Crystallinity in polymers: an

historical view

Geoffrey Allen"

We still have much to learn about the morphologies of

natural and synthetic polymers crystallized in bulk.

Nevertheless, conventional X-ray and thermodynamic

studies of crystallinity in polymeric materials over the past

60 years have given us a clear picture of the concept of

crystallinity and the molecular features which promote

crystallinity in these substances. Apart from issues of chain

connectivity, the science of conventional molecules proved

adequate for the task!

A few liquids of low molecular weight do not

readily crystallize. Apparently these substances are

composed of molecules that have some difficulty

in arranging themselves into a crystalline array.

The molecules usually have bulky substituent

groups which offer steric resistance to folding into

a compact form suitable for efficient packing in a

crystal lattice. Such liquids, on cooling, become

very viscous and ultimately form glasses at

temperatures around — 100°C. In this solid state

they show no sharp X-ray diffraction rings

indicative of randomly orientated crystals. In fact,

the diffuse X-ray diffraction pattern observed is

very similar to that of the corresponding liquid,

showing that the glassy solid has no long-range

molecular order. Some of these liquids can be

crystallized by holding a sample for many hours at

a specific temperature, some 20°C above the glass

formation temperature, until the substance suddenly

begins to crystallize. On warming, the melting point

of the crystals is well defined and located about

40—60°C above the temperature of glass formation.

Given that some relatively simple small molecules

find difficulty in forming crystals, what are we to

expect of the behaviour of polymer molecules?

A typical simple polymer molecule has some

10000 repeat units covalently linked into a long

chain, for example:

polyethylene-

-(CH 2 -CH 2 HCH 2 -CH 2 HCH 2 -CH 2 HCH 2 -CH 2 )-

polyethyleneoxide

-(CH 2 -CH 2 -OHCH 2 -CH 2 -O)-

and the chains may not be linear, as is often the case in polyethylene: for example

—CH2— CH2— CH2— CH—CH2—CH2—CH2—CH2—CH—CH2—CH2—

CH 2

CH2

CH 2

CH2

CH3

CH2

I

I

CH2

"Kobe Steel Ltd., Alton House, 174/177 High Holborn,

London WC1V 7AA, UK.

1062-7987/93/020197-10 $10.00

© 1993 by John Wiley & Sons, Ltd.

CH3

EUROPEAN REVIEW, Vol. 1, No. 2, 197-206 (1993)

Geoffrey Allen

198

since molecular branches can be formed during the polymerization process.

Even the linear chains of larger monomer units will have sizeable side groups: for example

polystyrene

CeHs

C9H5

C6H5

I

I

I

-CH 2 -CH-CH 2 -CH-CH 2 -CHCH3

CH3

CH3

I

I

I

polypropylene -CH 2 -CH-CH 2 -CH-CH 2 -CHR

R

R

I

polypeptide

I

I

-CH-C-NH-CH-C-NH-CH-C-NH-

II

O

and R may represent several different side groups

in the same polypeptide chain.

Now, bear in mind that each molecule can curl

into a randomly arranged coil, by virtue of

rotations about the bonds in the main chain. The

polymer melt is composed of these randomly

coiled chains and each chain is wriggling rapidly

through millions of conformations. Furthermore,

the long chains are entangled. To fit into a crystal

lattice, a chain must uncoil a well-defined section

of say 10—20 monomer units and align that section

with a similar one from another part of the same

chain or of a neighbouring chain. If a sufficient

number of segments can line up to form a stable

nucleus then crystal growth can occur. A priori, it

would seem to be an event of low probability even

in polymers composed of linear long chains of the

simplest chemical structure!

In fact, crystallization offlexiblechain molecules

of sufficient structural regularity is widely observed

in naturally occurring polymer systems such as

polypeptides, carbohydrates and natural rubber, as

well as in those of synthetic origin. The first

recorded observation was made by John Gough1

in a letter to the Manchester Literary and

Philosophical Society in 1805:

' If a thong of Caoutchouc be stretched, in water

warmer than itself, it retains its elasticity

unimpaired. If the experiment be made in water

cooler than itself, it loses part of its retractile

power, being unable to recover its former figure;

but let the thong be placed in hot water, while

it remains extended for want of spring, and the

heat will immediately make it contract briskly'.

Gough did not realize he was witnessing the partial

II

O

II

O

crystallization of the rubber strip followed by its

melting in the warmer water.

