LB115

86576312

10/98

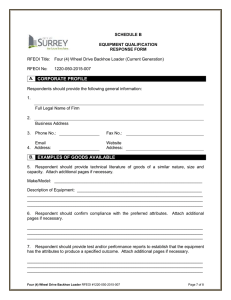

TO THE OWNER

The warranty coverage that is extended to your backhoe loader is explained in the Warranty and Limitation of

Liability form. Your dealer will provide you with a copy of the warranty and retain a copy which you have

signed. After you read the warranty, ask your dealer to explain any points that you may not understand.

This backhoe loader was designed to power and propel itself. It is intended to dig, load and move material in

normal and customary applications.

Do not modify or alter or permit anyone else to modify or alter this backhoe loader or any of its components or

any backhoe loader function without first consulting an authorized New Holland dealer. If you have any

questions regarding backhoe loader modifications, contact New Holland North America, Inc., 500 Diller

Ave., New Holland, PA 17557.

Your safety and the safety of those around you depends upon the care and good judgment you use while

operating this equipment. Read the safety precautions carefully.

After you have operated the backhoe loader for 50 hours, take your backhoe loader and this manual to your

selling dealer. He will perform the factory recommended 50-hour service. You will be responsible for the cost

of lubricants, fluids, filters and other items replaced as part of normal maintenance. Prior to taking the

backhoe loader to your selling dealer for service, it is recommended that you contact them to determine any

other charges for which you may be responsible.

All data given in this book is subject to production variations. Dimensions and weights are approximate only

and the illustrations do not necessarily show tractors in standard condition. For exact information about any

particular backhoe loader please consult your New Holland dealer.

CAUTION: THIS SYMBOL IS USED THROUGHOUT THIS BOOK WHENEVER PERSONAL SAFETY IS

INVOLVED. TAKE TIME TO READ AND FOLLOW THE INSTRUCTIONS. BE CAREFUL!

CAUTION: PICTURES IN THIS MANUAL MAY SHOW PROTECTIVE SHIELDING OPEN OR REMOVED

TO BETTER ILLUSTRATE A PARTICULAR FEATURE OR ADJUSTMENT.

BE CERTAIN, HOWEVER, TO CLOSE OR REPLACE ALL SHIELDING BEFORE OPERATING THE MACHINE.

IMPROVEMENTS

New Holland North America, Inc. is continually striving to improve its products. We reserve the right to make

improvements or changes when it becomes practical and possible to do so, without incurring any obligation

to make changes or additions to the equipment sold previously.

204

ã 1998 NEW HOLLAND NORTH AMERICA, INC.

0-1

This warranty shall NOT apply to any Product which is normally operated outside of the United States, and/or

Canada.

0-2

FEDERAL EMISSIONS WARRANTY

New Holland warrants that your new 1998 and later heavy-duty off-road diesel engine was designed, built, and equipped to conform to

applicable U.S. Environmental Protection Agency regulations for a period of use of five years or 3,000 hours of operation, whichever occurs

first.

The new model year, class of diesel engine, and emission application determination for your engine are identified on the emission control

information label affixed to the top of your engine’s rocker arm cover. The warranty period begins on the date the new equipment is sold to the

first retail purchaser.

Any emission control system parts which are proven defective during normal use will be repaired or replaced during the warranty period. The

warranty repairs and service will be performed by any authorized New Holland dealer at the dealer’s place of business, with no charge for parts

or labor (including diagnosis).

As the engine owner, you are responsible to perform all the required maintenance listed in your owner’s manual. New Holland will not deny an

emission warranty claim solely because you have no record of maintenance; however, a claim may be denied if your failure to perform

maintenance resulted in the failure of a warranted part. Receipts covering regular maintenance should be retained in the event of questions

and these receipts should be passed on to each subsequent owner of the engine.

It is recommended replacement parts used for maintenance or repairs be New Holland Service Parts to maintain the quality originally

designed into your emission certified engine. The use of non-New Holland parts does not invalidate the warranty on other components unless

the use of such parts causes damage to warranted parts.

New Holland wishes to assure the emission control systems warranty is being properly administered. If you believe you have not received the

service entitled to under this warranty, you should contact the nearest New Holland Branch Office for assistance. The address and phone

number of each Branch Office is in your vehicle owner’s manual. If additional assistance or information is needed, contact:

Service Department

New Holland North America, Inc.

500 Diller Avenue

New Holland, PA 17557

(717) 355-1121

Please note that the Emission Warranty does not cover:

1. Systems and parts that were not first installed on the new equipment or engine as original equipment by New Holland.

2. Part malfunctions caused by abuse, misuse, improper adjustment, modification, alteration, tampering, disconnection, improper or

inadequate maintenance, or use of non-recommended fuels and lubricating oils.

3. Accident caused damage, acts of nature, or other events beyond New Holland’s control.

4. Replacement of expendable items made in connection with scheduled maintenance.

5. Parts requiring replacement, inspection or adjustment maintenance intervals for reasons other than being defective.

6. Parts which are not New Holland Service Parts.

7. Loss of time, inconvenience, loss of use of equipment/engine or commercial loss.

8. Equipment with altered or disconnected hourmeter where the hours cannot be determined.

9. Equipment normally operated outside the United States.

10. Non-defective parts replaced by other than New Holland dealers.

Coverage

This emission control system warranty applies to the following 450 and 450T engine emission control parts.

Fuel Injection Pump

Fuel Injectors

Turbocharger

Intake Manifold

Exhaust Manifold

Boost Pressure Tubing-connection to Aneroid Device ON F.I.P.

0-3

0-4

TABLE OF CONTENTS

Section 1 -- Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1--1

Product Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1--2

Important Ecological Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1--5

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1--6

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1--14

Safety Features and Machine Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1--17

Universal Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1--19

Section 2 --Controls and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--1

Cab General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--3

Backhoe Loader as Viewed from the Left Hand Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--4

Backhoe Loader as Viewed from the Right Hand Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--4

Controls and Instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--6

Electronic Instrument Console Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--8

Electronic Instrument Panel Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--10

Loader Bucket Operation -- All Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--12

Multi Purpose Loader Bucket Clam Operation (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--12

Loader Arm Support -- All Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--12

Backhoe Hammer Attachment -- All Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--14

Stabilizers -- All Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--14

Backhoe Transport Boom Lock -- All Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--14

Hand Hammer Attachment (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--14

Backhoe Control Levers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--16

Handles and Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--22

Seat Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--23

Climate Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--26

Hand and Foot Controls (Power Shift) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--30

Instruments (Electronic) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--32

Maintenance Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--41

Bar Graph Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--43

Warning Indicator Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--44

Instrument Panel Calibration and Setting (Electronic) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--47

Transmission Controls (4x2 Power Shift) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--48

Driving with Powershift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--51

Operating the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--58

Driving the Backhoe Loader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--63

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--64

Backhoe Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--79

Ballasting and Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--88

Towing, Transporting and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--90

Section 3 -- Lubrication and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3--1

Filling and Service Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3--2

Daily Service or as required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3--7

Air Cleaner Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3--10

50--hour Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3--11

300--hour Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3--19

600--hour Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3--25

1200--hour/12 Month Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3--29

1200--hour/24 Month Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3--33

General Maintenance -- As Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3--34

Bulb Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3--38

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3--40

0-5

Section 4 -- Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4--1

Section 5 -- Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5--1

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5--13

Predelivery Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5--17

Delivery Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5--21

First 50--hour Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5--25

0-6

OWNER ASSISTANCE

We at New Holland and your New Holland dealer want you to be completely satisfied with your investment. Normally any problems with your equipment will be handled by your dealer’s Service Department. Sometimes, however, misunderstanding can occur. If your problem has not been handled to

your satisfaction, we suggest the following.

