for accessories 6-pin plug — Connection point for rear window wiper harness (W24) 2-pin plug for rear window washer pump 4-pin plug for right tail, brake and turn signal lights 4-pin plug for left tail, brake and turn signal lights 2-pin plug for license plate/fender worklight, left 2-pin plug for license plate/fender worklight, right 2-pin plug for differential lock switch 2-pin plug for cigarette lighter 7-pin signal socket 68-pin plug for user interface controller (UIC) 1-pin plug — Connection point, fender-mounted worklights 1-pin plug — Connection point for license plate/fender worklight, right 1-pin plug — Connection point for license plate light 1-pin plug — Connection point for license plate/fender worklight, left 3-pin plug for the remote-control switch of the rear PTO (switch on l.h. side) 2-pin plug for seat switch 2-pin plug for handbrake switch 4-pin plug for cruise control potentiometer 3-pin plug — Connection point of harness for 3-terminal power outlet socket (W14) 3-pin plug for HMS switch 3-pin plug for rear PTO preselector switch 3-pin plug for front wheel drive switch 26-pin plug for monitor unit 26-pin plug for lighting monitor unit 10-pin plug for worklight switch 2-pin plug for windshield washer pump 68-pin plug for TCU 3-pin plug for AutoPowr selector 6-pin plug for accelerator pedal potentiometer 45-pin plug for PLC 42-pin plug — Connection point for cab roof wiring harness (W19) 42-pin plug — Connection point for cowl wiring harness (W09) 42-pin plug — Connection point for cowl wiring harness (W09) 24-pin plug — ECU wiring harness connection point 24-pin plug — Connection point for shift console harness (W10) or Command Arm harness (W12) 16-pin plug — SIC harness connection point (W16) 42-pin plug — Connection point for harness at rear of transmission (W30) 3-pin plug for record/save switch 42-pin plug — Connection point for engine wiring harness (W02) 4-pin plug, switch for worklights on rear of cab roof Section 40 page 108 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X472/2 X473 X481 X482 X483/1 X483/2 X484 X485 X488 X522 X544 X545 X571 X577 X577/1 X623 XGND1 XGND4 XGND5 XGND6 XGND43 XGND44 XGND45 XGND47 XGND48 XGND49 XGND50 XGND52 <- Go to Section TOC Group 10: Wiring Harnesses 4-pin plug, switch for worklights on front of cab roof 2-pin plug — Connecting point for power supply wiring harness (W01) 42-pin plug, connection point for harness at front end of transmission (W28) 42-pin plug — Connection point for valve block wiring harness (W29) 68-pin plug for BCU 45-pin plug for BCU 24-pin plug — connecting point for speed control lever and hand throttle harness (W11) or for Command Arm harness (W12) 45-pin plug for the SFA controller 2-pin plug for operator′s seat 10-pin plug — Connection point for GreenStar wiring harness (cab); W39 2-pin plug — Connection point for harness of access-step light and battery cut-off switch (W35) 2-pin plug for implement switch 9-pin service socket (CAN BUS) 7-pin plug — Connection point for fan and air-conditioning harness (W26) 2-pin plug — Connection point for ClimaTrak harness (W26) 3-pin plug for the remote-control switch of the rear PTO (switch on r.h. side) Ground point Collective ground point for XGND43 Ground point Collective ground point for XGND43 Ground point for electronics Collective ground point for XGND5 Collective ground point for XGND1 Ground point Ground point Ground point Ground point Ground point Section 40 page 109 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W09 — Cowl, with Stage I Engine to 97/68/EC LEGEND: S01 S09 X20A X20B X25 X26 X120/1 X120/2 X126 X238 Plug for main (key) switch Plug for light switch Connecting point — windshield wiper harness (W23) Connecting point — windshield wiper harness (W18) Plug for basic informator (BIF) Plug for basic informator (BIF) Plug for air-brake pressure gauge Plug for air-brake pressure gauge Plug for hazard warning light switch Plug for accelerator pedal potentiometer <- Go to Section TOC Section 40 page 110 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X270 X322 X324 X403 X404 X487 X490/1 XGND40 <- Go to Section TOC Group 10: Wiring Harnesses Plug for CAN BUS terminator (29-bit) Connecting point — clutch sender harness (W13) Plug for brake switch Connecting point — cowl harness (W08) Connecting point — cowl harness (W08) Connecting point — multi-function lever harness (W17) Plug for electrical reverser control Ground point Section 40 page 111 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W09 — Cowl, with Stage II Engine to 97/68/EC LEGEND: S01 S09 X20A X20B X25 X26 X120/1 X120/2 X126 X238 Plug for main (key) switch Plug for light switch Connecting point — windshield wiper harness (W23) Connecting point — windshield wiper harness (W18) Plug for basic informator (BIF) Plug for basic informator (BIF) Plug for air-brake pressure gauge Plug for air-brake pressure gauge Plug for hazard warning light switch Plug for accelerator pedal potentiometer <- Go to Section TOC Section 40 page 112 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X322 X324 X403 X404 X487 X490/1 X615 XGND40 <- Go to Section TOC Group 10: Wiring Harnesses Connecting point — clutch sender harness (W13) Plug for brake switch Connecting point — cowl harness (W08) Connecting point — cowl harness (W08) Connecting point — multi-function unit harness (W17) Plug for electrical reverser control Plug for CAN BUS terminator (29-bit) Ground point Section 40 page 113 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W09 — Cowl from Serial No. 398656 LEGEND: S01 S09 X20A X20B X25 X26 X120/1 X120/2 X126 X238 <- Go to Section TOC 8-pin plug for main (key) switch 5-pin plug for light switch 1-pin plug — Connection point for windshield wiper harness (W23) 3-pin plug — Connection point for windshield wiper harness (W18) 26-pin plug for basic informator (BIF) 26-pin plug for basic informator (BIF) 1-pin plug for air-brake pressure gauge 1-pin plug for air-brake pressure gauge 3-pin plug for hazard warning light switch 3-pin plug for accelerator pedal potentiometer Section 40 page 114 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X322 X324 X403 X404 X487 X615 X654 XGND40 <- Go to Section TOC Group 10: Wiring Harnesses 6-pin plug — Connection point for clutch sending unit harness (W13) 8-pin plug for brake switches 42-pin plug — Connection point for cowl wiring harness (W08) 42-pin plug — Connection point for cowl wiring harness (W08) 10-pin plug — Connection point for multi-function unit harness (W17) 6-pin plug for CAN BUS terminator (29-bit) 8-pin plug for electrical reverser control Ground point Section 40 page 115 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W09 — Cowl, with Stage I engine to 97/68/EC (AutoPowr/IVT transmission) LEGEND: S01 S09 X20A X20B X25 X26 X120/1 X120/2 X126 Plug for main (key) switch Plug for light switch Connecting point — windshield wiper harness (W23) Connecting point — windshield wiper harness (W18) Plug for basic informator (BIF) Plug for basic informator (BIF) Plug for air-brake pressure gauge Plug for air-brake pressure gauge Plug for hazard warning light switch <- Go to Section TOC Section 40 page 116 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X270 X322 X323 X324 X343 X403 X404 X487 XGND40 <- Go to Section TOC Group 10: Wiring Harnesses Plug for CAN BUS terminator (29-bit) Connecting point — clutch sender harness (W13) Plug for reverse drive lever Plug for brake switch Plug for neutral start switch Connecting point — cowl harness (W08) Connecting point — cowl harness (W08) Connecting point — multi-function unit harness (W17) Ground point Section 40 page 117 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W09 — Cowl, with Stage II engine to 97/68/EC (AutoPowr/IVT transmission) LEGEND: S01 S09 X20A X20B X25 X26 X120/1 X120/2 X126 Plug for main (key) switch Plug for light switch Connecting point — windshield wiper harness (W23) Connecting point — windshield wiper harness (W18) Plug for basic informator (BIF) Plug for basic informator (BIF) Plug for air-brake pressure gauge Plug for air-brake pressure gauge Plug for hazard warning light switch <- Go to Section TOC Section 40 page 118 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X322 X323 X324 X343 X403 X404 X487 X615 XGND40 <- Go to Section TOC Group 10: Wiring Harnesses Connecting point — clutch sender harness (W13) Plug for reverse drive lever Plug for brake switch Plug for neutral start switch Connecting point — cowl harness (W08) Connecting point — cowl harness (W08) Connecting point — multi-function unit harness (W17) Plug for CAN BUS terminator (29-bit) Ground point Section 40 page 119 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W09 — Cowl (AutoPowr/IVT Transmission) from Serial No. 398656 LEGEND: S01 S09 X20A X20B X25 X26 X120/1 X120/2 X126 <- Go to Section TOC 8-pin plug for main (key) switch 5-pin plug for light switch 1-pin plug — Connection point for windshield wiper harness (W23) 3-pin plug — Connection point for windshield wiper harness (W18) 26-pin plug for basic informator (BIF) 26-pin plug for basic informator (BIF) 1-pin plug for air-brake pressure gauge 1-pin plug for air-brake pressure gauge 3-pin plug for hazard warning light switch Section 40 page 120 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X322 X323 X324 X343 X403 X404 X487 X615 XGND40 Group 10: Wiring Harnesses 6-pin plug — Connection point for clutch sending unit harness (W13) 10-pin plug for reverse drive lever 8-pin plug for brake switches 2-pin plug for neutral start switch 42-pin plug — Connection point for cowl wiring harness (W08) 42-pin plug — Connection point for cowl wiring harness (W08) 10-pin plug — Connection point for multi-function unit harness (W17) 6-pin plug for CAN BUS terminator (29-bit) Ground point Removing and Installing Harness W10 — Shift Console LEGEND: X14/1 X14/2 X125 X127 X422 X471 <- Go to Section TOC Plug for position feedback unit Plug for sensitivity potentiometer Plug for rear PTO switch Plug for front PTO switch Connecting point — switch console harness (W08) Plug for program selector switch Section 40 page 121 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W11 — Transmission Shift and Hand Throttle LEGEND: X244 X249 X441 X460/1 X477 Plug for ECO/power mode switch Plug for gear selector switch Connecting point — harness for transmission shift and hand throttle (W08) Plug for hand throttle potentiometer Plug for range selector switch Removing and Installing Harness W11 — Speed Control Lever and Hand Throttle (AutoPowr/IVT transmission) <- Go to Section TOC Section 40 page 122 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: X334 X349 X370 X484 Group 10: Wiring Harnesses Plug for speed control lever Plug for potentiometer of speed control lever Plug for hand throttle potentiometer Connecting point — harness for speed control lever and hand throttle (W08) <- Go to Section TOC Section 40 page 123 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W12 — Command Arm (AutoPowr/IVT transmission) LEGEND: X125 X127 X334 X349 X370 X422 X428 X436 X437 X438 Plug for rear PTO switch Plug for front PTO switch Plug for speed control lever Plug for potentiometer of speed control lever Plug for hand throttle potentiometer Connecting point — Command Arm harness (W08) Connecting point — E-SCV / E-ICV controller (SIC) harness (W16) Plug for E-SCV 1 switch Plug for E-SCV 2 switch Plug for E-SCV 3 switch <- Go to Section TOC Section 40 page 124 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X439 X468 X469 X470 X471 X484 Group 10: Wiring Harnesses Plug for E-SCV 4 switch Plug for depth-setting regulator Plug for position feedback unit Plug for rapid withdrawal switch Plug for program switch Connecting point — Command Arm harness (W08) Removing and Installing Harness W13 — Clutch Sending Unit LEGEND: S72 X322 X328 Clutch switch Connecting point — clutch switch harness (W08) Plug for clutch pedal potentiometer Removing and Installing Harness W14 — 3-Terminal <- Go to Section TOC Section 40 page 125 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Power Outlet Socket LEGEND: X06-15 X06-31 X06-82 X239 Plug for 3-terminal power outlet socket Plug for 3-terminal power outlet socket Plug for 3-terminal power outlet socket Connecting point — harness for 3-terminal power outlet socket (W08) Removing and Installing Harness W15 — ECU for Stage I engines to 97/68/EC (Level 4 ECU) <- Go to Section TOC Section 40 page 126 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: X361 X409 X451 XGND1 Group 10: Wiring Harnesses Plug, ECU for Stage I engine to 97/68/EC (Level 4 ECU) Connecting point — ECU harness (W08) Connecting point — engine harness (W02) Ground point Removing and Installing Harness W15 — ECU for Stage II engines to 97/68/EC (Level 11 ECU) <- Go to Section TOC Section 40 page 127 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: X409 X451 X570/1 X570/2 X610 Group 10: Wiring Harnesses Connecting point — ECU harness (W08) Connecting point — engine harness (W02) Plug, ECU for Stage II engine to 97/68/EC (Level 11 ECU) Plug, ECU for Stage II engine to 97/68/EC (Level 11 ECU) Ground connection for screening of wires Removing and Installing Harness W15 — Engine Control Unit (Level 11 ECU) from Serial No. 398656 <- Go to Section TOC Section 40 page 128 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: X409 X451 X570/1 X570/2 X610 Group 10: Wiring Harnesses 24-pin plug — ECU wiring harness connection point (W08) 42-pin plug — Connection point for engine wiring harness (W02) 30-pin plug for control unit (ECU) 30-pin plug for control unit (ECU) Ground connection for screening of wires Removing and Installing Harness W16 — SIC with Stage I engine to 97/68/EC <- Go to Section TOC Section 40 page 129 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: X219 X220 X226 X423 X428 X456 X552 X553 X554 Group 10: Wiring Harnesses Plug for multi-function lever Plug for multi-function lever Plug for CAN BUS terminator (11-bit) Connecting point — E-SCV / E-ICV controller (SIC) harness (W12) Connecting point — E-SCV / E-ICV controller (SIC) harness (W08) Plug for E-SCV / E-ICV controller (SIC) Plug for E-SCV encoder Plug for E-SCV transport lock Plug for E-SCV indicator light <- Go to Section TOC Section 40 page 130 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W16 — SIC with Stage II engine to 97/68/EC W16 - Wiring harness, SIC with E-SCV / E-ICV <- Go to Section TOC Section 40 page 131 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses W16 - Wiring harness, SIC with E-ICV LEGEND: X219 X220 X423 X428 X456 X552 X553 X554 X619 Plug for multi-function lever Plug for multi-function lever Connecting point — E-SCV / E-ICV controller (SIC) harness (W12) Connecting point — E-SCV / E-ICV controller (SIC) harness (W08) Plug for E-SCV / E-ICV controller (SIC) Plug for E-SCV encoder Plug for E-SCV transport lock Plug for E-SCV indicator light Plug for CAN BUS terminator (11-bit) <- Go to Section TOC Section 40 page 132 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W17 — Multifunction Unit LEGEND: S08/LH S08/RH S10 X59 X60 X61 X62 X487 Left-turn signal switch Right-turn signal switch Full/dipped-beam switch Plug for horn switch Plug for horn switch Plug for flash-to-pass switch Plug for flash-to-pass switch Connecting point — multi-function lever harness (W09) Removing and Installing Harness W18 — Windshield Wiper Switch (Without Intermittent Wipe) <- Go to Section TOC Section 40 page 133 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: S15 S31 X20B X39 X63 X64 Group 10: Wiring Harnesses Plug for windshield wiper switch Digital instrument set switch Connecting point — washer switch harness (W09) Connecting point — windshield wiper harness (W23) Plug for windshield washer switch Plug for windshield washer switch Removing and Installing Harness W18 — Windshield Wiper Switch (with Intermittent Wipe) <- Go to Section TOC Section 40 page 134 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: K26 S15 S31 X20B X39 X63 X64 <- Go to Section TOC Group 10: Wiring Harnesses Intermittent-wipe relay Plug for windshield wiper switch Digital instrument set switch Connecting point — washer switch harness (W09) Connecting point — windshield wiper harness (W23) Plug for windshield washer switch Plug for windshield washer switch Section 40 page 135 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W19 — Cab Roof, with Stage I Engine to 97/68/EC LEGEND: B28/LH B28/RH X43 X105 X121 X142/1 X142/2 X158 X227 X400 <- Go to Section TOC Door switch for dome light, l.h. Door switch for dome light, r.h. Plug for rear window wiper motor Plug for radio Plug for dome and console lights Prewiring for beacon light Ground terminal with ring, for beacon light Plug for radio antenna ground Plug for CAN BUS terminator (29-bit) Connecting point — cab roof harness (W08) Section 40 page 136 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X401 X433 X434 X442 X443 X475 X486 X530 X531/1 X531/2 X531/3 X532/1 X532/2 XGND10 XGND14 XGND41 <- Go to Section TOC Group 10: Wiring Harnesses Connecting point — harness for electric rear-view mirror (W34) Connecting point — harness for worklights at rear of cab roof (W22) Connecting point — harness for worklights at front of cab roof (W21) Connecting point — harness for r.h. turn-signal and clearance lights (W20) Connecting point — harness for l.h. turn-signal and clearance lights (W20) Connecting point — not used Plug for performance monitor (PRF) Connecting point — JDLink harness (W41) Plug for heated rear window switch Plug for heated rear window switch Plug for heated rear window switch Plug for heated rear window resistor Plug for heated rear window resistor Ground point Ground point Ground point Section 40 page 137 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W19 — Cab Roof, with Stage II Engine to 97/68/EC LEGEND: B28/LH B28/RH X43 X121 X142/1 X142/2 X158/1 X158/2 X400 X401 <- Go to Section TOC Door switch for dome light, l.h. Door switch for dome light, r.h. Plug for rear window wiper motor Plug for dome and console lights Prewiring for beacon light Ground terminal with ring, for beacon light Plug for radio antenna ground Plug for radio antenna Connecting point — cab roof harness (W08) Connecting point — harness for electric rear-view mirror (W34) Section 40 page 138 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X433 X434 X442 X443 X475 X486 X530 X531/1 X531/2 X531/3 X532/1 X532/2 X613 X614 XGND10 XGND14 XGND41 <- Go to Section TOC Group 10: Wiring Harnesses Connecting point — harness for worklights at rear of cab roof (W22) Connecting point — harness for worklights at front of cab roof (W21) Connecting point — harness for r.h. turn-signal and clearance lights (W20) Connecting point — harness for l.h. turn-signal and clearance lights (W20) Connecting point — not used Plug for performance monitor (PRF) Connecting point — JDLink harness (W41) Plug for heated rear window switch Plug for heated rear window switch Plug for heated rear window switch Plug for heated rear window resistor Plug for heated rear window resistor Plug for radio Plug for CAN BUS terminator (29-bit) Ground point Ground point Ground point Section 40 page 139 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W20 — Turn Signal and Clearance Lights W20 - Harness for l.h. turn-signal and clearance lights <- Go to Section TOC Section 40 page 140 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses W20 - Harness for r.h. turn-signal and clearance lights <- Go to Section TOC Section 40 page 141 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses W20 - Harness for l.h. turn-signal and clearance lights <- Go to Section TOC Section 40 page 142 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses W20 - Harness for r.h. turn-signal and clearance lights LEGEND: X108 X109 X110 X115 X162/1 X162/2 X111 X116 X442 <- Go to Section TOC Plug for r.h. turn signal and clearance lights Plug for l.h. turn signal and clearance lights Plug for light on left of cab frame Plug for light on right of cab frame Plug for worklight on left side of cab frame Plug for worklight on right side of cab frame Plug for light on left of cab frame Plug for light on right of cab frame Connecting point — harness for r.h. turn-signal and clearance lights (W19) Section 40 page 143 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X443 Group 10: Wiring Harnesses Connecting point — harness for l.h. turn-signal and clearance lights (W19) Removing and Installing Harness W21 — Worklights on Front of Cab Roof LEGEND: X434 X452/1F1 X452/1F2 X452/2F1 X452/2F2 Connecting point — harness for worklights at front of cab roof (W19) Plug for outer right worklight on front of cab roof Plug for inner right worklight on front of cab roof Plug for outer left worklight on front of cab roof Plug for inner left worklight on front of cab roof Removing and Installing Harness W22 — Worklights on Rear of Cab Roof <- Go to Section TOC Section 40 page 144 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: X433 X114/1F1 X114/1F2 X114/2F1 X114/2F2 Group 10: Wiring Harnesses Connecting point — harness for worklights at rear of cab roof (W19) Plug for outer right worklight on rear of cab roof Plug for inner right worklight on rear of cab roof Plug for outer left worklight on rear of cab roof Plug for inner left worklight on rear of cab roof Removing and Installing Harness W22 — Xenon (HID) Worklights on Rear of Cab Roof <- Go to Section TOC Section 40 page 145 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: X433 X542/1 X542/2 Group 10: Wiring Harnesses Connecting point — harness for worklights at rear of cab roof (W19) Plug of ballast unit for Xenon (HID) worklights at rear of cab roof, left Plug of ballast unit for Xenon (HID) worklights at rear of cab roof, right Removing and Installing Harness W23 — Windshield Wiper Switch (Without Switch for Windshield) <- Go to Section TOC Section 40 page 146 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM <- Go to Section TOC Group 10: Wiring Harnesses Section 40 page 147 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: X20A X38 X39 Group 10: Wiring Harnesses Connecting point — windshield wiper harness (W09) Plug for windshield wiper motor Connecting point — windshield wiper harness (W18) Removing and Installing Harness W23 — Windshield Wiper (With Switch for Windshield) <- Go to Section TOC Section 40 page 148 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM <- Go to Section TOC Group 10: Wiring Harnesses Section 40 page 149 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: X20A X38 X39 X583F X583M S17 Group 10: Wiring Harnesses Connecting point — windshield wiper harness (W09) Plug for windshield wiper motor Connecting point — windshield wiper harness (W18) Plug of harness for windshield switch Plug of harness for windshield switch Windshield switch Removing and Installing Harness W24 — Rear Window Wiper LEGEND: S20 X40 X42M Rear window switch Connecting point — rear window wiper harness (W08) Connecting point — harness for rear window wiper switch (W25) Removing and Installing Harness W25 — Rear Window Wiper Switch <- Go to Section TOC Section 40 page 150 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: X42 X42F Group 10: Wiring Harnesses Plug for rear window wiper switch Connecting point — rear window wiper harness (W24) Removing and Installing Harness W26 — Fan and Air-Conditioner <- Go to Section TOC Section 40 page 151 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: X28 X46 X47 X48 X50 X73/1 X73/2 X100 X448 X449/1 X449/2 XGND15 Group 10: Wiring Harnesses Plug for pressure switch (air-conditioning) Plug for fan motor Plug for fan motor Plug for resistors Connecting point — fan harness (W08) Plug for thermostat switch Plug for thermostat switch Plug for fan switch Plug for air-conditioning switch Plug for de-icer switch Plug for de-icer switch Ground point Removing and Installing Harness W26 — Fan and Air-conditioner from Serial No. 398656 <- Go to Section TOC Section 40 page 152 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: X28 X46 X47 X48 X73/1 X73/2 X100 X448 X449/1 X449/2 X577 X665 XGND15 Group 10: Wiring Harnesses 2-pin plug for air-conditioner pressure switch 2-pin plug for fan motor 2-pin plug for fan motor 4-pin plug for resistors 1-pin plug for thermostat switch 1-pin plug for thermostat switch 6-pin plug for fan switch 3-pin plug for air conditioner switch 1-pin plug for de-icer switch 1-pin plug for de-icer switch 7-pin plug — Connection point for fan wiring harness (W08) 1-pin plug, voltage-to-ground on evaporator Ground point Removing and Installing Harness W26 — ClimaTrak (Cab) <- Go to Section TOC Section 40 page 153 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses LEGEND: X577 X577/1 X595 X599 X600 X602 X655 <- Go to Section TOC 7-pin plug — Connection point for fan and air-conditioning harness (W08) 2-pin plug — Connection point for ClimaTrak harness (cab) (W08) 42-pin plug — Connection point for ClimaTrak harness (cab roof) (W47) 8-pin plug — Connection point for ClimaTrak harness (cowl) (W48) 3-pin plug for refrigerant pressure sending unit 2-pin plug for inside air temperature sender 6-pin plug for water valve Section 40 page 154 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X664 XGND15 <- Go to Section TOC Group 10: Wiring Harnesses 7-pin plug — Connection point for ClimaTrak harness (evaporator housing) (W49) Ground point Section 40 page 155 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W28 — Front End of Transmission LEGEND: X30 X80 X83 X86 X91 <- Go to Section TOC Prewiring for radar connection Plug for switch that warns of a restriction at the transmission oil filter Plug for sending unit (engagement oil warning light) Plug for sending unit (fuel gauge and fuel transfer pump) Plug for solenoid valve (front-wheel drive) Section 40 page 156 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X307 X420 X459 X492 X493 X494 X495 X496 X497 X499/1 X499/2 X500 X546 <- Go to Section TOC Group 10: Wiring Harnesses Plug for sending unit (transmission oil temperature) Plug for air brake system solenoid valve Plug for sending unit (transmission enable pressure) Plug for K3 solenoid (Y32) Plug for forward solenoid valve (Y33) Plug for reverse solenoid valve (Y36) Plug for proportional valve (Y38) Plug for K2 solenoid valve (Y39) Plug for K1 solenoid valve (Y40) Plug for transmission speed sender Plug for transmission speed sender Connecting point — harness at front end of transmission (W08) Plug for switch that warns of a restriction at the hydraulic oil filter Section 40 page 157 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W28 — Front End of Transmission (AutoPowr/IVT transmission) LEGEND: X30 X86 X91 X336 X337 <- Go to Section TOC Prewiring for radar connection Plug for sending unit (fuel gauge and fuel transfer pump) Plug for solenoid valve (front-wheel drive) Plug for transmission speed sender Plug for switch at transmission oil filter Section 40 page 158 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X338 X339 X340/1 X340/2 X341 X375 X397 X410 X413 X420 X481 X546 Group 10: Wiring Harnesses Plug for transmission oil pressure switch Plug for sending unit (hydrostatic speed) Plug for park lock solenoid valve Plug for park lock solenoid valve Plug for sending unit (transmission input speed) Plug for sending unit (transmission output speed) Plug for cold-weather starting pressure switch Plug for sending unit (front-wheel drive speed) Plug for sending unit (park lock pressure) Plug for air brake system solenoid valve Connecting point — harness at front end of transmission (W08) Plug for switch that warns of a restriction at the transmission oil filter Removing and Installing Harness W29 — Valve Block (AutoPowr/IVT transmission) W29 - Valve block harness (AutoPowr/IVT transmission) <- Go to Section TOC Section 40 page 159 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses W29 - Valve block harness with GreenStar port, for Stage I engines to 97/68/EC (AutoPowr/IVT transmission) LEGEND: X482 X482/1 X543 X543/1 <- Go to Section TOC Connecting point — valve block harness (W08) Plug for valve block Connecting point — Harness for 60-amp GreenStar socket (W36) Connecting point — Harness for 60-amp GreenStar socket (W36) Section 40 page 160 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W30 — Rear End of Transmission W30 - Wiring Harness - Rear End of Transmission <- Go to Section TOC Section 40 page 161 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses W30 - Wiring Harness - Rear End of Transmission (with E-SCV / E-ICV) LEGEND: X71 X87 X88/1 X88/2 X92 X94 X95 X96 Plug for draft potentiometer Plug for differential lock solenoid Plug for sending unit (wheel speed) Plug for sending unit (wheel speed) Plug for stepper motor (hitch control) Plug for sending unit (rear PTO speed) Plug for rear PTO solenoid valve Plug for position sensor (hitch control) <- Go to Section TOC Section 40 page 162 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X234 X430 X462 X524 X525 X526 Group 10: Wiring Harnesses Connecting point — harness for -7-terminal power outlet socket (W31) Connecting point — harness at rear end of transmission (W08) Connecting point — stepper motor harness (W32) Plug for cab suspension solenoid Plug for cab suspension solenoid Plug for position sensor (cab suspension) Removing and Installing Harness W31 — 7-Terminal Power Outlet Socket LEGEND: X05 X234 Plug for 7-terminal power outlet socket Connecting point — harness for 7-terminal power outlet socket (W30) <- Go to Section TOC Section 40 page 163 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W32 — Stepper Motors, with Stage I engine to 97/68/EC W32 - Wiring harness, stepper motors with E-SCV / E-ICV <- Go to Section TOC Section 40 page 164 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses W32 - Wiring harness, stepper motors with E-ICV LEGEND: X251 X252 X258 X318 X462 X464 X465 X466 X467 <- Go to Section TOC Plug for E-ICV 2 stepper motor Plug for E-ICV 3 stepper motor Plug for CAN BUS terminator (11-bit) Plug for E-ICV 1 stepper motor Connecting point — stepper motor harness (W30) Plug for E-SCV 1 stepper motor Plug for E-SCV 2 stepper motor Plug for E-SCV 3 stepper motor Plug for E-SCV 4 stepper motor Section 40 page 165 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W32 — Stepper Motors, with Stage II engine to 97/68/EC W32 - Wiring harness, stepper motors with E-SCV / E-ICV <- Go to Section TOC Section 40 page 166 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses W32 - Wiring harness, stepper motors with E-ICV <- Go to Section TOC Section 40 page 167 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses W32 - Wiring harness, stepper motors with E-SCV LEGEND: X251 X252 X318 X462 X464 X465 X466 X467 X622 <- Go to Section TOC Plug for E-ICV 2 stepper motor Plug for E-ICV 3 stepper motor Plug for E-ICV 1 stepper motor Connecting point — stepper motor harness (W30) Plug for E-SCV 1 stepper motor Plug for E-SCV 2 stepper motor Plug for E-SCV 3 stepper motor Plug for E-SCV 4 stepper motor Plug for CAN BUS terminator (11-bit) Section 40 page 168 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W33 — Service LEGEND: X522 X571 Connecting point — service harness (W08) Service plug (CAN BUS) Removing and Installing Harness W34 — Electric Rear-View Mirrors <- Go to Section TOC Section 40 page 169 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: X401 X556/1 X556/2 X557 X558 X559 Group 10: Wiring Harnesses Connecting point — harness for electric rear-view mirror (W19) Plug for adjusting motor (left) Plug for adjusting motor (right) Plug for mirror adjusting switch Plug for mirror support adjusting switch Plug for mirror heater switch Removing and Installing Harness W35 — Access Step Lighting and Battery Cut-off Switch (Version 1) <- Go to Section TOC Section 40 page 170 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses LEGEND: X544 X593 X606/1 X606/2 X607 Connecting point — wiring harness, access-step light and battery cutoff switch (W08) Plug for switch that operates the battery cut-off switch Plug for r.h. access-step light Plug for l.h. access-step light Connecting point — harness for battery cut-off switch (W42) Removing and Installing Harness W35 — Access <- Go to Section TOC Section 40 page 171 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Step Lighting and Battery Cut-off Switch (Version 2) LEGEND: X544 X606/1 X606/2 X696 X697 <- Go to Section TOC Connecting point — wiring harness, access-step light and battery cutoff switch (W08) Plug for r.h. access-step light Plug for l.h. access-step light Plug for the switch that operates the battery cut-off switch Connecting point — harness for battery cut-off switch (W42) Section 40 page 172 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W36 — 60-amp GreenStar Socket for Stage I Engine to 97/68/EC LEGEND: F16 F17 K46 K47 <- Go to Section TOC Fuse for 60-amp socket Fuse for 60-amp socket Relay for 60-amp socket Relay for 60-amp socket Section 40 page 173 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM R20 R21 X533/1 X533/2 X533/3 X541 X543 X543/1 X574 XGND51 Group 10: Wiring Harnesses Resistor Resistor Plug for 60-amp socket Plug for 60-amp socket 60-amp socket Terminal with ring for battery power Connecting point — wiring harness of GreenStar port (W37 or W29) Connecting point — wiring harness of GreenStar port (W37 or W29) Plug for implement switch Ground point Removing and Installing Harness W36 — 60-amp GreenStar Implement Socket <- Go to Section TOC Section 40 page 174 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: F16 F17 K46 K47 R20 R21 X533/1 X533/2 X533/3 <- Go to Section TOC Group 10: Wiring Harnesses Fuse for implement BUS (components) Fuse for implement BUS (CAN BUS) Relay for implement BUS (components) Relay for implement BUS (CAN BUS) Resistor Resistor 2-pin plug for 60-amp implement socket 4-pin plug for 60-amp implement socket 60-amp implement socket Section 40 page 175 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X541 X543 X574 XGND51 Group 10: Wiring Harnesses Terminal with ring for battery power 10-pin plug — Connection point for GreenStar (60-amp implement socket) (W39) 2-pin plug for implement switch Ground point Removing and Installing Harness W37 — GreenStar Port LEGEND: X482 X543 X543/1 Connecting point — valve block harness (W08) Connecting point — Harness for 60-amp GreenStar socket (W36) Connecting point — Harness for 60-amp GreenStar socket (W36) Removing and Installing Harness W39 — GreenStar (Cab), for Stage I Engine to 97/68/EC <- Go to Section TOC Section 40 page 176 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: K51 X522 X522/1 X535 X540 <- Go to Section TOC Group 10: Wiring Harnesses Timer Connecting point — service harness (W08) Connecting point — service harness (W33) Connecting point — wiring harness, GreenStar (cab roof) (W40) Connecting point — wiring harness, GreenStar (cab) (W08) Section 40 page 177 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X591F X591M Group 10: Wiring Harnesses Connecting point — CAN BUS (GreenStar) Connecting point — CAN BUS (GreenStar) Removing and Installing Harness W39 — GreenStar (Cab) LEGEND: K51 X522 5-pin plug for timer 10-pin plug — Connection point for GreenStar (cab) (W08) <- Go to Section TOC Section 40 page 178 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X535 X543 X571F X571M X591F X591M Group 10: Wiring Harnesses 10-pin plug — Connection point for GreenStar (cab roof) (W40) 10-pin plug — Connection point for GreenStar harness (60-amp implement socket) (W36) 9-pin plug for CAN BUS connection 9-pin service socket (CAN BUS) 4-pin plug — Connection point for CAN BUS (GreenStar) 4-pin plug — Connection point for CAN BUS (GreenStar) Removing and Installing Harness W39 — GreenStar with TEC (Cab), for Stage I Engine to 97/68/EC <- Go to Section TOC Section 40 page 179 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: X522 X522/1 X535 X540 X572 <- Go to Section TOC Group 10: Wiring Harnesses Connecting point — service harness (W08) Connecting point — service harness (W33) Connecting point — wiring harness, GreenStar (cab roof) (W40) Connecting point — wiring harness, GreenStar (cab) (W08) Plug for TEC Section 40 page 180 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X591F X591M <- Go to Section TOC Group 10: Wiring Harnesses Connecting point — CAN BUS (GreenStar) Connecting point — CAN BUS (GreenStar) Section 40 page 181 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W39 — GreenStar with Tractor Equipment interface Controller (Cab) LEGEND: X522 X535 X543 X571F X571M X572 X591F <- Go to Section TOC 10-pin plug — Connection point for GreenStar wiring harness (cab); W39 10-pin plug — Connection point for GreenStar harness (cab roof) (W40) 10-pin plug — Connection point for GreenStar harness (60-amp implement socket) (W36) 9-pin plug for CAN BUS connection 9-pin service socket (CAN BUS) 68-pin plug for tractor equipment interface controller (TEC) 4-pin plug — Connection point for CAN BUS (GreenStar) Section 40 page 182 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X591M X615F/2 X615M/1 X636 X641 X656 X659 Group 10: Wiring Harnesses 4-pin plug — Connection point for CAN BUS (GreenStar) 6-pin plug for CAN BUS terminator (29-bit) 6-pin plug for CAN BUS connection (29-bit) 3-pin plug for AutoTrac switch or connection point, harness for AutoTrac Command Arm (W53) 4-pin plug — Connection point for AutoTrac wiring harness (cab) (W51) 24-pin plug (GSD 2100) 3-pin plug (GSD 2100) Removing and Installing Harness W40 — GreenStar (Cab Roof), for Stage I Engine to 97/68/EC LEGEND: <- Go to Section TOC Section 40 page 183 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X535 X536 X538 X539 X565 Group 10: Wiring Harnesses Connecting point - wiring harness, GreenStar (cab roof) (W39) Plug for CAN BUS terminator (GreenStar) Plug for mapping processor Plug for GreenStar display Plug for GPS position receiver Removing and Installing Harness W40 — GreenStar (Cab Roof) LEGEND: X535 X536 X538 X539 X565 10-pin plug — Connection point for GreenStar wiring harness (cab roof) (W39) 6-pin plug for CAN BUS terminator (GreenStar) 10-pin plug for mapping processor 10-pin plug for GreenStar display 12-pin plug, connection point for position receiver (GPS) <- Go to Section TOC Section 40 page 184 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W41 — JDLink LEGEND: X529 X530 Plug for JDLink control unit (JDL) Connecting point — JDLink harness (W19) Removing and Installing Harness W42 — Battery Cut-Off Switch, Version 1 <- Go to Section TOC Section 40 page 185 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: K48 X607 X86 X86/1 XGND56 XGND57 <- Go to Section TOC Group 10: Wiring Harnesses Relay for battery cut-off switch Connecting point — wiring harness, access-step light and battery cut-off switch (W35) Connecting point - harness at front end of transmission (W28) Plug for fuel gauge and fuel pump Ground point Ground terminal with ring, for battery cut-off relay Section 40 page 186 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W42 — Battery Cut-Off Switch, Version 2 LEGEND: K56 K57 X86 X86/1 <- Go to Section TOC Battery cut-off relay Relay for battery cut-off switch Connecting point — harness at front end of transmission (W28) Plug for fuel gauge and fuel pump Section 40 page 187 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X697 XGND56 Group 10: Wiring Harnesses Connecting point — wiring harness, access-step light and battery cut-off switch (W35) Ground point Removing and Installing Harness W47 — ClimaTrak (Cab Roof) LEGEND: X594 <- Go to Section TOC 2-pin plug for rear ambient air temperature sensor Section 40 page 188 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X595 X597 X614F/1 X614M/1 X652 Group 10: Wiring Harnesses 42-pin plug — Connection point for ClimaTrak harness (cab roof) (W26) 32-pin plug — Connection point for ClimaTrak control unit (ATC) 6-pin plug for CAN BUS terminator (29-bit) 6-pin plug for CAN BUS connection (29-bit) 2-pin plug of defog sensor for windshield Removing and Installing Harness W48 — ClimaTrak (Cowl) <- Go to Section TOC Section 40 page 189 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: X599 X601 X605 Group 10: Wiring Harnesses 8-pin plug — Connection point for ClimaTrak harness (cowl) (W26) 2-pin plug for sending unit for actual outlet air temperature 6-pin plug of adjusting motor for air distribution Removing and Installing Harness W49 — ClimaTrak <- Go to Section TOC Section 40 page 190 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses (Evaporator Housing) LEGEND: X46 X47 X598 X603 X664 X665 2-pin plug for fan motor 2-pin plug for fan motor 2-pin plug, sending unit for evaporator core temperature 6-pin plug for the fan motor driver unit 7-pin plug — Connection point for ClimaTrak harness (evaporator housing) (W26) 1-pin plug, voltage-to-ground on evaporator <- Go to Section TOC Section 40 page 191 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W50 — GreenStar (CAN BUS Terminator) LEGEND: X543 X658 10-pin plug — Connection point for GreenStar harness (60-amp implement socket) (W36) 6-pin plug for CAN BUS terminating resistor Removing and Installing Harness W51 — AutoTrac (Cab) <- Go to Section TOC Section 40 page 192 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: X615F/2 X615M/2 X631/1 X631/2 X631/3 X632/1 X632/2 X635 <- Go to Section TOC Group 10: Wiring Harnesses 6-pin plug for CAN BUS terminator (29-bit) 6-pin plug for CAN BUS connection (29-bit) 32-pin plug for AutoTrac control unit (SSU) 48-pin plug for AutoTrac control unit (SSU) 32-pin plug for AutoTrac control unit (SSU) 4-pin plug for steering input device 4-pin plug for steering input device 4-pin plug for steering valve Section 40 page 193 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM X637 X641 XGND60 Group 10: Wiring Harnesses 6-pin plug — Connection point for AutoTrac wiring harness (steering angle sensor) (W52) 4-pin plug — Connection point for AutoTrac wiring harness (cab) (W39) Ground point Removing and Installing Harness W52 — AutoTrac (Steering Angle Sensor) <- Go to Section TOC Section 40 page 194 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: X633 X637 Group 10: Wiring Harnesses 6-pin plug for steering angle sensor 6-pin plug — Connection point for AutoTrac wiring harness (steering angle sensor) (W51) Removing and Installing Harness W53 — AutoTrac (Command Arm) LEGEND: X636 X636/1 <- Go to Section TOC 3-pin plug — Connection point for AutoTrac wiring harness (Command Arm) (W39/1) 3-pin plug for AutoTrac switch Section 40 page 195 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 10: Wiring Harnesses Removing and Installing Harness W55 — Display LEGEND: X656 X692 X693 X698 Connecting point - GreenStar wiring harness with TEC (Cab); W39/1 Plug for UIM controller Plug for RCD display Connecting point - serial interface harness, adapter (W56) Removing and Installing Harness W56 — Serial Interface, Adapter <- Go to Section TOC Section 40 page 196 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: X698 X699 X712 Group 10: Wiring Harnesses Connecting point - serial interface harness, adapter (W55) Plug for serial interface 1 Plug for serial interface 2 Removing and Installing Harness W57 — Electrohydraulic Pick-up Hitch (Cab) <- Go to Section TOC Section 40 page 197 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: X37F X37M X644 X645 Group 10: Wiring Harnesses Plug for front loader Connecting point — front loader (W08) Connecting point — wiring harness for electro-hydraulic pick-up hitch (valves) (W58) Plug for switch that operates the pick-up hitch Removing and Installing Harness W58 — Electrohydraulic Pick-up Hitch (Valves) <- Go to Section TOC Section 40 page 198 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: X642 X643 X644 Group 15: Charging Circuit Plug for solenoid valve of electro-hydraulic pick-up hitch (on/off switch) Plug for solenoid valve of electro-hydraulic pick-up hitch (retract/extend) Connecting point — wiring harness for electro-hydraulic pick-up hitch (cab) (W57) <- Go to Section TOC Section 40 page 199 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 15: Charging Circuit Group 15 - Charging Circuit Charging Circuit - Summary of References ”Special tools” ”Specifications” ”Repairing the alternator” ”Disconnecting electrical circuits” ”Relieving tension on the drive belt” ”Removing/installing the alternator” ”Pulley removal and installation” Special Tools →NOTE: Order tools according to information given in the U.S. SERVICEGARD ™ Catalog or European Microfiche Tool Catalog (MTC). KJD10227- Special tool KJD10278- Special tool Specifications Item Measurement Specification Hex. nut at terminal 30 Torque 18 N˙m 13 lb-ft Hex. nut at terminal D+ Torque 5 N˙m 4 lb-ft Cap screws Torque 50 N˙m 37 lb-ft Pulley on alternator shaft Torque 80 N˙m 60 lb-ft Repairing the Alternator <- Go to Section TOC Section 40 page 200 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 15: Charging Circuit For complete repair information the component technical manual (CTM) “Alternators and Starting Motors” is also required. Use the component technical manual in conjunction with this machine manual. Disconnecting Electrical Circuits Before working on the electrical system, always disconnect battery ground cable (-). Relieving Drive Belt Tension <- Go to Section TOC Section 40 page 201 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 15: Charging Circuit Open the hood. Take off the cover that conceals the cap screw. Tighten tensioner roll (C) cap screw clockwise (arrow) using a 15 mm (19/32 in.) wrench until holes (A) and (B) are in alignment. Insert a 5 mm (0.2 in.) dia. pin into the two holes that are in alignment. For tensioning, turn tensioner roll slightly to release metal pin and pull it from the bores. The drive belt tensioner returns to its tensioning position automatically. <- Go to Section TOC Section 40 page 202 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 15: Charging Circuit Remove/Install the Alternator LEGEND: A B C Wire (terminal 30) Wire (terminal D+) Attaching screws Open the hood. CAUTION: Disconnect the battery ground cable (-). IMPORTANT: Always relieve tension on drive belt before removing the alternator. Take the drive belt off the pulley. Disconnect wires (A) and (B) from the alternator. <- Go to Section TOC Section 40 page 203 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 15: Charging Circuit Take out the two attaching screws (C). Replace the alternator. Assemble in reverse order. Tightening torques for installation: Item Measurement Specification Hex. nut (A) at terminal 30 Torque 18 N˙m 13 lb-ft Hex. nut (B) at terminal D+ Torque 5 N˙m 4 lb-ft Attaching screws (C) Torque 50 N˙m 37 lb-ft <- Go to Section TOC Section 40 page 204 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 15: Charging Circuit Remove and Install the Pulley LEGEND: A Pulley Tools for pulley removal LEGEND: [ Torque wrench Commercially-available tool ] A B KJD10227Special tool C KJD10278Special tool [ Extension with 1/2 in. drive (50 mm, 2 in. in length) Commercially-available tool ] D [ Ratchet with 1/2 in. drive Commercially-available tool ] E Open the hood. <- Go to Section TOC Section 40 page 205 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 20: Starter Motor Circuit CAUTION: Disconnect negative (-) cable from battery. IMPORTANT: Always relieve tension on drive belt before removing the pulley. Take the drive belt off the pulley. Remove pulley using tools (A), (B), (C), (D) and (E). Tightening torque for installation: Item Measurement Specification Pulley on alternator shaft Torque 80 N˙m 60 lb-ft <- Go to Section TOC Section 40 page 206 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 20: Starter Motor Circuit Group 20 - Starter Motor Circuit Starter Motor Circuit - Summary of References ”Special tools” ”Specifications” ”Repairing the starter motor” ”Disconnecting electrical circuits” ”Removing and installing the starter motor” Special tools →NOTE: Order tools according to information given in the U.S. SERVICEGARD ™ Catalog or European Microfiche Tool Catalog (MTC). KJD10213 Special wrench Removing and installing the starter motor Specifications Item Measurement Specification Hex. nut (A) at terminal 30 Torque 30 N˙m 23 lb-ft Cheese-head screw (C) at terminal 50 Torque 1 - 1.3 N˙m 9 - 11 lb-in. Repairing the Starter Motor <- Go to Section TOC Section 40 page 207 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 20: Starter Motor Circuit For complete repair information, the component technical manual (CTM) ”Alternators and Starter Motors” is also required. Use the component technical manual in conjunction with this machine manual. Disconnecting Electrical Circuits Before working on the electrical system, always disconnect battery ground cable (-). <- Go to Section TOC Section 40 page 208 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 20: Starter Motor Circuit Removing and installing the starter motor LEGEND: A B C D Hex. nut Cover Wire and fillister-head screw Special box wrench KJD10213 Open the hood and take off the l.h. side panel. CAUTION: Disconnect negative (-) cable from battery. Remove hex. nut (A). Disconnect the wires at the connecting pins. Remove cover (B). <- Go to Section TOC Section 40 page 209 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Disconnect wires (C) at the solenoid switch. Use special box wrench KJD10213 (D) KJD10213 Special wrench Removing and installing the starter motor to remove the starter motor. Assemble in reverse order. Tightening torques for installation: Item Measurement Specification Hex. nut (A) at terminal 30 Torque 30 N˙m 23 lb-ft Fillister-head screw (C) at terminal 50 Torque 1 - 1,3 N˙m 9 - 11 lb-in. <- Go to Section TOC Section 40 page 210 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Group 25 - Fuses, Relays and Switches Fuses, Relays and Switches — Recondition (Summary of References) ”Removing trim panels from cowl”. ”Disconnecting electrical circuits” . ”Fuse and relay boxes on tractors with operator′s cab up to serial no. 398655” . ”Fuse and relay boxes on tractors with operator′s cab from serial no. 398656”. ”Fuse and relay boxes on tractors with operator′s cab and AutoPowr/IVT transmission up to serial no. 398790” . ”Fuse and relay boxes on tractors with operator′s cab and AutoPowr/IVT transmission from serial no. 398791”. ”Replacing the main fuses” . ”Replacing fuses of electrical starting aid for Stage I and II engines to 97/68/EC (Level 4 or 11 ECUs)” . ”Replacing fuses of electric starting aid for Stage I and II engines to 97/68/EC (Level 4 or 11 ECUs) (AutoPowr/IVT transmission)”. ”Replacing fuse for fuel injection pump (with Stage I engines to 97/68/EC (Level 4 ECU)” . ”Replacing fuse for fuel injection pump (with Stage I engines to 97/68/EC (Level 4 ECU) (AutoPowr/IVT transmission)”. ”Replacing the LTC coolant pump fuse (AutoPowr/IVT transmission)”. ”Replacing the fuse for the implement BUS (60-amp implement socket)”. ”Replacing starting motor relay for Stage I and II engines to 97/68/EC (Level 4 or 11 ECUs)” . ”Replacing starting motor relay for Stage I and II engines to 97/68/EC (Level 4 or 11 ECUs) (AutoPowr/IVT transmission)”. ”Replacing relay of electrical starting aid for Stage I and II engines to 97/68/EC (Level 4 or 11 ECUs)” . ”Replacing relay of electric starting aid for Stage I and II engines to 97/68/EC (Level 4 or 11 ECUs) (AutoPowr/IVT transmission)”. ” Replacing relay for fuel injection pump with Stage I engines to 97/68/EC (Level 4 ECU)” . ”Replacing the power supply relay for the implement BUS”. ”Replacing the battery cut-off relay”. ”Replacing the battery cut-off switch relay”. ”Replacing the main switch” . ”Replacing the brake switches” . ”Replacing the light switch” . ”Replacing the worklight switches” . ”Replacing the switch for lights on cab frame” ”Replacing the beacon light switch” . ”Replacing the hazard warning light switch” . ”Replacing switches on multi-function unit” . <- Go to Section TOC Section 40 page 211 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches ”Replacing the rear window wiper and washer switch” . ”Replacing the windshield/rear window switch” . ”Replacing the dome light door switch” ”Replacing the handbrake switch” . ”Replacing the front-wheel drive switch” . ”Replacing the Headland Management (HMS) switch” . ”Replacing the record/save switch” . ”Replacing the program switch” . ”Replacing the rear PTO preselector switch” . ”Replacing the switch for AutoQuad transmission” ”Replacing the switch for gear selector and Auto-mode” . ”Replacing the park lock switch on tractors with PowrQuad Plus and AutoQuad transmissions” . ”Replacing the fan switch” . Replacing the switch of the air-conditioning system compressor” . ”Replacing the differential lock switch” . ”Replacing the PTO switches” . ”Replacing the external control switch for the rear PTO” . ”Replacing the rockshaft remote control switch” . ”Replacing the switch for the electrical rear-view mirrors” ”Replacing the switch for the heated rear-view mirrors” ”Replacing the switch for the heated rear window” ”Replacing switch of battery cut-off switch”. ”Replacing the AutoTrac switch”. ”Replacing the switch for the electro-hydraulic pick-up hitch” ”Replacing the cruise control potentiometer on tractors with AutoQuad transmission” . ”Replacing the cruise control potentiometer on tractors with AutoPowr/IVT transmission” . ”Replacing the Auto-mode potentiometer on tractors with AutoQuad Plus transmission”. ”Hitch control” . ”Electrical activators for Selective Control Valves (E-SCV)” . ”Electrical activators for Independent Control Valves (E-ICV)” . General Information Switches not mentioned in this Group are described in the Groups dealing with the corresponding components. Special Tools →NOTE: Order tools according to information given in the U.S. SERVICEGARD ™ Catalog or European Microfiche Tool Catalog (MTC). <- Go to Section TOC Section 40 page 212 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Extraction tool JDG777 Removing electrical connectors <- Go to Section TOC Section 40 page 213 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Specifications Item Measurement Specification Cable to starter motor relay, M8 hex. nut Torque 6 N˙m 4.4 lb-ft Cable to starter motor relay, M5 hex. nut Torque 3.5 to 4 N˙m 2.6 to 3 lb-ft Starter motor relay to bracket, M6 cap screws Torque 8 N˙m 5.9 lb-ft Cable to relay for electrical starting aid, M8 hex. nut Torque 6 N˙m 4.4 lb-ft Cable to relay for electrical starting aid, M5 hex. nut Torque 3.5 to 4 N˙m 2.6 to 3 lb-ft Relay for electrical starting aid to bracket, M6 cap screws Torque 8 N˙m 5.9 lb-ft Battery cable to battery cut-off relay (version 1), M10 hex. nut Torque 18 to 22 N˙m 13 to 16 lb-ft Control line to battery cut-off relay (version 1), M5 hex. nut Torque 3 to 5 N˙m 2.2 to 3.7 lb-ft Battery cable to battery cut-off relay (version 2), M10 hex. nut Torque 15 to 20 N˙m 11 to 15 lb-ft Control line to battery cut-off relay (version 2), M4 cap screw Torque 2.2 N˙m 1.6 lb-ft Steering wheel to steering column, hex. nut Torque 50 N˙m 35 lb-ft Removing Trim Panels from Cowl LEGEND: A Cooling compartment Open cooling compartment (A). <- Go to Section TOC Section 40 page 214 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: B C Group 25: Fuses, Relays and Switches Screw Trim panel Remove screws (B). Remove panels (C). Disconnecting Electrical Circuits <- Go to Section TOC Section 40 page 215 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Before working on the electrical system, always disconnect battery ground cable (-). <- Go to Section TOC Section 40 page 216 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Fuse and Relay Boxes on Tractors with Operator′s Cab up to Serial No. 398655 Fuse and relay boxes up to serial no. 398655 →NOTE: Depending on how the tractor is equipped, it may not have all the fuses and relays shown below. The fuse and relay boxes are located behind the operator′s seat just below the rear window. Press down latches (A) and lift off the trim panel. LEGEND: A B C D E F <- Go to Section TOC Relay box K01 Relay box K02 Fuse box F03 Fuse box F04 Fuse box F05 Fuse box F06 Section 40 page 217 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM G H I J Group 25: Fuses, Relays and Switches Fuse box F07 Relay box K08 Relay box K09 Relay box K10 Relays (relay box K01) up to serial no. 398655 DEFINITIONS: K01/1 K01/2 K01/3 K01/4 <- Go to Section TOC Relay for accessories Relay for power supply to electronics Relay for accessories Acoustic alarm Section 40 page 218 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Relays (relay box K02) up to serial no. 398655 DEFINITIONS: K02/1 K02/2 K02/3 K02/4 K02/5 K02/6 K02/7 <- Go to Section TOC Not used Alternator relay Not used Not used Relay for power supply to E-ICV Not used Not used Section 40 page 219 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Fuses (fuse box F03) up to serial no. 398655 IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. DEFINITIONS: F03/01 10-amp, Basic Control Unit (power supply) 10-amp, Basic Control Unit (BCU) (PTO, front-wheel drive, differential F03/02 lock, HMS II, handbrake, wheel-speed sending unit, radar) <- Go to Section TOC Section 40 page 220 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM F03/03 F03/04 F03/05 F03/06 F03/07 F03/08 F03/09 F03/10 F03/11 F03/12 F03/13 F03/14 F03/15 F03/16 Group 25: Fuses, Relays and Switches 20-amp, right turn signal, hazard warning lights 20-amp, left turn signal Not used 10-amp, brake light 20-amp, brake switch 10-amp, controller for suspended front axle (SFA) (battery voltage) Not used 20-amp, power supply to E-ICV Not used Not used 10-amp, SIC controller (battery voltage) 10-amp, JDLink, GreenStar 10-amp, SIC controller (power supply) 20-amp, heated rear window Fuses (fuse box F04) up to serial no. 398655 <- Go to Section TOC Section 40 page 221 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. DEFINITIONS: F04/01 F04/02 F04/03 F04/04 F04/05 <- Go to Section TOC 10-amp, ECU controller (power supply) 20-amp, ECU controller (battery voltage) Not used 15-amp, main switch (BAT) 30-amp, accessories Section 40 page 222 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM F04/06 F04/07 F04/08 F04/09 F04/10 F04/11 F04/12 F04/13 F04/14 F04/15 F04/16 Group 25: Fuses, Relays and Switches 30-amp, power supply for electronics 30-amp, accessories 20-amp, fuel preheater 10-amp, basic informator, SFA controller (power supply) 10-amp, basic informator (battery voltage) 10-amp, fuel pump, injection pump shut-off valve 10-amp, performance monitor (PRF) 10-amp, CAN BUS terminator, service socket 10-amp, electrical reverser control 10-amp, EPC controller (power supply) 10-amp, EPC controller (battery voltage) Fuses (fuse box F05) up to serial no. 398655 <- Go to Section TOC Section 40 page 223 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. DEFINITIONS: F05/01 F05/02 F05/03 F05/04 F05/05 <- Go to Section TOC 10-amp, air-conditioning system and relay for fan 10-amp, 2-pin plug for front loader Not used Not used Not used Section 40 page 224 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM F05/06 F05/07 F05/08 F05/09 F05/10 F05/11 F05/12 F05/13 F05/14 F05/15 F05/16 Group 25: Fuses, Relays and Switches Not used Not used 10-amp, windshield wiper and washer 10-amp, rear window wiper and washer 10-amp, electrical rear-view mirror 10-amp, GreenStar, TEC controller (power supply) 10-amp, dome light, radio (battery voltage) 20-amp, fan 20-amp, fan 10-amp, 3-terminal socket, socket strip (power supply) 30-amp, 3-terminal socket, socket strip (battery voltage) Fuses (fuse box F06) up to serial no. 398655 <- Go to Section TOC Section 40 page 225 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. DEFINITIONS: F06/01 F06/02 F06/03 F06/04 F06/05 <- Go to Section TOC 10-amp, horn 10-amp, cigarette lighter 10-amp, operator′s seat 10-amp, radio (power supply) 10-amp, console light, radio lighting Section 40 page 226 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM F06/06 F06/07 F06/08 F06/09 F06/10 F06/11 F06/12 F06/13 F06/14 F06/15 F06/16 Group 25: Fuses, Relays and Switches 10-amp, beacon light 10-amp, front corner worklight 10-amp, worklights on fenders (rear-facing) 10-amp, outer worklight on rear of cab roof 10-amp, inner worklight on rear of cab roof 10-amp, outer worklight on front of cab roof 10-amp, inner worklight on front of cab roof Fuse tester Not used Not used 15-amp, light switch (pin B) Fuses (fuse box F07) up to serial no. 398655 <- Go to Section TOC Section 40 page 227 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. DEFINITIONS: F07/01 Not used F07/02 Not used F07/03 Not used F07/04 10-amp, worklights on cab frame F07/05 Not used <- Go to Section TOC Section 40 page 228 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM F07/06 F07/07 F07/08 F07/09 F07/10 F07/11 F07/12 F07/13 F07/14 F07/15 F07/16 Group 25: Fuses, Relays and Switches 10-amp, dipped-beam headlight, left 10-amp, dipped-beam headlight, right 15-amp, full-beam headlights 30-amp, lights on cab frame 10-amp, r.h. tail light, l.h. clearance light, license plate light 10-amp, l.h. tail light, r.h. clearance light 10-amp, lighting 10-amp, dipped beam, left (lights on cab frame) 10-amp, dipped beam, right (lights on cab frame) 30-amp, headlights 15-amp, full-beam headlights Relays (relay box K08) up to serial no. 398655 <- Go to Section TOC Section 40 page 229 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM DEFINITIONS: K08/1 K08/2 K08/3 K08/4 K08/5 K08/6 K08/7 Group 25: Fuses, Relays and Switches Relay for full-beam headlights Relay for dipped-beam headlights Relay for lights on cab frame Relay for headlights and worklights on cab frame Relay for worklights on front of cab roof Relay for worklights on rear of cab roof Relay for front corner/fender worklights (rear-facing) Relays (relay box K09) up to serial no. 398655 <- Go to Section TOC Section 40 page 230 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches DEFINITIONS: K09/1 3-amp, lighting diode K09/1 1-amp, diode for power supply to electronics K09/2 3-amp, CAN BUS diode K09/2 1-amp, CAN BUS diode K09/3 Relay for fuel preheater K09/4 Relay for air-conditioning system K09/5 Transmission enable relay K09/6 Not used K09/7 3-amp, diode (not connected) K09/7 1-amp, diode for electronic engine control (ECU, Level 1) <- Go to Section TOC Section 40 page 231 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Relays (relay box K10) up to serial no. 398655 DEFINITIONS: K10/1 K10/2 K10/3 K10/4 <- Go to Section TOC Fan relay Not used Relay for 3-terminal socket, power outlet strip Plug for ”come home” mode Section 40 page 232 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Fuse and Relay Boxes on Tractors with Operator′s Cab from Serial No. 398656 Fuse and relay boxes from serial no. 398656 →NOTE: Depending on how the tractor is equipped, it may not have all the fuses and relays shown below. The fuse and relay boxes are located behind the operator′s seat just below the rear window. Press down latches (A) and lift off the trim panel. LEGEND: A B C D E F <- Go to Section TOC Relay box K01 Relay box K02 Fuse box F03 Fuse box F04 Fuse box F05 Fuse box F06 Section 40 page 233 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM G H I J Group 25: Fuses, Relays and Switches Fuse box F07 Relay box K08 Relay box K09 Relay box K10 Relays (relay box K01) from serial no. 398656 DEFINITIONS: K01/1 K01/2 K01/3 K01/4 <- Go to Section TOC Relay for accessories Relay for power supply to electronics Relay for accessories Acoustic alarm Section 40 page 234 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Relays (relay box K02) from serial no. 398656 DEFINITIONS: K02/1 K02/2 K02/3 K02/4 K02/5 K02/6 K02/7 <- Go to Section TOC Not used Alternator relay Not used Not used Relay for power supply to E-ICV Not used Not used Section 40 page 235 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Fuses (fuse box F03) from serial no. 398656 IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. DEFINITIONS: F03/01 10-amp, Basic Control Unit (power supply) 10-amp, Basic Control Unit (BCU) (PTO, front-wheel drive, differential F03/02 lock, HMS II, handbrake, wheel-speed sending unit and radar) <- Go to Section TOC Section 40 page 236 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM F03/03 F03/04 F03/05 F03/06 F03/07 F03/08 F03/09 F03/10 F03/11 F03/12 F03/13 F03/14 F03/15 F03/16 Group 25: Fuses, Relays and Switches 20-amp, right turn signal, hazard warning lights 20-amp, left turn signal Not used 10-amp, brake light 20-amp, brake switch 10-amp, controller for suspended front axle (SFA) (battery voltage) Not used 20-amp, power supply to E-ICV Not used Not used 10-amp, SIC controller (battery voltage) 10-amp, service plug, JDLink, GreenStar (battery power) 10-amp, SIC controller (power supply) 20-amp, heated rear window Fuses (fuse box F04) from serial no. 398656 <- Go to Section TOC Section 40 page 237 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. DEFINITIONS: F04/01 10-amp, ECU controller (power supply) F04/02 10-amp, ECU controller (battery voltage) F04/03 10-amp, GreenStar (power supply) F04/04 15-amp, main (key) switch (battery voltage) F04/05 30-amp, accessories <- Go to Section TOC Section 40 page 238 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM F04/06 F04/07 F04/08 F04/09 F04/10 F04/11 F04/12 F04/13 F04/14 F04/15 F04/16 Group 25: Fuses, Relays and Switches 30-amp, power supply for electronics 30-amp, accessories 20-amp, fuel preheater 10-amp, basic informator BIF, SFA controller (power supply) 10-amp, basic informator BIF (battery voltage) 10-amp, fuel pump, injection pump shut-off valve 10-amp, performance monitor PRF, JDLink (power supply) 10-amp, CAN BUS terminator Not used Not used Not used Fuses (fuse box F05) from serial no. 398656 <- Go to Section TOC Section 40 page 239 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. DEFINITIONS: 10-amp, air-conditioning system, relay for fan, ClimaTrak (power F05/01 supply) F05/02 10-amp, 2-pin plug for front loader F05/03 Not used F05/04 10-amp, EPC controller (power supply) <- Go to Section TOC Section 40 page 240 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM F05/05 F05/06 F05/07 F05/08 F05/09 F05/10 F05/11 F05/12 F05/13 F05/13 F05/14 F05/14 F05/15 F05/16 Group 25: Fuses, Relays and Switches 10-amp, EPC controller (battery voltage) 10-amp, EPC controller (gear selection) 10-amp, accessories 10-amp, windshield wiper and washer 10-amp, rear window wiper and washer 10-amp, electric rear-view mirrors, signal socket 10-amp, GreenStar, TEC controller (power supply) 10-amp, dome light, radio (battery voltage) 20-amp, fan 30-amp, ClimaTrak (fan) 20-amp, fan 10-amp, ClimaTrak (battery voltage) 10-amp, 3-terminal socket, socket strip (power supply) 30-amp, 3-terminal socket, socket strip (battery voltage) Fuses (fuse box F06) from serial no. 398656 <- Go to Section TOC Section 40 page 241 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. DEFINITIONS: F06/01 10-amp, horn F06/02 10-amp, cigarette lighter F06/03 15-amp, operator′s seat F06/04 10-amp, radio (power supply) F06/05 10-amp, shift console light, radio lighting <- Go to Section TOC Section 40 page 242 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM F06/06 F06/07 F06/08 F06/09 F06/10 F06/11 F06/12 F06/13 F06/14 F06/15 F06/16 Group 25: Fuses, Relays and Switches 10-amp, beacon light 10-amp, front corner worklight 10-amp, worklights on fenders (rear-facing) 15-amp, outer worklight on rear of cab roof or Xenon (HID) worklight on right rear of cab roof 15-amp, inner worklight on rear of cab roof or Xenon (HID) worklight on left rear of cab roof 10-amp, outer worklight on front of cab roof 10-amp, inner worklight on front of cab roof Fuse tester 10-amp, AutoTrac (power supply) 10-amp, AutoTrac (battery voltage) 15-amp, light switch (pin B) Fuses (fuse box F07) from serial no. 398656 <- Go to Section TOC Section 40 page 243 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. DEFINITIONS: F07/01 Not used F07/02 Not used F07/03 Not used F07/04 10-amp, worklights on cab frame F07/05 Not used <- Go to Section TOC Section 40 page 244 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM F07/06 F07/07 F07/08 F07/09 F07/10 F07/11 F07/12 F07/13 F07/14 F07/15 F07/16 Group 25: Fuses, Relays and Switches 10-amp, dipped-beam headlight, left 10-amp, dipped-beam headlight, right 15-amp, full-beam headlights 30-amp, lights on cab frame 10-amp, r.h. tail light, l.h. clearance light, license plate light 10-amp, l.h. tail light, r.h. clearance light 10-amp, lighting 10-amp, dipped beam, left (lights on cab frame) 10-amp, dipped beam, right (lights on cab frame) 30-amp, headlights 15-amp, full-beam headlights Relays (relay box K08) from serial no. 398656 <- Go to Section TOC Section 40 page 245 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM DEFINITIONS: K08/1 K08/2 K08/3 K08/4 K08/5 K08/6 K08/7 Group 25: Fuses, Relays and Switches Relay for full-beam headlights Relay for dipped-beam headlights Relay for lights on cab frame Relay for headlights and worklights on cab frame Relay for worklights on front of cab roof Relay for worklights on rear of cab roof Relay for front corner/fender worklights (rear-facing) Relays (relay box K09) from serial no. 398656 <- Go to Section TOC Section 40 page 246 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM DEFINITIONS: K09/1 K09/1 K09/2 K09/2 K09/3 K09/4 K09/5 K09/6 K09/7 <- Go to Section TOC Group 25: Fuses, Relays and Switches 3-amp, lighting diode 1-amp, diode for power supply to electronics 3-amp, CAN BUS diode 1-amp, CAN BUS diode Relay for fuel preheater Relay for air-conditioning system Transmission enable relay Not used Not used Section 40 page 247 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Relays (relay box K10) from serial no. 398656 DEFINITIONS: K10/1 K10/1 K10/3 K10/4 <- Go to Section TOC Fan relay ClimaTrak bridging plug Relay for 3-terminal socket, power outlet strip Plug for ”come home” mode Section 40 page 248 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Fuse and Relay Boxes on Tractors with Operator′s Cab and AutoPowr/IVT Transmission up to Serial No. 398655 Fuse and relay boxes on tractors with AutoPowr/IVT transmission up to serial no. 398655 →NOTE: Depending on how the tractor is equipped, it may not have all the fuses and relays shown below. The fuse and relay boxes are located behind the operator′s seat just below the rear window. Press down latches (A) and lift off the trim panel. LEGEND: A B C <- Go to Section TOC Relay box K01 Relay box K02 Fuse box F03 Section 40 page 249 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM D E F G H I J Group 25: Fuses, Relays and Switches Fuse box F04 Fuse box F05 Fuse box F06 Fuse box F07 Relay box K08 Relay box K09 Relay box K10 Relays (relay box K01) on tractors with AutoPowr/IVT transmission up to serial no. 398655 DEFINITIONS: K01/1 <- Go to Section TOC Relay for accessories Section 40 page 250 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM K01/2 K01/3 K01/4 Group 25: Fuses, Relays and Switches Relay for power supply to electronics Relay for accessories Acoustic alarm Relays (relay box K02) on tractors with AutoPowr/IVT transmission up to serial no. 398655 DEFINITIONS: K02/1 K02/2 K02/3 K02/4 K02/5 <- Go to Section TOC Enable relay Alternator relay Relay for LTC coolant pump Not used Relay for power supply to E-ICV Section 40 page 251 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM K02/6 K02/7 Group 25: Fuses, Relays and Switches Relay for power supply to E-SCV 3, E-SCV 4 Relay for power supply to E-SCV 1, E-SCV 2 Fuses (fuse box F03) on tractors with AutoPowr/IVT transmission up to serial no. 398655 IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. <- Go to Section TOC Section 40 page 252 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches DEFINITIONS: F03/01 10-amp, Basic Control Unit (power supply) 10-amp, Basic Control Unit (BCU) (PTO, front-wheel drive, differential F03/02 lock, HMS II, handbrake, wheel-speed sending unit, radar) F03/03 20-amp, right turn signal, hazard warning lights F03/04 20-amp, left turn signal F03/05 Not used F03/06 10-amp, brake light F03/07 20-amp, brake switch F03/08 10-amp, controller for suspended front axle (SFA) (battery voltage) F03/09 20-amp, LTC coolant pump F03/10 20-amp, power supply to E-ICV F03/11 10-amp, power supply to E-SCV 3, E-SCV 4 F03/12 10-amp, power supply to E-SCV 1, E-SCV 2 F03/13 10-amp, SIC controller (battery voltage) F03/14 10-amp, JDLink, GreenStar F03/15 10-amp, SIC controller (power supply) F03/16 20-amp, heated rear window Fuses (fuse box F04) on tractors with AutoPowr/IVT transmission up to serial no. 398655 <- Go to Section TOC Section 40 page 253 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. DEFINITIONS: F04/01 F04/02 F04/03 F04/04 F04/05 <- Go to Section TOC 10-amp, ECU controller (power supply) 20-amp, ECU controller (battery voltage) Not used 15-amp, main switch (BAT) 30-amp, accessories Section 40 page 254 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM F04/06 F04/07 F04/08 F04/09 F04/10 F04/11 F04/12 F04/13 F04/14 F04/15 F04/16 Group 25: Fuses, Relays and Switches 30-amp, power supply for electronics 30-amp, accessories 20-amp, fuel preheater 10-amp, basic informator, SFA controller (power supply) 10-amp, basic informator (battery voltage) 10-amp, fuel pump 10-amp, performance monitor (PRF) 10-amp, CAN BUS terminator, service socket 10-amp, UIC controller (power supply) 10-amp, TCU controller (power supply) Not used Fuses (fuse box F05) on tractors with AutoPowr/IVT transmission up to serial no. 398655 <- Go to Section TOC Section 40 page 255 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. DEFINITIONS: F05/01 F05/02 F05/03 F05/04 F05/05 <- Go to Section TOC 10-amp, air-conditioning system and relay for fan 10-amp, 2-pin plug for front loader 10-amp, PLC controller (power supply) 10-amp, PLC controller (battery voltage) 10-amp, TCU controller (battery voltage) Section 40 page 256 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM F05/06 F05/07 F05/08 F05/09 F05/10 F05/11 F05/12 F05/13 F05/14 F05/15 F05/16 Group 25: Fuses, Relays and Switches Not used Not used 10-amp, windshield wiper and washer 10-amp, rear window wiper and washer 10-amp, electrical rear-view mirror 10-amp, GreenStar, TEC controller (power supply) 10-amp, dome light, radio (battery voltage) 20-amp, fan 20-amp, fan 10-amp, 3-terminal socket, socket strip (power supply) 30-amp, 3-terminal socket, socket strip (battery voltage) Fuses (fuse box F06) on tractors with AutoPowr/IVT transmission up to serial no. 398655 <- Go to Section TOC Section 40 page 257 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. DEFINITIONS: F06/01 F06/02 F06/03 F06/04 F06/05 <- Go to Section TOC 10-amp, horn 10-amp, cigarette lighter 10-amp, operator′s seat 10-amp, radio (power supply) 10-amp, shift console light, radio lighting Section 40 page 258 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM F06/06 F06/07 F06/08 F06/09 F06/10 F06/11 F06/12 F06/13 F06/14 F06/15 F06/16 Group 25: Fuses, Relays and Switches 10-amp, beacon light 10-amp, front corner worklight 10-amp, worklights on fenders (rear-facing) 10-amp, outer worklight on rear of cab roof 10-amp, inner worklight on rear of cab roof 10-amp, outer worklight on front of cab roof 10-amp, inner worklight on front of cab roof Fuse tester Not used Not used 15-amp, light switch (pin B) Fuses (fuse box F07) on tractors with AutoPowr/IVT transmission up to serial no. 398655 <- Go to Section TOC Section 40 page 259 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. DEFINITIONS: F07/01 Not used F07/02 Not used F07/03 Not used F07/04 10-amp, worklights on cab frame F07/05 Not used <- Go to Section TOC Section 40 page 260 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM F07/06 F07/07 F07/08 F07/09 F07/10 F07/11 F07/12 F07/13 F07/14 F07/15 F07/16 Group 25: Fuses, Relays and Switches 10-amp, dipped-beam headlight, left 10-amp, dipped-beam headlight, right 15-amp, full-beam headlights 30-amp, lights on cab frame 10-amp, r.h. tail light, l.h. clearance light, license plate light 10-amp, l.h. tail light, r.h. clearance light 10-amp, lighting 10-amp, dipped beam, left (lights on cab frame) 10-amp, dipped beam, right (lights on cab frame) 30-amp, headlights 15-amp, full-beam headlights Relays (relay box K08) on tractors with AutoPowr/IVT transmission up to serial no. 398655 <- Go to Section TOC Section 40 page 261 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM DEFINITIONS: K08/1 K08/2 K08/3 K08/4 K08/5 K08/6 K08/7 Group 25: Fuses, Relays and Switches Relay for full-beam headlights Relay for dipped-beam headlights Relay for lights on cab frame Relay for headlights and worklights on cab frame Relay for worklights on front of cab roof Relay for worklights on rear of cab roof Relay for front corner/fender worklights (rear-facing) Relays (relay box K09) on tractors with AutoPowr/IVT transmission up to serial no. 398655 <- Go to Section TOC Section 40 page 262 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM DEFINITIONS: K09/1 K09/1 K09/2 K09/2 K09/3 K09/4 K09/5 K09/6 K09/7 <- Go to Section TOC Group 25: Fuses, Relays and Switches 3-amp, lighting diode 1-amp, diode for power supply to electronics 3-amp, CAN BUS diode 1-amp, CAN BUS diode Relay for fuel preheater Relay for air-conditioning system Not used Not used Not used Section 40 page 263 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Relays (relay box K10) on tractors with AutoPowr/IVT transmission up to serial no. 398655 DEFINITIONS: K10/1 K10/2 K10/3 K10/4 <- Go to Section TOC Fan relay Acoustic alarm for park lock Relay for 3-terminal socket, power outlet strip Plug for ”come home” mode Section 40 page 264 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Fuse and Relay Boxes on Tractors with Operator′s Cab and AutoPowr/IVT Transmission from Serial No. 398656 Fuse and relay boxes on tractors with AutoPowr/IVT transmission from serial no. 398656 →NOTE: Depending on how the tractor is equipped, it may not have all the fuses and relays shown below. The fuse and relay boxes are located behind the operator′s seat just below the rear window. Press down latches (A) and lift off the trim panel. LEGEND: A B C <- Go to Section TOC Relay box K01 Relay box K02 Fuse box F03 Section 40 page 265 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM D E F G H I J Group 25: Fuses, Relays and Switches Fuse box F04 Fuse box F05 Fuse box F06 Fuse box F07 Relay box K08 Relay box K09 Relay box K10 Relays (relay box K01) on tractors with AutoPowr/IVT transmission from serial no. 398656 DEFINITIONS: K01/1 <- Go to Section TOC Relay for accessories Section 40 page 266 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM K01/2 K01/3 K01/4 Group 25: Fuses, Relays and Switches Relay for power supply to electronics Relay for accessories Acoustic alarm Relays (relay box K02) on tractors with AutoPowr/IVT transmission from serial no. 398656 DEFINITIONS: K02/1 K02/2 K02/3 K02/4 K02/5 <- Go to Section TOC Enable relay Alternator relay Not used Not used Relay for power supply to E-ICV Section 40 page 267 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM K02/6 K02/7 Group 25: Fuses, Relays and Switches Relay for power supply to E-SCV 3, E-SCV 4 Relay for power supply to E-SCV 1, E-SCV 2 Fuses (fuse box F03) on tractors with AutoPowr/IVT transmission from serial no. 398656 IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. <- Go to Section TOC Section 40 page 268 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches DEFINITIONS: F03/01 10-amp, Basic Control Unit (power supply) 10-amp, Basic Control Unit (BCU) (PTO, front-wheel drive, differential F03/02 lock, HMS II, handbrake, wheel-speed sending unit and radar) F03/03 20-amp, right turn signal, hazard warning lights F03/04 20-amp, left turn signal F03/05 Not used F03/06 10-amp, brake light F03/07 20-amp, brake switch F03/08 10-amp, controller for suspended front axle (SFA) (battery voltage) F03/09 Not used F03/10 20-amp, power supply to E-ICV F03/11 10-amp, power supply to E-SCV 3, E-SCV 4 F03/12 10-amp, power supply to E-SCV 1, E-SCV 2 F03/13 10-amp, SIC controller (battery voltage) F03/14 10-amp, service plug, JDLink, GreenStar F03/15 10-amp, SIC controller (power supply) F03/16 20-amp, heated rear window Fuses (fuse box F04) on tractors with AutoPowr/IVT transmission from serial no. 398656 <- Go to Section TOC Section 40 page 269 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. DEFINITIONS: F04/01 10-amp, ECU controller (power supply) F04/02 10-amp, ECU controller (battery voltage) F04/03 10-amp, GreenStar (power supply) F04/04 15-amp, main (key) switch (battery voltage) F04/05 30-amp, accessories <- Go to Section TOC Section 40 page 270 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM F04/06 F04/07 F04/08 F04/09 F04/10 F04/11 F04/12 F04/13 F04/14 F04/15 F04/16 Group 25: Fuses, Relays and Switches 30-amp, power supply for electronics 30-amp, accessories 20-amp, fuel preheater 10-amp, basic informator BIF, SFA controller (power supply) 10-amp, basic informator BIF (battery voltage) 10-amp, fuel pump 10-amp, performance monitor PRF, JDLink (power supply) 10-amp, CAN BUS terminator 10-amp, UIC controller (power supply) 10-amp, TCU controller (power supply) Not used Fuses (fuse box F05) on tractors with AutoPowr/IVT transmission from serial no. 398656 <- Go to Section TOC Section 40 page 271 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. DEFINITIONS: 10-amp, air-conditioning system, relay for fan, ClimaTrak (power F05/01 supply) F05/02 10-amp, 2-pin plug for front loader F05/03 10-amp, PLC controller (power supply) F05/04 10-amp, PLC controller (battery voltage) <- Go to Section TOC Section 40 page 272 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM F05/05 F05/06 F05/07 F05/08 F05/09 F05/10 F05/11 F05/12 F05/13 F05/13 F05/14 F05/14 F05/15 F05/16 Group 25: Fuses, Relays and Switches 10-amp, TCU controller (battery voltage) Not used 10-amp, accessories 10-amp, windshield wiper and washer 10-amp, rear window wiper and washer 10-amp, electric rear-view mirrors, signal socket 10-amp, GreenStar, TEC controller (power supply) 10-amp, dome light, radio (battery voltage) 20-amp, fan 30-amp, ClimaTrak (fan) 20-amp, fan 10-amp, ClimaTrak (battery voltage) 10-amp, 3-terminal socket, socket strip (power supply) 30-amp, 3-terminal socket, socket strip (battery voltage) Fuses (fuse box F06) on tractors with AutoPowr/IVT transmission from serial no. 398656 <- Go to Section TOC Section 40 page 273 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. DEFINITIONS: F06/01 10-amp, horn F06/02 10-amp, cigarette lighter F06/03 15-amp, operator′s seat F06/04 10-amp, radio (power supply) F06/05 10-amp, shift console light and radio lighting <- Go to Section TOC Section 40 page 274 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM F06/06 F06/07 F06/08 F06/09 F06/10 F06/11 F06/12 F06/13 F06/14 F06/15 F06/16 Group 25: Fuses, Relays and Switches 10-amp, beacon light 10-amp, front corner worklight 10-amp, worklights on fenders (rear-facing) 15-amp, outer worklight on rear of cab roof or Xenon (HID) worklight on right rear of cab roof 15-amp, inner worklight on rear of cab roof or Xenon (HID) worklight on left rear of cab roof 10-amp, outer worklight on front of cab roof 10-amp, inner worklight on front of cab roof Fuse tester 10-amp, AutoTrac (power supply) 10-amp, AutoTrac (battery voltage) 15-amp, light switch (pin B) Fuses (fuse box F07) on tractors with AutoPowr/IVT transmission from serial no. 398656 <- Go to Section TOC Section 40 page 275 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. DEFINITIONS: F07/01 Not used F07/02 Not used F07/03 Not used F07/04 10-amp, worklights on cab frame F07/05 Not used <- Go to Section TOC Section 40 page 276 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM F07/06 F07/07 F07/08 F07/09 F07/10 F07/11 F07/12 F07/13 F07/14 F07/15 F07/16 Group 25: Fuses, Relays and Switches 10-amp, dipped-beam headlight, left 10-amp, dipped-beam headlight, right 15-amp, full-beam headlights 30-amp, lights on cab frame 10-amp, r.h. tail light, l.h. clearance light, license plate light 10-amp, l.h. tail light, r.h. clearance light 10-amp, lighting 10-amp, dipped beam, left (lights on cab frame) 10-amp, dipped beam, right (lights on cab frame) 30-amp, headlights 15-amp, full-beam headlights Relays (relay box K08) on tractors with AutoPowr/IVT transmission from serial no. 398656 <- Go to Section TOC Section 40 page 277 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM DEFINITIONS: K08/1 K08/2 K08/3 K08/4 K08/5 K08/6 K08/7 Group 25: Fuses, Relays and Switches Relay for full-beam headlights Relay for dipped-beam headlights Relay for lights on cab frame Relay for headlights and worklights on cab frame Relay for worklights on front of cab roof Relay for worklights on rear of cab roof Relay for front corner/fender worklights (rear-facing) Relays (relay box K09) on tractors with AutoPowr/IVT transmission from serial no. 398656 <- Go to Section TOC Section 40 page 278 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM DEFINITIONS: K09/1 K09/1 K09/2 K09/2 K09/3 K09/4 K09/5 K09/6 K09/7 <- Go to Section TOC Group 25: Fuses, Relays and Switches 3-amp, lighting diode 1-amp, diode for power supply to electronics 3-amp, CAN BUS diode 1-amp, CAN BUS diode Relay for fuel preheater Relay for air-conditioning system Not used Not used Not used Section 40 page 279 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Relays (relay box K10) on tractors with AutoPowr/IVT transmission from serial no. 398656 DEFINITIONS: K10/1 K10/1 K10/2 K10/3 K10/4 Fan relay ClimaTrak bridging plug Acoustic alarm for park lock Relay for 3-terminal socket, power outlet strip Plug for ”come home” mode Replacing the Main Fuses <- Go to Section TOC Section 40 page 280 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: A B C Group 25: Fuses, Relays and Switches Fuse covers Main fuse (F13) Main fuse (F14) The two main fuses are located under the engine hood, where they are secured on the r.h. side of the hood frame just above the battery. F13–80-amp battery circuit (main power supply) F14–80-amp battery circuit (main power supply) IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. Open the hood. Take covers (A) off the two fuses. Replace fuse (B) or (C). <- Go to Section TOC Section 40 page 281 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Put the covers back on the fuses. <- Go to Section TOC Section 40 page 282 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing Fuses of Electrical Starting Aid for Stage I and II Engines to 97/68/EC (Level 4 or 11 ECUs) The fuses for the electrical starting aid are on the right side of the engine block. Open the hood. Replacing the fuse for the heater element (electrical starting aid) LEGEND: A Fuse F09 for heater element (electrical starting aid) F09 - 70-amp, heating element in electrical starting aid IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. Take the cover off the fuse. <- Go to Section TOC Section 40 page 283 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replace fuse (A). Put the cover back on the fuse. Replacing the indicator light fuse (electrical starting aid) LEGEND: B Fuse F11 for indicator light (electrical starting aid) F11 - 10-amp, indicator light in electrical starting aid IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. Take the cover off the fuse. Replace fuse (B). Put the cover back on the fuse. <- Go to Section TOC Section 40 page 284 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing Fuses of Electrical Starting Aid for Stage I and II Engines to 97/68/EC (Level 4 or 11 ECUs) (AutoPowr/IVT Transmission) The fuses for the electrical starting aid are on the right side of the engine block. Open the hood. Replacing the fuse for the heater element (electrical starting aid) LEGEND: A Fuse (F09) for heater element (electrical starting aid) F09 - 70-amp, heating element in electrical starting aid IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. <- Go to Section TOC Section 40 page 285 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Take the cover off the fuse. Replace fuse (A). Put the cover back on the fuse. Replacing the indicator light fuse (electrical starting aid) LEGEND: B Fuse F11 for indicator light (electrical starting aid) F11 - 10-amp, indicator light in electrical starting aid IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. Take