The systematic study of crystalline polymers

parallels the development of polymer science from

its origins in the early 1920s. Following the

discovery that crystalline substances diffract X-rays

and that the diffraction pattern can be resolved to

give unit cells and hence crystal structures, Michael

Polanyi (in his days as a physical chemist, before

he became a professional philosopher) obtained

diffraction patterns from a bundle of parallel ramie

fibres. Polanyi2 concluded that the pattern of spots

corresponded to crystallites of cellulose orientated

with one axis parallel to the fibre axis. The

empirical structure of cellulose was known to be

C 6 H 10 O 5 ; Polanyi found that the unit cell was

orthorhombic, measuring 7.9 x 8.4 x 10.2 A (1 A =

10~ lo m). He concluded that the cell contained

either two cyclic disaccharides or two disaccharide

units of polysaccharide chains. The concept of the

existence of polymer chains was not at the time

accepted by organic chemists and the second

option was not well received. Polanyi3 wrote in his

memoirs in 1962:

'Unfortunately I lacked the chemical sense for

eliminating the first alternative . . .

I was gleefully witnessing the chemists at cross

purposes with conceptual reform . . .

I should have been better occupied in definitely

establishing the chain structure.'

In the mid 1920s, Katz4 observed that an

amorphous natural rubber strip when extended

six-fold produces a sharp X-ray diffraction pattern

' characteristic of a body containing crystallites' in

addition to the amorphous halo. Katz estimated

Crystallinity in polymers

that the same cell could only accommodate three

isoprene units. In the same year, 1925, Staudinger

and his colleagues5 published studies of 'oligomers

and high polymers' (that is polymer chains so long

that the molecular weight could not be determined

by the methods then available) of formaldehyde,

• • -O-CH 2 -O-CH 2 -O-CH 2 -O-CH 2 -- • •

X-ray diffraction from the oligomers showed

reflections characteristic of the length of the

extended molecules but in addition there were

reflections due to a subcell that enclosed sections

of the chain. As the length of the oligomers

increased, the subcell reflections became more

pronounced and it was possible to retain by

extrapolation the diffraction pattern of the high

polymer. By 1928, X-ray studies by K. H. Meyer

and Herman Mark6 demonstrated that the crystal

structures of cellulose, silk fibroin, chitin and

natural rubber were due to the packing of

long-chain molecules. The concept of a long-chain

molecule was fully accepted.

The paper on silk fibroin described for the first

time a polypeptide chain in the fully extended

conformation—now known as the ^-structure.

In the next decade Astbury7 found that there were

two crystalline forms, a and /?. Later, from

crystallographic measurements on aminoacids and

peptides Pauling and his school argued that the

/?-form was composed of helical molecules with 3.6

amino acids per turn and a pitch of 1.5 A. Pauling8

deduced this structure from molecular models as

well as crystallographic data. Later still, this

combination was to be crucial in the work of Crick

and Watson9 on the structure of DNA. The X-ray

diffraction method is now a cornerstone of

molecular biology.

Many common synthetic polymers such as

polystyrene and polymethylmethacrylate (Perspex)

did not crystallize, they were only available as

glassy (amorphous) substances in the solid state.

Furthermore, the various known forms of

polyethylene crystallized only to a degree of about

40%, that is, they remained a mixture of crystalline

and amorphous fractions. However, in the early

1950s Ziegler10 reported a new family of catalysts

which produced highly crystalline polyethylene of

high molecular weight. Natta11 reported similar

catalysts which produced crystalline versions of

polymers such as polystyrene, polymethylmethacrylate and polypropylene of high molecular weight.

199

These new materials were effectively the last links

in establishing the molecular structure criteria for

crystallizable polymers.

The new forms of polyethylene contained linear

chains or chains with very few branch points. Natta

showed from crystallographic data that his

polymers, which had pendant side groups, had

structural regularity, i.e. stereoregularity.

