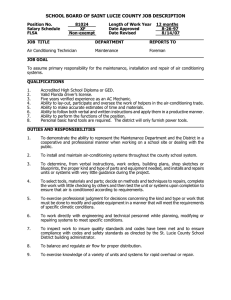

The American Society of Heating, Refrigerating and Air-conditioning Engineers (ASHRAE) defines air-conditioning as “the process of treating air so as to control simultaneously its temperature, humidity, cleanliness and distribution to meet the requirements of the conditioned space”. From the definition, the important actions involved in the operation of an air-conditioning system are: • Temperature control • Humidity control • Air filtering, cleaning and purification • Air movement and circulation Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS An air-conditioning system is for: • Temperature control • Humidity control • Air filtering, cleaning and purification • Air movement and circulation Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS The Cardinal Principle of Air-conditioning / Refrigeration is Heat Transfer……. Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Air-conditioning / Refrigeration means the reduction of the temperature of a particular space or of any substance. This is achieved by removing heat from the space where air-conditioning is required, or from the substance to be refrigerated. Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS • Any change of state transfers a large amount of energy. • At saturation temperature, materials are sensitive to addition or removal of heat. • Refrigerants use the same principles as ice. For any given pressure, all refrigerants have a saturation temperature. • If the pressure is low, the saturation temperature is low. If pressure is high, saturation temperature is high. Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS • Heat is a form of energy that is transferred from one object to another object by a difference in temperature. Heat transfer can occur, when there is a temperature difference between two or more objects. Greater the temp. difference, greater the heat transfer. • Heat will only flow from a warm object to a colder object. Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS 1 – 2 : Low Pressure Refrigerant (Gas) is Compressed to (relatively) high temperature & pressure Superheated vapour & sent via Discharge Line. 2 – 3 : Compressed Refrigerant (Gas) Condenses to low temperature & high pressure liquid by losing heat to air/water in the Condenser & sent via Liquid Line. 3 – 4 : Liquid Refrigerant Expands in volume through Expansion valve and enters Evaporator as low pressure, low temperature 2 phase saturated Liquid/Gas. Two-phase liquid-vapor mixture 4 – 1 : 2 phase Liquid/Gas Evaporates drawing heat from the Refrigerated space/object & returns via Suction Line. Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Expansion Valve Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Piston compressors are also called as reciprocating compressors and use a piston and cylinder arrangement to provide compressive force . The reciprocating motion of the piston due to external power compresses the refrigerant inside the cylinder. Piston compressors have a low initial cost and a simple, easy to install design. They have a large power output range and can reach extremely high pressures. However, they have high maintenance costs, potential vibrational issues, and are not typically designed to run continuously at full capacity. Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS TYPICAL USAGE: (a) Weld –sealed = up to 20 Tons (b) Semi-hermetic = 2 to 50 tons & (c) Open type = 5 to 150 Tons. Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Rotary compressors have two rotating elements or vanes ( like gears) , between which the refrigerant is compressed.. These compressors are very efficient because the actions of taking in the refrigerant & compressing it occur simultaneously. They have very few moving parts, low rotational speeds, low initial and maintenance costs, and can work even in very dirty environments. However, they are limited to smaller volumes of the gas and produce less pressure than other types of compressors. Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS TYPICAL USAGE: Rotary Compressors are most often used in appliances, such as refrigerators, freezers, water coolers, but it is also used for residential air conditioning and heat pump products up to 5 tons.(Nowadays upto even 7.5 tons). Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Screw compressors use a pair of helical rotors or screws which mesh together to compress the refrigerant between them. They can produce high pressure for a small quantity of gas and consume less power than reciprocating compressors.. They have low to medium initial and maintenance costs and few moving parts. However, they are difficult to operate in dirty environments, have high rotational speeds, and have shorter life expectancies than other designs. Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS TYPICAL USAGE: Screw type compressors compete with open reciprocating compressors in large commercial and industrial market, and have a wider range of capacities from 20 to 750 tons. Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Scroll compressors use two offset spiral disks nested together to compress the refrigerant. The upper disk is stationary while the lower disk moves in orbital fashion. Scroll compressors are quiet, smoothoperating units with few moving parts and the highest efficiency ratio of all compressor types. They also are more flexible for handling refrigerants in the liquid form. However, as fully hermetic designs, scroll compressors cannot be easily repaired. They also typically cannot rotate in both directions. \. Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS TYPICAL USAGE: Scroll Compressors are used from 5 to 10 tons and are popular for cooling, and for large residential and light commercial Central systems. The range is increasing nowadays up to 20 tons. Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Centrifugal compressors use the rotating action of an impeller wheel to exert centrifugal force on refrigerant inside a round chamber (volute). Unlike other designs, centrifugal compressors do not operate on the positive displacement principle, but have fixed volume chambers. They are well suited to compressing large volumes of refrigerant to relatively low pressures. The compressive force generated by an impeller wheel is small, so systems that use centrifugal compressors usually employ two or more stages (impellers) in series to generate high compressive forces. Centrifugal compressors are desirable for their simple design, few moving parts, and energy efficiency when operating multiple stages. Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS TYPICAL USAGE: Centrifugal compressors are used in systems requiring capacities of more than 150 tons and are usually available upto 10,000 tons capacity while several custom built compressors of even greater than 20,000 tons are in use. Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS • Based on flow , Evaporators can be: a. Natural Convection b. Forced Convection • Based on construction, it can be: a. Tube and Plate b. Finned type Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS Senthil Kumar, AGM(CEM) AIR-CONDITIONING BASICS