the cover off the fuse. Replace fuse (B). Put the cover back on the fuse. <- Go to Section TOC Section 40 page 286 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing Fuse for Fuel Injection Pump (with Stage I Engines to 97/68/EC (Level 4 ECU) LEGEND: A Fuse covers B Fuse F10 for fuel injection pump (Level 4 ECU) The injection pump fuse is located on the right side of the engine block. F10—20-amp, fuel injection pump (Level 4 ECU) IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. Open the hood. Take cover (A) off the fuse. Replace fuse (B). <- Go to Section TOC Section 40 page 287 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Put the cover back on the fuse. <- Go to Section TOC Section 40 page 288 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing Fuse for Fuel Injection Pump (with Stage I Engines to 97/68/EC (Level 4 ECU) (AutoPowr/IVT Transmission) LEGEND: A B Fuse covers Injection pump fuse (F10) The injection pump fuse is located on the right side of the engine block. F10—20-amp, fuel injection pump (Level 4 ECU) IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. Open the hood. Take cover (A) off the fuse. <- Go to Section TOC Section 40 page 289 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replace fuse (B). Put the cover back on the fuse. <- Go to Section TOC Section 40 page 290 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the LTC Coolant Pump Fuse (AutoPowr/IVT Transmission) LEGEND: A Fuse covers B Fuse F22 for LTC coolant pump fuse (AutoPowr/IVT transmission) The fuse for the LTC coolant pump is on the right side of the engine block. F22 - 30-amp, LTC coolant pump IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. Open the hood. Take cover (A) off the fuse. Replace fuse (B). <- Go to Section TOC Section 40 page 291 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Put the cover back on the fuse. <- Go to Section TOC Section 40 page 292 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replace the Fuse for the Implement BUS (60-amp Implement Socket) LEGEND: A Fuse covers B Fuse for power supply to implement BUS (components) (F16) C Fuse for power supply to implement BUS (CAN BUS) (F17) The two fuses for the power supply to the implement BUS are located under the engine hood, where they are secured on the l.h. side of the hood frame just above the battery. F16—60-amp, power supply to implement BUS (components) F17—30-amp, power supply to implement BUS (CAN BUS) IMPORTANT: To prevent damage to the electrical system, never use a fuse with a rating higher than the one already installed. Lift hood. <- Go to Section TOC Section 40 page 293 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Take covers (A) off the two fuses. Replace fuse (B) or (C). Put the covers back on the fuses. <- Go to Section TOC Section 40 page 294 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing Starting Motor Relay for Stage I and II Engines to 97/68/EC (Level 4 or 11 ECUs) LEGEND: A B C Starting motor relay cover Cap screw Starting motor relay (K01) The starting motor relay is on the left side of the engine block. CAUTION: Disconnect the battery ground cable (-). Open the hood. Remove cap screw (B) and cover (A). <- Go to Section TOC Section 40 page 295 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches →NOTE: For identification purposes, mark the wires before disconnecting them. Disconnect relay (C) and insert a new one. Assemble in reverse order. Tightening torques for installation: Item Measurement Specification Cable to starter motor relay, M8 hex. nut Torque 6 N˙m 4.4 lb-ft Cable to starter motor relay, M5 hex. nut Torque 3.5 to 4 N˙m 2.6 to 3 lb-ft Starter motor relay to bracket, M6 cap screws Torque 8 N˙m 5.9 lb-ft <- Go to Section TOC Section 40 page 296 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing Starting Motor Relay for Stage I and II Engines to 97/68/EC (Level 4 or 11 ECUs) (AutoPowr/IVT Transmission) LEGEND: A B C Starting motor relay cover Cap screw Starting motor relay (K01) The starting motor relay is on the left side of the engine block. CAUTION: Disconnect the battery ground cable (-). Open the hood. Remove cap screw (B) and cover (A). <- Go to Section TOC Section 40 page 297 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches →NOTE: For identification purposes, mark the wires before disconnecting them. Disconnect relay (C) and insert a new one. Assemble in reverse order. Tightening torques for installation: Item Measurement Specification Cable to starter motor relay, M8 hex. nut Torque 6 N˙m 4.4 lb-ft Cable to starter motor relay, M5 hex. nut Torque 3.5 to 4 N˙m 2.6 to 3 lb-ft Starter motor relay to bracket, M6 cap screws Torque 8 N˙m 5.9 lb-ft <- Go to Section TOC Section 40 page 298 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing Relay of Electrical Starting Aid for Stage I and II Engines to 97/68/EC (Level 4 or 11 ECUs) LEGEND: A B C Cover of relay for electrical starting aid Nut with protective cap Relay K36, electrical starting aid The electrical starting aid relay is located at the right-hand side of the engine block. CAUTION: Disconnect the battery ground cable (-). Open the hood. Take off the protective cap and nut (B). Remove cover (A). <- Go to Section TOC Section 40 page 299 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches →NOTE: For identification purposes, mark the wires before disconnecting them. Disconnect relay (C) and insert a new one. Assemble in reverse order. Tightening torques for installation: Item Measurement Specification Cable to relay for electrical starting aid, M8 hex. nut Torque 6 N˙m 4.4 lb-ft Cable to relay for electrical starting aid, M5 hex. nut Torque 3.5 to 4 N˙m 2.6 to 3 lb-ft Relay for electrical starting aid to bracket, M6 cap screws Torque 8 N˙m 5.9 lb-ft <- Go to Section TOC Section 40 page 300 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing Relay of Electrical Starting Aid for Stage I and II Engines to 97/68/EC (Level 4 or 11 ECUs) (AutoPowr/IVT Transmission) LEGEND: A B C Cover of relay for electrical starting aid Nut with protective cap Relay K36, electrical starting aid The electrical starting aid relay is located at the right-hand side of the engine block. CAUTION: Disconnect the battery ground cable (-). Open the hood. Take off the protective cap and nut (B). <- Go to Section TOC Section 40 page 301 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Remove cover (A). →NOTE: For identification purposes, mark the wires before disconnecting them. Disconnect relay (C) and insert a new one. Assemble in reverse order. Tightening torques for installation: Item Measurement Specification Cable to relay for electrical starting aid, M8 hex. nut Torque 6 N˙m 4.4 lb-ft Cable to relay for electrical starting aid, M5 hex. nut Torque 3.5 to 4 N˙m 2.6 to 3 lb-ft Relay for electrical starting aid to bracket, M6 cap screws Torque 8 N˙m 5.9 lb-ft Replacing Relay for Fuel Injection Pump (with Stage I Engines to 97/68/EC only (Level 4 ECU)) LEGEND: A B C Attaching screw Plug Injection pump relay (K40) The injection pump relay is located under the engine hood, where it is secured on the r.h. side of the hood frame just above the battery. Open the hood. <- Go to Section TOC Section 40 page 302 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Take out attaching screw (A). Disconnect plug (B). Replace relay (C) with a new one. Assemble in reverse order. Replace the Power Supply Relay for the Implement BUS LEGEND: A Attaching screw B Plug C Relay for power supply to implement BUS (components) (K46) D Attaching screw E Plug F Relay for power supply to implement BUS (CAN BUS) (K47) The two relays for the power supply to the implement BUS are located under the engine hood, where they are secured on the l.h. side of the hood frame just above the battery. Lift hood. Remove attaching screw (A) or (D). Disconnect plug (B) or (E). Replace relay (C) or (F) with a new one. Assemble in reverse order. <- Go to Section TOC Section 40 page 303 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing Battery Cut-off Switch Relay Version 1 LEGEND: A B C D Nut and washer Nut and washer Screw Battery cut-off relay (version 1) (K50) Cab The battery cut-off relay (version 1) is located under the engine hood, just above the battery CAUTION: Disconnect the battery ground cable (-). Open the hood. Disconnect the battery. Remove nuts and washers (A) and battery cable. Remove nut and washer (B) and control line. Take out screws (C) and replace battery cut-off relay (version 1) (D) with a new one. Assemble in reverse order. Tightening torques for installation: <- Go to Section TOC Section 40 page 304 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Item Measurement Specification Battery cable to battery cut-off relay (version 1), M10 hex. nut Torque 18 to 22 N˙m 13 to 16 lb-ft Control line to battery cut-off relay (version 1), M5 hex. nut Torque 3 to 5 N˙m 2.2 to 3.7 lb-ft Version 2 LEGEND: A B C D E F Latches Covers Nuts and washers Screws and washers Screws and nuts Battery cut-off relay (version 2) (K56) Cab The battery cut-off relay (version 2) is located under the engine hood, just above the battery <- Go to Section TOC Section 40 page 305 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches CAUTION: Disconnect the battery ground cable (-). Open the hood. Disconnect the battery. Open latches (A) and remove covers (B). Remove nuts and washers (C) and battery cable. →NOTE: For identification purposes, mark the wires before disconnecting them. Remove screws and washers (D) and control line. Take off screws and nuts (E) and replace the battery cut-off relay (version 2) (F). Assemble in reverse order. Item Measurement Specification Battery cable to battery cut-off relay (version 2), M10 hex. nut Torque 15 to 20 N˙m 11 to 15 lb-ft Control line to battery cut-off relay (version 2), M4 cap screw Torque 2.2 N˙m 1.6 lb-ft <- Go to Section TOC Section 40 page 306 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing Battery Cut-off Switch Relay Version 1 LEGEND: A B C Screw Relay K48 for battery cut-off switch (version 1) Plug Cab The relay for the battery cut-off switch (version 1) is located under the engine hood, just above the battery Open the hood. Take out screw (A) and remove relay (B). Disconnect plug (C) and replace relay. Assemble in reverse order. Version 2 <- Go to Section TOC Section 40 page 307 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: A B C Group 25: Fuses, Relays and Switches Screw Relay K57 for battery cut-off switch (version 2) Plug Cab The relay for the battery cut-off switch (version 2) is located under the engine hood, just above the battery Open the hood. Take out screw (A) and remove relay (B). Disconnect plug (C) and replace relay. Assemble in reverse order. Replacing the Main Switch LEGEND: A B C Main switch Plug Special nut If necessary: Carry out preliminary work, refer to“Removing Trim Panels from Cowl”. CAUTION: Disconnect negative (-) cable from battery. Take off the special nut (C) on the outside. <- Go to Section TOC Section 40 page 308 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Pull out main switch (A). Pull off plug (B) and install new switch. For installation, follow removal procedure in reverse order. <- Go to Section TOC Section 40 page 309 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the Brake Switches LEGEND: A B C Brake switch Plug Screws For preliminary work, refer to“Removing Trim Panels from Cowl”. Disconnect plug (B). Take out screws (C) and replace brake switch (A) with a new one. For brake switch adjustment (brake valve with Power-Fill), refer to “Brake Valve with PowerFill”, Section 60, Group 15. For brake switch adjustment (Power-Fill brake valve with MFWD and disk brake), refer to “Power-Fill Brake Valve with MFWD and Disk Brake“, Section 60, Group 15. For installation, follow removal procedure in reverse order. IMPORTANT: Only on tractors with AutoPowr/IVT transmission: If you replace the brake switches, you should check the user interface controller (UIC) for diagnostic trouble codes. Refer to “Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. Replacing the Light Switch <- Go to Section TOC Section 40 page 310 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: A B C D E Group 25: Fuses, Relays and Switches Screws Screws Console Sheet-metal nut Light switch Pull the knob off the light switch. Take out screws (A) and lift off the dashboard trim. Take out screws (B) and tilt console (C). Take off sheet-metal nut (D) and pull out the light switch (E). Disconnect the plug and replace the light switch with a new one. For installation, follow removal procedure in reverse order. <- Go to Section TOC Section 40 page 311 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the Worklight Switches LEGEND: A B C D Worklight switches Plugs Worklight switch Plug Carefully pry out the console using a screwdriver at the locations indicated (arrows). Disconnect plugs (B). Press the worklight switches (A) out to the front of the console and replace them with new ones. or Disconnect plug (D). Extract the wires of the relevant worklight switch (C) from the plug using a JDG777 Extraction tool JDG777 <- Go to Section TOC Section 40 page 312 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Removing electrical connectors extraction tool. Extract terminals from plug (refer to“METRI PACK Connectors with Terminal Lock at the Rear”in Section 40, Group 05). →NOTE: For identification purposes, mark the layout of the leads before you extract them. Press the worklight switches (C) out to the front of the console and replace them with new ones. For installation, follow removal procedure in reverse order. <- Go to Section TOC Section 40 page 313 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the Switch for Lights on Cab Frame LEGEND: A B Switch for lights on cab frame Plug Carefully pry out the console using a screwdriver at the locations indicated (arrows). Disconnect plug (B). Extract the wires of the switch (A; for lights on cab frame) from the plug using a JDG777 Extraction tool JDG777 Removing electrical connectors <- Go to Section TOC Section 40 page 314 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches extraction tool. Extract terminals from plug (refer to“METRI PACK Connectors with Terminal Lock at the Rear”in Section 40, Group 05). →NOTE: For identification purposes, mark the layout of the leads before you extract them. Press the switch for lights on cab frame (A) out to the front of the console and replace it with a new one. For installation, follow removal procedure in reverse order. <- Go to Section TOC Section 40 page 315 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the Beacon Light Switch LEGEND: A B Beacon light switch Plug Carefully pry out the console using a screwdriver at the locations indicated (arrows). Disconnect plug (B). Extract the wires of the switch (A; for beacon light) from the plug using a JDG777 Extraction tool JDG777 Removing electrical connectors <- Go to Section TOC Section 40 page 316 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches extraction tool. Extract terminals from plug (refer to“METRI PACK Connectors with Terminal Lock at the Rear”in Section 40, Group 05). →NOTE: For identification purposes, mark the layout of the leads before you extract them. Press the beacon light switch (A) out to the front of the console and replace it with a new one. For installation, follow removal procedure in reverse order. Replacing the Hazard Warning Light Switch LEGEND: A B C D Screws Screws Console Hazard warning light switch Take out screws (A) and lift off the dashboard trim. Take out screws (B) and tilt console (C). Disconnect the plug. Press out hazard warning light switch (D) to the front of the console and replace it with a new one. For installation, follow removal procedure in reverse order. <- Go to Section TOC Section 40 page 317 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches IMPORTANT: If you replace the hazard warning light switch, you should check the basic control unit (BCU) for diagnostic trouble codes. See “Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. <- Go to Section TOC Section 40 page 318 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing Switches on Multi-Function Unit Tractor with electrical reverser control (PowrQuad Plus and AutoQuad transmissions) up to serial no. 398655 (version 1) →NOTE: The lever for electrical reverser control (version 1) is no longer available. The version 1 lever is now replaced by a special version 2 lever that is available as a spare part. <- Go to Section TOC Section 40 page 319 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: A B C D E F G H J Group 25: Fuses, Relays and Switches Switch (turn signal/horn/full-beam) Switch (electrical reverser control) Screws Screws Screws Screws Screws Wiring harness (W18; windshield wiper switch) Microswitch (roll mode) <- Go to Section TOC Section 40 page 320 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM K L M N O P Group 25: Fuses, Relays and Switches Lever (roll mode) Windshield wiper and washer switch Mounting Grip for windshield wiper and washer Cover Guide sleeve Remove the steering wheel. Take out screws (F) and lift off cover (O). Take out screws (C) and lift off switch (A). Take out screws (E) and (D) and lift off switch (B). Take out screws (G) and lift off guide sleeve (P). Replace switches (A) or (B) as complete assemblies. Pull out the intermittent-wipe relay. Pull mounting (M) with grip (N) out of its guide. Disconnect plug from switch (L) and replace switch. Pull lever (K) out of its guide and replace microswitch (J). Assemble in reverse order. Tighten the steering wheel nut. Item Measurement Specification Steering wheel to steering column, hex. nut Torque 50 N˙m 35 lb-ft IMPORTANT: If you replace switch (A) or microswitch (J), you must check the basic control unit (BCU) for diagnostic trouble codes. See ”Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. IMPORTANT: If you replace switch (B), you must check the electronic PowrQuad controller (EPC) for diagnostic trouble codes. See ”Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. <- Go to Section TOC Section 40 page 321 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Tractor with electrical reverser control (PowrQuad Plus and AutoQuad Plus transmissions) from serial no. 398656 (version 2) LEGEND: A B C D E Switch (turn signal/horn/full-beam) Switch (reverser control) Screws Cover Screws <- Go to Section TOC Section 40 page 322 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM F G H J K L M N O P Group 25: Fuses, Relays and Switches Screws Screws Guide sleeve Wiring harness (W18; windshield wiper switch) Intermittent-wipe relay Microswitch (roll mode) Lever (roll mode) Windshield wiper and washer switch Mounting Grip for windshield wiper and washer Remove the steering wheel. Take out screws (C) and remove cover (D). Take out screws (E) and lift off switch (A). Take out screws (F) and lift off switch (B). Take out screws (G) and lift off guide sleeve (H). Replace switches (A) or (B) as complete assemblies. Pull out the intermittent-wipe relay (K). Pull out mounting (O) and grip (P). Disconnect plug from switch (N) and replace switch. Pull lever (M) out of its guide and replace microswitch (L). Assemble in reverse order. Tighten the steering wheel nut. Item Measurement Specification Steering wheel to steering column, hex. nut Torque 50 N˙m 35 lb-ft <- Go to Section TOC Section 40 page 323 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches IMPORTANT: If you replace switch (A) or microswitch (L), you must check the basic control unit (BCU) for diagnostic trouble codes. See ”Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. IMPORTANT: If you replace switch (B), you must check the electronic PowrQuad controller (EPC) for diagnostic trouble codes. See ”Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. Tractors with reverser control (AutoPowr/IVT transmission) <- Go to Section TOC Section 40 page 324 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: A B C D E F G H J K Group 25: Fuses, Relays and Switches Switch (turn signal/horn/full-beam) Switch (reverser control) Screws Cover Screws Screws Screws Guide sleeve Wiring harness (W18; windshield wiper switch) Intermittent-wipe relay <- Go to Section TOC Section 40 page 325 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM L M N O P Group 25: Fuses, Relays and Switches Microswitch (roll mode) Lever (roll mode) Windshield wiper and washer switch Mounting Grip for windshield wiper and washer Remove the steering wheel. Take out screws (C) and remove cover (D). Take out screws (E) and lift off switch (A). Take out screws (F) and lift off switch (B). Take out screws (G) and lift off guide sleeve (H). Replace switches (A) or (B) as complete assemblies. Pull out the intermittent-wipe relay (K). Pull out mounting (O) and grip (P). Disconnect plug from switch (N) and replace switch. Pull lever (M) out of its guide and replace microswitch (L). Assemble in reverse order. Tighten the steering wheel nut. Item Measurement Specification Steering wheel to steering column, hex. nut Torque 50 N˙m 35 lb-ft IMPORTANT: If you replace switch (A) or microswitch (L), you must check the basic control unit (BCU) for diagnostic trouble codes. See ”Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. IMPORTANT: If you replace switch (B), you must check the user interface controller (UIC) for diagnostic trouble codes. See ”Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. <- Go to Section TOC Section 40 page 326 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the Rear Window Wiper and Washer Switch LEGEND: A B C Knob Sheet-metal nut Symbol disk Carefully pry out the console using a screwdriver at the locations indicated (arrows). →NOTE: For identification purposes, mark the plugs before you pull them out. Disconnect plug and remove consoles. Pull off knob (A). Remove sheet-metal nut (B) and symbol disk (C). Pull the rear window wiper and washer switch out to the rear. <- Go to Section TOC Section 40 page 327 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Disconnect the plug and replace the rear window wiper and washer switch with a new one. For installation, follow removal procedure in reverse order. <- Go to Section TOC Section 40 page 328 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the Windshield/Rear Window Switch Replacing the windshield switch LEGEND: A B C D Wiring connector Screws Cover Windshield switch For preliminary work, refer to“Removing Trim Panels from Cowl”. Disconnect connector (A). →NOTE: For identification purposes, mark the layout of the leads before you extract them. Using JDG777 Extraction tool <- Go to Section TOC Section 40 page 329 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches JDG777 Removing electrical connectors tool, extract male terminal body. Extract terminals from plug (refer to“METRI PACK Connectors with Terminal Lock at the Rear”in Section 40, Group 05). →NOTE: Attach a fish-tape (wire-snake) to the old wiring harness to aid installation of the new harness. Take out the attaching screws (B) and remove cover (C) of the windshield switch (D). Pull out switch/harness assembly and replace with new parts. CAUTION: Make sure that wires are connected correctly. Terminal no. Wire no. and cross section Wire color A .......... 224KZ-1 .......... yellow B .......... 236KZ-1 .......... light blue C .......... 227KZ-1 .......... purple Setting: Set the windshield switch so that windshield wiper can operate properly when the windshield is locked shut. For installation, follow removal procedure in reverse order. <- Go to Section TOC Section 40 page 330 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the rear window switch LEGEND: A B Screws Rear window switch Remove the trim panel around the fuse and relay boxes. Remove the screws (A) that hold on the rear window switch. Cut off wires directly at the rear window switch (B). Connect wires to new rear window switch by soldering, and insulate them. Setting: Set the rear window switch so that rear window wiper can operate properly when the rear window is locked shut. For installation, follow removal procedure in reverse order. Replacing the Dome Light Door Switch LEGEND: <- Go to Section TOC Section 40 page 331 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM A Group 25: Fuses, Relays and Switches Dome light door switch Remove cab frame cover. Remove the screws that hold on dome light door switch (A). Cut off wires directly at the dome light door switch. Connect wires to new dome light door switch by soldering, and insulate them. Setting: Set the dome light switch to position 2. Set the dome light door switch so that the dome light goes out when the door is closed. For installation, follow removal procedure in reverse order. <- Go to Section TOC Section 40 page 332 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the Handbrake Switch LEGEND: A B C D E F G Screws Trims Screws Washers Bracket Plug Handbrake switch Take out screws (A) and remove trims (B). Remove trim panels from the rear wall of the cab. <- Go to Section TOC Section 40 page 333 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Take out screws (C) and lift off washers (D). Take off bracket (E). Disconnect plug (F). Replace handbrake switch (G) together with wiring harness. Setting: Adjust the handbrake switch so that the handbrake indicator light comes on when the 2nd notch above the lowest point is reached. Pressure on the handbrake lever in this position must not cause the indicator light to go out. In the lowest position, raising the handbrake lever slightly should not cause the handbrake indicator light to come on. For installation, follow removal procedure in reverse order. IMPORTANT: If you replace the handbrake switch, you should check the basic control unit (BCU) for diagnostic trouble codes. See “Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. <- Go to Section TOC Section 40 page 334 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the Front Wheel Drive Switch LEGEND: A B Front-wheel drive switch Plug Carefully pry out the console using a screwdriver at the locations indicated (arrows). Disconnect plug (B). Press the front-wheel drive switch (A) out to the front of the console and replace it with a new one. For installation, follow removal procedure in reverse order. IMPORTANT: If you replace the front-wheel drive switch, you should check the basic control unit (BCU) for diagnostic trouble codes. See “Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. <- Go to Section TOC Section 40 page 335 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the Headland Management (HMS) Switch LEGEND: A Switch for Headland Management System (HMS) B Plug Carefully pry out the console using a screwdriver at the locations indicated (arrows). Disconnect plug (B). Press out the HMS switch (A) to the front of the console and replace it with a new one. For installation, follow removal procedure in reverse order. IMPORTANT: If you replace the HMS switch, you should check the basic control unit (BCU) for diagnostic trouble codes. See “Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. <- Go to Section TOC Section 40 page 336 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the Record/Save Switch LEGEND: A B Record/save switch Plug Carefully pry out the console using a screwdriver at the locations indicated (arrows). Disconnect plug (B). Press the record/save switch (A) out to the front of the console and replace it with a new one. For installation, follow removal procedure in reverse order. IMPORTANT: If you replace the record/save switch, you should check the basic control unit (BCU) for diagnostic trouble codes. See “Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. <- Go to Section TOC Section 40 page 337 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the Program Switch Tractors with shift console LEGEND: A B C Program switch Plug SCV control levers Remove the grips from the SCV control levers (C). Remove cover from switch console. Disconnect plug (B). Press the program switch (A) out to the front of the console and replace it with a new one. For installation, follow removal procedure in reverse order. <- Go to Section TOC Section 40 page 338 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches IMPORTANT: If you replace the program switch, you should check the basic control unit (BCU) for diagnostic trouble codes. See “Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. Tractors with Command Arm LEGEND: A B <- Go to Section TOC Screws Screws Section 40 page 339 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM C D E Group 25: Fuses, Relays and Switches Cover Program switch Plug On the underside of the Command Arm, take out screws (A). Take out screws (B) and lay the panel on one side. Fold out cover (C). Disconnect plug (E). From the inside, press out program switch (D) and replace it with a new one. For installation, follow removal procedure in reverse order. IMPORTANT: If you replace the program switch, you should check the basic control unit (BCU) for diagnostic trouble codes. See “Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. <- Go to Section TOC Section 40 page 340 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the Rear PTO Preselector Switch LEGEND: A B Rear PTO preselector switch Plug Carefully pry out the console using a screwdriver at the locations indicated (arrows). Disconnect plug (B). Press the rear PTO preselector switch (A) out to the front of the console and replace it with a new one. For installation, follow removal procedure in reverse order. IMPORTANT: If you replace the rear PTO preselector switch, you should check the basic control unit (BCU) for diagnostic trouble codes. See “Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. <- Go to Section TOC Section 40 page 341 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the Switch for AutoQuad Transmission LEGEND: A B Switch for AutoQuad transmission Plug Carefully pry out the console using a screwdriver at the locations indicated (arrows). Disconnect plugs (B). Press out switch (A; for AutoQuad transmission) to the front of the console and replace it with a new one. For installation, follow removal procedure in reverse order. IMPORTANT: If you replace the switch for AutoQuad transmission, you should check the electronic PowrQuad controller (EPC) for diagnostic trouble codes. See “Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. <- Go to Section TOC Section 40 page 342 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replace the Switch for Gear Selector and Automode Switches on range shift lever LEGEND: 1 2 A B C Shift lever for PowrQuad Plus and AutoQuad transmissions Shift lever for AutoQuad Plus transmission Screws Grip Plug <- Go to Section TOC Section 40 page 343 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM D Group 25: Fuses, Relays and Switches Microswitch Cab Take out screws (A) and disassemble grip (B) on the range shift lever. Pull off plug (C) and replace micro-switch (D) with a new one. Assemble in reverse order. CAUTION: The symbols on all the gear selector switches must match (i.e. the symbols must be the same at the switches on the range shift lever and on the console). IMPORTANT: If you replace the micro-switches on the range shift lever, you must check the electronic PowrQuad controller (EPC) for diagnostic trouble codes. See ”Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. Switch in shift console up to serial no. 398655 LEGEND: A B Gear selector switch Plug Cab Remove panel from control console. <- Go to Section TOC Section 40 page 344 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Disconnect plug (B). Press gear selector switch (A) out to the top and replace it with a new one. Assemble in reverse order. CAUTION: The symbols on all the gear selector switches must match (i.e. the symbols must be the same at the switches on the console and on the range shift lever). IMPORTANT: If you replace the gear selector switch on the shift console, you must check the electronic PowrQuad controller (EPC) for diagnostic trouble codes. See ”Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. Switch in shift console from serial no. 398656 <- Go to Section TOC Section 40 page 345 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: A B C D E F Group 25: Fuses, Relays and Switches Bowden cables Screws Screw Cable binder Plug Gear selector switch Cab Remove floor mat and control console trim panels. Put identifying marks on the existing bowden cables (A), then remove them. Take out screws (B). Take out screw (C). Carefully lift the shift unit up a little. Take off cable binder (D). Disconnect plug (E). Press out gear selector switch (F) to the front of the console and replace it with a new one. <- Go to Section TOC Section 40 page 346 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Assemble in reverse order. CAUTION: The symbols on all the gear selector switches must match (i.e. the symbols must be the same at the switches on the console and on the range shift lever). IMPORTANT: If you replace the gear selector switch on the shift console, you must check the electronic PowrQuad controller (EPC) for diagnostic trouble codes. See ”Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. <- Go to Section TOC Section 40 page 347 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the Park Lock Switch on Tractors with PowrQuad Plus, AutoQuad or AutoQuad Plus Transmissions Tractors with cab and PowrQuad Plus or AutoQuad transmissions up to serial no. 398655 LEGEND: A B C D E Park lock switch Stud with nut Plug Neutral position of range shift lever Switch point Remove floor-mat and take trim elements off the control console. Disconnect plug (C). Take the nuts off studs (B). <- Go to Section TOC Section 40 page 348 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replace the park lock switch (A) as a complete unit. Adjustment: Adjust the park lock switch until switch point (E) is not located in the neutral position (D) of range shift lever when it is moved to park lock position. Assemble in reverse order. IMPORTANT: If you replace the park lock switch, you should check the electronic PowrQuad controller (EPC) for diagnostic trouble codes. See ”Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. Tractors with cab and PowrQuad Plus or AutoQuad Plus transmissions from serial no. 398656 LEGEND: A Park lock switch The park lock switch can be replaced only as an assembly together with the park lock quadrant. See”Reconditioning the Range Shift Mechanism (PowrQuad Plus and AutoQuad Plus transmissions from tractor serial no. 398656)”. IMPORTANT: If you replace the park lock switch, you should check the electronic PowrQuad controller (EPC) for diagnostic trouble codes. See ”Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. <- Go to Section TOC Section 40 page 349 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the Fan Switch <- Go to Section TOC Section 40 page 350 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: A B C D E F G H Group 25: Fuses, Relays and Switches Console Knobs Phillips-head screws Panel Phillips-head screws Cover Phillips-head screws Cover Carefully pry out consoles (A) using a screwdriver at the locations indicated (arrows). →NOTE: For identification purposes, mark the plugs before you pull them out. Disconnect plug and remove consoles. Pull off knobs (B). Remove Phillips-head screws (C). Pull plugs off the air-conditioning system compressor switch, the speed ("cruise") control, the cigarette lighter and the rear window wiper/washer switch, and remove trim panel (D). Remove Phillips-head screws (E) and cover (F) and fold out heater control unit. Remove Phillips-head screws (G) and cover (H). Pull out the fan switch and disconnect the plug. Replace the fan switch with a new one. For installation, follow removal procedure in reverse order. <- Go to Section TOC Section 40 page 351 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the Switch of the Air-Conditioning System Compressor LEGEND: A B Compressor switch (air conditioning) Plug Carefully pry out the console using a screwdriver at the locations indicated (arrows). →NOTE: For identification purposes, mark the plugs before you pull them out. Disconnect plug and remove console. Press out the air-conditioning compressor switch (A) from the inside. Pull off plug (B) and install a new switch. For installation, follow removal procedure in reverse order. <- Go to Section TOC Section 40 page 352 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the Differential Lock Switch. LEGEND: A B C Differential lock switch Floor plate Screws Remove the floor-mat. Take screws (C) out of floor-plate (B), and remove the floor-plate. Pull out the plug. Remove differential lock switch (A) from the floor-plate, and replace it with a new one. For installation, follow removal procedure in reverse order. IMPORTANT: If you replace the differential lock switch, you should check the basic control unit (BCU) for diagnostic trouble codes. See “Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. <- Go to Section TOC Section 40 page 353 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the PTO Switches Removing the rear PTO switch and/or front PTO switch from tractors with shift console Rear PTO switch Front PTO switch LEGEND: A B PTO switch Plug Remove panel from control console. Disconnect plug (B). Replacing the PTO switch on tractors with shift console <- Go to Section TOC Section 40 page 354 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: A B C D E F G H I Group 25: Fuses, Relays and Switches Knob Knob cap Snap ring Washer Spring Washer Collar Shift console Switch Remove knob cap (B) and snap ring (C). Remove knob (A) and parts (D - G). Replace parts or switch (I) as necessary. <- Go to Section TOC Section 40 page 355 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches For installation, follow removal procedure in reverse order. IMPORTANT: If you replace the rear PTO switch or front PTO switch, you should check the basic control unit (BCU) for diagnostic trouble codes. See “Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. Removing the rear PTO switch and/or front PTO switch from tractors with Command Arm <- Go to Section TOC Section 40 page 356 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: A B C D E F G Group 25: Fuses, Relays and Switches Screws Screws Cover Rear PTO switch Plug Front PTO switch Plug On the underside of the Command Arm, take out screws (A). Take out screws (B) and lay the panel on one side. Open out cover (C). Disconnect plug (E) or (G). From the inside, press out rear PTO switch (D) or front PTO switch (F) and replace it/them with (a) new one(s). For installation, follow removal procedure in reverse order. IMPORTANT: If you replace the rear PTO switch or the front PTO switch, you should check the basic control unit (BCU) for diagnostic trouble codes. See “Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. <- Go to Section TOC Section 40 page 357 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the External Control Switch for the Rear PTO LEGEND: A B C D Screws Cover Plug Threaded bushing Take out screws (A) and remove cover (B). Disconnect plug (C). On the inside of the fender, screw down threaded bushing (D). Pull out the external control switch for the rear PTO and replace it with a new one. For installation, follow removal procedure in reverse order. <- Go to Section TOC Section 40 page 358 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches IMPORTANT: If you replace the external control switch for the rear PTO, you should check the basic control unit (BCU) for diagnostic trouble codes. See “Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. <- Go to Section TOC Section 40 page 359 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the Rockshaft′s Remote Control Switch LEGEND: A B C D Screws Cover Plug Screws Take out screws (A) and remove cover (B). Disconnect plug (C). On the inside of the fender, take out Phillips-head screws (D). Pull out the rockshaft′s remote control switch and replace it with a new one. Assemble in reverse order. IMPORTANT: If you replace the rockshaft′s remote control switch, you should check the basic control unit (BCU) for diagnostic trouble codes. See ”Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. <- Go to Section TOC Section 40 page 360 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the Switches for the Electrical Rear-View Mirrors LEGEND: A B Switch for the electrical rear-view mirrors Plugs Carefully pry out the consoles using a screwdriver at the locations indicated (arrows). →NOTE: For identification purposes, mark the plugs before you pull them out. Disconnect plugs (B). Press out switches (A; for electrical rear-view mirrors) to the front of the console and replace them with new ones. For installation, follow removal procedure in reverse order. <- Go to Section TOC Section 40 page 361 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the Switch for the Heated Rear-View Mirrors LEGEND: A B Switch for the heated rear-view mirrors Plug Carefully pry out the consoles using a screwdriver at the locations indicated (arrows). Disconnect plug (B). Press out switch (A; for heated rear-view mirror) to the front of the console and replace it with a new one. For installation, follow removal procedure in reverse order. Replacing the Switch for the Heated Rear Window <- Go to Section TOC Section 40 page 362 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: A B Group 25: Fuses, Relays and Switches Switch for the heated rear window Plug Carefully pry out the consoles using a screwdriver at the locations indicated (arrows). →NOTE: For identification purposes, mark the plugs before you pull them out. Disconnect plug (B). Press out switch (A; for heated rear window) to the front of the console and replace it with a new one. For installation, follow removal procedure in reverse order. <- Go to Section TOC Section 40 page 363 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing Switch of Battery Cut-off Switch Version 1 LEGEND: A B C D Console Lock-nut Switch of battery cut-off switch (version 1) (S117) Plug Tractors with cab, and SE tractors Remove left-hand access step. Remove locknut (B). Pull the switch (C) inwards out of the console (A). Disconnect plug (D) and replace the switch that operates the battery cut-off switch with a new one. Assemble in reverse order. Version 2 <- Go to Section TOC Section 40 page 364 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: A B C Group 25: Fuses, Relays and Switches Console Switch of battery cut-off switch (version 2) (S125) Plug Tractors with cab, and SE tractors Remove left-hand access step. Pull plug (C) out of the switch that operates the battery cut-off switch. Press switch (B) forward out of console (A). Assemble in reverse order. <- Go to Section TOC Section 40 page 365 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replace the AutoTrac Switch Tractors with shift console Remove the grips from the selective control valve levers. Remove cover from switch console. Disconnect plug. Press out AutoTrac switch (A) to the front of the console and replace it with a new one. Assemble in reverse order. IMPORTANT: If you replace the AutoTrac switch with a new one, you must check the AutoTrac control unit (SSU) for diagnostic trouble codes. See ”Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. Tractors with Command Arm <- Go to Section TOC Section 40 page 366 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: A B C D E Group 25: Fuses, Relays and Switches Screws Screws Cover AutoTrac switch Plug On the underside of the Command Arm, take out screws (A). Take out screws (B) and lay the panel on one side. Open out cover (C). <- Go to Section TOC Section 40 page 367 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Disconnect plug (E). From the inside, press out AutoTrac switch (D) and replace it with a new one. Assemble in reverse order. IMPORTANT: If you replace the AutoTrac switch with a new one, you must check the AutoTrac control unit (SSU) for diagnostic trouble codes. See ”Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. <- Go to Section TOC Section 40 page 368 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the Switch for the Electro-hydraulic Pickup Hitch LEGEND: A B C D E Screws Screws Cover Switch for the electro-hydraulic pick-up hitch Plug Tractors with cab and CommandArm only <- Go to Section TOC Section 40 page 369 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches On the underside of the CommandArm, take out screws (A). Take out screws (B) and lay the panel on one side. Fold out cover (C). Disconnect plug (E). From the inside, press out the switch for the electro-hydraulic pick-up hitch (D), and replace it with a new one. Assemble in reverse order. <- Go to Section TOC Section 40 page 370 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the Cruise Control Potentiometer on Tractors with AutoQuad Transmission LEGEND: A B C Knob Hex. nut Plug Carefully pry out the console using a screwdriver at the locations indicated (arrows). →NOTE: For identification purposes, mark the plugs before you pull them out. Disconnect plug and remove console. Pull off knob (A). Take off hex. nut (B) and pull the cruise control potentiometer inwards out of the guide. Disconnect plug (C) and replace the cruise control potentiometer with a new one. <- Go to Section TOC Section 40 page 371 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches For installation, follow removal procedure in reverse order. IMPORTANT: If you replace the cruise control potentiometer, you should check the engine control unit (ECU) for diagnostic trouble codes. See “Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. <- Go to Section TOC Section 40 page 372 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the Cruise Control Potentiometer on Tractors with AutoPowr/IVT Transmission LEGEND: A B C Knob Hex. nut Plug Carefully pry out the console using a screwdriver at the locations indicated (arrows). →NOTE: For identification purposes, mark the plugs before you pull them out. Disconnect plug and remove console. Pull off knob (A). Take off hex. nut (B) and pull the cruise control potentiometer inwards out of the guide. Disconnect plug (C) and replace the cruise control potentiometer with a new one. <- Go to Section TOC Section 40 page 373 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches For installation, follow removal procedure in reverse order. IMPORTANT: If you replace the cruise control potentiometer, you should check the user interface controller (UIC) for diagnostic trouble codes. See “Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. <- Go to Section TOC Section 40 page 374 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replace the Auto-mode Potentiometer on Tractors with AutoQuad Plus Transmission Carefully pry out the console using a screwdriver at the locations indicated (arrows). →NOTE: For identification purposes, mark the plugs before you pull them out. Disconnect plugs and remove console. Pull off knob (A). Take off hex. nut (B) and pull the Auto-mode potentiometer inwards out of the guide. Disconnect plug (C) and replace the Auto-mode potentiometer with a new one. Assemble in reverse order. <- Go to Section TOC Section 40 page 375 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches IMPORTANT: If you replace the Auto-mode potentiometer, you must check the electronic PowrQuad controller (EPC) for diagnostic trouble codes. See ”Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. <- Go to Section TOC Section 40 page 376 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Rockshaft Control Replacing the sensitivity potentiometer of rockshaft control on tractors with shift console LEGEND: A B C D E <- Go to Section TOC Sensitivity potentiometer of rockshaft control Shield Plug Screw Hex. nut Section 40 page 377 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Remove cover from switch console. Disconnect plug (C). Take out screw (D) and remove shield (B). Pull off the knob. Take off hex. nut (E). Replace the sensitivity potentiometer (A) with a new one. For installation, follow removal procedure in reverse order. IMPORTANT: If you replace the sensitivity potentiometer of rockshaft control, you should check the basic control unit (BCU) for diagnostic trouble codes. See “Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. IMPORTANT: If you replace the sensitivity potentiometer of rockshaft control, you should recalibrate the basic control unit (BCU). See Reference 245-BCU-002 , Calibration and Input Addresses (Rockshaft Control)”. Replacing position feedback unit on tractors with shift console <- Go to Section TOC Section 40 page 378 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: A B C D Group 25: Fuses, Relays and Switches Position feedback unit Plug Hex. socket screws SCV control levers Remove the grips from the SCV control levers (D). Take the covers off the control console. Pull off connector (B) and remove the control console cover that has position feedback unit (A) on it. Take out hex. socket screws (C). Remove the position feedback unit from the control console cover and install a new unit. For installation, follow removal procedure in reverse order. <- Go to Section TOC Section 40 page 379 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches IMPORTANT: If you replace the position feedback unit, you should check the basic control unit (BCU) for diagnostic trouble codes. See “Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. IMPORTANT: If you replace the rockshaft′s position feedback unit, you should recalibrate the basic control unit (BCU). See Reference 245-BCU-002 , Calibration and Input Addresses (Hitch Control)”. Replacing the position feedback unit′s potentiometer and switch on tractors with shift console <- Go to Section TOC Section 40 page 380 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: A B C D E F Group 25: Fuses, Relays and Switches Knobs Hex. nuts Depth-setting potentiometer of rockshaft control Hex. socket screw Screws Position feedback unit′s harness Remove the control console cover that has the position feedback unit on it. For removal of the position feedback unit, refer to “Replacing the Position Feedback Unit”, Section 40, Group 25. Pull off knobs (A). Take off hex. nuts (B). Using a screwdriver, carefully press out the depth-setting potentiometer (C). Unscrew the hex. socket screw (D). Disassemble the position feedback unit as shown in the illustration. Remove the two screws (E). Replace the position feedback unit′s harness (F) together with its potentiometer and switch. For installation, follow removal procedure in reverse order. <- Go to Section TOC Section 40 page 381 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches IMPORTANT: If you replace the position feedback unit′s harness, you should check the basic control unit (BCU) for diagnostic trouble codes. See “Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. IMPORTANT: If you replace the rockshaft′s position feedback unit′s harness, you should recalibrate the basic control unit (BCU). See Reference 245-BCU-002 , Calibration and Input Addresses (Rockshaft Control)”. Replacing the rockshaft control potentiometer on tractors with Command Arm <- Go to Section TOC Section 40 page 382 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: A B C D E Group 25: Fuses, Relays and Switches Screws Screws Cover Rockshaft control potentiometers Plug On the underside of the Command Arm, take out screws (A). Take out screws (B) and lay the panel on one side. Fold out cover (C). Pull off the knobs. Take off the lock nut. Disconnect plug (E). Pull out potentiometer (D) and install a new one. For installation, follow removal procedure in reverse order. IMPORTANT: If you replace the potentiometers, you should check the basic control unit (BCU) for diagnostic trouble codes. See “Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. IMPORTANT: If you replace the rockshaft control potentiometers, you should recalibrate the basic control unit (BCU). See Reference 245-BCU-002 , Calibration and Input Addresses (Hitch Control)”. <- Go to Section TOC Section 40 page 383 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Replacing the depth-setting potentiometer on tractors with Command Arm LEGEND: A B C D E Screws Screws Cover Depth-setting potentiometer of rockshaft control Plug On the underside of the Command Arm, take out screws (A). <- Go to Section TOC Section 40 page 384 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Take out screws (B) and lay the panel on one side. Fold out cover (C). Carefully pry out the depth-setting potentiometer (D) using a screwdriver at the location indicated (arrow). Disconnect plug (E). Replace the depth-setting potentiometer with a new one. For installation, follow removal procedure in reverse order. IMPORTANT: If you replace the depth-setting potentiometer of rockshaft control, you should check the basic control unit (BCU) for diagnostic trouble codes. See “Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. IMPORTANT: If you replace the depth setting potentiometer of rockshaft control, you should recalibrate the basic control unit (BCU). See Reference 245-BCU-002 , Calibration and Input Addresses (Rockshaft Control)”. Replacing the rapid withdrawal switch on tractors with Command Arm <- Go to Section TOC Section 40 page 385 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: A B C D E Group 25: Fuses, Relays and Switches Screws Screws Cover Rockshaft control rapid withdrawal switch Plug On the underside of the Command Arm, take out screws (A). Take out screws (B) and lay the panel on one side. Fold out cover (C). Disconnect plug (E). From the inside, press out rapid withdrawal switch (D) and replace it with a new one. For installation, follow removal procedure in reverse order. <- Go to Section TOC Section 40 page 386 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches IMPORTANT: If you replace the rapid withdrawal switch, you should check the basic control unit (BCU) for diagnostic trouble codes. See “Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. IMPORTANT: If you replace the rapid withdrawal switch, you should recalibrate the basic control unit (BCU). See Reference 245-BCU-002 , Calibration and Input Addresses (Rockshaft Control). <- Go to Section TOC Section 40 page 387 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Electrical Activators for Selective Control Valves (ESCV) Replacing the control lever LEGEND: A B C D E Screws Screws Cover Electrical activators of the selective control valves Plugs <- Go to Section TOC Section 40 page 388 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM F Group 25: Fuses, Relays and Switches Screws On the underside of the Command Arm, take out screws (A). Take out screws (B) and lay the panel on one side. Fold out cover (C). Disconnect the relevant plug (E). Take out the relevant screw (F). Take out the relevant electrical SCV activator (D), and install a new one. For installation, follow removal procedure in reverse order. IMPORTANT: If you replace any of the SCVs′ electrical activators, you should check the ESCV/E-ICV controller (SIC) for diagnostic trouble codes. See “Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. IMPORTANT: If you replace any of the SCVs′ electrical activators, you should recalibrate the E-SCV/E-ICV controller (SIC). See Reference 245-SIC-001 , Calibration and Input Addresses (E-SCV and E-ICV)”. Replacing the function adjustment wheel <- Go to Section TOC Section 40 page 389 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: A B C D E Group 25: Fuses, Relays and Switches Function adjustment wheel Grub screws Control knob Nut Plug Carefully pry out the console using a screwdriver at the locations indicated (arrows). Slacken off grub screws (B) and pull off control knob (C). Take off nut (D) and pull out the function adjustment wheel. Disconnect plug (E) and replace the function adjustment wheel with a new one. For installation, follow removal procedure in reverse order. Replacing the transport lock switch <- Go to Section TOC Section 40 page 390 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: A B Group 25: Fuses, Relays and Switches Transport lock switch Plug Carefully pry out the console using a screwdriver at the locations indicated (arrows). Disconnect plug (B). Press out transport lock switch (A) to the front of the console and replace it with a new one. For installation, follow removal procedure in reverse order. <- Go to Section TOC Section 40 page 391 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Electrical Activators for Independent Control Valves (E-ICV) Removing the multi-function lever console LEGEND: A B C D Hex. socket screw Multi-function lever console Bracket Armrest of operator′s seat Disconnect the plug behind the operator′s seat. <- Go to Section TOC Section 40 page 392 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 25: Fuses, Relays and Switches Take out hex. socket screw (A). Lift the multi-function lever console (B) and bracket (C) out of the armrest (D) on the operator′s seat. Pull the wires out of the guides in the armrest. For installation, follow removal procedure in reverse order. IMPORTANT: If you replace the multi-function lever console, you should check the ESCV/E-ICV controller (SIC) for diagnostic trouble codes. See “Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. IMPORTANT: If you replace the multi-function lever console, you should recalibrate the E-SCV/E-ICV controller (SIC). See Reference 245-SIC-001 , Calibration and Input Addresses (E-SCV and E-ICV)”. Replacing the multi-function lever and/or transport lock switch <- Go to Section TOC Section 40 page 393 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: A B C D E F G H J K L M Group 25: Fuses, Relays and Switches Phillips-head screw Cover Plug Transport lock switch Screw Clamp Screw Pin Actuator of interlock switch Hex. socket screw Multi-function lever Bracket For removal of the multi-function lever console, see “Removing the Multi-Function Lever Console”, Section 40, Group 25. Take out the five Phillips-head screws (A) and lift off cover (B). <- Go to Section TOC Section 40 page 394 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 30: Monitoring Systems Disconnect plug (C), press out transport lock switch (D), and replace it with a new switch. Take out screw (E) and remove the wiring harness from clamp (F). Take out screws (G) and press pin (H) out of the guide. Take off the actuator of multi-function lever interlock switch (J). Take out hex. socket screws (K). Pull the multi-function lever (L) out through bracket (M) and replace it together with the wiring harness. For installation, follow removal procedure in reverse order. IMPORTANT: If you replace the multi-function lever, you should check the E-SCV/E-ICV controller (SIC) for diagnostic trouble codes. See “Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. IMPORTANT: If you replace the multi-function lever, you should recalibrate the E-SCV / EICV controller (SIC). See 245-SIC-001 , Calibration and Input Addresses (ESCV and E-ICV)”. <- Go to Section TOC Section 40 page 395 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 30: Monitoring Systems Group 30 - Monitoring Systems Monitoring Systems - Recondition (Summary of References) ”General information” ”Information for tractors with Stage I engine to 97/68/EC (Level 4 ECU)” ”Information for tractors with Stage II engine to 97/68/EC (Level 11 ECU)” ”Information for tractors with AutoTrac (SSU controller)” ”Disconnecting electrical circuits” ”Replacing the sending unit for the coolant temperature gauge (B08)” ”Replacing acoustic warning signal sending unit” ”Replacing the acoustic alarm (park lock) on tractors with AutoPowr/IVT transmission” General Information Sending units not mentioned in this Group are described in the Groups dealing with the corresponding components. Information for Tractors with Stage I Engine to 97/68/EC (Level 4 ECU) For tractors with Stage I engines to 97/68/EC (Level 4 ECU), the sending units are dealt with in the Component Technical Manual ” POWERTECH ™ 4.5 l & 6.8 l Diesel Engines Level 4 Electronic Fuel Systems With Bosch VP44 Pump”. IMPORTANT: If you replace a sending unit on a tractor with a Stage I engine to 97/68/EC (Level 4 ECU), you should check the engine control unit (ECU) for diagnostic trouble codes. See ”Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. Information for Tractors with Stage II Engine to 97/68/EC (Level 11 ECU) For tractors with Stage II engines to 97/68/EC (Level 11 ECU), the sending units are dealt with in the Component Technical Manual ” POWERTECH ™ 4.5 l & 6.8 l Diesel Engines Level 11 Electronic Fuel Systems with Denso HPCR”. <- Go to Section TOC Section 40 page 396 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 30: Monitoring Systems IMPORTANT: If you replace a sending unit on a tractor with a Stage II engine to 97/68/EC (Level 11 ECU), you should check the engine control unit (ECU) for diagnostic trouble codes. See ”Reference 245-05-002 , Accessing the Addresses and Diagnostic Trouble Codes”. Information for Tractors with AutoTrac (SSU Control Unit) On tractors with AutoTrac (SSU control unit), the wheel angle sensor (WAS) is dealt with in the Component Technical Manual for Front-Wheel Drive Axles 730, 733, 740, 745 and 750. IMPORTANT: If you replace a wheel angle sensor (WAS) on a tractor with AutoTrac (SSU control unit), you must check the SSU control unit for diagnostic trouble codes. SeeOperation and General Information on Diagnostics - Accessing the Addresses and Diagnostic Trouble Codes. IMPORTANT: If you replace a wheel angle sensor (WAS) on a tractor with AutoTrac (SSU control unit), you must recalibrate the SSU control unit. See SSU Calibration and Input Addresses. Disconnecting electrical circuits Before working on the electrical system, always disconnect battery ground strap (-). <- Go to Section TOC Section 40 page 397 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 30: Monitoring Systems Replacing the sender for the coolant temperature gauge (B08) LEGEND: A Sender for coolant temperature gauge (B08) B Connectors C Coolant temperature sender (B56) CAUTION: Any coolant that emerges may be hot! The sender for the coolant temperature gauge is located in the thermostat housing. Open the hood. Partially drain the coolant. See “Removing the radiator” , section 30, group 20. →NOTE: Pay attention to colors of the leads at the plug connection! Terminal number Function Wire no. and cross–section Wire color A .......... Signal lead .......... 329-1 .......... white B .......... Ground .......... 050-1 .......... black Disconnect plugs (B). Replace the coolant temperature sender (A). <- Go to Section TOC Section 40 page 398 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 30: Monitoring Systems Assemble in reverse order. Add coolant until it reaches the required level. IMPORTANT: If you replace the sender for the coolant temperature gauge, you should check the instrument panel (BIF) for diagnostic codes. See “245-05-002 , Calling up addresses and diagnostic codes”. Replacing Acoustic Warning Signal Sending Unit LEGEND: A B Latches Acoustic alarm The acoustic alarm is located in the fuse and relay boxes behind the operator′s seat just below the rear window. Press down latches (A) and lift off the trim panel. Pull out acoustic alarm (B) and replace it with a new one. <- Go to Section TOC Section 40 page 399 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 30: Monitoring Systems For installation, follow removal procedure in reverse order. <- Go to Section TOC Section 40 page 400 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 40: Electrical Components Replace the Acoustic Alarm (Park Lock) on Tractors with AutoPowr/IVT Transmission LEGEND: A B Latches Acoustic Alarm for Park Lock The acoustic alarm for the park lock is located in the fuse and relay boxes behind the operator′s seat just below the rear window. Press down latches (A) and lift off the trim panel. Pull out the park lock′s acoustic alarm (B) and replace it with a new one. Re-assemble all parts in reverse order. IMPORTANT: If you replace the park lock sending unit on tractors with AutoPowr/IVT transmission, you must check the park lock controller (PLC) for diagnostic trouble codes. SeeOperation and General Information on Diagnostics Accessing the Addresses and Diagnostic Trouble Codes. <- Go to Section TOC Section 40 page 401 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM <- Go to Section TOC Group 40: Electrical Components Section 40 page 402 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 40: Electrical Components Group 40 - Electrical Components Electrical Components - Recondition (Summary of References) ”General information” ”Special tools” ”Specifications” ”Disconnecting electrical circuits” ”Replacing the 7-terminal power outlet socket” ”Replacing the 3-terminal power outlet socket” ”Replacing the multiple power-outlet socket strip” ”Replacing the service socket” ”Removing the wiper motor” ”Adjusting the headlights” ”Adjusting the lights on the cab frame” ”Safety instructions for replacing a halogen bulb” ”Safety instructions for replacing xenon (HID) bulbs and ballast units” ”Replacing xenon (HID) worklights and ballast units” General Information Parts not mentioned in this Group are described in the Groups dealing with the corresponding components. Special or Essential Tools →NOTE: Order tools according to information given in the U.S. SERVICEGARD ™ Catalog or European Microfiche Tool Catalog (MTC). Wiring harness repair kit JDG359 <- Go to Section TOC Section 40 page 403 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 40: Electrical Components Repairing DEUTSCH connectors Specifications Item Measurement Specification Wires to multiple power-outlet socket strip, hex. nut Torque 3 N˙m 2.2 lb-ft Multiple power-outlet socket strip to bracket, M6 cap screw Torque 5 N˙m 3.7 lb-ft Bracket of multiple power-outlet socket strip, M6 cap screw Torque 11 N˙m 8.5 lb-ft Disconnecting electrical circuits Before working on the electrical system, always disconnect battery ground strap (-). <- Go to Section TOC Section 40 page 404 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 40: Electrical Components Replacing the 7-Terminal Power Outlet Socket Take out the screws. Pull the cover off the rear of the power outlet socket. Pull the connector out of the rear of the power outlet socket. Replace the power outlet socket. Assemble in reverse order. Check the power supply to the seven terminals in the socket. Terminal 3 (A) is the ground connection. <- Go to Section TOC Section 40 page 405 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 40: Electrical Components Terminal Function Wire no. and cross section Wire color 1 (L) .......... L.h. turn signal .......... 125E-1 .......... dark green 2 (54G) .......... not used 3 (31) .......... Ground .......... 310DH-2.5 .......... black 4 (R) .......... R.h. turn signal .......... 107D-1 .......... pale purple 5 (58R) .......... R.h. tail light .......... 128D-1 .......... gray 6 (54) .......... Brake lights .......... 106E-1 .......... light blue 7 (58L) .......... L.h. tail light .......... 118D-1 .......... gray →NOTE: Power is supplied to terminals 1 (L) and 4 (R) via the turn signal control circuit. Terminals 5 (58R) and 7 (58L) are supplied with power via the light switch. Terminal 6 (54) is supplied with power via the brake switches. Terminal 2 (54G) does not receive any power. <- Go to Section TOC Section 40 page 406 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 40: Electrical Components Replacing the 3-Terminal Power Outlet Socket CAUTION: Disconnect negative (-) cable from battery. The 3-terminal power outlet socket is located in the rear wall of the operator′s cab, just below the fuse box on the r.h. side. Open the cover on the fuse box. Remove the trim panel. →NOTE: For identification purposes, mark the wires before disconnecting them. <- Go to Section TOC Section 40 page 407 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 40: Electrical Components Disconnect plug. Take out the screws that hold the socket on. Replace the power outlet socket. Connect wires to new socket. CAUTION: Make sure the wires are connected properly. For installation, follow removal procedure in reverse order. Check the power supply to the three terminals in the socket. Terminal 31 is the ground connection. Terminal no. Function Wire no. and cross section Wire color 15/30 .......... Battery voltage .......... 307HB-2.5 .......... purple 31 .......... Ground .......... 310HB-4 .......... black 82 .......... Electronics .......... 312HB-1.5 .......... red →NOTE: Terminal 82 is supplied via relay K10/3 when the main switch is in position IGN. During the starting procedure this terminal is dead. Terminal 15/30 is supplied with battery voltage from fuse F05/16. <- Go to Section TOC Section 40 page 408 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 40: Electrical Components Replacing the Multiple Power-Outlet Socket Strip CAUTION: Disconnect the battery ground cable (-). Remove floor mat and control console trim. Remove bracket cap screws from the outside of fender. Remove socket strip from bracket by removing the cap screws and nuts. →NOTE: For identification purposes, mark the wires before disconnecting them. Disconnect wires and replace socket strip. <- Go to Section TOC Section 40 page 409 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 40: Electrical Components CAUTION: Make sure wires are connected correctly. Connect wires to new socket strip. Item Measurement Specification Wires to multiple power-outlet socket strip, hex. nut Torque 3 N˙m 2.2 lb-ft Check the power supply to the three terminals in the multiple socket strip. Terminal 3 is the ground connection. Terminal Function Wire no. and cross section Wire color 1 .......... Electronics .......... 312D-2.5 .......... red 2 .......... Battery voltage .......... 214B-2.5 .......... yellow 3 .......... Ground .......... 310DH-4 .......... black →NOTE: Terminal 1 is supplied via relay K10/3 when the main switch is in position IGN. During the starting procedure this terminal is dead. Terminal 2 is supplied with battery voltage from fuse F05/16. Install socket strip to bracket using cap screws and nuts. Item Measurement Specification Multiple power-outlet socket strip to bracket, M6 cap screw Torque 5 N˙m 3.7 lb-ft Use cap screws to secure the socket strip to the fender. Item Measurement Specification Bracket of multiple power-outlet socket strip, M6 cap screw Torque 11 N˙m 8.5 lb-ft Replace trim and floor mat. <- Go to Section TOC Section 40 page 410 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 40: Electrical Components Replacing the Service Socket Operator′s cab (tractors with Stage I engine to 97/68/EC) The service socket is located in the rear wall of the operator′s cab, just below the fuse box on the l.h. side. Open the cover on the fuse box. Remove the trim panel. Disconnect the socket from the wiring harness. Take out the screws that hold the socket on. Replace socket and harness. For installation, follow removal procedure in reverse order. Operator′s cab (tractors with Stage II engine to 97/68/EC) <- Go to Section TOC Section 40 page 411 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 40: Electrical Components CAUTION: Disconnect negative (-) cable from battery. The service socket is located in the rear wall of the operator′s cab, just below the fuse box on the l.h. side. Open the cover on the fuse box. Remove the trim panel. Take out the screws that hold the socket on. Pull out socket to the rear. →NOTE: For identification purposes, mark the wires before extracting them. Extract service socket terminals using the appropriate extraction tool from JDG359 electrical repair tool kit. Wiring harness repair kit JDG359 Repairing DEUTSCH connectors For extracting service socket terminals refer to “"DEUTSCH Connectors"” in Section 40, Group 05. <- Go to Section TOC Section 40 page 412 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 40: Electrical Components CAUTION: Make sure that wires are connected correctly. Terminal no. Function Wire no. and cross section Wire color A .......... Ground 050-1 .......... black B .......... Battery voltage 952-1 .......... red C .......... CAN-BUS 934-1 .......... yellow D .......... CAN-BUS 935-1 .......... dark green E .......... — vacant F .......... — vacant G .......... — vacant H .......... — vacant J .......... — vacant Connect wires to new socket. For installation, follow removal procedure in reverse order. Removing the Wiper Motor <- Go to Section TOC Section 40 page 413 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: A B C D E F Group 40: Electrical Components Nut Wiper arm Motor cover Plug Screw Attaching screws Before removing the outer roof, see “ Removing the Outer Roof ”, Section 90, Group 25. Slide the roof back to gain access to the wiper motor. →NOTE: Mark the position of the wiper on the windshield. Take off nut (A) and pull off wiper arm (B). Remove motor cover (C). Disconnect plug (D). <- Go to Section TOC Section 40 page 414 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 40: Electrical Components Take out screw (E) and lift off the ground cable. Take out attaching screws (F) and lift off the wiper assembly. →NOTE: The wiper motor is not repairable. Replace the wiper motor assembly with a new one. Assemble in reverse order. <- Go to Section TOC Section 40 page 415 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 40: Electrical Components Adjusting the Headlights With testing device To adjust headlights, use a commercial headlight testing device with optical lens system. Test each light individually. Make the required corrections by turning adjusting screws (A). Without testing device <- Go to Section TOC Section 40 page 416 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 40: Electrical Components Park tractor on a level surface 5 m (16 ft 6 in) from a vertical wall. Using the adjusting screws, adjust each headlight so that the bright/dark border forms a horizontal line 5 cm (2 in.) lower than headlight height (H). Switch to full beam. Align the lights sideways so that the distance between the center of the light beams on the wall is the same as the distance (A) between the lights. Adjusting the Lights on the Cab Frame Adjust the setting of the lights by slackening screw (A) and nut (B). <- Go to Section TOC Section 40 page 417 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 40: Electrical Components Park tractor on a level surface 5 m (16.5 ft) from a vertical wall. Adjust each light so that the bright/dark border forms a horizontal line 29 cm (11 in.) lower than the height (H) of the lights. Switch to full beam. Align the lights sideways so that the distance between the center of the light beams on the wall is the same as the distance (A) between the lights. <- Go to Section TOC Section 40 page 418 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 40: Electrical Components Safety Instructions for Replacing a Halogen Bulb When replacing a halogen bulb, always comply with the following safety instructions: CAUTION: Always switch the lights off before you change a bulb. CAUTION: First allow the bulb to cool down (may cause burns). CAUTION: Wear safety goggles and gloves when changing the bulb. CAUTION: The bulb is made of glass and contains halogen gas; the bulb is under high pressure, so there is a risk of it shattering. CAUTION: Do NOT use any bulbs that have fallen on the ground or have scratches on their surface, as there is a risk of them shattering. CAUTION: Make sure that the bulb is seated correctly in its holder in the light. CAUTION: Check the light for signs of damage and make sure the seals are seated correctly. <- Go to Section TOC Section 40 page 419 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 40: Electrical Components IMPORTANT: Use only bulbs that are of the same type, same voltage and same wattage as the bulb that is being replaced. IMPORTANT: Never touch the glass surface of the halogen bulb, hold it only by its base. IMPORTANT: Use a clean cloth and alcohol to remove any fingerprints from the glass bulb. IMPORTANT: Old halogen bulbs that have been replaced must be disposed of properly (i.e. as hazardous waste). <- Go to Section TOC Section 40 page 420 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 40: Electrical Components Safety Instructions for Replacing Xenon (HID) Bulbs and Ballast Units When replacing a xenon (HID) bulb or ballast unit, it is essential to comply with the following safety instructions: CAUTION: Switch the light off and disconnect it from the power supply before changing a bulb. CAUTION: Never insert foreign objects or fingers into the bulb holder (high-tension voltage - potential for FATAL ACCIDENTS). CAUTION: The ballast unit must never be operated when the bulb is missing, as this may cause a dangerous flash-over at the bulb sockets, resulting in serious damage (high-tension voltage - potential for FATAL ACCIDENTS). CAUTION: First allow the bulb to cool down (may cause burns). CAUTION: Wear safety goggles and gloves when changing the bulb. CAUTION: The bulb is made of glass and contains xenon gas and metallic salts; the bulb is under high pressure, so there is a risk of it shattering. <- Go to Section TOC Section 40 page 421 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 40: Electrical Components CAUTION: Do NOT use any bulbs that have fallen on the ground or have scratches on their surface, as there is a risk of them shattering. CAUTION: Make sure that the bulb is seated correctly in its holder in the light. CAUTION: If a xenon (HID) bulb ever bursts inside a closed space (e.g. workshop), leave the area, making sure it is well ventilated, and wait for 20 minutes before returning. This will eliminate the risk to health caused by gases. CAUTION: Check the light for signs of damage and make sure the seals are seated correctly. CAUTION: High-tension voltage is conducted by the electrical connection between the worklights and the ballast unit; this connection must never be broken (high-tension voltage - potential for FATAL ACCIDENTS). CAUTION: Make sure that the power supply line between the worklights and ballast unit is never twisted through more than 90° and/or bent for more than a length of 20 mm (0.79 in.). IMPORTANT: Use only bulbs that are of the same type and wattage as the bulb that is being replaced. <- Go to Section TOC Section 40 page 422 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 40: Electrical Components IMPORTANT: Never touch the glass surface of the xenon bulb, hold it only by its base. IMPORTANT: Use a clean cloth and alcohol to remove any fingerprints from the glass bulb. IMPORTANT: Old xenon (HID) bulbs that have been replaced must be disposed of properly (i.e. as hazardous waste). <- Go to Section TOC Section 40 page 423 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 40: Electrical Components Replacing Xenon (HID) Worklights and Ballast Units General information CAUTION: For safety reasons, never attempt to repair a xenon (HID) worklight! CAUTION: Before replacing a xenon (HID) worklight or its ballast unit, always make sure that the battery is disconnected! CAUTION: Comply with safety instructions! The tractor may be equipped with high-intensity discharge (HID) xenon worklights. The identifying characteristic of these worklights is that they are elongated in comparison with other worklights. →NOTE: Unlike the bulbs on H3 worklights, which fail suddenly when the filament burns through or breaks, xenon (HID) bulbs show that they are approaching the end of their useful life by slowly losing their brightness. The end comes when the ballast unit ceases to ignite the xenon bulb. <- Go to Section TOC Section 40 page 424 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 40: Electrical Components Xenon (HID) worklights come in two versions: Version 1: In this case, the ballast unit is fixed to the worklight. Replacement always involves the ballast unit. Version 2: In this case, the ballast unit is connected to the worklight by a plug. The worklight and ballast unit can be replaced separately. →NOTE: Only complete xenon (HID) worklights including the ballast unit are supplied as spare parts. Removing xenon (HID) worklights <- Go to Section TOC Section 40 page 425 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM LEGEND: A B C D E 1 2 3 Group 40: Electrical Components Plug Lead Grommet Nut and washer Strap Green lead White lead Brown lead CAUTION: For safety reasons, never attempt to repair a xenon (HID) worklight! CAUTION: Before replacing a xenon (HID) worklight or its ballast unit, always make sure that the battery is disconnected! CAUTION: Comply with safety instructions! Before removing the outer roof, see reference ” Removing the Outer Roof ” in Section 90, Group 25. Pull out plug (A). Pull out the terminal lock and extract the terminals. <- Go to Section TOC Section 40 page 426 TM4756-REPAIR MANUAL Section 40 - ELECTRICAL SYSTEM Group 40: Electrical Components Pull lead (B) through grommet (C). Take off nuts and washers (D) and remove strap (E). Lift off the xenon (HID) worklight as an assembly complete with its mounting. Disassemble the mounting and replace the xenon (HID) worklight with a new one. Assemble in reverse order. Plug arrangement: Pull out the terminal lock. Insert the green lead in chamber 1, the white lead in chamber 2 and the brown lead in chamber 3; press them in until they engage. Press in the terminal lock. Removing the ballast unit LEGEND: A B C <- Go to Section TOC Plug Plug Rivets Section 40 page 427 TM4756-REPAIR MANUAL AUTOPOWR/IVT TRANSMISSION (g) by Belgreen CAUTION: For safety reasons, never attempt to repair a xenon (HID) worklight! CAUTION: Before replacing a xenon (HID) worklight or its ballast unit, always make sure that the battery is disconnected! CAUTION: Comply with safety instructions! Before removing the outer roof, see reference ” Removing the Outer Roof ” in Section 90, Group 25. Disconnect plugs (A) and (B). On the outside of the roof, drill out rivets (C). Replace the ballast unit with a new one. Assemble in reverse order. <- Go to Section TOC Section 40 page 428 TM4756-REPAIR MANUAL TM4756-REPAIR MANUAL (g) by Belgreen Section 53 - AUTOPOWR/IVT TRANSMISSION Table of contents Group 00 - Removal and Installation of AutoPowr/IVT Transmission ............................... 1 Special Tools .......................................................................................................................... 1 Dealer-Fabricated Special Tools ............................................................................................. 2 Repair Specifications .............................................................................................................. 3 Remove the AutoPowr/IVT Transmission ................................................................................ 5 Install the AutoPowr/IVT Transmission ................................................................................. 14 Group 05 - Transmission Shift Controls ............................................................................... 22 AutoPowr/IVT Transmission Shift Units - Reconditioning (Summary of References) ............. 22 Reconditioning the Speed Control Lever .............................................................................. 23 Reverser control, reconditioning .......................................................................................... 34 Reconditioning the Clutch Actuation Mechanism ................................................................. 37 Reconditioning the Manual Park Lock Release Mechanism .................................................. 43 Releasing the Park Lock Manually ........................................................................................ 45 Group 10 - Input Housing ....................................................................................................... 49 AutoPowr/IVT Transmission Input Housing - Reconditioning (Summary of References) ....... 49 Special Tools ........................................................................................................................ 50 Specifications ....................................................................................................................... 51 Installing and Removing the Vibration Damper (Repair Level 1 and 2) ................................ 53 Removing Clutch Control Block (Repair Level 1 and 2) ........................................................ 57 Repairing Clutch Control Block (Repair Level 1 and 2) ......................................................... 59 Installing Clutch Control Block (Repair Level 1 and 2) ......................................................... 66 Installing and Removing the Transmission Oil Filter (Repair Level 1 and 2) ........................ 71 Removing the System Pressure Control Block (Repair Level 1 and 2) ................................. 73 Installing System Pressure Control Block (Repair Level 1 and 2) ......................................... 76 Replacing Thermostat Valve (Repair Level 1 and 2) ............................................................ 81 Replacing Filter By-Pass Valve (Cold-Weather Starting) (Repair Level 1 and 2) ................... 82 Removing the Transmission Oil Pump (Repair Level 1 and 2) .............................................. 83 Repairing the Transmission Oil Pump (Repair Level 1 and 2) ............................................... 85 Installing the Transmission Oil Pump (Repair Level 1 and 2) ............................................... 89 Removing and Installing Front Plate (Repair Level 1 and 2) ................................................. 93 Separating Transmission Halves, Input/Output Housing (Repair Level 2) ............................ 99 Removing BG Disk Brake (Repair Level 2) ......................................................................... 101 Installing BG Disk Brake (Repair Level 2) ........................................................................... 104 Removing Shift Turret (Repair Level 2) .............................................................................. 107 Installing Shift Turret (Repair Level 2) ............................................................................... 111 Repairing Through-Drive Shaft (Repair Level 2) ................................................................. 113 Repairing P4 Planet Pinion Carrier and C3/C4 Clutch (Repair Level 2) ............................... 118 Repairing P4/BG Ring Gear (Repair Level 2) ...................................................................... 124 Removing Hydrostatic Unit (Repair Level 2) ...................................................................... 129 Installing Hydrostatic Unit (Repair Level 2) ........................................................................ 133 Repairing Hydrostatic Unit Output Shaft (Repair Level 2) .................................................. 139 Preparations for Installation of Individual Components in Input Housing (Repair Level 2) ..................................................................................................................................... 146 Measuring Gaps Between Transmission Shafts in Input/Output Housing (Repair Level 2) ..................................................................................................................................... 149 Joining Transmission Halves, Input/Output Housing (Repair Level 2) ................................. 155 <- Go to Global Table of contents TM4756-REPAIR MANUAL TM4756-REPAIR MANUAL (g) by Belgreen Layout and Location of the Individual Transmission Sending Units .................................... 157 Replacing Pressure Sending Units B87, S73, S74 of System Pressure Control Block (Repair Level 1 and 2) ............................................................................................................. 159 Replace Hydrostatic Unit Speed Sending Unit (B62) (Repair Level 1 and 2) ...................... 161 Group 15 - Output Housing .................................................................................................. 