1. Contact the owner or General Manager of the dealership, explain the problem, and request assistance. When additional assistance is needed, your dealer has direct access to our branch office.

2. If you cannot obtain satisfaction by doing this, contact the branch office in your area and provide

them with:

·

·

·

·

·

Your name, address, and telephone number

Machine model and serial number

Dealership name and address

Machine purchase date and amount of use

Nature of problem

Atlanta

4727 N Royal Atlanta Dr Suite P

Caller Service 105018

Tucker, GA 30085-5018

Telephone: (770) 723-3602

States: AL, FL, GA, KY, MS,

NC, SC, TN, VA

New Holland

200 Commerce St.

P.O. Box 527

Mountville, PA 17554-0527

Telephone: (717) 285-8350

States: CT, DE, IN, MA, MD, ME,

MI, NH, NJ, NY, OH, PA ,RI, VT,

WV

Dallas

1340 Walnut Hill Lane Bldg 2

P.O. Box 167528

Irving, TX 75016-7528

Telephone: (972) 756-4914

States: AR, AZ, CA, CO, HI, KS,

LA, MO, NM, NV, OK, TX, UT

Calgary

Suite 220

3030 Third Ave. NE

Box 1616, Stn M

Calgary, AB

CANADA T2P 2M7

Telephone: (403) 569-3212

Minneapolis

6301 W Old Shakopee Rd

P.O. Box 1342

Minneapolis, MN 55440-1342

Telephone: (612) 887-4200

States: AK, IA, ID, IL, MN, MT,

ND, NE, OR, SD, WA, WI, WY

3. If you need further assistance contact:

Service Department

Mail Station 500

New Holland North America, Inc.

New Holland, PA 17557

When contacting your branch office or Service Department, be aware that your problem will likely be

resolved in the dealership using the dealer’s facilities, equipment, and personnel. So it is important that

your initial contact be with the dealer.

A Service Publications Catalog & Order Form is available which lists the operator’s and service manuals for many prior model and most current model Ford - New Holland - Versatile tractors, equipment,

and consumer products. To obtain a copy of this catalog, please call 1-800-635-4913.

0-7

PRECAUTIONARY

STATEMENTS

PERSONAL SAFETY

Throughout this manual and on machine decals, you will find precautionary statements (“CAUTION”,

“WARNING”, and “DANGER”) followed by specific instructions. These precautions are intended for the

personal safety of you and those working with you. Please take the time to read them.

CAUTION: THE WORD “CAUTION” IS USED WHERE A SAFE BEHAVIORAL PRACTICE ACCORDING TO OPERATING AND MAINTENANCE INSTRUCTIONS AND COMMON SAFETY

PRACTICES WILL PROTECT THE OPERATOR AND OTHERS FROM ACCIDENT INVOLVEMENT.

WARNING: THE WORD “WARNING” DENOTES A POTENTIAL OR HIDDEN HAZARD WHICH

HAS A POTENTIAL FOR SERIOUS INJURY. IT IS USED TO WARN OPERATORS AND OTHERS

TO EXERCISE EVERY APPROPRIATE MEANS TO AVOID A SURPRISE INVOLVEMENT WITH

MACHINERY.

DANGER: THE WORD “DANGER” DENOTES A FORBIDDEN PRACTICE IN CONNECTION WITH

A SERIOUS HAZARD.

FAILURE TO FOLLOW THE “CAUTION”, “WARNING”, AND “DANGER” INSTRUCTIONS MAY

RESULT IN SERIOUS BODILY INJURY OR DEATH.

MACHINE SAFETY

Additional precautionary statements (“ATTENTION” and “IMPORTANT”) are followed by specific instructions. These statements are intended for machine safety.

ATTENTION: The word “ATTENTION” is used to warn the operator of potential machine damage if a

certain procedure is not followed.

IMPORTANT: The word “IMPORTANT” is used to inform the reader of something he needs to know to

prevent minor machine damage if a certain procedure is not followed.

0-8

SECTION 1

INTRODUCTION TO THE OWNER

SAFETY

QUICK REFERENCE GUIDE

Pages 1-6 through to 1-13 list the precautions to be

observed, to ensure your safety and the safety of

others. Read the precautions and follow the advice

offered BEFORE operating the machine.

Page

Contents

1-2 . . . . . . . . . Product Identification

1-5 . . . . . . . . . Ecological Considerations

SERVICE PARTS

1-6 . . . . . . . . . Safety Precautions

The company would like to point out that

‘non--genuine’ parts have not been examined and

approved by the Company. The installation and/or

use of such products could have negative effects

upon the design characteristics of your machine and

thereby affect its safety. The Company is not liable for

any damage caused by the use of ‘non--genuine’

parts and accessories.

1-14 . . . . . . . . . Safety Decals

1-17 . . . . . . . . . Machine Safety and Security

1-18 . . . . . . . . . On Road Travel Requirements

1-19 . . . . . . . . . Universal Symbols

1--1

SECTION 1 -- INTRODUCTION

PRODUCT IDENTIFICATION

Your Backhoe Loader and its major components are

identified by various numbers and letters for

recognition in After Sales Service. The following

information provides the locations of these

identification plates, stamped numbers and

examples of what can be found on your machine.

1

VEHICLE SERIAL NUMBER (1), Figure 1.

The Serial Number is stamped on the top of the right

hand main frame, in front of the right hand loader

post, in position (1). . . . . . . Example: *031005017*

2

NOTE: The Serial Number and identification

numbers of components may be required by your

dealer when requesting parts or service. These

numbers will also be required as an aid to identifying

the machine if it is ever stolen, keep them safe.

VEHICLE IDENTIFICATION PLATE’S (2),

Figure 1.

The machine identification plate’s are located on the

right--hand loader post, as shown at position (2).

Record the data of your machine below.

MODEL/TECHNICAL TYPE

Example: *699.510.700*

UNIT SERIAL NO.

Example: *031005017*

1

YEAR

Example: *1998*

ENGINE IDENTIFICATION, Figure 2.

The engine identification information is located on

the right hand engine sump rail. Record the

information below for quick reference.

MODEL NO.

Example: *EA5*

SERIAL NO.

Example:

*57018*

DATE CODE.

Example:*8J25*=8(1998),J(SEPTEMBER),25(DAY)

2

1--2

SECTION 1 -- INTRODUCTION

FRONT AXLE IDENTIFICATION, Figure 3

The serial number and axle type is printed on the

plate (1), located on the front axle housing. Record

the information below for quick reference.

AXLE TYPE

Example: *26--25*

SERIAL NO.

Example: *000102*

RATIO

Example: 18.46:1

3

REAR AXLE IDENTIFICATION, Figure 3

The serial number and axle type is printed on the

plate (1), located on the rear axle housing. Record

the information below for quick reference.