The so-called isotactic polymer chain of the

R

I

polymer -CH-CH 2 - (e.g., polystyrene or polypropylene) has all the pendant groups on the same

side of the plane of the carbon atoms as shown in

Figure l(a). In the syndiotactic form, the pendant

groups alternate strictly on either side of the chain

as in Figure l(b). The atactic form has the pendant

groups placed at random on either side of the chain

as in Figure l(c). The Ziegler/Natta catalysts

produce long runs of either iso- or syndiotactic

chain sequences with much shorter sections of

atactic sequences. The isotactic chains are regular

and can fit into a crystal lattice; so can syndiotactic

chains, although the resulting structure will be

different. Polymers composed of long atactic

sequences do not crystallize because they do not

possess sufficient steric regularity to produce stable

nuclei from which crystals can grow or allow the

chain to fit into a crystal lattice. These forms of

polymer exist only as glasses in the solid state.

Thus, the principles governing the formation of

R

R

R

R

R

|al Isoiuclic

H

VH

H

VH

H

V

V (f

V H

V H

H

(hi SMHIIOUI

|c| ALICUC

V R

Figure 1. Schematic representation of isotactic, syndiotactic and atactic vinyl polymers.

Geoffrey Allen

200

crystals in polymeric substances include the

following:

(i) The chemical repeat unit plays a role similar

to discrete molecules in crystals of a normal

organic compound.

(ii) The molecular chains must have long

sequences of stereoregularity.

(iii) Linear polymer molecules facilitate crystallization.

(iv) The unit cell contains only a small number

of repeat units.

(v) More than one chain may pass through a

unit cell.

On this basis, crystallization in all known synthetic

or natural polymers can be rationalized in terms

of the structure of the molecular chains. Apart

from the fact that a polymer molecule passes

through a large number of consecutive unit cells,

the crystal lattice is analogous to that of a simple

organic compound.

Crystallization and melting

Conceptual difficulties with the phenomenon of

crystallization in polymeric materials arise from the

fact that with the exception of polymethylene oxide

-(CH 2 -O) n - and certain proteins, macroscopic

single crystals are very rarely encountered.

Polymers do not crystallize completely; the

submicroscopic crystallites are embedded in the

remaining amorphous matrix.

X-ray diffraction again proved useful in establishing these facts. Pioneering studies in the early 1930s

showed that when a polymer is cooled slowly from

the melt (i.e., the rubbery state) sharp diffraction

rings are observed, showing that the sample

contains randomly orientated crystals. When the

sample is held in the temperature range where the

sharp rings increase in intensity, crystallization

eventually ceases, as judged from the X-ray

intensities, and there is a residual amorphous halo

demonstrating that amorphous material remains.

If cooling is continued to very low temperatures

there is no change in the pattern, despite the fact

that the sample will have changed from a rough

leathery texture to a hard solid. On warming, the

crystalline diffraction pattern disappears over a

range of temperature, but there is a well-defined

temperature at which the last traces disappear. This

melting temperature limit is some 20°C above the

temperature of the maximum rate of crystallization.

Rapid cooling often results in no crystallization

despite transformation of rubber to a hard brittle

glassy material.

Since there must be volume changes accompanying crystallization of the sample, dilatometric

studies were made to parallel the X-ray observations. The pioneering results obtained by Bekkedahl12 in 1934 on natural rubber showed a

volume-temperature curve obtained at slow rates

of cooling with crystallization and a contraction in

volume occurring near 0°C. Warming from liquid

air temperature shows a second-order change in

the volume—temperature relation at —72°C,

followed by a first-order melting process in the

range 6 to 16°C which is accompanied by an

expansion of 2.7%. This agrees with the X-ray

determination of the melting temperature of the

crystallites. By contrast, when the sample is cooled

rapidly to liquid air temperature it remains

amorphous. On warming, only the second-order

transition at — 72°C is observed as the sample

changes from glass to rubber. Thus, the melting

point of natural rubber is ~ 16°C and its

glass-transition temperature — 72°C. A combination

of X-ray and volumetric data shows that

unstretched natural rubber, taken to its limit of

crystallization, still contains some 70% of amorphous material.

Further work by Wood and Bekkedahl13

revealed behaviour which is known now to be

typical of the crystallization of many polymer

systems. First, the rate of crystallization showed a

maximum at about 0°C and the rate decreased on

further cooling—behaviour which is characteristic

of a system controlled by nucleation. Second, the

temperature range of melting was found to be a

function of the temperature at which crystallization

occurred. As the temperature of crystallization is

lowered, the temperature of melting of the crystals

produced also falls but the temperature range over

which melting is observed becomes greater, i.e.,

the melting is more diffuse. Under all conditions,

melting only begins some 5-10°C above the

crystallization temperature. To obtain the highest

melting point, crystallization must be carried out

above the temperature at which the optimum rate

of crystallization occurs. Since this is a region

where crystallization is slow, this effect has led to

Crystallinity in polymers

various melting points being reported for the same

material.