162 AutoPowr/IVT Transmission Output Housing - Reconditioning (Summary of References) ..................................................................................................................................... 162 Special Tools ...................................................................................................................... 163 Specifications ..................................................................................................................... 165 Removing Park Lock Control Block (Repair Level 1 and 2) ................................................. 167 Repairing Park Lock Control Block (Repair Level 1 and 2) .................................................. 169 Installing Park Lock Control Block (Repair Level 1 and 2) .................................................. 188 Repairing Locking Pawl of Park Lock (Repair Level 1 and 2) .............................................. 190 Removing Direction Turret and Reverse Intermediate Shaft (Repair Level 2) .................... 195 Removing Hydrostatic Unit Drive Shaft (Repair Level 2) .................................................... 200 Removing Through-Drive Shaft (Repair Level 2) ................................................................ 203 Removing Pneumatic Pump and Idler Gear (Repair Level 2) .............................................. 206 Installing Pneumatic Pump and Idler Gear (Repair Level 2) ............................................... 213 Installing Hydrostatic Unit Drive Shaft (Repair Level 2) ..................................................... 226 Installing Through-Drive Shaft (Repair Level 2) ................................................................. 230 Installing Direction Turret and Reverse Intermediate Shaft (Repair Level 2) ..................... 235 Layout and Location of the Individual Transmission Sending Units .................................... 241 Replacing Transmission Speed Sending Unit (B63) (Repair Level 1 and 2) ........................ 243 Replacing Transmission Input Speed Sending Unit (B61) (Repair Level 1 and 2) ............... 244 Replace the Transmission Output Speed Sending Unit (B84) (Repair Level 1 and 2) ......... 244 Replace Pressure Sending Unit (B90) for Park Lock Control Block (Repair Level 1 and 2) ..................................................................................................................................... 245 Group 20 - Differential Drive Shaft Assembly ................................................................... 247 AutoPowr/IVT Transmission - Differential Drive Shaft, Summary of References ................. 247 Specifications ..................................................................................................................... 247 Sectional View of Differential Drive Shaft .......................................................................... 247 Removing the Differential Drive Shaft ................................................................................ 249 Disassemble Differential Drive Shaft .................................................................................. 250 Cone Point Adjustment ....................................................................................................... 253 Assembling the Differential Drive Shaft ............................................................................. 256 <- Go to Global Table of contents TM4756-REPAIR MANUAL Group 00: Removal and Installation of AutoPowr/IVT Transmission Section 53 - AUTOPOWR/IVT TRANSMISSION Group 00 - Removal and Installation of AutoPowr/IVT Transmission Special Tools →NOTE: Order tools according to information given in the U.S. SERVICEGARD ™ Catalog or in the European Microfiche Tool Catalog (MTC). Lifting eye JDG19 Installing and removing tractor components Load-positioning sling D01042AA Installing and removing tractor components [ This tool permits the adjustment of the angle of the load being handled. ] <- Go to Section TOC Section 53 page 1 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 00: Removal and Installation of AutoPowr/IVT Transmission Dealer-Fabricated Special Tools Unlocking Device dealer fabricated LEGEND: A B C D E F Threaded rod M6, 170 mm (6.7 in.) Nut M6 (14M7272) Washer 20 mm x 2.5 mm (3/4” x 0.1 in.) Nut M6 (14M7272) Yoke (L80051) Pin (AL79051) For unlocking the park lock. Suspension Device dealer fabricated <- Go to Section TOC Section 53 page 2 TM4756-REPAIR MANUAL Group 00: Removal and Installation of AutoPowr/IVT Transmission Section 53 - AUTOPOWR/IVT TRANSMISSION LEGEND: A B C D E F G H I 145 mm (5.7 in.) 15 mm (0.6 in.) 15 mm (0.6 in.) Bore, 13 mm (1/2”) Bore, 11 mm (7/16”) 90 mm (3.54 in.) 15 mm (0.6 in.) 15 mm (0.6 in.) Bore, 11 mm (7/16”) For suspending the AutoPowr/IVT transmission horizontally.As feedstock, use equal angle steel 35 x 35 x 5 mm (1.4 x 1.4 x 0.2 in.) in accordance with DIN EN 10 025 (or similar norms). Repair Specifications Item Measurement Specification Cap Screws, AutoPowr/IVT Transmission to Differential Housing Torque 135 N˙m (100 lb.-ft.) Attaching Screws, Suction Line to Input Housing Torque 18 N˙m (13.5 lb.-ft.) <- Go to Section TOC Section 53 page 3 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 00: Removal and Installation of AutoPowr/IVT Transmission Item Measurement Specification Cap Screws, Front Cab Mountings to Main Frame Torque 240 N˙m 175 lb.-ft. <- Go to Section TOC Section 53 page 4 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 00: Removal and Installation of AutoPowr/IVT Transmission Remove the AutoPowr/IVT Transmission [1] - Tilt the cab up. See Tilting the Operator′s Cab Upward in Section 90, Group 00. [2] - Remove the front-wheel drive clutch. See Remove the Front-Wheel Drive Clutch in Section 56, Group 00. [3] - LEGEND: A B Drain Plug, AutoPowr/IVT Transmission Drain Plug, Differential Housing Remove plugs (A) and (B) and drain transmission/hydraulic oil. [4] - Remove the transmission oil filter(s) and hydraulic oil filter(s). [5] - Disconnect oil cooler hoses (B) where they join the transmission. Trap the oil as it emerges. Remove u.j. shaft and ring-shaped cooler (A). See Removing and Installing the Ring-Shaped Cooler in Section 56, Group 05. <- Go to Section TOC Section 53 page 5 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 00: Removal and Installation of AutoPowr/IVT Transmission [6] - Loosen the plastic ties at the fuel tank, push the tank outward and remove the mounting screws (A) of the front left cab mounting. Remove cab mounting. CAUTION: Depending on the amount of fuel in the tank, it can weigh up to approx. 200 kg (440 lb). Therefore proceed with due care and if in doubt, support the fuel tank to prevent it from falling. [7] - Remove suction line (A) and detach fittings (B) from the input housing. →NOTE: Trap the oil as it emerges. <- Go to Section TOC Section 53 page 6 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 00: Removal and Installation of AutoPowr/IVT Transmission [8] - Disconnect fittings (A), (B) and (C). [9] - Mark all the connectors so that they can be reinstalled in the same position, and completely detach the transmission harness from the input housing. Disconnect connectors (A), (B; 3 used), (C), (D) and (E). →NOTE: Some of the connectors are not visible in this illustration. Always mark all of the connectors to facilitate their re-installation, then disconnect them from the output housing. <- Go to Section TOC Section 53 page 7 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 00: Removal and Installation of AutoPowr/IVT Transmission Pull hose (F) off the hose fitting. Seal the end of the hose and the hose fitting, so that no dust can penetrate. [10] - Disengage the bowden cable for park lock disengagement both at yoke (A) and at counterbracket (B). In place of the bowden cable, install unlocking device (C; dealer-fabricated) as shown anddisengage the park lock. Do this by tightening the hex. nut on the device until the lever reaches the position (2) shown in the illustration. Disengage the park lock LEGEND: A B C 1 2 Yoke Counter-Bracket Special Tool (Dealer-Fabricated) Park Lock Engaged Park Lock Disengaged Unlocking Device dealer fabricated <- Go to Section TOC Section 53 page 8 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 00: Removal and Installation of AutoPowr/IVT Transmission LEGEND: A B C D E F Threaded rod M6, 170 mm (6.7 in.) Nut M6 (14M7272) Washer 20 mm x 2.5 mm (3/4” x 0.1 in.) Nut M6 (14M7272) Yoke (L80051) Pin (AL79051) For unlocking the park lock. CAUTION: The disengaging lever is subject to great tension. Improper handling may result in personal injury. [11] - <- Go to Section TOC Section 53 page 9 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 00: Removal and Installation of AutoPowr/IVT Transmission LEGEND: A B C D Special Tool (Dealer-Fabricated) JDG19 Lifting Eye JDG19 Lifting Eye D01042AA Load-Positioning Sling Screw the dealer-fabricated special tool (A) onto the output housing as shown and attach a lifting eye (B) to it. Attach another lifting eye (C) at the input housing. Lifting eye JDG19 Installing and removing tractor components Suspension Device dealer fabricated <- Go to Section TOC Section 53 page 10 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 00: Removal and Installation of AutoPowr/IVT Transmission LEGEND: A B C D E F G H I 145 mm (5.7 in.) 15 mm (0.6 in.) 15 mm (0.6 in.) Bore, 13 mm (1/2”) Bore, 11 mm (7/16”) 90 mm (3.54 in.) 15 mm (0.6 in.) 15 mm (0.6 in.) Bore, 11 mm (7/16”) For suspending the AutoPowr/IVT transmission horizontally.As feedstock, use equal angle steel 35 x 35 x 5 mm (1.4 x 1.4 x 0.2 in.) in accordance with DIN EN 10 025 (or similar norms). Load-positioning sling D01042AA <- Go to Section TOC Section 53 page 11 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 00: Removal and Installation of AutoPowr/IVT Transmission Installing and removing tractor components [ This tool permits the adjustment of the angle of the load being handled. ] Using load-positioning slings as a means of suspension (D), attach lifting tackle. IMPORTANT: When securing lifting eyes and lifting tackle, be sure to use high-grade hardware. Select screws that are long enough to be screwed in to the maximum depth available. →NOTE: The AutoPowr/IVT transmission must to be tilted as it is lifted out. It is therefore essential to use the D01042AA load-positioning slings. [12] - Take out all the screws on the flange. Then use a crowbar at the locations provided to lever the AutoPowr/IVT transmission off. →NOTE: Due to the use of flexible sealant, the housing flanges adhere to each other strongly. <- Go to Section TOC Section 53 page 12 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 00: Removal and Installation of AutoPowr/IVT Transmission Move the AutoPowr/IVT transmission as far forward as possible (viewed in direction of travel). [13] - Using the D01042AA load-positioning sling (A), move the AutoPowr/IVT transmission to the position shown and at the same time lift it up and out. →NOTE: As you raise the AutoPowr/IVT transmission, tilt it gradually. [14] - Put the AutoPowr/IVT transmission down and seal all the openings so that no dust can get in. <- Go to Section TOC Section 53 page 13 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 00: Removal and Installation of AutoPowr/IVT Transmission Install the AutoPowr/IVT Transmission [1] - Clean the housing flanges thoroughly and coat one side with a thin layer of LOCTITE ™ 574 (64500) flexible sealant. [2] - Install special tool (C; dealer-fabricated) anddisengage the park lock. Do this by tightening the hex. nut on the device until the lever reaches the position shown in the illustration (2). Disengage the park lock LEGEND: C 1 2 Special Tool (Dealer-Fabricated) Park Lock Engaged Park Lock Disengaged Unlocking Device dealer fabricated LEGEND: A B C Threaded rod M6, 170 mm (6.7 in.) Nut M6 (14M7272) Washer 20 mm x 2.5 mm (3/4” x 0.1 in.) <- Go to Section TOC Section 53 page 14 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION D E F Group 00: Removal and Installation of AutoPowr/IVT Transmission Nut M6 (14M7272) Yoke (L80051) Pin (AL79051) For unlocking the park lock. CAUTION: The disengaging lever is subject to great tension. Improper handling may result in personal injury. [3] - Install shaft (A). [4] - <- Go to Section TOC Section 53 page 15 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 00: Removal and Installation of AutoPowr/IVT Transmission LEGEND: A B C D Special Tool (Dealer-Fabricated) JDG19 Lifting Eye JDG19 Lifting Eye D01042AA Load-Positioning Sling Screw the dealer-fabricated special tool (A) onto the output housing as shown and attach a lifting eye (C) to it. Attach another lifting eye (B) at the input housing. Use load-positioning sling (D) to suspend the AutoPowr/IVT transmission at an angle (i.e. tilted), as shown. Lifting eye JDG19 Installing and removing tractor components Suspension Device dealer fabricated <- Go to Section TOC Section 53 page 16 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 00: Removal and Installation of AutoPowr/IVT Transmission For suspending the AutoPowr/IVT transmission horizontally. [ This bracket is bolted to the output housing. A JDG19 suspension eye is secured to the hole marked (D). ] Load-positioning sling D01042AA Installing and removing tractor components [ This tool permits the adjustment of the angle of the load being handled. ] <- Go to Section TOC Section 53 page 17 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 00: Removal and Installation of AutoPowr/IVT Transmission IMPORTANT: When securing lifting eyes and lifting tackle, be sure to use high-grade hardware. Select screws that are long enough to be screwed in to the maximum depth available. →NOTE: As you lower the transmission, gradually align the input housing until it is horizontal in relation to the differential housing. [5] - When the AutoPowr/IVT transmission is in the position shown, the input flange of the transmission must be turned until you feel the teeth engage. Then place the AutoPowr/IVT transmission against the differential housing so that proper contact is achieved, and install the attaching screws. [6] - Tighten all attaching screws to the specified torque. Item Measurement Specification Cap Screws, Output Housing to Differential Housing Torque 135 N˙m (100 lb.-ft.) <- Go to Section TOC Section 53 page 18 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 00: Removal and Installation of AutoPowr/IVT Transmission →NOTE: Some of the attaching screws are hard to reach. In this case, use a suitable, commercially-available tool. [7] - Engage the park lock, remove unlocking device (A) and install the bowden cable. CAUTION: The disengaging lever is subject to great tension. Improper handling may result in personal injury. [8] - For further installation, follow removal procedure in reverse order. <- Go to Section TOC Section 53 page 19 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 00: Removal and Installation of AutoPowr/IVT Transmission [9] - For information on installing the ring-shaped cooler and u.j. shaft (A), see Removing and Installing the Ring-Shaped Cooler in Section 56, Group 05. Connect the oil hoses (B). IMPORTANT: Every time you disconnect an oil hose with a quick-coupler, replace the retaining clip with a new one. Once clips are installed, check that they are seated correctly. The bent ends of the clip must touch each other. Otherwise, the coupler can become loose. [10] - Connect transmission harness (B) at all its connecting points, and lay out the harness. IMPORTANT: Pay attention to the following points when laying out harnesses and hoses: Before installing, inspect for damage and replace if necessary Do not subject them to tension, crushing or bending forces Do not install them in the vicinity of moving parts Keep them away from sharp edges <- Go to Section TOC Section 53 page 20 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 05: Transmission Shift Controls [11] - Check the seals, install suction line (A) and tighten the attaching screws to the specified torque. Item Measurement Specification Attaching Screws, Suction Line to Input Housing Torque 18 N˙m (13.5 lb.-ft.) Connect lines (B). [12] - Install front-wheel drive clutch. See Install the Front-Wheel Drive Clutch in Section 56, Group 00. [13] - Top up with transmission/hydraulic oil. [14] - Install cab mounting and tighten cap screws (A) to the specified torque. Item Measurement Specification Cap Screws, Front Cab Mountings to Main Frame Torque 240 N˙m 175 lb.-ft. [15] - Install fuel tank. [16] - Tilt operator′s cab back down. See Tilting the Operator′s Cab Downward in Section 90, Group 00. <- Go to Section TOC Section 53 page 21 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 05: Transmission Shift Controls Group 05 - Transmission Shift Controls AutoPowr/IVT Transmission Shift Units Reconditioning (Summary of References) ”Reconditioning the speed control lever” ”Reconditioning the reverser control” ”Reconditioning the clutch actuation mechanism” ”Reconditioning the manual park lock release mechanism” ”Releasing the park lock manually” <- Go to Section TOC Section 53 page 22 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 05: Transmission Shift Controls Reconditioning the Speed Control Lever CAUTION: When performing the work described below, comply with the safety instructions in the relevant Technical Manuals. CAUTION: Components that are coated with locking paint must NOT be opened, adjusted or repaired. These components may only be replaced as complete assemblies. IMPORTANT: DISCONNECT ELECTRICAL CIRCUIT Before working on the electrical system, always disconnect battery ground cable (-). Removing and installing the grip on the speed control lever <- Go to Section TOC Section 53 page 23 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 05: Transmission Shift Controls [1] - Take out the attaching screw (A) and lift off half (B) of the grip. [2] - Using a screwdriver, carefully pry out cover (A) together with its bearing (see exploded view). [3] - Take out support (A). →NOTE: Hold the potentiometer still while you unscrew the support. [4] - Remove speed wheel (B). <- Go to Section TOC Section 53 page 24 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 05: Transmission Shift Controls [5] - Disconnect plug (A), which connects potentiometer (B). [6] - Remove attaching screws (A). [7] - Remove half (B) of the grip from the speed control lever. [8] - Remove the lower halves (A) of the grip. <- Go to Section TOC Section 53 page 25 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 05: Transmission Shift Controls [9] - Recondition the speed control lever as required. Assembly: Re-assemble the parts in reverse order, referring to the exploded view (drawing). IMPORTANT: When installing the potentiometer on the rear threads (see arrow), apply a little LOCTITE ™ 241 in order to secure support (C) (see exploded view). Hold the potentiometer still while you tighten support (C). Item Measurement Specification Support Torque 1.2 N˙m 0.89 lb-ft Exploded view showing the grip on the speed control lever <- Go to Section TOC Section 53 page 26 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION LEGEND: A B C D E F G H K Group 05: Transmission Shift Controls Cover Bearing Support Speed wheel Left half of grip Potentiometer Right half of grip Bottom left half of grip Bottom right half of grip Removing and installing the operation unit <- Go to Section TOC Section 53 page 27 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 05: Transmission Shift Controls [1] - Take out attaching screws (A). [2] - Remove operation unit (B) together with its cover. [3] - Disconnect the operation unit from its electrical connectors. →NOTE: Before pulling out the connectors, mark them so as to avoid installing them in the wrong positions. [4] - Remove strap (A). <- Go to Section TOC Section 53 page 28 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 05: Transmission Shift Controls [5] - Remove attaching screws (B). [6] - Pull out connector (C). [7] - Take the operation unit out of its cover. Removing and installing the operation unit (tractors with Command Arm) [1] - Take out attaching screws (A). <- Go to Section TOC Section 53 page 29 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 05: Transmission Shift Controls [2] - On the underside, take out attaching screws (A). [3] - Disconnect the operation unit (A) from its electrical connectors. →NOTE: Before pulling out the connectors, mark them so as to avoid installing them in the wrong positions. [4] - Remove attaching screws (A). <- Go to Section TOC Section 53 page 30 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 05: Transmission Shift Controls [5] - Take the operation unit out of its cover. Replacing the potentiometer and switchboard [1] - Take off cable binders (A). [2] - Take out attaching screws (B) and disconnect plug (C). [3] - Take off the wiring harness together with the switchboard. [4] - Remove retaining nuts (A). <- Go to Section TOC Section 53 page 31 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 05: Transmission Shift Controls [5] - Carefully pull potentiometer (B) out of toothed segment (C). →NOTE: While doing so, make sure that spring (D) does not fall out. [6] - Assembly: Re-assemble the parts in reverse order, referring to the exploded view (drawing). IMPORTANT: When installing the potentiometer, make sure that the toothed segment is inserted as shown, with the broad tooth (A) in the corresponding gap. Also, remember to check that spring (B) is installed in the correct position. The toothed segment must be free to move within the backlash range; it must be returned by the force of the spring. Exploded view of operation unit <- Go to Section TOC Section 53 page 32 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION LEGEND: A B C D E F G H I J <- Go to Section TOC Group 05: Transmission Shift Controls Right half of grip Grip assembly Gate (with Command Arm) Gate Strap Potentiometer Wiring harness assembly and switchboard Operation unit Spring Toothed segment Section 53 page 33 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 05: Transmission Shift Controls Reverser control, reconditioning CAUTION: When performing the work described below, comply with the safety instructions in the relevant Technical Manuals. CAUTION: Components that are coated with locking paint must NOT be opened, adjusted or repaired. These components may only be replaced as complete assemblies. IMPORTANT: DISCONNECT ELECTRICAL CIRCUIT Before working on the electrical system, always disconnect battery ground cable (-). <- Go to Section TOC Section 53 page 34 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 05: Transmission Shift Controls [1] - Remove steering wheel (A). [2] - Remove multi-function unit (B). [3] - Remove attaching screws (A). [4] - Fold back trim panel (A). <- Go to Section TOC Section 53 page 35 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 05: Transmission Shift Controls [5] - Remove attaching screws (A). [6] - Remove the reverse drive lever (A) from the multi-function unit. →NOTE: Do not remove any more parts from reverse drive lever. The reverse drive lever can only be replaced as an assembly (order through normal parts channels). Install new reverse drive lever, reversing removal procedure. <- Go to Section TOC Section 53 page 36 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 05: Transmission Shift Controls Reconditioning the Clutch Actuation Mechanism CAUTION: When performing the work described below, comply with the safety instructions in the relevant Technical Manuals. CAUTION: Components that are coated with locking paint must NOT be opened, adjusted or repaired. These components may only be replaced as complete assemblies. IMPORTANT: DISCONNECT ELECTRICAL CIRCUIT Before working on the electrical system, always disconnect battery ground cable (-). Replacing the potentiometer <- Go to Section TOC Section 53 page 37 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 05: Transmission Shift Controls [1] - Fold back the cup holder (A). [2] - Use a Phillips-head screwdriver to take out retaining screws (B), and lift off trim (C). [3] - Disengage ball joint (A) at the potentiometer. [4] - Take out attaching screws (A). [5] - Pull off connector (B) and take off the potentiometer. Assembly: Re-install the parts in reverse order, referring to the exploded view (drawing). <- Go to Section TOC Section 53 page 38 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 05: Transmission Shift Controls Reconditioning the clutch pedal [1] - Disengage ball joint (A) at the potentiometer. [2] - Take off hex. nut (B). →NOTE: Proceed with care, as the components are subject to preload. [3] - Take out retaining screw (C) and lift out the clutch pedal. [4] - Take belleville spring (A), back-up ring (B) and friction washer (C) off the bearing journal (D). <- Go to Section TOC Section 53 page 39 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 05: Transmission Shift Controls [5] - Recondition the clutch actuation as required. Assembly: Re-install the parts in reverse order, referring to the exploded view (drawing). [6] - Locate the clutch pedal on adapter (A) and tighten hex. nut (B) by hand. [7] - Now install the clutch pedal on the bearing journal of the console. [8] - Tighten retaining screw (C) just enough for the pedal to touch console but remain free of play. Now tighten the attaching screw to its final torque value. Item Measurement Specification Self-locking retaining screw, clutch pedal to console Torque 10 N˙m 7 lb-ft IMPORTANT: The clutch pedal′s retaining screw has a self-locking capability; for this reason, every time it is removed, it must be replaced with a new one. [9] - Adjust the preload at spring (A). Screw in hex. nut (B) until dimension (C) is 7.5 mm (0.3 in.). Exploded view of clutch actuation mechanism <- Go to Section TOC Section 53 page 40 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION LEGEND: A B C D E F G H I J K L M N O <- Go to Section TOC Group 05: Transmission Shift Controls Console Belleville spring Back-up ring Friction washer Hex. nut Bearing Ball socket Clutch pedal Bushing Washer Self-locking fillister screw Stop Potentiometer (B65) Cover Ball end Section 53 page 41 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION P Q R S T U V <- Go to Section TOC Group 05: Transmission Shift Controls Ball joint assembly Leaf spring Adapter Spring Adapter Retaining screw Wiring harness, with clutch pedal switch (S72) Section 53 page 42 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 05: Transmission Shift Controls Reconditioning the Manual Park Lock Release Mechanism [1] - Fold back the cup holder (A). [2] - Use a Phillips-head screwdriver to take out retaining screws (B), and lift off trim (C). [3] - Referring to the drawing that shows the exploded view, remove and install the park lock release bowden cable (A). IMPORTANT: When removing and installing the bowden cable, take care not to bend it. When routing the bowden cable, take care that it does not chafe and is not subjected to tension. Exploded view of manual park lock release mechanism <- Go to Section TOC Section 53 page 43 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION LEGEND: A B C D E F G H <- Go to Section TOC Group 05: Transmission Shift Controls Threaded pin Knurled nut Bowden cable Clamp Plug Clamp Spring clip Pin Section 53 page 44 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 05: Transmission Shift Controls Releasing the Park Lock Manually CAUTION: Perform the manual park lock release procedure only when the tractor needs to be towed and the park lock cannot be released normally. CAUTION: The reverse drive lever must be in the "Park" position in order to manually release the park lock. CAUTION: The tractor must never be operated (even for short test drives) when the park lock is manually released. CAUTION: The tractor can roll away when the park lock is disengaged. Secure the tractor so that it cannot roll either forwards or backwards. CAUTION: After towing, the manual park lock release cable must be reconnected. <- Go to Section TOC Section 53 page 45 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 05: Transmission Shift Controls [1] - Fold back the cup holder (A). [2] - Use a Phillips-head screwdriver to take out retaining screws (B), and lift off trim (C). [3] - Take plug (A) out of the threaded bore. [4] - Disconnect bowden cable (A) from the clamp. <- Go to Section TOC Section 53 page 46 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 05: Transmission Shift Controls [5] - Unscrew threaded stud (A) and knurled nut (B). [6] - Slightly depress the clutch pedal. [7] - Thread the bowden cable (A) through the eye (B) on the clutch pedal or adapter. <- Go to Section TOC Section 53 page 47 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [8] - Adjust the cable with knurled nut (A) until all slack is removed. Knurled section must be uppermost. IMPORTANT: The cable must be tight in order to assure complete release of the park lock. [9] - Fully depress clutch pedal. IMPORTANT: If the clutch pedal cannot be depressed to the stop and the threaded stud cannot be adjusted further, unscrew the knurled nut until the clutch pedal can be depressed against its stop. [10] - Screw threaded stud (A) into opening (B) in order to secure the clutch in this position and maintain the park lock in the released position. <- Go to Section TOC Section 53 page 48 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Group 10 - Input Housing AutoPowr/IVT Transmission Input Housing Reconditioning (Summary of References) ”Special tools” ”Specifications” ”Installing and removing the vibration damper” ”Removing the clutch control block” ”Reconditioning the clutch control block” ”Installing the clutch control block” ”Removing and installing the transmission oil filter” ”Removing the system pressure control block” ”Installing the system pressure control block” ”Replacing the thermostat valve” ”Replacing the filter by-pass valve (cold-weather starting)” ”Removing the transmission oil pump” ”Reconditioning the transmission oil pump” ”Installing the transmission oil pump” ”Removing and installing the front plate” ”Removing the BG disk brake” ”Installing the BG disk brake” ”Removing the shift turret” ”Installing the shift turret” ”Reconditioning the through-drive shaft” ”Reconditioning the P4 planetary carrier and C3/C4 clutch” ”Reconditioning the ring gear (P4/BG)” <- Go to Section TOC Section 53 page 49 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing ”Removing the hydrostatic unit” ”Installing the hydrostatic unit” ”Reconditioning the hydrostatic unit output shaft” ”Preparations for installation of individual components in input housing” ”Measuring gaps between transmission shafts in input/output housing” ”Separating transmission halves, input/output housing” ”Joining transmission halves, input/output housing” ”Layout/location of individual transmission sending units” ”Replacing pressure sending units (B87, S73, S74) of system pressure control block” ”Replacing the hydrostatic speed sending unit (B62)” Special Tools →NOTE: Order tools according to information given in the U.S. SERVICEGARD ™ Catalog or European Microfiche Tool Catalog (MTC). Seal installer KJD10235 Installation of transmission oil pump seal (repair level 1 and 2) <- Go to Section TOC Section 53 page 50 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Specifications Item Measurement Specification Fitting, vibration damper Torque 80 N˙m 59 lb-ft Solenoid valves to control block, attaching screws Torque 6 N˙m 4 lb-ft Proportional valves to control block, attaching screws Torque 6 N˙m 4 lb-ft Passage plate to control block, attaching screws Torque 10 N˙m 7 lb-ft Clutch control block to input housing, attaching screws Torque 10 N˙m 7 lb-ft Screw plug on cover, clutch control block Torque 25 N˙m 18 lb-ft Clutch control block cover to housing, attaching screws Torque 10 N˙m 7 lb-ft Thermostat valve, M36 x 1.5 screw plug Torque 130 N˙m 95 lb-ft Filter by-pass valve (cold-weather starting), M22 x 1.5 screw plug Torque 30 N˙m 22 lb-ft Filter housing to system pressure control block Torque 50-60 N˙m 37-44 lb-ft System pressure control block, screws for filter plate on valve plate Torque 6 N˙m 4 lb-ft System pressure control block to transmission housing, attaching screws Torque 10 N˙m 7 lb-ft Pressure sending unit on filter housing Torque 12 N˙m 9 lb-ft Cable holder to filter housing, attaching screw Torque 9 N˙m 7 lb-ft Transmission oil pump attaching screws Torque 23 N˙m 17 lb-ft Front plate, M14x1.5 screw plug Torque 35 N˙m 26 lb-ft Front plate, M18x1.5 screw plug Torque 50 N˙m 37 lb-ft Front plate, M20x1.5 screw plug Torque 55 N˙m 40 lb-ft Front plate attaching screws <- Go to Section TOC Torque Section 53 page 51 23 N˙m TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Item Group 10: Input Housing Measurement Specification 17 lb-ft Front plate, fitting Torque 80 N˙m 59 lb-ft BG disk brake, attaching screws Torque 115 N˙m 85 lb-ft Cable holder, attaching screws Torque 10 N˙m 7 lb-ft Hydrostatic unit, end play End play 0.2 — 0.5 mm 0.008 — 0.020 in. Pressure hose to fitting Torque 40 N˙m 30 lb-ft Pressure hose to hydrostatic unit, hollow screw Torque 50 N˙m 37 lb-ft Hydrostatic unit, attaching cap screws Torque 115 N˙m 85 lb-ft Pressure hose to elbow Torque 80 N˙m 59 lb-ft Transmission housing, M14x1.5 screw plugs Torque 35 N˙m 26 lb-ft Transmission housing, M38x2 screw plugs Torque 140 N˙m 103 lb-ft Elbow, hex. nut Torque 80 N˙m 59 lb-ft Hydrostatic unit pressure hose, fitting Torque 50 N˙m 37 lb-ft End play between shift turret and direction turret End play 0,20 — 0,40 mm 0.008 — 0.016 in. Direction turret taper roller bearing End play 0 — 0,08 mm 0 — 0.003 in. Output to input housing, attaching screws Torque 46 N˙m 34 lb-ft Hydrostatic speed sending unit Torque 10 N˙m 7 lb-ft <- Go to Section TOC Section 53 page 52 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Installing and Removing the Vibration Damper (Repair Level 1 and 2) Vibration damper removal [1] - Loosen fittings (A) and remove vibration damper (B). [2] - Remove the line. <- Go to Section TOC Section 53 page 53 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [3] - Remove the fitting. [4] - Remove the line. [5] - Remove fitting with filter. Vibration damper installation <- Go to Section TOC Section 53 page 54 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [1] - Install O-rings (A) and (B) at the fittings. Fitting with filter Fitting [2] - Install fitting with filter (A) onshorter end of vibration damper. <- Go to Section TOC Section 53 page 55 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [3] - Install fitting (B). Tighten the fittings (A) and (B). Item Measurement Specification Fitting, vibration damper Torque 80 N˙m 59 lb-ft [4] - Install lines at vibration damper but do not tighten connections yet. [5] - Install vibration damper (B) with lines on transmission and align [6] - Tighten the fittings (A). Item Measurement Specification Fitting, vibration damper Torque 80 N˙m 59 lb-ft <- Go to Section TOC Section 53 page 56 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Removing Clutch Control Block (Repair Level 1 and 2) Preliminary work: For information on removing the left half of the main frame, refer to “Removing and installing the main frame (summary of references)” . [1] - Remove screw plug (A) from the underside of the cover and drain oil. [2] - Take attaching screws (B) out of the cover. Remove cover and gasket. [3] - Disconnect harness from solenoid and proportional valves. [4] - Pull temperature sending unit (A) out of the bore. <- Go to Section TOC Section 53 page 57 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [5] - Take the attaching screws out of the control block. While doing this, make sure not to drop the control block. [6] - Remove control block and gasket <- Go to Section TOC Section 53 page 58 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Repairing Clutch Control Block (Repair Level 1 and 2) Preliminary work: Refer to “Removing the clutch control block” . Clutch control block - Sectional view LEGEND: A B C <- Go to Section TOC Solenoid valve, BG disk brake Solenoid valve, C1 clutch Solenoid valve, C2 clutch Section 53 page 59 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION D E F G H I J Group 10: Input Housing Solenoid valve, C4 clutch Solenoid valve, C3 clutch CF proportional valve Damper piston CF Damper piston CR CR proportional valve Pressure reduction valve Disassembly of clutch control block [1] - Take attaching screws (A) out of the passage plate. Remove passage plate and gasket. [2] - If required, remove both screens (see arrows) from the passage plate. <- Go to Section TOC Section 53 page 60 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [3] - Remove attaching screws (A) and retaining plates (B) of proportional valves. [4] - Pull both proportional valves out of bore. [5] - Remove attaching screws and retaining plates. Remove the solenoid valves. →NOTE: The solenoid valves are subject to great tension. →NOTE: Do not remove any more parts from clutch control block. The clutch control block can be ordered as an assembly through normal parts channels. Clutch control block assembly <- Go to Section TOC Section 53 page 61 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [1] - Before re-installing proportional and solenoid valves check O-rings (A), and replace them as necessary. [2] - Install solenoid valves using retaining plates and screws. →NOTE: Insert retaining plates with the claw facing the housing. →NOTE: Align solenoid valves before tightening, using the drawing as a guide. Item Measurement Specification Solenoid valves to control block, attaching screws Torque 6 N˙m 4 lb-ft <- Go to Section TOC Section 53 page 62 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [3] - Install proportional valves using retaining plates and screws. →NOTE: Insert retaining plates with the claw facing the housing. →NOTE: Align proportional valves before tightening, using the drawing as a guide. Item Measurement Specification Proportional valves to control block, attaching screws Torque 6 N˙m 4 lb-ft [4] - Align solenoid and proportional valves as shown on drawing and tighten them. <- Go to Section TOC Section 53 page 63 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [5] - Place gasket on control block. →NOTE: For easier installation use two attaching screws (see arrows). [6] - Insert both screens (A) in passage plate. IMPORTANT: The convex side of the screens must face downward. <- Go to Section TOC Section 53 page 64 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [7] - Place passage plate on control block. [8] - Insert attaching screws (A) and tighten them. Item Measurement Specification Passage plate to control block, attaching screws Torque 10 N˙m 7 lb-ft Final assembly: Refer to “Installing the clutch control block” . <- Go to Section TOC Section 53 page 65 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Installing Clutch Control Block (Repair Level 1 and 2) [1] - Install control block with gasket (A). [2] - Slightly tighten attaching screws. →NOTE: During installation, note the different screw lengths. <- Go to Section TOC Section 53 page 66 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [3] - For the time being, tighten attaching screws to 7 N˙m (5 lb-ft) in ascending order of the position numbers indicated in the drawing. [4] - Tighten attaching screws now to their final torque in ascending order of the position numbers indicated in the drawing. Item Measurement Specification Clutch control block to input housing, attaching screws Torque 10 N˙m 7 lb-ft <- Go to Section TOC Section 53 page 67 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [5] - Put harness in place and connect to solenoid and proportional valves. [6] - The mounting depth of temperature sending unit is limited by a cable binder. Mounting depth is 20 mm (0.78 in.); it must be checked before installation. [7] - Insert temperature sending unit (A) into the bore. <- Go to Section TOC Section 53 page 68 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [8] - Install screw plug with O-ring on cover and tighten. Item Measurement Specification Screw plug on cover, clutch control block Torque 25 N˙m 18 lb-ft [9] - Install the gasket. <- Go to Section TOC Section 53 page 69 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [10] - Install cover. IMPORTANT: During installation take care that the gasket remains in place and the harness is not trapped. [11] - Install attaching screws and tighten them evenly. Item Measurement Specification Clutch control block cover to housing, attaching screws Torque 10 N˙m 7 lb-ft Final assembly: For information on installing the left half of the main frame, refer to “Removing and installing the main frame (summary of references)” . <- Go to Section TOC Section 53 page 70 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Installing and Removing the Transmission Oil Filter (Repair Level 1 and 2) Removing the transmission oil filter [1] - Remove filter housing (A). [2] - Take the filter element out of the filter housing. [3] - Remove O-ring (A). Installing the transmission oil filter <- Go to Section TOC Section 53 page 71 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [1] - Check O-ring (A) and filter element. Replace, if necessary. [2] - Install O-ring (B) in the groove in the filter housing. [3] - Attach filter housing (A) with element and tighten. Item Measurement Specification Filter housing to system pressure control block Torque 50—60 N˙m 37—44 lb-ft <- Go to Section TOC Section 53 page 72 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Removing the System Pressure Control Block (Repair Level 1 and 2) Preliminary work: Refer to "Remove engine u.j. shaft" . Refer to “Removing and installing the transmission oil filter” . [1] - Remove the cable holder. [2] - LEGEND: A B C Sending unit, cold-weather starting valve (B87): Sending unit, oil filter restriction indicator light (S73) Sending unit, system pressure indicator light (S74) Remove sending units (A), (B) and (C). <- Go to Section TOC Section 53 page 73 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [3] - Take the attaching screws out of the control block. [4] - Lift off filter plate and gasket. <- Go to Section TOC Section 53 page 74 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [5] - Remove valve plate and gasket. →NOTE: Only the cold-weather starting valve may be replaced on the system pressure control block. Refer to"Replacing filter by-pass valve (coldweather starting)". Do not remove any more parts. →NOTE: The valve plate can be ordered as an assembly through normal parts channels. Final assembly: Refer to “Installing the system pressure control block” . <- Go to Section TOC Section 53 page 75 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Installing System Pressure Control Block (Repair Level 1 and 2) [1] - LEGEND: A B C D Gasket Valve plate Gasket Filter plate Assemble system pressure control block using two attaching screws (see illustration). →NOTE: If transmission is removed, use two opposite attaching screws. If transmission is not removed, use the two long upper attaching screws. <- Go to Section TOC Section 53 page 76 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [2] - Install the system pressure control block. [3] - Insert attaching screws. [4] - For the time being, tighten attaching screws to 7 N˙m (5 lb-ft) in ascending order of position numbers indicated in the drawing. [5] - <- Go to Section TOC Section 53 page 77 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Tighten attaching screws now to their final torque in ascending order of the position numbers indicated in the drawing. Item Measurement Specification System pressure control block to transmission housing, attaching screws Torque 10 N˙m 7 lb-ft <- Go to Section TOC Section 53 page 78 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [6] - Check the O-ring (A) at the pressure sending unit and replace if necessary. [7] - LEGEND: A B C Sending unit for filter by-pass valve (B87; cold-weather starting) Sending unit, oil filter restriction indicator light (S73) Sending unit, system pressure indicator light (S74) Secure pressure sending units (A), (B) and (C). Item Measurement Specification Pressure sending unit on filter housing Torque 12 N˙m 9 lb-ft <- Go to Section TOC Section 53 page 79 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [8] - Secure cable from sending unit for system pressure indicator light using the cable holder. Item Measurement Specification Cable holder to filter housing, attaching screw Torque 9 N˙m 7 lb-ft [9] - Tie the sending unit cables together as illustrated by using cable straps. Final assembly: Reference ”Removing and installing the transmission oil filter” . Reference "Install engine u.j. shaft" . <- Go to Section TOC Section 53 page 80 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Replacing Thermostat Valve (Repair Level 1 and 2) [1] - Take out screw plug (A). [2] - Thermostat valve - exploded view LEGEND: A B C D E Spring Thermal element Disk O-ring Screw plug Disassemble thermostat valve. [3] - After installation of new valve tighten screw plug to the specified torque. Item Measurement Specification Thermostat valve, M36 x 1.5 screw plug Torque 130 N˙m 95 lb-ft <- Go to Section TOC Section 53 page 81 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Replacing Filter By-Pass Valve (Cold-Weather Starting) (Repair Level 1 and 2) [1] - Take out screw plug (A). [2] - Filter by-pass valve (cold-weather starting) - exploded view LEGEND: A B C D E Thermal element Piston Spring O-ring Screw plug Disassemble filter by-pass valve (cold-weather starting). [3] - After installation of new valve tighten screw plug to the specified torque. Item Measurement Specification Filter by-pass valve (cold-weather starting), M22 x 1.5 screw plug Torque 30 N˙m 22 lb-ft <- Go to Section TOC Section 53 page 82 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Removing the Transmission Oil Pump (Repair Level 1 and 2) Preliminary work: Refer to "Remove engine u.j. shaft" . [1] - Remove shaft seal ring from housing. →NOTE: Removal always damages the seal ring. [2] - Remove the snap ring. <- Go to Section TOC Section 53 page 83 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [3] - Take out the attaching screws. [4] - Use two M6 screws (A) to press off the transmission oil pump′s housing and then remove it. <- Go to Section TOC Section 53 page 84 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Repairing the Transmission Oil Pump (Repair Level 1 and 2) Preliminary work: Refer to “Removing the transmission oil pump” . Disassembling the transmission oil pump [1] - Remove O-ring (A). [2] - Remove pump gear (C) and toothed ring (B) from housing (A). <- Go to Section TOC Section 53 page 85 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [3] - Remove the snap ring. [4] - Remove the ball bearing. Assembling the transmission oil pump [1] - Install the ball bearing. <- Go to Section TOC Section 53 page 86 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [2] - Install the snap ring. [3] - Install the toothed ring with chamfer (see arrow) facing downward. [4] - Install the pump gear with chamfer (see arrow) facing downward. <- Go to Section TOC Section 53 page 87 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [5] - Install O-ring (A). Final assembly: Refer to “Installing the transmission oil pump” . <- Go to Section TOC Section 53 page 88 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Installing the Transmission Oil Pump (Repair Level 1 and 2) [1] - Heat up bearing cone of ball bearing. [2] - Move the transmission oil pump to correct position at the front plate until it stops. <- Go to Section TOC Section 53 page 89 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [3] - Tighten the attaching screws on the transmission oil pump. Item Measurement Specification Transmission oil pump attaching screws Torque 23 N˙m 17 lb-ft <- Go to Section TOC Section 53 page 90 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [4] - Install the snap ring. →NOTE: If the snap ring does not engage, the through-drive shaft has to be pulled out until it can go no further. →NOTE: Before attaching extracting tool remove O-ring from through-drive shaft to avoid damage. <- Go to Section TOC Section 53 page 91 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [5] - Install seal ring with LOCTITE ™ 242 (TY9370). Seal installer KJD10235 Installation of transmission oil pump seal. [6] - Use KJD10235 seal installer (A) to install the seal ring. →NOTE: Insert seal ring flush with base of the chamfer. Do not insert seal ring up to stop. Final assembly: Refer to "Install engine u.j. shaft" . <- Go to Section TOC Section 53 page 92 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Removing and Installing Front Plate (Repair Level 1 and 2) Preliminary work: Refer to “Removing the system pressure control block” . Refer to “Removing the transmission oil pump” . Removing the front plate [1] - Remove threaded connector, if necessary. [2] - Take the retaining screws out of the front plate. CAUTION: Secure the front plate so that it does not fall off (see next step). <- Go to Section TOC Section 53 page 93 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [3] - Detach the front plate from the housing. CAUTION: During disassembly, secure the front plate with two M8 threaded rods (A) so that it does not fall off. [4] - Remove front plate. <- Go to Section TOC Section 53 page 94 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [5] - Remove gasket. Installing the front plate [1] - Insert dowel pins (A) into housing as far as they will go. [2] - Install gasket on housing. <- Go to Section TOC Section 53 page 95 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [3] - Install screw plugs in front plate and tighten them. Item Measurement Specification Front plate, M14x1.5 screw plug Torque 35 N˙m 26 lb-ft Front plate, M18x1.5 screw plug Torque 50 N˙m 37 lb-ft Front plate, M20x1.5 screw plug Torque 55 N˙m 40 lb-ft [4] - Move front plate to correct position. <- Go to Section TOC Section 53 page 96 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [5] - Make sure front plate contacts housing and tighten attaching screws slightly. →NOTE: Do not tighten the attaching screws to their final torque until after the transmission oil pump has been installed. Item Measurement Specification Front plate attaching screws Torque 23 N˙m 17 lb-ft <- Go to Section TOC Section 53 page 97 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [6] - Install screw union to front plate and tighten. Item Measurement Specification Front plate, fitting Torque 80 N˙m 59 lb-ft Final assembly: Refer to “Installing the transmission oil pump” . Refer to “Installing the system pressure control block” . <- Go to Section TOC Section 53 page 98 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Separating Transmission Halves, Input/Output Housing (Repair Level 2) Preliminary work: Refer to “Removing the AutoPowr/IVT transmission” . [1] - LEGEND: A B Input housing Output housing Secure transmission by attaching it to a suitable hoist and turn it by 90°. [2] - Secure input housing by attaching it to a suitable hoist and remove attaching screws. <- Go to Section TOC Section 53 page 99 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [3] - Separate transmission halves by using a pry bar. →NOTE: The transmission halves are held in position by two dowel pins which cannot be removed. [4] - Be careful when separating the transmission halves. →NOTE: Push harness connector evenly in the direction indicated by the arrow to avoid damage to it. <- Go to Section TOC Section 53 page 100 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Removing BG Disk Brake (Repair Level 2) Preliminary work: See reference”Separating Transmission Halves, Input/Output Housing”. [1] - If necessary, remove bearing cup of double gear bearing with rollers. →NOTE: Make sure not to drop the rollers during disassembly. [2] - If necessary, remove direction turret bearing cup. <- Go to Section TOC Section 53 page 101 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [3] - Remove cable holder. [4] - Disconnect both connections to hydrostatic unit. →NOTE: Before pulling out the connectors, mark them so as to avoid installing them in the wrong positions. [5] - Remove BG disk brake attaching screws. <- Go to Section TOC Section 53 page 102 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [6] - Pry BG-housing from dowel pins. [7] - Remove BG disk brake. →NOTE: Do not remove any more parts from BG disk brake. The BG disk brake can be ordered as an assembly through normal parts channels. Final assembly: See reference”Installing the BG Disk Brake”. <- Go to Section TOC Section 53 page 103 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Installing BG Disk Brake (Repair Level 2) [1] - Apply some petroleum jelly to O-rings (A) before inserting them into new BG disk brake. [2] - Place BG disk brake on shift turret. IMPORTANT: Make sure that all disks are properly positioned and the BG disk brake contacts housing. <- Go to Section TOC Section 53 page 104 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [3] - Drive in both dowel pins until they are flush with the surface. [4] - Install BG disk brake attaching screws and tighten them. Item Measurement Specification BG disk brake, attaching screws Torque 115 N˙m 85 lb-ft <- Go to Section TOC Section 53 page 105 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [5] - Place wiring harness in cover notch and fix it by means of cable holders. Item Measurement Specification Cable holder, attaching screws Torque 10 N˙m 7 lb-ft [6] - Join both plug connections to hydrostatic unit. →NOTE: Note the marks to avoid installation in the wrong position. →NOTE: Make sure that the cables are not under tension. Final assembly: See reference”Measuring Gaps between Transmission Shafts in Input/Output Housing”. <- Go to Section TOC Section 53 page 106 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Removing Shift Turret (Repair Level 2) Preliminary work: See reference”Removing BG Disk Brake”. [1] - Carefully lift shift turret out of the transmission housing. [2] - Remove shim. <- Go to Section TOC Section 53 page 107 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [3] - Remove ring gear (P4/BG) from P4 planetary drive. [4] - Remove spacer. <- Go to Section TOC Section 53 page 108 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [5] - Lift P4 planetary drive-C3/C4 clutch assembly out of shift turret. [6] - If necessary, pull through-drive shaft (A) out of shift turret. [7] - Remove gear (B). <- Go to Section TOC Section 53 page 109 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [8] - If necessary, remove shift turret ball bearing. →NOTE: Do not remove any more parts from shift turret. The shift turret with through-drive shaft can be ordered as an assembly through normal parts channels. Final assembly: See reference”Repairing Through-Drive Shaft”. See reference”Installing Shift Turret”. <- Go to Section TOC Section 53 page 110 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Installing Shift Turret (Repair Level 2) [1] - Heat up ball bearing (A) and insert it into housing as far as it will go. [2] - Make sure that the five seal rings (A) are installed in the middle of the shaft. [3] - Carefully install shift turret making sure not to damage seal rings on shaft. <- Go to Section TOC Section 53 page 111 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Final assembly: See reference”Installing the BG Disk Brake”. <- Go to Section TOC Section 53 page 112 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Repairing Through-Drive Shaft (Repair Level 2) Preliminary work: See reference”Removing Shift Turret”. [1] - Insert ball bearing into P1 planetary drive as far as it will go. [2] - Install gear. <- Go to Section TOC Section 53 page 113 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [3] - Apply some petroleum jelly to O-ring and install it in through-drive shaft ring groove (arrow). [4] - Install three seal rings (A) and close them. →NOTE: Apply some petroleum jelly to the seal rings and position them in the middle of the shaft. [5] - Support shift turret and carefully insert pre-assembled through-drive shaft. <- Go to Section TOC Section 53 page 114 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [6] - Turn shift turret by 180°; while doing this hold through-drive shaft and gear in position. [7] - Check test dimension (experience has shown that this value is 38.5 mm; 1.5 in.) between shift turret face and C1/C2 clutch cylinder face. →NOTE: If all components are installed correctly, test dimension is 38.5 mm (1.5 in.). [8] - Install three seal rings (A) and close them. →NOTE: Apply some petroleum jelly to the seal rings and position them in the middle of the shaft. <- Go to Section TOC Section 53 page 115 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [9] - Install P4 planetary drive with C3/C4 clutch. →NOTE: Frequently turn P4 planetary drive with C3/C4 clutch slightly and raise it at the same time in order to engage the disks in the splines. [10] - Check test dimension (experience has shown that this value is 76 mm; 3 in.) between shift turret face and C3/C4 clutch carrier face. →NOTE: If installation was carried out correctly, test dimension is 76 mm (3 in.). <- Go to Section TOC Section 53 page 116 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [11] - Install P4/BG ring gear. [12] - Install five seal rings (A) and close them. →NOTE: Apply some petroleum jelly to the seal rings and position them in the middle of the shaft. Final assembly: See reference”Installing Shift Turret”. <- Go to Section TOC Section 53 page 117 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Repairing P4 Planet Pinion Carrier and C3/C4 Clutch (Repair Level 2) Preliminary work: See reference”Removing Shift Turret”. Removing P4 planet pinion carrier and C3/C4 clutch [1] - Remove shim (shift turret end play). [2] - Remove ring gear (P4/BG) from P4 planetary drive. <- Go to Section TOC Section 53 page 118 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [3] - Remove spacer. [4] - Lift P4 planetary drive-C3/C4 clutch assembly out of shift turret. →NOTE: Do not remove any more parts from P4 planetary drive with C3/C4 clutch. The P4 planetary drive with C3/C4 clutch can be ordered as an assembly through normal parts channels. Installing P4 planet pinion carrier and C3/C4 clutch <- Go to Section TOC Section 53 page 119 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [1] - Before installing the planet pinion carrier, check the three seal rings (A). Install the seal rings and close them. →NOTE: Apply some petroleum jelly to the seal rings and position them in the middle of the shaft. [2] - Check test dimension (experience has shown that this value is 38.5 mm; 1.5 in.) between shift turret face and C1/C2 clutch cylinder face. →NOTE: If all components are installed correctly, test dimension is 38.5 mm (1.5 in.). <- Go to Section TOC Section 53 page 120 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [3] - Install P4 planetary drive with C3/C4 clutch. →NOTE: Frequently turn P4 planetary drive with C3/C4 clutch slightly and raise it at the same time in order to engage the disks in the splines. [4] - Install the spacer. <- Go to Section TOC Section 53 page 121 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [5] - Check test dimension (experience has shown that this value is 76 mm; 3 in.) between shift turret face and C3/C4 clutch carrier face. →NOTE: If installation was carried out correctly, test dimension is 76 mm (3 in.). [6] - Install P4/BG ring gear. <- Go to Section TOC Section 53 page 122 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [7] - Install shim. Final assembly: See reference”Installing Shift Turret”. <- Go to Section TOC Section 53 page 123 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Repairing P4/BG Ring Gear (Repair Level 2) Preliminary work: See reference”Removing Shift Turret”. Removal and disassembly of ring gear (P4/BG) [1] - Remove shim (shift turret end play). [2] - Remove ring gear (P4/BG) from P4 planetary drive. <- Go to Section TOC Section 53 page 124 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [3] - Remove snap ring (A). [4] - Remove ring gear carrier (A) from ring gear. [5] - Remove snap ring (A) and ball bearing. Assembly of ring gear (P4/BG) <- Go to Section TOC Section 53 page 125 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [1] - Install ring gear carrier in BG ring gear as shown. [2] - Install the snap ring. [3] - Insert ball bearing. <- Go to Section TOC Section 53 page 126 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [4] - Install the snap ring. [5] - Install the ring gear (P4/BG). [6] - Install shim (shift turret end play). <- Go to Section TOC Section 53 page 127 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Final assembly: See reference”Installing Shift Turret”. <- Go to Section TOC Section 53 page 128 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Removing Hydrostatic Unit (Repair Level 2) Preliminary work: See reference”Removing Shift Turret”. [1] - Remove pressure hoses (A) and (B) to hydrostatic unit. [2] - Remove the hydrostatic unit attaching screws. <- Go to Section TOC Section 53 page 129 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [3] - Carefully lift hydrostatic unit out of the transmission housing. [4] - Remove pressure hose. [5] - Remove the fitting, if necessary. <- Go to Section TOC Section 53 page 130 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [6] - Remove hollow screw and pressure hose. →NOTE: Do not remove any more parts from hydrostatic unit. The hydrostatic unit can be ordered as an assembly through normal parts channels. [7] - Remove the fitting, if necessary. <- Go to Section TOC Section 53 page 131 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [8] - Remove elbow, if necessary. →NOTE: Mark radial position of elbow for re-installation. [9] - Remove wiring harness from housing, if necessary. Final assembly: See reference”Installing Hydrostatic Unit”. <- Go to Section TOC Section 53 page 132 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Installing Hydrostatic Unit (Repair Level 2) [1] - Determine dimension from hydrostatic unit contact surface to flat surface of snap ring in output shaft. As an example, the dimension is 191.80 mm (7.551 in.). [2] - Determine dimension (A) from output shaft face to metal bushing of rubber mounting. As an example, dimension (A) is 189.20 mm (7.448 in.) [3] - Subtract specified end play (e.g. 0.20 mm; 0.008 in.) from the difference of the two dimensions. The result is the thickness of the shim to be used. Item Measurement Specification Hydrostatic unit, end play End play 0.2 - 0.5 mm 0.008 - 0.020 in. <- Go to Section TOC Section 53 page 133 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [4] - Example: Dimension (A): 191.80 mm (7.551 in.) Dimension (B): 189.20 mm (7.448 in.) 191.80 mm - 189.20 mm = 2.60 mm 7.551 in. - 7.448 in. = 0.102 in. 2.60 mm - 0.20 mm end play = 2.40 mm 0.102 in. - 0.008 in. = 0.094 in. Shim thickness in the example is 2.40 mm (0.094 in.). [5] - Install the required shim with a thickness of 2.40 mm (0.094 in.) in the hollow output shaft. [6] - Install fitting for the pressure hose with O-ring to hydrostatic unit and tighten it. Item Measurement Specification Hydrostatic unit pressure hose, fitting Torque 50 N˙m 37 lb-ft [7] - Coat O-ring (A) with oil and install it in the ring-shaped groove. <- Go to Section TOC Section 53 page 134 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [8] - Install pressure hose in the position shown and tighten it. Item Measurement Specification Pressure hose to fitting Torque 40 N˙m 30 lb-ft [9] - Install O-ring (A) in the ring-shaped groove. <- Go to Section TOC Section 53 page 135 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [10] - Install O-ring on hollow screw, and install pressure hose in the position shown to damper. [11] - Tighten the hollow screw. Item Measurement Specification Pressure hose to hydrostatic unit, hollow screw Torque 50 N˙m 37 lb-ft [12] - Insert hydrostatic unit into input housing and install it on output shaft. <- Go to Section TOC Section 53 page 136 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [13] - Insert hydrostatic unit attaching screws and tighten them. Item Measurement Specification Hydrostatic unit, attaching cap screws Torque 115 N˙m 85 lb-ft [14] - Connect pressure hose (A) to housing and tighten. Item Measurement Specification Pressure hose to fitting Torque 40 N˙m 30 lb-ft [15] - Connect pressure hose (B) to housing and tighten. Item Measurement Specification Pressure hose to elbow Torque 80 N˙m 59 lb-ft Final assembly: <- Go to Section TOC Section 53 page 137 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing If necessary, see reference”Preparations for installation of individual components in transmission housing”. See reference”Installing Shift Turret”. <- Go to Section TOC Section 53 page 138 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Repairing Hydrostatic Unit Output Shaft (Repair Level 2) Preliminary work: See reference”Removing Hydrostatic Unit”. Removing hydrostatic unit output shaft [1] - Pull out hollow output shaft. [2] - Remove shim (hydrostatic unit end play) and snap ring from shaft. <- Go to Section TOC Section 53 page 139 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [3] - Remove snap ring. [4] - Remove snap ring and closure disk from the shaft. [5] - Remove snap ring. <- Go to Section TOC Section 53 page 140 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [6] - Pull the shaft out of the gear, using a suitable internal puller. [7] - Remove ball bearing from hollow output shaft. [8] - Remove gear from housing. <- Go to Section TOC Section 53 page 141 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [9] - Extract ball bearing by using a slide hammer. Installing hydrostatic unit output shaft [1] - Insert ball bearing as far as it will go into bore. [2] - Press ball bearing on output shaft until it is in contact with the short collar. <- Go to Section TOC Section 53 page 142 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [3] - Heat up ball bearing. [4] - Insert gear and output shaft as far as it will go. IMPORTANT: Re-seat output shaft after ball bearing has cooled down. <- Go to Section TOC Section 53 page 143 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [5] - Install output shaft snap ring. [6] - Insert closure disk into hollow shaft with the curved side down and install snap ring to secure it. <- Go to Section TOC Section 53 page 144 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [7] - Install snap ring (mounting for shim determining hydrostatic unit end play). IMPORTANT: The thickness of the shim (for hydrostatic unit end play) must be determined. See Installing the Hydrostatic Unit. [8] - Install hollow output shaft. Final assembly: If necessary, see reference”Preparations for installation of individual components in transmission housing”. See reference”Installing Hydrostatic Unit”. <- Go to Section TOC Section 53 page 145 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Preparations for Installation of Individual Components in Input Housing (Repair Level 2) [1] - Install wiring harness in input housing. Check the two O-rings (A) and make sure they are installed correctly. [2] - Attach wiring harness using a cable strap (B). [3] - Remember to include the O-rings, screw in all plugs and tighten. Item Measurement Specification Transmission housing, M14x1.5 screw plugs Torque 35 N˙m 26 lb-ft Item Measurement Specification Transmission housing, M38x2 screw plugs Torque 140 N˙m 103 lb-ft <- Go to Section TOC Section 53 page 146 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [4] - Install O-ring (A) on elbow and insert O-rings (B) into ring grooves. [5] - Insert elbow and align. →NOTE: When aligning, note radial position or mark applied to elbow before removal. <- Go to Section TOC Section 53 page 147 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [6] - Tighten the elbow fitting. Item Measurement Specification Elbow, hex. nut Torque 80 N˙m 59 lb-ft [7] - Install the fitting for the pressure hose with O-ring to hydrostatic unit and tighten it. Item Measurement Specification Hydrostatic unit pressure hose, fitting Torque 50 N˙m 37 lb-ft <- Go to Section TOC Section 53 page 148 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Measuring Gaps Between Transmission Shafts in Input/Output Housing (Repair Level 2) Adjusting end play between shift turret and direction turret IMPORTANT: In order to obtain a correct result of the various play adjustments, carry out measuring procedure on transmission housing in vertical position. Make sure that shift turret, direction turret or the transmission shafts, bearings and components concerned are installed in centered position. [1] - Rotate shift turret several times in both directions to seat the parts (axial needle bearings). Determine dimension (A) measured from (input) transmission housing flange surface to ball bearing cone of P4 planetary drive. As an example, dimension (A) is 13,60 mm (0.535 in.) <- Go to Section TOC Section 53 page 149 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [2] - Place gasket (A) on the flange surface of transmission housing (output transmission). IMPORTANT: Make sure that direction turret is centered and correctly positioned on the taper roller bearing. [3] - Measure dimension (B) from the gasket on flange surface to face of direction turret hollow shaft. As an example, dimension (B) is 11.40 mm (0.448 in.) [4] - Subtract specified end play from the difference of the two dimensions. The higher range of the end play tolerance is preferable (e.g. 0.30 mm; 0.012 in.). The result is the thickness of the shim to be used. Item Measurement Specification End play between shift turret and direction turret End play 0.20 - 0.40 mm 0.008 - 0.016 in. Example: As an example, dimension (A) is 13.60 mm (0.535 in.) As an example, dimension (B) is 11.40 mm (0.448 in.) 13.60 mm - 11.40 mm = 2.20 mm 0.535 in. - 0.448 in. = 0.087 in. Difference 2.20 mm - specified end play 0.30 mm = 1.90 mm Difference 0.087 in. - specified end play 0.012 in. = 0.075 in. Shim thickness in the example is 1.90 mm (0.075 in.). <- Go to Section TOC Section 53 page 150 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [5] - Install a shim of the calculated thickness. →NOTE: Use some petroleum jelly to keep shim in position on bearing. Adjustment of direction turret taper roller bearing [1] - Measure distance (A) between transmission housing (input transmission) flange and shoulder of taper roller bearing cup seat. As an example, dimension (A) is 4.24 mm (0.167 in.) <- Go to Section TOC Section 53 page 151 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [2] - The taper roller bearing cup must be placed in exactly centered position. Place gasket (A) on the flange surface of transmission housing (output transmission). Measure dimension (B) from the gasket on flange surface of output transmission to taper roller bearing cup. Measure at various points and determine the average value. As an example, average value of dimension (B) is 2.45 mm (0.096 in.). IMPORTANT: Make sure that direction turret is centered and correctly positioned on the taper roller bearing. [3] - Subtract specified end play from the difference of the two dimensions. The middle range of the end play tolerance is preferable (e.g. 0.04 mm; 0.0016 in.). The result is the thickness of the shim to be used. Item Measurement Specification Direction turret taper roller bearing End play 0 - 0.08 mm 0 - 0.003 in. Example: As an example, dimension (A) is 4.24 mm (0.167 in.) As an example, dimension (B) is 2.45 mm (0.096 in.) 4.24 mm - 2.45 mm = 1.79 mm 0.167 in. - 0.096 in. = 0.070 in. Difference 1.79 mm - specified end play 0.04 mm = 1.75 mm Difference 0.070 in. - specified end play 0.0016 in. = 0.069 in. Shim thickness in the example is 1.75 mm (0.069 in.). <- Go to Section TOC Section 53 page 152 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [4] - Install a shim of the calculated thickness. [5] - Install taper roller bearing cup as far as it will go. [6] →NOTE: Heat the bearing cone before installation. <- Go to Section TOC Section 53 page 153 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Heat bearing cone of double gear bearing with rollers and install as far as it will go. →NOTE: Reseat bearing cone after it has cooled down. [7] →NOTE: Use some petroleum jelly to keep rollers in position and to prevent them from falling out. Install roller bearing of double gear as far as it will go. Final assembly: See reference”Joining Transmission Halves, Input/Output Housing”. <- Go to Section TOC Section 53 page 154 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Joining Transmission Halves, Input/Output Housing (Repair Level 2) Preliminary work: Refer to"Measuring gaps between transmission shafts in input/output housing". [1] - Using a suitable hoist, move input housing (A) to a position above output housing (B). [2] - Make sure that gasket (C) is properly positioned. [3] - Lower input housing until it contacts output housing. →NOTE: For easier installation turn the various shafts when joining the transmission halves →NOTE: Be sure not to damage the wiring harness connector (D) when joining the transmission halves. [4] - Evenly drive in both dowel pins. <- Go to Section TOC Section 53 page 155 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing [5] - Install and tighten attaching screws. Item Measurement Specification Output to input housing, attaching screws Torque 46 N˙m 34 lb-ft Final assembly: Refer to "Installing the AutoPowr/IVT transmission" . <- Go to Section TOC Section 53 page 156 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Layout and Location of the Individual Transmission Sending Units LEGEND: 1 Transmission speed sending unit (B63) 2 Transmission input speed sending unit (B61) 3 Transmission ouput speed sending unit (B84) 4 Sending unit, system pressure indicator light (S74) 5 Sending unit, oil filter restriction indicator light (S73) 6 Sending unit for filter by-pass valve (B87; cold-weather starting) 7 Hydrostatic speed sending unit (B62) 8 Pressure sending unit (B90), park lock control block 9 Wiring harness 10 Locking paint →NOTE: When replacing speed sending units (1) and (7), the retaining screws must be coated with locking paint. Pressure sending unit for park lock control block (8) is located on the side of the transmission, inside the park lock control block. For replacing transmission sending units refer to: “Replacing Pressure Sending Units (B87, S73, S74 of System Pressure Control Block” <- Go to Section TOC Section 53 page 157 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing “Replace Pressure Sending Unit (B90) for Park Lock Control Block” “Replacing the Hydrostatic Speed Sending Unit (B62)” “Replacing Transmission Speed Sending Unit (B63)” “Replacing Transmission Input Speed Sending Unit (B61)” “Replacing Transmission Output Speed Sending Unit (B84)” <- Go to Section TOC Section 53 page 158 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Replacing Pressure Sending Units B87, S73, S74 of System Pressure Control Block (Repair Level 1 and 2) [1] - LEGEND: A B C Sending unit for filter by-pass valve (B87; cold-weather starting) Sending unit, oil filter restriction indicator light (S73) Sending unit, system pressure indicator light (S74) <- Go to Section TOC Section 53 page 159 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 10: Input Housing Disconnect pressure sending unit plugs from transmission wiring harness. →NOTE: Before pulling out the connectors, mark them so as to avoid installing them in the wrong positions. [2] - Remove attaching screw and cable holder. [3] - Remove the pressure sending units. [4] - Put an O-ring (see arrow) on each of the pressure sending units. [5] - Install the pressure sending units. Item Measurement Specification Pressure sending unit to system pressure control block Torque 12 N˙m 9 lb-ft [6] - Secure cable from sending unit for system pressure indicator light using the cable holder. Item Measurement Specification Cable holder to filter housing, attaching screw Torque 9 N˙m 7 lb-ft [7] - Tie pressure sending unit cables together by means of cable straps. [8] - Connect pressure sending unit plugs to transmission wiring harness. <- Go to Section TOC Section 53 page 160 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing Replace Hydrostatic Unit Speed Sending Unit (B62) (Repair Level 1 and 2) [1] - Apply oil to the O-ring (see arrow) and install it on the sending unit. [2] - Align and tighten speed sending unit at transmission housing as shown. Item Measurement Specification Hydrostatic speed sending unit Torque 10 N˙m 7 lb-ft IMPORTANT: After tightening the fillister-head screw, secure it with thread lock paint (L116666). This simultaneously serves as confirmation that the speed sending unit has been correctly installed. <- Go to Section TOC Section 53 page 161 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing Group 15 - Output Housing AutoPowr/IVT Transmission Output Housing Reconditioning (Summary of References) ”Special tools” ”Specifications” ”Removing the park lock control block” ”Reconditioning the park lock control block” ”Installing the park lock control block” ”Reconditioning the locking pawl of park lock” ”Removing direction turret and reverse intermediate shaft” ”Installing direction turret and reverse intermediate shaft” ”Removing the hydrostatic unit drive shaft” ”Installing the hydrostatic unit drive shaft” ”Removing the through-drive shaft” ”Installing the through-drive shaft” ”Removing the pneumatic pump and idler gear” ”Installing the pneumatic pump and idler gear” ”Layout/location of individual transmission sending units” ”Replacing transmission speed sending unit (B63)” ”Replacing transmission input speed sending unit (B61)” ”Replacing transmission output speed sending unit (B84)” ”Replacing the pressure sending unit (B90) for park lock control block” <- Go to Section TOC Section 53 page 162 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing Special Tools →NOTE: Order tools according to information given in the U.S. SERVICEGARD ™ Catalog or European Microfiche Tool Catalog (MTC). Installation tool dealer-fabricated Removing and installing the park lock control block and the check valve (repair level 1 and 2) Tube <- Go to Section TOC Section 53 page 163 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing dealer-fabricated Removing and installing the park lock control block cylinder and piston (repair level 1 and 2) Lifting bail KJD10242 Removal and installation of direction turret (repair level 2) Adapter [ Adapter KJD 10241 must be used on tractors up to serial no. 327230. ] KJD10241 Removal and installation of direction turret, pulling off taper roller bearing (repair level 2) Adapter [ Adapter KJD 10477 must be used on tractors from serial no. 327231. ] KJD10477 Removal and installation of direction turret, pulling off taper roller bearing (repair level 2) <- Go to Section TOC Section 53 page 164 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing Specifications Item Measurement Specification Check valve (A), park lock control block Torque 18 N˙m 13 lb-ft Check valve (B), park lock control block Torque 15 N˙m 11 lb-ft M40 x 2 screw plug, park lock control block Torque 70 N˙m 52 lb-ft Check valve, park lock control block Torque 10 N˙m 7 lb-ft M14 x 1.5 screw plug, park lock control block Torque 15 N˙m 11 lb-ft Pressure sending unit, park lock control block Torque 10 N˙m 7 lb-ft Attaching screws, solenoid valve Torque 10 N˙m 7 lb-ft Test port, park lock control block Torque 15 N˙m 11 lb-ft Attaching screws, park lock control block Torque 11 N˙m 8 lb-ft M18 x 1.5 screw plug Torque 50 N˙m 37 lb-ft Pneumatic pump, screw plug Torque 140 N˙m 104 lb-ft Idler gear Rolling drag torque 0.1—0.8 N˙m 0.074—0.60 lb-ft Transmission housing, M14x1.5 screw plug Torque 35 N˙m 26 lb-ft Transmission housing, M10x1 screw plug Torque 25 N˙m 18 lb-ft Transmission housing, M18x1.5 screw plug Torque 50 N˙m 37 lb-ft Transmission housing, M20x1.5 screw plug Torque 55 N˙m 41 lb-ft Transmission housing, M38x2 screw plug Torque 140 N˙m 104 lb-ft Threaded pins, through-drive shaft Torque 15 N˙m 11 lb-ft Transmission speed sending unit <- Go to Section TOC Torque Section 53 page 165 10 N˙m TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Item Group 15: Output Housing Measurement Specification 7 lb-ft Transmission input speed sending unit Torque 30 N˙m 22 lb-ft Transmission output speed sending unit Torque 30 N˙m 22 lb-ft <- Go to Section TOC Section 53 page 166 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing Removing Park Lock Control Block (Repair Level 1 and 2) Preliminary work: • Depending on how the tractor is equipped or on the amount of work, remove right main frame half. Refer to "Removing and Installing the Main Frame (Summary of References)" . • Alternatively, the transmission assembly can be completely removed. Refer to “Removing the AutoPowr/IVT transmission” . [1] - Remove attaching screws (A) and lift off cover (B). [2] - Pull out pin (A). <- Go to Section TOC Section 53 page 167 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [3] - Remove attaching screws (A). [4] - Remove control block (B). <- Go to Section TOC Section 53 page 168 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing Repairing Park Lock Control Block (Repair Level 1 and 2) Preliminary work: Refer to “Removing the Park Lock Control Block” . Park lock control block — Sectional view LEGEND: A B C D E F G H I J K L M N O <- Go to Section TOC Lever Lever arm Pressure sending unit Screw plug Check valve Solenoid valve Housing Screw plug Tappet Cylinder Piston Washer Spring Spring Rod Section 53 page 169 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing Disassembling the park lock control block [1] - Remove nuts (A). [2] - Remove the coils from the solenoid valves. [3] IMPORTANT: If the cylinder and piston are to be removed, you MUST first take out the check valve that lies under screw plug (A). <- Go to Section TOC Section 53 page 170 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [4] - Remove plate (C) and solenoid valves (B). Remove pressure sending unit (A) and connecting fitting (D). [5] - Take out screw plug (A). <- Go to Section TOC Section 53 page 171 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [6] - Use an installation tool (A; dealer-fabricated) Installation tool dealer-fabricated Removing and installing the park lock control block and the check valve. to remove the check valve. →NOTE: As soon as the check valve has been removed, the cylinder and piston can be taken out. [7] - If required, remove all the other check valves. <- Go to Section TOC Section 53 page 172 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [8] - Take out screw plug (A). [9] - Remove snap ring (A). <- Go to Section TOC Section 53 page 173 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [10] - Use a compression device and tube (A; dealer-fabricated) to press the cylinder downward. Tube dealer-fabricated Removing and installing the park lock control block, cylinder and piston. [11] - While it is compressed, remove lever (B) and lever arm (C). <- Go to Section TOC Section 53 page 174 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [12] - Remove cylinder (B) and tappet (A). [13] - Take the seal rings off the cylinder. [14] - Remove piston (A). [15] - Take the seal rings off the piston. [16] - Remove rod (B) and washer (A). <- Go to Section TOC Section 53 page 175 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [17] - Remove springs (A) and (B) and washer (C). Assembling the park lock control block [1] - Press bushing (A) into the housing until it is flush. [2] - Press bushing (A) in until it is flush, and install seal ring (B). <- Go to Section TOC Section 53 page 176 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [3] - Install check valves (A), (B) and (C). Item Measurement Specification Check valve (A), park lock control block Torque 18 N˙m 13 lb-ft Item Measurement Specification Check valve (B), park lock control block Torque 15 N˙m 11 lb-ft [4] - Install check valve (A). Item Measurement Specification Check valve (A), park lock control block Torque 18 N˙m 13 lb-ft <- Go to Section TOC Section 53 page 177 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [5] - Install check valve (A). Item Measurement Specification Check valve, park lock control block Torque 18 N˙m 13 lb-ft [6] - Install O-ring (A) in the cylinder. [7] - Carefully compress back-up ring (A), and install. <- Go to Section TOC Section 53 page 178 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [8] - Make sure that the seal ring is making proper contact. [9] - Install O-ring (A). [10] - Install O-ring (A) on the piston. <- Go to Section TOC Section 53 page 179 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [11] - Install back-up ring (A). [12] - Place washer (A) in the housing bore. [13] - Install the outer and inner springs. <- Go to Section TOC Section 53 page 180 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [14] - Install rod (B) and washer (A). [15] - Apply oil to the seal rings on piston (A). [16] - Insert the piston. [17] - Apply oil to the seal rings on cylinder (B). [18] - Install the cylinder and tappet (A). <- Go to Section TOC Section 53 page 181 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [19] - Turn the cylinder so that the opening in the cylinder is properly aligned with the housing. [20] - Use a compression device and tube (A; dealer-fabricated) to press the cylinder downward. Tube dealer-fabricated Removing and installing the park lock control block, cylinder and piston. <- Go to Section TOC Section 53 page 182 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [21] - While it is compressed, install lever (B) and lever arm (C). [22] - Install snap ring (A) on the lever arm. [23] - Install screw plug (A). Item Measurement Specification M40 x 2 screw plug, park lock control block Torque 70 N˙m 52 lb-ft <- Go to Section TOC Section 53 page 183 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [24] - Install check valve (A). [25] - Use an installation tool (A; dealer-fabricated) to tighten the check valve. Item Measurement Specification Check valve, park lock control block Torque 10 N˙m 7 lb-ft <- Go to Section TOC Section 53 page 184 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [26] - Install screw plug (A). Item Measurement Specification M14 x 1.5 screw plug, park lock control block Torque 15 N˙m 11 lb-ft [27] - Install pressure sending unit (A) and connecting fitting (B). Item Measurement Specification Pressure sending unit, park lock control block Torque 10 N˙m 7 lb-ft <- Go to Section TOC Section 53 page 185 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [28] - Install solenoid valves (A). [29] - Install plate (C) by means of retaining screws (B), and tighten. Item Measurement Specification Attaching screws, solenoid valve Torque 10 N˙m 7 lb-ft [30] - Install coils (A) on the solenoid valves. <- Go to Section TOC Section 53 page 186 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [31] - Screw in test port (A) and tighten it. Item Measurement Specification Test port, park lock control block Torque 15 N˙m 11 lb-ft Final assembly: Refer to “Installing the park lock control block” . <- Go to Section TOC Section 53 page 187 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing Installing Park Lock Control Block (Repair Level 1 and 2) [1] - Align control block (B) and gasket at housing. [2] - Tighten attaching screws (A). Item Measurement Specification Attaching screws, park lock control block Torque 11 N˙m 8 lb-ft [3] - Install pin (A). <- Go to Section TOC Section 53 page 188 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [4] - Install cover (B) and gasket. Tighten attaching screws (A). Item Measurement Specification Attaching screws, park lock control block Torque 