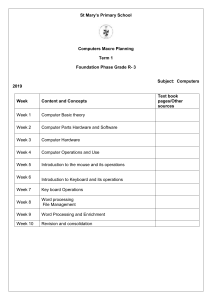

3/16/2019 January - April, 2019 A. W. Jayawardena 1 Introduction Flow in pipes is important for many reasons, for example, Study of turbulence in pipes have led to a better understanding of the turbulence in general, e.g. boundary layer The need to determine head losses in pipe systems connected via pumps and turbines Boundary shear (stress) is important in gas flow Heat and fluid transfer in engineering is always via ducts. Laminar flow exists for Reynolds Number up to about 2300 (Re = VDν ; where D is the hydraulic diameter which is 4 times the hydraulic radius). For engineering applications, Re < 2000 is considered laminar Re > 2000 is considered turbulent 层状的 3/16/2019 January - April, 2019 A. W. Jayawardena 2 Momentum equation for fully developed flow Fully developed flow refers to the condition when 0, p , u have attained their maximum values. The momentum flux for a fully developed flow is D2 4 x V V where is the momentum correction factor, given by 3/16/2019 2 u dA V2A January - April, 2019 A. W. Jayawardena 3 Momentum equation for fully developed flow.... Considering a control volume inside a pipe, we may write pD 2 4 0Ddx ( p dp) D 2 4 Fig. 1: Forces acting on a fluid element in pipe flow πD2 πD2 πD2 d p p dp τ 0 π Ddx ρβV 2 dx 4 dx 4 4 which, for fully developed incompressible flow, simplifies to dp 4τ 0 dβ dV d ρV ρV 2 β ρV βV dx D dx dx dx 3/16/2019 dp Δp 4τ 0 dx L JanuaryD- April, 2019 A. W. Jayawardena 4 Momentum equation for fully developed flow.... d ρV 0 dx Because, not depend on x. βV dβ dV 0 , 0 ; dx dx and 0 does i.e. the pressure decreases with increasing x and the pressure drop is used in overcoming wall shear stress. For developing flow, at the entrance of a pipe = 1 and approaches = 4/3 for fully developed laminar flow in circular pipes. For turbulent flow, 1.03 Therefore, for developing flow, the momentum 4τ dβ equation becomes dp ρV dx D dx 0 because 3/16/2019 2 D2V1January = D2V-2April, 2019V1 A. = W. V2 Jayawardena ; therefore, dV 0 dx and d ρV 0 . dx 5 3/16/2019 January - April, 2019 A. W. Jayawardena 6 3/16/2019 January - April, 2019 A. W. Jayawardena 7 Momentum equation for fully developed flow.... For compressible flow, dβ 0 dx but V varies with x because of density variations. Therefore, 0 and dp vary dx with x, giving, dp 4τ 0 dV βρV dx D dx 0.5 0 t0 1.0 t r0 V r u max Velocity profile and shear in laminar flow January - April, 2019 A.distribution W. Jayawardena 3/16/2019 8 Fully developed flow in pipes The pressure head per unit length, , can be obtained using dimensional analysis. Δp f ( D, k ,V , , ) L where D is the diameter of the pipe, k is the pipe roughness, V is the average velocity, and are the density and viscosity of fluid. There are six (n = 6) variables with three (m = 3) fundamental dimensions, M, L and T. Therefore, according to Buckingham’s π theorem there will be at least one set of (n - m) independent dimensionless groups in a dimensional analysis. 3/16/2019 January - April, 2019 A. W. Jayawardena 9 Fully developed flow in pipes…. Each of these will consist of m (= 3) variables in common, and are called repeating variables. The rules for selection of repeating variables are The repeating variables must include among them, all fundamental quantities Dependent variables should not be used as repeating variables For a fluid system, the most significant groups will result if the repeating variables are chosen so that one is a geometrical characteristic, one is a fluid property and one is a flow characteristic After the repeating variables are chosen, each one of the remaining variables is included in these groups. In this case, the repeating variables are D, ρ and V (average velocity). Therefore, 