Taken together, these observations of melting

point ranges and incomplete crystallization mean

that when crystallization ceases, an equilibrium

state is not reached between the amorphous phase

and the crystalline phase. There will be a

distribution of crystallites of different degrees of

imperfection and also of different sizes. Because of

surface energy considerations, the smaller crystals

and more imperfect crystals will have lower melting

points. Further, there may be entanglements and

other constraints (for example, high viscosity) in

the amorphous phase which prevents reorganization

and recrystallization to produce an array of more

stable crystallites.

Polyethylene has provided further insights into

the nature of crystallization in polymers. Since

normal paraffins, CnH2n + 2, are well-defined chemicals, certainly up to C 94 H 190 , and within the series

their melting behaviour is very similar to that of

normal organic substances, it is possible to estimate

by extrapolation the melting point of an infinitely

long chain.

n

Tm°C

30

44

62.1

86.2

94

114.2

CO

140

The result is that polyethylene of high molecular

weight should melt at about 140°C. This result was

known at a time when polyethylene was manufactured from ethylene by a high-pressure process

using a free radical catalyst. Unfortunately, the

melting point of the product was only 115°C, well

below the estimate for a very long linear chain.

Furthermore, the polyethylene showed a limited

degree of crystallizability. From X-ray and

spectroscopic studies it was concluded that

polyethylene molecules made by this process are

highly branched. The whole issue was resolved

when Ziegler's new catalyst, which synthesized

chains with a very much lower degree of branching,

yielded highly crystalline products, initially with

melting temperatures of about 135°C and later in

the region of 140°C.

Now a strict comparison could be made of the

crystallization and melting behaviour of a polymer

201

with its discrete short-chain homologues, in this

case the n-paraffins. Figure 2(a) shows volumetemperature curves for C 44 H 90 and C 94 H 190 , and

Figure 2(b), curves for an unfractionated linear

polyethylene sample of number-average molecular

weight 32000. The dilatometric results give

evidence that it is possible to obtain melting curves

in polymers that are comparable with those of

single substances of low molecular weight. The

temperature at which the last traces of crystallinity

disappear is clearly defined for each sample. The

fact that the polymer sample contains a distribution

of chain lengths as well as some branched molecules

and a distribution of crystal imperfections does

broaden the melting range. Comparison of the

results for the polymer sample which was cooled

slowly from the melt, with the same sample

carefully crystallized at 130°C for 40 days, shows

that the latter sample attained a higher degree of

crystallinity. Both samples gave Tm = 140°C.

Thus, the differences in crystallization and

melting between substances of low molecular

weight and polymers is one of degree rather than

kind.14 Fusion in polymers is also a first-order

thermodynamic process. However, the main

difference is that polymers crystallize only in part.

This results in the observation of a glass transition,

with second-order character, in the residual rubber

phase at a temperature much lower than Tm.

Fibre formation is one of the most important

features of crystallizable polymers. The early X-ray

workers on cellulose noted that the crystallites

were orientated with their long axis parallel to the

fibre axis. In fact, the drawing of the fibre to align

the polymer molecules along the fibre axis and

hence promote the growth of orientated crystallites

is an essential feature of all synthetic fibre

processes, nylon, terylene, polypropylene, rayon,

etc. There are many natural examples, including

cotton, wool and silk. However, although these

systems attain quite high degrees of crystallinity

and because of crystallite orientation the bulk

properties are anisotropic, exactly the same

concepts of crystallization apply.

Crystallization and morphology

Crystalline polymers have the capacity to present a

complex hierarchy of morphologies extending from

Geoffrey Allen

202

T(°C)

106 108 110 112

^< ii6 118

11

<^-

14

•• 18

C

12

C

H

44 90

94 H 190

J

L

16

1

o

<u

10

CO

8•

J

6

(Q)

85

•o

o

•

14

•

o

12

86 87 88 89 90

i

I

i

i

1.3

1.25

o

o

d>

E

1.2

1.15

o

Specil

o

1.1

1.05

(b) 0.95

-40-20 0 20 40 60 80 100 120 140160 180

T (°C)

Figure 2. (a) Fusion of n-hydrocarbons. Plot of dilatometric scale reading against temperature for C 44 H 90 and

C 94 H 190 . (b) Specific volume-temperature relations for an unfractionated linear polyethylene sample. Slowly cooled

from melt o; isothermally crystallized at 130°C for 40 days, then cooled to room temperature •.