11 N˙m 8 lb-ft Final assembly: Refer to "Removing and Installing the main frame (summary of references)" . Refer to "Installing the AutoPowr/IVT transmission" . <- Go to Section TOC Section 53 page 189 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing Repairing Locking Pawl of Park Lock (Repair Level 1 and 2) Preliminary work: Refer to “Removing the Park Lock Control Block” . Park lock - exploded view LEGEND: A B C D E F G H I J K L M N <- Go to Section TOC Locking pawl Cotter pin Pin Washer Roller Lock cam Thrust bearing Axial needle bearing Bushing Shaft Compression spring O-ring Screw plug Lever Section 53 page 190 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION O Group 15: Output Housing Spring pin Removing locking pawl of park lock [1] - Take out screw plug (A) and compression spring (B). [2] - Drive out pin and remove lever (A). [3] - Pull out shaft (A). <- Go to Section TOC Section 53 page 191 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [4] - Remove locking pawl (B). [5] - Remove lock cam (A), thrust bearing and bushing (B). [6] - Check the roller (A), it must be undamaged and turn freely. [7] - If required, remove cotter pin, shim and pin (B). [8] - Replace roller (A) and reassemble the locking pawl. Installing locking pawl of park lock <- Go to Section TOC Section 53 page 192 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [1] - Install lock cam (A) and axial bearing (B). [2] - Install bushing (A). [3] - Install locking pawl (B) and shaft (A). <- Go to Section TOC Section 53 page 193 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [4] - Align lever (A) as shown and drive in spring pin. [5] - Install compression spring (B). Tighten screw plug (A). Item Measurement Specification M18 x 1.5 screw plug Torque 50 N˙m 37 lb-ft Final assembly: Refer to “Installing the park lock control block” . <- Go to Section TOC Section 53 page 194 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing Removing Direction Turret and Reverse Intermediate Shaft (Repair Level 2) Preliminary work: See reference ”Removing the AutoPowr/IVT Transmission” . See reference”Separating Transmission Halves, Input/Output Housing”. [1] - Remove gasket and O-rings (A). [2] - Remove connecting tube (A). <- Go to Section TOC Section 53 page 195 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [3] - Before removing direction turret and reverse intermediate shaft, remove speed sending units (A) and (B). IMPORTANT: To avoid damage, the speed sending units must be removed before the direction turret. [4] - Take out the screw plug. →NOTE: The screw plug secures the direction turret. [5] - <- Go to Section TOC Section 53 page 196 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing Attach KJD10242 lifting bail and KJD10241 adapter [ Adapter KJD 10241 must be used on tractors up to serial no. 327230. Adapter KJD 10477 must be used on tractors from serial no. 327231. ] to direction turret taper roller bearing. Lifting bail KJD10242 Removal and installation of direction turret Adapter KJD10241 Removal and installation of direction turret, pulling off taper roller bearing [6] - Slightly lift reverse intermediate shaft and direction turret at the same time. [7] - Remove reverse intermediate shaft and direction turret from transmission housing. <- Go to Section TOC Section 53 page 197 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [8] - Remove seal rings. [9] - Pry roller bearing from reverse intermediate shaft. Make sure that the bearing rollers do not fall out. →NOTE: The bearing cone remains in the output housing. <- Go to Section TOC Section 53 page 198 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [10] - Remove direction turret taper roller bearing cup. [11] - If necessary, remove all screw plugs. Final assembly: See reference”Installing the Direction Turret and Reverse Intermediate Shaft”. <- Go to Section TOC Section 53 page 199 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing Removing Hydrostatic Unit Drive Shaft (Repair Level 2) Preliminary work: See reference”Removing the Direction Turret and Reverse Intermediate Shaft”. [1] - Pull hollow shaft off drive shaft. [2] - Remove snap ring from hollow shaft. <- Go to Section TOC Section 53 page 200 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [3] - Remove the snap ring. [4] - Pull drive shaft with ball bearing out of the housing. [5] - Press ball bearing from drive shaft. <- Go to Section TOC Section 53 page 201 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [6] - Remove both snap rings (A). [7] - Press second ball bearing from drive shaft. Final assembly: See reference”Installing hydrostatic unit drive shaft”. <- Go to Section TOC Section 53 page 202 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing Removing Through-Drive Shaft (Repair Level 2) Preliminary work: See reference”Removing the Direction Turret and Reverse Intermediate Shaft”. [1] - Remove the seven seal rings. [2] - Remove the snap ring. <- Go to Section TOC Section 53 page 203 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [3] - Turn housing through 180° and remove the second snap ring. [4] - Remove through-drive shaft using a suitable puller. [5] - Remove the snap ring. [6] - Pull off ball bearing (A). [7] - Remove seal rings (B) from through-drive shaft. Final assembly: <- Go to Section TOC Section 53 page 204 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing See reference”Installing through-drive shaft”. <- Go to Section TOC Section 53 page 205 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing Removing Pneumatic Pump and Idler Gear (Repair Level 2) Preliminary work: See reference”Removing the Direction Turret and Reverse Intermediate Shaft”. Removing idler gear [1] - Remove snap ring (shaft, pneumatic pump). [2] - Remove shaft using a slide hammer. <- Go to Section TOC Section 53 page 206 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [3] - Remove snap ring (shaft, idler gear) and shim behind it. [4] - Remove shaft using a slide hammer. [5] - Take idler gear (A) out of housing. →NOTE: While doing so, make sure that bearing cones do not fall out. <- Go to Section TOC Section 53 page 207 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [6] - If necessary, remove both bearing cups (A) from idler gear. [7] - Move gear (A) (gear with cam-pneumatic pump) to the rear position (see arrow). [8] - Remove gear (B) (hydrostatic unit drive gear, through-drive shaft) from transmission housing. <- Go to Section TOC Section 53 page 208 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [9] - Remove gear (A) (gear with cam-pneumatic pump) from transmission housing. →NOTE: Make sure that the two needle bearings and the thrust washer between them do not fall out. [10] - Remove needle bearings and the thrust washer between them from gear. [11] - Remove thrust washer from transmission housing. Removing pneumatic pump <- Go to Section TOC Section 53 page 209 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [1] - Remove the pneumatic pump′s tappet (A). [2] - Take out the screw plug. [3] - Remove the snap ring. <- Go to Section TOC Section 53 page 210 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [4] - Remove the valve with its O-ring, washer and spring. [5] - Pull out the piston. [6] - Remove ball and retaining ring from piston. <- Go to Section TOC Section 53 page 211 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [7] - Take out the screw plug. [8] - Remove piston and spring from the housing. Final assembly: See reference”Installing pneumatic pump and idler gear”. <- Go to Section TOC Section 53 page 212 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing Installing Pneumatic Pump and Idler Gear (Repair Level 2) Installing pneumatic pump [1] - Install the pneumatic pump′s tappet in bore. [2] - Insert thrust washer. IMPORTANT: Be sure to insert washer correctly. Lug on washer must be positioned in recess in housing to prevent washer from turning. <- Go to Section TOC Section 53 page 213 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [3] - Insert pump gear into transmission housing. IMPORTANT: Be sure to insert gear correctly. Cam on gear must point downward to tappet. [4] - Install both needle bearings with thrust washer (A) in pump gear. <- Go to Section TOC Section 53 page 214 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [5] - Loosely install hydrostatic unit drive gear in transmission housing before securing pump gear with shaft. [6] - Install cylindrical pin in shaft as far as it will go. <- Go to Section TOC Section 53 page 215 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [7] - Align pump gear and install shaft. →NOTE: Align shaft so that the cylindrical pin is located in the housing recess. [8] - Install the snap ring. <- Go to Section TOC Section 53 page 216 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [9] - LEGEND: A B C D E F G H I Snap ring Valve O-ring Washer Spring Retaining ring Ball Piston Pneumatic pump tappet Check pneumatic pump parts before installation. Replace, if necessary. [10] - Install the ball and retaining ring on the piston. →NOTE: Be sure to insert ball and retaining ring correctly (install retaining ring with ball socket pointing to the ball). <- Go to Section TOC Section 53 page 217 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [11] - Install piston with ball and retaining ring. [12] - Install the spring. [13] - Install the O-ring and washer on the valve. <- Go to Section TOC Section 53 page 218 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [14] - Install the valve. [15] - Install the snap ring. [16] - Install screw plug with O-ring. [17] - Tighten screw plug. Item Measurement Specification Pneumatic pump, screw plug Torque 140 N˙m 104 lb-ft <- Go to Section TOC Section 53 page 219 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [18] - Install the spring and piston in the housing. [19] - Install screw plug with O-ring. [20] - Tighten screw plug. Item Measurement Specification M18 x 1.5 screw plug Torque 50 N˙m 37 lb-ft Installing idler gear <- Go to Section TOC Section 53 page 220 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [1] - Install snap ring. →NOTE: Install snap ring in contact with upper groove face. [2] - Measure dimension (A) from housing flange to lower side of snap ring. As an example, dimension (A) is 178.30 mm (7.02 in.) →NOTE: The snap ring must be in contact with upper groove face. [3] - Remove snap ring again afterwards. <- Go to Section TOC Section 53 page 221 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [4] - Install both bearing cups (A) as far as they will go. [5] - Install both bearing cones. [6] - Align idler gear for shaft installation. <- Go to Section TOC Section 53 page 222 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [7] - Heat up housing and bearing cones. [8] - Chill idler gear shaft before installation. [9] - Insert shaft into idler gear. Make sure that shaft contacts bearing cone and a slight bearing preload is noticeable. IMPORTANT: When turning idler gear, a slightly increased bearing preload must be felt. <- Go to Section TOC Section 53 page 223 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [10] - Measure dimension (B) from housing flange to shaft face. As an example, dimension (B) is 180.30 mm (7.02 in.) Thedifference of the two dimensions is the thickness of the shim to be used. Example As an example, dimension (A) is 178.30 mm (7.02 in.) As an example, dimension (B) is 180.30 mm (7.10 in.) 180.30 mm - 178.30 mm = 2.00 mm 7.10 in. - 7.02 in. = 0.08 in. Difference 2.00 mm (0.08 in.) Shim thickness in the example is 2.00 mm (0.08 in.). [11] - Insert a shim of the calculated thickness. <- Go to Section TOC Section 53 page 224 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [12] - Install snap ring. [13] - Remove slight bearing preload which was previously applied by using a slide hammer. [14] - Afterwards check rolling drag torque by turning idler gear. Item Measurement Specification Idler gear Rolling drag torque 0.1—0.8 N˙m 0.074—0.60 lb-ft If the required rolling drag torque is not obtained, adjust to correct value by using an appropriate shim. Final assembly: See reference”Installing the Direction Turret and Reverse Intermediate Shaft”. <- Go to Section TOC Section 53 page 225 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing Installing Hydrostatic Unit Drive Shaft (Repair Level 2) [1] - Press ball bearing on drive shaft until it stops. [2] - Secure ball bearing with snap ring. <- Go to Section TOC Section 53 page 226 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [3] - Install snap ring for second ball bearing. [4] - Press ball bearing on shaft until it contacts the snap ring. [5] - Install drive shaft. <- Go to Section TOC Section 53 page 227 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [6] - Secure drive shaft with snap ring. [7] - Install snap ring in hollow shaft. [8] - Install hollow shaft until it contacts the drive shaft. <- Go to Section TOC Section 53 page 228 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing Final assembly: See reference”Installing the Direction Turret and Reverse Intermediate Shaft”. <- Go to Section TOC Section 53 page 229 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing Installing Through-Drive Shaft (Repair Level 2) [1] - Install direction turret taper roller bearing cup as far as it will go. [2] - Apply sealing compound LOCTITE ™ 270 (high strength) to the four threaded pins. [3] - Install threaded pins and tighten to specification. Item Measurement Specification Threaded pins, through-drive shaft Torque 15 N˙m 11 lb-ft <- Go to Section TOC Section 53 page 230 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [4] - Heat up ball bearing. [5] - Install hot ball bearing on through-drive shaft as far as it will go. [6] - Install the snap ring. <- Go to Section TOC Section 53 page 231 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [7] - Install four seal rings (A) and close them. IMPORTANT: Apply some petroleum jelly to the seal rings and position them in the middle of the shaft. [8] - Insert through-drive shaft in housing or in gear (hydrostatic unit drive gear) which had been inserted beforehand. <- Go to Section TOC Section 53 page 232 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [9] - Secure through-drive shaft with snap ring. [10] - Turn housing through 180° and install second snap ring. <- Go to Section TOC Section 53 page 233 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [11] - Install the seven seal rings and close them. IMPORTANT: Apply some petroleum jelly to the seal rings and position them in the middle of the shaft. Final assembly: See reference”Installing the Direction Turret and Reverse Intermediate Shaft”. <- Go to Section TOC Section 53 page 234 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing Installing Direction Turret and Reverse Intermediate Shaft (Repair Level 2) [1] - Install connecting tube as far as it will go. [2] - Install the seal ring and close it. →NOTE: Use some petroleum jelly to keep the seal ring centered. <- Go to Section TOC Section 53 page 235 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [3] - Attach KJD10242 lifting bail (A) and KJD10241 adapter [ Adapter KJD 10241 must be used on tractors up to serial no. 327230. Adapter KJD 10477 must be used on tractors from serial no. 327231. ] (B) to direction turret taper roller bearing. Lifting bail KJD10242 Removal and installation of direction turret Adapter KJD10241 Removal and installation of direction turret, pulling off taper roller bearing [4] - Assemble direction turret and shaft (C). <- Go to Section TOC Section 53 page 236 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [5] - Carefully insert direction turret/reverse intermediate shaft as far as it will go. IMPORTANT: Install direction turret and reverse intermediate shaft as an assembly. IMPORTANT: Take care not to damage the seal rings during installation. [6] - Remembering to include the O-ring, screw in plug and tighten. Item Measurement Specification Transmission housing, M14x1.5 screw plug Torque 35 N˙m 26 lb-ft →NOTE: The screw plug secures the direction turret. <- Go to Section TOC Section 53 page 237 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [7] - Remembering to include O-rings, screw in all plugs and tighten. Item Measurement Specification Transmission housing, M10x1 screw plug Torque 25 N˙m 18 lb-ft Transmission housing, M14x1.5 screw plug Torque 35 N˙m 26 lb-ft Transmission housing, M18x1.5 screw plug Torque 50 N˙m 37 lb-ft Transmission housing, M20x1.5 screw plug Torque 55 N˙m 41 lb-ft Transmission housing, M38x2 screw plug Torque 140 N˙m 104 lb-ft [8] - Coat O-rings (A) with oil and install them on connecting tube. <- Go to Section TOC Section 53 page 238 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [9] - Install connecting tube (A). [10] - Install O-rings (B). [11] - Drive in both dowel pins (A). →NOTE: Drive in dowel pins until their tops are 3 mm (0.47 in.) above flange surface. →NOTE: Finally, when transmission halves are joined the dowel pins are pressed in even further. [12] - Afterwards place gasket on housing. Final assembly: See reference”Measuring Gaps between Transmission Shafts in Input/Output Housing”. See reference”Joining Transmission Halves, Input/Output Housing”. <- Go to Section TOC Section 53 page 239 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing See reference ”Installing the AutoPowr/IVT Transmission” . <- Go to Section TOC Section 53 page 240 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing Layout and Location of the Individual Transmission Sending Units LEGEND: 1 Transmission speed sending unit (B63) 2 Transmission input speed sending unit (B61) 3 Transmission ouput speed sending unit (B84) 4 Sending unit, system pressure indicator light (S74) 5 Sending unit, oil filter restriction indicator light (S73) 6 Sending unit for filter by-pass valve (B87; cold-weather starting) 7 Hydrostatic speed sending unit (B62) 8 Pressure sending unit (B90), park lock control block 9 Wiring harness 10 Locking paint →NOTE: When replacing speed sending units (1) and (7), the retaining screws must be coated with locking paint. Pressure sending unit for park lock control block (8) is located on the side of the transmission, inside the park lock control block. For replacing transmission sending units refer to: “Replacing Pressure Sending Units (B87, S73, S74 of System Pressure Control Block” <- Go to Section TOC Section 53 page 241 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing “Replace Pressure Sending Unit (B90) for Park Lock Control Block” “Replacing the Hydrostatic Speed Sending Unit (B62)” “Replacing Transmission Speed Sending Unit (B63)” “Replacing Transmission Input Speed Sending Unit (B61)” “Replacing Transmission Output Speed Sending Unit (B84)” <- Go to Section TOC Section 53 page 242 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing Replacing Transmission Speed Sending Unit (B63) (Repair Level 1 and 2) [1] - Apply oil to the O-ring (see arrow) and install it on the sending unit. [2] - Align and tighten speed sending unit at transmission housing as shown. Item Measurement Specification Transmission speed sending unit Torque 10 N˙m 7 lb-ft IMPORTANT: After tightening the fillister-head screw, secure it with thread lock paint (L116666). This simultaneously serves as confirmation that the speed sending unit has been correctly installed. <- Go to Section TOC Section 53 page 243 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing Replacing Transmission Input Speed Sending Unit (B61) (Repair Level 1 and 2) [1] - Apply oil to the O-ring (see arrow) and install it on the sending unit. [2] - Align and tighten speed sending unit at transmission housing as shown. Item Measurement Specification Transmission input speed sending unit Torque 30 N˙m 22 lb-ft IMPORTANT: After tightening the fillister-head screw, secure it with thread lock paint (L116666). This simultaneously serves as confirmation that the speed sending unit has been correctly installed. Replace the Transmission Output Speed Sending Unit (B84) (Repair Level 1 and 2) <- Go to Section TOC Section 53 page 244 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 15: Output Housing [1] - Apply oil to O-ring (A) and install it on the sending unit. [2] - Position speed sending unit (A) on the transmission housing as shown and tighten to the specified torque. Item Measurement Specification Transmission output speed sending unit Torque 12 N˙m 9 lb-ft Replace Pressure Sending Unit (B90) for Park Lock Control Block (Repair Level 1 and 2) <- Go to Section TOC Section 53 page 245 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 20: Differential Drive Shaft Assembly [1] - Apply oil to the O-ring (A) and install it on the sender. [2] - Place sending unit (A) on park lock control block and tighten it. Item Measurement Specification Pressure sending unit, park lock control block Torque 10 N˙m 7 lb-ft <- Go to Section TOC Section 53 page 246 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 20: Differential Drive Shaft Assembly Group 20 - Differential Drive Shaft Assembly AutoPowr/IVT Transmission - Differential Drive Shaft, Summary of References AutoPowr/IVT Transmission - Differential Drive Shaft, Summary of References Repair Specifications Differential Drive Shaft, Sectional View Remove the Differential Drive Shaft Disassemble the Differential Drive Shaft Cone Point Adjustment Assemble the Differential Drive Shaft Specifications Item Measurement Specification Special nut at differential drive shaft Torque 550 N˙m 400 lb-ft Differential drive shaft Axial play 0.01 — 0.08 mm 0.0004 — 0.003 in. Differential drive shaft assembly to differential housing, cap screws Torque 90 N˙m 65 lb-ft Sectional View of Differential Drive Shaft <- Go to Section TOC Section 53 page 247 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION LEGEND: A B C D E F G H I J K L <- Go to Section TOC Group 20: Differential Drive Shaft Assembly O-ring Seal ring Ring Housing Shim (quantity and thickness as required) Cap screw (6 used) Cover Differential drive shaft Special nut Shim (quantity and thickness as required) Front-wheel drive gear Snap-ring Section 53 page 248 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 20: Differential Drive Shaft Assembly Removing the Differential Drive Shaft Preliminary work: See reference ”Removing the AutoPowr/IVT Transmission” in Section 53, Group 00. [1] - Remove cap screws. [2] - Unlock and slightly loosen special nut. [3] - Use two M8 screws (A) to press housing off. <- Go to Section TOC Section 53 page 249 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 20: Differential Drive Shaft Assembly Disassemble Differential Drive Shaft [1] - Remove O-ring (B). [2] - Remove special nut (A). [3] - Press differential drive shaft from bearing seat of taper roller bearing. [4] - Remove taper roller bearing cone (C), spacer (B) and washers (A). <- Go to Section TOC Section 53 page 250 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 20: Differential Drive Shaft Assembly [5] - Remove snap ring from groove. [6] - Pull out the differential drive shaft. Remove snap ring (A). [7] - Press the taper roller bearing cone from the differential drive shaft. <- Go to Section TOC Section 53 page 251 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 20: Differential Drive Shaft Assembly [8] - Separate the cover and housing. [9] - Remove the front-wheel drive gear (A). [10] - Remove the tapered roller bearing cup. <- Go to Section TOC Section 53 page 252 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 20: Differential Drive Shaft Assembly Cone Point Adjustment [1] - <- Go to Section TOC Section 53 page 253 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 20: Differential Drive Shaft Assembly Note the letter (A) stamped on the upper left side of the front face of the differential housing and refer to the chart below for the corresponding dimension. →NOTE: If letter is absent, assume a measurement of 205.00 mm (8.071 in.). Letter on housing Measurement A 204.89 mm (8.067 in.) B 204.95 mm (8.069 in.) C 205.00 mm (8.071 in.) D 205.05 mm (8.073 in.) E 205.10 mm (8.075 in.) [2] - Measure bore depth (B) at cover. [3] - Note the measurement (C) stamped on the pinion face. [4] - Determine bearing width (D). <- Go to Section TOC Section 53 page 254 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 20: Differential Drive Shaft Assembly [5] - Calculate thickness of spacer washer pack (X). Add the bore depth (B) to value (A), to be read from the table. Subtract the dimension (C) and bearing width (D). Formula: X = A + B - C - D Cone point adjustment - Example Character read from differential housing and dimension from table... A = 204.89 mm (8.067 in.) Bore depth measured at cover... B = 22.23 mm (0.875 in.) Dimension stamped on bevel gear face, read... C =180.02 mm (7.088 in.) Width of taper roller bearing is... D = 46.26 mm (1.821 in.) X = 204.89 mm + 22.23 mm - 180.02 mm - 46.26 mm X = 0.84 mm X = 8.067 in. + 0.875 in - 7.088 in - 1.821 in. X = 0.033 in. Shims are available in the following thicknesses: 0.254 mm (0.010 in.) 0.127 mm (0.005 in.) 0.076 mm (0.003 in.) In the example three 0.254 mm (0.010 in.) shims and one 0.076 mm (0.003 in.) shim are to be used. <- Go to Section TOC Section 53 page 255 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 20: Differential Drive Shaft Assembly Assembling the Differential Drive Shaft [1] - Install shims of calculated thickness (to adjust cone point). [2] - Press tapered roller bearing cup into the cover. [3] - Press tapered roller bearing cup (A) into housing. <- Go to Section TOC Section 53 page 256 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 20: Differential Drive Shaft Assembly [4] - Install front-wheel drive gear (A) in housing. [5] - Install dowel pins (A). Press cover and housing together. [6] - Heat up tapered roller bearing cone (A) and install on differential drive shaft. <- Go to Section TOC Section 53 page 257 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 20: Differential Drive Shaft Assembly [7] - Align snap ring (A) and install differential drive shaft [8] - Install snap ring in groove. [9] - Insert piston ring (A) on spacer and engage. <- Go to Section TOC Section 53 page 258 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 20: Differential Drive Shaft Assembly [10] - Install spacer. [11] - Install shims (to adjust end play of differential drive shaft). [12] - Heat up tapered roller bearing cone and install. <- Go to Section TOC Section 53 page 259 TM4756-REPAIR MANUAL Section 53 - AUTOPOWR/IVT TRANSMISSION Group 20: Differential Drive Shaft Assembly [13] - Reseat bearing. [14] - Install special nut (A) and tighten. Item Measurement Specification Special nut at differential drive shaft Torque 550 N˙m 400 lb-ft [15] - Move the differential drive shaft to and fro to seat the bearings. <- Go to Section TOC Section 53 page 260 TM4756-REPAIR MANUAL POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS (g) by Belgreen [16] - Measure axial play of differential drive shaft. Item Measurement Specification Differential drive shaft Axial play 0.01 — 0.08 mm 0.0004 — 0.003 in. [17] - Adjust the axial play through removal or installation as required. Tighten special nut to specification. [18] - Check axial play again. [19] - When the axial play has been set correctly, the special nut must be locked. [20] - Install differential drive shaft assembly in differential housing. Tighten the cap screws. Item Measurement Specification Differential drive shaft assembly to differential housing, cap screws Torque 90 N˙m 65 lb-ft [21] - Cover O-ring (A) with a thin layer of Vaseline and install on housing. Next step: See reference ”Installing the AutoPowr/IVT Transmission” in Section 53, Group 00. <- Go to Section TOC Section 53 page 261 TM4756-REPAIR MANUAL TM4756-REPAIR MANUAL (g) by Belgreen Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Table of contents Group 00 - Removal and Installation of Components .......................................................... 1 Special Tools .......................................................................................................................... 1 Dealer-Fabricated Special Tools ............................................................................................. 1 Repair Specifications .............................................................................................................. 2 PowrQuad Plus Transmission, Removal and Installation ........................................................ 2 Remove and Install the AutoQuad Transmission .................................................................... 3 Remove PowrQuad Transmission ........................................................................................... 4 Install PowrQuad Transmission .............................................................................................. 8 Remove the Creeper Transmission ...................................................................................... 11 Install the Creeper Transmission .......................................................................................... 13 Remove Range Transmission ............................................................................................... 15 Install Range Transmission .................................................................................................. 17 Group 05 - Transmission Shift Controls ............................................................................... 19 PowrQuad Transmission Shift Units - Reconditioning (Summary of References) .................. 19 Specifications ....................................................................................................................... 19 Repairing the Range Shift Linkage (PowrQuad Plus and AutoQuad Transmissions) ............. 20 Reconditioning the Range Shift Linkage (PowrQuad Plus and AutoQuad Plus Transmissions from Tractor Ser. No. 398656) ...................................................................................... 25 Checking and Adjusting the Shift Controls/Linkages (PowrQuad Plus and AutoQuad transmissions) ............................................................................................................... 37 Checking and Adjusting the Shift Controls/Linkages (PowrQuad Plus and AutoQuad Plus Transmissions from Tractor Ser. No. 398656) ............................................................... 44 Repairing the Clutch Actuation (PowrQuad Plus, AutoQuad and AutoQuad Plus Transmissions) ....................................................................................................................................... 48 Group 10 - PowrQuad Module ................................................................................................ 55 PowrQuad, PowrQuad Plus and AutoQuad Transmissions - Summary of References ........... 55 Special tools ......................................................................................................................... 56 Specifications ....................................................................................................................... 58 Transmission Components ................................................................................................... 59 Replacing the temperature sensor and pressure switches .................................................. 61 Removing and Installing the Oil Filter Housing .................................................................... 62 Replacing the Oil Filter ......................................................................................................... 63 Removing and Installing the Front Valve Housing ................................................................ 64 Removing and Installing the Valves in the Front Valve Housing .......................................... 66 Removing and Installing the Front Transmission Cover ....................................................... 71 Removing and Installing the Valves in the Front Transmission Cover .................................. 73 Removing and Installing the Shift Valve Housing ................................................................. 77 Remove and Install the Valves in the Shift Valve Housing ................................................... 78 Removing the Transmission Oil Pump .................................................................................. 82 Repairing the Transmission Oil Pump ................................................................................... 84 Installing the Transmission Oil Pump ................................................................................... 93 Removing the Gear-Shift Planetary Drive ............................................................................ 94 Repairing the Gear-Shift Planetary Drive ............................................................................. 96 Install Gear-Shift Planetary Drive ....................................................................................... 104 Removing the B1 Brake Housing ........................................................................................ 111 <- Go to Global Table of contents TM4756-REPAIR MANUAL TM4756-REPAIR MANUAL (g) by Belgreen Reconditioning the B1 Brake .............................................................................................. 113 Installing the B1 Brake Housing ......................................................................................... 115 Removing the B2-B3 Brake Housing .................................................................................. 115 Reconditioning the B2 Brake .............................................................................................. 117 Reconditioning the B3 Brake .............................................................................................. 119 Installing the B2-B3 Brake Housing .................................................................................... 121 Removing the C4 Clutch .................................................................................................... 122 Reconditioning the C4 Clutch ............................................................................................. 123 Installing the C4 Clutch ...................................................................................................... 135 Removing the reverse brake .............................................................................................. 136 Repairing the reverse brake ............................................................................................... 138 Installing the reverse brake ............................................................................................... 140 Removing the Forward Clutch with Planetary Drive (Forward/Reverse) ............................. 142 Reconditioning the Forward Clutch with Planetary Drive (Forward/Reverse) ..................... 143 Installing the Forward Clutch with Planetary Drive (Forward/Reverse) .............................. 161 Replacing the output shaft ................................................................................................. 163 Group 15 - Creeper Transmission ....................................................................................... 166 Creeper Transmission - Reconditioning (Summary of References) .................................... 166 Special tools ....................................................................................................................... 166 Repair specifications .......................................................................................................... 166 Removing the creeper transmission .................................................................................. 166 Repairing the creeper transmission ................................................................................... 168 Installing the creeper transmission .................................................................................... 185 Group 20 - Range Transmission .......................................................................................... 187 Range Transmission - Reconditioning (Summary of References) ....................................... 187 Special tools ....................................................................................................................... 187 Repair specifications .......................................................................................................... 189 Removing the range transmission ..................................................................................... 189 Range Transmission - Sectional View ................................................................................. 190 Repairing the Range Transmission ..................................................................................... 192 Installing the range transmission ....................................................................................... 220 Repairing the shift cover .................................................................................................... 221 Replacing the speed sender ............................................................................................... 224 <- Go to Global Table of contents TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 00: Removal and Installation of Components Group 00 - Removal and Installation of Components Special Tools →NOTE: Order tools according to information given in the U.S. SERVICEGARD ™ Catalog or European Microfiche Tool Catalog (MTC). Lifting eye JD-244-1 Removing and installing tractor components Lifting eye JDG19 Removing and installing tractor components Dealer-Fabricated Special Tools See also Section 99, Group 05. <- Go to Section TOC Section 55 page 1 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 00: Removal and Installation of Components Device for suspending the PowrQuad module during removal and installation Repair Specifications Item Measurement Specificatio n Cap Screw, PowrQuad Module to Creeper Transmission Torque 70 N˙m 50 lb.-ft. Cap Screw, Range Transmission Housing to Differential Housing Torque 90 N˙m 66 lb.-ft. Cap Screw, PowrQuad Module to Range Transmission Torque 70 N˙m 50 lb.-ft. Cap Screw, Creeper Transmission to Range Transmission Torque 70 N˙m 50 lb.-ft. Cap Screw, Suction Line to PowrQuad Module Torque 18 N˙m 13.3 lb.-ft. Cap Screw, U.J. Shaft to Torsion Damper and Drive Flange Torque 135 N˙m 100 lb.-ft. PowrQuad Plus Transmission, Removal and Installation See Remove PowrQuad Transmission . See Install PowrQuad Transmission . <- Go to Section TOC Section 55 page 2 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 00: Removal and Installation of Components Remove and Install the AutoQuad Transmission See Remove PowrQuad Transmission . See Install PowrQuad Transmission . <- Go to Section TOC Section 55 page 3 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 00: Removal and Installation of Components Remove PowrQuad Transmission →NOTE: The following applies regardless of what transmission type is used on the tractor, provided it is based on the PowrQuad module. [1] - Open the hood. Disconnect the negative terminal (—) on the battery. The version shown here has a negative terminal at the location marked (A). CAUTION: Always pay close attention to battery terminals. Comply with safety instructions on how to handle batteries (see Section 05). [2] - Tilt up the operator′s cab; see Tilting the Operator′s Cab Upward in Section 90, Group 00. [3] - Remove drain screw (A) and allow the transmission oil to drain out. <- Go to Section TOC Section 55 page 4 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 00: Removal and Installation of Components [4] - Remove u.j. shaft (B). See Removing the U.J. Shaft (Engine) in Section 56, Group 05. On tractors with creeper transmission, remove cooler (A); see Removing and Installing the Ring-Shaped Cooler in Section 56, Group 05. →NOTE: Trap any oil as it emerges. Seal the open ends so that no dust can penetrate. [5] - Mark all the connectors on the transmission wiring harness to facilitate their re-installation, then disconnect them. Disconnect both oil cooler hoses (A) at the junction with the PowrQuad module. If equipped, pull hose (C) from the hose fitting. Remove line (B). →NOTE: Trap any oil as it emerges. Seal the open ends so that no dust can penetrate. On tractors with creeper transmission, remove transmission oil filter. [6] - If the PowrQuad module has mechanical shifting and mechanically actuated reverser control, disengage the bowden cables. <- Go to Section TOC Section 55 page 5 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 00: Removal and Installation of Components [7] - Take out screws (A) and pull suction line (B) out of the differential housing. →NOTE: Trap any oil as it emerges. Seal the open ends so that no dust can penetrate. [8] - Remove cable clamp (A) and move the wiring harness to the rear after disconnecting all connectors. [9] - <- Go to Section TOC Section 55 page 6 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 00: Removal and Installation of Components Install dealer-fabricated suspension device (A) on the PowrQuad module and attach lifting tackle. Suspension Device dealer fabricated Device for suspending the PowrQuad module during removal and installation Take all screws (B) out of the flange, move the PowrQuad module to the front, and lift it out. <- Go to Section TOC Section 55 page 7 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 00: Removal and Installation of Components Install PowrQuad Transmission →NOTE: The following applies regardless of what transmission type is used on the tractor, provided it is based on the PowrQuad module. [1] - Install dealer-fabricated suspension device (A) on the PowrQuad module and attach lifting tackle. Suspension Device dealer fabricated <- Go to Section TOC Section 55 page 8 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 00: Removal and Installation of Components Device for suspending the PowrQuad module during removal and installation Clean the sealing surfaces thoroughly, install gasket (C) and, if necessary, keep it in place with grease. →NOTE: Check that the bushing (B) is seated correctly. Move the drive shaft to help the gears to mesh. Locate the PowrQuad module against the range transmission or creeper, and tighten all the screws (D) in the flange to the prescribed torque. Item Measurement Specification Cap Screws, PowrQuad Module to Range Transmission or Creeper Torque 70 N˙m 50 lb.-ft. IMPORTANT: Tighten screws in flange in cross-wise fashion (alternately by small amounts). <- Go to Section TOC Section 55 page 9 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 00: Removal and Installation of Components [2] - Check all seals, install suction line (B) and tighten screws (A) to the specified torque. Item Measurement Specification Attaching Screws, Suction Line to PowrQuad Module Torque 18 N˙m 13 lb.-ft. →NOTE: Check all gaskets/seals before installing. [3] - For further assembly, follow disassembly procedure in reverse order. [4] - Fill with transmission oil. Check oil level and top up, if necessary. [5] - When assembly is completed, perform the following: Adjusting the reverse drive linkage (if equipped), Section 55, Group 05. Installing the U.j. Shaft (Engine) , Section 56, Group 05. [6] IMPORTANT: Every time you disconnect an oil hose with a quick-coupler, replace the retaining clip with a new one. Once clips are installed, check that they are seated correctly. The bent ends of the clip must touch each other. Otherwise, the coupler can become loose. For further assembly, follow disassembly procedure in reverse order. <- Go to Section TOC Section 55 page 10 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 00: Removal and Installation of Components Remove the Creeper Transmission Remove the PowrQuad module. See Remove PowrQuad Module in this Group. Disengage linkage (A) and bowden cable (B). Attach lifting eyes JD-244-1 (A) and secure the housing to a suitable hoist. Lifting eye JD-244-1 <- Go to Section TOC Section 55 page 11 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 00: Removal and Installation of Components Removing and installing tractor components Remove bracket (D). Remove cap screws (B). →NOTE: A further cap screw is located in line connector bore (C); this screw must also be removed. Remove creeper transmission. →NOTE: The housing flanges are sealed with flexible sealant. Therefore, the housings adhere firmly to each other even after the cap screws have been removed. <- Go to Section TOC Section 55 page 12 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 00: Removal and Installation of Components Install the Creeper Transmission Use TY6305 cleaning agent to clean residual sealant off the housing sealing surfaces. →NOTE: Carefully scrape off any residual sealant with a scraper. Then apply a thin, even layer of LOCTITE ™ 574 (L64500) sealant to the housing flange. Attach lifting eyes JD-244-1 (A) and secure the housing to a suitable hoist. Lifting eye JD-244-1 Removing and installing tractor components Applying even pressure, locate the creeper transmission on the range transmission. <- Go to Section TOC Section 55 page 13 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 00: Removal and Installation of Components Install cap screws (A) and tighten them to the specified torque. Item Measurement Specification Cap Screws, Creeper Transmission to Range Transmission Torque 70 N˙m 50 lb.-ft. →NOTE: A further cap screw (B) is located in the line connector bore; this screw must be tightened also. For further assembly, follow disassembly procedure in reverse order. <- Go to Section TOC Section 55 page 14 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 00: Removal and Installation of Components Remove Range Transmission [1] - Remove PowrQuad module or creeper transmission. See Remove PowrQuad Module or Remove the Creeper Transmission in this Group. [2] - Mark the bowden cables (A) of the shift cover, as well as the respective levers, so as to facilitate reassembly. Then disengage all the bowden cables. →NOTE: Depending on transmission version, cable arrangement may be different. [3] - Disconnect connector (A) of the solenoid valve for the front-wheel drive clutch. Remove pressure line (B) from the front-wheel drive valve. Remove the front-wheel drive clutch. See Remove the Front-Wheel Drive Clutch in Section 80, Group 00. →NOTE: It is not absolutely necessary to remove the front-wheel drive clutch. However, it makes it easier to perform the subsequent tasks on the range transmission. <- Go to Section TOC Section 55 page 15 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 00: Removal and Installation of Components [4] - Screw the JDG19 lifting eyes (A) onto the housing and attach the hoist. Lifting eye JDG19 Removing and installing tractor components IMPORTANT: When securing lifting eyes and lifting tackle, be sure to use high-grade hardware. Select screws that are long enough to be screwed in to the maximum depth available. Remove all screws (B) and move the range transmission towards the front. Then lift out the housing. →NOTE: The housing flanges are sealed with flexible sealant. Therefore, the housings adhere firmly to each other even after the cap screws have been removed. <- Go to Section TOC Section 55 page 16 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 00: Removal and Installation of Components Install Range Transmission [1] - Thoroughly clean sealing surfaces of the housing. →NOTE: Carefully scrape off any residual sealant with a scraper. Then apply a thin, even layer of LOCTITE ™ 574 (L64500) sealant to the housing flange. [2] - Screw the JDG19 lifting eyes (A) onto the housing and attach the hoist. Lifting eye JDG19 Removing and installing tractor components IMPORTANT: When securing lifting eyes and lifting tackle, be sure to use high-grade hardware. Select screws that are long enough to be screwed in to the maximum depth available. Position the range transmission on the differential housing. →NOTE: Make sure that the housing is suspended exactly horizontally. Screw in all cap screws (B) and tighten in cross-wise fashion to the torque prescribed. Item Measurement Specification Cap Screws, Range Transmission to Differential Housing Torque 90 N˙m 65 lb.-ft. <- Go to Section TOC Section 55 page 17 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls [3] - For further assembly, follow disassembly procedure in reverse order. Then see Install PowrQuad Transmission or Install Creeper or Option Transmission . <- Go to Section TOC Section 55 page 18 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls Group 05 - Transmission Shift Controls PowrQuad Transmission Shift Units - Reconditioning (Summary of References) ”Specifications” ”Reconditioning the range shift linkage (PowrQuad Plus and AutoQuad transmissions)” ”Checking and adjusting the shift controls/linkages (PowrQuad Plus and AutoQuad transmissions)” ”Reconditioning the range shift linkage (PowrQuad Plus and AutoQuad Plus transmissions from tractor ser. no. 398656)” ”Checking and adjusting the shift controls/linkages (PowrQuad Plus and AutoQuad Plus transmissions from tractor ser. no. 398656)” ”Reconditioning the clutch actuation (PowrQuad Plus, AutoQuad and AutoQuad Plus transmissions)” Specifications Item Measurement Specification Shift lever to support, self-locking hex. nut Torque 35 N˙m 25 lb-ft Shift elements to bearing pins Preload 0.9 to 1.5 mm 0.035 to 0.059 in. Self-locking retaining screw, clutch pedal to console Torque 10 N˙m 7 lb-ft Bearing pin attaching screw Torque 25 N˙m 19 lb-ft Attaching screw, shift quadrant stop Torque 25 N˙m 19 lb-ft <- Go to Section TOC Section 55 page 19 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls Repairing the Range Shift Linkage (PowrQuad Plus and AutoQuad Transmissions) LEGEND: 1 2 3 4 5 6 7 8 9 10 <- Go to Section TOC Gear selector Handle Shifting gate Park lock switch Cap screw Washer Bearing bushing Shift quadrant, park lock Support pin Support pin Section 55 page 20 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 Group 05: Transmission Shift Controls Belleville spring Shift quadrant, ranges A and B Support Self-locking hex. nut Shift lever with harness Shift quadrant, ranges C and D Shift quadrant, range E Rubber bearing Washer Shim (thickness as required) Bracket Bowden cable, park lock Bowden cable, ranges A and B Bowden cable, ranges C and D Bowden cable, range E Rubber sleeve Cap screw [1] - Repair or assemble the parts of the shift mechanism as required, using the illustration as a guide. [2] - Apply John Deere EP multi-purpose grease to all the moving parts on support pin (10). [3] - Tighten self-locking hex. nut (14). Item Measurement Specification Shift lever to support, self-locking hex. nut Torque 35 N˙m 25 lb-ft [4] →NOTE: Threads of attaching screws and the threaded bores must be clean and dry (i.e. free of oil and grease). Coat screws (5) and (27) with (LOCTITE ™ 242) and tighten screws to specified torque. Item Measurement Specification Support pin attaching screw Torque 25 N˙m 19 lb-ft Adjusting preload at quadrants <- Go to Section TOC Section 55 page 21 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls [1] - Install parts 5 to 18. →NOTE: Note specified tightening torques. [2] - Without pretensioning the belleville springs (11), measure distance (a), which is how far support pin (10) sticks out. [3] - Adjust the preload at the shift linkage parts. Calculate thickness of shims (d). Add the preload value to the distance the support pin sticks out. Item Measurement Specification Shift elements to support pin Preload 0.9 to 1.5 mm 0.035 to 0.059 in. The sum represents the thickness of shims to be used (19). d (min.) = a + 0.9 mm (0.035 in.) d (max.) = a + 1.5 mm (0.059 in.) [4] - If necessary, round off the result. When (d) is at its minimum, round the sum up; when (d) is at its maximum, round the sum down. →NOTE: A selection of shims with different thicknesses is available through normal parts channels. Example <- Go to Section TOC Section 55 page 22 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls Measured distance (a) (distance the support pin sticks out): a = 0.3 mm (0.012 in.) d (min.) = 0.3 mm + 0.9 mm = 1.2 mm d (min.) = 0.012 in + 0.035 in = 0.047 in d (max.) = 0.3 mm + 1.5 mm = 1.8 mm d (max.) = 0.012 in. + 0.059 in. = 0.071 in. In this example, shim (19) must be 1.5 mm (0.059 in.) thick. Removing and installing the bowden cables IMPORTANT: When removing and installing bowden cables, take care not to bend them. When routing the bowden cables, take care that they do not chafe and are not subjected to tension. [1] - Removing the bowden cable together with the damper Disconnect the bowden cable′s yoke. [2] - When removing the bowden cable, hold down locking lug (A) and at the same time twist the cable through 90°. [3] - The bowden cable can now be pulled out of the console. <- Go to Section TOC Section 55 page 23 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls [4] - Installing the bowden cable together with the damper When installing a bowden cable, insert it into the console as shown. [5] - Twist the bowden cable through 90° until locking lug (A) clicks into place. [6] - Attach the bowden cables to the transmission as illustrated. LEGEND: A B C D <- Go to Section TOC Bowden cable, park lock Bowden cable, range E Bowden cable, ranges A and B Bowden cable, ranges C and D Section 55 page 24 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls Reconditioning the Range Shift Linkage (PowrQuad Plus and AutoQuad Plus Transmissions from Tractor Ser. No. 398656) Reconditioning the selector grip with gear-shift switches [1] - Shift lever, AutoQuad Plus Shift lever, PowrQuad Plus The PowrQuad Plus shift lever and the AutoQuad Plus shift lever are both disassembled in the same way. <- Go to Section TOC Section 55 page 25 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls [2] - LEGEND: A Attaching screws Take screws (A) out of the back of the grip, and lift off the front half of the grip. [3] - LEGEND: A B C Circuit board with gear-shift switches Attaching screws Grip Carefully pull the circuit board with gear-shift switches (A) off the plug. Take out attaching screws (B) and pull off grip (C). Recondition or assemble the selector grip with gear-shift switches as required, using the exploded view as a guide. Removing the shifter unit <- Go to Section TOC Section 55 page 26 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls [1] - Take off the trim panels. LEGEND: A B C Electrical plug connection Electrical plug connection Electrical plug connection [2] - Disconnect the shifter unit from electrical plug connections (A), (B) and (C). <- Go to Section TOC Section 55 page 27 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls [3] - LEGEND: A Bowden cables Put identifying marks on the existing bowden cables (A), then remove them. [4] - LEGEND: A Attaching screws Take out screws (A). <- Go to Section TOC Section 55 page 28 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls [5] - LEGEND: A B Attaching screw Shifter unit Take out attaching screw (A). [6] - Lift shifter unit (B) out of the console. Reconditioning the shifter unit →NOTE: Recondition or assemble the parts of the shift mechanism as required, using the illustration as a guide. To facilitate subsequent re-assembly, put identifying marks or numbers on the components before taking them off. <- Go to Section TOC Section 55 page 29 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls →NOTE: Attaching screws for which no tightening torque is quoted must be tightened to the maximum torque value for screws in their grade. See Reference ”Metric Bolt and Cap Screw Torque Values” . LEGEND: A B Spring Wire loop To make it easier to engage and disengage springs (A), make a loop of wire (B). The springs must be installed as shown. The springs must touch the sides of the cam (see arrow). <- Go to Section TOC Section 55 page 30 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS LEGEND: A B Group 05: Transmission Shift Controls Wiring harness Cable binder Secure harness (A) to the cam by means of cable binder (B), making sure that there is no tension in the harness regardless of whichever position the shift lever is in. To make sure, move the shift lever to each range in turn. Do not tighten the cable binder until you are sure that the harness is free of tension no matter what position the shift lever is in. <- Go to Section TOC Section 55 page 31 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS LEGEND: 1 2 3 4 5 6 Group 05: Transmission Shift Controls Handle assembly, AutoQuad Plus transmission Handle assembly, PowrQuad Plus transmission O-ring Screw Locking washer Console <- Go to Section TOC Section 55 page 32 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS LEGEND: 1 2 3 4 5 6 7 8 9 10 <- Go to Section TOC Group 05: Transmission Shift Controls Shift lever assembly with harness Bushing Pin assembly Spring pin Carriage bolt Console Screw Clamp Support Hex. nut Section 55 page 33 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS 11 12 13 14 15 16 17 18 19 20 21 22 <- Go to Section TOC Group 05: Transmission Shift Controls Support Screw Washer Washer Screw Spring Console Flanged nut Clamp Carriage bolt Bracket Screw Section 55 page 34 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls Exploded view, range shift A-E LEGEND: 1 2 3 4 5 6 7 <- Go to Section TOC Cams Side frame Bushing Retaining clip Screw Washer Lever Section 55 page 35 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS 8 9 10 11 12 13 14 15 16 17 18 19 20 21 <- Go to Section TOC Group 05: Transmission Shift Controls Pin End panel Belleville spring Quadrant, E Lever Quadrant, C-D Quadrant, A-B Quadrant, park lock Retaining washer Spacer Shaft Pin Park lock switch Spring Section 55 page 36 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls Checking and Adjusting the Shift Controls/Linkages (PowrQuad Plus and AutoQuad transmissions) CAUTION: Do not perform any adjustments with the engine running, as the tractor could move unexpectedly. Switch off the ignition and remove the key. IMPORTANT: Make this adjustment when the tractor is on firm, level ground. Checking and adjusting the range shift linkage [1] - <- Go to Section TOC Section 55 page 37 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls LEGEND: A B C D E Shift lever Bowden cable, range E Bowden cable, ranges C and D Bowden cable, ranges A and B Park lock cable Move range shift lever (A) back and forth in the neutral zone. • The shift lever must not bump, jam or catch against the shift gate. Use range-shift lever (A) to select each range and the park lock. • The shift lever must not bump, jam or catch against the shift gate. [2] - If necessary, disconnect bowden cables (B), (C) and (D), and adjust the range shift linkage. →NOTE: Slacken off the yoke′s locknut before disengaging the bowden cable. [3] - Turn the yoke until the holes in the yoke and in the shift quadrant are aligned precisely. [4] - Engage the bowden cable and lock it with the locknut. [5] - Re-check the adjustment once again. Adjusting the park lock <- Go to Section TOC Section 55 page 38 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls [1] - Disengage the park lock cable (A). [2] - Check the torque value to which attaching screws (A) and (B) are tightened. Tighten attaching screws (A) and (B) to the specified torque. Press the shift quadrant as far as it will go in the direction shown by the arrow. The shift quadrant must physically touch the stop and must not move in the opposite direction to the arrow. Item Measurement Specification Attaching screws Torque 25 N˙m 19 lb-ft [3] - <- Go to Section TOC Section 55 page 39 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls Check the adjustment of the shift quadrants and park lock switch. Adjust, if necessary. Park lock shift quadrant (D) is adjusted correctly when range shift quadrants (A), (B) and (C) are precisely aligned with park lock shift quadrant (D) (see the broken lines in the illustration). Press the shift quadrant (D) as far as it will go in the direction shown by the arrow. The shift quadrant must physically touch the stop and must not move in the opposite direction to the arrow. Park lock switch (A) is adjusted correctly when its actuating spring is pressed by the park lock shift quadrant, causing the switch to trip (see top arrow). At the same time as the switch trips, the shift quadrant should come into contact with the stop (see bottom arrow). The switch must not push the shift quadrant away from the stop. If necessary, adjust the shift quadrant or the park lock switch. <- Go to Section TOC Section 55 page 40 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls [4] - Take off the park lock switch. Slacken off attaching screws (A) and (B). [5] - Adjust stop (C) so that the park lock quadrant aligns with the range shift quadrants (see the broken lines in the illustration). [6] - Tighten attaching screws (A) and (B) to the specified torque value, changing repeatedly from one to the other and back again so that pressure is applied evenly. Make sure that stop (C) does not become displaced. Item Measurement Specification Attaching screws Torque 25 N˙m 19 lb-ft [7] - Install park lock switch (A) and tighten retaining nuts (B) by a small amount. Slide the switch (A) in the slots until its actuating spring is pressed by the park lock shift quadrant, causing the switch to trip (see top arrow). At the same time as the switch trips, the shift quadrant should come into contact with the stop (see bottom arrow). The switch must not push the shift quadrant away from the stop. <- Go to Section TOC Section 55 page 41 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls [8] - Tighten retaining nuts (B) to their full torque value. [9] - Engage the park lock bowden cable or - if the shift quadrant has been adjusted - adjust the bowden cable. [10] - Adjust the park lock cable Move range shift lever (A) to its neutral position. [11] - Disconnect the park lock cable (J). →NOTE: Slacken off the yoke′s locknut before disengaging the bowden cable. [12] IMPORTANT: Make sure that the park lock is disengaged properly. Do this by pressing the bowden cable (J) down (use force). <- Go to Section TOC Section 55 page 42 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls [13] - To make the adjustment, pull gently on the cable yoke so that the free play before actuation (approx. 2 mm; 0.08 in.) is removed from the cable. [14] - Hold the cable in this position (free of play) and turn the yoke until the yoke holes and shift quadrants are precisely aligned. [15] - Engage the bowden cable and lock it with the locknut. [16] - Re-check the adjustment. Checking the park lock [1] - Drive tractor on a slope (ramp) and bring it to a standstill. [2] - Shift lever to the "park" position. [3] - Slowly release the brake pedal. [4] - Park lock must engage and the tractor must not roll away. CAUTION: If the tractor does roll away, the park lock must be checked on the transmission end and the cause must be identified. <- Go to Section TOC Section 55 page 43 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls Checking and Adjusting the Shift Controls/Linkages (PowrQuad Plus and AutoQuad Plus Transmissions from Tractor Ser. No. 398656) CAUTION: Do not adjust the shift linkage with engine running because the tractor might move unexpectedly. Switch off the ignition and remove the key. Checking and adjusting the range shift linkage [1] - Move the range-shift lever (A) to neutral position. From there, the shift lever moves automatically to the shift position C-D. [2] - Use range-shift lever (A) to select each range and the park lock. →NOTE: Slight resistance can be felt when shifting from ranges A-B to the park position and from ranges C-D to range E. →NOTE: If the park lock should happen to have the teeth on the gear and on the pawl clashing against each other, slightly more force is required to engage the park lock. • The shift lever must not bump, jam or catch against the shift gate. <- Go to Section TOC Section 55 page 44 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls • It must be possible to move the shift lever to its park position without any difficulty whatsoever. [3] - LEGEND: A B C D Bowden cable, range E Bowden cable, ranges C and D Bowden cable, ranges A and B Park lock cable If necessary, disconnect cables (A), (B), or (C), and adjust the range shift linkage. →NOTE: Slacken off the locknut on the relevant yoke before disengaging the bowden cable. [4] - Turn the yoke of the bowden cable until the holes in the yoke and in the shift quadrant are aligned precisely. →NOTE: Make sure the hole in the shift quadrant is the correct one (the retaining pin can only be installed at this hole). [5] - Engage the bowden cables and lock them with the locknuts. [6] - Re-check the adjustment once again. <- Go to Section TOC Section 55 page 45 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls Adjusting the park lock [1] - Move the range-shift lever (A) to neutral position. From there, the shift lever moves automatically to the shift position C-D. [2] - Disengage the park lock bowden cable (B). →NOTE: Slacken off the yoke′s locknut before disengaging the bowden cable. <- Go to Section TOC Section 55 page 46 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls [3] IMPORTANT: Make sure that the park lock is disengaged properly. Do this by pressing the bowden cable (B) down (use force). [4] - Turn the yoke of the bowden cable until the holes in the yoke and in the shift quadrant are aligned precisely. →NOTE: Make sure the hole in the shift quadrant is the correct one (the retaining pin can only be installed at this hole). [5] - Engage the bowden cable and lock it with the locknut. [6] - Re-check the adjustment once again. Checking the park lock [1] - Drive tractor on a slope (ramp) and bring it to a standstill. [2] - Shift lever to the "park" position. [3] - Release the brake pedal. [4] - Park lock must engage and the tractor must not roll away. CAUTION: If the tractor does roll away, the park lock must be checked on the transmission end and the cause must be identified. <- Go to Section TOC Section 55 page 47 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls Repairing the Clutch Actuation (PowrQuad Plus, AutoQuad and AutoQuad Plus Transmissions) CAUTION: When performing the work described below, comply with the safety instructions in the relevant Technical Manuals. CAUTION: Components that are coated with locking paint must NOT be opened, adjusted or repaired. These components may only be replaced as complete assemblies. IMPORTANT: DISCONNECT ELECTRICAL CIRCUIT Before working on the electrical system, always disconnect battery ground cable (-). Replacing the potentiometer <- Go to Section TOC Section 55 page 48 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls [1] - Fold back the cup holder (A). [2] - Use a Phillips-head screwdriver to take out retaining screws (B), and lift off trim (C). [3] - Disengage ball joint (A) at the potentiometer. <- Go to Section TOC Section 55 page 49 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls [4] - Remove attaching screws (A). [5] - Pull off connector (B) and take off the potentiometer. Assembly: Re-install the parts in reverse order, referring to the exploded view (drawing). Repairing the clutch pedal [1] - Disengage ball joint (A). [2] - Remove hex. nut (B). →NOTE: Proceed with care, as the components are subject to preload. <- Go to Section TOC Section 55 page 50 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls [3] - Take out retaining screw (C) and lift out the clutch pedal. [4] - Take belleville spring (A), back-up ring (B) and friction washer (C) off the bearing journal (D). [5] - Recondition the clutch actuation as required. Assembly: Re-install the parts in reverse order, referring to the exploded view (drawing). [6] - Locate the clutch pedal on adapter (A). Apply some John Deere EP multipurpose grease to bearing (B) before installation. Install hex. nut (C). [7] - Now install the clutch pedal on the bearing journal of the console. <- Go to Section TOC Section 55 page 51 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls [8] - Tighten retaining screw (A) just enough for the pedal to touch console but remain free of play. Now tighten the attaching screw to its final torque value. Item Measurement Specification Self-locking retaining screw, clutch pedal to console Torque 10 N˙m 7 lb-ft IMPORTANT: The clutch pedal′s retaining screw has a self-locking capability; for this reason, every time it is removed, it must be replaced with a new one. [9] - Adjust the preload at spring (A). Screw in hex. nut (B) until dimension (C) between adapter and clutch pedal is 7.5 mm (0.3 in.). <- Go to Section TOC Section 55 page 52 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 05: Transmission Shift Controls Exploded view of clutch actuation mechanism LEGEND: A B C D E F G H I J K L M <- Go to Section TOC Console Belleville spring Back-up ring Friction washer Hex. nut Bearing Ball socket Clutch pedal Bushing Washer Self-locking fillister head screw Limit stop Potentiometer (B65) Section 55 page 53 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS N O P Q R S T U V <- Go to Section TOC Group 10: PowrQuad Module Cover Ball end Ball joint assembly Leaf spring Adapter Spring Adapter Attaching screw Wiring harness, with clutch pedal switch (S72) Section 55 page 54 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Group 10 - PowrQuad Module PowrQuad, PowrQuad Plus and AutoQuad Transmissions - Summary of References Before reconditioning the PowrQuad module, refer to the following: ”Special tools” ”Specifications” ”Replace the temperature sensor and pressure switches” ”Remove and install the oil filter housing” ”Remove and install the front valve housing” ”Remove and install the valves in the front valve housing” ”Remove and install the front transmission cover” ”Remove and install the valves in the front transmission cover” ”Remove and install the shift valve housing” ”Remove and install the valves in shift valve housing” ”Remove transmission oil pump” ”Recondition transmission oil pump” ”Install transmission oil pump” ”Remove the gear-shift planetary drive” ”Recondition the gear-shift planetary drive” ”Install the gear-shift planetary drive” ”Remove the B1 brake housing” ”Recondition the B1 brake” ”Install the B1 brake housing” ”Remove the B2-B3 brake housing” ”Recondition the B2 brake” ”Recondition the B3 brake” ”Install the B2-B3 brake housing” ”Remove the C4 clutch” ”Recondition the C4 clutch” ”Install the C4 clutch” ”Remove the reverse brake” ”Recondition the reverse brake” ”Install the reverse brake” ”Remove the forward clutch with planetary drive (forward/reverse)” ”Recondition the forward clutch with planetary drive (forward/reverse)” ”Install the forward clutch with planetary drive (forward/reverse)” ”Replace the output shaft” <- Go to Section TOC Section 55 page 55 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Special tools →NOTE: Order tools according to information given in the U.S. SERVICEGARD ™ Catalog or European Microfiche Tool Catalog (MTC). Seal installer JDG775 Installing the seal ring in front valve housing Bushing installer JDG765 Installing bushings Installation tool for the input planetary JDG772 Assembling the planetary housing Bushing, bearing, and seal driver sets <- Go to Section TOC Section 55 page 56 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module D01045AA Driving in bushings, bearings and seals Hydraulic puller set D01048AA Removal of bearings Mechanical puller set D01173AA Removal of bearings <- Go to Section TOC Section 55 page 57 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Specifications Item Measurement Specificatio n System pressure, pressure switch Torque 4 to 7 N˙m 3 to 5 lb-ft Clutch pressure, pressure switch Torque 9 N˙m 6 lb-ft Pressure switch, restriction indicator of the transmission oil filter Torque 4 to 7 N˙m 3 to 5 lb-ft Temperature sensor Torque 4 to 7 N˙m 3 to 5 lb-ft Oil filter housing, screw Torque 11 N˙m 8 lb-ft Transmission oil filter to filter housing Torque 30 N˙m 22 lb-ft Front valve housing, screw Torque 11 N˙m 8 lb-ft Transmission oil filter by-pass valve, plug Torque 20 N˙m 15 lb-ft Cooler relief valve, plug Torque 30 N˙m 22 lb-ft Lube oil relief valve, plug Torque 20 N˙m 15 lb-ft Reverse solenoid (Y36) Torque 45 N˙m 33 lb-ft Forward solenoid (Y33) Torque 45 N˙m 33 lb-ft Enable proportional solenoid (Y38), screw Torque 25 N˙m 18 lb-ft Front transmission cover, screw Torque 60 N˙m 44 lb-ft Cover for return valve and gear-to-gear modulation valve, screw Torque 12 N˙m 9 lb-ft Pressure-regulating valve, plug Torque 30 N˙m 22 lb-ft Cooling oil control valves and cooling valve, plug Torque 20 N˙m 15 lb-ft Shift valve housing, screw Torque 11 N˙m 8 lb-ft K1 solenoid valve (Y40) <- Go to Section TOC Torque Section 55 page 58 45 N˙m TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Item Group 10: PowrQuad Module Measurement Specificatio n 33 lb-ft K2 solenoid valve (Y39) Torque 45 N˙m 33 lb-ft K3 solenoid valve (Y32) Torque 45 N˙m 33 lb-ft Transmission oil pump to front transmission cover, screw Torque 25 N˙m 18 lb-ft Ring gear cover, screw Torque 10 N˙m 7 lb-ft B1 brake housing, screw Torque 60 N˙m 44 lb-ft B3 piston plate, screw Torque 6 N˙m 4.4 lb-ft C4 clutch cover, screws Torque 25 N˙m 18 lb-ft Reverse brake housing, screw Torque 50 N˙m 37 lb-ft Forward clutch drum, screw Torque 50 N˙m 37 lb-ft Transmission Components <- Go to Section TOC Section 55 page 59 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Electrically actuated PowrQuad module LEGEND: A B C D E F G H Disk brake housing (reverse brake) Planet gear housing with forward clutch and C4 clutch B2-B3 brake housing B1 brake housing Front transmission cover Front valve housing Transmission oil filter housing Shift valve housing <- Go to Section TOC Section 55 page 60 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Replacing the temperature sensor and pressure switches →NOTE: Before installing the pressure switches, check that the bores are clean and allow a through-passage. LEGEND: A System pressure, pressure switch B Pressure switch for clutch pressure C Pressure switch for the transmission oil filter restriction indicator Replace system pressure switch (A), and tighten it to its proper torque value. Item Measurement Specification System pressure, pressure switch Torque 4 to 7 N˙m 3 to 5 lb-ft Replace clutch pressure switch (B), and tighten it to its proper torque value. Item Measurement Specification Clutch pressure, pressure switch Torque 9 N˙m 6 lb-ft Replace pressure switch (C; for indicating a restriction at the transmission oil filter), and tighten it to its proper torque value. Item Measurement Specification Pressure switch, restriction indicator of the transmission oil filter Torque 4 to 7 N˙m 3 to 5 lb-ft <- Go to Section TOC Section 55 page 61 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module →NOTE: Before installing the temperature sensor, check that its bore is clean and allows a through-passage. Replace temperature sensor (A), and tighten it to its proper torque value. Item Measurement Specification Temperature sensor Torque 4 to 7 N˙m 3 to 5 lb-ft Removing and Installing the Oil Filter Housing [1] - Take screws (A) out of the oil filter housing. [2] →NOTE: Before installing the oil filter housing, clean all the sealing faces. Use a new gasket, if necessary. Keep all the screws and bores clean and dry (i.e. free of oil and grease). Install the oil filter housing, tightening all the screws evenly. Before tightening, allow the <- Go to Section TOC Section 55 page 62 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module screws at least 3 minutes to settle. Item Measurement Specification Oil filter housing, screw Torque 11 N˙m 8 lb-ft Replacing the Oil Filter [1] - Coat the sealing ring (A) on the new oil filter with a little grease or oil. By hand, screw the oil filter onto the filter housing. [2] - Tighten the transmission oil filter to the specified torque value. Item Measurement Specification Transmission oil filter to filter housing Torque 30 N˙m 22 lb-ft <- Go to Section TOC Section 55 page 63 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Removing and Installing the Front Valve Housing Preliminary work: Refer to “Removing the PowrQuad Transmission” in this Section, Group 00. Refer to “Removing and Installing the Oil Filter Housing” . Removing and installing the front valve housing [1] - Take screws (A) out of the front valve housing. [2] - Remove two gaskets and separator plate. <- Go to Section TOC Section 55 page 64 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [3] - If necessary, replace seal ring (A). Use oil seal installer JDG775 to do this. Seal installer JDG775 Installing the seal ring in front valve housing [4] →NOTE: Before installing the front valve housing, clean all the sealing faces. Use a new gasket, if necessary. →NOTE: Tighten screws in clockwise direction, starting with the innermost screws. Keep all the screws and bores clean and dry (i.e. free of oil and grease). Install the front valve housing and tighten the screws evenly to a temporary torque of 10 N˙m (7 lb-ft). [5] - Before tightening to a final torque, allow the screws at least 5 minutes to settle. Item Measurement Specification Front valve housing, screw Torque 11 N˙m 8 lb-ft Final assembly: Refer to “Removing and Installing the Oil Filter Housing” . Refer to “Installing the PowrQuad Transmission” in this Section, Group 00. <- Go to Section TOC Section 55 page 65 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Removing and Installing the Valves in the Front Valve Housing Exploded view of valves and front valve housing LEGEND: A B C D E F Transmission oil filter by-pass valve Cooler relief valve Lube oil relief valve Reverse solenoid (Y36) and shift valve (reverse) Forward solenoid (Y33) and shift valve (forward) Enable proportional solenoid (Y38) Reconditioning the by-pass valve of the transmission oil filter <- Go to Section TOC Section 55 page 66 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [1] - Remove plug (A), spring (B) and valve (C). [2] - Check components for wear. Replace, if necessary. [3] →NOTE: Before installing the valve, check that its bore is clean. Install valve (C), spring (B) and plug (A). Tighten the plug. Item Measurement Specification Transmission oil filter by-pass valve, plug Torque 20 N˙m 15 lb-ft Reconditioning the pressure-relief valve of the cooler [1] - Remove plug (A), spring (B) and valve (C). [2] - Check components for wear. Replace, if necessary. [3] →NOTE: Before installing the valve, check that its bore is clean. <- Go to Section TOC Section 55 page 67 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Install valve (C), spring (B) and plug (A). Tighten the plug. Item Measurement Specification Cooler relief valve, plug Torque 30 N˙m 22 lb-ft Reconditioning the lube oil relief valve [1] - Remove plug (A), spring (B) and valve (C). [2] - Check components for wear. Replace, if necessary. [3] →NOTE: Before installing the valve, check that its bore is clean. Install valve (C), spring (B) and plug (A). Tighten the plug. Item Measurement Specification Lube oil relief valve, plug Torque 20 N˙m 15 lb-ft Reconditioning the reverse solenoid (Y36) and the shift valve <- Go to Section TOC Section 55 page 68 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [1] - Remove solenoid valve (A), spring (B) and shift valve (C). [2] - Check components for wear. Replace, if necessary. [3] →NOTE: Before installing the valve, check that its bore is clean. Install shift valve (C), spring (B) and solenoid valve (A). Tighten solenoid valve (A). Item Measurement Specification Reverse solenoid (Y36) Torque 45 N˙m 33 lb-ft Reconditioning the forward solenoid (Y33) and shift valve [1] - Remove solenoid valve (A), spring (B) and shift valve (C). [2] - Check components for wear. Replace, if necessary. [3] →NOTE: Before installing the valve, check that its bore is clean. <- Go to Section TOC Section 55 page 69 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Install shift valve (C), spring (B) and solenoid valve (A). Tighten solenoid valve (A). Item Measurement Specification Forward solenoid (Y33) Torque 45 N˙m 33 lb-ft Reconditioning the enable proportional solenoid (Y38) [1] - Remove the enable proportional solenoid valve (A). [2] - Replace, if necessary. [3] →NOTE: Before installing the valve, check that its bore is clean. Install the enable proportional solenoid valve (A) and tighten it to its proper torque. Item Measurement Specification Enable proportional solenoid (Y38), screw Torque 25 N˙m 18 lb-ft <- Go to Section TOC Section 55 page 70 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Removing and Installing the Front Transmission Cover Preliminary work: Refer to “Removing and Installing the Front Valve Housing” . [1] - Take screws (A) out of the front transmission cover. →NOTE: On the side with the shift valve housing, two screws (A) are inserted into the front transmission cover from the rear. <- Go to Section TOC Section 55 page 71 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [2] - Before installing the front transmission cover, clean the sealing faces. Use a new gasket, if necessary. [3] - Install the front transmission cover, tightening all the screws evenly. Item Measurement Specification Front transmission cover, screw Torque 60 N˙m 44 lb-ft Final assembly: Refer to “Removing and Installing the Front Valve Housing” . <- Go to Section TOC Section 55 page 72 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Removing and Installing the Valves in the Front Transmission Cover Exploded view, front transmission cover LEGEND: A Return valve, gear-to-gear modulation B Gear-to-gear modulator valve and accumulator (gear-to-gear modulation) C Pressure-regulating valve D Cooling oil control valves and clutch cooling valve Reconditioning the return valve of the gear-to-gear modulator valve <- Go to Section TOC Section 55 page 73 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [1] - Remove cover (A). [2] - Remove return valve (A) and spring (B). [3] - Check components for wear. Replace, if necessary. [4] →NOTE: Before installing the valve, check that its bores are clean and allow a through-passage. Keep all the screws and bores clean and dry (i.e. free of oil and grease). Reinstall the return valve and put the cover back on. Tighten cap screws. Item Measurement Specification Cover for return valve and gear-to-gear modulation valve, screw Torque 12 N˙m 9 lb-ft Reconditioning the gear-to-gear modulator valve and pressure accumulator <- Go to Section TOC Section 55 page 74 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [1] - Remove cover (A). [2] - Remove accumulator (A), pin (B), the two springs (C) and modulator valve (D). [3] - Check components for wear. Replace, if necessary. [4] →NOTE: Before installing the valve, check that its bores are clean and allow a through-passage. Keep all the screws and bores clean and dry (i.e. free of oil and grease). Reinstall the valves and put the cover back on. Tighten cap screws. Item Measurement Specification Cover for return valve and gear-to-gear modulation valve, screw Torque 12 N˙m 9 lb-ft Reconditioning the pressure-regulating valve <- Go to Section TOC Section 55 page 75 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [1] - Remove plug (A) together with washers (B), spring (C) and pressure-regulating valve (D). [2] - Check parts for wear and replace if necessary. [3] →NOTE: Before installing the valve, check that its bore is clean. Install the pressure-regulating valve and tighten the plug. Item Measurement Specification Pressure-regulating valve, plug Torque 30 N˙m 22 lb-ft Reconditioning the cooling oil control valves and cooling valve [1] - Take out plug (A) and remove the cooling oil control valves (B), clutch cooling valve (C) and springs (D). [2] - Check components for wear. Replace, if necessary. <- Go to Section TOC Section 55 page 76 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [3] →NOTE: Before installing the valves, check that the bore is clean and allows a through-passage. Install the valves and tighten the plug. Item Measurement Specification Cooling oil control valves and clutch cooling valve, plug Torque 20 N˙m 15 lb-ft Removing and Installing the Shift Valve Housing [1] - Take screws (A) out of the shift valve housing. [2] →NOTE: Before installing the shift valve housing, clean all the sealing faces. Use a new gasket, if necessary. Keep all the screws and bores clean and dry (i.e. free of oil and grease). Install the shift valve housing, tightening all the screws evenly. Item Measurement Specification Shift valve housing, screw Torque 11 N˙m 8 lb-ft <- Go to Section TOC Section 55 page 77 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Remove and Install the Valves in the Shift Valve Housing Exploded view of shift valve housing LEGEND: A K1 solenoid valve (Y40) and B1-B2 shift valve B K2 solenoid valve (Y39) and B2-B3 shift valve C K3 solenoid valve (Y32) and B3-C4 shift valve <- Go to Section TOC Section 55 page 78 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module IMPORTANT: The K3 solenoid valve (Y32) is omitted from tractor serial no. 398656. Solenoid valve K1 is now designated as solenoid valve 2 (Y63); it shifts B3C4. Solenoid valve K2 is now designated as solenoid valve 1 (Y62); it shifts B1B2. Solenoid valve and B1-B2 shift valve [1] - Remove the K1 solenoid valve (A; Y40), shift valve (B) and spring (C). [2] - Check components for wear. Replace, if necessary. [3] →NOTE: Before installing the valve, check that its bore is clean. Install the valve, tightening it to its proper torque. Item Measurement Specification K1 solenoid valve (Y40) Torque 45 N˙m 33 lb-ft Solenoid valve and B2-B3 shift valve <- Go to Section TOC Section 55 page 79 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [1] - Remove the K2 solenoid valve (A; Y39), shift valve (B) and spring (C). [2] - Check components for wear. Replace, if necessary. [3] →NOTE: Before installing the valve, check that its bore is clean. Install the valve, tightening it to its proper torque. Item Measurement Specification K2 solenoid valve (Y39) Torque 45 N˙m 33 lb-ft Solenoid valve and B3-C4 shift valve [1] - Remove the K3 solenoid valve (A; Y32), shift valve (B) and spring (C). [2] - Check components for wear. Replace, if necessary. [3] →NOTE: Before installing the valve, check that its bore is clean. <- Go to Section TOC Section 55 page 80 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Install the valve, tightening it to its proper torque. Item Measurement Specification K3 solenoid valve (Y32) Torque 45 N˙m 33 lb-ft IMPORTANT: The K3 solenoid valve (Y32) is omitted from tractor serial no. 398656. Instead of the solenoid valve, a screw plug is installed. <- Go to Section TOC Section 55 page 81 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Removing the Transmission Oil Pump Preliminary work: See reference “Removing and Installing the Front Valve Housing” in this Group. See reference “Removing and Installing the Front Transmission Cover” in this Group. [1] - Remove snap ring (A). [2] - Take screws (A) out of the transmission oil pump. <- Go to Section TOC Section 55 page 82 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [3] - Check flange face (A) of the transmission oil pump. Surface (A) must be free of scoring and other signs of damage. If necessary, replace the housing. <- Go to Section TOC Section 55 page 83 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Repairing the Transmission Oil Pump Preliminary work: Refer to “Removing the Transmission Oil Pump” in this Group. Exploded view of the transmission oil pump LEGEND: A B C D E F G H I J K L M N O <- Go to Section TOC Bushing Input shaft Bearing Screw (6 used Pump housing Dowel pin (2 used) Drive gear Idler gear Air pump operating pin Pump piston Rubber ball Lower spring retainer Spring Upper spring retainer with O-ring Snap ring Section 55 page 84 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS P Q R S T U V W X Y Group 10: PowrQuad Module Front