AXLE TYPE

Example: *26--25*

SERIAL NO.

Example: *000102*

4

RATIO

Example: 18.46:1

TRANSMISSION IDENTIFICATION 4x2

POWER SHIFT, Figure 5

The serial number and type is printed on the plate (1),

on the lower part of the rear of the transmission.

Record the information below for quick reference.

MODEL NO.

Example: *11.11 -- FT16000--1*

SERIAL NO.

Example: *PBEA 000201* P=96, BE= Belgium

5

1--3

SECTION 1 -- INTRODUCTION

CAB IDENTIFICATION PLATES, Figure 6

The cab serial number and details are printed on the

certification plate‘s (1) on the rear left hand window.

Record the serial number below for quick reference.

Serial No.

Date Code

6

1--4

SECTION 1 -- INTRODUCTION

IMPORTANT ECOLOGICAL CONSIDERATIONS

The following are recommendations which may be of

assistance:

Where no legislation exists, obtain information from

suppliers of oils, fuels, antifreeze, cleaning agents,

etc., with regard to their effect on man and nature and

how to safely store, use and dispose of these

substances.

Become acquainted with and ensure that you

understand the relative legislation applicable to your

country.

HELPFUL HINTS

Modern coolant mixtures, i.e. antifreeze and other

additives, should be replaced every two years. They

should not be allowed to get into the soil but should

be collected and disposed of safely.

Avoid filling tanks using cans or inappropriate

pressurized fuel delivery systems which may cause

considerable spillage.

Do not open the Air--Conditioning system yourself.

Your dealer or air conditioning specialist has a special

equipment for discharging and charging the system.

In general, avoid skin contact with all fuels, oils,

acids, solvents, etc. Most of them contain

substances which can be harmful to your health.

Repair any leaks or defects in the engine cooling or

hydraulic system immediately.

Modern oils contain additives. Do not burn

contaminated fuels and/or waste oils in ordinary

heating systems.

Do not increase the pressure in a pressurized circuit

as this may lead to a catastrophic failure of the

system components.

Avoid spillage when draining off used engine coolant

mixtures, engine, gearbox and hydraulic oils, brake

fluids, etc. Do not mix drained brake fluids or fuels

with lubricants. Store them safely until they can be

disposed of in a proper way to comply with local

legislation and available resources.

Protect hoses during welding as penetrating weld

splatter may burn a hole or weaken them, causing

the loss of oils, coolant, etc.

1--5

SECTION 1 -- INTRODUCTION

SAFETY PRECAUTIONS

A careful operator is the best operator. Most accidents can be avoided by observing certain precautions. To help

prevent accidents read and take the following precautions before operating the machine. Equipment should be

operated only by those who are responsible and instructed to do so.

IMPORTANT: In this manual references are made to positions of switches and components as located to the

Left Hand and Right Hand side of the machine. In most situations the position described is when the operator

is seated on the machine and looking forward, unless otherwise stated.

THE BACKHOE LOADER

Ensure attached or trailed equipment is operated

and maintained in accordance with the

instructions issued by the equipment or accessory

manufacturer.

IMPORTANT: Never leave the machine with the

loader or backhoe raised, always lower the loader

and backhoe to the ground when not in use. Unless

the loader support and Backhoe transport lock are

engaged.

4. With the machine operational always use the seat

belt.

1. Do not allow anyone to operate the machine

without proper instruction. Legislation in many

countries requires that all operators be instructed

on the proper procedures and operation of the

machine and safety procedures before use.

5. Use the grab handles and step plates when

getting on and off the machine to prevent falls.

Keep steps and platform clear of mud and debris.

2. Read the Operator’s Manual carefully before

using the machine. Lack of operating knowledge

can lead to accidents.

3. Ensure any attached equipment or accessories

are correctly installed and are approved for use

with the machine.

6. Do not permit anyone but the operator to ride on

the machine. There is no safe place for extra

passengers.

‘DO NOT OVERLOAD THE MACHINE’

1--6

SECTION 1 -- INTRODUCTION

6. Escaping hydraulic/diesel fluid under pressure

can penetrate the skin causing serious injury.

7. Remember that your machine, if abused or

incorrectly used can be dangerous and become a

hazard both to the operator and bystanders. Do

not overload or operate with attached equipment

which is unsafe, not designed for the particular

task or is poorly maintained.

WARNING

Do not use your hand to check for leaks. Use a

piece of cardboard or paper to search for leaks.

8. Replace all missing, illegible, or damaged safety

decals.

Stop the engine and relieve pressure before

connecting or disconnecting lines.

9. Keep safety decals clean of dirt and grime.

Tighten all connections before starting the engine or

pressurizing lines.

SERVICING THE MACHINE

If fluid is injected into the skin obtain medical attention

immediately or gangrene may result.

1. The engine cooling system operates under

pressure which is controlled by the radiator cap in

the header tank. It is dangerous to disassemble

any components while the system is hot. Always

turn the header tank cap slowly to the first stop and

allow the pressure to escape before removing the

cap entirely.

7. Do not attempt to service the air conditioning

system. It is possible to be severely frostbitten or

injured by escaping refrigerant. See your dealer

for service.

8. Do not modify or alter or permit anyone else to

modify or alter this machine or any of its

components or any machine function without first

consulting your dealer.

9. The fuel oil in the injection system is under high

pressure and can penetrate the skin. Unqualified

persons should not remove or attempt to adjust a

pump, injector, nozzle or any other part of the fuel

injection system. Failure to follow these

instructions can result in serious injury.

2. Do not smoke while refueling the machine. Keep

any type of open flame away. Wait for the engine

to cool before refuelling.

10. Continuous long term contact with used engine oil

may cause skin cancer. Avoid prolonged contact

with used engine oil. Wash skin promptly with

soap and water.

11. Never allow anyone to stand or work under or

reach through the loader lift arms when the loader

is raised, unless the loader cylinders are blocked

in the extended position, using the loader arm

support.

3. Keep the machine and equipment, particularly

brakes and steering, maintained in a reliable and

satisfactory condition to ensure your safety and

comply with legal requirements.

4. To prevent fires or explosions keep open flames

away from battery or cold weather starting aids. To

prevent sparks which could cause explosion, use

jumper cables according to instructions in this

manual.

12. Never allow anyone to stand under or work under

a raised backhoe bucket or boom.

13. Never attempt to repair or tighten hoses under

pressure.

5. Stop the engine, apply the handbrake and lower

the loader and backhoe to the ground before

performing any service on the machine.

14. Always check pivot pins, snap rings and attaching

pins on a daily basis.

1--7

SECTION 1 -- INTRODUCTION

OPERATING THE MACHINE

15. When it is necessary to remove pins from the

backhoe and loader bucket that require a hammer

and drift, use only a brass hammer and a brass

drift and wear safety glasses.

IMPORTANT: In the interests of safety ensure

suitable clothing is worn to suit the situation.

16. Do not lubricate or make mechanical adjustments

while the unit is in motion or when the engine is

running. However, if minor engine adjustments

must be made, apply the parking brake, securely

block the wheels, and use extreme caution. Be

certain that the loader is fully lowered or

supported so that it cannot fall.