Crystallinity in polymers

203

unit cell dimensions, to crystallites in fibres and

isotropic substances of the order of 100-1000 A,

on to polycrystalline aggregates extending up to a

millimetre or so. In rare instances, macroscopic

single crystals can be obtained. At the molecular

level an individual chain may pass once or even

twice through a unit cell. The observation of

limited degrees of crystallinity attained in bulkcrystallized materials and estimates of crystallite

size suggests that a long molecule may emerge from

a crystallite, have a coiled segment embedded in

an amorphous domain and then return to the same

crystallite or enter a different one.

Thus, for many years, the accepted morphological structure of an unorientated, crystallized

polymer was the 'fringed micelle' model. 15 The

long molecules meander through a two-phase

structure in which the randomly arranged crystallites are bundles of orientated segments of polymer

chain some 100-1000 A long and the amorphous

domains are tangles of coiled chain. The model,

largely due to Bunn, is shown in Figure 3. It

incorporates the possibility that one molecule can

traverse several crystallites and the intervening

amorphous domains. Fibre formation is envisaged as

a straightening out of the chain and a consequent

growth of crystals orientated in the direction of

draw.

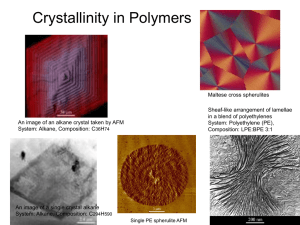

In 1945, Bunn 16 reported a larger scale of

ordering, following a study of polyethylene in a

polarizing optical microscope. These entities,

called spherulites, are micrometers in size, consisting

of approximately spherical arrays of equivalent

radiating crystalline units. It was not obvious how

(b)

Figure 4- Polyethylene lamellae crystallized from solution: (a) lozenge-shaped; (b) truncated lozenge-shaped.

(Courtesy of Dr. D. C. Bassett.)

Figure 3. Schematic representation of the fringedmicelle model (after Bunn).

the small crystallites of the fringed micelle model

could give rise to these structures since the

spherulites were orders of magnitude larger. Even

more curious and more difficult to accommodate

in the model was the observation deduced from

the optical birefringence that the polyethylene

chain axis was tangential rather than radial, i.e.,

perpendicular to the direction of the radiating

fibrils.

204

Geoffrey Allen

This difficulty remained until 1957 when

studies were made of the new linear (i.e.,

unbranched) polyethylene crystallized as individual

crystals from dilute solution. Examination in a

transmission electron microscope showed the

crystals to be lozenge-shaped, about 100 A in

thickness and several micrometres in length.

Keller17 demonstrated that within the crystal the

molecular chain axis was roughly perpendicular to

the plane of the lamella. Since the molecules were,

on average, about 1 urn long, Keller deduced that

they could be accommodated in a 100 A thick

crystal only by the chain folding back on itself

repeatedly at the crystal surfaces. These results

triggered a major international research effort on

individual lamellae and aggregates of lamellae

grown from linear polymers in solution.

Much work has been done on individual

polyethylene lamellae to validate the remarkable

finding by Keller. Electron diffraction has confirmed

that the c-axis of the unit cell is close to

perpendicular to the plane of the crystal and thus

so is the chain axis. It is accepted that each polymer

molecule folds back upon itself many times at the

upper and lower crystal surfaces (the 'fold

surfaces') rather like a Chinese cracker. However,

there is still controversy over the exact nature of

the fold. The Keller school argues that most of the

folds are tight, having four CH2 groups per turn

and molecular models show that this is quite

possible. The Flory school, mainly devoted to

thermodynamic studies, favours a model in which

a molecular chain at a surface may leave the crystal

and not necessarily return to an adjacent site via a

tight fold—a switchboard model18 in which some

folds contain a large number of carbon atoms to

re-enter the crystal at a more distant site.

Nevertheless in both models the polymer crystal

can be considered to have two components with

different properties—a well-ordered crystalline

interior plus lamellar surfaces which incorporate

the fold planes. We know now that many polymer

chains adopt folded-chain conformations in

lamellar structures. Keller himself19 has recently

recorded the history of his discovery and the

stormy debates which followed.