transmission cover Bearing Snap ring Seal ring O-ring Input flange Plastic binder Bellows Input flange Input shaft Disassembling the transmission oil pump [1] - LEGEND: A B C Pump housing Pump gears Input shaft Remove input shaft (C). [2] - Take the pump gears (B) out of the pump housing. <- Go to Section TOC Section 55 page 85 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [3] - Check the input shaft for wear. LEGEND: A B Input shaft on tractor 6820 Input shaft on tractor 6920 [4] - Check bearing bushing (A). Replace, if necessary. [5] - Install new bearing bushing using JDG765 bushing installer. Bushing installer JDG765 Installing bushings <- Go to Section TOC Section 55 page 86 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [6] - Check the needle bearing (A). Replace, if necessary. [7] - Insert the needle bearing (A) so that it lies flush with the surface. Do this using a mandrel and the 82.6 mm (3-1/4") and 93.7 mm (3-11/16") dia. washers. Bushing, bearing and seal driver sets D01045AA Driving in bushings, bearings and seals [8] - Check the ball bearing (A) in the front transmission cover. Replace, if necessary. [9] →NOTE: When installing or removing the ball bearing, support the rear surface of the bearing bore to prevent damage to the housing. Insert the ball bearing and press it right down. Do this using a mandrel and the 44.5 mm (1-3/4") and 73 mm (2-7/8") dia. washers. Bushing, bearing and seal driver sets D01045AA Driving in bushings, bearings and seals Hydraulic puller set <- Go to Section TOC Section 55 page 87 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module D01048AA Removal of bearings Mechanical puller set D01173AA Removal of bearings Repairing the pneumatic pump <- Go to Section TOC Section 55 page 88 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [1] - LEGEND: A B C D E F G Pneumatic pump operating pin Piston Rubber ball Lower spring retainer Spring Upper spring retainer with O-ring Snap ring Remove the air pump operating pin (A) from the pump housing. <- Go to Section TOC Section 55 page 89 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [2] - Remove snap ring (G). →NOTE: When disassembling, proceed with care as the snap ring is under pressure. [3] - Remove upper spring retainer (F), spring (E), lower spring retainer (D), rubber ball (C) and piston (B). [4] - Check components (A) to (G) for signs of wear. Replace, if necessary. [5] →NOTE: Apply clean oil to all moving parts before installing. Insert air pump operating pin (A) and install parts (B) to (F). [6] - Install snap ring (G). Assembling the transmission oil pump [1] - Drive in the dowel pins until dimension “a” is 6 ± 1 mm (0.24 ± 0.04 in.). <- Go to Section TOC Section 55 page 90 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [2] →NOTE: Apply clean oil to all moving parts before installing. Install the pneumatic pump operating pin (A) in pump housing. [3] - Install pump gears (A) and (B) in the pump housing so that the side of the gears marked “UP” (C) is visible. IMPORTANT: Install the pump gears so that the side of the gears marked “UP” (C) faces away from the housing (chamfered side of gears must face towards the base of the pump housing). <- Go to Section TOC Section 55 page 91 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [4] - Insert input shaft (A). Note the position of the pneumatic pump operating pin. Final assembly: Refer to “Installing the Transmission Oil Pump” in this Group. <- Go to Section TOC Section 55 page 92 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Installing the Transmission Oil Pump [1] - Install the transmission oil pump on the front transmission cover. [2] IMPORTANT: The attaching screws have self-locking characteristics, and must therefore be replaced with new screws every time they are taken out. Tighten attaching screws (A) evenly. Item Measurement Specification Transmission oil pump to front transmission cover, screw Torque 25 N˙m 18 lb-ft [3] - Install snap ring (A). Final assembly: See reference “Removing and Installing the Front Transmission Cover” in this Group. See reference “Removing and Installing the Front Valve Housing” in this Group. <- Go to Section TOC Section 55 page 93 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Removing the Gear-Shift Planetary Drive Preliminary work: See reference ”Removing and Installing the Front Transmission Cover” in this Group. [1] - LEGEND: A B Cover Ring gear Remove cover (A) and ring gear (B). →NOTE: From tractor serial no. 424468, partial uncovering no longer suffices; it must be uncovered fully. <- Go to Section TOC Section 55 page 94 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [2] - LEGEND: A B C D Planetary carrier 3rd gear sun gear 2nd gear sun gear 1st gear sun gear Remove the planetary carrier assembly (A). [3] - Remove sun gears (B to D). →NOTE: When removing the sun gears, take care not to pull the C4 clutch hub out of the disk pack. <- Go to Section TOC Section 55 page 95 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Repairing the Gear-Shift Planetary Drive Preliminary work: See reference ”Removing the Gear-Shift Planetary Drive” in this Group. Exploded view of the planetary drive LEGEND: A B C D E F G H I J B1 brake housing Screw Bushing 1st gear sun gear Thrust washer 2nd gear sun gear [ A bearing bushing is integrated into the sun gear only from tractor serial no. 392759. ] K Thrust washer 3rd gear sun gear with thrust washer Planetary carrier Thrust washer Spiral ring L Spiral ring M N O P Ring gear with thrust washer Planet gear shaft Retaining pin Thrust washer [ The spiral rings are omitted from tractor serial number 343455. ] [ The spiral rings are omitted from tractor serial number 343455. ] <- Go to Section TOC Section 55 page 96 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Q R S T U Bearing Spacer Planet gear Thrust washer Cover V Screw Group 10: PowrQuad Module [ From tractor serial no. 424468, partial uncovering no longer suffices; it must be uncovered fully. ] [1] - LEGEND: A B Thrust washer Ring gear Inspect thrust washer (A) and ring gear (B). Replace, if necessary. <- Go to Section TOC Section 55 page 97 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [2] - LEGEND: A B Spiral ring Spiral ring Inspect spiral rings (A) and (B). Replace, if necessary. [ The spiral rings are omitted from tractor serial number 343455. ] CAUTION: Take care when disassembling. The spiral rings are under pressure. <- Go to Section TOC Section 55 page 98 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [3] - LEGEND: A B C 3rd gear sun gear with thrust washer Thrust washer 2nd gear sun gear D E F Thrust washer 1st gear sun gear Thrust washer [ A bearing bushing is integrated into the sun gear only from tractor serial no. 392759. ] Check parts (A) to (F). Replace, if necessary. [4] - LEGEND: A Thrust washer Check the 3rd gear sun gear with its thrust washer (A). Replace, if necessary. <- Go to Section TOC Section 55 page 99 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [5] - LEGEND: A Bearing bushing Check the 2nd gear sun gear with its bearing bushing (A). Replace, if necessary. →NOTE: A bearing bushing is integrated into the sun gear only from tractor serial no. 392759. [6] - LEGEND: A Bearing bushing Check the 1st gear sun gear with its bearing bushing (A). Replace, if necessary. [7] - Install bushing flush with surface of gear. Do this using a mandrel and the 93.7 mm (3-13/16") and 109.5 mm (4-5/16") dia. washers. Bushing, bearing and seal driver sets D01045AA Driving in bushings, bearings and seals <- Go to Section TOC Section 55 page 100 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Disassembling the planetary carrier [1] - In order to remove the planet gear shafts, the retaining pins must be driven into the planet gears shafts. IMPORTANT: Take care when driving in a retaining pin. Force it in only far enough for it to be concealed by the planet gear shaft. [2] - Pull out the planet gear shaft and remove the retaining pin. <- Go to Section TOC Section 55 page 101 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [3] - LEGEND: A B C D E F G Planetary carrier Planet gear Planet gear shaft Retaining pin Thrust washers Needle bearing Spacer Remove needle bearings (F) and spacers (G) from planet gear (B). [4] - Clean and check the various parts. Replace, if necessary. Assembling the planetary carrier [1] - LEGEND: A B Needle bearing Spacer Insert needle bearings (A) and spacer (B) into the planet gear. <- Go to Section TOC Section 55 page 102 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [2] IMPORTANT: Before assembling, make sure that the oil passages in the planet gear shafts and planetary carrier are not blocked. LEGEND: A B Thrust washer Planet gear shaft Insert the planet gear in the planetary carrier, remembering to include thrust washers (B). [3] - Install planet gear shaft (B). [4] - Drive in the retaining pin until it is flush. Final assembly: See reference ”Installing the Gear-Shift Planetary Drive” in this Group. <- Go to Section TOC Section 55 page 103 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Install Gear-Shift Planetary Drive [1] - LEGEND: A B Thrust washer Spiral ring Check thrust washer (A). The thrust washer must not be worn or damaged. [2] - Install the bottom spiral ring (B) [ The spiral rings are omitted from tractor serial number 343455. ] . <- Go to Section TOC Section 55 page 104 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [3] - LEGEND: A Mark Apply paint to indicate the three marks (A) stamped on the edge of the ring gear (as help in installing the planetary carrier), as the marks are concealed when the top spiral ring [ The spiral rings are omitted from tractor serial number 343455. ] is put on. <- Go to Section TOC Section 55 page 105 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [4] - LEGEND: A Spiral ring Install the top spiral ring (A) [ The spiral rings are omitted from tractor serial number 343455. ] in such a way that the ends (A) of the top and bottom spiral rings are at opposite sides. <- Go to Section TOC Section 55 page 106 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [5] - LEGEND: A B Timing mark on ring gear Timing mark on planet gear Install the planet gear carrier in the ring gear in such a way that the timing marks on the planet gears are opposite the timing marks on the ring gear. [6] - Turn the planet gear carrier and ring gear. Make sure the marks remain synchronized with each other. <- Go to Section TOC Section 55 page 107 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [7] - Install the JDG772 planetary installation tool. Planetary holding tool JDG772 Assembling the planetary housing [8] - LEGEND: A Teeth Place the transmission housing in the vertical position. [9] - Align the teeth on disks (A). <- Go to Section TOC Section 55 page 108 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [10] - LEGEND: A B C D E F G 1st gear sun gear 2nd gear sun gear 3rd gear sun gear Thrust washer Thrust washer Thrust washer Thrust washer on 3rd gear sun gear Refer to the cross-sectional view before installing the sun gears and thrust washers. [11] - LEGEND: A B C 1st gear sun gear 2nd gear sun gear 3rd gear sun gear with thrust washer Install sun gears (A), (B) and (C), remembering to include thrust washers. <- Go to Section TOC Section 55 page 109 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [12] - Install the planetary drive on the sun gears using a JDG772 planetary holding tool. →NOTE: Turn the planetary drive to and fro; this will help facilitate its installation. <- Go to Section TOC Section 55 page 110 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [13] - LEGEND: A Cover Put on cover (A). Coat the screws with Thread Lock and Sealer LOCTITE ™ 243 (L41475), and tighten. Item Measurement Specification Ring gear cover, screw Torque 10 N˙m 7 lb-ft →NOTE: From tractor serial no. 424468, partial uncovering no longer suffices; it must be uncovered fully. Final assembly: See reference ”Removing and Installing the Front Transmission Cover” in this Group. Removing the B1 Brake Housing Preliminary work: <- Go to Section TOC Section 55 page 111 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module See reference “Removing the Gear-Shift Planetary Drive” in this Group. Take out screws (A). <- Go to Section TOC Section 55 page 112 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Reconditioning the B1 Brake Preliminary work: See reference ”Removing the B1 Brake Housing” in this Group. [1] - LEGEND: A B Spring (4 used) Piston plate, B1-B2 disks Take off the parts of the B1-B2 brake and check them. Replace, if necessary. [2] - Remove B1 brake piston (A) and check it. Replace, if necessary. [3] - <- Go to Section TOC Section 55 page 113 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module LEGEND: A B C D E F B2-B3 brake housing Sealing ring B2 piston B2 piston plate B2 disk B1-B2 separator plate G H I J K L M Spring B1 disk B1 plate B1 piston plate B1 piston B1 brake housing Attaching screw [ From tractor ser. no. 411806, the separator plate is replaced by two thinner plates ] Refer to the exploded view before assembling the B1-B2 brake. Final assembly: See reference ”Installing the B1 Brake Housing” in this Group. <- Go to Section TOC Section 55 page 114 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Installing the B1 Brake Housing [1] - Insert seal ring (A) and the O-rings. [2] - Install the B1 brake housing. Make sure that the seal ring and O-rings are seated correctly. [3] - Tighten the attaching screws evenly. Item Measurement Specification B1 brake housing, attaching screws Torque 60 N˙m 44 lb-ft Final assembly: See reference “Installing the Gear-Shift Planetary Drive” in this Group. Removing the B2-B3 Brake Housing Preliminary work: See reference “Removing the B1 Brake Housing” in this Group. <- Go to Section TOC Section 55 page 115 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Remove the B2-B3 brake housing (A). <- Go to Section TOC Section 55 page 116 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Reconditioning the B2 Brake Preliminary work: See reference ”Removing the B2-B3 Brake Housing” in this Group. [1] - LEGEND: A B Springs (4 used) Piston plate, B1-B2 disks Take off the various parts of the B1-B2 brake and check them. Replace, if necessary. [2] - Remove B2 brake piston (A). Replace, if necessary. <- Go to Section TOC Section 55 page 117 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [3] - LEGEND: A B C D E F B2-B3 brake housing Seal ring B2 brake piston B2 piston plate B2 disk B1-B2 separator plate G H I J K L Spring B1 disk B1 plate B1 piston plate B1 brake piston B1 brake housing [ From tractor ser. no. 411806, the separator plate is replaced by two thinner plates ] Refer to the exploded view before assembling the B2 brake. Final assembly: See reference ”Installing the B2-B3 Brake Housing” in this Group. <- Go to Section TOC Section 55 page 118 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Reconditioning the B3 Brake Preliminary work: See reference “Removing the B2-B3 Brake Housing” in this Group. [1] - Remove B3 brake piston (A) and check it. Replace, if necessary. [2] - Take out screws (A). [3] - Take out the various components of the B3 brake and check them. Replace, if necessary. [4] - <- Go to Section TOC Section 55 page 119 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module LEGEND: A B C D E F G H I J Planet gear housing Seal B3 plate B3 disk B3 piston plate Spring B3 brake piston B2-B3 brake housing Dowel pin Screw Refer to the exploded view before assembling the B3 brake. [5] →NOTE: Keep all the screws and bores clean and dry (i.e. free of oil and grease). <- Go to Section TOC Section 55 page 120 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Tighten attaching screws (A) evenly. Item Measurement Specification B3 piston plate, screw Torque 6 N˙m 4.4 lb-ft Final assembly: See reference “Installing the B2-B3 Brake Housing” in this Group. Installing the B2-B3 Brake Housing [1] - Insert seal (A) and the O-rings. <- Go to Section TOC Section 55 page 121 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [2] - Install the B2-B3 brake housing (A). Make sure that the seal and O-rings are seated correctly. Final assembly: See reference “Installing the B1 Brake Housing” in this Group. Removing the C4 Clutch Preliminary work: See reference “Removing the B2-B3 Brake Housing” in this Group. Take out the C4 clutch (A). <- Go to Section TOC Section 55 page 122 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Reconditioning the C4 Clutch Preliminary work: See reference ”Removing the C4 Clutch” in this Group. Exploded view of C4 clutch LEGEND: A Planet gear housing B Thrust washer C Sealing ring D Bushing E C4 clutch drum F Dowel pin G Sealing ring H Sealing ring I C4 clutch piston J Clutch hub K Piston plate L Disk M Disk N Pin O Spring P Clutch cover Q Screw R Suction valves <- Go to Section TOC Section 55 page 123 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS S T U V W X Group 10: PowrQuad Module Dowel pin Thrust washer Bushing [ From tractor serial no. 392759, the bearing bushing is omitted from the C4 clutch drum. Thereafter, the bearing bushing is integrated into the 2nd gear sun gear. Remember this when ordering spare parts. ] Retainer Anti-cavitation check valve Thrust washer Recondition or assemble the C4 clutch as required, using the illustration as a guide. [1] - Take out screws (Q) and remove clutch cover (P). [2] - Remove clutch hub (J), disks (L) and (M) and piston plate (K). [3] - Remove springs (O) and pins (N). [4] - Remove the C4 clutch piston (I) and C4 clutch drum (E), and the piston seal rings (G) and (H). Assembling C4 clutch <- Go to Section TOC Section 55 page 124 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [1] - LEGEND: A Anti-cavitation check valves Inspect clutch piston and anti-cavitation check valves (A). →NOTE: LEGEND: A B Retainer Ball The anti-cavitation check valve consists of retainer (A) and ball (B). The valve ball must not be jammed; it must move freely. <- Go to Section TOC Section 55 page 125 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [2] - LEGEND: A Seal ring Coat seal ring (A) with grease and install it in the piston groove. →NOTE: Position the seal ring in the ring groove so that it is not damaged when the piston is installed. [3] - LEGEND: A Bushing Inspect bushing (A). Replace, if necessary. <- Go to Section TOC Section 55 page 126 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [4] - LEGEND: A Bushing Install new bushing using JDG765 Bushing Installer. Bushing installer JDG765 Installing bushings →NOTE: Press in bushing (A) until it is 1.5 mm (0.06 in.) below the surface. <- Go to Section TOC Section 55 page 127 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [5] - LEGEND: A Sun gear, bearing bushing From tractor serial no. 392759, the bearing bushing is omitted from the C4 clutch drum. Thereafter, bearing bushing (A) is integrated into the 2nd gear sun gear. [6] - LEGEND: A Bushing Inspect bushing (A). Replace, if necessary. <- Go to Section TOC Section 55 page 128 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [7] - LEGEND: A B Bushing Surface Install new bushing using D01045AA Driver Set. Do this using a mandrel and the 57.2 mm (2-1/4") and 66.7 mm (2-5/8") dia. washers. Bushing, bearing and seal driver sets D01045AA Driving in bushings, bearings and seals →NOTE: Press in bushing (A) until it is 0.5 mm (0.02 in.) below the surface (B). [8] - At the clutch drum, apply a light coat of grease to the mounting surfaces of the clutch piston. <- Go to Section TOC Section 55 page 129 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [9] - LEGEND: A Seal ring Coat seal ring (A) with grease and install it in the groove at the clutch drum. →NOTE: Position the seal ring in the ring groove so that it is not damaged when the piston is installed. [10] - LEGEND: A B Piston Guides Place piston (A) in clutch drum with guides (B) for piston plate installation in the position shown. [11] - Press piston (A) down in the clutch drum. IMPORTANT: Be careful to avoid damaging the seal rings. <- Go to Section TOC Section 55 page 130 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [12] - LEGEND: A Piston plate Insert piston plate (A). [13] - LEGEND: A Thrust washer Install the thrust washer (A). →NOTE: Slightly coat the thrust washer with grease to prevent it from falling out. <- Go to Section TOC Section 55 page 131 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [14] - LEGEND: A Clutch hub Insert the clutch hub (A). [15] - LEGEND: A B Disk with liner Disk without liner Assemble the disk pack as required. Start with a lined disk (A). [16] - Then install disks without liner (B) and disks with liner (A) alternately. <- Go to Section TOC Section 55 page 132 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [17] - LEGEND: A Guide pin Install the spring guide pins (A). [18] - LEGEND: A Spring Insert the springs (A). <- Go to Section TOC Section 55 page 133 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [19] - Apply sealing compound LOCTITE ™ 243 (medium strength) to the threaded bores. [20] - LEGEND: A B Hole Dowel pin Install the clutch cover. Position the clutch cover so that the bores (A) for the dowel pins (B) are aligned. <- Go to Section TOC Section 55 page 134 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [21] - LEGEND: A Attaching screw Insert clutch cover attaching screws (A) and slightly tighten them in cross-wise fashion until clutch cover contacts clutch drum. [22] - Tighten clutch cover attaching screws (A) to the specified torque. Item Measurement Specification C4 clutch cover, screws Torque 25 N˙m 19 lb-ft Final assembly: See reference ”Installing the C4 Clutch” in this Group. Installing the C4 Clutch <- Go to Section TOC Section 55 page 135 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [1] - Make sure that seal rings (A) and thrust washer (B) are positioned correctly. [2] - Check the suction valves (C) for the forward clutch and C4 clutch. The valve ball must not be jammed; it must move freely. [3] - Install the C4 clutch (A). Final assembly: See reference “Installing the B2-B3 Brake Housing” in this Group. Removing the reverse brake Preliminary work: See “Removing the PowrQuad transmission” . <- Go to Section TOC Section 55 page 136 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [1] - Take out screws (A) and remove the reverse brake housing. [2] - Repair the reverse brake. See “Repairing the reverse brake” in this group. <- Go to Section TOC Section 55 page 137 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Repairing the reverse brake Preliminary work: See “Removing the reverse brake” . [1] - Remove the pack of brake disks (A). [2] - Remove pressure plate (A) and springs (B). [3] - Removing the reverse brake piston (A). <- Go to Section TOC Section 55 page 138 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [4] - LEGEND: A B C D E F G H Dowel pin Bearing bushing Seal ring Mounting screw Reverse brake housing Gasket Reverse brake piston Piston plate Reverse brake disk (4 [ Tractors 6820 ] I or 5 [ Tractors 6920 ] J <- Go to Section TOC used) Spring (8 used) Section 55 page 139 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Reverse brake plate (3 [ Tractors 6820 ] K or 4 [ Tractors 6920 ] L M used) Ring gear Pressure plate Repair or assemble the reverse brake as required, using the exploded view as a guide. [5] - Check the bearing bushing (A) in the reverse brake housing. Replace, if necessary. [6] - When installing, turn bushing (A) so that its hole is aligned with the hole in the housing (see arrow). [7] - Press bushing (A) into the housing in such a way that it lies flush with the surface on the side of the piston. Do this using a mandrel and the 93.7 mm (3-11/16") and 100 mm (3-15/16") dia. washers. Bushing, bearing, and seal driver sets D01045AA Driving in bushings, bearings and seals Final assembly: Refer to “Installing the reverse brake” . Installing the reverse brake [1] - Clean the sealing surfaces and install the gasket. <- Go to Section TOC Section 55 page 140 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [2] - Install the reverse brake housing and tighten screws (A). Item Measurement Specification Reverse brake housing, screw Torque 50 N˙m 37 lb-ft Final assembly: See “Installing PowrQuad transmission” . <- Go to Section TOC Section 55 page 141 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Removing the Forward Clutch with Planetary Drive (Forward/Reverse) Preliminary work: See reference “Removing the Reverse Brake” in this Group. [1] - Remove pressure plate (A) and ring gear (B). [2] →NOTE: The forward clutch and planetary drive are very heavy. Proceed with care and use suitable lifting tackle. Remove the forward clutch with planetary drive. <- Go to Section TOC Section 55 page 142 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Reconditioning the Forward Clutch with Planetary Drive (Forward/Reverse) Preliminary work: See reference ”Removing the Forward Clutch with Planetary Drive (Forward/Reverse)” in this Group. Cross-sectional and exploded views of the forward clutch and planetary drive LEGEND: A B C <- Go to Section TOC Piston plate Disk Clutch plate Section 55 page 143 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS D E F G H I J K L M N O P Q R S T U V W <- Go to Section TOC Group 10: PowrQuad Module Planetary carrier Retaining pin Thrust washer Planet gear Planet gear shaft Clutch hub Thrust washer Needle bearing Bushing Spring Guide pin Seal ring Clutch piston Seal ring Bushing Drive shaft Snap-ring Thrust washer Clutch drum Overspeed relief valve Section 55 page 144 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS LEGEND: 1 2 3 4 5 6 7 8 <- Go to Section TOC Group 10: PowrQuad Module Planet gear housing Thrust washer Seal ring Drive shaft Snap-ring Clutch hub Snap-ring Bushing Section 55 page 145 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 Group 10: PowrQuad Module Clutch piston Seal ring Seal ring Thrust washer Clutch drum Attaching screw Bushing Ball Spring Retainer Spring Guide pin Piston plate Disk with liner Disk without liner Retaining pin Thrust washer Planet gear Needle bearing Planet gear shaft Planetary carrier Thrust washer Recondition or assemble the forward clutch and planetary drive as required, using the crosssection and exploded views as guidelines. [1] →NOTE: It is not necessary to remove drive shaft (A) unless it is damaged. <- Go to Section TOC Section 55 page 146 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module LEGEND: A B Drive shaft Snap-ring Drive shaft (A) is locked to the clutch drum by snap ring (B). Snap ring (B) will be damaged if the shaft is removed. Press the drive shaft (A) out in the direction shown by the arrow. [2] - LEGEND: A Clutch drum Take out the attaching screws and lift off clutch drum (A). <- Go to Section TOC Section 55 page 147 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [3] - LEGEND: A Disk pack Take disk pack (A) and the clutch hub, springs, guide pins and clutch piston out of the clutch drum. Check components for wear. Replace, if necessary. [4] - Install the forward clutch LEGEND: A Bushing Install bushing (A) in the clutch drum; make sure it is flush. Do this using a mandrel and the 57.2 mm (2-1/4") and 66.7 mm (2-5/8") dia. washers. Bushing, bearing and seal driver sets D01045AA Driving in bushings, bearings and seals <- Go to Section TOC Section 55 page 148 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [5] - LEGEND: A B Bushing Snap-ring Install bushing (A) in the hub; make sure it is flush. Do this using a mandrel and the 74.6 mm (2-15/16′′) dia. washer. Bushing, bearing and seal driver sets D01045AA Driving in bushings, bearings and seals [6] - Insert snap ring (B) into the ring groove in the hub. [7] - LEGEND: A Overspeed relief valves Check the clutch piston and the overspeed relief valves (A). →NOTE: The overspeed relief valve consists of a ball, spring and retainer. The valve ball must not be jammed; it must move freely against the spring. <- Go to Section TOC Section 55 page 149 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [8] - LEGEND: A Seal ring Coat seal ring (A) with grease and install it in the piston groove. →NOTE: Position the seal ring in the ring groove so that it is not damaged when the piston is installed. [9] - At the clutch drum, apply a light coat of grease to the mounting surfaces of the clutch piston. <- Go to Section TOC Section 55 page 150 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [10] - LEGEND: A Seal ring Coat seal ring (A) with grease and install it in the groove at the clutch drum. →NOTE: Position the seal ring in the ring groove so that it is not damaged when the piston is installed. [11] - LEGEND: A B Piston Guide Place piston (A) in clutch drum with guides (B) for piston plate installation in the position shown. [12] - Press piston (A) down in the clutch drum. IMPORTANT: Be careful to avoid damaging the seal rings. <- Go to Section TOC Section 55 page 151 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [13] - LEGEND: A B C Piston plate Guide pin Guides Insert the piston plate (A) together with the guide pins (B), paying attention to guides (C). [14] - LEGEND: A Thrust washer Install the thrust washer (A). →NOTE: Slightly coat the thrust washer with grease to prevent it from falling out. <- Go to Section TOC Section 55 page 152 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [15] - LEGEND: A Clutch hub Insert the clutch hub (A). [16] - LEGEND: A B Disk with liner Disk without liner Assemble the disk pack as required. Start with a lined disk (A). Then install disks without liner (B) and disks with liner (A) alternately. <- Go to Section TOC Section 55 page 153 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [17] - LEGEND: A Spring Insert the springs (A). [18] - LEGEND: A Clutch cover Position the clutch cover and planetary carrier so that the blind holes (A) for springs (B) are aligned. <- Go to Section TOC Section 55 page 154 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [19] - LEGEND: A Attaching screws Before turning the forward clutch with the planetary carrier through 180°, install two attaching screws (A) and tighten them a little, so that the various components stay in position. [20] - Take out the two attaching screws that were already installed. Apply sealing compound LOCTITE ™ 243 (medium strength) to all the attaching screws. <- Go to Section TOC Section 55 page 155 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [21] - Install the attaching screws and slightly tighten them in cross-wise fashion until the clutch cover touches the clutch drum. [22] - Now tighten the clutch cover attaching screws to the specified torque. Item Measurement Specification Forward clutch drum, screw Torque 50 N˙m 37 lb-ft <- Go to Section TOC Section 55 page 156 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [23] - LEGEND: A B Drive shaft Snap-ring Put snap ring (B) on the drive shaft (A). →NOTE: There is a chamfer on the front end of the splines in the clutch drum to allow the drive shaft with snap ring in place to be installed more easily. [24] - Press drive shaft (A) into the clutch drum as shown by the arrow. Reconditioning the planetary carrier <- Go to Section TOC Section 55 page 157 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [1] - In order to remove the planet gear shafts, the retaining pins must be driven into the planet gears shafts. IMPORTANT: Take care when driving in a retaining pin. Force it in only far enough for it to fall into the planet gear shaft. [2] - LEGEND: A B C Planet gear shaft Planet gear Retaining pin Pull out planet gear shaft (A) and take off planet gear (B) with its thrust washers and needle bearing. [3] - Remove retaining pin (C) from planet gear shaft (A). <- Go to Section TOC Section 55 page 158 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [4] - LEGEND: A B C D E Thrust washers Needle bearing Planet gear Planet gear shaft Retaining pin Check the components. Replace, if necessary. [5] - LEGEND: A B C Thrust washers Needle bearing Planet gear Assembling the planetary carrier Insert needle bearing (B) and install thrust washers (A) on planet gear (C). [6] IMPORTANT: Before installing, make sure that the oil passages in the planet gear shafts and planetary carrier are not blocked. <- Go to Section TOC Section 55 page 159 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Insert the planet gear in the planetary carrier, remembering to include TWO thrust washers (A). [7] - Install planet gear shaft (B). [8] - Drive in the retaining pin until it is flush. Final assembly: See reference ”Installing the Forward Clutch with Planetary Drive (Forward/Reverse)” in this Group. <- Go to Section TOC Section 55 page 160 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Installing the Forward Clutch with Planetary Drive (Forward/Reverse) [1] - Make sure that seal rings (A) and thrust washer (B) are positioned correctly. [2] →NOTE: The forward clutch and planetary drive are very heavy. Proceed with care and use suitable lifting tackle. →NOTE: Avoid damaging the sealing rings. Install the forward clutch with planetary drive. <- Go to Section TOC Section 55 page 161 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [3] - Install pressure plate (A) and ring gear (B). Final assembly: See reference “Installing the Reverse Brake” in this Group. <- Go to Section TOC Section 55 page 162 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module Replacing the output shaft Preliminary work: See “Removing the PowrQuad transmission” . Exploded view of output shaft LEGEND: A B C D E F G Seal ring Transmission output shaft Bearing bushing O-ring Snap ring Sleeve Rear PTO drive shaft Repair or assemble the components of the drive shaft as required, using the exploded view illustration as a guide. <- Go to Section TOC Section 55 page 163 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 10: PowrQuad Module [1] - Check the transmission output shaft, the rear PTO drive shaft, the sleeve and all components for wear. Replace, if necessary. LEGEND: A B C Sleeve Rear PTO drive shaft Transmission output shaft [2] - LEGEND: A B C D Seal ring O-rings Bushing Oil passage Press in the bushing (C) to a depth of 2 mm (0.079 in.) beneath the base of the chamfer in the transmission output shaft. Do this using a mandrel and the 93.7 mm (3-11/16") and 100 mm (3-15/16") dia. washers. Bushing, bearing, and seal driver sets D01045AA Driving in bushings, bearings and seals [3] - Make sure the oil passages (D) of the transmission output shaft are open. <- Go to Section TOC Section 55 page 164 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 15: Creeper Transmission Final assembly: See “Installing PowrQuad transmission” . <- Go to Section TOC Section 55 page 165 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 15: Creeper Transmission Group 15 - Creeper Transmission Creeper Transmission - Reconditioning (Summary of References) ”Removing the creeper transmission” ”Reconditioning the creeper transmission” ”Installing the creeper transmission” Special tools →NOTE: Order tools according to information given in the U.S. SERVICEGARD ™ Catalog or European Microfiche Tool Catalog (MTC). Bushing, bearing, and seal driver set D01045AA Install bushings, bearings, and seals Repair specifications Item Measurement Specification Shifter fork detent pin, spring Free length approx. 20 mm approx. 0.8 in. Test length 12 mm at 58 to 72 N 0.5 in. at 12 to 16 lb Friction brake, spare part Disk thickness 2,33 to 2,43 mm 0.092 to 0.096 in. Plate thickness 1,52 mm to 1,62 mm 0.060 to 0.064 in. Backing plate to input shaft, hex. socket screw Torque 4 N˙m 3 lb-ft Intermediate plate to range transmission, cap screw Torque 70 N˙m 50 lb-ft <- Go to Section TOC Section 55 page 166 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 15: Creeper Transmission Removing the creeper transmission Preliminary work: For information on removing the PowrQuad, PowrQuad Plus and AutoQuad transmissions, see “Removing the PowrQuad transmission” . Before removing the creeper transmission, see “Removing the creeper or intermediate transmission” . [1] - Remove creeper transmission. [2] - If necessary, remove intermediate plate (A). [3] - Remove cap screws (B) and intermediate plate. <- Go to Section TOC Section 55 page 167 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 15: Creeper Transmission Repairing the creeper transmission Preliminary work: See “Removing the creeper transmission” . Creeper transmission — Sectional view <- Go to Section TOC Section 55 page 168 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS <- Go to Section TOC Section 55 page 169 Group 15: Creeper Transmission TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS LEGEND: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 Group 15: Creeper Transmission Roller bearing Snap ring Snap ring Wear sleeve Ball bearing Snap ring Snap ring Lube passage seal Input shaft with gear Drive sleeve Housing Shift collar Output gear Thrust washer Snap ring Output drive gear/friction brake Snap ring Bushing Spring (friction brake) Brake disks (3 used) Externally splined disk (3 used) Backing plate Cap screw (3 used) Thrust washer Needle bearing Snap ring Transmission lube oil seal Countershaft Needle bearing Countershaft drive gear Intermediate plate Exploded view of the input/output drive shaft and shifter assembly <- Go to Section TOC Section 55 page 170 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS LEGEND: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 <- Go to Section TOC Group 15: Creeper Transmission Output sleeve Input shaft Shift collar Dowel pin Spring pin Shift fork Ball bearing Snap ring Snap ring O-ring Shifter shaft Lever Detent pin Spring Section 55 page 171 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 Group 15: Creeper Transmission Washer Plug Shifter fork detent Sealing sleeve Snap ring Thrust washer Needle bearing Snap ring Snap ring Thrust washer Drive gear Input shaft Bushing Spring washer Externally splined disk (3 used) Brake disks (3 used) Backing plate Hex. socket screw (3 used) Repair or assemble the input/output shaft and shifter assembly as required, using the exploded view illustration as a guide. Shifter assembly components — Sectional view LEGEND: A B C <- Go to Section TOC Shifter shaft O-ring Spring pin Section 55 page 172 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS D E F G H I J Group 15: Creeper Transmission Shift fork Dowel pin Distance 6.75 to 7.25 mm (0.266 to 0.285 in.) Spring Detent pin Washer Plug Repairing the input/output shaft and shifter assembly [1] - Remove snap ring (A), thrust washer (B) and gear (C). [2] - Remove plug (A) and shifter fork detent parts. Item Measurement Specification Shifter fork detent pin, spring Free length approx. 20 mm approx. 0.8 in. Test length 12 mm at 58 N to 72 N 0.5 in. at 12 lb to 16 lb <- Go to Section TOC Section 55 page 173 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 15: Creeper Transmission [3] - LEGEND: A B C D E Shifter fork Spring pins Lever, shifter shaft Shift collar Dowel pins Turn shifter fork (A) to the front and remove shift collar (D). Now the output shaft can be removed. [4] - If necessary, remove spring pins (B) and pull out lever (C) with shifter shaft. [5] - Check the dowel pins (E) for wear. Replace, if necessary. The dowel pins must protrude 6.75 to 7.25 mm (0.266 to 0.285 in.) from finished face of the shifter fork. [6] - LEGEND: A B C D Snap ring Shaft Bearing Snap ring Remove snap ring (A). [7] - Remove input/output shaft (B) rearward through bearing (C). <- Go to Section TOC Section 55 page 174 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 15: Creeper Transmission [8] - Check bearing (C) for wear. Replace, if necessary. →NOTE: To disassemble the bearing the countershaft drive gear must be removed. See "Repairing the countershaft". [9] - Remove bearing snap ring (D). [10] - Remove the countershaft drive gear. [11] - Remove bearing (C) using the driver (102 mm; 4 in. dia.). Bushing, bearing, and seal driver set D01045AA Install bushings, bearings, and seals [12] - Install a new bearing (C) using a 110 mm (4-5/16 in.) driver disk and a 70 mm (2-3/4 in.) pilot disk. Bushing, bearing, and seal driver set D01045AA Install bushings, bearings, and seals [13] - Install bearing snap ring (D). [14] - Remove snap ring (A), the roller bearing (B) of the range transmission shaft and thrust washers. [15] - Remove internal snap ring (C). [16] - Remove output shaft/friction brake (A) from input shaft (B). <- Go to Section TOC Section 55 page 175 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 15: Creeper Transmission [17] - Remove drive sleeve (C) from shaft. [18] - Take out cap screws (A). [19] - LEGEND: A B C D Backing plate Brake disks (3 used) Externally splined disk (3 used) Spring washer Remove parts (A—D). Item Measurement Specification Friction brake, spare part Disk thickness 2,33 to 2,43 mm 0.092 to 0.096 in. Plate thickness 1,52 mm to 1,62 mm 0.060 to 0.064 in. [20] - Inspect the bearing bushing (A) for wear. Replace, if necessary. <- Go to Section TOC Section 55 page 176 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 15: Creeper Transmission [21] - Install new bearing bushing using a 50 mm (1-15/16 in.) driver disk and a 46 mm (1-13/16 in.) pilot disk. Bushing, bearing, and seal driver set D01045AA Install bushings, bearings, and seals →NOTE: Insert the bearing at a depth of up to 1 mm (0.039 in.) beneath the surface of the hub. [22] - LEGEND: A B C D Backing plate Brake disks Externally splined disks Spring washer Install spring washer (D) with ID against the hub face. [23] - Alternately install three disks (B) and three externally splined disks (C), starting with an externally splined disk against the spring washer. [24] - Install backing plate (A). [25] - Apply L41475 ( LOCTITE ™ 243) to threads of cap screws (A). [26] - Install hex. socket screws. Do not tighten the at this stage. [27] - Align the tangs (B) on the brake disks. <- Go to Section TOC Section 55 page 177 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 15: Creeper Transmission [28] - Align the splines on the input drive shaft with the brake disk tangs and install the input drive shaft (A) into the output drive shaft/friction brake assembly (B). [29] - Tighten the hex. socket screws (C). Item Measurement Specification Backing plate to input shaft, hex. socket screw Torque 4 N˙m 3 lb-ft [30] - Remove the input drive shaft (A) from the assembly. [31] - Install the transmission drive sleeve (C) onto the input drive shaft (B). [32] - Install the output shaft/friction brake (A) onto the input drive shaft (B). [33] - Install internal snap ring (C). [34] - Install the roller bearing (B) of the range box shaft, together with a thrust washer on each end. [35] - Install snap ring (A). <- Go to Section TOC Section 55 page 178 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 15: Creeper Transmission [36] - LEGEND: A B C D Snap ring Shaft Bearing Snap ring Push the input/output shaft (B) through bearing (C). [37] - Install snap ring (A). [38] - Position the shift collar (A) at the dowel pins (C) of the shifter fork (B) and push onto the output drive shaft. <- Go to Section TOC Section 55 page 179 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 15: Creeper Transmission [39] - Install output drive gear (C) onto the shaft. [40] - Install thrust washer (B) and snap ring (A). Exploded view of the countershaft and housing LEGEND: A B C D <- Go to Section TOC Cap screw (8 used) Dowel pin (2 used) Intermediate plate Countershaft drive gear Section 55 page 180 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS E F G H I J K L M N O P Q R S Group 15: Creeper Transmission Dowel pin (2 used) Cap screw (2 used) Housing Roller bearing Snap ring Snap ring Wear sleeve Cover Cap screw (5 used) Oil seal Countershaft Needle bearing Cap screw (3 used) Plug O-ring Repair or assemble the countershaft as required, using the illustration as a guide. Repairing the countershaft [1] - LEGEND: A B C D E Shaft snap ring Shaft Countershaft drive gear Bearing snap ring Shaft bearing Pull the snap ring (A) and the countershaft (B) rearwards out of the bearing and the countershaft drive gear (C). [2] - Take the drive gear (C) out of the housing. [3] - Remove the snap ring (D) and remove bearing (E) from housing, if necessary. <- Go to Section TOC Section 55 page 181 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 15: Creeper Transmission [4] - Remove bearing from the rear using a 60 mm (2-3/8 in.) driver. Bushing, bearing, and seal driver set D01045AA Install bushings, bearings, and seals [5] - Remove needle bearing (A) from housing, if necessary, using a 50 mm (2 in.) driver. Bushing, bearing, and seal driver set D01045AA Install bushings, bearings, and seals [6] - Install a new bearing in the housing. Use a 64 mm (2-1/2 in.) driver disk with a 43 mm (1-11/16 in.) pilot disk. Bushing, bearing, and seal driver set D01045AA Install bushings, bearings, and seals [7] - Install the new bearing from rear of housing until rear bearing surface is flush with housing surface. [8] - Remove transmission lube oil seal (A) from rear of countershaft, if necessary. [9] - Install new seal ring using a 30 mm (1-3/16 in.) socket wrench. <- Go to Section TOC Section 55 page 182 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 15: Creeper Transmission [10] - Remove wear sleeve (A) from front of countershaft, if necessary. [11] - Install new sleeve using a 32 mm (1-1/4 in.) driver. Bushing, bearing, and seal driver set D01045AA Install bushings, bearings, and seals [12] - LEGEND: A B C D E Shaft snap ring Shaft Countershaft drive gear Bearing snap ring Shaft bearing If required, install a new bearing (E) using a 60 mm (2-3/8-in.) driver disk and a 28.5 mm (1-1/8 in.) pilot disk. Bushing, bearing, and seal driver set D01045AA Install bushings, bearings, and seals [13] - Install snap ring (D). [14] - Install countershaft drive gear (C) into the housing with widest flange toward front of housing. <- Go to Section TOC Section 55 page 183 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 15: Creeper Transmission [15] - Install countershaft (B) into the housing through rear needle bearing, drive gear, and front roller bearing (E). [16] - Install snap ring (A). Final assembly: See “Installing the creeper transmission” . <- Go to Section TOC Section 55 page 184 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 15: Creeper Transmission Installing the creeper transmission [1] - Check cover (A) and sealing sleeve (B). Replace, if necessary. [2] - Install cover (A) in range transmission using L41477 ( LOCTITE ™ 603). [3] - Install sealing sleeve (B). [4] - Install intermediate plate (A). [5] - Apply a thin and even layer of L64500 ( LOCTITE ™ 574) to the sealing faces. [6] - Tighten cap screws (B). Item Measurement Specification Intermediate plate to range transmission, cap screw Torque 70 N˙m 50 lb-ft <- Go to Section TOC Section 55 page 185 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission [7] - Install the creeper transmission. See “Installing the creeper or option transmission” . Final assembly: See “Installing PowrQuad transmission” . <- Go to Section TOC Section 55 page 186 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission Group 20 - Range Transmission Range Transmission - Reconditioning (Summary of References) ”Special tools” ”Specifications” ”Removing the range transmission” ”Range transmission - Sectional view” ”Reconditioning the range transmission” ”Installing the range transmission” ”Reconditioning the shift cover” ”Replace speed sending unit” Special tools →NOTE: Order tools according to information given in the U.S. SERVICEGARD ™ Catalog or European Microfiche Tool Catalog (MTC). 2-1/2 in. heavy duty socket JDT44 Removing and tightening intermediate shaft nut Bushing, bearing, and seal driver set D01045AA Removal and installation of bearings and bushings Puller set D01047AA Removal of bearings and bushings <- Go to Section TOC Section 55 page 187 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission Bracket Dealer-fabricated A-Flat steel bar 25x10x145 mm; (1x0.4x5.7 in.) Holding the shift rod detent when adjusting the shifting mechanism <- Go to Section TOC Section 55 page 188 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission Repair specifications Item Measurement Specification Drive shaft Axial play 0.013 to 0.080 mm 0.0005 to 0.0030 in. Adjustment ring retaining plate, cap screw Torque 25 N˙m 18 lb-ft Park lock pawl, spring Free length approx. 62 mm approx. 2.44 in. Test length 57 mm at 38±9 N 2.2 in. at 8.5±2 lb Intermediate shaft nut Torque 550 N˙m 405 lb-ft Adjusting intermediate shaft Axial play 0.013 to 0.080 mm 0.0005 to 0.0030 in. Shift fork detent, spring Free length approx. 43 mm approx. 1.69 in. Test length 35.9 mm at 100±10 N 1.41 in. at 22.05 ± 2.2 lb Threaded pins of shift forks Torque 40 N˙m 30 lb-ft Shift cover to range transmission, cap screws Torque 70 N˙m 50 lb-ft Mounting screws, speed sender Torque 20 N˙m 15 lb-ft Removing the range transmission Preliminary work: Before removing the range transmission, see “Removing the range transmission” . <- Go to Section TOC Section 55 page 189 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission CAUTION: The range transmission is heavy. Support it securely before carrying out any service work to avoid personal injury. Range Transmission - Sectional View Range transmission (40 km/h; 25 mph version) LEGEND: <- Go to Section TOC Section 55 page 190 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS A B C D E F G H I J K L M N <- Go to Section TOC Group 20: Range Transmission Drive shaft Gear, range C Synchronizer unit Gear, range D Synchronizer unit Gear, range E Differential drive shaft Gear Gear Front-wheel drive gear Gear Gear, range B Synchronizer unit Gear, range A Section 55 page 191 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission Repairing the Range Transmission Preliminary work: “Removing the range transmission” . →NOTE: Repairing the 40 km/h (25 mph) range transmission is explained here. Shifter assembly components — Sectional view LEGEND: A B C D E F Shifter fork, ranges C and D Shift rod, range E Shift rod, ranges C and D Shift rod, ranges A and B Balls Locking pin Repair (remove and install) the shifter assembly parts using the sectional view illustration as a guide. <- Go to Section TOC Section 55 page 192 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission →NOTE: Shift rods and forks are marked. The shift forks are marked with the range designations (e.g., “A - B”). The shift rods have the designations stamped on the front. Removing the differential drive shaft [1] - Parking lock lever (A) in park position Move parking lock lever to park position to prevent differential drive shaft from rotating. [2] - Remove intermediate shaft nut using special tool JDT44 or a commercial socket. 2-1/2 in. Heavy Duty Socket JDT44 Remove and install differential drive shaft nut <- Go to Section TOC Section 55 page 193 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission [3] - Remove shift cover (A). [4] - Remove detent springs (A). Using a magnet, remove detent balls. [5] - Remove plug (A) and spring (B). [6] - Remove snap ring (C) and parking lock pawl. <- Go to Section TOC Section 55 page 194 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission [7] - Remove shift rod (A) and shift fork of range A and B. →NOTE: During removal, pay attention to the locking pin and detent balls of the shift rods. See sectional view illustration of shifter assembly parts. [8] - Lightly strike the end of differential drive shaft with a plastic hammer until bearing cone can be removed. <- Go to Section TOC Section 55 page 195 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission [9] - Carefully pull out differential drive shaft and remove parts from shaft. Removing the drive shaft [1] - LEGEND: A B C D Shift rod, range E Shift fork, range E Shift rod, ranges C and D Shift fork, ranges C and D Remove shift rods and forks. <- Go to Section TOC Section 55 page 196 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission [2] - Remove cap screw (A) and locking plate (B). [3] - Turn adjusting ring (C) counterclockwise and remove. [4] - Take out drive shaft. Exploded view of drive shaft <- Go to Section TOC Section 55 page 197 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission 40 km/h (25 mph) drive shaft - Exploded view LEGEND: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 <- Go to Section TOC Snap ring Taper roller bearing cup Cap screw Housing Plug Retaining plate Cap screw Taper roller bearing cup Adjusting ring Sealing sleeve Taper roller bearing cone Drive shaft Gear, range E Synchronizer unit Thrust washer Sleeve Gear (range D) Section 55 page 198 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS 18 19 20 21 22 23 Group 20: Range Transmission Synchronizer unit Sleeve Gear, range C Thrust washer Taper roller bearing cone Snap ring (thickness as required) 50 km/h (31 mph) drive shaft - Exploded view LEGEND: 1 2 3 4 5 <- Go to Section TOC Snap ring Taper roller bearing cup Cap screw Housing Plug Section 55 page 199 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 Group 20: Range Transmission Retaining plate Cap screw Taper roller bearing cup Adjusting ring Sealing sleeve Taper roller bearing cone Thrust washer Needle bearing Gear, range A Sleeve Drive shaft Thrust washer Gear, range E Synchronizer unit Thrust washer Sleeve Gear, range D Synchronizer unit Gear, range C Thrust washer Taper roller bearing cone Snap ring (thickness as required) Check the drive shaft and repair or assemble it as required, using the exploded view illustration as a guide. Exploded view of differential drive shaft <- Go to Section TOC Section 55 page 200 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS LEGEND: A B C D E F G H I J K L M N O P Group 20: Range Transmission Differential drive shaft Taper roller bearing assy. Spacer washer (quantity and thickness as required) Spacer Spacer washer (quantity and thickness as required) Taper roller bearing assy. Adjusting ring Wear sleeve Gear, range A Synchronizer unit Sleeve Gear, range B Gear, range E Front-wheel drive gear Gear, range D Gear, range C Check the differential drive shaft and repair or assemble it as required, using the exploded view illustration as a guide. <- Go to Section TOC Section 55 page 201 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission Shifting mechanism - Exploded view LEGEND: 1 2 3 4 5 6 7 8 9 10 11 Ball Locking pin Spring Shift rod, range E Shift rod, ranges C and D Shift rod, ranges A and B Shift fork, ranges C and D Shift fork, range E Shifter fork, ranges A and B Wear lining Threaded pin Check the shifting mechanism and repair or assemble it as required, using the exploded view illustration as a guide. <- Go to Section TOC Section 55 page 202 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission →NOTE: When installing, refer to the sectional view illustration of the shifter assembly parts as well. Apply grease to balls and locking pins so that the shift rods remain in place during installation. Shift rods and forks are marked. The shift forks are marked with the range designations (e.g., “A - B”). The shift rods have the designations stamped on the front. Park lock - exploded view LEGEND: 1 2 3 4 <- Go to Section TOC Pin Bushing Washer Locking pawl Section 55 page 203 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 Group 20: Range Transmission Bushing Shaft Snap ring Spring O-ring Plug Cotter pin Locking cam Thrust washer Needle bearing Washer Lever arm Spring pin O-ring Dowel pin Spring Square plate Washer Bushing Cotter pin Retaining clip Lever arm Support bushing Washer Screw Rod Hex. nut Slotted nut Check the park lock components and repair or assemble it as required, using the exploded view illustration as a guide. Repairing the drive shaft [1] - Remove snap ring (A). <- Go to Section TOC Section 55 page 204 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission [2] - Place puller as shown in the illustration. Pull off taper roller bearing cone (B) and remove the components. Puller Set D01047AA Remove bearings and bushings [3] CAUTION: Heat bearing in a bearing heater. Do not exceed 150°C (300°F). Proceed with care to avoid burns. Install bearing cone (A). <- Go to Section TOC Section 55 page 205 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission [4] - Install range E gear (C), synchronizer (B) and thrust washer (A). [5] - Install range D gear (B) with sleeve and synchronizer (A). [6] - Install range C gear (B) with sleeve and thrust washer (A). <- Go to Section TOC Section 55 page 206 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission [7] CAUTION: Heat bearing in a bearing heater. Do not exceed 150°C (300°F). Proceed with care to avoid burns. Install bearing cone (A). [8] →NOTE: Snap rings (A) are available in various thicknesses. Use the thickest snap ring that fits in the groove. Install snap ring (A). Installing the drive shaft <- Go to Section TOC Section 55 page 207 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission [1] - Insert taper roller bearing cup (B) in housing and install snap ring (A). [2] - Press taper roller bearing cup (A) into adjusting ring (B). [3] - Install drive shaft in housing. <- Go to Section TOC Section 55 page 208 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission [4] - Screw in adjustment ring (A). Adjusting end play of drive shaft [1] - Tighten adjusting ring until specified end play is obtained. Item Measurement Specification Drive shaft adjustment End play 0.013 to 0.080 mm 0.0005 to 0.0030 in. <- Go to Section TOC Section 55 page 209 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission [2] - Install locking plate (B) and cap screw (A). [3] →NOTE: If necessary, turn adjusting ring until locking plate fits in the next recess. Tighten cap screw. Item Measurement Specification Adjusting ring - locking plate, cap screw Torque 25 N˙m 18 lb-ft [4] - LEGEND: A B C D Shift rod, range E Shift fork, range E Shift rod, ranges C and D Shift fork, ranges C and D Install drive shaft shift rods and forks. →NOTE: When installing, refer to the sectional and exploded view illustrations of the shifter assembly parts. <- Go to Section TOC Section 55 page 210 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission Install drive shaft and adjust cone point [1] - Note the letter (A) stamped on the upper left side of the front face of the differential housing and refer to the chart below for the corresponding dimension. →NOTE: If letter is absent, always assume a measurement of 205.00 mm (8.071 in.). Letter on housing Measurement A 204.89 mm (8.067 in.) B 204.95 mm (8.069 in.) C 205.00 mm (8.071 in.) D 205.05 mm (8.073 in.) E 205.10 mm (8.075 in.) [2] - The fixed measurement is always 24.06 mm (0.947 in.) [3] - Note the measurement (C) stamped on the pinion face. <- Go to Section TOC Section 55 page 211 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission [4] - Calculate thickness of spacer washer pack (D). D=A-B-C Example: Letter from housing and corresponding measurement from chart .......... A=204.89 mm (8.067 in.) Specified fixed measurement .......... B=24.06 mm (0.947 in.) Measurement stamped on pinion face .......... C=180.05 mm (7.088 in.) D = 204.89 mm - 24.06 mm - 180.05 mm D = 0.78 mm D = 8.067 in. - 0.947 in. - 7.088 in. D = 0.030 in. [5] - Install shims (A) of the calculated thickness. [6] - Install taper roller bearing cup (A). <- Go to Section TOC Section 55 page 212 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission [7] CAUTION: Heat bearing in a bearing heater. Do not exceed 150°C (300°F). Proceed with care to avoid burns. Install taper roller bearing cone (A) on differential drive shaft. →NOTE: Press taper roller bearing cone as far as it will go. [8] - Push differential drive shaft into housing and install parts. →NOTE: Also install shift fork for ranges A and B on synchronizer. When installing shifter fork later, all the shift rods have to be removed again. <- Go to Section TOC Section 55 page 213 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission [9] - Install spacer (A) and shims (B). →NOTE: If differential drive shaft end play has to be re-adjusted, shims of 2 mm (0.078 in.) thickness must be installed. [10] - Install taper roller bearing cone (C). [11] - Install shift rod (A), ranges A and B. →NOTE: When installing, refer to the sectional and exploded view illustrations of the shifter assembly parts. <- Go to Section TOC Section 55 page 214 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission [12] - Install parking lock pawl and snap ring (C). [13] - Install spring (B) and plug (A). Item Measurement Specification Parking lock pawl spring Free length approx. 62 mm approx. 2.44 in. Test length 57 mm at 38±9 N 2.2 in. at 8.5±2 lb Adjusting end play of differential drive shaft <- Go to Section TOC Section 55 page 215 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission [1] - Install shims of 2 mm (0.078 in.) thickness behind taper roller bearing cone. [2] - Temporarily attach shift cover with two screws and move parking lock lever to parking position to prevent differential drive shaft from rotating. [3] - Tighten differential drive shaft nut using special tool JDT44 or a commercial socket. 2-1/2 in. Heavy Duty Socket JDT44 Remove and install differential drive shaft nut Item Measurement Specification Differential drive shaft nut Torque 550 N˙m 405 lb-ft [4] - Determine end play. [5] - Remove shims until specified end play is obtained. Item Measurement Specification Differential drive shaft adjustment End play 0.013 to 0.080 mm 0.0005 to 0.0030 in. <- Go to Section TOC Section 55 page 216 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission [6] - Tighten differential drive shaft nut again using special tool JDT44 or a commercial socket and secure it in two places. 2-1/2 in. Heavy Duty Socket JDT44 Remove and install differential drive shaft nut Item Measurement Specification Differential drive shaft nut Torque 550 N˙m 405 lb-ft [7] - Install balls and springs (A) of shift rod detent. Item Measurement Specification Shift fork lock, spring Free length approx. 43 mm approx. 1.69 in. Test length 35.9 mm at 100±10 N 1.41 in. at 22.05 ± 2.2 lb force Adjusting the range shift linkage <- Go to Section TOC Section 55 page 217 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission [1] - Attach the dealer-manufactured retainer (A) that acts as a detent for the shift rods. Retainer dealer-fabricated A-Flat steel bar 25x10x145 mm; (1x0.4x5.7 in.) Holding the shift rod detent when adjusting the shifting mechanism [2] - Thoroughly clean threaded pins and apply L41475 ( LOCTITE ™ 243) to them. [3] - Move the shift rods to their neutral positions. [4] - Adjust shift forks by means of threaded pins until they are centered in relation to shift collars. [5] - Move the shift forks to all positions. →NOTE: Shift forks must not rub laterally at the shift collars in ANY of the shift positions. <- Go to Section TOC Section 55 page 218 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission [6] - Tighten threaded pins of shift forks. Item Measurement Specification Threaded pins of shift forks Torque 40 N˙m 30 lb-ft [7] - Check the shift mechanism again. Final assembly: “Installing the range transmission” . <- Go to Section TOC Section 55 page 219 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission Installing the range transmission [1] - Move range transmission (shift rods) in neutral position. [2] - Install the two cap screws (A) for attaching the range transmission. [3] - Align shift levers on shift cover with the shift rods in the housing. Install shift cover on housing. [4] - Tighten cap screws (B). Item Measurement Specification Shift cover to range transmission, cap screws Torque 70 N˙m 50 lb-ft [5] - Install the range transmission. Final assembly: Before installing the range transmission, see “Installing the range transmission” . <- Go to Section TOC Section 55 page 220 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission Repairing the shift cover [1] - Remove shift cover (A). <- Go to Section TOC Section 55 page 221 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission [2] - LEGEND: A B C D E F G H I J K L M N O P Q Lever Spring pin Gasket Dowel pin Shift cover Locking cam Thrust washer Needle bearing Cap screw O-ring Washer Lever arm O-ring Lever, ranges A and B Lever, range E Spring pin Lever, ranges C and D Repair or assemble the shift cover as required, using the exploded view illustration as a guide. <- Go to Section TOC Section 55 page 222 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission [3] - Install the two cap screws (A) for attaching the range transmission. [4] - Align shift levers on shift cover with the shift rods in the housing. Install shift cover on housing. [5] - Tighten cap screws (B). Item Measurement Specification Shift cover to range transmission, cap screws Torque 70 N˙m 50 lb-ft <- Go to Section TOC Section 55 page 223 TM4756-REPAIR MANUAL Section 55 - POWRQUAD PLUS, AUTOQUAD AND AUTOQUAD PLUS TRANSMISSIONS Group 20: Range Transmission Replacing the speed sender [1] - LEGEND: A Sender for ground speed (B35) Sender for ground speed (B09) [ For tractors with creeper ] B Sender for transmission speed (B104/1) Disconnect speed sender from plugs. →NOTE: Before disconnecting the plugs, mark them so as to avoid installing them in the wrong positions. [2] - Remove mounting screw (C). [3] - Pull sender out of housing. [4] - <- Go to Section TOC Section 55 page 224 TM4756-REPAIR MANUAL DRIVE SYSTEMS (g) by Belgreen LEGEND: A B Ground speed sender (B35) Ground speed sender (B09) C D E F G Transmission speed sender (B104/1) O-ring Protective cap Terminal Mounting screw [ For tractors with creeper ] Install new sender in housing with O-ring. [5] - Tighten mounting screws (C). Item Measurement Specification Mounting screw, speed sender Torque 20 N˙m 15 lb-ft <- Go to Section TOC Section 55 page 225 TM4756-REPAIR MANUAL TM4756-REPAIR MANUAL (g) by Belgreen Section 56 - DRIVE SYSTEMS Table of contents Group 00 - Removal and Installation of Components .......................................................... 1 Special Tools .......................................................................................................................... 1 Dealer-Fabricated Special Tools ............................................................................................. 4 Repair Specifications .............................................................................................................. 8 Remove the Front-Wheel Drive Clutch ................................................................................... 9 Install the Front-Wheel Drive Clutch .................................................................................... 11 Remove the Differential Housing ......................................................................................... 13 Install the Differential Housing ............................................................................................. 27 Remove Final Drives ............................................................................................................ 33 Install Final Drives ................................................................................................................ 41 Remove Rear PTO ................................................................................................................ 47 Install Rear PTO .................................................................................................................... 50 Remove Front PTO ............................................................................................................... 51 Install Front PTO ................................................................................................................... 54 Group 05 - U-Jointed Shafts and Torsion Damper .............................................................. 55 Summary of References (U-Jointed Shafts and Torsion Damper) ......................................... 55 Special Tools ........................................................................................................................ 55 Use of Special Tool KJD10426 .............................................................................................. 57 Repair specifications ............................................................................................................ 58 Remove Front-Wheel Drive U.j. Shaft ................................................................................... 59 Reconditioning the U.j. Shaft (Front-Wheel Drive) ............................................................... 61 Install Front-Wheel Drive U.j. Shaft ...................................................................................... 65 Removing the U.J. Shaft (Engine) ......................................................................................... 68 Removing and Installing the Ring-Shaped Cooler ................................................................ 69 Removing the Torsion Damper ............................................................................................ 70 Changing the Torsion Damper Bearings ............................................................................... 71 Installing the Torsion Damper .............................................................................................. 71 Installing the U.j. Shaft (Engine) ........................................................................................... 73 Group 10 - Front-Wheel Drive Clutch ................................................................................... 74 Drive Systems - Front-Wheel Drive Clutch, Summary of References ................................... 74 Special tools ......................................................................................................................... 75 Other material ...................................................................................................................... 76 Repair Specifications ............................................................................................................ 77 Front-Wheel Drive Clutch - Sectional View ........................................................................... 77 Front-Wheel Drive Clutch — Exploded View ......................................................................... 79 Front-Wheel Drive Clutch - Replace Front-Wheel Drive Axle Speed Sensor (B89) ................ 82 FWD Clutch — Replacing Solenoid Valve ............................................................................. 83 Replacing the FWD Clutch .................................................................................................... 85 Group 15 - Differential .......................................................................................................... 105 Drive Systems - Differential, Summary of References ....................................................... 105 Special tools ....................................................................................................................... 105 Differential - Specifications ................................................................................................ 106 Differential - Sectional View ............................................................................................... 106 Differential - Exploded View ............................................................................................... 108 Remove the Differential ..................................................................................................... 110 Recondition the Differential ............................................................................................... 113 <- Go to Global Table of contents TM4756-REPAIR MANUAL TM4756-REPAIR MANUAL (g) by Belgreen Install the Differential ......................................................................................................... 120 Differential - Adjust Preload ............................................................................................... 122 Differential - Adjust Backlash ............................................................................................. 124 Group 20 - Hydraulic Pump Drive ....................................................................................... 126 Hydraulic Pump Drive — Summary of References ............................................................. 126 Special tools ....................................................................................................................... 127 Repair Specifications .......................................................................................................... 127 Remove and Disassemble Pump Drive Pinion Gear ........................................................... 129 Remove and Disassemble the Pump Drive Gear ................................................................ 132 Assemble and Install Pump Drive Pinion Gear .................................................................... 134 Assembling and installing the pump drive pinion ............................................................... 137 Checking and adjusting the backlash of the pump drive pinion ......................................... 141 Group 25 - Final Drives ......................................................................................................... 142 Drive Systems - Final Drives, Summary of References ...................................................... 142 Final Drives - Special Tools ................................................................................................ 142 Final Drives - Repair Specifications .................................................................................... 143 Final Drives - Sectional View .............................................................................................. 143 Remove Planetary Carrier .................................................................................................. 145 Disassemble Planetary Carrier ........................................................................................... 147 Assemble Planetary Carrier ................................................................................................ 149 Remove Axle Housing ........................................................................................................ 152 Disassemble and Asssemble Axle Housing ........................................................................ 153 Disassemble and Assemble Axle Shaft ............................................................................... 155 Final Drives - Install Axle Housing ...................................................................................... 157 Final Drives - Install Planetary Carrier and Check Rolling Drag Torque .............................. 158 Group 30 - Rear PTO ............................................................................................................. 167 Drive Systems - Rear PTO, Summary of References .......................................................... 167 Special tools ....................................................................................................................... 168 Specifications ..................................................................................................................... 170 Repair Instructions ............................................................................................................. 170 Repair Rear PTO ................................................................................................................. 172 Remove and Disassemble Countershaft ............................................................................ 185 Assemble and Install Countershaft ..................................................................................... 189 Remove and Disassemble Output Shaft ............................................................................. 192 Assemble and Install PTO Output Shaft .............................................................................. 198 Remove PTO Shifter ........................................................................................................... 202 Install PTO Shifter ............................................................................................................... 205 Replacing Oil Seal on PTO Output Shaft ............................................................................. 207 Remove Modulating Valve .................................................................................................. 207 Disassemble and Assemble Modulating Valve ................................................................... 209 Install Modulating Valve ..................................................................................................... 211 Changing and adjusting the bowden cable ........................................................................ 212 Group 35 - Front PTO ............................................................................................................ 216 Front PTO - Reconditioning (Summary of References) ....................................................... 216 Other Material .................................................................................................................... 216 Specifications ..................................................................................................................... 217 General Repair Procedures ................................................................................................ 218 Replace Y01 - Solenoid Valve for Front PTO ....................................................................... 218 Reconditioning the Modulator Valve .................................................................................. 220 Replace B58 - Front PTO Speed Sensor .............................................................................. 222 <- Go to Global Table of contents TM4756-REPAIR MANUAL TM4756-REPAIR MANUAL (g) by Belgreen Cleaning and Replacing the Filter ...................................................................................... 222 Reconditioning the Pressure-Regulating Valve .................................................................. 224 Checking the Cooler Relief and Filter By-Pass Valves ........................................................ 225 Removing and Installing the Valve Plate ............................................................................ 225 Front PTO — Sectional View ............................................................................................... 227 Disassembling the Front PTO ............................................................................................. 231 Reconditioning the Oil Pump .............................................................................................. 234 Reconditioning the PTO Clutch ........................................................................................... 239 Reconditioning the PTO Brake ............................................................................................ 245 Reconditioning the Intermediate Gear Shaft (PTO Rotating Counterclockwise) ................. 249 Reconditioning the Drive Shaft .......................................................................................... 251 Assembling the Front PTO .................................................................................................. 257 Group 40 - Front Implement Drive ...................................................................................... 266 Front Implement Drive (Summary of References) .............................................................. 266 General Information ........................................................................................................... 266 Special Tools ...................................................................................................................... 266 Repair Specifications .......................................................................................................... 267 Summary of Torques .......................................................................................................... 267 Preliminary Work ................................................................................................................ 268 Installing and Removing Drive Shaft .................................................................................. 270 <- Go to Global Table of contents TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components Group 00 - Removal and Installation of Components Special Tools →NOTE: Order tools according to information given in the U.S. SERVICEGARD ™ Catalog or European Microfiche Tool Catalog (MTC). Pulling device KJD10169 Pulling dowel pins out of main frame Support stand JT05723 Removing and installing the transmission assembly and differential housing. Also required: 2 commercial 8-metric ton vehicle jacks Support stand <- Go to Section TOC Section 56 page 1 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components JT05724 Raising and supporting front end of tractor. Also required: 2 commercial 5-metric ton vehicle jacks Support stand JT05725 Supporting tractor during rear wheel removal. Also required: 1 commercial 12-ton vehicle jack Lifting sling JDG23 <- Go to Section TOC Section 56 page 2 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components Removal and installation of the operator′s cab Support stand D05007ST Removing and installing final drives, front axle or front-wheel drive axle Flywheel turning tool JDG820 Turning flywheel on 6-cylinder engines <- Go to Section TOC Section 56 page 3 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components Dealer-Fabricated Special Tools Adapter Strut dealer fabricated LEGEND: A B C D E F G H 80 mm (3.2 in.) 45 mm (1.8 in.) 400 mm (16 in.) 360 mm (14.17 in.) 140 mm (5.51 in.) 13 mm (1/2 in.) dia. bore 19 mm (3/4 in.) dia. bore 8 mm (5/16”) Allows installation of the JT05723 stand on the rear PTO housing. Made from U-shaped steel to U-80 DIN1026-St37-2 (UNP-80 EN10279) standard. When selecting hardware, be sure to choose high-tensile attaching screws. When securing the adapter strut, only use DIN6918 washers, which have a tilt of 8%, on the inside of the strut. Hardware required: Two M12 x 60 mm cap screws and two M16 x 40 mm cap screws. Holding fixture dealer fabricated <- Go to Section TOC Section 56 page 4 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS LEGEND: a b c d e f A Group 00: Removal and Installation of Components 250 mm (10 in.) 50 mm (2 in.) 15 mm (0.6 in.) 205 mm (8.1 in.) 16 mm (0.6 in.) 18 mm (45/64 in.) dia. hole M12x30mm Screw Used in conjunction with support stand D05007ST during the removal of tractor components. Also required: two M16x350 mm threaded rods. When used to remove the final drives, screw (A) is used to support the edge of the flat piece of metal. Lifting eyes (2 used) dealer fabricated <- Go to Section TOC Section 56 page 5 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components LEGEND: A Commercial M16, DIN 582 Lifting Eye Nut B M16 Nut C Threaded Rod M16 x 100 mm (4 in.), Grade 8.8 Coat threaded rod (C) with LOCTITE ™ 270 (L41476), and screw it into eye nut (A) until it bottoms. Lock with nut (B). Holding fixture dealer fabricated <- Go to Section TOC Section 56 page 6 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components Removal and installation of final drive housings and other tractor components. Used in conjunction with support stand D05007ST. <- Go to Section TOC Section 56 page 7 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components Repair Specifications Item Measurement Specificatio n Cap Screws, Range Transmission to Differential Housing Torque 90 N˙m 66 lb.-ft. Cap Screws, Differential Housing to Main Frame Torque 525 N˙m 385 lb.-ft. Cap Screws, Final Drive Housing to Differential Housing Torque 230 N˙m 170 lb.-ft. Cap Screws, Rear Cab Mounting Torque 200 N˙m 145 lb.-ft. Hex. Socket Screw, Bracket of Stabilizer Bar to Final Drive Housing Torque 710 N˙m 525 lb.-ft. Cap Screws, Front-Wheel Drive Clutch Housing to Range Transmission Torque 50 N˙m 37 lb.-ft. Cap Screws, Rear PTO Housing to Differential Housing Torque 240 N˙m 175 lb.-ft. Attaching Screws, Center Link Bracket to PTO Housing / Differential Housing Torque 340 N˙m 250 lb.-ft. Cap Screws, Front PTO to Support Torque 600 N˙m 445 lb.-ft. <- Go to Section TOC Section 56 page 8 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components Remove the Front-Wheel Drive Clutch Disconnect handbrake bowden cable (A) and remove lever (B). Remove U-jointed front-wheel drive shaft. See Remove the U.J. Shaft (Front-Wheel Drive Axle) in Section 56, Group 05. Remove transmission oil drain screw (B) at front-wheel drive clutch housing and drain oil into a suitable container. Then disconnect pressure line (A) at the solenoid valve. Also disconnect connector (C). →NOTE: Seal the open ends with plastic plugs. <- Go to Section TOC Section 56 page 9 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components Place hoist underneath front-wheel drive clutch housing, then remove attaching screws. →NOTE: To gain access to all the screws, first remove the front-wheel drive clutch solenoid valve. Remove housing from below. →NOTE: Housing flanges are coated with flexible sealant. For this reason, the housings may stick to each other even if the cap screws have been removed. If a pick-up hitch is equipped, carefully guide the front-wheel drive clutch housing past shield (A). <- Go to Section TOC Section 56 page 10 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components Install the Front-Wheel Drive Clutch Thoroughly clean sealing surfaces of range transmission housing and front-wheel drive clutch housing, then coat them with LOCTITE ™ 574 (L64500) flexible sealant. Using a hoist, move front-wheel drive clutch housing under range transmission housing. Move front-wheel drive clutch housing until it contacts range transmission, making sure that the two dowel pins are correctly located in the bores provided. Tighten the cap screws to the specified torque. Item Measurement Specification Cap Screws, Front-Wheel Drive Clutch Housing to Range Transmission Torque 50 N˙m 37 lb.