Loose fitting garments and jewelry should not be

worn, as they may become entangled with the

operating levers and controls.

17. Always wear safety goggles when servicing or

repairing the machine.

1. Position the transmission in neutral and apply the

parking brake before starting the machine.

2. Do not start the engine or operate controls while

standing outside of the machine. Always sit in the

machine seat when starting the engine or

operating the controls.

18. Always use caution when driving onto a trailer

3. Do not bypass the safety start switch. Consult

your dealer if your safety start controls

malfunction. Use jumper cables only in the

recommended manner. Improper use can result in

a machine runaway, see Section 3 for instructions.

19. If it is necessary to tow the machine disconnect

the transmission prop shafts (unless engine is

kept running). Do not tow the machine over long

distances, tow only according to instructions in

this manual, see Section 3.

4. Avoid accidental contact with the gear shift lever

or power reversing lever while the engine is

running. Unexpected machine movement can

result from such contact.

20. Adequately block up the backhoe or loader when

they are detached from the machine.

21.Backhoe Loader wheels are very heavy. Handle

with care and ensure, when stored, that they can

not topple and cause injury.

5. Do not get off the machine while it is in motion.

1--8

SECTION 1 -- INTRODUCTION

14. Do not run the engine in a closed building without

adequate ventilation, as exhaust fumes can

suffocate you.

6. Never attach chains, ropes or cables to the loader,

cab or backhoe for pulling purposes.

7. Never leave the machine without first lowering the

backhoe and loader buckets to the ground.

8. Stop the engine, apply the parking brake and put

the gear shift lever and power reversing lever into

neutral before dismounting.

9. Do not engage the parking brake while the

machine is in motion.

15. Always carry out the recommended checks

before commencing work each day.

10. Never leave the machine when it is parked on an

incline. Always park the machine on level ground

where possible. If the machine is to be parked on

an incline, always lower the buckets so that the

cutting lips contact the ground, apply the parking

brake, and securely block the wheels.

16. Always place the power reversing lever in neutral

before operating the backhoe.

17. Always check the location of gas pipes, water

pipes and electrical lines before you start to dig.

11. Always keep a lookout for bystanders and warn

people. Use the horn before starting the engine.

12. Always check overhead clearance, particularly

when transporting the machine.

18. Watch out for overhead and underground

high-voltage electrical lines when operating the

loader or backhoe.

13. If the engine or power steering ceases operating,

stop the machine immediately.

1--9

SECTION 1 -- INTRODUCTION

19. To prevent upsets, avoid full reach and swinging

the bucket to the downhill side when operating on

a slope.

Do not attempt to jump out of the machine in the

event of an overturn, keep inside the cab.

24. Do not transport anyone in the loader bucket.

25. Always carry the loader bucket low for maximum

stability and visibility, whether the bucket is loaded

or empty.

20. Always deposit the spoil on the uphill side when

operating on a slope. When traveling on a slope

always keep the backhoe on the uphill side.

26. Be careful when handling round objects such as

bales, or poles. Lifting too high or rolling back too

far could result in these objects rolling rearward

down the loader arms onto the operator.

27. Never move, lift, or swing a load over anyone.

21. Always travel slowly over uneven ground.

22. Take special care when excavating with a high

capacity bucket, excess weight may unbalance

the machine.

Do not attempt to jump out of the machine in the

event of an overturn, keep inside the cab.

28. Be careful when working near ditches or on soft

ground, familiarize yourself with local conditions.

23. Always use the recommended amount of

counter-weighting where a backhoe is not fitted to

ensure good stability.

1--10

SECTION 1 -- INTRODUCTION

29. Never undercut a high bank or overhang because

of the danger of rock or landslides.

30. Be alert for hazards especially when entering

tunnels or underpasses.

2. Never allow the machine to over-run when going

downhill. Do not coast or free-wheel down hills.

3. Always use the transport lock when transporting

the machine refer to Section 2 and Section 1 for

On Road requirements.

4. Lock the foot brake pedals together when

travelling on the highways to provide two wheel

braking.

5. Do not engage the differential lock when turning

the machine. When engaged, the lock will prevent

the machine turning.

31. Never enter or allow anyone to enter the area of

the backhoe swing area during operation.

6. Always sit in the driver’s seat and wear your seat

belt when driving the machine.

7. Dim the lights when meeting a vehicle at night.

Ensure the lights are adjusted to avoid blinding an

oncoming driver.

8. Subject to Local Laws and Legislation, use bucket

tooth guards and rotating beacon when travelling

on public roads both day and night. Refer to

Section 1 for On Road requirements.

32. Do not dig under the machine or stabilizer for your

own safety

DRIVING THE UNIT

1. Always drive with care and at speeds compatible

with safety, especially when operating over rough

ground, crossing ditches and turning. When

traveling down inclines a low gear must be

selected to prevent excess speeds.

1--11

9. Avoid accidental contact with the gear shift lever

or power reversing lever while the engine is

running. Unexpected machine movement can

result.

10. Any towed machine whose total weight exceeds

that of the towing machine must be equipped with

brakes for safe operation.

SECTION 1 -- INTRODUCTION

11.Be careful when driving through doorways or

working in confined spaces with low headroom.

5. Do not fill the fuel tank to capacity. Allow room for

expansion.

6. Wipe up spilled fuel immediately.

7. Always tighten the fuel tank cap securely.

8. If the original fuel tank cap is lost, replace it with

an approved cap. A non--approved, proprietary

cap may not be safe.

9. Keep equipment clean and properly maintained.

12. Stay alert when working along the side of quarries,

cliffs, ditches or hillsides.

10. Do not drive equipment near open fires.

11. Never use the fuel for cleaning purposes.

12. Arrange fuel purchases so that summer grade

fuels are not held over and used in the winter.

ANGLE OF OPERATION

IMPORTANT: In the interests of safety and efficient

running of the machine, ensure the angle of operation

as shown is not exceeded.

DIESEL FUEL

1. Under no circumstances should gasoline, alcohol

or blended fuels be added to diesel fuel. These

combinations can create an increased fire or

explosive hazard. In a closed container such as a

fuel tank such blends are more explosive than

pure gasoline. Do not use these blends.

2. Never remove the fuel cap or refuel with the

engine running or hot.

3. Do not smoke while refuelling or when standing

near fuel.

4. Maintain control of the fuel filler pipe nozzle when

filling the tank.

1--12

7

SECTION 1 -- INTRODUCTION

SAFETY CAB OR ROPS

ROPS MAINTENANCE AND INSPECTION

Your machine is equipped with a Safety Cab or ROPS

and it must be maintained in a serviceable condition.

DAMAGE TO THE ROPS

NOTE: The following statements are for your own

protection as well as other people

If the tractor has rolled over or the ROPS has been

damaged (such as striking an overhead object during

transport), the ROPS must be replaced to provide the

original amount of protection.

1. Do not modify, drill or alter the Safety Cab or

ROPS frame in any ways as doing so could render

you liable to legal prosecution.

After an accident, check for damage to the ROPS,

operator’s seat, seat belt and seat belt mountings.

Before you operate the tractor, replace all damaged

parts.

2. Do not attempt to straighten or weld any part of the

frame or retaining brackets which have suffered

damage. By doing so you may weaken the

structure and endanger your safety.