3/16/2019 January - April, 2019 A. W. Jayawardena 10 p L 1 D a1 b1V c1 2 D a 2 b 2V c 2 k 3 D a3 b3V c3 3/16/2019 January - April, 2019 A. W. Jayawardena 11 Fully developed flow in pipes…. Substituting the fundamental quantities M, L and T for each, it can be shown that (Twice the friction factor, f) 3/16/2019 (Relative roughness of a pipe) 3 μ VDρ ( January - April, 2019 ) A. W. Jayawardena 12 Fully developed flow in pipes…. Thus, we can write Δp 4f ρV 2 L D 2 This form of the head loss equation is called the Darcy - Weisbach equation. It can also be written as ∆p = ℎ𝑓 ρg⇒ Δp hf ρg 2 LV 4f D 2g 4fV 2 L 2Dg hf Note: The relationship that π1 is twice the friction factor f is based on the values of f given in the English system. In the US, the value of f is 4 times that defined by the above relationships. With their values of friction factor, the Darcy-Weisbach equation becomes 3/16/2019 January - April, 2019 A. W. Jayawardena 13 Fully developed flow in pipes…. f 'V 2 L 2Dg hf where f’ = 4f The friction factor f is a function of relative roughness and Reynolds Number. Δp D 4τ τ0 From Eq. dp Δp , 0 dx L 2 Δp 4f ρV Since , τ0 L D 2 L 4 D 4f ρV 2 D fV 2 D 2 4 2 The shear velocity is defined as u* 0 = V f 2 [For circular pipes, the characteristic length is D; for non-circular pipes it is the hydraulic diameter (not radius!) Dh = 4A ; hydraulic diameter is P the same as the geometrical diameter] When using US equations, appropriate adjustments should be made 3/16/2019 January - April, 2019 A. W. Jayawardena 14 Fully developed flow in pipes…. f 'V 2 L 2Dg hf where f’ = 4f The friction factor f is a function of relative roughness and Reynolds Number. Δp D 4τ τ0 From Eq. dp Δp , 0 dx L 2 Δp 4f ρV Since , τ0 L D 2 L 4 D 4f ρV 2 D fV 2 D 2 4 2 The shear velocity is defined asu* 0 = V f 2 [For circular pipes, the characteristic length is D; for non-circular pipes 4A it is the hydraulic diameter (not radius!) Type equation here.Dh = ; P hydraulic diameter is the same as the geometrical diameter] When using US equations, appropriate adjustments should be made 3/16/2019 January - April, 2019 A. W. Jayawardena 15 Critical Reynolds Number The transition from laminar to turbulent flow takes place when the Reynolds number is around 2000. The critical velocity for this Re is 2000 ucrit For water, ν =1.15x10-6 m2/s; d therefore, for a pipe of 25 mm diameter, ucrit =92 mm/s. This is a very small velocity when compared to the velocities that are normally encountered. If the velocity is to be greater, a smaller diameter would be needed. However, a diameter smaller than 25 mm is not of any practical value. For oil, ν is 200 times that of water; therefore, for a pipe of 25 mm diameter, ucrit =18.4 m/s. This means that the transition takes place when the velocity is around 18.4 m/s which is a very high velocity. Therefore, all oil flows can be considered as laminar. 3/16/2019 January - April, 2019 A. W. Jayawardena 16 Laminar fully developed flow Rounded entrance from tank Fully developed parabolic profile A Boundary layer L' Unestablished flow 3/16/2019 January - April, 2019 A. W. Jayawardena B Established flow 17 Laminar fully developed flow.... Laminar boundary layer Turbulent boundary layer Uniform flow y r0 r Fully developed turbulence U U Viscous sublayer Xc 3/16/2019 January - April, 2019 A. W. Jayawardena 18 Laminar fully developed flow.... For circular pipes, (because y = R-r; dy = -dr) u du du y dy dr Therefore, du τ dr μ dp Δp 4τ (Because, 0 dx L D Δp r L 2μ ) Integration gives (boundary conditions: u = 0 at r = R) u 1 Δp 2 R r2 4μ L which is parabolic. The discharge through the cross section is p R p R R 4 p 2 2 Q 2rudr rudr r ( R r )dr 2 L 0 2 L 0 8 L 0 R This is usually known as Hagan-Poiseuille formula. 