The form of single-crystal lamellae obtained

from a very dilute solution of polyethylene in

xylene at lower temperatures is the simple lozenge

shape with {110} growth faces. At higher

temperatures these crystals develop {100} faces

which give the lamellae the appearance of

truncated lozenges. Both forms are shown in Figure

4. Because the monolayer crystal has the c-axis of

the unit cell perpendicular to the plane of the

crystal and the crystal is bounded by growth faces

of low crystallographic index, the crystal habit is

orthorhombic, reflecting the symmetry of the unit

cell. In the same way, hexagonal monolayer crystals

are produced by polyoxymethylene and isotactic

polystyrene because they have hexagonal unit cells.

Detailed studies show that all these ' single crystals'

are actually multiple twins because the crystal habit

referred to above exists in the lamellae in a number

of crystallographic regions, each associated with a

particular growth face.

Single lamellae can only be obtained under

carefully regulated conditions. More generally,

crystallization from solution and sometimes from

the melt produces multilayered lamellar aggregates.

These multilayered aggregates result from screw

dislocation imperfections in the crystal growth

caused by chain folds which are staggered and

which give rise to the proliferation of layers. Where

such defects are limited by crystallization conditions

and slow growth occurs in solutions of moderate

concentration or where growth occurs in melts

which are only slightly supercooled, well-ordered

multilayered crystals can be obtained.

More usually in polymers, screw dislocation

defects and the splaying of lamellae generate

sheaf-like structures and ultimately the spherically

symmetrical spherulites which are the building

blocks of the morphology of polymers crystallized

in bulk. Spherulites and the arrangement of

lamellae in spherulites continue to be studied

extensively to elucidate the relation between their

structure and the macroscopic properties of the

material.

Before proceeding with crystallization in the

polymer melt we must note that spherulites are not

found exclusively in polymeric substances; they are

observed in many organic and inorganic materials

where crystallization occurs from a viscous melt.

However, the formation of spherulites is still not

well understood. In polymer systems such

understanding is made more difficult by the fact

that the direct transmission electron microscopic

observations made on individual lamellae grown

from solution cannot be applied directly to

lamellae grown from the melt. Specimens of

melt-crystallized materials have to be prepared by

Crystallinity in polymers

205

Direction of growth

Figure 6. A model lamellar fibril in a polyethylene

spherulite (after Takayanagi). The a, b, c axes depict the

orientation of the unit cell along the spiralling fibril.

Figure 5. Sheaf-like aggregates crystallized from the melt

in a blend of linear and branched polyethylene at 125°C.

(Courtesy Dr. D. C. Bassett.)

crystallizing thin films or by sectioning bulkcrystallized samples. It is not certain that the forms

produced by crystallization in a very thin film are

representative of those produced in bulk. Neither

is it certain that sectioning does not deform the

structures. Lamellar structures in bulk often have

to be deduced with the aid of two less direct

methods. Staining of samples using chlorosulphonic

acid or osmium tetroxide is one technique which

was developed originally for biological specimens.

The second technique involves a potassium

permanganate/sulphuric acid etching reagent which

selectively removes disordered material from the

surface of a specimen so that the ordered structural

features are revealed.

Bassett and his colleagues20 have provided an

insight into the origins of spherulites by crystallizing

polymers under conditions where the nucleation

density is very high and the volume available for

growth constrained so that mature spherulites do

not develop. At high crystallization temperatures,

sheaf-like structures can be seen. Figure 5 shows

the lamellar structure of a sheaf-like 'axialite'

grown from a polyethylene melt. When these

structures grow in an unconfined sample it is quite

possible that the lamellae will branch through the

mechanism of screw dislocation and then splay

apart.

Unfortunately it is difficult to quench polyethylene samples and freeze in structures developed

through these stages of growth. However, in

isotactic polystyrene it is observed that lamellae

branch through screw dislocations and this

generates spiral structures containing several

layers. Successive layers then splay apart. Since

screw dislocations develop on all growth faces this

results in three-dimensional growth. If these

mechanisms hold for the growth of the sheaf-like

polyethylene structures, eventually all solid angles

will be filled and a spherulite form produced. It is

widely believed that axialite sheaves differ in degree

only from spherulites.