DO NOT TRY TO WELD OR STRAIGHTEN THE

ROPS.

WARNING

Never attach chains, ropes, or cables to the ROPS

or Cab for pulling purposes; this may cause the

tractor to tip backward. Be careful when driving

through door opening or under low overhead objects. Make sure there is sufficient overhead clearance for the roll bar

3. Do not secure any parts on the safety cab or

ROPS frame with other than the special high

tensile bolts and nuts specified.

4. Do not attach chains or ropes to the cab or ROPS

frame for pulling purposes.

WARNING

5. Do not take unnecessary risks even though your

safety cab or ROPS frame affords you the

maximum protection possible.

If the ROPS is removed or replaced, make certain

that the proper hardware is used and the recommended torque values are applied to the attaching

bolts.

ROLL OVER PROTECTION STRUCTURES

WARNING

A roll over protective structure (ROPS) and seat belt

were standard equipment for the tractor at time of

factory assembly. The seat belt, when used by the

operator, maximizes the protection offered by the

ROPS. ALWAYS use your seat belt with the ROPS -seat belts save lives when they are used.

Always wear your seat belt when the tractor is

equipped with a ROPS.

Whenever you see this symbol

ATTENTION: BECOME ALERT!

YOUR SAFETY IS INVOLVED!

1--13

it means

SECTION 1 -- INTRODUCTION

SAFETY DECALS

Warning and safety decals are placed on your machine as

shown through pages, 1-14 to 1-16. They are intended as a

guide for the personal safety of you and those working with

you. Please take this manual, walk around your machine and

note the content and location of them. Review these decals

with your machine operators. Keep the decals legible. If they

are not, obtain replacements from your dealer.

Part No. 83902684

Location: On parking brake lever

·

Start engine only from

operator’s seat, if safety start

switch is bypassed engine

can start with transmission in

gear.

·

Do not connect or short

across terminals on starter

solenoid.

·

Attach booster cables as

shown on battery decal.

Starting in gear causing runaway

can result in serious injury.

Part No. 83929338

Location: On engine

motor

starter

WARNING

DO NOT WORK

UNDER RAISED LOADER

UNLESS SUPPORTED

Part No. 83957616

Location: On right and left hand

loader arms

1--14

SECTION 1 -- INTRODUCTION

CAUTION

DANGER

·

AIR CONDITIONING SYSTEM

CONTAINS “HFC 134a”. A

NON OZONE DEPLETING

REFRIGERANT AND PAG OIL.

SERVICE, REPAIR OR

RECHARGING MUST BE

PERFORMED BY QUALIFIED

PERSONNEL ONLY.

EXPLOSIVE

CAN CAUSE BLINDNESS OR SEVERE INJURY.

PROTECT EYES. SPARKS, FLAMES AND

CIGARETTES CAN CAUSE EXPOSION. TOOLS AND

CABLE CLAMPS CAN CAUSE SPARKS. DO NOT

USE WITHOUT PROPER INSTRUCTION. KEEP

CAPS TIGHT AND LEVEL.

·

DISTRIBUTED BY

NEW HOLLAND, INC.

CAUSES SEVERE BURNS. CONTAINS SULFURIC

ACID. IN EVENT OF CONTACT, FLUSH WITH

WATER AND SEE A DOCTOR.

KEEP OUT OF REACH OF CHILDREN.

REPLACE WITH BATTERY F -- 150

REFRIGERANT HFC 134a

CHARGE 1.65 LBS (0.75 Kg)

ACID - POISON

Part No. 83960708

Location: On top of battery

Part No. 85703019

Location: On air conditioner

compressor

WARNING

FOR SAFETY

DO NOT ENTER PLATFORM FROM THE REAR

OPERATE BACKHOE FROM OPERATOR’S SEAT ONLY

INSTALL SWING LOCK PIN FROM OPERATOR’S SEAT ONLY

Part No. 83957646

Location: Lower rear cab panel

WARNING

WARNING

DO NOT USE TRANSPORT LOCK WHILE

CRANING TO AVOID VEHICLE DAMAGE

AND PERSONAL INJURY

KEEP HANDS

AND CLOTHING

AWAY FROM

ROTATING FAN

AND BELTS

TO PREVENT

SERIOUS INJURY

ATTENTION

CENTER & RAISE THE BOOM BEFORE

ENGAGING OR DISENGAGING THE

TRANSPORT LOCK TO AVOID VEHICLE

DAMAGE.

BOOM MAY HIT RAISED STABILIZER

CYLINDER WHEN SWINGING TO FULL

LEFT OT RIGHT.

Part No. 83957648

Location: Right and left hand fan

shroud

Part No. 83962229

Location: Backhoe lift cylinder

1--15

SECTION 1 -- INTRODUCTION

WARNING

WARNING

LOADER SAFETY

·

Know all operation, warning and safety instructions in

the operator’s manual before operating.

·

Operate only from the operator’s seat.

·

Stay out from under raised loader arms unless

supported.

·

Carry bucket low during transport for better visibility

and to avoid overturns.

·

Using front end loaders without special attachments

for handling large heavy objects such as large bales,

logs, and oil drums, is NOT recommended.

Handling large heavy objects with the loader can be

extremely dangerous due to the object rolling or sliding

down the loader arms onto the operator.

·

Use wheel ballast and/or rear weight for stability as

recommended in the operator’s manual.

·

When parking or servicing:

- Lower the bucket to the ground.

- Stop the engine

- Set the parking brake.

·

Before starting and operating:

- Know the operating and safety

instructions in the operator’s manual and

on the tractor.

- Clear the area of bystanders.

- Locate and know operations of controls.

·

Start engine only from operator’s seat

with transmission in neutral and hydraulic

controls in lowered position.

·

Do not permit anyone but the operator to

ride on the tractor. There is no

designed safe place for riders.

·

Lock brakes together, use warning lights

and SMV emblem when driving on roads.

·

Lower equipment, place gear shift in

neutral, stop engie and apply parking

brake before leaving tractor seat.

·

Loader bucket must be installed during

machine operation for proper balance.

Out of balance condition can result in

overturn and personal injury.

·

Do not enter platform from the rear.

Operate backhoe from operator’s seat

only.

·

Do not tow start.

·

When towing place gear lever in fourth

gear.

FAILURE TO FOLLOW ANY OF THE INSTRUCTIONS

ABOVE CAN CAUSE SERIOUS INJURY TO THE

OPERATOR OR OTHER PERSONS.

FAILURE TO FOLLOW ANY OF THE

ABOVE INSTRUCTIONS CAN CAUSE

SERIOUS INJURY TO THE OPERATOR

OR OTHER PERSONS.

Part No. 83963548

Location: On left hand loader

post

Part No. 85804400

Location: On cab pillar above

instrument console

WARNING

TO JUMP START

(Negative Grounded Battery)

1. Shield eyes. 2. Connect end of one cable to positive (+) terminals of each battery. 3.

Connect one end of other cable to negative (-) terminal of “Good” battery.

4. Connect other end to engine block of vehicle being started.

TO PREVENT DAMAGE to the other electrical components on vehicle being started, make

certain that the engine is at idle speed before disconnecting jumper cables.