-ft. For further assembly, follow disassembly procedure in reverse order. Fill with transmission oil. Check oil level and top up, if necessary (see operator′s manual). Adjust the handbrake. See Adjusting the Handbrake in Section 60, Group 20. <- Go to Section TOC Section 56 page 11 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components IMPORTANT: On tractors equipped with air brakes, it is vitally important to check that the trailer brake valve is set correctly. <- Go to Section TOC Section 56 page 12 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components Remove the Differential Housing [1] - Open the hood. Disconnect the negative terminal (—) on the battery. The version shown here has a negative terminal at the location marked (A). CAUTION: Always pay close attention to battery terminals. Comply with safety instructions on how to handle batteries (see Section 05). [2] - Take off the two rear wheels. See Removing the Front and Rear Wheels in Section 80, Group 10. [3] - Remove the fuel tank. See Removing the Fuel Tank in Section 30, Group 10. [4] - Remove the u.j. shaft of the front-wheel drive axle. See Remove the U.J. Shaft (FrontWheel Drive Axle) in Section 56, Group 05. [5] - If equipped, disengage the clutch cable. <- Go to Section TOC Section 56 page 13 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components [6] - Remove drain screw (A) and allow the transmission oil to drain out. →NOTE: Trap the oil in a container with a capacity of at least 60 liters (15 U.S.gal.). [7] - LEGEND: A B C D JT05724 Universal Support Stand JT05723 Universal Support Stand Front Support of JT05723 L78499 Bracket <- Go to Section TOC Section 56 page 14 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS E F Group 00: Removal and Installation of Components Wooden Block Adapter Strut (Dealer-Fabricated) Attach JT05724 support stand (A) to both main frame sides. Two L78499 brackets (D) may be used. Also put two suitable wooden blocks (E) between the main frame and the universal support stand. Support stand JT05724 Raising and supporting front end of tractor. Also required: 2 commercial 5-metric ton vehicle jacks Place support stand JT05723 (B) underneath the transmission unit. Adjust the supports so that the front one (C) makes contact under the front-wheel drive clutch and the rear one makes contact under the PTO housing. Support stand JT05723 Removing and installing the transmission assembly and differential housing. Also required: 2 <- Go to Section TOC Section 56 page 15 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components commercial 8-metric ton vehicle jacks To secure the support stand to the PTO housing, a dealer-fabricated adapter strut (F) must be used. This strut must be bolted securely both to the PTO housing and to the universal support stand. Adapter Strut dealer fabricated LEGEND: A B C D E F G H 80 mm (3.2 in.) 45 mm (1.8 in.) 400 mm (16 in.) 360 mm (14.17 in.) 140 mm (5.51 in.) 13 mm (1/2 in.) dia. bore 19 mm (3/4 in.) dia. bore 8 mm (5/16”) Allows installation of the JT05723 stand on the rear PTO housing. Made from U-shaped steel to U-80 DIN1026-St37-2 (UNP-80 EN10279) standard. When selecting hardware, be sure to choose high-tensile attaching screws. When securing the adapter strut, only use DIN6918 washers, which have a tilt of 8%, on the inside of the strut. Hardware required: Two M12 x 60 mm cap screws and two M16 x 40 mm cap screws. →NOTE: The adapter strut is not necessary for some tractor versions. IMPORTANT: When selecting hardware, be sure to choose high-tensile attaching screws. When securing the adapter strut, only use DIN6918 washers, which have a tilt of 8%, on the inside of the strut. <- Go to Section TOC Section 56 page 16 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components [8] - Install dealer-manufactured lifting eyes (B), lifting sling (A; JDG23) and lifting tackle on the roof of the operator′s cab. Lifting sling JDG23 Removal and installation of the operator′s cab Lifting eyes (2 used) dealer fabricated <- Go to Section TOC Section 56 page 17 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components LEGEND: A B C Commercial M16, DIN 582 Lifting Eye Nut M16 Nut Threaded Rod M16 x 100 mm (4 in.), Grade 8.8 Coat threaded rod (C) with LOCTITE ™ 271 (TY43513), and screw it into eye nut (A) until it bottoms. Lock with nut (B). [9] - Loosen the front cab mounting screws (A), but do NOT take them out. <- Go to Section TOC Section 56 page 18 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components [10] - On tractors with a cab, take out cap screws (A) (on both sides). [11] - To make the following jobs easier, the cab or open platform can now be raised at the rear by several centimeters. IMPORTANT: When doing this, make sure that none of the tractor′s components become strained. [12] - Take off the cover and disconnect the two connectors (A). <- Go to Section TOC Section 56 page 19 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components [13] - If the tractor has an independent control valve (ICV or E-ICV), unscrew fittings (C), trap any oil that emerges and seal the open ends so that no dust can get in. Then remove bracket (A) from bracket (B). Disconnect connector (D). [14] - <- Go to Section TOC Section 56 page 20 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components LEGEND: A B C D E F G H I J K Steering Pressure Line Steering LS Line SCV Bowden Cables Connector Height-Adjustable Trailer Hitch Rails Connector Bowden Cable Center Link Connector Connector Hose Disconnect or remove all components shown here. [15] - Disconnect all transmission shift bowden cables (A). →NOTE: There may be differences here depending on how the tractor is equipped. Disengage park lock bowden cable (B) at the lever and counter-bearing. Take out the screws that hold bracket (C) onto the final drive housing. <- Go to Section TOC Section 56 page 21 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components [16] - Unscrew brake line fittings (B) and take out the screws that hold on bracket (A). Release the brake lines from the clamps on the main frame. →NOTE: Trap any oil as it emerges. Seal the open ends so that no dust can penetrate. If the transmission assembly is subsequently to be disassembled, the brake lines can remain secured to the differential housing. [17] - Tractors with TLS front-wheel drive axle: Disconnect the two lines (A) and hose (B). <- Go to Section TOC Section 56 page 22 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components [18] - Take out screw (A). [19] - Disconnect return hose (A) and hose (B). Take out the screw that holds on the hose bracket. <- Go to Section TOC Section 56 page 23 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components [20] - Disconnect the oil cooler hoses (A). IMPORTANT: Every time you disconnect an oil hose with a quick-coupler, replace the retaining clip with a new one. Once clips are installed, check that they are seated correctly. The bent ends of the clip must touch each other. Otherwise, the coupler can become loose. [21] - Remove cap screws (A) using the special tools (B) and (C). Support stand D05007ST <- Go to Section TOC Section 56 page 24 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components Removal and installation of differential housing. Extension JDG749 Removal and installation of differential housing. IMPORTANT: Before doing so, make sure that the support stands are installed securely. CAUTION: Once the cap screws have been removed, do not perform any jobs between the main frame and transmission assembly or underneath the tractor, as these areas are potentially hazardous. <- Go to Section TOC Section 56 page 25 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components [22] - Roll the transmission assembly out to the rear. →NOTE: This job requires several assistants. Watch out for any additional equipment that may be installed. Take care to prevent hoses, wiring or bowden cables from getting caught. [23] - Remove all transmission housings, the final drive housings and the PTO housing. CAUTION: In this procedure, it is important to keep changing the position of the stand supports. When removing the first final drive housing, remember to support the other final drive housing (the one on the opposite side). For the necessary steps, see the following: Remove PowrQuad Transmission in Section 55, Group 00. Remove Range Transmission in Section 55, Group 00. Remove Final Drives in Section 56, Group 00. Remove Rear PTO in Section 56, Group 00. Removing and Installing the Charge Pump in Section 70, Group 10. Hitch - Remove Lift Cylinders in Section 70, Group 20. Removing the Selective Control Valves in Section 70, Group 25. <- Go to Section TOC Section 56 page 26 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components Install the Differential Housing [1] - Bolt the differential housing to a JT05723 support stand. CAUTION: Universal support stand JT05723 (A) must be installed with support (B) underneath the range transmission. Support stand JT05723 Removing and installing the transmission assembly and differential housing. Also required: 2 commercial 8-metric ton vehicle jacks [2] - Pre-assemble the transmission assembly. For the necessary steps, see the following: Install Range Transmission in Section 55, Group 00. Install Final Drives in Section 56, Group 00. Install Rear PTO in Section 56, Group 00. <- Go to Section TOC Section 56 page 27 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components [3] - Install the transmission assembly on the main frame, and align. →NOTE: This job requires several assistants. [4] IMPORTANT: During installation, put the flange (A) of the u.j. shaft into the transmission input shaft, and use the JDG820 flywheel turning tool to allow the splines on the shafts to mesh. Flywheel turning tool JDG820 Turning flywheel on 6-cylinder engines <- Go to Section TOC Section 56 page 28 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components [5] - Remove cap screws (A) using the special tools (B) and (C). Support stand D05007ST Removal and installation of differential housing. Extension JDG749 Removal and installation of differential housing. [6] - Reverse removal procedure to install the bowden cables, brake lines and hydraulic hoses back in place. <- Go to Section TOC Section 56 page 29 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components [7] - Lower and mount the operator′s cab. Tighten the front cab mounting screws (A) to the torques prescribed. Item Measurement Specification Front Cab Mounting, Cap Screw Torque 220 N˙m 160 lb.-ft. Tighten the rear cab mounting screws (A) to the specified torque. Item Measurement Specification Cab to Final Drive Housing, Cap Screw Torque 220 N˙m 160 lb.-ft. <- Go to Section TOC Section 56 page 30 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components [8] - Install oil cooler hoses (A). IMPORTANT: Every time you disconnect an oil hose with a quick-coupler, replace the retaining clip with a new one. Once clips are installed, check that they are seated correctly. The bent ends of the clip must touch each other. Otherwise, the coupler can become loose. [9] - Run the clutch cable along the left side of the flywheel housing to the clutch pedal. IMPORTANT: Run the clutch cable so that following criteria are met: The cable must The cable must The cable must The cable must operated. be free of tension. not come into contact with moving parts. not be bent or crushed. not chafe against other components when the clutch is [10] - For further assembly, follow disassembly procedure in reverse order. <- Go to Section TOC Section 56 page 31 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components [11] - When assembly is completed, perform the following: Check the adjustment of all shift mechanisms/linkages.With PowrQuad transmission, see Checking and Adjusting the Shift Mechanism/Linkages (Reverser Control on Steering Column) and Adjusting the Reverse Drive Lever (Reverser Control on Steering Column) in Section 55, Group 05. Check the adjustment of the speed control lever (mechanical speed control only). Accelerator Pedal with Mechanical Speed Control in Section 30, Group 05. Check the setting of the clutch pedal. Adjusting the Clutch Pedal (PowrQuad Transmission) or Adjusting the Clutch Pedal in Sections 50 or 55, Group 05. Bleed and check the brakes. Bleeding the Brakes (Power-Fill Brakes and MFWD and Disk Brake) in Section 60, Group 15 or 20. Bleed and check the hydraulic trailer brake (if equipped).See Bleeding the Trailer Brake Valve and Checking the Hydraulic Trailer Brake Valve in Section 60, Group 30. Check all functions and rectify any faults (refer to corresponding Technical Manual). <- Go to Section TOC Section 56 page 32 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components Remove Final Drives [1] - Open the hood. Disconnect the negative terminal (—) on the battery. The version shown here has a negative terminal at the location marked (A). CAUTION: Always pay close attention to battery terminals. Comply with safety instructions on how to handle batteries (see Section 05). [2] - Remove drain screw (A) and allow the transmission oil to drain out. →NOTE: Trap the oil in a container with a capacity of at least 60 liters (15 U.S.gal.). <- Go to Section TOC Section 56 page 33 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components [3] - Place chock blocks under the front wheels to prevent the tractor from rolling away. Raise tractor and support it SECURELY with support stand JT05725 (A). Support stand JT05725 Raising and supporting tractor <- Go to Section TOC Section 56 page 34 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components [4] - Take off one of the rear wheels. See Removing the Front and Rear Wheels in Section 80, Group 10. [5] - If equipped, remove bracket (A) of the stabilizer bar. [6] - When removing the right final drive housing: If equipped, disconnect lines (B), take out the screws that hold bracket (A) to bracket (C), and then take off bracket (C). <- Go to Section TOC Section 56 page 35 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components [7] - When removing the right final drive, also take off bracket (A). [8] - Install dealer-manufactured lifting eyes (B), lifting sling (A; JDG23) and lifting tackle on the roof of the operator′s cab. Lifting sling JDG23 Removal and installation of the operator′s cab Lifting eyes (2 used) dealer fabricated <- Go to Section TOC Section 56 page 36 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components LEGEND: A B C Commercial M16, DIN 582 Lifting Eye Nut M16 Nut Threaded Rod M16 x 100 mm (4 in.), Grade 8.8 Coat threaded rod (C) with LOCTITE ™ 271 (TY43513), and screw it into eye nut (A) until it bottoms. Lock with nut (B). [9] - Loosen the front cab mounting screws (A), but do NOT take them out. <- Go to Section TOC Section 56 page 37 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components [10] - When removing the left final drive from tractors equipped with air brakes, take off brackets (A), (B) and (C). [11] - Attach support stand D05007ST (A) to the final drive housing, using adapter (B) and holding device (C) (both dealer-fabricated). Support stand D05007ST <- Go to Section TOC Section 56 page 38 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components Removal and installation of final drive housings. Also required: dealer-fabricated holding devices, see Special Tools (Dealer-Fabricated). Holding fixture dealer fabricated LEGEND: a b c d e f A 250 mm (10 in.) 50 mm (2 in.) 15 mm (0.6 in.) 205 mm (8.1 in.) 16 mm (0.6 in.) 18 mm (45/64 in.) dia. hole M12x30 mm screw Removal and installation of final drive housings and other tractor components. Used in conjunction with support stand D05007ST. Holding fixture dealer fabricated <- Go to Section TOC Section 56 page 39 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components Removal and installation of final drive housings and other tractor components. Used in conjunction with support stand D05007ST. →NOTE: Use the screw in the center of holding device (C) to align the device horizontally. Take out all cap screws (D) and roll the final drive housing clear. IMPORTANT: As the housing is sealed with flexible sealant, in most cases it adheres firmly to the flange even after the cap screws have been taken out. For this reason, it is necessary to use a heavy plastic hammer to separate the housing from the flange. Take action to prevent the final drive shaft and brake disk from falling out. <- Go to Section TOC Section 56 page 40 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components Install Final Drives Before installing the final drives, make sure that the brake piston is properly in contact with the differential housing. Install the brake disk and brake plate. See Installing the Rear Brakes in Section 60, Group 15. IMPORTANT: Make sure that the ring gear is positioned as shown in the illustration, with the groove facing the differential housing (see arrow). <- Go to Section TOC Section 56 page 41 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components Thoroughly clean the housing flange, then coat flange (A) with LOCTITE ™ 574 (L64500) flexible sealant. Attach support stand D05007ST (B) to the final drive housing, using adapter (C) and holding device (D) (both dealer-fabricated). Support stand D05007ST <- Go to Section TOC Section 56 page 42 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components Removal and installation of final drive housings. Also required: dealer-fabricated holding devices, see Special Tools (Dealer-Fabricated). Holding fixture dealer fabricated LEGEND: a b c d e f A 250 mm (10 in.) 50 mm (2 in.) 15 mm (0.6 in.) 205 mm (8.1 in.) 16 mm (0.6 in.) 18 mm (45/64 in.) dia. hole M12x30 mm screw Removal and installation of final drive housings and other tractor components. Used in conjunction with support stand D05007ST. Holding fixture dealer fabricated <- Go to Section TOC Section 56 page 43 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components Removal and installation of front axle or front-wheel drive axle. Used in conjunction with support stand D05007ST. Install the final drive and tighten the cap screws crosswise to the specified torque. Item Measurement Specification Cap Screws, Final Drive Housing to Differential Housing Torque 230 N˙m 170 lb.-ft. <- Go to Section TOC Section 56 page 44 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components Lower the cab and tighten cap screws (A) to the specified torque. Item Measurement Specification Cap Screws, Rear Cab Mounting Torque 200 N˙m 145 lb.-ft. Install the bracket of the stabilizer bar and tighten the hex. socket screws to the specified torque. Item Measurement Specification Hex. Socket Screw, Bracket of Stabilizer Bar to Final Drive Housing Torque 710 N˙m 525 lb.-ft. <- Go to Section TOC Section 56 page 45 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components Install the rear wheel and tighten the wheel bolts to the value specified. See Installing the Front and Rear Wheels in Section 80, Group 10. Fill with transmission oil. Check oil level and top up, if necessary (see operator′s manual). Lubricate both rear axle bearings with 6 to 8 strokes of grease gun. Use John Deere EP Multipurpose Grease or SAE EP Multipurpose Grease. CAUTION: Bleed the brakes. See Bleeding the Brakes in Section 60, Group 15. <- Go to Section TOC Section 56 page 46 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components Remove Rear PTO [1] - Open the hood. Disconnect the negative terminal (—) on the battery. The version shown here has a negative terminal at the location marked (A). CAUTION: Always pay close attention to battery terminals. Comply with safety instructions on how to handle batteries (see Section 05). [2] - Remove drain screw (A) and allow the transmission oil to drain out. →NOTE: Trap the oil in a container with a capacity of at least 60 liters (15 U.S.gal.). <- Go to Section TOC Section 56 page 47 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components [3] - Disconnect connector (A). Remove the height-adjustable trailer hitch (B), if equipped. See Installing the Guide Rails in Section 80, Group 15. Disconnect connector (C) and bowden cable (D) and remove center link (E). Disconnect pressure line (F) to PTO housing. <- Go to Section TOC Section 56 page 48 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components [4] - Use a suitable hoist to remove PTO housing. Remove cap screws (A) and lift off PTO housing. →NOTE: Slide a suitable pipe section over the PTO stub shaft. This will allow the PTO housing to be removed from the differential housing at right angles. <- Go to Section TOC Section 56 page 49 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components Install Rear PTO [1] - Thoroughly clean the sealing surfaces and coat them with LOCTITE ™ 574 (L64500) flexible sealant. Suspend the housing from suitable lifting tackle and install it on the differential housing. →NOTE: To align the housing, use a tube as shown. Turning the PTO output shaft makes it easier for the gears to mesh. [2] - Tighten cap screws (A) in cross-wise fashion to the specified torque. Item Measurement Specification Cap Screws, Rear PTO Housing to Differential Housing Torque 240 N˙m 175 lb.-ft. Item Measurement Specification Attaching Screws, Center Link Bracket to PTO Housing / Differential Housing Torque 340 N˙m 250 lb.-ft. For further assembly, follow disassembly procedure in reverse order. When finished, add transmission oil and check the oil level. <- Go to Section TOC Section 56 page 50 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components Remove Front PTO [1] - Open the hood. Disconnect the negative terminal (—) on the battery. The version shown here has a negative terminal at the location marked (A). CAUTION: Always pay close attention to battery terminals. Comply with safety instructions on how to handle batteries (see Section 05). [2] - Remove grille screen. Disconnect hoses (A) from front PTO oil cooler and seal open ends. <- Go to Section TOC Section 56 page 51 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components [3] - Disconnect connector (A) from solenoid valve. [4] - Attach front PTO to hoist as shown. Remove cap screws (A) and lift away front PTO to the front. →NOTE: Using a tube (B) pushed onto PTO shaft, align housing. <- Go to Section TOC Section 56 page 52 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 00: Removal and Installation of Components CAUTION: Once the front PTO has been removed, it is essential to seal all the lines and remove the drive shaft BEFORE starting the tractor. <- Go to Section TOC Section 56 page 53 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 05: U-Jointed Shafts and Torsion Damper Install Front PTO [1] - Attach front PTO to suitable hoist and move in position. IMPORTANT: As you move the front PTO into position, pay special attention to the drive shaft. Slide in drive shaft. Use flywheel turning tool JDE83 to change position of shaft. →NOTE: Using a tube (B) pushed onto PTO shaft, align housing. [2] - Tighten cap screws (A) to the specified torque. Item Measurement Specification Cap Screws, Front PTO to Main Frame or Front Axle Support Torque 600 N˙m 445 lb.-ft. [3] - For further installation, follow removal procedure in reverse order. <- Go to Section TOC Section 56 page 54 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 05: U-Jointed Shafts and Torsion Damper Group 05 - U-Jointed Shafts and Torsion Damper Summary of References (U-Jointed Shafts and Torsion Damper) ”Special tools” ”Use of special tool KJD10426” ”Specifications” ”Removing the u.j. shaft (front-wheel drive)” ”Reconditioning the u.j. shaft (front-wheel drive)” ”Installing the u.j. shaft (front-wheel drive)” ”Removing the u.j. shaft (engine)” ”Removing and installing the ring-shaped cooler” ”Removing the torsion damper” ”Change torsion damper bearings” ”Installing the torsion damper” ”Installing the u.j. shaft (engine)” Special Tools →NOTE: Order tools according to information given in the U.S. SERVICEGARD ™ Catalog or European Microfiche Tool Catalog (MTC). Flywheel turning tool JDG820 Turning flywheel on 6-cylinder engines Adapter KJD10426 <- Go to Section TOC Section 56 page 55 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 05: U-Jointed Shafts and Torsion Damper Tighten the screws of the engine u.j. shaft. Also refer to“Use of Special Tool KJD10426”. <- Go to Section TOC Section 56 page 56 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 05: U-Jointed Shafts and Torsion Damper Use of Special Tool KJD10426 LEGEND: A B C D Torque wrench Socket wrench insert Adapter KJD10426 Torque wrench BeforeKJD10426adapter is used, the torque wrench must be adjusted. This determines a setting that compensates forKJD10426(C) being used on the longer lever arm. 1. 2. 3. 4. Adjust torque wrench (A) to 135 N˙m (100 lb-ft). InstallKJD10426adapter (C) on a second torque wrench. Connect both torque wrenches by using a standard 17 mm hex. socket insert (B). Turn the torque wrenches in opposite directions and correct the adjustment of wrench (D) until both wrenches trip at the same time. 5. Record value of (D) for next use. →NOTE: Now the torque wrench is actually set to 135 N˙m (100 lb-ft) though the torque value indicated is lower. <- Go to Section TOC Section 56 page 57 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 05: U-Jointed Shafts and Torsion Damper Repair specifications Item Measurement Specificatio n U.j. shaft to FWD axle, cap screw Torque 125 N˙m 92 lb-ft Anti-wrap guard, cap screw Torque 35 N˙m 26 lb-ft Torsion damper bearings, cap screw Torque 65 N˙m 48 lb-ft Torsion damper to flywheel, cap screw Torque 35 N˙m 26 lb-ft Engine u.j. shaft to flywheel and transmission flange, corrugated-head screws Torque 135 N˙m 100 lb-ft U.j. shaft (engine) and torsion damper LEGEND: A B C D <- Go to Section TOC M12 corrugated-head screw M12 corrugated-head screw M10 cap screw M8 cap screw Section 56 page 58 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 05: U-Jointed Shafts and Torsion Damper Remove Front-Wheel Drive U.j. Shaft [1] - LEGEND: A B Anti-wrap guard Anti-wrap guard Remove anti-wrap guards (A) and (B). <- Go to Section TOC Section 56 page 59 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 05: U-Jointed Shafts and Torsion Damper [2] - Tractor without TLS axle Tractors with TLS axle (not available for all models) LEGEND: A B U.j. shaft Screw Remove screws (B) from the flange. [3] - Disconnect u.j. shaft (A) from the flange and pull it off the clutch shaft. <- Go to Section TOC Section 56 page 60 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 05: U-Jointed Shafts and Torsion Damper Reconditioning the U.j. Shaft (Front-Wheel Drive) Disassembling the u.j. shaft (FWD) [1] - LEGEND: A Snap ring Remove snap ring (A) from each side of universal joint. [2] →NOTE: Use specially shaped blocks on the vise to protect shaft and fork. LEGEND: A B Bearing cup Connecting fork Place connecting fork (B) on top of an open vise. Do NOT clamp it in the vise! [3] - Drive bearing cup (A) out of jointed shaft. [4] - Turn jointed shaft round and remove bearing cup on opposite side. <- Go to Section TOC Section 56 page 61 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 05: U-Jointed Shafts and Torsion Damper [5] - Drive bearing cups out of connecting fork. [6] - Remove the universal joint. Assembling the u.j. shaft (FWD) [1] - Carefully pull the bearing cups out of the universal joint. [2] - Insert universal joint. <- Go to Section TOC Section 56 page 62 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 05: U-Jointed Shafts and Torsion Damper [3] - LEGEND: A B Universal joint Bearing cup Install first bearing cup in connecting fork. [4] - Slide universal joint (A) as far as possible into the bore to provide a guide for the needles of bearing cup (B). [5] - Drive bearing cup with universal joint far enough into bore of fork so that snap ring can be installed. [6] - LEGEND: A B Bearing cup Universal joint Insert second bearing cup (A) into bore of connecting fork. Slide universal joint (B) to the right and use it as a guide for the second bearing cup. [7] - Drive in and secure bearing cup. <- Go to Section TOC Section 56 page 63 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 05: U-Jointed Shafts and Torsion Damper [8] →NOTE: Install bearing cups in the same way as installing bearing cups in connecting fork. Install bearing cups in jointed shaft. [9] - LEGEND: A Snap ring Install the snap rings. [10] - Universal joints should have an axial play that is as close to zero as possible. <- Go to Section TOC Section 56 page 64 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 05: U-Jointed Shafts and Torsion Damper Install Front-Wheel Drive U.j. Shaft [1] - LEGEND: A B Back-up ring Plastic bushing Slide back-up ring (A) and plastic bushing (B) onto clutch shaft. <- Go to Section TOC Section 56 page 65 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 05: U-Jointed Shafts and Torsion Damper [2] - Tractor without TLS axle Tractors with TLS axle (not available for all models) LEGEND: A B U.j. shaft Screw Install u.j. shaft (A) on the clutch shaft and on the flange of the front-wheel drive axle. [3] IMPORTANT: When installing, always use new corrugated-head screws (L171873). Tighten screws (B) to the specified torque. Item Measurement Specification U.j. shaft to u.j. shaft flange, screws Torque 180 N˙m 133 lb-ft <- Go to Section TOC Section 56 page 66 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 05: U-Jointed Shafts and Torsion Damper [4] - LEGEND: A B Anti-wrap guard Anti-wrap guard Install anti-wrap guards (A) and (B) and tighten screws to the specified torque. Item Measurement Specification Anti-wrap guard to bracket, cap screw Torque 35 N˙m 26 lb-ft Item Measurement Specification Anti-wrap guard to front-wheel drive housing, cap screw Torque 25 N˙m 18 lb-ft <- Go to Section TOC Section 56 page 67 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 05: U-Jointed Shafts and Torsion Damper Removing the U.J. Shaft (Engine) [1] - Remove the four corrugated-head screws (A) at the torsion damper and the three cap screws (B) at the ring-shaped cooler. If necessary, remove the floor-plate from the cab or the open operator′s station. →NOTE: If a FWD axle with TLS is installed, or the transmission has an option housing, tip up the operator′s cab. Refer to “Tilting the Operator′s Cab Upward” in Section 90, Group 00. [2] - Push ring-shaped cooler (A) to the side and take out the four corrugated-head screws (B) at the clutch input shaft. →NOTE: Replace one of the four corrugated-head screws with an M12x40 threaded pin. This threaded pin makes installation easier. <- Go to Section TOC Section 56 page 68 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 05: U-Jointed Shafts and Torsion Damper Removing and Installing the Ring-Shaped Cooler [1] - Disconnect the coolant and transmission oil hoses from the ring-shaped cooler and seal the ends with dummy plugs. Trap any escaping fluids in a suitable container. [2] - Remove the four corrugated-head screws (A) at the torsion damper and the three cap screws (B) at the ring-shaped cooler. If necessary, remove the floor-plate from the cab or the open operator′s station. →NOTE: If a FWD axle with TLS is installed, or the transmission has an option housing, tip up the operator′s cab. Refer to “Tilting the Operator′s Cab Upward” in Section 90, Group 00. [3] - Push ring-shaped cooler (A) to the side and take out the four corrugated-head screws (B) at the clutch input shaft. Remove the universal-jointed shaft and ring-shaped cooler. →NOTE: Replace one of the four corrugated-head screws with an M12x40 threaded pin. This threaded pin makes installation easier. <- Go to Section TOC Section 56 page 69 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 05: U-Jointed Shafts and Torsion Damper [4] - For installation, follow removal procedure in reverse order. Item Measurement Specification Corrugated-head screws Torque 135 N˙m 100 lb-ft Check fluid levels. Refer to “Capacities” , Section 10, Group 05, and top up the fluids if necessary. →NOTE: Remember to replace the M12x40 threaded pin with a corrugated-head screw. IMPORTANT: Every time you connect an oil hose with a quick-coupler, make sure that the retaining clip on the hose coupler is seated correctly. The bent ends of the clip must be almost touching. If they are not, the coupler may come adrift. Removing the Torsion Damper CAUTION: The torsion damper is heavy. Danger of crushing! [1] - Tilt the operator′s cab up. Refer to “Tilting the Operator′s Cab Upward” , Section 90, Group 00. <- Go to Section TOC Section 56 page 70 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 05: U-Jointed Shafts and Torsion Damper [2] - Before removing engine u.j. shaft, refer to “Removing the U.J. Shaft (Engine)” in this Group. [3] - Remove cap screw (C) and cap screws (A). [4] - To press off the torsion damper, use two M10x80 screws (B). Changing the Torsion Damper Bearings [1] - LEGEND: A Bearing bushings Remove the torsion damper. Remove bearing housing. [2] - Press bearing bushings (A; 2 used) into the bearing housing. [3] - LEGEND: A B Torsion damper Bearing housing Install torsion damper (A) on bearing housing (B). [4] - Install torsion damper. <- Go to Section TOC Section 56 page 71 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 05: U-Jointed Shafts and Torsion Damper Installing the Torsion Damper [1] - Change the torsion damper bearing (B). [2] - Install washer (D) and tighten the cap screw or corrugated-head screw (C). Item Measurement Specification Torsion damper bearings, cap screw Torque 65 N˙m 48 lb-ft [3] IMPORTANT: If the bearing is held in place by a corrugated-head screw, the latter must be used only once, and then replaced. Tighten the six M8 cap screws. Item Measurement Specification Torsion damper to flywheel, cap screw Torque 35 N˙m 26 lb-ft [4] - Ensure seal (A) is seated correctly. <- Go to Section TOC Section 56 page 72 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch Installing the U.j. Shaft (Engine) IMPORTANT: The corrugated-head screws must be used once only and then be replaced. IMPORTANT: Under any circumstances follow the directions given in “Use of Special Tool KJD10426” if special tool KJD10426 Adapter KJD10426 Tightening u.j. shaft screws is used. Install the ring-shaped cooler on the universal-jointed shaft. Secure the ring-shaped cooler with the three flange screws (C). Tighten the four corrugated-head screws (A) and the four corrugated-head screws (B). Item Measurement Specification Engine u.j. shaft to flywheel and transmission flange, corrugated-head screws Torque 135 N˙m 100 lb-ft Tilt the operator′s cab down. Refer to “Tilting the Operator′s Cab Downward” , Section 90, Group 00. <- Go to Section TOC Section 56 page 73 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch Group 10 - Front-Wheel Drive Clutch Drive Systems - Front-Wheel Drive Clutch, Summary of References Special Tools Repair Specifications Front-Wheel Drive Clutch - Sectional View Front-Wheel Drive Clutch - Exploded View Front-Wheel Drive Clutch - Replace Front-Wheel Drive Axle Speed Sensor (B89) Front-Wheel Drive Clutch - Replace Solenoid Valve Recondition the Front-Wheel Drive Clutch <- Go to Section TOC Section 56 page 74 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch Special tools →NOTE: Order tools according to information given in the U.S. SERVICEGARD ™ Catalog or European Microfiche Tool Catalog (MTC). Puller JDG811 Removing the taper roller bearing cup from housing Bushing Dealer-fabricated Removing and installing Belleville spring Bushing, bearing, and seal driver set D01045AA Removing and installing bearings and bushings. <- Go to Section TOC Section 56 page 75 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch Other material Number Name • L41475 (us) Adhesive • 243 LOCTITE ™ (loctite) Use Cementing the oil transfer plate in the clutch drum • L64500 (us) Liquid sealant Clutch housing to transmission housing • 574 LOCTITE ™ (loctite) <- Go to Section TOC Section 56 page 76 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch Repair Specifications Item Measurement Specification Clutch shaft Axial play 0.025 to 0.100 mm 0.001 to 0.004 in. Bearing quill to housing, cap screw Torque 25 N˙m 18 lb-ft Handbrake band adjusting screw, lock nut Torque 37 ± 7 N˙m 27 ± 5 lb-ft FWD clutch, oil drain screw Torque 50 N˙m 35 lb-ft Solenoid valve, cap screw Torque 8 to 12 N˙m 6 to 9 lb-ft Solenoid valve coil, nut [ on earlier solenoid valves only ] Torque 3 to 4 N˙m 2.5 to 3.0 lb-ft Housing, dowel pins Amount of protrusion 12 mm 0.47 in. Front-Wheel Drive Clutch - Sectional View <- Go to Section TOC Section 56 page 77 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS LEGEND: A B C D E F G H I J K Group 10: Front-Wheel Drive Clutch L Clutch Shaft Belleville Spring Piston Housing Handbrake Band Piston Front-Wheel Drive Gear Disk Pack Check Valve Housing Solenoid Valve Hub Speed Sensor M Impulse Disk <- Go to Section TOC [ AutoPowr/IVT transmission only ] [ AutoPowr/IVT transmission only ] Section 56 page 78 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch Front-Wheel Drive Clutch — Exploded View <- Go to Section TOC Section 56 page 79 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS <- Go to Section TOC Group 10: Front-Wheel Drive Clutch Section 56 page 80 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch LEGEND: 1 Gear 2 Clutch drum 3 4 5 6 7 8 9 10 11 12 13 Spring Check valve (3 used) Lock washer (3 used) Taper roller bearing Thrust washer Thrust plate Oil transfer plate Bearing bushing (2 used) Clutch drum and gear Thrust washer Hub Externally splined disk (7 used [ 50 km/h version only ] [ 50 km/h version only ] [ at 6820 ] 14 ; 9 used [ 6920 and 6920S ] ) Internally splined disk (6 used [ 6820 ] 15 ; 8 used [ 6920 and 6920S ] 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 ) Bearing bushing Piston (thickness varies with no. of disks) O-ring Belleville spring Ring Snap ring Plug (8 mm; 0.32 in. dia.) Seal ring (2 used) Clutch shaft Seal ring Taper roller bearing Shim (quantity as required) Speed sending unit [ AutoPowr/IVT transmission only ] O-ring Bearing quill Seal ring Protective panel [ AutoPowr/IVT transmission only ] 34 Housing Speed sensor 35 36 37 Solenoid valve Dowel pin (2 used) LOCTITE ™ 574 (L64500) liquid sealant <- Go to Section TOC [ AutoPowr/IVT transmission only ] Section 56 page 81 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch Front-Wheel Drive Clutch - Replace Front-Wheel Drive Axle Speed Sensor (B89) LEGEND: A B Protective panel Sensor B89 [1] - Remove protective panel [ AutoPowr/IVT transmission only ] (A). [2] - Pull out plug on wiring harness and remove sensor B89 [ AutoPowr/IVT transmission only ] (B). [3] - Check sensor, and replace if necessary. [4] - Apply oil to new O-ring and install on sensor. [5] - Install sensor B89 (B) and put the wiring harness plug back in. Item Measurement Specification Front-wheel drive axle speed sensor (B89) to front-wheel drive clutch Torque 10 - 12 N˙m 7 - 9 lb-ft [6] - Attach protective panel (A). <- Go to Section TOC Section 56 page 82 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch FWD Clutch — Replacing Solenoid Valve Previous solenoid valve New solenoid valve [1] - Pull out wiring harness plug (A). [2] - Remove cap screws (B) on support plate. [3] - Remove solenoid valve. <- Go to Section TOC Section 56 page 83 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch [4] - Clean components, inspect them for wear or damage and replace as necessary. [5] - Install solenoid valve. [6] - Attach cap screws (B) on support plate. Item Measurement Specification Solenoid valve, cap screws Torque 8 to 12 N˙m 6 to 9 lb-ft [7] - Tighten the hex. nut [ on earlier solenoid valves only ] (C) on the coil. Item Measurement Specification Solenoid valve coil, nut Torque 3 to 4 N˙m 2.5 to 3.0 lb-ft [8] - Connect wiring harness plug (A). <- Go to Section TOC Section 56 page 84 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch Replacing the FWD Clutch →NOTE: Before removing the FWD clutch, refer to “Removing the FWD Clutch” in this Section, Group 00. Disassembling FWD clutch [1] - Remove the solenoid valve. Refer to “FWD Clutch - Replacing Solenoid Valve” in this Group. [2] - Remove the speed sending unit. Refer to “FWD Clutch - Replacing Speed Sensor” in this Group. [3] - Remove cap screws (A) and bearing quill (B). [4] - Remove plug (C). [5] - Remove spring pin (A) and pull out lever shaft (B). <- Go to Section TOC Section 56 page 85 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch [6] - Remove plug (A). [7] - Use an M6 screw to pull out shaft (A). [8] - Pull out the clutch shaft (A). [9] - Remove shims and taper roller bearing cup. <- Go to Section TOC Section 56 page 86 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch [10] - Remove the clutch and handbrake band from the housing. [11] - Remove handbrake band from clutch. <- Go to Section TOC Section 56 page 87 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch [12] - Remove the taper roller bearing cup using JDG811 puller. Bearing cup removal tool JDG811 Remove taper roller bearing cup from housing <- Go to Section TOC Section 56 page 88 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch [13] - Use dealer-fabricated bushing (A) to compress the belleville springs in a spring compressor. Bushing dealer-fabricated Removing and installing belleville spring [14] - Remove the snap ring. <- Go to Section TOC Section 56 page 89 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch [15] - Take off ring (A) and belleville spring (B). [16] - Remove piston (A). [17] - Remove hub (A). <- Go to Section TOC Section 56 page 90 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch [18] - Remove the pressure ring (A) and the thrust washer underneath it. [19] - Remove disk pack (B). [20] - Remove retaining washer (A), check valve and spring. [21] - Remove retaining washers (B) and check valves. Assembling the FWD clutch <- Go to Section TOC Section 56 page 91 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch [1] - Assembly instructions: a. Clean the various parts, inspect them for wear or damage and replace as necessary. b. When assembling, coat all components with hydraulic oil. c. When assembling, coat pressure washers and seal rings with a thin film of grease. d. Never clean the disks with a cleaning agent. e. Before assembly, soak disks in hydraulic oil for 15 minutes. [2] - Press bushing (A) into the clutch drum. [3] - Apply a thin coating of LOCTITE ™ 243 (L41475) to the outside edge of oil transfer plate (A). Number Name Use • L41475 (us) Cementing the oil transfer plate in the clutch Threadlocker • 243 LOCTITE ™ (loctite) drum [4] - Attach oil transfer plate. [5] →NOTE: Install the check valves using the hole leading to the housing. <- Go to Section TOC Section 56 page 92 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch Install spring, check valve and retaining washer in hole (A). [6] - Install check valves and retaining washers in holes (B). [7] - Install thrust washer (A). [8] - Install thrust washer (A). <- Go to Section TOC Section 56 page 93 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch [9] - Install hub (A). [10] →NOTE: Before installing the disks, dip them in oil. Install disk pack (A). Start installing disks with an externally splined one. [11] - Press bushing (A) into the piston. <- Go to Section TOC Section 56 page 94 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch [12] - Apply oil to O-ring (A), and install. [13] - Installing the piston (A). [14] - Install the belleville spring (B) with the convex side facing the piston. [15] - Install O-ring (A). <- Go to Section TOC Section 56 page 95 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch [16] - Install snap ring. [17] - Use dealer-fabricated bushing (A) to compress the belleville springs in a spring compressor. Bushing dealer-fabricated Removing and installing belleville spring <- Go to Section TOC Section 56 page 96 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch [18] - Install the snap ring. [19] - Install taper roller bearing cup (A). [20] - Check handbrake components and replace, if necessary. Refer to “Exploded View of Handbrake - 6820 Tractor” or “Exploded View of Handbrake - 6920 and 6920S Tractors” in Section 60, Group 20. [21] →NOTE: Pin (B) is held in place by straps (A) only. When installing, hold the brake band linkage in the position shown, otherwise the pin will fall out. Install handbrake band onto clutch as shown in illustration. [22] →NOTE: Make sure the brake band linkage pin does not fall out. <- Go to Section TOC Section 56 page 97 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch Install clutch and handbrake band. [23] - Make sure that plug (A) has been inserted into the end of the clutch shaft. [24] - Replace seal rings (B), if necessary. [25] - Replace oil seal (C). [26] - Replace taper roller bearing (D), if necessary. <- Go to Section TOC Section 56 page 98 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch [27] - Install speed sender [ AutoPowr/IVT transmission only ] (A). [28] - Install clutch shaft (A). [29] - Install taper roller bearing cup. [30] - Install thrust washer (A). <- Go to Section TOC Section 56 page 99 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch [31] - Install thrust washer (A). [32] - Install bearing cone (A). [33] - Install shaft (A). <- Go to Section TOC Section 56 page 100 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch [34] - Screw in plug (A). [35] - Screw in plug (C). [36] - Install lever shaft (B) and drive in spring pin (A). [37] - If necessary, install new sealing ring (A) flush with bearing quill surface. [38] - Apply grease to the seal ring (A) between the sealing lips. [39] - Install new O-ring (B). <- Go to Section TOC Section 56 page 101 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch [40] - Install bearing quill (B) temporarily without shims. [41] - Tighten cap screws (A). Item Measurement Specification Bearing quill to housing, cap screw Torque 25 N˙m 18 lb-ft Adjusting end play of FWD clutch shaft [1] - Rotate the clutch assembly several times in both directions to seat the bearings. [2] - Measure end play. [3] - Install shims under the bearing quill in order to provide correct end play. Item Measurement Specification Clutch shaft End play 0.025 to 0.100 mm 0.001 to 0.004 in. [4] - Tighten bearing quill cap screws. Item Measurement Specification Bearing quill to housing, cap screw Torque 25 N˙m 18 lb-ft <- Go to Section TOC Section 56 page 102 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 10: Front-Wheel Drive Clutch [5] - Check end play again. FWD clutch — Final assembly [1] - Adjust the brake band at adjusting screw (A). The clutch drum must turn freely without any undue resistance. [2] - Tighten adjusting screw lock nut. Item Measurement Specification Lock nut Torque 37 ± 7 N˙m 27 ± 5 lb-ft [3] - Install oil drain plug (A). [4] - Install the speed sending unit. Refer to “FWD Clutch - Replacing Speed Sensor” in this Group. [5] - Install the solenoid valve. Refer to “FWD Clutch - Replacing Solenoid Valve” in this Group. <- Go to Section TOC Section 56 page 103 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 15: Differential [6] - Ensure the dowel pins (A) are inserted at the correct depth. Item Measurement Specification Dowel pins Protrusion 12 mm 0.47 in. [7] - Install front wheel drive clutch. Refer to “Installing the FWD Clutch” in Group 00 of this Section. <- Go to Section TOC Section 56 page 104 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 15: Differential Group 15 - Differential Drive Systems - Differential, Summary of References Special Tools Differential - Repair Specifications Differential - Sectional View Differential - Exploded View Remove Differential Recondition the Differential Install Differential Differential - Adjust Preload Differential - Adjust Backlash Special tools →NOTE: Order tools according to information given in the U.S. SERVICEGARD ™ Catalog or European Microfiche Tool Catalog (MTC). Seal installation tool JDG236 Installing seal rings and bearing cups 17-1/2 ton puller set D01173AA Removing and installing bearings Bushing, bearing, and seal driver set D01045AA <- Go to Section TOC Section 56 page 105 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 15: Differential Removing and installing bushings, bearings, bearing cups, and oil seal rings Differential removal tool JT07131 Removing and installing the differential Differential - Specifications Item Measurement Specification Differential lock solenoid valve Y05, screws Torque 8 - 12 N˙m 6 - 9 lb-ft Clutch disks Thickness (when new) 3.3 mm 0.129 in. Bevel pinion shaft, retaining screw Torque 150 N˙m 110 lb-ft Cover to housing, screw Torque 150 N˙m 110 lb-ft Bearing quill to differential housing, screw Torque 90 N˙m 65 lb-ft Differential Bearing preload 0.05 - 0.13 mm 0.002 - 0.005 in. Differential Backlash Value etched on outer circumference of gear, ± 0.11 mm (0.004 in.) Differential - Sectional View <- Go to Section TOC Section 56 page 106 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS LEGEND: A B C D E F G <- Go to Section TOC Group 15: Differential Left bearing quill Bearing cone Bearing cup Thrust washer Drive bevel gear Support Thrust washer Section 56 page 107 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS H I J K L M N O P Q R S T U V W Group 15: Differential Drive bevel gear Disks Disk Ring gear Piston Differential cover Bearing cup Bearing cone Right bearing quill Seal rings Thrust washer Shaft Needle bearing thrust washers Needle bearing Thrust washers (with tang) Snap rings Differential - Exploded View LEGEND: <- Go to Section TOC Section 56 page 108 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS A B C D E F G H I J K L M N O P Q R S T U V <- Go to Section TOC Group 15: Differential Bearing quill, l.h. side Shims (quantity as required) Tapered roller bearing cone Oil line Seal rings Tapered roller bearing cone Bearing quill, r.h. side Differential ring gear Shaft Cap screw Tapered roller bearing cup Housing Thrust washer Bevel gear Thrust washer Bevel gear Bevel gear Internally splined disk Externally splined disk Piston Housing cover Tapered roller bearing cup Section 56 page 109 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 15: Differential Remove the Differential Preliminary work: See Remove the Rear PTO in Section 56. See Remove the Final Drives in Section 56. [1] - LEGEND: A Oil line Remove oil line (A) of the differential lock. [2] →NOTE: Keep the shims with the corresponding bearing quill. Remove both bearing quills with shims. [3] - <- Go to Section TOC Section 56 page 110 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 15: Differential LEGEND: A B C D E F G Nut Bracket Threaded rod Bracket Handle Nut Extension InstallJT07131removal tool. [4] - Install nut (A) and bracket (B) on threaded rod (C). Tighten nut. [5] - Loosely install bracket (D), handle (E), and nut (F). [6] - Insert the tool assembly through the differential housing as illustrated. <- Go to Section TOC Section 56 page 111 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 15: Differential [7] - Rotate bracket (B) by a 1/4 turn and tighten nut (F). Make sure the bracket is retained crossways in the opening of the housing. [8] - Install extension (G) and remove the differential. Use a suitable hoist. Next step: See Recondition the Differential in Section 56. <- Go to Section TOC Section 56 page 112 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 15: Differential Recondition the Differential Preliminary work: See Remove the Differential in Section 56. Disassemble the differential [1] - LEGEND: A Screws Remove screws (A). [2] - Lift cover off housing. Replace the ring gear: IMPORTANT: Ring gear and differential shaft must be replaced as a matched set. Be sure numbers stamped on ring gear and on the end of the differential shaft are the same. Adjust cone point when replacing ring gear and differential shaft. See Install Differential Drive Shaft and Adjust Cone Point in Section 55. Inspect ring gear and differential shaft for excessive wear or damage. Remove ring gear from housing if necessary. [3] CAUTION: Heat ring gear in a bearing heater. Do not exceed 150 °C (300 °F). Proceed with care to avoid burns. Install ring gear. <- Go to Section TOC Section 56 page 113 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 15: Differential [4] - LEGEND: A Piston inlet Remove the differential lock piston from the cover by applying air to piston inlet (A). [5] - LEGEND: A B C Bevel gear Internally splined disks Externally splined disks Remove bevel gear (A) from housing. [6] - Remove disk pack (B) and (C). Item Measurement Specification Clutch disks Thickness (when new) 3.3 mm 0.129 in. [7] - Remove bearing cup from cover or housing. <- Go to Section TOC Section 56 page 114 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 15: Differential [8] - Remove screw (A). [9] - Remove the shaft. [10] - Take off the bevel gears and thrust washers. [11] - LEGEND: A B Differential pinion Thrust washer Remove the differential pinion (A) and thrust washer (B). Assemble the differential [1] - LEGEND: A B Tapered roller bearing cup Tapered roller bearing cup Install tapered roller bearing cup (A) in the housing. <- Go to Section TOC Section 56 page 115 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 15: Differential [2] - Install tapered roller bearing cup (B) on the housing cover using installation toolJDG236. [3] - LEGEND: A B Bevel gear Thrust washer Install thrust washer (B) and bevel gear (A) in the housing. [4] - LEGEND: A Tangs Apply light, clean grease to the curved thrust washers and install in housing. Make sure the tangs (A) are positioned in the recesses. [5] - Install bevel gears and shaft. <- Go to Section TOC Section 56 page 116 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 15: Differential [6] - LEGEND: A Screw Install screw (A) on the bevel gear shaft and tighten to specified torque. Item Measurement Specification Bevel gear shaft, retaining screw Torque 150 N˙m 110 lb-ft [7] - LEGEND: A B Bevel gear Thrust washer Install thrust washer (B) on bevel gear (A). <- Go to Section TOC Section 56 page 117 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 15: Differential [8] - LEGEND: A B C Bevel gear Internally splined disks Externally splined disks Install the internally splined disks (B) and externally splined disks (C) alternately on bevel gear (A). Start with an internally splined disk. [9] - Install the bevel gear and disk pack in the housing. [10] - LEGEND: A Piston Coat the seal lips with oil, install piston (A) in the differential cover and apply grease to retain the piston. <- Go to Section TOC Section 56 page 118 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 15: Differential [11] - LEGEND: A Screw Put the cover on the housing and tighten the screws to specified torque. Item Measurement Specification Cover to housing, screw Torque 150 N˙m 110 lb-ft [12] CAUTION: LEGEND: A B C Bearing quill Bearing quill Seal rings Heat tapered roller bearing cones in a bearing heater. Do not exceed 150 °C (300 °F). Proceed with care to avoid burns. Install tapered roller bearing cones in bearing quills (A) and (B). [13] - Check seal rings (C) on differential lock. Next step: SeeInstall the Differentialin Section 56. <- Go to Section TOC Section 56 page 119 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 15: Differential Install the Differential [1] - LEGEND: G Extension Use removal toolJT07131and extension (G) to lift the differential into the housing. [2] →NOTE: Install the shims that were used previously with the corresponding bearing quill. When using new bearings, install shims as necessary to obtain a measurable axial play and backlash. The differential lock oil line fitting is positioned on the right quill. Install both differential bearing quills with shims. [3] - Install screws on right-hand and left-hand differential bearing quills and tighten to specified torque. Item Measurement Specification Differential bearing quill, screw Torque 90 N˙m 66 lb-ft <- Go to Section TOC Section 56 page 120 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 15: Differential [4] - LEGEND: A B C D E F G Nut Bracket Threaded rod Bracket Handle Nut Extension RemoveJT07131removal tool. Next step: SeeDifferential - Adjust Preloadin Section 56. <- Go to Section TOC Section 56 page 121 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 15: Differential Differential - Adjust Preload Preliminary work: See Remove the Rear PTO in Section 56. See Remove the Final Drives in Section 56. [1] IMPORTANT: Rotate the differential several times in each direction to seat the roller bearings. Repeat before each axial play measurement. Measure the axial play. [2] →NOTE: Shims are available in various sizes. (See parts catalog). Measure shims individually for accurate measurement. If necessary, add or remove shims on both differential bearing quills (maintaining backlash) to obtain bearing preload. Item Measurement Specification Differential bearing Bearing preload 0.05 - 0.13 mm 0.002 - 0.005 in. <- Go to Section TOC Section 56 page 122 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 15: Differential [3] - Install screws on right-hand and left-hand differential bearing quills and tighten to specified torque. Item Measurement Specification Differential bearing quill, screws Torque 90 N˙m 66 lb-ft Next step: SeeDifferential - Adjust Backlashin Section 56. <- Go to Section TOC Section 56 page 123 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 15: Differential Differential - Adjust Backlash Preliminary work: SeeDifferential - Adjust Preloadin Section 56. [1] IMPORTANT: Adjust backlash after preload adjustment. →NOTE: Some ring gears may not have numbers on them. If the ring gear has a number on the outer circumference, it is metric. Make sure that the differential preload is adjusted correctly. [2] - Read the value etched onto the outer circumference of the ring gear. [3] - Measure backlash at three locations 120° apart. [4] - Backlash should be equivalent to the value read on the ring gear. Item Measurement Specification Differential Backlash <- Go to Section TOC Value etched on outer circumference of gear ± 0.11 mm (0.004 in.) Section 56 page 124 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 20: Hydraulic Pump Drive [5] IMPORTANT: Shims must not be removed or added. Shims are moved from one side to the other to adjust backlash. If backlash is excessive, transfer shims from the right to the left quill. If there is not enough backlash, transfer shims from the left to the right quill. If there is too much backlash, remove shims from the right quill and place them under the left quill. [6] - If there is not enough backlash, remove shims from the left quill and place them under the right quill. [7] - Install the differential lock oil line (A). Next step: SeeInstall the Rear PTOin Section 56. SeeInstall the Final Drivesin Section 56. <- Go to Section TOC Section 56 page 125 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 20: Hydraulic Pump Drive Group 20 - Hydraulic Pump Drive Hydraulic Pump Drive — Summary of References Before reconditioning the pump drive, refer to the following: ”Special tools” ”Specifications” ”Remove and disassemble pump drive pinion gear” ”Remove and disassemble pump drive gear” ”Assemble and install pump drive gear” ”Assemble and install pump drive pinion” ”Checking and adjusting the backlash of the pump drive pinion” <- Go to Section TOC Section 56 page 126 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 20: Hydraulic Pump Drive Special tools →NOTE: Order tools according to information given in the U.S. SERVICEGARD ™ Catalog or in the European Microfiche Tool Catalog (MTC). Bearing installer tool set JDG781 Installing the pump drive gear and pump drive pinion roller bearings Backlash adjusting tool JDG869 Adjusting pump drive pinion backlash Spigot wrench KJD10168 Removing, installing and adjusting the adjustment ring <- Go to Section TOC Section 56 page 127 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 20: Hydraulic Pump Drive Repair Specifications Item Measurement Specification Pump drive gear (snap ring and bearing cone) Axial play 0.11 mm 0.004 in. Pump drive pinion (snap ring and bearing cone) Axial play 0.11 mm 0.004 in. Pump drive pinion backlash Backlash 0.229—0.305 mm (0.009—0.012 in.) <- Go to Section TOC Section 56 page 128 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 20: Hydraulic Pump Drive Remove and Disassemble Pump Drive Pinion Gear LEGEND: A B C D E F G H I J K L M <- Go to Section TOC Pump Drive Pinion Gear Snap Ring Pinion Gear Bearing Cone (2 used) Pinion Gear Bearing Cup (2 used) Sleeve Bearing Spacer Ring (Inner) Bearing Snap Ring (Outer) Sleeve Locking Dowel Pin Bearing Snap Ring (Outer) Drive Gear Bearing Cup (2 used) Drive Gear Bearing Cone (2 used) Snap Ring Bearing Spacer Ring (Inner) Section 56 page 129 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS N O Group 20: Hydraulic Pump Drive Pump Drive Gear Shim Pack [1] - Remove the charge pump. See Removing the Charge Pump in Section 70, Group 10. [2] - Put marks (A), using a center punch, adjacent to each other on the sleeve and the differential housing. These marks are necessary for re-installation. [3] - Remove dowel pin (B). [4] - Remove the sleeve/drive pinion assembly usingKJD10168Ring Nut Socket. [5] - Install a knife-edge puller under the sleeve. [6] - Remove the snap ring (A) from the pinion shaft. Remove the shaft from the sleeve and the upper bearing using a press with a 44.5 mm (1-3/4 in.) disk. Bushing, Bearing, and Seal Driver Set D01045AA Remove and install bushings, bearings, bearing cups, and oil seals <- Go to Section TOC Section 56 page 130 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 20: Hydraulic Pump Drive [7] - Remove the bearing spacer ring. Install a knife-edge puller under the lower bearing and remove the shaft from the bearing using a 44.5 mm (1-3/4 in.) disk. [8] →NOTE: The bearing cups are a loose fit. Remove the bearing cups from the sleeve. [9] - Remove the bearing cup snap ring (A). <- Go to Section TOC Section 56 page 131 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 20: Hydraulic Pump Drive Remove and Disassemble the Pump Drive Gear [1] - Remove the differential. See Remove Differential in Section 56, Group 20. [2] - With AutoPowr/IVT transmission: See Remove the AutoPowr/IVT Transmission in Section 53, Group 00. All other transmissions: See Remove Range Transmission in Section 55, Group 00. [3] - Remove the pump drive pinion gear. See Remove and Disassemble Pump Drive Pinion Gear in this Group. [4] - Remove snap ring (A) from the drive gear shaft. [5] - Remove the drive gear from the differential housing and front bearing using a 44.5 mm (1-3/4 in.) driver disk, a 25.4 mm (1 in.) pilot disk, and a handle. [6] - Remove the bearing spacer. Install a knife-edge puller under the rear bearing and remove the shaft from the bearing using a 44.5 mm (1-3/4 in.) disk. [7] - Remove shims (A) from the shaft. <- Go to Section TOC Section 56 page 132 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 20: Hydraulic Pump Drive [8] →NOTE: The bearing cups are a loose fit. Remove the bearing cups and the outer bearing snap ring (A) from the differential housing. <- Go to Section TOC Section 56 page 133 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 20: Hydraulic Pump Drive Assemble and Install Pump Drive Pinion Gear [1] IMPORTANT: Each cup and cone of the bearing assembly is a matched set and must be assembled together. Install the bearing cup spacer snap ring (A) and bearing cups in the differential housing. [2] - Note the stamped number (A) on the upper left side of the front face of the differential housing. →NOTE: The stamped number is a reference for establishing the shim pack for the differential pinion shaft. If there is no number, use the 0.71 mm (0.028 in.) shim pack. <- Go to Section TOC Section 56 page 134 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 20: Hydraulic Pump Drive [3] - The stamped number, when referred to the pump drive gear shim chart below, provides the thickness of the shim pack to be used to adjust the cone point of the pump drive shaft. Pump drive gear shim chart Number on housing Shim pack thickness 1 0.46 mm (0.018 in.) 2 0.56 mm (0.022 in.) 3 0.64 mm (0.025 in.) 4 0.71 mm (0.028 in.) 5 0.79 mm (0.031 in.) 6 0.86 mm (0.034 in.) 7 0.94 mm (0.037 in.) 8 1.02 mm (0.040 in.) →NOTE: Shims are available in various sizes (see Parts Catalog). Measure shims individually for accurate measurement. [4] - Determine the correct shim pack using the Pump Drive Gear Shim Chart. [5] - Place the shim pack and the rear bearing on the pinion shaft. Make sure the side of the bearing with the larger diameter is against the shims. [6] - Install the bearing using a press and the bearing installer from JDG781 bearing installer tool set. Bearing Installer Tool Set JDG781 Install pump drive gear and pump drive pinion roller bearings <- Go to Section TOC Section 56 page 135 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 20: Hydraulic Pump Drive [7] - Install the bearing spacer ring on the shaft and install the shaft assembly in the differential housing. [8] - Install the front bearing onto the shaft, larger OD toward the driver, using the JDG781 Bearing Installer Tool Set. [9] →NOTE: Snap rings are available in various sizes (see Parts Catalog). [10] - Install the bearing cones tight against the pump drive gear shim pack and install the thickest snap ring (A) possible. Install two snap rings, if necessary. Item Measurement Specification Pump Drive Gear (Snap Ring and Bearing Cone) Axial Play 0.11 mm 0.004 in. [11] - Install the pump drive pinion gear. See Assemble and Install Pump Drive Pinion Gear in this Group. [12] - Install the differential. See Install Differential in Group 15 of this Section. <- Go to Section TOC Section 56 page 136 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 20: Hydraulic Pump Drive Assembling and installing the pump drive pinion [1] - <- Go to Section TOC Section 56 page 137 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 20: Hydraulic Pump Drive IMPORTANT: LEGEND: A B C D E F G H I Pump drive pinion Clamping ring Top bearing cone Bearing cup Bearing spacer ring Cup clamping ring Sleeve Bearing cup Bottom bearing cone Each cup and cone of the bearing assembly is a matched set and must be assembled together. Install the bearing cup clamping ring (F) and bearing cups (D) and (H) into the sleeve bore. <- Go to Section TOC Section 56 page 138 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 20: Hydraulic Pump Drive [2] - Install the bottom bearing cone (I) with the larger OD against the gear. To do so, use the bearing installer from the JDG781 bearing installer tool set. Bearing installer tool set JDG781 Installing the pump drive gear and pump drive pinion roller bearings [3] - Install the bearing cone shim (E) on the shaft. [4] - Install the sleeve assembly onto the drive shaft. [5] - Install the top bearing (C) on the shaft, with the larger bearing OD against the driver. To do so, use the bearing installer from the JDG781 bearing installer tool set. [6] →NOTE: Clamping rings are available in various sizes (see Parts Catalog). Install the bearing cones against the gear shoulder and install the thickest clamping ring (B) possible. Install two clamping rings, if necessary. Item Measurement Specification Pump drive pinion (clamping ring and bearing cone) Axial play 0.11 mm 0.004 in. [7] IMPORTANT: Take care to avoid cross-threading the sleeve during installation into the housing. Install the pinion shaft assembly into the differential housing. <- Go to Section TOC Section 56 page 139 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 20: Hydraulic Pump Drive [8] - Tighten the sleeve carefully using KJD10168 ring nut socket, until the pump drive pinion and the pump drive gear mesh and contact. Spigot wrench KJD10168 Removing, installing and adjusting the adjustment ring [9] - Loosen the sleeve to align the punch marks (A). [10] - Install the dowel pin (B). [11] - Check the pump drive pinion backlash. <- Go to Section TOC Section 56 page 140 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 25: Final Drives Checking and adjusting the backlash of the pump drive pinion [1] - Attach the JDG869 adjusting tool (A) and the dial indicator with the dial′s probe touching the line (B). [2] - Check the backlash at three different positions , each 120° apart. Item Measurement Specification Pump drive pinion Backlash 0.229—0.305 mm 0.009—0.012 in. [3] - Adjust the backlash by rotating the sleeve one notch at a time. Check backlash and repeat adjustment if necessary. [4] - Remove adjusting tool and insert dowel pin (C). [5] - Install the charge pump. See “Installing the charge pump” in section 70, group 10. <- Go to Section TOC Section 56 page 141 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 25: Final Drives Group 25 - Final Drives Drive Systems - Final Drives, Summary of References Drive Systems - Final Drives, Summary of References Final Drives - Special Tools Final Drives - Specifications Final Drives - Sectional View Final Drives - Exploded View Remove Planetary Carrier Disassemble Planetary Carrier Assemble Planetary Carrier Remove Axle Housing Disassemble and Assemble Axle Housing Disassemble and Assemble Axle Shaft Final Drives - Install Axle Housing Final Drives - Install Planetary Carrier and Check Rolling Drag Torque Final Drives - Special Tools →NOTE: Order tools according to information given in the U.S. SERVICEGARD ™ Catalog or in the European Microfiche Tool Catalog (MTC). JDG778A- Adjusting Tool DFLX42- Turning Device DFRW30- Lifting Tool JT01673- Installation Tool D01045AA- Bushing, Bearing, and Seal Driver Set <- Go to Section TOC Section 56 page 142 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 25: Final Drives Final Drives - Repair Specifications Item Measurement Specification Planetary Pinion, New Bearings Rolling Drag Torque 0.6 - 3.0 N˙m 6 - 24 lb.-in. Planetary Pinion, Used Bearings Rolling Drag Torque 0.3 - 1.5 N˙m 3 - 12 lb.-in. Axle Diameter at Outer Bearing New Diameter 81.050 - 81.083 mm 3.191 - 3.192 in. Planetary Carrier to Axle Shaft, Special Twelve-Point Screw Torque 400 N˙m 295 lb.-ft. Final Drive Housing, New Bearings Rolling Drag Torque 16 - 20 N˙m 12 - 15 lb.-ft. Final Drive Housing, Used Bearings Rolling Drag Torque 8 - 16 N˙m 6 - 12 lb.-ft. Planetary Carrier to Axle Shaft, Special Twelve-Point Screw Torque 908 N·m 670 lb.-ft. Final Drives - Sectional View <- Go to Section TOC Section 56 page 143 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS LEGEND: A B C D E F G H I J K L M N O P Q R S T U V W <- Go to Section TOC Group 25: Final Drives Retaining washer Screw Tapered roller bearing Planetary gear Outer tapered roller bearing Seal cup Outer seal Special twelve-point screw O-ring Retaining washer Locking plate Planetary carrier Ring gear Bronze thrust washer Inner tapered roller bearing Inner oil seal Housing Axle shaft Additional lubrication Brake piston Brake disk Retraction pin Brake plate Section 56 page 144 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 25: Final Drives Remove Planetary Carrier Preliminary work: See Remove the Final Drives in Section 56. [1] - LEGEND: A B C D Ring gear Planet gear screw Special twelve-point screw Locking plate Remove ring gear (A). [2] →NOTE: Because of the high torque applied to planet gear screws (B), loosen these screws while the planetary carrier is installed in the axle housing. This will prevent the planetary carrier from turning when loosening the screws. Loosen screws (B), if it is necessary to remove the planet gears. [3] - Remove O-ring and locking plate (D). Loosen or tighten special twelve-point screw (C), if necessary, for removal of plate. [4] - Remove the special twelve-point screw and lift out the planetary carrier. <- Go to Section TOC Section 56 page 145 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 25: Final Drives [5] - Check the condition of the locking plate. [6] - Replace plate, if distorted. <- Go to Section TOC Section 56 page 146 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 25: Final Drives Disassemble Planetary Carrier [1] →NOTE: Refer to final drive cross-sectional view during disassembly and assembly. Remove the planet pinion retaining cap screw and special washer. [2] - Remove the planet pinion and the top bearing cone from the carrier using a puller with a 50 mm (1-15/16 in.) driver disk fromD01045AAdriver set. [3] - Remove the bottom bearing cone from the carrier using a puller with a 50 mm (1-15/16 in.) driver disk fromD01045AAdriver set. <- Go to Section TOC Section 56 page 147 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 25: Final Drives [4] - Remove one bearing cup from the planet pinion using a brass drift (A). [5] - Remove the remaining bearing cup using a 75 mm (2-15/16 in.) driver disk fromD01045AAdriver set and a handle. <- Go to Section TOC Section 56 page 148 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 25: Final Drives Assemble Planetary Carrier LEGEND: A B C D E F G H I Planetary carrier Inner pinion bearing cone Inner pinion bearing cup Planet pinion Outer pinion bearing cup Outer pinion bearing cone Pinion retaining washer Pinion retaining cap screw Carrier-to-axle shaft retaining washer [1] - Install new bearing cups, small ID toward the inside shoulder, into the planet pinion. Install tight against the shoulder using a 76 mm (3-3/16 in.) driver disk and handle. [2] - Heat the bottom bearing cone and install with the large OD against the carrier shoulder. Allow the bearing cone to cool and seat the bearing cone using a brass drift. →NOTE: Install the carrier-to-axle shaft retaining washer in the center of the carrier with the stepped side facing the end of the axle shaft before installing the last planet pinion. [3] - Install the planet pinion assembly. <- Go to Section TOC Section 56 page 149 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 25: Final Drives [4] - Heat the top bearing cone and install leaving end play between the cup and the cone. [5] IMPORTANT: Thoroughly clean the oil from the internal and external threads. Use only the specified retaining compound. Clean the threads and apply a 12 mm (0.5 in.) bead of TY15941 Retaining Compound to the cap screw, starting at the thread end. [6] - Clean the threads and apply TY15941 Retaining Compound to the carrier threads. Make sure no retaining compound gets into the bearings. [7] - Apply oil to the bearing cones. [8] - Put the washers over the bearing cones and start the cap screws into the carrier. [9] - Tighten the cap screws while rotating the planet pinions until a slight drag occurs. [10] - InstallJDG778AAdjusting Tool (A) and note the drag torque while rotating the pinion with the tool. [11] - Tighten the cap screw until drag torque on the pinion is: Item Measurement Specification Planet pinion, new bearings Rolling drag torque 0.6 to 3.0 N˙m 6 to 24 lb-in. Planet pinion, used bearings Rolling drag torque 0.3 to 1.5 N˙m 3 to 12 lb-in. IMPORTANT: Rotate the pinion a minimum of three revolutions after each cap screw adjustment before checking the drag torque. <- Go to Section TOC Section 56 page 150 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 25: Final Drives [12] - Install the planetary carrier assembly and check the rolling drag torque. See “Install Planetary Carrier and Check Rolling Drag Torque” in this group. <- Go to Section TOC Section 56 page 151 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 25: Final Drives Remove Axle Housing [1] - Remove the ring gear. [2] - Remove planetary carrier. See “Remove Planetary Carrier” in this group. [3] - Remove the carrier-to-bearing thrust washer. [4] - Press axle shaft through inner bearing using a hydraulic jack andDFRW30tool (A). [5] - Remove the hydraulic jack and the tool. Remove bearing. [6] - Remove the axle housing from the axle shaft using a hoist. Be sure the housing is balanced on the chain or strap. [7] - Inspect the ring gear for damage. <- Go to Section TOC Section 56 page 152 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 25: Final Drives Disassemble and Asssemble Axle Housing [1] - Inspect outer seal retainer (A) for wear or damage. Pry retainer from housing to replace it, if necessary. [2] - Install seal retainer against outer face of housing. [3] - Install outer bearing cup against bottom shoulder usingJT01673Installer. →NOTE: Use a 0.05 mm (0.002 in.) feeler gauge to check that the bearing cup is in contact with the bottom shoulder of the housing. [4] - Remove the inner oil seal from the housing. <- Go to Section TOC Section 56 page 153 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 25: Final Drives [5] - Install the oil seal with the spring-loaded side facing the driver. Use 100 mm (4 in.) and 76 mm (3-1/16 in.) driver disks fromD01045AAdriver set and a handle (A). [6] - Install the inner bearing cup usingJT01673Installer. Install cup against bottom shoulder. →NOTE: Use a 0.05 mm (0.002 in.) feeler gauge to check that the bearing cup is in contact with the bottom shoulder of the housing. <- Go to Section TOC Section 56 page 154 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 25: Final Drives Disassemble and Assemble Axle Shaft [1] IMPORTANT: LEGEND: A B C D E F Strap Puller Puller legs Puller cross bar 76 mm (3 in.) disk Hydraulic jack DO NOT use a torch to remove axle bearings. Heating of the axle shaft will cause early failure. Inspect, remove, and replace parts as required. [2] - Remove parts from the axle shaft using puller tools and a hydraulic jack. Make sure the puller is hooked over the outer bearing spacer. [3] - Measure the axle diameter at the outer bearing. Item Measurement Specification Axle diameter at outer bearing New diameter 81.050 to 81.083 mm 3.191 to 3.192 in. <- Go to Section TOC Section 56 page 155 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 25: Final Drives [4] IMPORTANT: Install the oil seal with the metal side toward the outer end of the axle. If the seal has metal on both sides, follow the directions stamped on the seal. Install the outer seal over the spacer after the spacer has cooled. “This Side Out” must face the outer end of the axle. Make sure the oil seal lips are filled with grease before installing the axle shaft in the axle housing. [5] CAUTION: Heat bearing cone in a bearing heater. Use a thermometer and do not exceed 150°C (300°F). Proceed with care to avoid burns. Heat the outer bearing cone to 150°C (300°F) maximum and install on the shaft against the oil seal. Allow the bearing cone to cool and then reseat the bearing and spacer against the shaft shoulder using a brass drift. Lightly oil the bearing. Do not use grease at this time. [6] - Install the nylon spacer ring on the axle shaft with the chamfered inside facing the bearing. <- Go to Section TOC Section 56 page 156 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 25: Final Drives Final Drives - Install Axle Housing [1] - Before installing the axle shaft, coat the inner seal lip with grease and make sure the outer seal lips are filled with grease. [2] - Coat the splines of the axle shaft with heavy grease to prevent damage to the inner seal. [3] - Install the axle housing on the axle shaft using a hoist. Be sure housing is balanced and take care to avoid damaging the inner seal. [4] CAUTION: Heat bearing cone in a bearing heater. Use a thermometer and do not exceed 150°C (300°F). Proceed with care to avoid burns. Heat the inner bearing cone to 150°C (300°F) maximum and install on the shaft. DO NOT install the bearing cone tight into the bearing cup. This assures end play. [5] - Install the planetary carrier assembly and check the rolling drag torque. SeeFinal Drives - Install Planetary Carrier and Check Rolling Drag Torquein Section 56. [6] - Install the bronze thrust washer on the shaft against the inner bearing. <- Go to Section TOC Section 56 page 157 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 25: Final Drives Final Drives - Install Planetary Carrier and Check Rolling Drag Torque Install planetary carrier [1] - LEGEND: A B Special Twelve-Point Screw Washer Install planetary carrier on shaft. [2] →NOTE: Lubricate inner and outer bearings with oil before tightening the special twelve-point screw at the carrier retainer. Install the special twelve-point screw (A) through retainer (B) of the planetary carrier. [3] IMPORTANT: Do not re-use the special twelve-point screw; it may be used once only. <- Go to Section TOC Section 56 page 158 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 25: Final Drives LEGEND: A Special Twelve-Point Screw Manually screw the special twelve-point screw (A) into the axle shaft. While doing so, make sure the washer is in the specified position in the planetary carrier. [4] - LEGEND: A Special Twelve-Point Screw To press the bearings into the correct position, tighten special twelve-point screw (A) to the specified torque. Item Measurement Specification Planetary carrier to axle shaft, special twelve-point screw Torque 400 N˙m 295 lb-ft [5] - Rotate the axle housing at least six full revolutions in each direction to ensure proper seating of the bearing rollers. <- Go to Section TOC Section 56 page 159 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 25: Final Drives [6] - Tighten special twelve-point screw (A) once again to specified torque. Item Measurement Specification Planetary carrier to axle shaft, special twelve-point screw Torque 400 N˙m 295 lb-ft [7] - Remove the planetary carrier from the axle shaft and tap the end of the axle shaft as shown. This will relieve the bearing preload and thus provide some axial play between bearing and bearing cone. Check rolling drag torque [1] IMPORTANT: Do NOT check the rolling drag torque with the ring gear installed. LEGEND: A B DFLX42 - Turning Device Torque Wrench without Ratchet To measure the rolling drag torque of the final drives, use turning deviceDFLX42(A) and a torque wrench (B) without ratchet. <- Go to Section TOC Section 56 page 160 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 25: Final Drives [2] - Rotate the axle housing and record the rolling drag torque. Repeat the procedure three times and take the average of the results. This figure represents the initial rolling drag torque. [3] IMPORTANT: Be sure thrust washer (A) is still positioned correctly. →NOTE: Lead balls (R72232) can be ordered through normal parts channels. LEGEND: A B Lead Ball Thrust Washer 180° apart, place two lead balls with a diameter of 8 - 10 mm (0.3 - 0.4 in.) on end of the axle shaft. Apply grease to hold the balls in place. [4] - Install the planetary carrier and tighten the special twelve-point screw to 200 Nm (148 lb-ft). <- Go to Section TOC Section 56 page 161 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 25: Final Drives [5] - LEGEND: A B DFLX42 - Turning Device Torque Wrench without Ratchet Rotate the axle housing at least three full revolutions in each direction, then use turning deviceDFLX42(A) and torque wrench (B) to measure the rolling drag torque. Repeat the procedure at least three times, measure the rolling drag torque and take the average of the results. The following value must be added to the initial rolling drag torque: Item Measurement Specification Final drive housing, new bearings Rolling drag torque 16 - 20 N˙m 12 - 15 lb-ft Final drive housing, used bearings Rolling drag torque 8 - 16 N˙m 6 - 12 lb-ft Sample calculation: Calculated initial rolling drag torque (average of three measurements) .......... 10 N˙m (7.5 lb-ft) + rolling drag torque for new bearings .......... + 16-20 N˙m (12-15 lb-ft) = total rolling drag torque .......... = 26-30 N˙m (20-22 lb-ft) In the sample calculation, total rolling drag torque must be 26-30 N˙m (20-22 lb-ft). [6] - Tighten the special twelve-point screw in steps of 25-50 N˙m (18.5-37 lb-ft) each until the calculated total rolling drag torque is achieved. <- Go to Section TOC Section 56 page 162 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 25: Final Drives [7] - LEGEND: A B C Lead Ball Shim Pack Thrust Washer Remove and measure individual thickness of flattened lead balls (A). Average thickness of two lead balls equals thickness of shim pack required. [8] →NOTE: Shims must always be measured individually due to slight variations in thickness. Never measure an entire shim pack at once. Relieve the bearing preload by lifting the final drive and hitting the inner end of the axle with a heavy lead hammer. [9] - Install shim pack (B) of required thickness as determined previously. Be sure thrust washer (A) is positioned correctly. [10] IMPORTANT: Relieve any bearing preload before ADDING shims. <- Go to Section TOC Section 56 page 163 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 25: Final Drives Install the planetary carrier and tighten the special twelve-point screw to 200 Nm (148 lb-ft). [11] - LEGEND: A B DFLX42 - Turning Device Torque Wrench without Ratchet Rotate the axle housing at least three full revolutions in each direction, then use turning deviceDFLX42(A) and torque wrench (B) to measure the rolling drag torque. Repeat the procedure at least three times, measure the rolling drag torque and take the average of the results. [12] →NOTE: Adding or removing a shim with a thickness of 0.13 mm (0.005 in.) will change the rolling drag torque by approx. 8 N˙m (71 lb-in). →NOTE: Add shims if the rolling drag torque is too high or remove shims if the rolling drag torque is too low. Adjust the thickness of the shim pack as needed until the calculated rolling drag torque is achieved. <- Go to Section TOC Section 56 page 164 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 25: Final Drives [13] - LEGEND: A Torque Multiplier Tighten the special twelve-point screw using a torque multiplier (A) to the final torque as specified. Item Measurement Specification Planetary carrier to axle shaft, special twelve-point screw Torque 908 N·m 670 lb-ft [14] - LEGEND: A B C Locking Plate Lock Lugs O-Ring Replace the locking plate (A) if required. [15] - Install the locking plate with the lugs between the lock lugs (B) on the carrier. If the notches in the plate will not fit over the lock lugs, tighten the special twelve-point screw slightly (8° maximum). <- Go to Section TOC Section 56 page 165 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO [16] - Install the O-ring (C) around the head of the special twelve-point screw with the locking plate installed. [17] - Fill the outer bearing compartment and the bearing with grease. [18] - LEGEND: A Ring Gear Install ring gear (A) with groove (see arrow) facing upward. Next step: See Install the Final Drives in Section 56. <- Go to Section TOC Section 56 page 166 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO Group 30 - Rear PTO Drive Systems - Rear PTO, Summary of References Special Tools Specifications Repair Instructions Repair Rear PTO Remove and Disassemble Countershaft Assemble and Install Countershaft Remove and Disassemble Output Shaft Assemble and Install Output Shaft Remove PTO Shifter Install PTO Shifter Replacing Oil Seal on PTO Output Shaft Remove Modulating Valve Disassemble and Assemble Modulating Valve Install Modulating Valve Change and Adjust Bowden Cable <- Go to Section TOC Section 56 page 167 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO Special tools →NOTE: Order tools according to information given in the U.S. SERVICEGARD ™ Catalog or European Microfiche Tool Catalog (MTC). Driver JDG753 or KJD10171 Installing the seal ring on PTO output shaft Spring compressor JDG754 Compressing PTO clutch return springs PTO clutch bushing installer JDG755 Installing PTO clutch bushing 17-1/2 ton puller set <- Go to Section TOC Section 56 page 168 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO D01173AA Removing and installing bearings Bushing, bearing, and seal driver set D01045AA Removing and installing bearing cups, bearing cones, and bushings <- Go to Section TOC Section 56 page 169 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO Specifications Item Measurement Specification Clutch backing plate, cap screw Torque 35 N˙m 26 lb-ft Bearing support to PTO housing, cap screw Torque 90 N˙m 66 lb-ft Clutch assembly End play 0.015 to 0.15 mm 0.001 to 0.006 in. Countershaft bearing quill, cap screw Torque 50 N˙m 37 lb-ft Countershaft End play 0.025 to 0.13 mm 0.001 to 0.005 in. Output shaft End play 0.015 to 0.15 mm 0.001 to 0.006 in. Shifter support, cap screw Torque 70 N˙m 52 lb-ft Shift detent spring Free length approx. 20 mm approx. 0.8 in. Test length 12 mm at 65 N 0.5 in. at 15 lb force PTO modulating valve, outer spring Free length approx. 70 mm approx. 2.75 in. Test length 44 mm at 117 N 1.7 in. at 26 lb force PTO modulating valve, inner spring Free length approx. 111 mm approx. 4.4 in. Test length 89 mm at 33 N 3.5 in. at 7 lb force PTO modulating valve, test plug Torque 12 N˙m 9 lb-ft PTO modulating valve - valve housing and retaining plate, cap screw Torque 16 N˙m 11 lb-ft PTO modulating valve to PTO housing, cap screw Torque 16 N˙m 11 lb-ft Repair Instructions When assembling, coat all components with hydraulic oil. When assembling, coat needle bearings, thrust washers and sealing rings with a thin film of grease. Never clean the clutch plates in cleaning agent. Before assembling new clutch plates, <- Go to Section TOC Section 56 page 170 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO soak them for 15 minutes in hydraulic oil. Never heat bearing cones to temperatures higher than 150°C (300°F). <- Go to Section TOC Section 56 page 171 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO Repair Rear PTO [1] - Remove the rear PTO. See “Removing the Rear PTO” in Group 00 of this Section. [2] - Remove the PTO master-shield (A). [3] - Take the snap ring off the PTO output shaft and pull out the shaft. [4] - Remove oil deflector plate [ AutoPowr/IVT transmission only ] . [5] - Remove the bearing support (A). <- Go to Section TOC Section 56 page 172 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO [6] - Remove the bearing cup snap rings (A) of the clutch front bearing and output shaft. 