3/16/2019 January - April, 2019 A. W. Jayawardena 19 Laminar fully developed flow.... From this velocity profile it can be seen that the 1 Δp 2 R 4μ L maximum velocity is and the average velocity is half the maximum velocity. QA udA A It can also be shown that the friction factor f is 3/16/2019 f 16μ 16 VDρ Re D January - April, 2019 A. W. Jayawardena 20 3/16/2019 January - April, 2019 A. W. Jayawardena 21 Turbulent fully developed flow In turbulent flow the velocity profile is flatter than that for laminar flow. The higher the Re, the flatter the velocity profile. This is because of the radial component of the velocity. This means steep velocity gradients at the boundary and larger boundary shear stress. (for the same Re) Turbulent flow is not as simple as laminar flow. Using statistical representation of turbulence, Taylor simplified the solution of the Navier-Stokes equations by assuming the turbulence to be homogeneous and isotropic. As a result, several velocity profiles have been proposed; e.g. logarithmic velocity profile, universal velocity profile etc. 3/16/2019 January - April, 2019 A. W. Jayawardena 22 V Laminar flow R<2000 Smooth pipe R=10 7, f=0.012 Rough pipe R=10 7, f=0.04 3/16/2019 January - April, 2019 A. W. Jayawardena 23 3/16/2019 January - April, 2019 A. W. Jayawardena 24 For example, u* u 5.75log y 5.5 u* u max u τ0 ρ u mas u 1 R n u* κ y …………… ……………. 3/16/2019 January - April, 2019 A. W. Jayawardena 25 Flow regimes in viscous flow In viscous flow, 3 flow regimes can be identified: Hydraulically smooth region - roughness elements submerged within the sub-layer 0 u* k 5 ν Transitional region - roughness elements partly submerged within the sub-layer and partly projecting outside the sub-layer 5 u* k 70 ν Hydraulically rough region - all roughness elements project outside the sub-layer u* k 70 ν 3/16/2019 January - April, 2019 A. W. Jayawardena 26 Empirical equations for friction factor for smooth and rough pipes There are many empirical equations. e.g. Blasius, Moody, Nikuradse, Colebrook etc. Moody equation for smooth pipes is of the form 3 k 10 6 f 0.001375 1 20,000 D Re 1 Colebrook equation for smooth pipes is of the form 1 Re 1.8log ( ) 6.9 f Colebrook equation for rough pipes is of the form 1 2 log f 2.51 k Re f 3.71D Von Karman equation for rough pipes 3/16/2019 1 2 log f 3.71D k January - April, 2019 A. W. Jayawardena 27 Empirical equations for friction factor for smooth and rough pipes It is important to note that For laminar flow, f depends on Re only and is not affected by k. For hydraulically smooth pipes, f for turbulent flow also depends on Re only. k For hydraulically rough pipes, f depends only on D and not on Re.(von Karman Eq.) k For smooth-rough transition zone, f depends on D and Re. 3/16/2019 January - April, 2019 A. W. Jayawardena 28 3/16/2019 January - April, 2019 A. W. Jayawardena 29 Moody diagram: (Moody, 1944) In this diagram, a single line on the left hand side corresponds to laminar flow (Re < 2000) where f varies according to f 16Re or, f Re64 For turbulent flow, the curves are based on Nikuradse’s experiments. It is also important to note that the friction factors used in some text books (US origin) are four times those used in some other text books (British). This difference can be seen in the two Moody diagrams shown below. Care should therefore be taken when using these values in the appropriate head loss equation. It is important to check the formula used in Moody diagram. If the straight line part (for laminar flow) is represented by f = 64/Re, then the equation for head loss is hf = fLV2/2gD; if the straight line part is represented by f = 16/Re, then the equation 2/2gD. 3/16/2019 January - April,be 2019 4flV A. W. Jayawardena 30 for head loss should Moody diagram (British system) 3/16/2019 January - April, 2019 A. W. Jayawardena 31 Moody diagram (US system) 3/16/2019 January - April, 2019 A. W. Jayawardena 32 Typical pipe flow problems Typical pipe flow problems can be categorised into 3 types: Type I: Given Q, L, D, , k Find hf Type II: Given hf,, L, D, , k Find Q Type III: Given hf,, L, Q , k Find D • In all cases, it is necessary to use Darcy-Weisbach equation Continuity equation Moody diagram • Very often, an iterative approach is needed. 