Part No. 83984326

Location: On top of battery

1--16

SECTION 1 -- INTRODUCTION

8

SAFETY AND SECURITY, Figure 8.

1. LOADER ARM SUPPORT: Left Hand Side

2. CAB DOOR’S: Lockable with Key

3. BATTERY ISOLATOR: Manual Switch

4. STEERING CLAMP (Optional): Padlock and Key

6. TOOL BOX:-- Padlock and Key

7. HYDRAULIC FILLER CAP: Special Spanner

8. ENGINE SIDE COVERS: Lockable with Key

5. FUEL RESERVOIR CAP : Lockable with Key

1--17

SECTION 1 -- INTRODUCTION

ON ROAD TRAVEL REQUIREMENTS -- EXTERNAL

EXTERNAL ON ROAD REQUIREMENTS,

Figure 1-9.

Ensure that your machine complies with local

legislation with regard to the fitting of this equipment,

when traveling on the highway day or night.

9

1. BACKHOE

TRANSPORT

PIN

(WHERE

FITTED): Rotate the boom to transport position

and place pin into boom plate

2. SLOW

MOVING

MACHINE

WARNING

EMBLEM: (attachment by spring loaded attaching

clips to the bucket cylinder rod)

1--18

SECTION 1 -- INTRODUCTION

UNIVERSAL SYMBOLS

Thermostart

starting aid

Alternator

charge

Fuel level

Engine speed

(rev/min x 100)

Hours recorded

Turn signals

N

Front windscreen

wipe

Heater

temperature

control

Engine coolant

temperature

Air conditioner

Rear axle

oil temperature

Transmission

oil pressure

FWD

engaged

Air filter

blocked

machine

lights

Parking brake

Headlamp

main beam

Stop lamps

Headlamp

low beam

Transport lock

2 Wheel Steer

Engaged

Ground

speed

Rear windscreen

wash/wipe

Heater fan

Transmission

in neutral

Slow or

low setting

Front windscreen

wash

Engine oil

pressure

Coolant

level

Side lamps

Horn

Roof

beacon

Accessory

socket

Hydraulic and

transmission

filters

Hazard

warning lights

Malfunction!

See Operator’s

Manual

Read Operators

Manual

Variable

control

Brake reservoir

oil level

Pressurised!

Open carefully

Warning!

Warning!

Corrosive

substance

Sideshift

Lock

Hammer

Attachment

Crab Steer

Engaged

4 Wheel Steer

Engaged

10

UNIVERSAL SYMBOLS, Figure 10

As a guide to the operation of the machines, various

universal symbols have been utilized on the

instruments, controls, switches, and fuse box.

The symbols are shown with an indication of their

meaning, however not all decals may be on your

machine but are dependant upon options and

accessories fitted:

1--19

SECTION 1 -- INTRODUCTION

MACHINE FUNCTIONS THAT ARE MONITORED BY GAUGES WARNING

LIGHTS AND BUZZERS.

To protect the machine and identify operational items warning lights and buzzers will illuminate or sound should

they need to be addressed. Listed below for ease of identifying these items are the components along with the

respective light and buzzer.

Function

Warning Light

Instrument

Buzzer

Lights -- Main Beam

X

Engine Coolant Temperature

X

X

Engine Oil Pressure

X

X

Transmission Temperature

X

Transmission Pressure

X

Engine Air Filter Obstruction

X

X

Voltmeter

X

Engine Thermostart

X

Handbrake

X

X

Fuel Level

Fuel Minimum Level

X

X

X

X

Tachometer

X

Hour meter

X

Turn indicators

X

Hazard Flashers

X

Foot Brake Oil Level

X

Maintenance Requirements

X

Transmission Malfunction

X

2 Wheel Steer

X

4 Wheel Steer

X

Crab Steer

X

1--20

X

SECTION 2

CONTROLS AND OPERATION

BEFORE OPERATING

Controls and Instruments, Powershift, 2--6

Read this section thoroughly. It details the location

and operation of various instruments, switches and

controls on your machine.

Do not start the engine or attempt to drive or operate

the machine unless you are fully accustomed to the

controls.

IT IS TOO LATE TO LEARN ONCE THE MACHINE

IS MOVING.

Pay particular attention to the running in procedure,

and if in any doubt consult your Dealer.

LISTED FOR EASY REFERENCE

CONTENTS OF THIS SECTION

IS

THE

Description of Vehicle

Left Hand Side, 2--4

Right Hand Side, 2--4

Direction Indicator Stalk, 2--33

Engine Operation, 2--58

Engine Starting, 2--59

Cold Weather, 2--60

Engine Stopping, 2--62

Extendible Dipper, 2--76

Hammer Attachment, Backhoe, 2--77

Hand and Foot Controls, Powershift, 2--30

Hand Hammer Attachment, 2--86

Hydraulic Oil Reservoir, 2--4

Instrument Console, Electronic, 2--32

Hammer Attachment-- Hand, 2--14

Instrument Console Front, Electronic, 2--32, 2--33

Air Conditioning System, 2--26

Refrigerant R--143 A, 2--28

Instrument Console Side, Electronic, 2--37, 2--38

Instrument Panel -- Front, Electronic, 2--8, 2--10

All Wheel Steer, 2--34

Instrument Panel -- Side, Electronic, 2--8, 2--10

Backhoe Boom Lock, 2--78

Instrument Panel Side, Electronic, 2--37, 2--40,

2--41, 2--42

Backhoe Bucket Release

Mechanical, 2--85

Key Start , 2--58

Backhoe Controls, 2--16

Four Lever Pattern, 2--18

ISO Pattern, 2--20

Standard Pattern, 2--16

Loader Arm Support, 2--12, 2--69

Backhoe Hammer, Attachment, 2--14

Loader Bucket

Multi Purpose, 2--73

Multi Purpose, 2--12

Backhoe Operation, 2--79, 2--81

Loader Bucket Operation, 2--12

Backhoe Sideshifting, 2--80

Loader Bucket Removal, 2--67

Backhoe Transport Lock, 2--14

Loader Controls, 2--64

Backhoe Trenching, 2--83

Loader Operations, 2--69

Battery Isolator, 2--4

Machine Storage, 2--87

Cab

Air Flow Vents, 2--29

Doors, Windows, 2--22

Sunvisor, 2--29

Optional Equipment, Cooling Fan, 2--29

Powershift Lever

Driving, 2--51

Microprocessor Functions , 2--50

Quick Reference, 2--55

Cab Climate Controls, 2--26

2--1

SECTION 2 -- CONTROLS AND OPERATION

Stabilizer Pads Reversible, 2--75

Stabilizers Backhoe, 2--14

Seat Adjustment, 2--23

Steering Column Adjustable, 2--25

Seats and Belts, 2--24

Swing Frame Clamp, 2--75

Stabilizer Levers, 2--74

Towing, Transporting, Cleaning , 2--90

NOTES PAGE

2--2

SECTION 2 -- CONTROLS AND OPERATION

CAB GENERAL

The cab has been designed for your comfort and

convenience. The walls, roof and floor are designed

to reduce noise to a minimum for the operator.