17-1/2 Ton Puller Set D01173AA Remove and install bearings. [7] - Remove bearing cups (B). Remove and disassemble PTO clutch <- Go to Section TOC Section 56 page 173 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO PTO clutch—sectional view LEGEND: A B <- Go to Section TOC Bearing cone Bearing cup Section 56 page 174 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS C D E F G H I J K L M N O P Q R S T U V W <- Go to Section TOC Group 30: Rear PTO Snap ring Backing plate with gear Clutch hub with thrust washers Disk (4 used) Externally splined disk (3 used) Clutch return plate Clutch piston Clutch drum Brake plate Brake piston Seal ring (2 used) Bearing cup Bearing cone Snap ring Lube cut-off valve PTO housing Piston seal (2 used) Bushing Piston return spring (7 used) Snap ring Bearing support Section 56 page 175 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS LEGEND: A B C D E F G H I J K L M N O P Q R <- Go to Section TOC Group 30: Rear PTO Bearing cup Bearing cone Snap ring Lube cut-off valve Brake piston Brake plate Clutch drum Inner piston seal ring Outer piston seal ring Clutch piston Piston return spring (7 used) Snap ring Seal ring (2 used) Bushing Thrust washer (2 used) PTO clutch hub with thrust washer (2 used) Return plate Disk (4 used) Section 56 page 176 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS S T U V Group 30: Rear PTO Externally splined disk (3 used) Backing plate with gear Bearing cone Cap screw (6 used) [1] - Remove the output drive gear. [2] - Remove the PTO clutch assembly from the PTO housing. [3] - Remove the bearing cup from the PTO housing. 17-1/2 Ton Puller Set D01173AA Remove and install bearings. [4] - Remove the PTO brake plate and brake piston (A). [5] - Remove the clutch backing plate with gear. <- Go to Section TOC Section 56 page 177 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO [6] - Remove the front bearing cone using a press, a knife-edge puller and a 55.5 mm (2-3/16 in.) disk. Bushing, Bearing, and Seal Driver Set D01045AA Remove and install bearing cups, bearing cones, and bushings. [7] - LEGEND: A B C D PTO clutch hub Washers Externally splined disks Return plate Remove parts (A to D). [8] - Remove the lube cut-off valve retaining ring (A) and valve (B). [9] - Inspect the sealing rings (A). <- Go to Section TOC Section 56 page 178 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO [10] - Remove the rear bearing cone using a press, a knife-edge puller and a 44.5 mm (1-3/4 in.) disk. [11] - Put the clutch drum assembly in a press and install JDG754 Spring Compressor Tool. Spring compressor JDG754 Compress PTO clutch return springs [12] - Compress the return springs and remove the snap ring (A). [13] - Remove the return springs and the clutch piston. [14] - Replace the piston seals (A). Assemble and install PTO clutch <- Go to Section TOC Section 56 page 179 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO [1] - Install the rear bearing (A) on the clutch drum against the shoulder using a press and a 50 mm (2 in.) disk. [2] - Install the lube cut-off valve (B) and valve retainer (C). [3] - Install the sealing rings (A) making sure the ends are not in the line and are solidly hooked. [4] - Install the clutch piston. [5] - Install the seven return springs alternately, starting with the outer circumference against the piston. <- Go to Section TOC Section 56 page 180 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO [6] - Put the clutch drum assembly in a press and install JDG754 Spring Compressor Tool. Spring compressor JDG754 Compress PTO clutch return springs [7] - Compress the return springs and install the snap ring. [8] - Install the bushing using JDG755 Bushing Installer. PTO Clutch Bushing Installer JDG755 Install PTO clutch bushing <- Go to Section TOC Section 56 page 181 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO [9] - LEGEND: A B C D PTO clutch hub Disks (4 used) Externally splined disk (3 used) Return plate Install PTO clutch hub (A). [10] - Install the clutch return plate (D). [11] - Install the externally splined disks (C) and disks (B) alternately starting with a disk against the return plate. [12] - Heat the bearing cone and install on the backing plate. Allow the bearing cone to cool and seat the bearing against the shoulder using a brass drift. See Repair Instructions in this group. [13] - Install the clutch backing plate with gear. Tighten cap screws. Item Measurement Specification Clutch backing plate, cap screw Torque 35 N˙m 26 lb-ft <- Go to Section TOC Section 56 page 182 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO [14] - Install the brake piston and plate (A) in the housing. [15] - Install the output drive gear. [16] - Install the PTO clutch assembly into the PTO housing. [17] - Install the bearing support (A). <- Go to Section TOC Section 56 page 183 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO [18] - Tighten cap screws. Item Measurement Specification Bearing support to PTO housing, cap screw Torque 90 N˙m 66 lb-ft [19] - Install the front bearing cup and a thin snap ring. [20] - Rotate the clutch assembly several times in each direction to seat the bearings. [21] - Install a dial indicator with the pointer resting on the end of the clutch assembly. [22] - Force the clutch assembly up and down using a pry bar. Measure the end play. [23] - Measure the thickness of the snap ring installed during the end play check. →NOTE: Snap rings are available in various sizes (see Parts Catalog). [24] - Select a snap ring that will provide specified end play. Item Measurement Specification Clutch assembly End play 0.015 to 0.15 mm 0.001 to 0.006 in. [25] - Install [ AutoPowr/IVT transmission only ] oil deflector plate. [26] - Install the rear PTO. See “Installing the Rear PTO” in Group 00 of this Section. <- Go to Section TOC Section 56 page 184 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO Remove and Disassemble Countershaft [1] - Remove oil deflector plate [ AutoPowr/IVT transmission only ] . [2] - Remove the bearing support (A). [3] →NOTE: The front output drive gear bearing is a loose fit. Remove the output drive gear, front bearing and bearing-to-gear thrust washer. <- Go to Section TOC Section 56 page 185 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO PTO countershaft — sectional view LEGEND: A B C D E F G H I J <- Go to Section TOC Snap ring Countershaft drive gear Bearing cone Bearing cup Bearing quill Shim pack PTO housing Bearing cup Bearing cone Countershaft Section 56 page 186 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO PTO countershaft — exploded view LEGEND: A B C D E F G H I J K L <- Go to Section TOC Bearing cup Bearing cone Snap ring Output gear (540E rpm) Countershaft Bearing cone Bearing cup Shim pack Bearing quill Cap screw (4 used) Countershaft drive gear Snap ring Section 56 page 187 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO [4] - Remove the snap ring (A) and countershaft drive gear (B). [5] - Remove the bearing quill and shims (C). [6] - Remove the countershaft from the PTO housing. [7] - Remove the bearing cup from the quill using a press and a 72.6 mm (2-7/8 in.) driver disk. Bushing, Bearing, and Seal Driver Set D01045AA Remove and install bearing cups, bearing cones, and bushings. [8] - Install a new bearing cup using a 66.7 mm (2-5/8 in.) driver disk and a press. <- Go to Section TOC Section 56 page 188 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO Assemble and Install Countershaft [1] - Install a new rear bearing cup in the housing using a 74.6 mm (2-15/16 in.) driver disk. Bushing, Bearing, and Seal Driver Set D01045AA Remove and install bearing cups, bearing cones, and bushings. [2] - Install a new rear bearing cone (A) on the shaft using a 44.5 mm (1-3/4 in.) driver disk. [3] - Heat the front bearing cone (B) and install on the shaft. Allow the bearing cone to cool and seat the bearing against the shoulder using a brass drift. See “Repair Instructions” in this group. <- Go to Section TOC Section 56 page 189 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO [4] - Install the countershaft into the housing. [5] - Install the same shim pack that was removed. [6] - Install the bearing quill. Tighten cap screws. Item Measurement Specification Countershaft bearing quill, cap screw Torque 50 N˙m 37 lb-ft [7] - Rotate the countershaft several times in each direction to seat the bearings. [8] - Install a dial indicator with the pointer resting on the end of the countershaft. [9] - Force the countershaft up and down using a pry bar. Measure the end play. →NOTE: Shims are available in various sizes (see Parts Catalog). Measure shims individually for accurate measurement. [10] - Remove the quill and add or subtract shims to provide correct end play. Item Measurement Specification Countershaft End play 0.025 to 0.13 mm 0.001 to 0.005 in. [11] - Install the countershaft drive gear (B) and retaining snap ring (A). <- Go to Section TOC Section 56 page 190 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO [12] →NOTE: The front output drive gear bearing is a loose fit. Install the output shaft drive gear, thrust washer between gear and front bearing and front bearing. [13] - Install the bearing support. [14] - Install [ AutoPowr/IVT transmission only ] oil deflector plate. [15] - Tighten cap screws. Item Measurement Specification Bearing support to PTO housing, cap screw Torque 90 N˙m 66 lb-ft <- Go to Section TOC Section 56 page 191 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO Remove and Disassemble Output Shaft LEGEND: A B C D E F G H I J K L <- Go to Section TOC Bearing support Snap ring Bearing cup Bearing cone Thrust washer Output gear (1000 rpm) Snap ring Sleeve Collar Output gear (540 rpm) Output shaft Magnetic speed pickup disk Section 56 page 192 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO M N O P Q R S T Bearing cone Bearing cup PTO housing Oil seal Snap ring Thrust washer Needle bearing (2 used) Needle bearing spacer LEGEND: A B Shift collar (2 used) Output gear (540E rpm) <- Go to Section TOC Section 56 page 193 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS C D E F G H I E K L M N O P Q R S Group 30: Rear PTO Snap ring (4 used) Thrust washer Output gear (540E rpm) Shift collar support Thrust washer Needle bearing (2 used) Needle bearing spacer Output gear (1000 rpm) Thrust washer Bearing cone Output shaft Speed pick-up disk Bearing cone Bearing cup Seal ring Output shaft Snap ring [1] - Remove oil deflector plate [ AutoPowr/IVT transmission only ] . [2] - Remove bearing support (A). <- Go to Section TOC Section 56 page 194 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO [3] →NOTE: The front output drive gear bearing is a loose fit. Remove the front bearing, bearing-to-gear thrust washer and output shaft drive gear from the shaft. [4] - LEGEND: A B C D E F Spring pin Shifting gate Shift yoke and collar Countershaft snap ring Countershaft drive gear Bearing quill and shims Remove spring pin (A) between shifting gate and cam shaft. [5] - Push the shifting gate (B) against the housing. [6] - Remove the shift yoke and shift collar (C) from the shifter rails and the output shaft. [7] - Remove the snap ring (D) and gear (E). [8] - Remove the countershaft bearing quill and shims (F). [9] - Remove the countershaft from the PTO housing. [10] - Remove the output shaft from the PTO housing. <- Go to Section TOC Section 56 page 195 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO [11] - Remove rear oil seal (A). Do not install the new seal until after the output shaft is installed in the housing. See “Replacing Oil Seal on PTO Output Shaft” in this group. [12] - Remove rear bearing cup (B). [13] - Remove thrust washer (A) between shaft and output gear. [14] - Remove the snap ring (B) and sleeve (C). [15] - Remove the snap ring (A) and the 540 rpm output gear (B). <- Go to Section TOC Section 56 page 196 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO [16] - Remove the magnetic speed pickup disk and rear bearing using a press and a knife-edge puller. <- Go to Section TOC Section 56 page 197 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO Assemble and Install PTO Output Shaft [1] - Install the magnetic speed pick up disk against the shoulder using a brass drift. [2] - Heat the rear bearing cone and install on the shaft. Allow the bearing to cool and seat it against the magnetic speed pickup disk using a brass drift. See “Repair Instructions” in this group. [3] - Install the 540 rpm output gear (B) and snap ring (A). [4] - Install sleeve (C). [5] - Install the sleeve retaining snap ring (B). [6] - Install thrust washer (A) between shaft and output gear. <- Go to Section TOC Section 56 page 198 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO [7] - LEGEND: A B C D E F Spring pin Shifting gate Shift yoke and collar Countershaft snap ring Countershaft drive gear Bearing quill and shims Install the output shaft into the housing. [8] - Install the shift yoke and shift collar (C) on the shifter rails and the output shaft. [9] - Push the cam of shifting gate (B) inward aligning the yoke roller in the shifting gate track. [10] - Rotate the shifter shaft so the arm is pointing to the front. Install the spring pin (A). [11] - Install the output shaft into the housing. [12] - Install the countershaft into the PTO housing. [13] - Install the countershaft bearing quill with shims (F). Tighten cap screws. Item Measurement Specification Countershaft bearing quill, cap screw Torque 50 N˙m 37 lb-ft [14] - Install the countershaft drive gear (E) and snap ring (D). →NOTE: Make sure the thrust washer between output shaft and gear is installed. <- Go to Section TOC Section 56 page 199 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO [15] - Install the output gear, two bearings with a spacer between them and the thrust washer between output gear and front bearing. →NOTE: The front output drive gear bearing is a loose fit. [16] - Install the front bearing cone on the shaft. [17] - Install the bearing support. [18] - Tighten cap screws. Item Measurement Specification Bearing support to PTO housing, cap screw Torque 90 N˙m 66 lb-ft [19] - Install the front bearing cup and a thin snap ring. [20] - Rotate the output shaft several times in each direction to seat the bearings. [21] - Install a dial indicator with the pointer resting on the end of the shaft. [22] - Force the shaft up and down using a pry bar. Measure the end play. <- Go to Section TOC Section 56 page 200 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO [23] - Remove the front bearing retaining snap ring and measure the thickness. →NOTE: Snap rings are available in various sizes (see Parts Catalog). [24] - Select a snap ring that will provide specified end play. Item Measurement Specification Output shaft End play 0.015 to 0.15 mm 0.001 to 0.006 in. [25] - Install oil deflector plate [ AutoPowr/IVT transmission only ] . <- Go to Section TOC Section 56 page 201 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO Remove PTO Shifter PTO shifter components LEGEND: A B C D E F G H I J K L M N O O-ring Selector shaft Cap screw Bracket Shifting gate Bearing bushing (4 used) Spring pin (2 used) Bushing (2 used) Selector shaft bearing Cap screw (2 used) Shifter yoke Shifter yoke Cap screw Locking tab Detent spring [1] - Remove oil deflector plate [ AutoPowr/IVT transmission only ] . <- Go to Section TOC Section 56 page 202 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO [2] - Remove the bearing support (A). [3] →NOTE: The front output drive gear bearing is a loose fit. Remove output drive gear front bearing, thrust washer and gear with two bearings and bearing spacer. <- Go to Section TOC Section 56 page 203 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO [4] - Remove spring pin (A) between shifting gate and cam shaft. [5] - Push the cam (A) against the housing wall. [6] - Remove the shifter yoke and shift collar (B) from the shifter rails and the output shaft. [7] - Remove the spring pin between support (A) and cam shaft and remove the cam shaft from the housing, cam, and support. [8] - Remove the support (B) with the cam detent and detent spring. Item Measurement Specification Detent spring Free length approx. 20 mm approx. 0.8 in. Test length 12 mm at 65 N 0.5 in. at 15 lb [9] - Remove the shifter rails (C) with E-Clips from the housing. <- Go to Section TOC Section 56 page 204 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO Install PTO Shifter [1] - Install the shifter rails with E-Clips (C), short end first into the housing. [2] - Install the hollow dowels into the support (B) so one-half of the dowel protrudes from the support surface. [3] - Install the support (B) with the shifter detent hole on the bottom facing outward. Tighten cap screws. Item Measurement Specification Shifter support, cap screw Torque 70 N˙m 52 lb-ft [4] - Hold the shifting gate with detent reliefs on the bottom and the hub facing outward in line with the support. [5] - Install the cam shaft with O-ring through the housing, shifting gate and support. Install the spring pin (A). [6] - Install the detent spring and the detent in the support. [7] - Install the shift yoke and collar (B) onto the shifter rails and the output shaft with the large bushing on top. [8] IMPORTANT: The lever on the camshaft must point forward. Push the cam shaft into the shifting gate (A) until the spring pin holes align. <- Go to Section TOC Section 56 page 205 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO [9] - Install the spring pin. [10] →NOTE: The front output drive gear bearing is a loose fit. Install the output drive gear, two bearings and bearing spacer, thrust washer between gear and bearing, and front bearing cone. [11] - Install the bearing support (A). [12] - Install [ AutoPowr/IVT transmission only ] oil deflector plate. [13] - Tighten cap screws. Item Measurement Specification Bearing support to PTO housing, cap screw Torque 90 N˙m 66 lb-ft <- Go to Section TOC Section 56 page 206 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO [14] - Install the PTO. Replacing Oil Seal on PTO Output Shaft [1] - Remove the PTO output shaft snap ring, the shaft and the old oil seal. [2] - Install the new oil seal using seal installer JDG753 or KJD10171 (A). Driver JDG753 or KJD10171 Installing the oil seal on PTO output shaft [3] - Install the PTO output shaft and snap ring. Remove Modulating Valve [1] - Remove six valve housing cap screws (A) and remove the valve housing and gasket. <- Go to Section TOC Section 56 page 207 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO [2] - Remove housing-to-mounting plate cap screws (A) and remove the plate and gasket. <- Go to Section TOC Section 56 page 208 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO Disassemble and Assemble Modulating Valve [1] - LEGEND: A B C D E F G H I J K L Snap Ring Plug with O-Ring Accumulator Piston Outer Spring Inner Spring Pin Modulating Valve Test Port Plug with O-Ring (2 used) Valve Housing Valve Housing-to-Mounting Plate Plate Gasket Mounting Plate Mounting Plate-to-PTO Housing Gasket Inspect parts and replace as necessary. Item Measurement Specification PTO modulating valve, outer spring Free length approx. 70 mm approx. 2.75 in. Test length 44 mm at 117 N 1.7 in. at 26 lb force PTO modulating valve, inner spring Free length approx. 111 mm approx. 4.4 in. Test length 89 mm at 33 N 3.5 in. at 7 lb force <- Go to Section TOC Section 56 page 209 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO [2] - Tighten test port plugs with O-rings (H). Item Measurement Specification PTO modulating valve, test plug Torque 12 N˙m 9 lb-ft <- Go to Section TOC Section 56 page 210 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO Install Modulating Valve [1] - Install valve housing-to-mounting plate gasket and cap screws (A). Tighten screws. Item Measurement Specification PTO modulating valve - valve housing and retaining plate, cap screw Torque 16 N˙m 11 lb-ft [2] - Install six cap screws (A) and tighten. Item Measurement Specification PTO modulating valve to PTO housing, cap screw Torque 16 N˙m 11 lb-ft <- Go to Section TOC Section 56 page 211 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO Changing and adjusting the bowden cable Actuating components of PTO shift with Command Arm LEGEND: A B C <- Go to Section TOC Shifter shaft Yoke Lock nut Section 56 page 212 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS D E F G H I J K L M N O Group 30: Rear PTO Bowden cable Rubber sleeve Retainer Retainer PTO speed selector lever Handle Washer Hex. nut Washer Washer Spring washer Self-locking hex. nut [1] - <- Go to Section TOC Section 56 page 213 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 30: Rear PTO Actuating components of PTO shift without Command Arm LEGEND: A B C D E F G <- Go to Section TOC Shifter shaft Retainer Retainer Bowden cable Rubber sleeve Retainer Retainer Section 56 page 214 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS H I J K L M N O Group 35: Front PTO P PTO speed selector lever Handle Washer Hex. nut Cover Washer Spring washer Bushing Creeper selector lever Q R S Bushing Washer Self-locking hex. nut [ If equipped ] Disengage bowden cable (D) at shifter shaft (A). [2] - Remove the trim panels from the shift console and disengage bowden cable (D) at selector lever (H). [3] - Run the new bowden cable past the hydraulic pump and through the lift shaft support. [4] - Engage bowden cable in selector lever, and secure. Adjusting the PTO shift [1] - Move shifter shaft (A) at the transmission to the “1000 rpm” position. [2] - Also move selector lever (H) on the console to the “1000 rpm” position. [3] - Adjust the bowden cable on the yoke so that it is aligned with the holes in the shifter shaft. Secure with the retaining pin. [4] - Tighten the lock nut on the yoke, making sure that the yoke does not twist in relation to the shifter shaft. [5] - Check that PTO engages and disengages properly at all speeds. [6] - Attach the panels. <- Go to Section TOC Section 56 page 215 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO Group 35 - Front PTO Front PTO - Reconditioning (Summary of References) Before reconditioning the front PTO, refer to the following: ”Other material” ”Specifications” ”General repair procedures” ”Replacing the solenoid valve” ”Reconditioning the modulator valve” ”Replacing the front PTO speed sending unit (B58)” ”Cleaning and replacing the filter” ”Reconditioning the pressure-regulating valve” ”Checking the cooler relief and filter by-pass valves” ”Removing and installing the valve plate” ”Front PTO — Sectional view” ”Disassembling the front PTO” ”Reconditioning the oil pump” ”Reconditioning the PTO clutch” ”Reconditioning the PTO brake” ”Reconditioning the intermediate gear shaft (PTO rotating counterclockwise)” ”Reconditioning the drive shaft” ”Assembling the front PTO” Other Material Number Name Use • L64500 (loctite) Flexible sealant Sealing the surfaces on the front PTO • L41475 (loctite) Thread lock Cementing screws at the front PTO • L156817 (loctite) Molykote “Long Term” Applying grease to the spline on the drive shaft <- Go to Section TOC Section 56 page 216 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO Specifications Item Measurement Specification Y01 - Solenoid valve for front PTO to housing, screws Torque 8 - 10 N˙m 6 - 7.5 lb-ft Modulating valve to front PTO, screws Torque 16 N˙m 12 lb-ft B58 - Front PTO speed sensor to housing Torque 10-12 N˙m 7.5-9 lb-ft Pressure-regulating valve Pressure 1200 kPa 12 bar 174 psi Cooler relief valve, plug Torque 20 N˙m 15 lb-ft Valve plate to front PTO, screws Torque 10 N˙m 7.5 lb-ft Oil manifold, screw Torque 10 N˙m 7.5 lb-ft Oil pump installation, screws Torque 10 N˙m 7.5 lb-ft PTO clutch gear, screw Torque 23 N˙m 17 lb-ft PTO stub shaft, hex. nut Torque 50 N˙m 36.5 lb-ft Lid on clutch cage, screw Torque 10 N˙m 7.5 lb-ft Ring gear at PTO brake Torque 10 N˙m 7.5 lb-ft Drive shaft and housing cover, tapered roller bearings Capacity 20 ml 0.68 fl oz Housing cover, screw Torque 23 N˙m 17 lb-ft Bearing quill and housing cover, tapered roller bearings Capacity 40 ml 1.4 fl oz Bearing quill to housing cover, screw Torque 10 N˙m 7.5 lb-ft Output shaft, tapered roller bearings Preload 0.01 to 0.04 mm 0.0004 to 0.0016 in. Bearing quill to housing cover, screw Torque 10 N˙m 7.5 lb-ft <- Go to Section TOC Section 56 page 217 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO Item Measurement Specification Bearing quill to housing cover, screws Torque 10 N˙m 7.5 lb-ft Drive shaft, axial play Axial play 0.05 to 0.1 mm 0.002 to 0.004 in. Bearing quill to housing cover, screws Torque 10 N˙m 7.5 lb-ft Intermediate gear shaft, tapered roller bearings Preload 0 to 0.03 mm 0 to 0.0012 in. Bearing quill to housing cover, screw Torque 10 N˙m 7.5 lb-ft General Repair Procedures Thoroughly clean the PTO housing before taking it apart. Use LOCTITE ™ 574 (L64500) on sealing surfaces. Number Name Use • L64500 (loctite) Flexible sealant Sealing the surfaces on the front PTO Apply LOCTITE ™ 243 (L41475) thread lock and sealer to screws. Number Name Use • L41475 (loctite) Thread lock Cementing screws at the front PTO IMPORTANT: Heat bearing cones in a bearing heater. Use a thermometer and do not exceed 150°C (300°F). IMPORTANT: Do NOT use solvent to clean clutch plates or brake disks. Use a lint-free cloth. New disks should be soaked in hydraulic oil for 15 minutes before assembly. Replace Y01 - Solenoid Valve for Front PTO <- Go to Section TOC Section 56 page 218 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO [1] - LEGEND: A Solenoid valve Disconnect the connector. [2] - Take out the screws and remove solenoid valve (A). [3] - Install the new solenoid valve and tighten the screws to the specified torque. Item Measurement Specification Y01 - Solenoid valve for front PTO to housing, screws Torque 8 - 10 N˙m 6 - 7.5 lb-ft [4] - Connect the connectors. <- Go to Section TOC Section 56 page 219 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO Reconditioning the Modulator Valve [1] - Take out cap screws. [2] - Lift off modulator valve (A) together with its gasket. [3] - LEGEND: A B C D E F G H Spool Spring Spring Spring pin Sleeve O-ring Plug Snap ring Check the valve for damage, clean, oil and re-assemble. <- Go to Section TOC Section 56 page 220 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO [4] - LEGEND: A B Outer spring Inner spring Check spring forces. Item Measurement Specification Modulating valve, outer spring Free length approx. 70 mm approx. 2.75 in. Test length 43.5 mm at 105 to 130 N 1.7 in. at 23.6 to 29.3 lb Modulating valve, inner spring Free length approx. 100 mm approx. 3.95 in. Test length 60 mm at 68.5 to 84.5 N 2.35 in. at 15.4 to 19 lb [5] - Install modulator valve (A) together with its gasket. <- Go to Section TOC Section 56 page 221 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO [6] - Tighten the cap screws evenly. Item Measurement Specification Modulating valve to front PTO, cap screws Torque 16 N˙m 12 lb-ft Replace B58 - Front PTO Speed Sensor [1] - Disconnect the connector. [2] - Remove sensor (A). [3] - Install a new sensor using a new O-ring. [4] - Tighten the sensor to the specified torque. Item Measurement Specification B58 - Front PTO speed sensor to housing Torque 10-12 N˙m 7.5-9 lb-ft [5] - Connect the connectors. Cleaning and Replacing the Filter <- Go to Section TOC Section 56 page 222 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS LEGEND: A B C D Group 35: Front PTO Plug O-ring Filter element O-ring [1] - Remove plug (A). Remove the filter element. [2] - Wash the filter element in fuel. [3] - Install the filter element. Tighten the plug. <- Go to Section TOC Section 56 page 223 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO Reconditioning the Pressure-Regulating Valve LEGEND: A B C D E Plug O-ring Shim (quantity as required) Spring Valve spool [1] - Remove plug (A). Remove the valve. [2] - Check the valve for damage, clean, oil and re-assemble. [3] - Pressure can be adjusted by adding or removing shims (C). Item Measurement Specification Pressure-regulating valve Pressure 1200 kPa 12 bar 174 psi [4] - Install valve. Tighten the plug. <- Go to Section TOC Section 56 page 224 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO Checking the Cooler Relief and Filter By-Pass Valves LEGEND: A B Cooler relief valve Filter by-pass valve Apply Thread Lock and Sealer L41475 ( LOCTITE ™ 243) to the threads and contact surfaces of both plugs. Number Name Use • L41475 (loctite) Thread lock Cementing screws at the front PTO Tighten the cooler relief valve plug. Item Measurement Specification Cooler relief valve, plug Torque 20 N˙m 15 lb-ft Removing and Installing the Valve Plate <- Go to Section TOC Section 56 page 225 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO [1] - Remove modulator valve (B). [2] - Remove hex. socket screws of valve plate (A). [3] - When assembling parts, apply LOCTITE ™ 574 flexible sealant to the sealing surfaces. Number Name Use • L64500 (loctite) Flexible sealant Sealing the surfaces on the front PTO [4] - Tighten the hex. socket screws evenly. Item Measurement Specification Valve plate to front PTO, cap screws Torque 10 N˙m 7.5 lb-ft <- Go to Section TOC Section 56 page 226 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO Front PTO — Sectional View Clockwise-rotating front PTO (viewed in direction of travel) LEGEND: <- Go to Section TOC Section 56 page 227 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS A B C D E F G H I J K L M N O P <- Go to Section TOC Group 35: Front PTO Cover Special sealing ring Shift collar Drive gear Special sealing ring Drive shaft Ring gear Disk clutch Cover PTO stub shaft PTO brake Oil distribution baffle Spring Housing cover Pressure-regulating valve Housing Section 56 page 228 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO Counterclockwise-rotating front PTO (viewed in direction of travel) LEGEND: A B <- Go to Section TOC Cover Special sealing ring Section 56 page 229 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS C D E F G H I J K L M N O P Q <- Go to Section TOC Group 35: Front PTO Shift collar Drive gear Special sealing ring Drive shaft Idler gear shaft Ring gear Disk clutch Cover PTO stub shaft PTO brake Spacer bushing Oil distribution baffle Spring Housing cover Housing Section 56 page 230 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO Disassembling the Front PTO [1] - Drain the oil. [2] - Remove PTO guard. [3] - Before removing the front PTO, see reference “Removing the Front PTO” , Section 56, Group 00. [4] - Before disassembling the front PTO, see reference“General Repair Procedures”. Disassembly [1] - Take hex. socket screws (A) out of the housing cover. [2] - Put the back of the front PTO on a flat surface and support it. [3] - Remove bearing quills (A) and (B). When removing the quills, note position and number of shims. <- Go to Section TOC Section 56 page 231 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO [4] - Remove housing cover. When removing cover, shift pawl (D) may stick to the shift collar; therefore hold cover at an angle when lifting it off. [5] - Remove the outer taper roller bearing cup (A) from the housing cover. <- Go to Section TOC Section 56 page 232 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO [6] - Clockwise-rotating front PTO Counter-clockwise-rotating front PTO Take off metal cover (B). [7] - Remove output shaft (A). [8] - Remove drive shaft (C). [9] - PTO rotating counterclockwise: Remove intermediate gear shaft (D). <- Go to Section TOC Section 56 page 233 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO Reconditioning the Oil Pump Removing the oil pump Preliminary work: Before removing the output shaft, see reference“Disassembling the Front PTO”. [1] - Take off metal cover (A). [2] - Remove snap ring (B) and pull off gear (A). <- Go to Section TOC Section 56 page 234 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO [3] - Take out key (A). [4] - Take out cap screws (B). LEGEND: A B C D E F G H I J K <- Go to Section TOC Snap ring Gear Key Pin (4 used) Cover Bushing (4 used) Gear Gear Housing Cap screws (4 used) Cover Section 56 page 235 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS L M Group 35: Front PTO Oil manifold Hex. socket screw (4 used) Removing/installing the oil manifold [1] - Remove oil manifold (B), if necessary. [2] - When assembling parts, apply LOCTITE ™ 574 flexible sealant to the sealing surface which faces the PTO housing. Number Name Use • L64500 (loctite) Flexible sealant Sealing the surfaces on the front PTO [3] - Tighten hex. socket screws (A) evenly. Item Measurement Specification Oil manifold, hex. socket screw Torque 10 N˙m 7.5 lb-ft Installing the oil pump <- Go to Section TOC Section 56 page 236 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO [1] - When assembling the oil pump, coat cover-to-housing sealing surfaces with LOCTITE ™ 574 flexible sealant. Number Name Use • L64500 (loctite) Flexible sealant Sealing the surfaces on the front PTO Oil all parts. [2] - When installing the oil pump, coat oil pump-to-oil manifold sealing surfaces with LOCTITE ™ 574 flexible sealant. Number Name Use • L64500 (loctite) Flexible sealant Sealing the surfaces on the front PTO [3] - Tighten cap screws (B) evenly. Item Measurement Specification Oil pump installation, cap screws Torque 10 N˙m 7.5 lb-ft [4] - Install key (A). <- Go to Section TOC Section 56 page 237 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO [5] - Install gear (A) and secure it with snap ring (B). IMPORTANT: Rotate pump to make sure that all parts move easily. [6] - Install metal cover (A). Next step: Before installing the output shaft, see reference“Assembling the Front PTO”. <- Go to Section TOC Section 56 page 238 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO Reconditioning the PTO Clutch Preliminary work: Before removing the output shaft, see reference“Disassembling the Front PTO”. Disassembling the PTO clutch [1] - Position assembly in a vise as shown (PTO stub shaft clamped in the vise). Use specially shaped blocks on the vise to protect the shaft against damage. [2] - Slacken hex. nut (use a spanner with a width of 65 mm), then take the assembly out of the vise and take off the hex. nut. [3] - Pull out PTO stub shaft. [4] - Remove 18 hex. socket screws of gear. [5] IMPORTANT: Make sure that puller jaws are not positioned on the bearing cage. Pull out the bearing, using disks that match exactly. <- Go to Section TOC Section 56 page 239 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO Mechanical puller set D01173AA Pulling off the taper roller bearings [6] - Press the gear and roller bearing off the clutch cage. Use disks that match exactly! [7] - Remove snap ring (A). [8] - Remove hub (B) and disk pack. [9] CAUTION: The spring is tensioned! Remove snap ring (A). [10] →NOTE: Puller is in a slightly inclined position. Remove bearing; to do so, position a puller below the first spring coil. Mechanical puller set <- Go to Section TOC Section 56 page 240 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO D01173AA Pulling off the taper roller bearings Exploded view of PTO clutch LEGEND: A B C D E F G H I J K L <- Go to Section TOC Clutch cage Seal ring Seal ring Back-up ring Piston Disk with teeth on outside Disk with teeth on inside Pressure plate Snap ring Spring Spring support Pressure ring Section 56 page 241 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS M N O P Q R S T U V W X Group 35: Front PTO Roller bearing Snap ring Hub Gear Snap ring Thrust washer Roller bearing Hex. socket screw (18 used) Pressure ring Taper roller bearing PTO stub shaft Hex. nut Assembling the PTO clutch [1] - Press piston out of clutch cage, using compressed air. [2] - Check that the brake thrust pin (C; located in clutch cage) can move freely. [3] - Replace seal rings on shaft (A) and on piston (B). [4] - Re-install the piston. [5] - When installing piston, make sure that piston rings do not get damaged and that the piston is properly positioned. <- Go to Section TOC Section 56 page 242 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO [6] - Place spring, spring support and thrust washer into clutch cage. [7] - Press in bearing, using disks that match exactly! Do not press the bearing in deeper than necessary (it must be possible to install the snap ring). [8] - Install hub (B). [9] →NOTE: Before installing the disks, dip them in oil. Install disk pack; first place a disk with teeth on the outside against the piston, then install disks with teeth on inside and outside alternately. [10] - Install pressure plate last. [11] - Install snap ring (A). [12] - Coat gear contact surface on hub with LOCTITE ™ 574 flexible sealant. Number Name Use • L64500 (loctite) Flexible sealant Sealing the surfaces on the front PTO <- Go to Section TOC Section 56 page 243 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO [13] - Install snap ring in gear. [14] - Place gear on hub. Press in roller bearing and install spacer. Press in taper roller bearing. [15] - Tighten the hex. socket screws. Item Measurement Specification PTO clutch gear, hex. socket screw Torque 23 N˙m 17 lb-ft [16] - Insert PTO stub shaft. [17] - Coat the large hex. nut with LOCTITE ™ 243 thread lock and sealant, and tighten. Number Name Use • L41475 (loctite) Thread lock Cementing screws at the front PTO Item Measurement Specification PTO stub shaft, hex. nut (65 mm across flats) Torque 50 N˙m 36.5 lb-ft Next step: Before installing the output shaft, see reference“Assembling the Front PTO”. <- Go to Section TOC Section 56 page 244 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO Reconditioning the PTO Brake LEGEND: A B C D E F G H I J K <- Go to Section TOC Clutch cage Thrust pin (6 used) Pressure plate Disk with teeth on inside Disk with teeth on outside Spring (6 used) Cover Taper roller bearing Cap screw (4 used) Stop (4 used) Gear with stop Section 56 page 245 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO Preliminary work: Before removing the output shaft, see reference“Disassembling the Front PTO”. [1] CAUTION: The six springs (A) are tensioned! Remove hex. socket screws. [2] - Remove cover (B). [3] - Remove and check disk pack and pressure plate (C). Check thrust pins in clutch cage for free movement. Check taper roller bearing and replace, if necessary. Mechanical puller set D01173AA Pulling off the taper roller bearings [4] - Install pressure plate (A) with the blind holes facing upward (see arrow). <- Go to Section TOC Section 56 page 246 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO [5] →NOTE: Before installing the disks, dip them in oil. Install a disk with teeth on the outside first, then install disks with teeth on the inside and outside alternately. Position disks (B; with teeth on the outside) so that semicircular recesses are aligned with blind holes of the pressure plate (see arrow). [6] - Place springs (A) into blind holes of pressure plate. [7] - Install cover, making sure that springs are properly positioned in blind holes of cover. [8] - Coat hex. socket screws with LOCTITE ™ 243 thread lock and sealant, and tighten them evenly. Item Measurement Specification Lid on clutch cage, cap screw Torque 10 N˙m 7.5 lb-ft <- Go to Section TOC Section 56 page 247 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO [9] - Replace piston rings (A). [10] - Apply some grease to the piston rings and position them in the middle of the shaft. [11] - Make sure that oil bores (B) are not obstructed. [12] →NOTE: The piston rings may also be replaced with the housing closed by removing valve plate (C) from the back of the housing. <- Go to Section TOC Section 56 page 248 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO [13] - Replace ring gear (A). [14] - Install stops (B). [15] - Tighten cap screws (C). Item Measurement Specification Ring gear at PTO brake Torque 10 N˙m 7.5 lb-ft [16] - Make sure that springs are properly positioned. Next step: Before installing the output shaft, see reference“Assembling the Front PTO”. Reconditioning the Intermediate Gear Shaft (PTO Rotating Counterclockwise) LEGEND: A B <- Go to Section TOC Taper roller bearing assembly Intermediate gear shaft Section 56 page 249 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS C D E F F Group 35: Front PTO Taper roller bearing assembly Shim (quantity as required) Spacer bushing Cover Cap screws (4 used) Before removing or installing the intermediate gear shaft, see references“Disassembling the Front PTO”and“Assembling the Front PTO”. Inspect all components, and replace if necessary. <- Go to Section TOC Section 56 page 250 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO Reconditioning the Drive Shaft LEGEND: A B C D E F G H I J K L <- Go to Section TOC Seal ring Taper roller bearing assy. Special sealing ring Snap ring Washer Ball bearing Spacer Snap ring Gear Drive shaft Spring (5 used) Ball (5 used) Section 56 page 251 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS M N O P Q R S T U V W X Group 35: Front PTO Shift collar Special sealing ring Taper roller bearing assy. Key Snap ring Shift pawl Plastic tip (2 used) Shifter shaft O-ring Shift lever Shim (thickness as required) Cover [1] - LEGEND: A B C D E F Taper roller bearing cone Special seal Gear Shift collar Special seal Taper roller bearing cone Pull off tapered roller bearing cone (A) and remove special seal (B). [2] - Pull off tapered roller bearing cone (F) and remove special seal (E). <- Go to Section TOC Section 56 page 252 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO [3] - Remove shift collar (D). →NOTE: Be careful when removing the shift collar; locking balls and springs will be ejected! [4] - Remove snap ring (A). [5] - Remove washer (B). [6] - Press gear (C) down and off the shaft. [7] - Remove ball bearing (A). <- Go to Section TOC Section 56 page 253 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO [8] - Remove the shim(s). [9] - Remove snap ring (A) and ball bearing (B). [10] - Assemble the gear in reverse order. [11] - Install shift collar (D) on the new drive shaft. Make sure the springs and balls are pressed down. [12] - Install gear (C) and ring (B). <- Go to Section TOC Section 56 page 254 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO [13] - Install snap ring (A). [14] - Install special sealing ring (B) as shown in the drawing. IMPORTANT: Make absolutely certain that the sealing ring is installed in the correct position. →NOTE: The drawing shows the direction in which the ring′s sealing lip must face. [15] - Install tapered roller bearing (A). IMPORTANT: Heat the bearing cone in a bearing heater. Use a thermometer and do not exceed 150°C (300°F). <- Go to Section TOC Section 56 page 255 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO [16] - Do not assemble the drive shaft beyond the stage shown. Do not install the special seal and taper roller bearing (on the shift collar side) until the housing cover has been installed. <- Go to Section TOC Section 56 page 256 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO Assembling the Front PTO [1] - Before installing the drive shaft, fill the space (see arrow) between the sealing ring and tapered roller bearing with special grease (L154115). Item Measurement Specification Input shaft and housing cover, taper roller bearings Capacity 20 ml 0.68 fl oz Number Name Use • L154115 (us) Special grease Lubricating the taper roller bearings [2] - Install drive shaft. →NOTE: The special sealing ring becomes displaced when the drive shaft is installed. [3] - Install special sealing ring (A) so that it is properly in contact with the base of the hole. <- Go to Section TOC Section 56 page 257 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO [4] IMPORTANT: Make absolutely certain that the sealing ring is seated in the correct position. Check again that the special sealing ring is properly positioned. [5] IMPORTANT: When installing the output shaft, be careful not to damage the piston rings in the housing. Insert output shaft (A) into housing. [6] - Install metal cover (B). [7] - PTO rotating counterclockwise: Install the intermediate gear shaft (not illustrated). <- Go to Section TOC Section 56 page 258 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO [8] - As shown in the drawing, install special sealing ring (A) in the housing cover. IMPORTANT: Make absolutely certain that the sealing ring is installed in the correct position. →NOTE: The drawing shows the direction in which the ring′s sealing lip must face. <- Go to Section TOC Section 56 page 259 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO [9] - Coat housing sealing surfaces with sealant. Number Name Use • L64500 (loctite) Flexible sealant Sealing the surfaces on the front PTO [10] - Put on the housing cover (without bearing quill). Make sure that pads (A) of shifter fork are properly positioned in relation to the shift collar. [11] - Tighten the hex. socket screws on the housing cover. Item Measurement Specification Housing cover, hex. socket screw Torque 23 N˙m 17 lb-ft [12] - Install tapered roller bearing cone (C) on the drive shaft. Fill the space between special seal ring and taper roller bearing with special grease (L154115). Item Measurement Specification Bearing quill and housing cover, taper roller bearings Capacity 40 ml 1.4 fl oz Number Name Use • L154115 (us) Special grease Lubricating the taper roller bearings [13] - Make sure that the special seal does not get damaged! <- Go to Section TOC Section 56 page 260 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO [14] - Install taper roller bearing cups (A) and (B). [15] - Install seal ring (A). Adjusting the taper roller bearing at the output shaft <- Go to Section TOC Section 56 page 261 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO [1] - Install bearing quill (A) without shims to obtain a measurable axial play. Tighten the hex. socket screws evenly. Item Measurement Specification Bearing quill to housing cover, hex. socket screw Torque 10 N˙m 7.5 lb-ft [2] - Measure end play. [3] - Remove bearing quill. [4] - Place shims under bearing quill until a bearing preload is obtained. Item Measurement Specification Output shaft, taper roller bearings Preload 0.01 to 0.04 mm 0.0004 to 0.0016 in. [5] - Apply sealant to bearing quill and re-install it. Tighten the hex. socket screws. Number Name Use • L64500 (loctite) Flexible sealant Sealing the surfaces on the front PTO Item Measurement Specification Bearing quill to housing cover, hex. socket screw Torque 10 N˙m 7.5 lb-ft <- Go to Section TOC Section 56 page 262 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO Adjusting end play of drive shaft [1] - Install bearing quill (A). Tighten the hex. socket screws evenly. Item Measurement Specification Bearing quill to housing cover, hex. socket screws Torque 10 N˙m 7.5 lb-ft [2] - Measure end play. <- Go to Section TOC Section 56 page 263 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 35: Front PTO [3] - Remove bearing quill. [4] - Keep adding shims until the prescribed end play is reached. Item Measurement Specification Drive shaft, end play End play 0.05 to 0.1 mm 0.002 to 0.004 in. [5] - Fill the space between bearing and bearing quill with special grease (L154115). Number Name Use • L154115 (us) Special grease Lubricating the taper roller bearings [6] - Apply LOCTITE ™ 574 (L64500) flexible sealant to the sealing surface of the bearing quill. Install the bearing quill. Number Name Use • L64500 (loctite) Flexible sealant Sealing the surfaces on the front PTO [7] - Tighten the hex. socket screws. Item Measurement Specification Bearing quill to housing cover, hex. socket screws Torque 10 N˙m 7.5 lb-ft Adjusting the taper roller bearing of the intermediate gear shaft (not illustrated) [1] - At four locations separated from one another by 90°, use a suitable depth gauge to measure the distance from the bearing quill contact surface to the installed bearing. [2] - Place shimsunder the spacer until a bearing preload is obtained. Item Measurement Specification Intermediate gear shaft, taper roller bearings Preload 0 to 0.03 mm 0 to 0.0012 in. [3] - Apply sealant to bearing quill and re-install it. Tighten cap screws. Number Name Use • L64500 (loctite) Flexible sealant Sealing the surfaces on the front PTO Item Measurement Specification Bearing quill to housing cover, hex. socket screw Torque 10 N˙m 7.5 lb-ft Final assembly <- Go to Section TOC Section 56 page 264 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 40: Front Implement Drive [1] - Apply Molykote Long Term (L156817) to the splines on the drive shaft (see arrow). [2] - Before installing the front PTO, see reference“Installing the Front PTO”, Section 56, Group 00. [3] - Fill with fresh oil. [4] - Install PTO guard. <- Go to Section TOC Section 56 page 265 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 40: Front Implement Drive Group 40 - Front Implement Drive Front Implement Drive (Summary of References) ”General information” ”Special tools” ”Specifications” ”Summary of torques” ”Preliminary work” ”Removing and installing the drive shaft” General Information CAUTION: If a drive shaft is installed, the tractor may be operated only if a front implement is actually attached. Under no circumstances operate the tractor with a drive shaft in place but no front implement attached! IMPORTANT: If no front implement is to be fitted to the tractor, remove the drive shaft. Special Tools →NOTE: Order tools according to information given in the U.S. SERVICEGARD ™ Catalog or in the European Microfiche Tool Catalog (MTC). Flywheel turning tool JDG820 Turning flywheel on 6-cylinder engines <- Go to Section TOC Section 56 page 266 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 40: Front Implement Drive Repair Specifications Item Measurement Specification Damper to drive shaft, hex. socket screws Torque 34±3 N˙m 25±2 lb-ft Coupler to drive shaft, cap screws Torque 34±3 N˙m 25±2 lb-ft Coupler and shaft to torsion damper, cap screws Torque 46±3 N˙m 34±2 lb-ft Summary of Torques Drive shaft (6-cylinder tractors with Stage II engine to 97/68 EC) LEGEND: 1 M8 screw; 8 used/34±3 N˙m (25±2 lb-ft) 2 M8 screw; 8 used/34±3 N˙m (25±2 lb-ft) 3 M10 screw; 4 used/46±3 N˙m (34±2 lb-ft) <- Go to Section TOC Section 56 page 267 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 40: Front Implement Drive Preliminary Work Open the hood Pull the catch (see arrow) and lift the hood up. Removing the battery Disconnect battery terminals and remove the battery. CAUTION: Disconnect the negative terminal first. Always reconnect the positive terminal first. Always pay attention to the positive/negative markings on the battery. Take off the front plate or basic weight (if equipped) <- Go to Section TOC Section 56 page 268 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 40: Front Implement Drive Take off front plate (A) or basic weight. <- Go to Section TOC Section 56 page 269 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 40: Front Implement Drive Installing and Removing Drive Shaft What follows is a description telling you how to install the drive shaft. It is removed in reverse order. 6-cylinder tractors Secure damper (A) to the drive shaft. Tighten the hex. socket screws. Item Measurement Specification Damper to drive shaft, hex. socket screws Torque 34±3 N˙m 25±2 lb-ft <- Go to Section TOC Section 56 page 270 TM4756-REPAIR MANUAL Section 56 - DRIVE SYSTEMS Group 40: Front Implement Drive Install the shaft from the front. On tractors with suspended front-wheel drive axles, the radiator must be raised slightly to allow the drive shaft to be installed. Do this by slackening off the screws (A) that hold on the battery plate (to which the radiator is secured). 6-cylinder tractors (with Stage II engine to 97/68 EC) LEGEND: <- Go to Section TOC Section 56 page 271 TM4756-REPAIR MANUAL STEERING AND BRAKES A B C D E F (g) by Belgreen Coupler Drive shaft M8 cap screw M10 cap screw Torsion damper Washer Secure coupler (A) to the drive shaft (B). Tighten the eight cap screws (C) in cross-wise fashion. Item Measurement Specification Coupler to drive shaft, cap screws Torque 34±3 N˙m 25±2 lb-ft Secure the coupler and shaft to torsion damper (E). Tighten cap screws (D). Item Measurement Specification Coupler and shaft to torsion damper, cap screws Torque 46±3 N˙m 34±2 lb-ft →NOTE: On 6-cylinder tractors with engines up to serial no. 352949, replace the old torsion damper RE59827 with new torsion damper RE509264. <- Go to Section TOC Section 56 page 272 TM4756-REPAIR MANUAL TM4756-REPAIR MANUAL (g) by Belgreen Section 60 - STEERING AND BRAKES Table of contents Group 05 - Hydrostatic Steering ............................................................................................. 1 Hydrostatic Steering (Summary of References) ..................................................................... 1 Special Tools .......................................................................................................................... 2 Repair Specifications .............................................................................................................. 4 Preliminary Work .................................................................................................................... 4 Disconnect/Connect Steering or Brake Hoses ........................................................................ 5 Remove Steering Column and Steering Valve ........................................................................ 7 Disassembling the Steering Valve ........................................................................................ 14 Exploded View of Steering Valve .......................................................................................... 18 Assembling the Steering Valve ............................................................................................ 20 Adjusting the Shock Valves .................................................................................................. 31 Steering Wheel and Steering Column (With Cab) ................................................................. 32 Recondition the Steering Column ......................................................................................... 33 Install Steering Column and Steering Valve ......................................................................... 35 Group 10 - Brake Valve ........................................................................................................... 42 Steering and Brakes - Brake Valve, Summary of References ............................................... 42 Brake Valve - Special Tools .................................................................................................. 42 Brake Valve - Repair Specifications ...................................................................................... 43 Accumulators - Remove and Install from Tractor Serial Number 440694 ............................ 45 Recondition Guide Piece and Piston ..................................................................................... 47 Brake Valve - Exploded View ................................................................................................ 51 Remove Brake Valve (Power Fill Brakes) .............................................................................. 57 Recondition Brake Valve (Power Fill Brakes) ........................................................................ 59 Install Brake Valve (Power Fill Brakes) ................................................................................. 75 Power-Fill Brake Valve with MFWD and Disk Brake (up to Tractor Serial Number 444807) ....................................................................................................................................... 77 Remove Power-Fill Brake Valve with MFWD and Disk Brake .............................................. 102 Recondition Power-Fill Brake Valve with MFWD and Disk Brake ........................................ 106 Install Power-Fill Brake Valve with MFWD and Disk Brake .................................................. 125 Tests and Adjustments - Adjust the Brake Pedals and Switches ........................................ 128 Group 15 - Rear Wheel Brakes ............................................................................................ 132 Summary of References (Rear Brakes) .............................................................................. 132 Rear Brakes, Specifications ................................................................................................ 132 Preliminary Work ................................................................................................................ 132 Remove the Rear Brakes .................................................................................................... 132 Rear Brakes—Exploded View ............................................................................................. 133 Recondition the Rear Wheel Brakes ................................................................................... 135 Install the Rear Brakes ....................................................................................................... 137 Final Assembly ................................................................................................................... 138 Bleeding the Brakes (Brake Valve, Power-Fill Brakes and MFWD and Disk Brake) ............. 139 Group 20 - Handbrake ........................................................................................................... 143 Summary of References (Handbrake) ................................................................................ 143 Handbrake - Specifications ................................................................................................ 143 Preliminary work ................................................................................................................ 143 Remove Handbrake ............................................................................................................ 144 Exploded view of handbrake - Tractor 6820 ....................................................................... 147 <- Go to Global Table of contents TM4756-REPAIR MANUAL TM4756-REPAIR MANUAL (g) by Belgreen Exploded view of handbrake - Tractors 6920 and 6920S ................................................... 147 Installing the handbrake .................................................................................................... 150 Handbrake - Adjust the Brake Band ................................................................................... 153 Final assembly ................................................................................................................... 154 Handbrake components ..................................................................................................... 154 Handbrake - Replace Handbrake Cable .............................................................................. 156 Adjusting the Handbrake .................................................................................................... 158 Group 25 - Hydraulic Trailer Brake ..................................................................................... 159 Hydraulic Trailer Brake (Summary of References) ............................................................. 159 Special Tools ...................................................................................................................... 159 Specifications ..................................................................................................................... 159 Repair Instructions ............................................................................................................. 159 Hydraulic Trailer Brake Valve up to Serial No. 466428 ...................................................... 161 Hydraulic Trailer Brake Valve from Serial No. 466429 ....................................................... 167 Bleed Air from the Trailer Brake Valve ............................................................................... 169 Check Hydraulic Trailer Brake Valve .................................................................................. 170 Group 30 - Air Brakes up to Serial No. 398655 ................................................................. 172 Air Brakes up to Serial No. 398655 (Summary of References) ........................................... 172 Special tools ....................................................................................................................... 172 Repair specifications .......................................................................................................... 174 Safety instructions ............................................................................................................. 174 Screw Union Installation ..................................................................................................... 176 Change the Compressor ..................................................................................................... 177 Gaskets for the Compressor ............................................................................................... 178 Changing the compressed air tank .................................................................................... 181 Changing the preload valve ............................................................................................... 182 Changing the Pressure-Relief Valve ................................................................................... 183 Changing the pressure-regulating valve ............................................................................ 183 Changing the trailer control valve (dual-line + single-line brake) ...................................... 184 Changing the trailer control valve (single-line brake) ........................................................ 186 Changing the Coupling Ends .............................................................................................. 188 Changing the Pressure Gauge ............................................................................................ 189 Test Sequence ................................................................................................................... 191 Checking the system for leaks ........................................................................................... 192 Check the Supply Coupling End ......................................................................................... 192 Check the Dual-Line Brakes ............................................................................................... 194 Checking the Single-Line Brakes ........................................................................................ 196 Adjusting the air brake system handbrake ........................................................................ 196 Group 31 - Air Brakes from Serial No. 398656 .................................................................. 198 Air Brakes from Serial No. 398656 (Summary of References) ............................................ 198 Special Tools ...................................................................................................................... 198 Repair Specifications .......................................................................................................... 199 Safety Instructions ............................................................................................................. 199 Screw Union Installation ..................................................................................................... 201 Change the Compressor ..................................................................................................... 202 Gaskets for the Compressor ............................................................................................... 203 Change Compressed Air Tank ............................................................................................ 206 Changing the Pressure-Regulating Valve ........................................................................... 207 Changing the Precharge Valve ........................................................................................... 208 Changing the Trailer Control Valve (Dual-Line Brake) ........................................................ 209 <- Go to Global Table of contents TM4756-REPAIR MANUAL TM4756-REPAIR MANUAL (g) by Belgreen Changing the Trailer Control Valve (Single-Line Brake) ..................................................... 210 Change the Coupling Ends ................................................................................................. 212 Change the Pressure Gauge ............................................................................................... 213 Test Sequence ................................................................................................................... 214 Check the System for Leaks ............................................................................................... 215 Check the Supply Coupling End ......................................................................................... 215 Check Dual-Line Brake ....................................................................................................... 217 Checking the Single-Line Brakes ........................................................................................ 219 Adjusting the Handbrake (with Air Brake System) ............................................................. 219 Group 40 - AutoTrac .............................................................................................................. 221 Steering and Brakes - AutoTrac, Summary of References .................................................. 221 Specifications ..................................................................................................................... 221 Remove and Install Steering Control Valve (Y49) ............................................................... 222 Remove and Install Steering Wheel Position Sensor (B138) ............................................... 224 <- Go to Global Table of contents TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Group 05 - Hydrostatic Steering Hydrostatic Steering (Summary of References) “Special tools” “Repair specifications” “Preliminary work” “Disconnecting/connecting steering or brake hoses” “Removing steering column and steering valve” “Disassembling the steering valve” “Assembling the steering valve” “Adjusting the shock valves ” “Steering wheel and steering column (with cab)” “Repairing the steering column” “Installing steering column and steering valve” <- Go to Section TOC Section 60 page 1 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Special Tools →NOTE: Order tools according to information given in the U.S. SERVICEGARD ™ Catalog or in the European Microfiche Tool Catalog (MTC). Disconnecting tool KJD10293 Disconnecting/connecting steering or brake hoses Assembly tool set KML10018A LEGEND: A B C D E F G <- Go to Section TOC Base (KML10018-1) Spring installer (KML10018-3) Shaft holder (KML10018-4) Seal installer (KML10018-2) Piston (KML10018-5) Seal installer (KML10018-6) Piston (KML10018-7) Section 60 page 2 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Repair of steering units Special tools required for repair Steering valve type [ see type plate on steering valve ] A B C D E X X OSPF 160 LS (Danfoss) X X OSPQ 125/200 LS (Danfoss) X X F G X X Hydraulic hand-operated pump D01019AA Adjusting the shock valves Adapter JT03248 Adjusting the shock valves <- Go to Section TOC Section 60 page 3 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Repair Specifications Item Measurement Specification Steering wheel to spindle, cap screw (up to tractor serial no. 359011) Torque 50 N˙m (35 lb-ft) Steering wheel to spindle, cap screw (from tractor serial no. 359012) Torque 30 N˙m (22 lb-ft) Adjusting ring on spindle, self-locking hex. nut Torque 20 N˙m (15 lb-ft) Shock valves Adjustment pressure 23500 to 25500 kPa (235 to 255 bar; 3400 to 3700 psi) Cover to housing, cap screws Torque 30 N˙m (23 lb-ft) Threaded plugs of shock valves Torque 30 N˙m (23 lb-ft) Threaded plug on control valve (OSPQ 125/200 LS) Torque 50 N˙m (35 lb-ft) Connectors (straight) to steering valve (connections for pressure lines) Torque 55 N˙m (40 lb-ft) Connector (elbow) to steering valve (connection for LS-line) Torque 35 N˙m (25 lb-ft) Steering wheel and column Steering valve Preliminary Work Disconnect battery ground strap (—). <- Go to Section TOC Section 60 page 4 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Disconnect/Connect Steering or Brake Hoses →NOTE: Some of the following illustrations show the hydraulic hoses when removed. →NOTE: Trap oil as it emerges in a suitable container. Seal the openings so that no dust can penetrate. Place KJD10293 disconnecting tool Disconnecting tool KJD10293 Disconnecting/connecting steering or brake hoses (A) on hydraulic hose. <- Go to Section TOC Section 60 page 5 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Press tool down (in the direction indicated by the arrow) until the red ring (B) is visible and then disconnect coupler. Connect steering or brake hoses Without using a tool, push hydraulic hose into coupler until it engages. Move hydraulic hose several times in the directions indicated by the arrows to ensure it is connected properly. <- Go to Section TOC Section 60 page 6 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Remove Steering Column and Steering Valve Steering valve (without steering column) Remove cap screws (A) and (B). Remove trim panel (C). Also remove second trim panel on the opposite side. Remove screws (A) on both sides of trim. Take out screw (C). →NOTE: By removing the screws it is possible to lift trim (B) slightly. This makes the removal of steering valve attaching screws easier. <- Go to Section TOC Section 60 page 7 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Remove trim (A). Disconnect hydraulic lines at steering valve (B). Remove screws (A) and steering valve. Steering column and steering valve Remove screws (A) and (B). Remove trim panel (C). Also remove second trim panel on the opposite side. <- Go to Section TOC Section 60 page 8 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Remove screws (A) on both sides of trim. Take out screw (C). →NOTE: By removing the screws it is possible to lift trim (B) slightly. This makes it easier to unplug the multi-function unit connectors. Remove cover (A). Remove self-locking hex. nut (A). <- Go to Section TOC Section 60 page 9 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Remove adjusting ring (B) and washer. Remove hex. nut (A) and pull off the steering wheel. Remove snap ring (A). Remove washer (B). Pull off knob (A). Take out screws (B) and remove cover (C). <- Go to Section TOC Section 60 page 10 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Take out screws (A) and lift up instrument unit (B). Disconnect connectors and remove instrument unit. Remove screws (A) and lift panel (B). Disconnect all connectors at bracket. Remove screws (A). <- Go to Section TOC Section 60 page 11 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Disconnect all multi-function unit (A) connectors from below. Remove multi-function unit. Remove housing (A) and pull off handle (B). Remove cover (A). <- Go to Section TOC Section 60 page 12 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Remove screws (A). Remove steering column (B). Remove trim (A). Disconnect hydraulic lines at steering valve (B). Remove screws (A) and steering valve. <- Go to Section TOC Section 60 page 13 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Disassembling the Steering Valve →NOTE: The type plate shows the steering valve type (e.g. OSPQ 125/200 LS). Place steering valve on assembly plate KML10018-1 (B). Remove cover (A). LEGEND: A B C D Stator Rotor Rotor shaft Distributor plate Take off rotor (B) and stator (A). Take off rotor shaft (C) and distributor plate (D). <- Go to Section TOC Section 60 page 14 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Remove check valve (A) and suction valves (B). →NOTE: Shock valves are set to a specific pressure. Readjustment is necessary after removal. Remove plug (A). Remove the shock valves. <- Go to Section TOC Section 60 page 15 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering On steering valve OSPQ 125/200 LS only: Remove the control valve Take out threaded plug (A). Remove spring (B) and piston (A) from the control valve. Place cross pin parallel to flattened face of steering valve by turning both spool and sleeve. Remove spool and sleeve by applying slight pressure to valve spool and simultaneously turning valve sleeve. <- Go to Section TOC Section 60 page 16 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES LEGEND: A B C D E F Group 05: Hydrostatic Steering Thrust bearing assy. Retaining ring Leaf springs Valve sleeve Valve spool Cross-pin Remove thrust bearing (A) and retaining ring (B). Remove cross-pin (F). Push valve spool (E) out of valve sleeve (D). Remove leaf springs (C). Remove seal ring (A) from housing. Remove back-up ring and O-ring. <- Go to Section TOC Section 60 page 17 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Exploded View of Steering Valve LEGEND: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 <- Go to Section TOC Shock valve (2 used) Threaded plug (2 used) Seal ring (2 used) Adjusting screw (2 used) Spring (2 used) Spring guide (2 used) Ball (2 used) Suction valve assembly (2 used) Seal ring assembly Thrust washer Thrust bearing Thrust washer Retaining ring Valve spool Section 60 page 18 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES 15 16 Group 05: Hydrostatic Steering 17 Cross-pin Valve sleeve Control valve assembly 18 Threaded plug with O-ring 19 Spring 20 Control piston assembly 21 Control piston 22 Pin 23 Spring 24 Ball 25 Plug 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 Seal ring Housing Ball Threaded bushing Leaf springs Rotor shaft O-ring Distributor plate Rotor O-ring Stator Cover Seal washers (7 used) Cap screw (6 used) Cap screw with spring pin Type plate Impact screws <- Go to Section TOC [ Steering valve OSPQ 125/200 LS only ] [ Steering valve OSPQ 125/200 LS only ] [ Steering valve OSPQ 125/200 LS only ] [ Steering valve OSPQ 125/200 LS only ] [ Steering valve OSPQ 125/200 LS only ] [ Steering valve OSPQ 125/200 LS only ] [ Steering valve OSPQ 125/200 LS only ] [ Steering valve OSPQ 125/200 LS only ] [ Steering valve OSPQ 125/200 LS only ] Section 60 page 19 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Assembling the Steering Valve Using a hammer and suitable round steel bar, lightly drive new seal ring (A) into housing groove. Coat the seal ring assembly, which consists of O-ring (A) and back-up ring (B), with grease and install it on small piston KML10018-5 [ OSPF 200 steering valves ] (C) or KML10018-7 [ OSPQ 125/200 LS ] . On steering valve OSPQ 125/200 LS, the broad end of the back-up ring must face away from the tool. <- Go to Section TOC Section 60 page 20 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Install the seal ring: [1] - Press sleeve (B) of special tool KML10018-2 [ OSPF 200 steering valves ] (A) or KML10018-6 [ OSPQ 125/200 LS ] up to stop into steering valve housing. [2] - Then slide large piston into sleeve until it bottoms. [3] - Pull sleeve out of steering valve together with large piston. →NOTE: Small piston remains in steering unit until it is pushed out when spool and sleeve are installed. <- Go to Section TOC Section 60 page 21 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Here the seal rings of the different types of steering valve are shown in their installed positions. Steering valve type Seal ring OSPF steering valves .......... A OSPQ 125/200 LS .......... B <- Go to Section TOC Section 60 page 22 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Place the two straight leaf springs in the slot in the spool. Slide the curved leaf springs between the straight leaf springs. Assemble valve spool and sleeve. IMPORTANT: The slots in the spool must face the holes in the sleeve (see arrows). <- Go to Section TOC Section 60 page 23 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Align and center the leaf springs. Install retaining ring (A). IMPORTANT: The retaining ring must be able to turn freely without interference from the leaf springs. Insert cross-pin (A) in valve assembly. <- Go to Section TOC Section 60 page 24 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Install thrust washer (C), thrust bearing (B) and thrust washer (A). IMPORTANT: Chamfered side of thrust washer (C) must face towards top surface of valve spool. Coat valve spool assembly with oil and then install. IMPORTANT: Make sure that cross-pin of valve spool and sleeve is horizontal. →NOTE: Insert valve spool and sleeve into housing bore, applying slight turning movements. <- Go to Section TOC Section 60 page 25 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Installing check valve: [1] - Place ball of check valve into the bore provided. [2] - Screw in threaded bushing (A) until it is just below the surface of the housing. Install both suction valves (spring pin assemblies with balls) in bores as shown. Install distributor plate and rotor shaft: [1] - Place O-ring in groove of housing. <- Go to Section TOC Section 60 page 26 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering [2] - Install distributor plate (A) so that the bores are aligned with the corresponding bores in the housing. [3] - Insert drive shaft (B) and hold with tool KML10018-4 (C). LEGEND: A B C D Stator Rotor Cross-pin Rotor shaft Coat O-rings of stator (A) with grease. Position rotor (B) and stator as shown. CAUTION: Avoid accidents! Cross-pin must be in position shown. IMPORTANT: Rotor (B) and cross-pin (C) must be positioned as shown to ensure reliable functioning of steering system. <- Go to Section TOC Section 60 page 27 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Install cover. Tighten the cap screws crosswise to 30 N˙m (23 lb-ft). →NOTE: Screw cap screw with spring pin into bore with threaded bushing. Steering valve OSPQ 125/200 LS only Install piston (A) and spring (B) in the control valve. <- Go to Section TOC Section 60 page 28 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Tighten threaded plug (A) to 50 N˙m (35 lb-ft). Install shock valves: [1] - Place shock valve balls in their bores. [2] - Coat spring guides (B) with grease and install them on springs (A). [3] - Insert springs (A) together with spring guides (B) into the relevant bores. [4] - Coat adjusting screws (C) with LOCTITE 243 (L41475) and screw them in until pressure is applied to the springs. Adjust the shock valves. <- Go to Section TOC Section 60 page 29 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Tighten threaded plug (A) to 30 N˙m (23 lb-ft). <- Go to Section TOC Section 60 page 30 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Adjusting the Shock Valves LEGEND: A B C D E F G H D01019AA hand-pump with gauge and hydraulic hose Hydraulic hose Adapter L38860 Coupler JT03248 Fitting Valve spool Shock valve (right-hand lock) Shock valve (left-hand lock) →NOTE: Shock valves must be readjusted if they have been removed. Connecting the manually-operated hand-pump Attach coupler JT03248 (D) and adapter L38860 (C) to hydraulic hose of hand pump D01019AA. Install a L41383 O-ring on the L41898 fitting (E) and on the “R” or “L” connection of the steering valve. Secure hydraulic hose AL41621 (B) to the fitting and to the L38860 adapter (C). Checking and adjusting the shock valves Operate the hand pump to obtain a pressure of 23500 to 25500 kPa (235 to 255 bar; 3400 to 3700 psi). Valve is set correctly if pressure then drops sharply. If necessary, adjust the shock valves as follows: [1] - Remove threaded plugs from shock valves (G) and (H) and coat the adjusting screws underneath with LOCTITE 243 (L41475). <- Go to Section TOC Section 60 page 31 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering [2] - Screw adjusting screws in or out until a pressure of 23500 to 25500 kPa (235 to 255 bar; 3400 to 3700 psi) is obtained. →NOTE: Turning adjusting screws clockwise increases pressure. Turning adjusting screws counterclockwise reduces pressure. [3] - Tighten threaded plugs to 30 N˙m (23 lb-ft). Steering Wheel and Steering Column (With Cab) LEGEND: A B C <- Go to Section TOC Cover O-ring Self-locking hex. nut Section 60 page 32 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES D E F G H I J K L M N Group 05: Hydrostatic Steering Washer Adjusting ring Hex. nut Retaining plate Steering wheel Snap ring Washer Steering column assembly Top collar Collar insulator Bottom collar Recondition the Steering Column LEGEND: A B C D E F <- Go to Section TOC Cap Pin Lever Spring Pin Gas compression cylinder Section 60 page 33 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES G H I J K L M <- Go to Section TOC Group 05: Hydrostatic Steering Bushing Hex. socket screws Snap-ring Washer Steering column Pin Shaft (replace as complete assembly) Section 60 page 34 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Install Steering Column and Steering Valve Installing steering valve (w/o steering column) Secure steering valve (B) with screws (A). Secure hydraulic lines to the steering valve. Attach trim panel (A). Install screws (A) on both sides of trim panel. <- Go to Section TOC Section 60 page 35 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Install screw (B). Install cover (C) using screws (A) and (B). Install second cover and connect battery ground strap (—). Steering column and steering valve Secure steering valve (B) with screws (A). Secure the hydraulic lines to the steering valve. <- Go to Section TOC Section 60 page 36 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Secure steering column (B) by means of screws (A). Attach trim panel (A). Install cover (A) and handle (B). →NOTE: Install panel attaching screws only after installation of multi-function unit. <- Go to Section TOC Section 60 page 37 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Install multi-function unit (A) and connect plugs. Install screws (A). Connect all the plugs to the console (B). Put the console and the screws in place at the same time. Attach console by means of screws (A). Connect plugs to instrument unit (B). Secure instrument unit using screws (A). <- Go to Section TOC Section 60 page 38 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Install cover (C) and attach by means of screws (B). Install knob (A). Install screws (A) on both sides of trim panel. Install screw (B). Install washer (B) and snap ring (A). <- Go to Section TOC Section 60 page 39 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 05: Hydrostatic Steering Put on the steering wheel. Install the retaining plate and hex. nut (A). Tighten hex. nut (A) to specified torque. Item Measurement Specification Steering wheel to spindle, hex. nut (up to tractor serial no. 359011) Torque 50 N˙m (35 lb-ft) Steering wheel to spindle, hex. nut (from tractor serial no. 359012) Torque 30 N˙m (22 lb-ft) Fold retaining plate. Install washer and adjusting ring (B). Install self-locking hex. nut (A) and tighten to 20 N˙m (15 lb-ft). <- Go to Section TOC Section 60 page 40 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Install cover (A). Install cover (C) using screws (A) and (B). Install second cover and connect battery ground strap (—). <- Go to Section TOC Section 60 page 41 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Group 10 - Brake Valve Steering and Brakes - Brake Valve, Summary of References Brake Valve - Special Tools Brake Valve - Repair Specifications Accumulators - Remove and Install from Tractor Serial Number 440694 Recondition Guide Piece and Piston Brake Valve - Exploded View Remove Brake Valve (Power Fill Brakes) Recondition Brake Valve (Power Fill Brakes) Install Brake Valve (Power Fill Brakes) Power-Fill Brake Valve with MFWD and Disk Brake (up to Tractor Serial Number 444807) Remove Power-Fill Brake Valve with MFWD and Disk Brake Recondition Power-Fill Brake Valve with MFWD and Disk Brake Install Power-Fill Brake Valve with MFWD and Disk Brake Tests and Adjustments - Adjust the Brake Pedals and Switches Brake Valve - Special Tools →NOTE: Order tools according to information given in the U.S. SERVICEGARD ™ Catalog or European Microfiche Tool Catalog (MTC). DFLX41- Socket Wrench Insert <- Go to Section TOC Section 60 page 42 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Brake Valve - Repair Specifications Item Measurement Specification Brake Valve Attachment, Hex. Socket Screws Torque 100 N˙m 75 lb.-ft. Adjusting the Brake Pedals Pedal Play 0.15 - 0.20 mm 0.006 - 0.008 in. Point at which Brake Switch Trips Pedal Travel 6 mm 0.24 in. Point at which Brake Switch Trips (with AutoPowr/IVT) Voltage 0.9 - 1.1 volts Brake Switch to Bracket Torque 5 - 7 N˙m 4 - 5 lb.-ft. Valve (Tractors with MFWD and Disk Brake) Torque 10 N˙m 7.4 lb.-ft. Brake Valve, Attaching Screws Torque 100 N·m 75 lb.-ft. Brake Switch to Bracket Torque 12 N·m 9 lb.-ft. Restrictor (Filter Element) Torque 5 N·m 4 lb.-ft. Valve (Tractors with MFWD and Disk Brake) Torque 10 N·m 7.4 lb.-ft. Without Suspended Cab: M20x45 Screw on Final Drive Housing Torque 200 N·m 148 lb.-ft. Guide Piece to Brake Valve Torque 100 N·m 75 lb.-ft. Plug to Brake Valve Torque 100 N·m 75 lb.-ft. Valve to Brake Valve, Plug Torque 15 N·m 11 lb.-ft. Inlet Check Valve to Brake Valve Torque 10 N·m 7.5 lb.-ft. Fitting to Brake Valve Torque 45 N·m 33 lb.-ft. Plug to Brake Valve Torque 45 N·m 33 lb.-ft. Cover to Brake Valve, Screws Torque 12 N·m 9 lb.-ft. Outlet Valve to Brake Valve Torque 45 N·m 33 lb.-ft. <- Go to Section TOC Section 60 page 43 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Item Measurement Specification Filter in Brake Valve Torque 5 N·m 4 lb.-ft. <- Go to Section TOC Section 60 page 44 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Accumulators - Remove and Install from Tractor Serial Number 440694 IMPORTANT: From tractor serial number 440694, tractors are equipped with an accumulator; pressure has to be relieved at this accumulator before the system can be serviced or repaired. Removal: Pressure is relieved as follows: 1. Shut off the tractor/ignition switched off. 2. At the rear of the tractor, put a transparent hose over each of the bleed valves; see reference ”Bleeding the Brake Valve (Power-Fill Brake Valve with MFWD and Disk Brake)” . 3. Unlock the brake pedals. 4. Pump the left and right brake pedals up and down until pedal travel becomes very long and no pressure can be felt on the pedal. 