3/16/2019 January - April, 2019 A. W. Jayawardena 33 Common problems Water supply distribution (from WSD): 3/16/2019 January - April, 2019 A. W. Jayawardena 34 Common problems Gravity flow from one reservoir to the other (whenever possible): H 3/16/2019 January - April, 2019 A. W. Jayawardena 35 Common problems Gravity flow from one reservoir to the other (whenever possible): H 3/16/2019 January - April, 2019 A. W. Jayawardena 36 Common problems rvice reservoirs: 3/16/2019 January - April, 2019 A. W. Jayawardena 37 For a sudden contraction, it can be shown (Ref. p 300, Fluid Mechanics by Streeter, Wylie, and Bedford) that 2 1 2 V hL ( - 1 ) C 2g c where Cc is the coefficient of contraction. Entrance losses - In calculating the pressure drop, it is customary to use fully developed friction factors and add a correction factor hL to account for entrance effects. 3/16/2019 January - April, 2019 A. W. Jayawardena 38 Entrance conditions h'e hf EL V2/ 2g HGL P/ v V B D C A 3/16/2019 January - April, 2019 A. W. Jayawardena 39 Submerged discharge losses EL V2/ 2g HGL (c) (a) 3/16/2019 January - April, 2019 A. W. Jayawardena (b) 40 Minor losses in pipes Losses at entrance, exit, bends, contractions, expansions and pipe fittings etc. are called minor losses. They are usually expressed as a velocity head in the form 2 V hL k L 2g where kL is loss coefficient which needs to be experimentally determined, except for sudden expansions. For a sudden expansion from A1 to A2, the loss coefficient is A k (1 ) 1 L 3/16/2019 2 A2 January - April, 2019 A. W. Jayawardena 41 Minor losses Device losses of elbows and tees. Elbow 45o : 90o : KL = 0.4 KL = 0.75 Tee line flow: KL = 0.4 branch flow: KL = 1.5 http://www.youtube.com/watch?v=t8aDK3gaqo0 3/16/2019 January - April, 2019 A. W. Jayawardena 42 Minor losses Device losses of valves: 3/16/2019 January - April, 2019 http://www.youtube.com/watch?v=zqYbHBWE1XI http://www.youtube.com/watch?v=bRHGt83RWEQ http://www.youtube.com/watch?v=9h4YcBLTJJ8 A. W. Jayawardena 43 Minor losses Device losses of valves: Globe valve KL = 10.0 (fully open) KL = 12.5 (½ open) Gate valve fully open KL = 0.2 ¾ open 0.9 ½ open 4.5 ¼ open 20.0 3/16/2019 January - April, 2019 A. W. Jayawardena 44 Example 1: Determine the size of galvanized steel pipe needed to carry water a distance of 180 m at 85l/s with a head loss of 9 m. hf 9 4 f (180) 0.085 2 1 ( 2 ) D D / 4 2(9.81) D 5 0.0478 f 0.085 D 9.49 x10 4 Re = D 2 / 4 1.14x10 6 D VD For galvanized steel, k = 0.15 mm Try f = 0.006. Then D = 0.1956 and Re = 4.85 x 106; k 0.00077. D k , Moody diagram gives f = 0.00475. D k Substituting back, D = 0.1867 and Re = 5.08 x 105; 0.00080. D For these values, f = 0.0048 which is close enough to the previous value. Therefore, use a diameter of 200 mm. For these values of Re and 3/16/2019 January - April, 2019 A. W. Jayawardena 45 3/16/2019 January - April, 2019 A. W. Jayawardena 46 Fig. xx: Energy grade line (EGL) and Hydraulic grade line (HGL) 3/16/2019 January - April, 2019 A. W. Jayawardena 47 Example 2: Calculate the steady rate at which water will flow through a cast iron pipe 100 mm diameter and 1200 m long under a head of 50 m. For cast iron, k = 0.25 mm; therefore k 0.0025 D Assume f = 0.0065 (guessed). Then, 4 fL V 2 4x 0.0065x1200 V 2 50 = D 2g 0.10 19.62 Re V 1.733m / s. 1.733x0.10 6 0 . 