Standard

features

include

a

fresh

air

heater/defroster, sun visor, interior light, rear view

mirror, grab handles, an operator’s manual storage

facility and cigar lighter / 12 volt auxiliary socket.

Entry and exit from the cab is aided by wide doors,

foot steps with anti--slip treads and convenient assist

handles.

Both doors rear--hinged, have gas struts attached to

the ‘B’ pillar to assist opening and closing and to hold

them in the fully open position. Heavy duty anti--burst

locks are fitted, that may be locked from the outside

by means of the keys provided.

NOTE: It is recommended a note is kept of the key

number, so a replacement may be obtained, if

necessary.

The upper side windows may be opened a few inches

or completely, and attached to an adjacent window by

a retainer.

The rear window may be opened and guided by rails,

can be stowed above the operator’s head.

Excellent visibility is offered through the generous

window areas along with the installation of mirrors

and front and rear windscreen wipe/wash facility.

An interior light is mounted in the cab roof above the

front instrument panel for use during hours of

darkness. The light is operated by sliding the switch

in the lamp forward for wide angle cab lighting or

rearward for spot lighting.

2--3

1

SECTION 2 -- CONTROLS AND OPERATION

BACKHOE LOADER AS VIEWED FROM THE LEFT HAND SIDE, Figure 2

1. CAB

6. FUEL TANK

Deluxe Model

Capacity 106 Litres (28 gallons).

2. BACKHOE

With Standard Dipper or optional:

7. FUEL TANK FILLER CAP

Hydraulically Extendible Dipper H.E.D.

Lockable using the machine key’s as supplied.

3. BACKHOE BUCKET

Standard Bucket shown or optional:

8. HYDRAULIC OUTLET PORTS

Larger Specialist Buckets

External Hand Hammer Attaching Ports (optional)

4. BACKHOE

Sideshift or Centre Pivot

5. BACKHOE STABILIZERS

9. ENGINE SIDE PANELS

Hydraulically operated from the cab.

Removeable and lockable with key’s supplied.

BACKHOE LOADER AS VIEWED FROM THE RIGHT HAND SIDE, Figure 3

6. TOOL BOX

1. FRONT LOADER FRAME

Mounted in the top of the hydraulic reservoir is an

integral tool box. It contains the Hydraulic

Reservoir Filler Cap Wrench.

2. FRONT LOADER BUCKET

Standard but

including:

optional sizes

are available

Multi Purpose -- with clam

Multi Purpose -- with clam and Lift Forks

7. BATTERY ISOLATOR

NOTE: The battery isolator mounted below the

fuel injection pump is only accessible with the right

hand engine side panel removed.

3. AXLE’S

ALL Wheel Steer and Drive as illustrated.

Rotation of the isolator effectively switches off the

battery power to the ignition. This enables repairs

to be performed safely and acts as an anti theft

device when turned ‘OFF’ and the right hand

engine side panel locked shut.

4. HYDRAULIC OIL RESERVOIR FILLER CAP

Removable only with Anti--Theft Wrench supplied

5. HYDRAULIC OIL RESERVOIR

Capacity 137 Litres (36.2 gallons)

2--4

SECTION 2 -- CONTROLS AND OPERATION

SH4WS038

2

SH4WS038

3

2--5

SECTION 2 -- CONTROLS AND OPERATION

CONTROLS AND INSTRUMENTS, Figure 4.

1. Direction Indicators, Front Windscreen Wiper

stalk and Front Windscreen Washer Control

14. Hammer Operating Pedal (Optional Equipment)

2. Foot Throttle Pedal

15. Air Flow Direction Outlet

3. Loader Lever (with integrated Transmission Disconnect Switch and Horn Switch)

16. De Luxe Seat with Document Pouch to the rear

4. Heater Control Panel / Air Conditioning (when

fitted)

17. Radio Placement / Miscellaneous Objects Holder

18. Drink Holder

5. Key Start

19. Independent Brake Pedals and Pedal Latch

6. Auxiliary Power Outlet

WARNING

When travelling on the road the brake pedals must

be latched together for straight line braking.

If the pedals are not latched pressure applied to one

pedal only, could result in the machine veering

severely to the left or right hand side.

7. Side Mounted Instrument Panel

8. Parking Brake

20. Hazard Flasher Button

9. Hand Throttle Lever

21. POWER SHIFT 4X2 -- Transmission Forward /

Reverse and Gear Selection Lever

10. Stabilizer Leg Levers

22. Air Flow Direction Outlet

11. Air Flow Direction Outlet

23. Steering Wheel (Adjustable)

12. Hydraulically Extendible Dipper, H.E.D Operating

Pedal (Optional Equipment)

24. Front Instrument Panel

25. Air Flow Direction Outlet

13. Backhoe Control Lever Patterns

Standard:

2 Lever -- Cross Pattern with Horn Button

26. Key Operated -- Steering Selection Switch:

1= Standard Steering

2= Double steering

3= Crab Steering

Optional:

4 Lever -- Fore / Aft Pattern

2--6

SECTION 2 -- CONTROLS AND OPERATION

6

7

8

16

9

15

14

13

12

11

10

4

2--7

SECTION 2 -- CONTROLS AND OPERATION

ELECTRONIC INSTRUMENT CONSOLE LAYOUT

FRONT INSTRUMENT CONSOLE, Figure 5.

IMPORTANT: The position of switches, gauges and

warning lamps may vary slightly from that shown,

dependant upon country and options fitted.

Thoroughly familiarize yourself with the layout of your

machine before operation.

3. Hand Hammer Switch

4. Front Instrument Panel

1. Blanking plate for optional equipment.

5. Main Light Switch

2. Four Wheel Drive Operating Switch mounted in

the front instrument console controls selection of 2

or 4 wheel drive.

6. Rotating Beacon Switch

Position 1 (Forward) = Rear Wheel Drive with four

wheel drive braking.

Position 2 (Center) = Four Wheel Drive. “Switch

illuminated”

Position 3 (Rearward) = Rear Wheel Drive Only.

With Rear Wheel Braking

7. Blanking plate for optional equipment.

8. Hazard flasher button

SIDE MOUNTED INSTRUMENT CONSOLE, Figure 6.

1. 12 volt Auxiliary Power socket.

7. Key Start

0= Off

I= Ignition ‘‘ON’’

II= Thermostart (Engine Pre Heat)

III= Engine Start (cranking)

2. Electronic side instrument panel.

3. Rear Window Wiper and Washer Switch.

8. Blank switch panel (optional equipment).

4. Boom Lock Switch for Transport on road

(On= Boom Unlocked).

9. Quick Coupling Attachment Switch

(Optional Equipment).

5. Sideshift Carriage Clamp Switch

(Side Shift Models Only)

On= Carriage Unlocked.

10.Blank switch panel (optional equipment).

6. Rear Work Lamp Switch.

11.Front Work Lamp Switch.

2--8

SECTION 2 -- CONTROLS AND OPERATION

5

6

2--9

SECTION 2 -- CONTROLS AND OPERATION

ELECTRONIC INSTRUMENT PANEL FUNCTIONS

FRONT INSTRUMENT PANEL, Figure 7

1. Left and Right turn signal indicator lamp .

5. High beam warning indicator lamp.

2. Digital speedometer displaying road speed as

Miles per hour or Kilometers per hour, selectable

as required.

