4D by Fabio Perini S.p.A.

Fabio Perini Confidential Information

1

Concept

4D

“New Chemical Engraving developed to improve paper properties”

Patented by Perini

Fabio Perini Confidential Information

2

Why is this a successful embossing technology?

Applicable to any type of embossing pattern

No visual variation to esthetics

Improves finished product resistance

Improves poor paper quality and resistance properties

Enhance good quality paper with additional resistance, bulk and absorbency

Fabio Perini Confidential Information

3

Why is this a successful embossing technology?

It can therefore be applied on cases where:

Same finished product needs to be obtained using a poorer quality of paper

Better finished product needs to be obtained using the same quality of paper

Extra features (bulk, absorbency and resistance) can be obtained

Fabio Perini Confidential Information

4

Fabio Perini Confidential Information

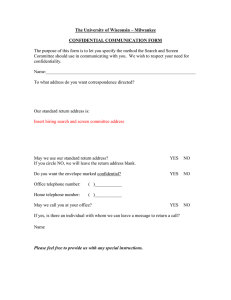

Agenda

5

Fabio Perini Confidential Information

Agenda

6

Main characteristics

Comparison to existing patterns

MECHANICAL CHEMICAL

Fabio Perini Confidential Information 7

Technical Features

Based on the orientation of the point, the side angles of the engraved object vary in order to modify the impact of the engraved point on the paper. In this manner the paper resistance can be modified upon request.

Each product request needs to be properly studied to maximize effects of new technique.

Fabio Perini Confidential Information 8

Fabio Perini Confidential Information

Technical Features

9

Main benefits

Current R&D initiatives to improve paper resistance are focused on paper making process

This solution gives a different prospective on methods that can improve paper properties using Embossing.

Initiatives to improve paper resistance can be transferred from making to converting

Fabio Perini Confidential Information

10

Suggestions/Suggested applicability

Suitable for any embossing roll technology:

• Point to point

• Desl

• Spot

• Rubber to steel

Suitable for Toilet, Kitchen towel and industrial products, even though effects on resistance are more appreciated on Kitchen towels

Fabio Perini Confidential Information

11

Suggestions/Suggested applicability

Possible to produce micro rollers, with higher density than the current one, to be used as a pre-embossing station to change the difference between the tensile strengths in MD with respect to CD

Fabio Perini Confidential Information

12

Competitors – Test results

New technology, no comparable products in the market.

Comparison results are with traditional embossing patterns.

4D Improved tensile strength 2 Plies HHT (in Dry state)

Machine Direction (MD)

Cross Direction (CD)

+13,1%

+7,8%

4D Improved tensile strength 3 Plies HHT (in Dry state)

Machine Direction (MD)

Cross Direction (CD)

Fabio Perini Confidential Information

+17,0%

+12,3%

13

Thank you for your attention www.fabioperini.com

Fabio Perini Confidential Information

16