15 x 10 1.14 x10 -6 For this pair of Re and Therefore, Q 3/16/2019 D 2 4 k , Moody diagram gives a f value of 0.0065 which is close enough. D V 14l / s. January - April, 2019 A. W. Jayawardena 48 Example 3: Oil of specific gravity 0.83 and dynamic viscosity 0.08 kg/m.s passes through a circular pipe of 12 mm diameter with a mean velocity of 2.3 m/s. Determine the (i) (ii) (iii) (iv) Reynolds Number Maximum velocity Volumetric flow rate Pressure gradient along the pipe VD (0.83x1000)(2.3)(12 x10 3 ) Re 286.35 0.08 This value of Re is small enough to have laminar flow. Maximum velocity = 2V = 4.6 m/s Flow rate Q = Area x Average velocity = (0.012) 2 4 x2.3 2.601x10 4 m3/s. 8 x 2.601x10 4 x0.08 8Q 40886 Pa / m Pressure gradient = = (0.006) 4 R 4 3/16/2019 January - April, 2019 A. W. Jayawardena 49 Example 4 Derive an expression for the power required to pump a volumetric flow rate of Q through a horizontal pipe-line of constant diameter D, length L and friction factor f assuming that the only losses in the pipe-line are due to friction only For the purpose of project calculations the total cost of moving a fluid over a distance by pipe-line at a steady flow rate Q can be broken down into two parts. First, the manufacture, laying and maintenance including interest charges are represented by the cost C1, which is proportional to D3. The second item C2 depends solely on the energy required to pump the fluid. A preliminary design study for a particular project showed that the total cost was a minimum for D = 600 mm. If fuel prices are increased by 150%, and assuming only C2 is affected, make a revised estimate of the optimum pipe diameter. (Example 7.4, Mechanics of Fluids by B. Massey and J. Ward-Smith, 8th edition) • • gh f Q p 4 fLV 2 4 fLV 2 P ; hf p g 2 gD 2D Power required, P: From continuity, V Q D 2 / 4 Eliminating V and substituting for ∆p, 32 fLQ 3 P 2D 5 From the expression for power, C2 is proportional to D-5 3/16/2019 January - April, 2019 A. W. Jayawardena 50 Example 4 Total cost C= C1 + C2 = aD3 + bD-5 C is a minimum when i.e. when D8 dC 3aD 2 5bD 6 0 dD 5b 5b , or , D 8 3a 3a The diameter of the original pipe is given by The diameter of the new pipe, D2 is given by D2 8 Therefore, D1 8 5b1 3a 5b2 8 5(2.5b1 ) 3a 3a D2 8 2.5 D1 8 2.5(600) 673mm 3/16/2019 January - April, 2019 A. W. Jayawardena 51 Calculation Example with Minor Losses Finding pipe size for a given discharge (previous example) A smooth-walled pipeline 3500 m long is to connect two reservoirs whose free water surfaces are 7 m different in elevation. If a flow of water (under gravity) at 0.03m3/s is required, what pipe diameter should be used? Answer considering only pipe friction d = 0.228 m Now include the following device losses: Entry is abrupt Outlet is a conical diffuser Two globe valves Five 60 bends 3/16/2019 January - April, 2019 A. W. Jayawardena 52 Calculation Example with Minor Losses Solution d = 0.228 m, without minor losses Use the data for minor losses from handbook In the form of equivalent pipe length: – – – – 3/16/2019 an abrupt entry is equivalent to a diffuser outlet is equivalent to a globe valve is equivalent to a 60 bend is equivalent to 25 diameters of pipe 6 diameters of pipe 75 diameters of pipe 22 diameters of pipe The total additional length of pipe equivalent to all fittings is: 25 + 6 + (275) + (522) = 291 diameters 8 flQ 2 5 d 2 or a effective length of: 2910.228 = 66 m gh f Thus total (equivalent) length of pipeline is : 3500+66 = 3566 m With this length, new d5 = old d5 3566/3500 new d = 0.229 m (Minor losses!) January - April, 2019 A. W. Jayawardena 53