Spherulite structures observed in several different

polymers have common features. By examining the

edge of a spherulite it can be shown that the thicker

lamellae develop first and, in doing so, enclose

columns of melt which later crystallize isothermally

near the centre of the spherulite or when the sample

is quenched, near the tips of the growing lamellae.

The forms of the overall structures observed are

dictated by the early-formed, thicker or so-called

dominant lamellae. The lamellae that form later are

thinner and in-fill the already established dominant

spherulite frame at interstitial sites. They are

termed subsidiary lamellae.

Using solvent extraction, it has been shown that

in polyethylene samples the longest, most linear

molecules crystallize first. Thus, they tend to be

located in the dominant lamellae. Shorter molecules

crystallize isothermally within the frame of

dominant lamellae and shorter chains still, in

regions which do not crystallize except on

quenching. Chains which do not crystallize form

a tenuous amorphous matrix. This molecular

fractionation influences macroscopic properties.

The regions in which material of lower molecular

weight is concentrated provide relatively easy

206

Geoffrey Allen

routes through which cracks propagate. This is one

reason why spherulite size and structure are

considered to be important in the control of bulk

properties of crystalline polymers.

In all structures, the observation made over 40

years ago by Bunn, that the polymer chain axes lie

tangential and not radial to the spherulite structure,

is explained by Keller's folded chain. The chains

are folded within the spiralling lamellae with the

chain axis perpendicular to the growing faces, as

shown schematically in Figure 6.

14. L. Mandelkern (1989) In Comprehensive Polymer

Science, edited by G. Allen and J. H. Bevington.

(Pergamon Press) 2,, 363.

15. C.W. Bunn (1953) Fibres from Synthetic Polymers,

edited by R. Hill. (Amsterdam: Elsevier), p. 240.

16. C.W. Bunn and T.C. Alcock (1945) Trans Faraday

Soc 41, 317.

17. A. Keller (1957) Philos Mag [8] 2, 1171; (1958)

Discuss Faraday Soc 25, 114.

18. P. J. Flory (1989) In Comprehensive Pofymer Science,

edited by G. Allen and J. H. Bevington (Oxford:

Pergamon Press).

REFERENCES

1. J. Gough (1805) Mem Lit Phil Soc Manchester 2, 288.

2. M. Polanyi (1921) Naturwiss 9, 228.

3. M. Polanyi (1962) In 50 Years of X-ray Diffraction

edited by P.P. Ewald. Vosthoek.

4. J.R. Katz (1925) Kolloid Z. 37, 19.

19. A. Keller (1991) In Sir Charles Frank: An Eightieth

Birthday Tribute, edited by R.G. Chambers, J.E. Enderby,

A. Keller, A.R. Lang and J.W. Steels (Bristol: Adam

Hilger), p. 265.

20. A.S. Vaughan and D.C. Bassett (1989) In Comprehensive Polymer Science, edited by G. Allen and J.H.

Bevington. (Oxford: Pergamon Press), 2, 415.

5. H. Staudinger and M. Luthy (1925) Helv Chim Acta

8,65.

6. K.H. Meyer and H. Mark (1928) Berichte B61, 593,

1932, 136, 1939.

7. W.T. Astbury (1938) Tram Faraday Soc 34, 378.

8. L. Pauling, R.B. Carey and H.R. Branson (1951) Proc

Nat Acad Sci USA 37, 205.

9. F.H.C. Crick and J.D. Watson (1953) Nature 171,

737, 964.

10. K. Ziegler, E. Holzkamp, H. Brell and H. Martin

(1955) Angew Chem 67, 541.

11. G. Natta, I.W. Bassi and P. Corradini (1955)

Makromol Chem 18-19, 455.

12. N. Bekkedahl (1934) J Res Nat Bur Stand 13, 411.

13. L.A. Wood and N. Bekkedahl (1946) ] Appl Phys

17, 362.

Author's biography:

Geoffrey Allen is a Fellow of the Royal Society

and a Foreign Member of the Engineering Academy

of Japan. He was formerly Professor of Chemical

Technology at the Imperial College of Science and

Technology. He then became Chairman of the

Science and Engineering Research Council and

following that appointment was Research and

Engineering Director of Unilever for nine years.

He is now Executive Adviser to Kobe Steel Ltd.

He has written numerous papers on the thermodynamic properties of polymers and on the

application of structural techniques to plastics and

rubbers.