5. Slowly unscrew the fitting on the accumulator. <- Go to Section TOC Section 60 page 45 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve →NOTE: Before unscrewing the fittings, put down a suitable container to trap the oil. Installation: After installation, check the level of the transmission oil, and add more oil if necessary (see relevant Operator′s Manual). Air must then be bled from the brake system; see reference ”Bleeding the Brake Valve (Power-Fill Brake Valve with MFWD and Disk Brake)” . If the bracket was removed from the final drive housing, the following specification applies when it is re-installed. Item Measurement Specification Without suspended cab: M20x45 cap screw on final drive housing Torque 185 - 215 N˙m 135 - 160 4 lb-ft →NOTE: On tractors with suspended cab, the usual torque value applies; see the torque table in ”Torques for Metric Screws” . <- Go to Section TOC Section 60 page 46 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Recondition Guide Piece and Piston Preliminary work: Remove the guide piece and piston SeeRemove Brake Valve (Power Fill Brakes)in Section 60. or SeeRemove Power-Fill Brake Valve with MFWD and Disk Brakein Section 60. Assembly [1] - LEGEND: A B O-ring Snap ring Install O-ring (A) and snap ring (B) on the piston. <- Go to Section TOC Section 60 page 47 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [2] - LEGEND: A B Seal ring Seal ring Install seal rings (A) and (B). [3] - LEGEND: A O-ring Install O-ring (A) on annular piston. <- Go to Section TOC Section 60 page 48 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [4] - LEGEND: A Seal ring Install seal ring (A). [5] - LEGEND: A Snap ring Install the annular piston on the piston. [6] - Install snap ring (A). <- Go to Section TOC Section 60 page 49 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [7] - LEGEND: A B Wiper seal O-ring Install O-ring (B) and wiper seal (A) on the guide piece. [8] - LEGEND: A B Spring Guide Install guide piece (B) on the piston. [9] - Install spring (A). Next step: Install the guide piece and piston SeeInstall Brake Valve (Power Fill Brakes)in Section 60. or SeeInstall Power-Fill Brake Valve with MFWD and Disk Brakein Section 60. <- Go to Section TOC Section 60 page 50 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Brake Valve - Exploded View Exploded view of power fill brake valve Exploded view of power fill brake valve LEGEND: 1 2 3 4 5 6 <- Go to Section TOC Cover Intermediate Cover Gasket Stop Screw Restrictor O-Ring Section 60 page 51 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 Group 10: Brake Valve Valve O-Ring O-Ring Valve O-Ring Plug LS Check Valve Assembly Piston Snap Ring Seal Ring and O-Ring Annular Piston Seal Ring and O-Ring Seal Ring Spring Cover O-Ring O-Ring Valve Assembly Spring Spool Spring O-Ring Plug Wiper Seal O-Ring Guide Piece O-Ring Inlet Check Valve Assembly O-Ring Valve Assembly O-Ring Fitting O-Ring Fitting Orifice Spring O-Ring Fitting Outlet Valve Assembly Exploded view - Power-fill brake valve with MFWD and disk brake (up to tractor serial number 444807) <- Go to Section TOC Section 60 page 52 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES LEGEND: 1 4 5 6 7 8 9 10 11 12 13 <- Go to Section TOC Group 10: Brake Valve Cap Screw (8 used) Cover Intermediate Cover Gasket Plug O-Ring Valve O-Ring O-Ring LS Check Valve Assembly Plugs (2 used) Section 60 page 53 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 <- Go to Section TOC Group 10: Brake Valve O-Ring (2 used) Spring (2 used) Spool (2 used) Expansion Plug Spring (2 used) Valve Assembly (2 used) O-Ring (2 used) O-Ring (2 used) Cover (2 used) Plug O-Ring Spool O-Ring O-Ring Expansion Plug (4 used) Expansion Plug (2 used) Orifice (2 used) Spring (2 used) O-Ring (2 used) Fitting (2 used) Outlet Valve Assembly (2 used) O-Ring Fitting O-Ring Valve Assembly O-Ring Fitting Inlet Check Valve Assembly Wiper Seal (2 used) O-Ring (2 used) Guide Piece (2 used) O-Ring (2 used) Piston (2 used) Snap Ring (4 used) Seal Ring and O-Ring (2 used) Annular Piston (2 used) Seal Ring and O-Ring (2 used) Seal Ring (2 used) Spring Cap Screw (2 used) Hex. Nut (2 used) Threaded Pin with Filter Insert Valve (2 used) O-Ring Fitting O-Ring Spring [ Valve Spool Parts must not be interchanged ] [ Seal Ring Parts must not be interchanged ] Section 60 page 54 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Exploded view - Power-fill brake valve with MFWD and disk brake (from tractor serial number 444808) Exploded view of power-fill brake valve with MFWD and disk brake LEGEND: 1 2 3 4 5 6 7 8 9 <- Go to Section TOC Brake Valve Assembly Cover Assembly Intermediate Cover Gasket O-Ring O-Ring Spring Valve Back-Up Ring Section 60 page 55 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 Group 10: Brake Valve 25 LS Check Valve Assembly O-Ring O-Ring Plug Expansion Plug Spool Spring O-Ring Plug Spring Valve Assembly O-Ring O-Ring Cover Expansion Plug Spool Assembly 26 Back-Up Ring 27 Back-Up Ring 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 O-Ring Plug Fitting O-Ring Spring Orifice Expansion Plug Fitting Fitting assembly O-Ring Fitting Valve Assembly O-Ring Piston O-Ring Guide Piece O-Ring Wiper Seal Snap Ring Seal Ring and O-Ring Annular Piston Seal Ring and O-Ring O-Ring Spring Brake Housing Cap Screw Hex. Nut Threaded Pin with Filter Insert Valve O-Ring Cap Screws <- Go to Section TOC [ Parts must not be interchanged ] [ Parts must not be interchanged ] [ Parts must not be interchanged ] Section 60 page 56 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Remove Brake Valve (Power Fill Brakes) Preliminary work: Disconnect battery ground cable (—). Relieve accumulator pressure, seeAccumulators - Remove and Installin Section 60. Remove the brake valve [1] - LEGEND: A B C Screws Grip Trim Panel Take out screws (A) and remove grip (B). [2] - Fold trim panel (C) up. <- Go to Section TOC Section 60 page 57 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [3] - LEGEND: A Pin Take out pin (A) and lift off the brake pedals. [4] - LEGEND: A B C D E Hydraulic Hose Hydraulic Hose Screw Screw Hydraulic Lines Pull out the brake switch connectors and remove the brake switches. [5] - Take off hydraulic hoses (A) and (B). [6] - Disconnect hydraulic lines (E) from the brake valve. [7] - Take out screw (C). [8] - Take out the lower screw (D) and lift off the brake valve. Next step: SeeRecondition Brake Valve (Power Fill Brakes)in Section 60. <- Go to Section TOC Section 60 page 58 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Recondition Brake Valve (Power Fill Brakes) Preliminary work: SeeRemove Brake Valve (Power Fill Brakes)in Section 60. Disassemble the brake valve [1] - LEGEND: A Cover Remove cover (A). [2] - LEGEND: A Valves Remove valves (A). <- Go to Section TOC Section 60 page 59 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [3] - LEGEND: A Filter Remove filter (A). [4] →NOTE: When removing the plug and the spool, remember the spring force. LEGEND: A Plug Remove plug (A). [5] IMPORTANT: Note correct side, correct direction and relation of the parts for reinstallation. <- Go to Section TOC Section 60 page 60 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve LEGEND: A B Spool Spring Remove spring (B) and spool (A). [6] - LEGEND: A B C D E F Cover O-Ring O-Ring Valve Assembly Spring Spool Disassemble the spool, check individual parts for wear and replace if necessary. Clean and assemble the parts. <- Go to Section TOC Section 60 page 61 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [7] - LEGEND: A Socket Wrench Unscrew the guide piece using socket wrenchDFLX41(A). [8] - Remove the guide piece and piston. <- Go to Section TOC Section 60 page 62 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [9] - Disassemble the guide piece and piston, check for wear and replace parts as necessary. SeeRecondition Guide Piece and Pistonin Section 60. [10] - LEGEND: A Fitting Remove fitting (A). [11] - Remove the inlet check valve. <- Go to Section TOC Section 60 page 63 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [12] - LEGEND: A Plug Remove plug (A). [13] - Drive out the LS check valve. <- Go to Section TOC Section 60 page 64 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [14] - LEGEND: A Outlet Valve Remove outlet valves (A). Assemble the brake valve IMPORTANT: Before assembly, clean all components using clean hydraulic oil and blow compressed air through them, then coat all components with oil and assembly them. →NOTE: Examine all the components for signs of wear or damage. Damaged parts must be replaced. <- Go to Section TOC Section 60 page 65 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [1] - LEGEND: A B C Orifice Spring Fitting Install orifices (A), springs (B) and fittings (C). [2] - Tighten the outlet valves to the specified torque. [3] - LEGEND: A O-Ring Install O-ring (A) on the inlet check valve. <- Go to Section TOC Section 60 page 66 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [4] - Install the inlet check valve and tighten to the specified torque. Item Measurement Specification Inlet check valve to brake valve Torque 10 N˙m 7.5 lb-ft [5] - LEGEND: A Fitting Install fitting (A) and tighten to the specified torque. Item Measurement Specification Fitting to brake valve Torque 45 N˙m 33 lb-ft <- Go to Section TOC Section 60 page 67 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [6] - LEGEND: A B O-Ring O-Ring Install O-rings (A) and (B) on the LS check valve and coat them with oil. [7] - Install the LS check valve. <- Go to Section TOC Section 60 page 68 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [8] - LEGEND: A Plug Install plug (A) and tighten to the specified torque. Item Measurement Specification Plug to brake valve Torque 45 N˙m 33 lb-ft [9] - LEGEND: A B Spring Guide Piece Disassemble the piston with spring (A) and guide piece (B), check for wear and replace parts as necessary. SeeRecondition Guide Piece and Pistonin Section 60. <- Go to Section TOC Section 60 page 69 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [10] - Position the piston and guide piece. [11] - Using socket wrenchDFLX41(A), tighten the guide piece to the specified torque. Item Measurement Specification Guide piece to brake valve Torque 100 N˙m 75 lb-ft [12] IMPORTANT: Note correct side, correct direction and relation of the parts for reinstallation. <- Go to Section TOC Section 60 page 70 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve LEGEND: A B Spool Spring Install spool (A) and spring (B). [13] →NOTE: When installing the plug, remember the spring force. LEGEND: A Plug Install plug (A) and tighten to the specified torque. Item Measurement Specification Plug to brake valve Torque 100 N˙m 75 lb-ft <- Go to Section TOC Section 60 page 71 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [14] - LEGEND: A Filter Install filter (A) and tighten to the specified torque. Item Measurement Specification Filter in brake valve Torque 5 N˙m 4 lb-ft [15] - LEGEND: A Valves Install valves (A) and tighten to the specified torque. Item Measurement Specification Valve to brake valve, plug Torque 15 N˙m 11 lb-ft <- Go to Section TOC Section 60 page 72 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [16] - LEGEND: A Intermediate Cover Remove intermediate cover (A), clean it and install it on the cover. [17] IMPORTANT: Soak the gasket in clean hydraulic oil for 4 hours and allow it to expand. LEGEND: A Gasket Install the expanded gasket (A) on the housing with the writing underneath. [18] IMPORTANT: Tighten screws (B) in the sequence shown. <- Go to Section TOC Section 60 page 73 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Brake Valve - Tightening Sequence for Screws LEGEND: A B Cover Screws Install cover (A) and tighten screws (B) to the specified torque in the sequence shown. Item Measurement Specification Cover to brake valve, screws Torque 12 N˙m 9 lb-ft Next step: SeeInstall Brake Valve (Power Fill Brakes)in Section 60. <- Go to Section TOC Section 60 page 74 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Install Brake Valve (Power Fill Brakes) Install the brake valve [1] →NOTE: Do not tighten the screw at this stage; allow the brake valve some freedom of movement. Install hydraulic hoses (A) and (B). [2] - Secure hydraulic lines (E) to the brake valve. [3] - Install screws (C) and (D) and tighten to the specified torque. Item Measurement Specification Attaching Screws, Brake Valve Torque 100 N˙m 75 lb-ft [4] - Install brake switch (F), tighten to the specified torque and connect the connector. Item Measurement Specification Brake Switch to Bracket Torque 12 N˙m 9 lb-ft <- Go to Section TOC Section 60 page 75 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [5] - LEGEND: A Pin Secure the brake pedals with pin (A). Next step: SeeTests and Adjustments - Adjust Brake Pedals and Brake Switchin Section 260 of the relevant Diagnostic Manual. <- Go to Section TOC Section 60 page 76 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Power-Fill Brake Valve with MFWD and Disk Brake (up to Tractor Serial Number 444807) Preliminary work Disconnect battery ground cable (—). Remove the Brake Valve Take out screws (A) and (B). Remove trim panel (C). <- Go to Section TOC Section 60 page 77 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Take out pin (A) and lift off the brake pedals. Pull out the brake switch connector (B). Disconnect hydraulic lines (E) and (F) from the brake valve. Take out hex. socket screw (C). Slacken off the lower hex. socket screw (D) slightly. Take off hydraulic hose (A). Take off hydraulic hose (A). <- Go to Section TOC Section 60 page 78 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Take out the lower hex. socket screw (A) and lift off the brake valve. Disassemble the brake valve LEGEND: A Cover →NOTE: Depending on tractor version, the brake switch may have to be taken off first. Remove cover (A). <- Go to Section TOC Section 60 page 79 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Remove valves (A). Remove filter (A). Use socket wrench Socket Wrench Insert dealer fabricated <- Go to Section TOC Section 60 page 80 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Socket wrench insert for removing the guide piece on brake valves with power-fill. (A; dealer-fabricated) to unscrew the guide piece. Take out the guide piece and piston. Disassemble the guide piece and piston. <- Go to Section TOC Section 60 page 81 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Remove plug (A). Take out spring (B) and spool (A). Disassemble the spool. Remove plug (A). <- Go to Section TOC Section 60 page 82 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Remove valve (A). Remove fitting (A). Unscrew the inlet check valve. <- Go to Section TOC Section 60 page 83 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Remove plug (A). Drive out the LS check valve. Exploded view <- Go to Section TOC Section 60 page 84 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES LEGEND: 1 4 5 6 7 8 9 10 11 12 13 <- Go to Section TOC Group 10: Brake Valve Cap Screw (8 used) Cover Intermediate Cover Gasket Plug O-Ring Valve O-Ring O-Ring LS Check Valve Assembly Plugs (2 used) Section 60 page 85 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 <- Go to Section TOC Group 10: Brake Valve O-Ring (2 used) Spring (2 used) Spool (2 used) Expansion Plug Spring (2 used) Valve Assembly (2 used) O-Ring (2 used) O-Ring (2 used) Cover (2 used) Plug O-Ring Spool O-Ring O-Ring Expansion Plug (4 used) Expansion Plug (2 used) Orifice (2 used) Spring (2 used) O-Ring (2 used) Fitting (2 used) Outlet Valve Assembly (2 used) O-Ring Fitting O-Ring Valve Assembly O-Ring Fitting Inlet Check Valve Assembly Wiper Seal (2 used) O-Ring (2 used) Guide Piece (2 used) O-Ring (2 used) Piston (2 used) Snap Ring (4 used) Seal Ring and O-Ring (2 used) Annular Piston (2 used) Seal Ring and O-Ring (2 used) Seal Ring (2 used) Spring Cap Screw (2 used) Hex. Nut (2 used) Threaded Pin with Filter Insert Valve (2 used) O-Ring Fitting O-Ring Spring [ Valve Spool Parts must not be interchanged ] [ Seal Ring Parts must not be interchanged ] Section 60 page 86 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Assemble the brake valve LEGEND: A B C Orifice Spring Fitting Install the outlet valves. Put O-ring (A) onto the inlet check valve. <- Go to Section TOC Section 60 page 87 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Screw in the inlet check valve. Screw in fitting (A). Screw in the valve and tighten to specified torque. Item Measurement Specification Valve Torque 10 N˙m 7.4 lb.-ft. Tighten plug (A). <- Go to Section TOC Section 60 page 88 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Put O-rings (A) and (B) onto the LS check valve. Install the LS check valve (A). <- Go to Section TOC Section 60 page 89 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Screw in plug (A). Install snap ring (B) on piston. Install O-ring (A). Install seal ring (B). Install seal ring (A). <- Go to Section TOC Section 60 page 90 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Install O-ring (A) on annular piston. Install seal ring (A). Install the annular piston on the piston. Install snap ring (A). <- Go to Section TOC Section 60 page 91 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Install O-ring (B) and wiper seal (A) on the guide piece. Install guide piece (B) on the piston. Install spring (A). LEGEND: A B C D E F <- Go to Section TOC Cover O-Ring O-Ring Valve Assembly Spring Spool Section 60 page 92 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Assemble the spool. Install spool (A) and spring (B). Screw in plug (A). <- Go to Section TOC Section 60 page 93 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Install piston and guide piece. Use socket wrench Socket Wrench Insert dealer fabricated Socket wrench insert for removing the guide piece on brake valves with power-fill. (A; dealer-fabricated) to screw in the guide piece. Screw in filter (A) and tighten. Item Measurement Specification Torque 5 N˙m 4 lb.-ft. <- Go to Section TOC Section 60 page 94 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Install valves (A). Install gasket (A). Install intermediate cover (A) on the cover. <- Go to Section TOC Section 60 page 95 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Install cover (A). Install the brake valve →NOTE: Do not tighten the hex. socket screw at this stage; allow the brake valve some freedom of movement. Secure the brake valve at the lower hex. socket screw (A). <- Go to Section TOC Section 60 page 96 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES LEGEND: A B Group 10: Brake Valve Hydraulic Hose Brake switch, AutoPowr/IVT Install hydraulic hose (A) and brake switch (B). Install hydraulic hose (A). Connect the brake switch connectors (B). Secure hydraulic lines (E) and (F) to the brake valve. <- Go to Section TOC Section 60 page 97 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Tighten hex. socket screws (C) and (D). Item Measurement Specification Brake Valve Attaching Screws Torque 100 N˙m 75 lb.-ft. Secure the brake pedals with pin (A). Adjusting the brake pedals [1] - Lock the brake pedals together. <- Go to Section TOC Section 60 page 98 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [2] - Measure pedal play at both pistons. Pedal play must be within the following range. Item Measurement Specification Brake Pedals Pedal Play 0.15 to 0.20 mm 0.006 to 0.008 in. [3] IMPORTANT: Never adjust the pedals singly. The only way to adjust the pedals and ensure that the brakes operate properly is to lock them together. Adjust pedal play at screws (A). →NOTE: If the specified degree of play cannot be obtained at both pedals, one pedal may have a greater play. Adjust the brake switches (without AutoPowr/IVT) [1] - Make sure that the brake pedals are adjusted correctly. [2] - Adjust the brake switches at adjusting screws (A) so that the switches trip when the pedal has travelled a specified distance. Item Measurement Specification Brake Switch Clearance 6 mm 0.24 in. Adjusting the brake switches (with AutoPowr/IVT) <- Go to Section TOC Section 60 page 99 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [1] - Make sure that the brake pedals are adjusted correctly. [2] - Unlock the brake pedals. [3] - Ignition on. [4] - Before entering the diagnostic mode, see Reference 245-05-001, General Operation and Entering the Program Mode (on tractors with performance monitor, press the service button for 2 seconds and select the controller). [5] - Access the UIC control unit, and confirm. [6] - Access address 27 (voltage display for left brake pedal). [7] - Screw in adjusting screw (A) until voltage is between 0.9 and 1.1 volts. [8] - Counterlock adjusting screw (A). [9] - Access address 28 (voltage display for right brake pedal). [10] - Screw in adjusting screw (B) until voltage is between 0.9 and 1.1 volts. [11] - Counterlock adjusting screw (B). [12] - Check the brake switch: At the moment when the switch can be heard to trip, the voltage on the display must be between 1.45 and 1.65 volts. →NOTE: The voltages at the pedals must not deviate from each other by more than 0.15 volts. Final assembly <- Go to Section TOC Section 60 page 100 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Attach trim panel (C) by means of screws (A) and (B). Connect ground (—) cable to battery. Bleed air from the brakes SeeTests and Adjustments - Adjust the Brake Pedals and Switchesin Section 60. <- Go to Section TOC Section 60 page 101 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Remove Power-Fill Brake Valve with MFWD and Disk Brake Preliminary work: Disconnect battery ground cable (—). Relieve pressure at accumulator. SeeAccumulators - Removal and Installationin Section 60. Remove the brake valve <- Go to Section TOC Section 60 page 102 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [1] - LEGEND: A B C Screws Grip Trim Panel Take out screws (A) and remove grip (B). [2] - Fold trim panel (C) up. [3] - LEGEND: A Pin Take out pin (A) and lift off the brake pedals. <- Go to Section TOC Section 60 page 103 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [4] - LEGEND: A B C D E F Hydraulic Hose Connector Screw Screw Hydraulic Line Hydraulic Line Pull out the brake switch connector (B). [5] - Disconnect hydraulic lines (E) and (F) from the brake valve. [6] - Take out screw (C). [7] - Loosen lower screw (D), do not remove it. [8] - Take off hydraulic hose (A). [9] - LEGEND: A Hydraulic Hose Take off hydraulic hose (A). <- Go to Section TOC Section 60 page 104 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [10] - LEGEND: A Screw Remove screw (A) and brake valve. Next step: SeeRecondition Power-Fill Brake Valve with MFWD and Disk Brakein Section 60. <- Go to Section TOC Section 60 page 105 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Recondition Power-Fill Brake Valve with MFWD and Disk Brake Preliminary work: SeeRemove Power-Fill Brake Valve with MFWD and Disk Brakein Section 60. Disassemble the brake valve [1] →NOTE: Depending on tractor version, the brake switch may have to be taken off first. LEGEND: A Cover Remove cover (A). <- Go to Section TOC Section 60 page 106 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [2] - LEGEND: A Valves Remove valves (A). [3] - LEGEND: A Filter Remove filter (A). [4] →NOTE: When removing the plug and the spool, remember the spring force. <- Go to Section TOC Section 60 page 107 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve LEGEND: A Plug Remove plug (A). [5] IMPORTANT: Note correct side, correct direction and relation of the parts for reinstallation. LEGEND: A B Spool Spring Remove spring (B) and spool (A). <- Go to Section TOC Section 60 page 108 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [6] - LEGEND: A B C D E F Cover O-Ring O-Ring Valve Assembly Spring Spool Check components of spool for wear, and replace if necessary. Clean and assemble the parts. [7] - LEGEND: A Socket Wrench Unscrew the guide piece using socket wrenchDFLX41(A). <- Go to Section TOC Section 60 page 109 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [8] - Remove the guide piece and piston. [9] - Disassemble the guide piece and piston, check for wear and replace parts as necessary. SeeRecondition Guide Piece and Pistonin Section 60. <- Go to Section TOC Section 60 page 110 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [10] - LEGEND: A Plug Remove plug (A). [11] - LEGEND: A B Valve Spring Remove valve (A) and spring (B). <- Go to Section TOC Section 60 page 111 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [12] - LEGEND: A Fitting Remove fitting (A). [13] - Remove the inlet check valve. <- Go to Section TOC Section 60 page 112 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [14] - LEGEND: A Plug Remove plug (A). [15] - Drive out the LS check valve. <- Go to Section TOC Section 60 page 113 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [16] - LEGEND: A B C Orifice Spring Fitting Remove orifices (A), springs (B) and fittings (C). Assemble the brake valve IMPORTANT: Before assembly, clean all components using clean hydraulic oil and blow compressed air through them, then coat all components with oil and assembly them. →NOTE: Examine all the components for signs of wear or damage. Damaged parts must be replaced. <- Go to Section TOC Section 60 page 114 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [1] - LEGEND: A B C Orifice Spring Fitting Install orifices (A), springs (B) and fittings (C). [2] - Tighten the outlet valves to the specified torque. Item Measurement Specification Outlet valve to brake valve Torque 45 N˙m 33 lb-ft [3] - LEGEND: A O-Ring Install O-ring (A) on the inlet check valve. <- Go to Section TOC Section 60 page 115 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [4] - Install the inlet check valve and tighten to the specified torque. Item Measurement Specification Inlet check valve to brake valve Torque 10 N˙m 7.5 lb-ft [5] - LEGEND: A Fitting Install fitting (A) and tighten to the specified torque. Item Measurement Specification Fitting to brake valve Torque 45 N˙m 33 lb-ft <- Go to Section TOC Section 60 page 116 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [6] - LEGEND: A B O-Ring O-Ring Install O-rings (A) and (B) on the LS check valve and coat them with oil. [7] - LEGEND: A LS Check Valve Install the LS check valve (A). <- Go to Section TOC Section 60 page 117 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [8] - LEGEND: A Plug Install plug (A) and tighten to the specified torque. Item Measurement Specification Plug to brake valve Torque 45 N˙m 33 lb-ft [9] - LEGEND: A B Valve Compression Spring Install valve and compression spring. <- Go to Section TOC Section 60 page 118 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [10] - LEGEND: A Plug Install plug (A) and tighten to the specified torque. Item Measurement Specification Plug to brake valve Torque 45 N˙m 33 lb-ft [11] - LEGEND: A B Spring Guide Piece Disassemble the piston with spring (A) and guide piece (B), check for wear and replace parts as necessary. SeeRecondition Guide Piece and Pistonin Section 60. <- Go to Section TOC Section 60 page 119 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [12] - Install the piston and guide piece. [13] - LEGEND: A DFLX41 - Socket Wrench Insert Using socket wrenchDFLX41(A), tighten the guide piece to the specified torque. Item Measurement Specification Guide piece to brake valve Torque 100 N˙m 75 lb-ft [14] IMPORTANT: Note correct side, correct direction and relation of the parts for reinstallation. <- Go to Section TOC Section 60 page 120 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve LEGEND: A B Spool Spring Install spool (A) and spring (B). [15] →NOTE: When installing the plug, remember the spring force. LEGEND: A Plug Install plug (A) and tighten to the specified torque. Item Measurement Specification Plug to brake valve Torque 100 N˙m 75 lb-ft <- Go to Section TOC Section 60 page 121 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [16] - LEGEND: A Filter Install filter (A) and tighten to the specified torque. Item Measurement Specification Filter in brake valve Torque 5 N˙m 4 lb-ft [17] - LEGEND: A Valves Install valves (A) and tighten to the specified torque. Item Measurement Specification Valve to brake valve, plug Torque 15 N˙m 11 lb-ft <- Go to Section TOC Section 60 page 122 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [18] - LEGEND: A Intermediate Cover Remove intermediate cover (A), clean it and install it on the cover. [19] IMPORTANT: Soak the gasket in clean hydraulic oil for 4 hours and allow it to expand. LEGEND: A Gasket Install the expanded gasket (A) on the housing with the writing underneath. [20] IMPORTANT: Tighten screws (B) in the sequence shown. <- Go to Section TOC Section 60 page 123 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Brake Valve - Tightening Sequence for Screws LEGEND: A B Cover Screws Install cover (A) and tighten screws (B) to the specified torque in the sequence shown. Item Measurement Specification Cover to brake valve, screws Torque 12 N˙m 9 lb-ft Next step: SeeInstall Power-Fill Brake Valve with MFWD and Disk Brakein Section 60. <- Go to Section TOC Section 60 page 124 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Install Power-Fill Brake Valve with MFWD and Disk Brake [1] →NOTE: Do not tighten the screw at this stage; allow the brake valve some freedom of movement. LEGEND: A Screw Secure the brake valve using the lower screw (A). <- Go to Section TOC Section 60 page 125 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [2] - LEGEND: A B Hydraulic Hose Brake Switch (with AutoPowr/IVT) Install hydraulic hose (A) and brake switch (B). [3] - Install hydraulic hose (A). [4] - Connect the brake switch connectors (B). [5] - Secure hydraulic lines (E) and (F) to the brake valve. <- Go to Section TOC Section 60 page 126 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [6] - Install screws (C) and (D) and tighten to the specified torque. Item Measurement Specification Brake Valve Attaching Screws Torque 100 N·m 75 lb.-ft. [7] - LEGEND: A Pin Secure the brake pedals with pin (A). Next step: SeeTests and Adjustments - Adjust Brake Pedals and Brake Switchin Section 260 of the relevant Diagnostic Manual. <- Go to Section TOC Section 60 page 127 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve Tests and Adjustments - Adjust the Brake Pedals and Switches Adjusting the brake pedals [1] IMPORTANT: Brake pedals are adjusted with the pedals uncoupled; the setting is checked with the pedals coupled together. LEGEND: A B C Adjusting Screw Roller Piston Unlock the brake pedals. [2] - Using adjusting screws (A), adjust the pedals so that rollers (B) can be turned by hand. However, there must be no play noticeable between the roller and piston (C). [3] IMPORTANT: The locking pin must slide in easily; it may be necessary to re-adjust the pedal stops. Lock the brake pedals together and check the setting at the two pistons once again. →NOTE: It must be possible to turn the rollers by hand; however, the rollers must not rise from the pistons. Next step: See Adjust the brake switches (without AutoPowr/IVT) or Adjust the brake switches (with <- Go to Section TOC Section 60 page 128 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve AutoPowr/IVT). Adjust the brake switches (without AutoPowr/IVT) LEGEND: A Adjusting Screws [1] - Make sure that the brake pedals are adjusted correctly. [2] - Adjust the brake switches at adjusting screws (A) so that the switches trip when the pedal has travelled a specified distance. Item Measurement Specification Brake Switch Clearance 6 mm 0.24 in. [3] - LEGEND: A B C Screws Grip Trim Panel Attach trim panel (C) using screws (A) and re-install handle (B). <- Go to Section TOC Section 60 page 129 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 10: Brake Valve [4] - Connect ground (—) cable to battery. Next step: SeeSteering and Brakes - Bleed Air from the Brakesin Section 260. Adjust the brake switches (with AutoPowr/IVT) LEGEND: A B Adjusting Screw Adjusting Screw [1] - Make sure that the brake pedals are adjusted correctly. [2] - Unlock the brake pedals. [3] - Ignition on. [4] - For entering the diagnostic mode, seeOperation and General Information on Diagnostics - Summary of Referencesin Section 245. [5] - Access the UIC control unit, and confirm. [6] - Access address 27 (voltage display for left brake pedal). [7] - Screw in adjusting screw (A) until voltage is between 0.9 and 1.1 volts. [8] - Counterlock adjusting screw (A). [9] - Access address 28 (voltage display for right brake pedal). [10] - Screw in adjusting screw (B) until voltage is between 0.9 and 1.1 volts. [11] - Counterlock adjusting screw (B). <- Go to Section TOC Section 60 page 130 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 15: Rear Wheel Brakes [12] - Brake switch test: At the moment when the switch can be heard to trip, the voltage on the display must be between 1.45 and 1.65 volts. →NOTE: The voltages at the pedals must not deviate from each other by more than 0.15 volts. [13] - LEGEND: A B C Screws Grip Trim Panel Attach trim panel (C) using screws (A) and re-install handle (B). [14] - Connect ground (—) cable to battery. Next step: SeeSteering and Brakes - Bleed Air from the Brakesin Section 260. <- Go to Section TOC Section 60 page 131 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 15: Rear Wheel Brakes Group 15 - Rear Wheel Brakes Summary of References (Rear Brakes) ”Remove Rear Brakes” ”Rear Brakes — Exploded View” ”Repairing the Rear Brakes” ”Installing the Rear Brakes” ”Final Assembly” ”Bleeding the Brakes (Brake Valve with Power-Fill Brakes, MFWD and Disk Brake)” Rear Brakes, Specifications Item Measurement Specification Brake disk Thickness 5.5 mm 0.216 in. Installation of retraction pins in brake plate Height 23.5 mm 0.925 in. Preliminary Work See “Removing the Final Drives” , Section 56, Group 00. Remove the Rear Brakes Preliminary work: SeeRemove the Final Drivesin Section 56. <- Go to Section TOC Section 60 page 132 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 15: Rear Wheel Brakes [1] - LEGEND: A B C Brake plate Final drive shaft Brake disk Remove brake plate (A), brake disk (C) and final drive shaft (B). [2] - Remove the brake piston using a crowbar. Rear Brakes—Exploded View <- Go to Section TOC Section 60 page 133 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES LEGEND: A B C D E F G H <- Go to Section TOC Group 15: Rear Wheel Brakes Ball O-ring Bleed screw Seal ring Seal ring Brake piston Brake disk Backing plate Section 60 page 134 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 15: Rear Wheel Brakes Recondition the Rear Wheel Brakes Preliminary work: SeeRemove the Rear Wheel Brakesin Section 60. [1] - LEGEND: A B Brake piston Brake plate Inspect brake piston (A) and backing plate (B) for flatness and for wear on the braking surfaces. [2] - LEGEND: A Brake disk Check the lining of brake disk (A). [3] - Check the splines (see arrow) of the brake disk for wear and damage. Item Measurement Specification Brake disk Thickness (Minimum) 5.5 mm (0.216 in.) <- Go to Section TOC Section 60 page 135 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 15: Rear Wheel Brakes [4] - LEGEND: A Seal ring Grease new seal ring (A) and install it on the brake piston. [5] - LEGEND: A Seal ring Grease new seal ring (A) and install it on the housing. Next step: SeeInstall the Rear Wheel Brakesin Section 60. <- Go to Section TOC Section 60 page 136 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 15: Rear Wheel Brakes Install the Rear Brakes [1] - LEGEND: A B Brake piston Sealing surface Thoroughly clean sealing surface (B). [2] IMPORTANT: Drive the brake piston as far as it will go into the differential housing. Drive brake piston (A) in evenly. [3] - LEGEND: A B C Brake plate Final drive shaft Brake disk Install brake plate (A), brake disk (C) and final drive shaft (B) as shown. <- Go to Section TOC Section 60 page 137 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 15: Rear Wheel Brakes Next step: SeeInstall the Final Drivesin Section 56. Final Assembly See “Installing the Final Drives” , Section 56, Group 00. <- Go to Section TOC Section 60 page 138 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 15: Rear Wheel Brakes Bleeding the Brakes (Brake Valve, Power-Fill Brakes and MFWD and Disk Brake) CAUTION: Always follow the steps described here precisely. This is the only way of assuring the tractor brakes have been correctly bled. →NOTE: To avoid oil foaming while bleeding, the procedure should not be started after fast driving, working with hydraulic implements or carrying out hydraulic tests. After such operation the tractor should be allowed to stand for one hour to allow the oil to lose any accumulated foam. Bleeding sequence: Without trailer brake: 1. Left rear brake 2. Right rear brake With hydraulic trailer brake 1. Left rear brake 2. Trailer brake valve With air brake system: 1. Trailer control valve, rear bleed screw 2. Trailer control valve, front bleed screw With air brake system and MFWD with disk brake: 1. 2. 3. 4. Left front brake Right front brake Trailer control valve, bleed screw Left rear brake With hydraulic trailer brake and MFWD with disk brake: <- Go to Section TOC Section 60 page 139 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES 1. 2. 3. 4. Group 15: Rear Wheel Brakes Left front brake Right front brake Left rear brake Trailer brake valve Bleeding procedure [1] - Without trailer brake LEGEND: A B Hex. nut Bleed screw With the engine running, turn the steering wheel slowly and evenly two or three times from left full lock to right full lock and back again. This fills the brake valve housing via the steering valve return line. Shut off the engine. [2] - With hydraulic trailer brake <- Go to Section TOC Section 60 page 140 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 15: Rear Wheel Brakes With air brake system With MFWD and disk brake Tractors without trailer brake: On both rear brakes, slacken off lock nut (A) and open bleed screw (B) by one-and-a-half turns. Tractors with hydraulic trailer brake: On the left-hand rear brake, slacken off lock nut (A) and open bleed screw (B) by one-and-a-half turns. Slide a transparent bleed tube over the bleed screw on the trailer brake valve. Put the other end of the tube in the filler neck. Open the bleed screw by half a turn. Tractors with air brake system: Slide two transparent bleed tubes over the bleed screws. Place the other ends of the two bleed tubes in the oil filler neck. Open the bleed screws by <- Go to Section TOC Section 60 page 141 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 20: Handbrake half a turn. Tractors with MFWD and disk brake: Slide a transparent bleed tube over each bleed screw (refer to Bleeding Sequence). Put the tube ends into a suitable container. Open the bleed screws by half a turn. [3] - Start the engine. [4] - Couple the brake pedals together. Depress the pedals and hold them depressed for at least 15 seconds. [5] - Then depress the pedals briefly and release. Repeat this a few times. This should flush out any air bubbles left in the fluid. [6] - If necessary, repeat step 4. [7] - Air brake system (MFWD and disk brake) LEGEND: A B C Hex. nut Bleed screw Breather Hold the pedals in the depressed position and close the bleed screws. Retighten the lock nuts (if equipped). [8] - Shut off the engine and actuate the brake pedals several times each (separately!) with the engine shut off. This bleeds the last of the air out of the brake valve. There must be perceptible (increasing) resistance before each pedal reaches its limit of travel. IMPORTANT: If pedal does sink noticeably after resistance has been reached, leaks in the brake system may be the cause. <- Go to Section TOC Section 60 page 142 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 20: Handbrake Group 20 - Handbrake Summary of References (Handbrake) ”Specifications” ”Preliminary work” ”Remove handbrake” ”Exploded view of handbrake - Tractor 6820” ”Exploded view of handbrake - Tractors 6920 and 6920S” ”Install handbrake” ”Adjusting the brake band” ”Final assembly” ”Handbrake components” ”Replacing the handbrake cable” ”Adjusting the handbrake” Handbrake - Specifications Item Measurement Specification Quill of front-wheel drive clutch, screws Torque 25 N·m 18 lb.-ft. Locknut Torque 37 ± 7 N·m 27 ± 5 lb.-ft. Preliminary work Remove FWD clutch. See “Removing the FWD clutch” , section 56, group 00. <- Go to Section TOC Section 60 page 143 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 20: Handbrake Remove Handbrake Preliminary work: SeeRemove the Front-Wheel Drive Clutchin Section 56. [1] - LEGEND: A B Screws Bearing quill Take out screws (A) and remove bearing quill (B). [2] - LEGEND: A B C Spring pin Lever shaft Plug Remove plug (C). [3] - Remove spring pin (A) and pull out lever shaft (B). <- Go to Section TOC Section 60 page 144 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 20: Handbrake [4] - LEGEND: A Plug Remove plug (A). [5] - LEGEND: A Shaft Use a screw to remove shaft (A). <- Go to Section TOC Section 60 page 145 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 20: Handbrake [6] - LEGEND: A Output shaft Remove output shaft (A). [7] - Take off the shims and tapered roller bearing. [8] - Remove the clutch and brake band from the housing. [9] - Take the brake band off the clutch. <- Go to Section TOC Section 60 page 146 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 20: Handbrake Exploded view of handbrake - Tractor 6820 LEGEND: A B C D E F G H I J K L <- Go to Section TOC Lever Strap Lever Brake band Strap Lever shaft Strap Lever Arm Strap Seal ring Shaft Section 60 page 147 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 20: Handbrake Exploded view of handbrake - Tractors 6920 and 6920S LEGEND: A B C D E F G H I J <- Go to Section TOC Lever Strap Lever Brake band Brake band Strap Strap Lever shaft Strap Lever Section 60 page 148 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES K L M N <- Go to Section TOC Group 20: Handbrake Arm Strap Seal ring Shaft Section 60 page 149 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 20: Handbrake Installing the handbrake Install taper roller bearing cone (A) in housing. To prevent the thrust washer (A) from falling out during clutch installation, coat it with grease. Install the thrust washer on the clutch. Check the handbrake components, and replace if necessary. Preassemble the handbrake band using the exploded view illustration as a guide. Install the <- Go to Section TOC Section 60 page 150 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 20: Handbrake band on the clutch as shown. →NOTE: Pin (B) is held in position only by the straps (A). When installing, hold the brake band linkage in the position shown, otherwise the pin will fall out. Install clutch and brake band. →NOTE: Make sure that the thrust washer and pin do not fall out. Install shaft (A). Install taper roller bearing. <- Go to Section TOC Section 60 page 151 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 20: Handbrake Install shaft (A). Screw in plug (A). Screw in plug (C). Install lever shaft (B) and drive in spring pin (A). <- Go to Section TOC Section 60 page 152 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 20: Handbrake →NOTE: If you have not replaced any of the components that affect the axial play of the FWD clutch (for example, if you have replaced only the brake band), the old shims can be reused. In this housing, there is no need to adjust the axial play. Otherwise, see “Repairing the FWD clutch” , section 56, group 10. Install shims. Attach bearing quill (B). Tighten cap screws (A). Item Measurement Specification Cap screws (A) Torque 25 N˙m 18 lb-ft Handbrake - Adjust the Brake Band [1] →NOTE: The clutch drum must turn freely without any undue resistance. <- Go to Section TOC Section 60 page 153 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 20: Handbrake LEGEND: A Adjusting screw Adjust the brake band at adjusting screw (A). [2] - Tighten locknut on adjusting screw to specified torque. Item Measurement Specification Locknut Torque 37 ± 7 N·m 27 ± 5 lb.-ft. Next step: SeeInstall the Front-Wheel Drive Clutchin Section 56. Final assembly Install the FWD clutch. See “Installing the FWD clutch” , section 56, group 00. Handbrake components <- Go to Section TOC Section 60 page 154 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES LEGEND: A B C D E F G H I J K L M N O P <- Go to Section TOC Group 20: Handbrake Spring Unlocking rod Handle Handbrake lever Locking pawl Toothed segment Bracket Sender for handbrake indicator light Console Trim panel Rubber sleeve Handbrake cable (top part) Handbrake cable (bottom part) Terminal Bracket Bracket (AutoPowr/IVT transmission only) Section 60 page 155 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 20: Handbrake Handbrake - Replace Handbrake Cable 1. LEGEND: A Yoke Release the handbrake fully. 2. Disengage yoke (A) at the front-wheel drive clutch. 3. LEGEND: A B Screws Trim panel Take out screws (A) and remove trim panel (B). <- Go to Section TOC Section 60 page 156 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 20: Handbrake 4. LEGEND: A B Pin Locking plate Remove pin (A) and locking plate (B) from the handbrake lever. 5. Disconnect handbrake cable. Removal [1] →NOTE: The handbrake cable can be disconnected underneath the cab. If required, the two parts may be replaced independently of one another. LEGEND: A B C D Snap ring Sleeve Locknut Handbrake cable (top part) Remove snap ring (A). [2] - Unfasten locknut (C) and unscrew the sleeve (B). <- Go to Section TOC Section 60 page 157 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 25: Hydraulic Trailer Brake [3] - Disconnect the top and bottom parts of the handbrake cable. Installation [1] - Connect the top and bottom parts of the handbrake cable by pushing their ends together. [2] - Screw the sleeve (B) onto the thread of the top part (D) of the handbrake cable. The end of the sleeve must come between the grooves. [3] - Coat the thread with Loctite ™ 243 (medium strength) and tighten locknut (C). [4] - Install snap ring (A). Next step: SeeTests and Adjustments - Check and Adjust Handbrakein Section 260 of the relevant Diagnostic Manual. Adjusting the Handbrake [1] - Pull the handbrake lever up (apply brake). It must be possible to pull the lever into the 4th notch using a force of 100 to 150 N (22 to 34 lb). [2] - If necessary, adjust the handbrake by turning yoke (A). [3] →NOTE: Slackening the yoke makes the handbrake slacker. Tightening the yoke makes the handbrake tighter. Check the handbrake again. <- Go to Section TOC Section 60 page 158 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 25: Hydraulic Trailer Brake Group 25 - Hydraulic Trailer Brake Hydraulic Trailer Brake (Summary of References) Special tools Specifications Repair information Hydraulic trailer brake valve up to serial no. 466428 Hydraulic trailer brake valve from serial no. 466429 Bleeding the trailer brake valve Check hydraulic trailer brake valve Special Tools →NOTE: Order tools according to information given in the U.S. SERVICEGARD ™ Catalog or from the European Microfiche Tool Catalog (MTC). FKM10002 / JT05470- Universal pressure test kit AR52361- Coupler socket Specifications Item Measurement Specification Brake valve to console, cap screws Torque 10 to 12 N˙m (7 to 9 lb-ft) Cover to valve housing, hex. socket screws Torque 13 N˙m (9.5 lb-ft) Brake pressure, max. Pressure 12000—14000 kPa (120—140 bar; 1740—2031 psi) Repair Instructions CAUTION: High pressure may be present at any of the hydraulic connections. Avoid injury by relieving system pressure before disconnecting any hydraulic lines, fittings or connections. IMPORTANT: Absolute cleanliness is essential when working on the hydraulic system. Clean the area around the trailer brake valve thoroughly before removing or servicing parts. <- Go to Section TOC Section 60 page 159 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 25: Hydraulic Trailer Brake Replace all seals and O-rings. Check for signs of wear, damage or deformation. Clean all components in a clean detergent, and dry them with compressed air. Do NOT use rags to wipe the components dry! Before assembly, coat all internal components with clean hydraulic oil. The valve spool must not jam in the housing bore. When work on the trailer brake valve is completed, see “ Bleed the Brakes ” in Section 60, Group 20. <- Go to Section TOC Section 60 page 160 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 25: Hydraulic Trailer Brake Hydraulic Trailer Brake Valve up to Serial No. 466428 Changing the trailer brake valve LEGEND: A B Cap screws Washers Disconnect lines at the brake valve and remove cap screws (A). Install washers (B) between the brake valve and the bracket. Tighten cap screws (A) to 10 to 12 N˙m (7 to 9 lb-ft) and connect lines. Cleaning the trailer brake valve →NOTE: From tractor serial no. 466429, the trailer brake valve cannot be cleaned. <- Go to Section TOC Section 60 page 161 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 25: Hydraulic Trailer Brake IMPORTANT: Absolute cleanliness is essential when working on the trailer brake valve. There is no need to remove the brake valve for cleaning. Take out the three hex. socket screws (B) and carefully remove cover (A). Take care, as components may fall out. LEGEND: A B C Valve spool Disk Spring Use a magnet to extract the spring, disk and valve spool from the hole. Clean the components and the hole, and re-install. Make sure they are located correctly. The collar on disk (B) must face the spring. LEGEND: A B C Valve body Spring Guide Use a magnet to extract the guide, spring and pressure-limiting valve body from the hole. Clean the components and the hole, and re-install. Make sure they are located correctly. <- Go to Section TOC Section 60 page 162 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES LEGEND: A B C D Group 25: Hydraulic Trailer Brake Restriction valve Cover O-ring L53976 O-ring R76617 Clean restriction valve (A) and blow compressed air through it. Do NOT remove or adjust the valve! Insert new O-rings (C) and (D). Install cover (B) and tighten the three hex. socket screws to 13 N˙m (9.5 lb-ft). Repeat the tests. If the specifications are still not met, replace the trailer brake valve with a new one. Cleaning the screen Hydraulic line and fitting <- Go to Section TOC Section 60 page 163 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES LEGEND: A B C Group 25: Hydraulic Trailer Brake Hydraulic line Fitting Screen Disconnect hydraulic line (A) from fitting (B). Slacken the fitting and turn it to one side. Remove the screen (C) from the hydraulic line. Clean the screen. Insert the screen, and secure the hydraulic line and fitting. Replacing the check valve LEGEND: A B <- Go to Section TOC Check valve Trailer brake valve Section 60 page 164 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 25: Hydraulic Trailer Brake When installing, make sure that ring (A) and O-ring (B) are seated correctly in check valve (C). The O-ring faces towards the check valve. Adjusting hydraulic trailer brake valve [1] - Run the engine at 1500 rpm. →NOTE: Oil temperature must be at approx. 50°C (120°F). [2] - Depress r.h. brake pedal until pilot pressure (see chart) has been reached. <- Go to Section TOC Section 60 page 165 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 25: Hydraulic Trailer Brake [3] - Use an allen key to slacken off the valve pin by about 1 to 2 turns, and flush for approx. 10 seconds. [4] - Release the brakes. CAUTION: Do NOT screw the valve pin as far as it can go, as this may damage the valve seat. [5] - Depress r.h. brake pedal until pilot pressure (see chart) has been reached. [6] - Screw in the valve pin (by about 1 to 2 turns) until the corresponding brake pressure (see chart) has been obtained. [7] - Release the brakes. [8] - Check that the correct pilot pressure is achieved at the correct brake pressure (see table below). Ratio [ See reference ”Ascertaining the Pressure Ratio” in Section 260, Group 20 ] (pilot and brake pressure) 1:6 1:9 Pilot pressure 1700 kPa 17 bar 247 psi 1100 kPa 11 bar 160 psi Brake pressure (at coupler) 9400—11000 kPa 9500—10800 kPa 94—110 bar 95—108 bar 1365—1600 psi 1378—1566 psi If the brake pressure does not correspond to the specification quoted, screw the valve pin in or out (see the test at point 6). [9] - Lock the hex. nut and install protective cap. <- Go to Section TOC Section 60 page 166 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 25: Hydraulic Trailer Brake Hydraulic Trailer Brake Valve from Serial No. 466429 Changing the trailer brake valve LEGEND: A B Cap screws Washers Disconnect lines at the brake valve and remove cap screws (A). Install washers (B) between the brake valve and the bracket. Tighten cap screws (A) to 10 to 12 N˙m (7 to 9 lb-ft) and connect lines. Cleaning the trailer brake valve →NOTE: The trailer brake valve cannot be cleaned anymore. Cleaning the screen <- Go to Section TOC Section 60 page 167 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES LEGEND: A B C Group 25: Hydraulic Trailer Brake Hydraulic line Fitting Screen Disconnect hydraulic line (A) from fitting (B). Slacken the fitting and turn it to one side. Remove the screen (C) from the hydraulic line. Clean the screen. Insert the screen, and secure the hydraulic line and fitting. Replacing the check valve <- Go to Section TOC Section 60 page 168 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES LEGEND: A B LEGEND: A B Group 25: Hydraulic Trailer Brake Check valve Trailer brake valve O-ring Check valve When installing, make sure that O-ring (A) is seated correctly in check valve (B). Bleed Air from the Trailer Brake Valve See “ Bleed the Brakes ” in Section 60, Group 20. <- Go to Section TOC Section 60 page 169 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 25: Hydraulic Trailer Brake Check Hydraulic Trailer Brake Valve LEGEND: A Pressure Gauge FKM10207 B Connector FKM10302 C Pressure Hose FKM10209 D Connector FKM10303 E Connector FKM10305 F Quick Coupler Socket G H Coupler Plug Pressure Gauge FKM10205 I Connector FKM10303 J Fitting KJD10128 <- Go to Section TOC [ Included in pressure gauge set FKM10002 ] [ Included in pressure gauge set FKM10002 ] [ Included in pressure gauge set FKM10002 ] [ Included in pressure gauge set FKM10002 ] [ Included in pressure gauge set FKM10002 ] [ Available as spare part ] [ Included in pressure gauge set FKM10002 ] [ Included in pressure gauge set FKM10002 ] [ Included in pressure gauge set FKM10002 ] Section 60 page 170 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 30: Air Brakes up to Serial No. 398655 IMPORTANT: To ensure proper function of the trailer brake valve, the tractor brakes must be in full working order. Make sure that hydraulic brakes and trailer brake valve have been bled properly, and that there are no leaks in the brake system. [1] - For brake pressure check: Connect pressure gauge (A) to coupler plug. [2] - For pilot pressure check: Remove bleed screw from trailer brake valve. Install ring L76408 on fitting KJD10128 (J). Screw in fitting and connect pressure gauge (H). [3] - Heat hydraulic oil to 50°C (120°F). [4] - Run the engine at 1500 rpm. [5] - Read pressure with brake pedal not depressed. With brake pedal not depressed, no pressure must be shown! [6] - If pressure ratio of trailer brake valve is 1:6 Depress the right brake pedal until a pilot pressure of 930 - 1070 kPa (9.3 - 10.7 bar; 134.9 155.2 psi) is obtained. The brake pressure at the coupler must now be 6000 kPa (60 bar; 870 psi). Repeat the test at the following values: Pilot pressure at brake valve: 1700 kPa (17 bar; 246 psi). Brake pressure at coupler: 9400 - 10800 kPa (94 - 108 bar; 1364 - 1568 psi) Maximum pressure test: Pilot pressure at brake valve: 2000 - 2300 kPa (20 - 23 bar; 290 - 330 psi) Brake pressure at coupler: 12000 - 14000 kPa (120 - 140 bar; 1740 - 2031 psi) [7] - If pressure ratio of trailer brake valve is 1:9 Depress the right brake pedal until a pilot pressure of 1100 kPa (11 bar; 160 psi) is obtained at the trailer brake valve. Brake pressure at coupler: 9500 - 10800 kPa (95 - 108 bar; 1378 - 1566 psi) Perform the maximum pressure test at the following pressure. Pilot pressure at brake valve: 1400 kPa (14 bar; 203 psi) Brake pressure at coupler: 12000 - 14000 kPa (120 - 140 bar; 1740 - 2031 psi) Up to serial no. 466428: If the brake pressure at the coupler does not correspond to the specification quoted, the trailer brake valve must be dismantled and cleaned. From serial no. 466429: If the brake pressure at the coupler does not correspond to the specification quoted, the screen has to be cleaned, seeHydraulic Trailer Brake Valve from Serial No. 466429. <- Go to Section TOC Section 60 page 171 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 30: Air Brakes up to Serial No. 398655 Group 30 - Air Brakes up to Serial No. 398655 Air Brakes up to Serial No. 398655 (Summary of References) ”Special tools” ”Specifications” ”Safety instructions” ”Screw union installation” ”Changing the compressor” ”Gaskets for the compressor” ”Change compressed air tank” ”Change the preload valve” ”Changing the pressure-relief valve” ”Changing the pressure-regulating valve” ”Changing the trailer control valve (dual-line + single-line brake)” ”Changing the trailer control valve (single-line brake)” ”Change the coupling ends” ”Change the pressure gauge” ”Test sequence” ”Check the system for leaks” ”Checking the ”Supply” coupling end” ”Checking the dual-line brake” ”Checking the single-line brake” ”Adjusting the handbrake (with air brake system)” Special tools →NOTE: Order tools according to information given in the U.S. SERVICEGARD SERVICEGARD ™ Catalog or in the European Microfiche Tool Catalog (MTC). Pressure test kit KJD10194 <- Go to Section TOC Section 60 page 172 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 30: Air Brakes up to Serial No. 398655 Checking the air brake system <- Go to Section TOC Section 60 page 173 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 30: Air Brakes up to Serial No. 398655 Repair specifications Item Measurement Specification Operating pressure (downstream of pressureregulating valve) Pressure 790 to 830 kPa (7.9 to 8.3 bar; 115 to 120 psi) Leak test Pressure drop within a period of 10 min max. 16 kPa (0.16 bar; 2.3 psi) Dual-line brake check Pressure with foot brake or hand brake engaged 700 to 740 kPa (7.0 to 7.4 bar; 102 to 107 psi) Single-line brake check Pressure with foot brake and hand brake disengaged 500 to 540 kPa (5.0 to 5.4 bar; 73 to 78 psi) —15 L (3.96 US.gal.) Time approx. 2.25 minutes at rated speed Compressed air line for pressure gauge Torque 14 N˙m (10 lb-ft) Cylinder head screws Torque 20 N˙m (15 lb-ft), then turn an additional 90° Hex. nut, belt pulley to crankshaft Torque 100 N˙m (75 lb-ft) Screws, belt pulley to crankshaft Torque 25 N˙m (20 lb-ft) Screws on connecting rod bearing Torque 6 N˙m (4.5 lb-ft), then turn an additional 70° Screws, bearing flange to crankcase Torque 12 N˙m (9 lb-ft) Time required to fill compressed air tank Air compressor Safety instructions IMPORTANT: Safety instructions IMPORTANT: When performing the work described here, comply with the safety instructions in section 05. IMPORTANT: Work on the brake system must be performed by qualified personnel only. <- Go to Section TOC Section 60 page 174 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 30: Air Brakes up to Serial No. 398655 IMPORTANT: Absolute cleanliness is essential when working on the air brake system. IMPORTANT: When replacing components of the air brake system, check for deposits caused by burnt oil. If necessary, remove such deposits. IMPORTANT: Before working on the air brake system, all pressure must be released from the system by activating the drain valve (A). Never do any welding on the air brake system. <- Go to Section TOC Section 60 page 175 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 30: Air Brakes up to Serial No. 398655 Screw Union Installation Use a tool for cutting plastic pipe or a sharp knife to cut straight across the plastic hose. After cutting the hose,carefully de-burr the ends; do NOT make the ends sharp. Install collar nut (A), cutting ring (B) and sleeve (C). Install the cutting ring (B) with the thick section first (narrower section facing the hose end). Push sleeve (C) on until its collar is in contact. <- Go to Section TOC Section 60 page 176 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 30: Air Brakes up to Serial No. 398655 When hose (A) is ready, slide it on as far as it will go and tighten the collar nut by hand as far as it will go in relation to the cutting ring. Then use a wrench to tighten the collar nut by a further 1 1/2 to 1 3/4 turns. Change the Compressor LEGEND: A B C D E Pressure Oil Line Return Oil Line Air Intake Line Compressed Air Line Cap Screws Relieve tension on drive belt (see Relieving Tension on the Drive Belt in Section 30, Group 20). Remove drive belt. Disconnect lines (A), (B), (C) and (D). Remove the four cap screws (E). Re-install in reverse order. <- Go to Section TOC Section 60 page 177 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 30: Air Brakes up to Serial No. 398655 Gaskets for the Compressor <- Go to Section TOC Section 60 page 178 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES <- Go to Section TOC Group 30: Air Brakes up to Serial No. 398655 Section 60 page 179 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES LEGEND: A B C D E F G H I J K L M N O Group 30: Air Brakes up to Serial No. 398655 Aluminium ring Plug Cylinder head screw (4 used) Cylinder head Gasket Valve plate Gasket Crankcase (compressor) O-ring Bearing quill Seal ring Nut Hex. socket screw (4 used) Aluminium ring Plug When replacing the gaskets, refer to the drawing opposite. After assembly, take out plug (O). Add approx. 0.25 L (0.065 US.gal.) of engine oil to the crankcase. Tightening torques for installing the screws: Tighten cylinder-head screws (C) cross-wise to 20 N˙m (15 lb-ft). Then turn them cross-wise through a further 90°. Tighten hex. nut (L; belt pulley to crankshaft) to 100 N˙m (75 lb-ft). Tighten the screws used in assembling the belt pulley (not illustrated) to 25 N˙m (20 lb-ft). Tighten the screws on the con-rod bearing (not illustrated) to 6 N˙m (4.5 lb-ft). Then turn them through a further 70°. Tighten screws (M; bearing quill to crankcase) to 12 N˙m (9 lbft). <- Go to Section TOC Section 60 page 180 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 30: Air Brakes up to Serial No. 398655 Changing the compressed air tank Support the tractor properly and remove the right rear wheel. Disconnect lines (A), (B), (C) and (D). Disconnect cable (E) on preload valve Remove the two cap screws (F). Replace the compressed air tank with a new one. For installation, reverse the removal procedure. Tighten line (D) to the following torque: Item Measurement Specification Compressed air hose Torque 14 N˙m (10 lb-ft) <- Go to Section TOC Section 60 page 181 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES LEGEND: 1 2 3 4 5 6 7 8 9 10 Group 30: Air Brakes up to Serial No. 398655 Test and filler connection Fitting Lock nut Thrust ring O-ring Compressed air tank Bracket Drain valve Elbow fitting Fitting Changing the preload valve Support the tractor properly and remove the right rear wheel. Disconnect cable (A) on preload valve (D). Remove cap screws (B). Loosen collar nuts (C and E) and pull out hoses. <- Go to Section TOC Section 60 page 182 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 30: Air Brakes up to Serial No. 398655 Remove preload valve (D). For installation, reverse the removal procedure. Item Measurement Specification Preload valve cap screw (M8x50) Torque 28 N˙m (20 lb-ft) Changing the Pressure-Relief Valve Disconnect the hoses (A and B) at the collar nuts. Take out cap screws (C) and remove pressure-relief valve (D). For installation, follow removal procedure in reverse order. Item Measurement Specification Preload valve, cap screw (M8x75) Torque 28 N˙m (20 lb-ft) Changing the pressure-regulating valve <- Go to Section TOC Section 60 page 183 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 30: Air Brakes up to Serial No. 398655 IMPORTANT: Before carrying out any work, be sure to observe all safety instructions. Support the tractor properly and remove the right rear wheel. Loosen collar nut (A) and remove cap screws (B, C). Move pressure-regulating valve and preload valve (D) to the back. Remove the hose clamp (A) and take out the damping element (B). Loosen the lock nut (C) and remove the pressure-regulating valve by turning it. For installation, reverse the removal procedure. Changing the trailer control valve (dual-line + single-line brake) <- Go to Section TOC Section 60 page 184 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 30: Air Brakes up to Serial No. 398655 Tilt cab (see "Tilting cab" , section 90, group 00). Support the tractor properly and remove the left rear wheel. Disconnect linkage (A) at handbrake. Disconnect lines (B), (C), (D), and (G) and remove the dual-line brake valve (F) from the bracket (E). For installation, reverse the removal procedure. Adjust linkage (A) so that the threaded pin lies easily (tension-free) in the detents when the handbrake is released. →NOTE: Bleed the hydraulic brakes (see "Bleeding the foot brakes" , section 60, group 20). <- Go to Section TOC Section 60 page 185 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 30: Air Brakes up to Serial No. 398655 Changing the trailer control valve (single-line brake) LEGEND: A B C D E Hose to coupling end “black, single-line brake” Hose to trailer control valve (dual-line brake) Hose from trailer control valve (dual-line brake) Hose to trailer control valve (dual-line brake) M20x60 cap screw Support the tractor properly and remove the left rear wheel. Disconnect hoses (A), (B), (C) and (D). Remove screw (E). For installation, reverse the removal procedure. →NOTE: Bleed the hydraulic brakes, see “Bleeding the brakes (Power-Fill brakes and MFWD and disk brake)” , section 60, group 15. Exploded view of trailer control valve <- Go to Section TOC Section 60 page 186 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES LEGEND: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Group 30: Air Brakes up to Serial No. 398655 Bracket O-ring Thrust ring Lock nut Elbow fitting Cutting ring Backup sleeve Collar nut Hose (from trailer control valve; dual-line brake) Hose (to trailer control valve; dual-line brake) Hose (to trailer control valve; dual-line brake) Lock nut Thrust ring O-ring Trailer control valve (single-line brake) Single-line brake <- Go to Section TOC Section 60 page 187 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 30: Air Brakes up to Serial No. 398655 Changing the Coupling Ends <- Go to Section TOC Section 60 page 188 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES LEGEND: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 Group 30: Air Brakes up to Serial No. 398655 Plug (M22x1) Quick-release valve O-ring Pressure ring Hex. nut Elbow fitting Elbow fitting Hex. nut Fitting Pressure ring O-ring Coupling end (red, supply) Bracket Coupling end (black, single-line brake) Fitting Coupling end (yellow, dual-line brake) Hex. nut Hose Hose clamp Elbow fitting Cap screw Disconnect the appropriate line (A). Disconnect the appropriate coupling end (B) and take out the screw-in element. For installation, follow removal procedure in reverse order. Changing the Pressure Gauge Take pressure gauge (A) out of its housing. Take out plug (C) and remove line (B). Re-install in reverse order. <- Go to Section TOC Section 60 page 189 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 30: Air Brakes up to Serial No. 398655 Tighten line (B) to 14 N˙m (10 lb-ft). Install toothed disks (D) between bracket (E) and the pressure gauge housing. <- Go to Section TOC Section 60 page 190 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 30: Air Brakes up to Serial No. 398655 Test Sequence IMPORTANT: Before checking the air brakes, make sure that the tractor′s brakes are operating correctly. Visual check Operational check Test run Check for any damage: Check that components function correctly: Test drive the tractor, operate the components: •Do the lines and hoses rub? •Compressor drive •Leaks in the system •Loose or defective attachments? •Air cleaner •Reaction time •Coupling ends, function and condition •Lube supply •Variability of trailer control valve •Is there corrosion or dirt in the system? •Pressure control valve •Handbrake •Linkage, cables and joints must move freely. Any sign of damage? •Trailer control valves •Any build-up of burnt-oil deposits? •Pressure gauge •Drain valve •Pressure limiting valve (if equipped) •Time taken for filling <- Go to Section TOC Section 60 page 191 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 30: Air Brakes up to Serial No. 398655 Checking the system for leaks [1] - LEGEND: A B KJD10194-1 pressure gauge KJD10194-2 test hose Connect pressure test kit KJD10194 to test/filler connection Pressure test kit KJD10194 Checking the air brake system for leaks [2] - Run engine at a speed of 1200 rpm until the pressure-regulating valve switches off. [3] - Shut off engine. [4] - Wait until the pressure-regulating valve stabilizes. It takes at least one minute for the valve to stabilize. Now check the pressure reading.Pressure must be between 790 and 830 kPa (7.9 - 8.3 bar; 115 - 120 psi). [5] - Check the pressure reading again after 10 minutes.Pressure drop within a period of 10 minutes must not exceed 16 kPa (0.16 bar; 2.3 psi). [6] - If pressure drops too fast, check all connections for leaks by applying soap. Check the Supply Coupling End <- Go to Section TOC Section 60 page 192 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES LEGEND: A B C D Group 30: Air Brakes up to Serial No. 398655 KJD10194-1 Pressure Gauge KJD10194-2 Hose KJD10194-5 Coupling End (Red) KJD10194-7 Test Fitting [1] - Connect the KJD10194 pressure test kit to the red Supply coupling end. [2] - Run the engine until the air brake system reaches operating pressure. CAUTION: Pressure at the coupling end must be between 790 and 830 kPa (7.9 and 8.3 bar; 115 and 120 psi). <- Go to Section TOC Section 60 page 193 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 30: Air Brakes up to Serial No. 398655 Check the Dual-Line Brakes LEGEND: A B C D KJD10194-1 pressure gauge KJD10194-2 hose KJD10194-4 coupler (yellow) KJD10194-7 test fitting →NOTE: Before bleeding the brakes, see reference ”Bleeding the Brakes (Power-Fill Brake Valve with MFWD and Disk Brake)” or”Bleeding the Brakes (Brake Valve without Power-Fill)”in Section 60, Group 20. [1] - Make sure that the hydraulic brakes and the trailer control valve are bled correctly. Make sure there are no leaks anywhere in the brake system. [2] Pressure test kit KJD10194 Pressure testing (dual-line brakes) Connect the KJD10194 pressure gauge set to the coupler (yellow). [3] - Run engine until the air brake system reaches its operating pressure. [4] - Read pressure with handbrake and foot brakes not applied. With neither footbrake not handbrake applied, the pressure reading at the yellow coupling end should be zero. Tractors with MFWD and disk brake With neither footbrake nor handbrake applied(but ignition on) , the pressure reading at the yellow coupling end should be zero. With neither footbrake nor handbrake applied(but ignition off) , pressure should be between 100 and 160 kPa (1.0 and 1.6 bar; 14.5 and 23.22 psi). <- Go to Section TOC Section 60 page 194 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 30: Air Brakes up to Serial No. 398655 [5] - Apply foot brakes and read pressure. With brake pedal fully depressed, pressure at the yellow coupling end should be between 650 and 810 kPa (6.5 and 8.1 bar; 94 and 118 psi). [6] - Release foot brakes. No pressure should be registered any more. [7] - Apply handbrake and read pressure. With handbrake applied, pressure at yellow coupling end should be between 650 and 810 kPa (6.5 and 8.1 bar; 94 and 118 psi). <- Go to Section TOC Section 60 page 195 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 30: Air Brakes up to Serial No. 398655 Checking the Single-Line Brakes LEGEND: A B C D KJD10194-1 pressure gauge KJD10194-2 hose KJD10194-3 coupler (black) KJD10194-6 test fitting →NOTE: Before bleeding the brakes, see reference ”Bleeding the Brakes (Power-Fill Brake Valve with MFWD and Disk Brake)” or”Bleeding the Brakes (Brake Valve without Power-Fill)”in Section 60, Group 20. [1] - Make sure that the hydraulic brakes and the trailer control valve are bled correctly. Make sure there are no leaks anywhere in the brake system. [2] - Connect pressure test kit KJD10194 to single-line air brake coupler (black). [3] - Run engine until the air brake system reaches its operating pressure. [4] - Read pressure with handbrake and foot brakes not applied. With handbrake and foot brakes not applied, pressure at coupler (black) should be between 500 and 540 kPa (5.0 and 5.4 bar; 73 and 78 psi). [5] - Apply foot brakes and read pressure.With the brake pedal depressed fully, the pressure reading at the black coupling end should be zero. [6] - Release foot brakes. Now pressure should once again be between 500 and 540 kPa (5.0 and 5.4 bar; 73 and 78 psi). [7] - Apply handbrake and read pressure.With the handbrake applied, the pressure reading at the black coupling end should also be zero. Adjusting the air brake system handbrake <- Go to Section TOC Section 60 page 196 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 31: Air Brakes from Serial No. 398656 If necessary, adjust linkage (A) until the prescribed pressure is reached. Item Measurement Specification Dual-line brake check Pressure with foot brake or hand brake engaged 700 to 740 kPa (7.0 to 7.4 bar; 102 to 107 psi) Single-line brake check Pressure with foot brake and hand brake disengaged 500 to 540 kPa (5.0 to 5.4 bar; 73 to 78 psi) Pressure test IMPORTANT: Other checks, such as measuring the braking force and the variability of the trailer control valve, must be carried out at properly equipped workshops. Some of these checks are included in the regular vehicle inspections prescribed by law. Exceptions may apply in certain countries. <- Go to Section TOC Section 60 page 197 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 31: Air Brakes from Serial No. 398656 Group 31 - Air Brakes from Serial No. 398656 Air Brakes from Serial No. 398656 (Summary of References) ”Special tools” ”Specifications” ”Safety instructions” ”Screw union installation” ”Changing the compressor” ”Gaskets for the compressor” ”Change compressed air tank” ”Changing the pressure-regulating valve” ”Changing the precharge valve” ”Changing the trailer control valve (dual-line brake)” ”Changing the trailer control valve (single-line brake)” ”Changing the coupling ends” ”Change the pressure gauge” ”Test sequence” ”Check the system for leaks” ”Checking the ”Supply” coupling end” ”Checking the dual-line brake” ”Checking the single-line brake” ”Adjusting the handbrake (with air brake system)” Special Tools →NOTE: Order tools according to information given in the U.S. SERVICEGARD SERVICEGARD ™ Catalog or in the European Microfiche Tool Catalog (MTC). KJD10194- Pressure gauge set for air brakes <- Go to Section TOC Section 60 page 198 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 31: Air Brakes from Serial No. 398656 Repair Specifications Item Measurement Specification Operating Pressure (Downstream of Pressure Control Valve) Pressure 790 to 830 kPa (7.9 to 8.3 bar; 115 to 120 psi) Leak Test Pressure drop within 10 minutes max. 16 kPa (0.16 bar; 2.3 psi) Dual-Line Brake Pressure with Brake Pedal Depressed or Handbrake Applied 700 to 740 kPa (7.0 to 7.4 bar; 102 to 107 psi) Single-Line Brake Pressure with Brake Pedal and Handbrake Released 500 to 540 kPa (5.0 to 5.4 bar; 73 to 78 psi) —15 L (3.96 US.gal.) Time approx. 2.25 minutes at rated engine speed Compressed-Air Line for Pressure Gauge Torque 14 N˙m (10 lb.-ft.) Cheese-Head Screws Torque 20 N˙m (15 lb.-ft.), then turn through a further 90° Hex. Nut, Belt Pulley to Crankshaft Torque 100 N˙m (75 lb.-ft.) Screws, Pulley to Crankshaft Torque 25 N˙m (20 lb.-ft.) Screws, Connecting Rod Bearing Torque 6 N˙m (4.5 lb.-ft.), then turn through a further 70° Screws, Bearing Flange to Crankcase Torque 12 N˙m (9 lb.-ft.) Compressed Air Tank Fill Time Air Compressor Safety Instructions IMPORTANT: Safety instructions IMPORTANT: When performing the work described here, also comply with the safety instructions in Section 05. IMPORTANT: Work on the brake system should be performed by qualified personnel only. <- Go to Section TOC Section 60 page 199 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 31: Air Brakes from Serial No. 398656 IMPORTANT: When working on the air brakes, cleanliness is of the utmost importance. IMPORTANT: When replacing air brake components, check for deposits caused by burnt oil. If necessary, remove such deposits. IMPORTANT: Before working on the air brakes, always make the system pressure-free. Operate drain valve (A) to make the system pressure-free. Do not carry out any welding jobs on the air brake system. <- Go to Section TOC Section 60 page 200 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 31: Air Brakes from Serial No. 398656 Screw Union Installation Use a tool for cutting plastic pipe or a sharp knife to cut straight across the plastic hose. After cutting the hose,carefully de-burr the ends; do NOT make the ends sharp. Install collar nut (A), cutting ring (B) and sleeve (C). Install the cutting ring (B) with the thick section first (narrower section facing the hose end). Push sleeve (C) on until its collar is in contact. <- Go to Section TOC Section 60 page 201 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 31: Air Brakes from Serial No. 398656 When hose (A) is ready, slide it on as far as it will go and tighten the collar nut by hand as far as it will go in relation to the cutting ring. Then use a wrench to tighten the collar nut by a further 1 1/2 to 1 3/4 turns. Change the Compressor LEGEND: A B C D E Pressure Oil Line Return Oil Line Air Intake Line Compressed Air Line Cap Screws Relieve tension on drive belt (see Relieving Tension on the Drive Belt in Section 30, Group 20). Remove drive belt. Disconnect lines (A), (B), (C) and (D). Remove the four cap screws (E). Re-install in reverse order. <- Go to Section TOC Section 60 page 202 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 31: Air Brakes from Serial No. 398656 Gaskets for the Compressor <- Go to Section TOC Section 60 page 203 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES <- Go to Section TOC Group 31: Air Brakes from Serial No. 398656 Section 60 page 204 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES LEGEND: A B C D E F G H I J K L M N O Group 31: Air Brakes from Serial No. 398656 Aluminium ring Plug Cylinder head screw (4 used) Cylinder head Gasket Valve plate Gasket Crankcase (compressor) O-ring Bearing quill Seal ring Nut Hex. socket screw (4 used) Aluminium ring Plug When replacing the gaskets, refer to the drawing opposite. After assembly, take out plug (O). Add approx. 0.25 L (0.065 US.gal.) of engine oil to the crankcase. Tightening torques for installing the screws: Tighten cylinder-head screws (C) cross-wise to 20 N˙m (15 lb-ft). Then turn them cross-wise through a further 90°. Tighten hex. nut (L; belt pulley to crankshaft) to 100 N˙m (75 lb-ft). Tighten the screws used in assembling the belt pulley (not illustrated) to 25 N˙m (20 lb-ft). Tighten the screws on the con-rod bearing (not illustrated) to 6 N˙m (4.5 lb-ft). Then turn them through a further 70°. Tighten screws (M; bearing quill to crankcase) to 12 N˙m (9 lbft). <- Go to Section TOC Section 60 page 205 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 31: Air Brakes from Serial No. 398656 Change Compressed Air Tank Support the tractor safely and remove the right rear wheel. Disconnect lines (B), (C), (D) and (E). Take out the two cap screws (A). Replace the compressed air tank with a new one. For installation, follow removal procedure in reverse order. Tighten line (B) to the following torque. Item Measurement Specification Compressed-air hose Torque 14 N˙m (10 lb-ft) <- Go to Section TOC Section 60 page 206 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES LEGEND: 1 2 3 4 5 6 7 8 9 10 11 Group 31: Air Brakes from Serial No. 398656 Test and filler connection Sealing washer Fitting Lock nut Thrust ring O-ring Compressed air tank Bracket Water drain valve Elbow fitting Fitting Changing the Pressure-Regulating Valve Support the tractor safely and remove the right rear wheel. Remove compressed air tank. Remove pressure-regulating valve (A). For installation, follow removal procedure in reverse order. <- Go to Section TOC Section 60 page 207 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES LEGEND: 1 2 3 4 5 6 Group 31: Air Brakes from Serial No. 398656 Compressed air tank Lock nut Thrust ring O-ring Pressure-regulating valve Fitting Changing the Precharge Valve <- Go to Section TOC Section 60 page 208 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 31: Air Brakes from Serial No. 398656 Support the tractor safely and remove the right rear wheel. Disconnect lines (B), (C), (D) and (E). Take out cap screws (A) and remove the precharge valve (F). For installation, follow removal procedure in reverse order. Tighten lines (B) to the following torque. Item Measurement Specification Compressed-air hose Torque 14 N˙m (10 lb-ft) Changing the Trailer Control Valve (Dual-Line Brake) <- Go to Section TOC Section 60 page 209 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 31: Air Brakes from Serial No. 398656 Support the tractor safely and remove the left rear wheel. Disconnect handbrake linkage at ball head (E). Disconnect lines (A), (B) and (C). Disconnect the brake lines (D). Remove the two screws (F). For installation, follow removal procedure in reverse order. →NOTE: Bleed the hydraulic brakes, see "Bleeding the Brakes" , Section 60, Group 15). Changing the Trailer Control Valve (Single-Line Brake) Support the tractor safely and remove the left rear wheel. <- Go to Section TOC Section 60 page 210 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 31: Air Brakes from Serial No. 398656 Disconnect lines (A), (B) and (C). Remove the two screws (D). For installation, follow removal procedure in reverse order. →NOTE: Bleed the hydraulic brakes, see"Bleeding the Brakes", Section 60, Group 15). <- Go to Section TOC Section 60 page 211 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 31: Air Brakes from Serial No. 398656 Change the Coupling Ends Disconnect the appropriate line. Disconnect the appropriate coupling end (A) and take out the screw-in element. For installation, follow removal procedure in reverse order. LEGEND: 1 <- Go to Section TOC Coupling End (Yellow, Dual-Line Brake) Section 60 page 212 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES 2 3 4 5 6 7 8 9 10 11 12 13 14 Group 31: Air Brakes from Serial No. 398656 O-Ring Thrust Ring Hex. Nut Elbow Fitting Coupling End (Black, Single-Line Brake) O-Ring Thrust Ring Fitting Hex. Nut Coupling End (Red, Supply) Cap Screw [ Coupling End (Supply) For Great Britain only ] [ Coupling End (Dual-Line Brake) For Great Britain only ] Change the Pressure Gauge Remove pressure gauge and housing from bracket. Take pressure gauge (A) out of its housing (C). Take out connector (D) and remove line (B). For installation, follow removal procedure in reverse order. Tighten line (B) to 14 N˙m (10 lb.-ft.). Install the toothed disks between bracket and the pressure gauge (C) housing. <- Go to Section TOC Section 60 page 213 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 31: Air Brakes from Serial No. 398656 Test Sequence IMPORTANT: Before checking the air brakes, make sure that the tractor′s brakes are operating correctly. Visual check Operational check Test run Check for any damage: Check that components function correctly: Test drive the tractor, operate the components: •Do the lines and hoses rub? •Compressor drive •Leaks in the system •Loose or defective attachments? •Air cleaner •Reaction time •Coupling ends, function and condition •Lube supply •Variability of trailer control valve •Is there corrosion or dirt in the system? •Pressure control valve •Handbrake •Linkage, cables and joints must move freely. Any sign of damage? •Trailer control valves •Any build-up of burnt-oil deposits? •Pressure gauge •Drain valve •Pressure limiting valve (if equipped) •Time taken for filling <- Go to Section TOC Section 60 page 214 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 31: Air Brakes from Serial No. 398656 Check the System for Leaks [1] - LEGEND: A B KJD10194-1 Pressure Gauge KJD10194-2 Hose Connect the KJD10194 pressure test kit to the check/fill port Pressure Test Kit KJD10194 Checking the air brake system for leaks . [2] - Run engine at a speed of 1200 rpm until the pressure regulating valve switches off. [3] - Shut off the engine. [4] - Wait until enough time has elapsed for the pressure control valve to stabilize. It takes at least one minute for the valve to stabilize. Then take the pressure reading.Pressure must be between 790 and 830 kPa (7.9 and 8.3 bar; 115 and 120 psi). [5] - Check the pressure reading again after 10 minutes.Pressure drop within a period of 10 minutes must not exceed 16 kPa (0.16 bar; 2.3 psi). [6] - If pressure drops too fast, check all connections for leaks by applying soap. Check the Supply Coupling End <- Go to Section TOC Section 60 page 215 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES LEGEND: A B C D Group 31: Air Brakes from Serial No. 398656 KJD10194-1 Pressure Gauge KJD10194-2 Hose KJD10194-5 Coupling End (Red) KJD10194-7 Test Fitting [1] - Connect the KJD10194 pressure test kit to the red Supply coupling end. [2] - Run the engine until the air brake system reaches operating pressure. CAUTION: Pressure at the coupling end must be between 790 and 830 kPa (7.9 and 8.3 bar; 115 and 120 psi). <- Go to Section TOC Section 60 page 216 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 31: Air Brakes from Serial No. 398656 Check Dual-Line Brake LEGEND: A B C D KJD10194-1 Pressure Gauge KJD10194-2 Hose KJD10194-4 Coupling End (Yellow) KJD10194-7 Test Fitting →NOTE: Before bleeding the brakes, see Bleeding the Brakes (Power-Fill Brakes and MFWD and Disk Brake) orBleeding the Brakes (Brake Valve without PowerFill)in Section 60, Group 20. [1] - Make sure that the hydraulic brakes and the trailer control valve are bled correctly and that there are no leaks anywhere in the brake system. [2] Pressure test kit KJD10194 Pressure testing (dual-line brakes) Connect the pressure test kit to the coupling end (yellow). [3] - Run engine until the air brake system reaches its operating pressure. [4] - With neither footbrake nor handbrake applied, the pressure reading at the yellow coupling end must be zero. [5] - Apply foot brakes and read pressure. With brake pedal fully depressed, pressure at the yellow coupling end must be between 650 and 810 kPa (6.5 and 8.1 bar; 94 and 118 psi). [6] - Release foot brakes. No pressure should be registered any more. <- Go to Section TOC Section 60 page 217 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 31: Air Brakes from Serial No. 398656 [7] - Apply handbrake and read pressure. With handbrake applied, pressure at yellow coupling end must be between 650 and 810 kPa (6.5 and 8.1 bar; 94 and 118 psi). <- Go to Section TOC Section 60 page 218 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 31: Air Brakes from Serial No. 398656 Checking the Single-Line Brakes LEGEND: A B C D KJD10194-1 pressure gauge KJD10194-2 hose KJD10194-3 coupler (black) KJD10194-6 test fitting →NOTE: Before bleeding the brakes, see reference ”Bleeding the Brakes (Power-Fill Brake Valve with MFWD and Disk Brake)” or”Bleeding the Brakes (Brake Valve without Power-Fill)”in Section 60, Group 20. [1] - Make sure that the hydraulic brakes and the trailer control valve are bled correctly. Make sure there are no leaks anywhere in the brake system. [2] - Connect pressure test kit KJD10194 to single-line air brake coupler (black). [3] - Run engine until the air brake system reaches its operating pressure. [4] - Read pressure with handbrake and foot brakes not applied. With handbrake and foot brakes not applied, pressure at coupler (black) should be between 500 and 540 kPa (5.0 and 5.4 bar; 73 and 78 psi). [5] - Apply foot brakes and read pressure.With the brake pedal depressed fully, the pressure reading at the black coupling end should be zero. [6] - Release foot brakes. Now pressure should once again be between 500 and 540 kPa (5.0 and 5.4 bar; 73 and 78 psi). [7] - Apply handbrake and read pressure.With the handbrake applied, the pressure reading at the black coupling end should also be zero. Adjusting the Handbrake (with Air Brake System) <- Go to Section TOC Section 60 page 219 TM4756-REPAIR MANUAL Section 60 - STEERING AND BRAKES Group 40: AutoTrac Support the tractor safely and remove the left rear wheel. Apply the handbrake. Adjust linkage (A) until the prescribed pressure is reached. IMPORTANT: Other checks, such as measuring the braking force and the variability of the trailer control valve, must be carried out at properly equipped workshops. Some of these checks are included in the regular vehicle inspections prescribed by law. Exceptions may apply in cer