6. Low level warning for brake oil reservoir.

7. Miles Per Hour Indicator.

3. Normal Two Wheel Steer Indicator.

4. Low beam warning indicator lamp.

8. Kilometers Per hour Indicator.

SIDE MOUNTED INSTRUMENT PANEL, Figure 8

1. Total running hours

programming key.

display

mode

and

11. Handbrake on warning light

12.Crab Steer Engaged

2. Partial Hours and programming key.

13.Air Cleaner restricted warning light

3. Engine oil pressure gauge.

14.Service requirement -- level 2

4. Engine coolant temperature gauge.

5. Digital Revolution Counter displaying true engine

speed also engine start code and service hours.

6. Fuel Level Gauge

15.Normal Two Wheel Steer Engaged

16.Service requirement -- level 1

17.Spare

7. Battery voltage indicator

18.All Wheel Steer Engaged

8. Key for displaying hours remaining in service

levels 1 and 2.

19.Engine Shutdown

9. Alternator charge warning light

20.Torque convertor oil temperature

10.Engine pre heat

21.Torque Convertor Oil Pressure

2--10

SECTION 2 -- CONTROLS AND OPERATION

7

8

2--11

SECTION 2 -- CONTROLS AND OPERATION

LOADER BUCKET OPERATION -- ALL MODELS, Figure 9.

1. Loader and Bucket Shift Movements, as viewed seated in the drivers seat looking to the front of the machine.

DUAL OPERATION -Diagonal movement of the loader

lever allows dual operation of loader

arms and bucket.

INDIVIDUAL OPERATION -Straight line movement of the loader

lever operates loader arms and

bucket.

LOADER ARMS ‘‘FLOAT’’

LOADER ARMS LOWER

LOADER BUCKET ROLL BACK

LOADER BUCKET DUMP

LOADER BUCKET ‘‘RETURN TO DIG’’

LOADER ARMS LIFT

2. Loader Control Lever

3. Transmission Disconnect Switch

MULTI PURPOSE LOADER BUCKET CLAM OPERATION

(OPTIONAL), Figure 10.

1. Loader Lever

3. Bucket Clam Close’s

2. Loader Lever Twist Grip Movement For Bucket

Clam:

-- Counter Clockwise rotation of Lever opens the

bucket clam

-- Clockwise rotation of the Lever closes the

bucket clam.

4. Bucket Clam Open’s

LOADER ARM SUPPORT -- ALL MODELS, Figure 11.

Raise the Loader to full height and proceed with the

following:

1. Remove the Retaining pins and loader support (1)

from the Lift Arm and place onto the loader piston

(2).

2. Fit the Retaining Strap into the Loader Support

3. Gently Lower the Loader Arms into the fully

Supported Position

2--12

SECTION 2 -- CONTROLS AND OPERATION

9

10

11

2--13

SECTION 2 -- CONTROLS AND OPERATION

BACKHOE HAMMER ATTACHMENT -- ALL MODELS

(OPTIONAL EQUIPMENT), Figure 12

IMPORTANT: The Hydraulic Extendible Dipper

(where fitted) must be fully retracted and locked in the

transport position before the hammer can be used.

1. HAMMER Operating pedal

2. H.E.D -- Hydraulic Extendible Dipper

‘Position Pedal’

3. H.E.D -- Hydraulic Extendible Dipper

‘Transport Locking Pin ’

PIN position nearest to bucket= Operating Position

PIN position furthest from bucket= H.E.D held in

transport position

If the hammer is used with the dipper extended

excess forces will be applied to the dipper which could

result in premature wear of the dipper and invalidate

the machine warranty.

STABILIZERS -- ALL MODELS

(LOWER TO GROUND PRIOR TO USING BACKHOE), Figure 13

1. Right Hand Stabilizer Lever (With Operator Seated

Facing to the rear of the Machine)

2. Left Hand Stabilizer Lever (With Operator Seated

Facing to the rear of the Machine)

IMPORTANT: The Hydraulic stabilizer circuit may be

equipped with a lock out valve on each stabilizer and

will stop the stabilizers falling to the ground in the

event of a burst hose. Should this occur ensure the

fault is rectified immediately.

WARNING

Do not attempt to use the backhoe with a failed

stabilizer circuit, as the machine will be unstable.

BACKHOE TRANSPORT BOOM LOCK -- ALL MODELS, Figure 14

With switch (3) ‘ON’ and illuminated, the transport

Lock (1) will be in the ‘UNLOCKED POSITION’ and

the backhoe is free to operate, the warning lamp (2)

will be off.

Do Not attempt to operate the backhoe with the

boom lock in the LOCKED POSITION as damage

to the mechanism could occur.

With switch (3) ‘OFF’ not illuminated, the transport

Lock is in ‘LOCKED POSITION’ and the backhoe

cannot be operated, the warning lamp (2) will be on.

IMPORTANT: The transport lock when activated will

only become effective when the boom is crowded into

the transport position.

WARNING

HAND HAMMER ATTACHMENT (OPTIONAL), Figure 15

With the hand hammer switch (1) ‘‘ON’’ and

illuminated a portable hammer can be used.

WARNING

Do not attempt to Connect or disconnect the

hammer with the switch (1) ‘on’ as the hydraulic

system will be pressurized and injury could result.

The hammer can be operated externally of the

machine while the backhoe is in operation, however

caution must be taken for personal safety that the

operator of the hand hammer does not enter the

working area of the backhoe.

IMPORTANT: Ensure the machine parking brake is

applied and the transmission levers are in neutral

before hammer operation.

2--14

SECTION 2 -- CONTROLS AND OPERATION

12

13

14

15

2--15

SECTION 2 -- CONTROLS AND OPERATION

BACKHOE CONTROL LEVERS (STANDARD

PATTERN), Figure 16

IMPORTANT: Ensure the Sideshift Carriage Clamp switch (3) is ON before operating the backhoe

RIGHT HAND -- Backhoe Operating Lever (1), is with the operator seated in the cab facing rearward.

DUAL OPERATION -Diagonal movement of the backhoe

lever (1) allows dual operation of

dipstick and bucket.

INDIVIDUAL OPERATION -Straight line movement of the backhoe

lever (1) operates dipstick and bucket.

DIPSTICK CROWDS OUT

BUCKET CURLS OUT

BUCKET CURLS IN

DIPSTICK CROWDS IN

LEFT HAND -- Backhoe Operating Lever (2), is with the operator seated in the cab facing rearward.

INDIVIDUAL OPERATION -Straight line movement of the backhoe

lever (2) operates boom and swing.

DUAL OPERATION -Diagonal movement of the backhoe

lever (2) allows dual operation of

boom and swing.

BOOM LOWERS

BOOM SWINGS RIGHT

BOOM SWINGS LEFT

BOOM LIFTS

1

FEATHERING CAPABILITY -Operating both backhoe Levers and the H.E.D foot pedal (1)

together (when fitted) allows multiple feathering operations.

2--16

SECTION 2 -- CONTROLS AND OPERATION

16

2--17

SECTION 2 -- CONTROLS AND OPERATION

BACKHOE CONTROL LEVERS (OPTIONAL FOUR LEVER

PATTERN), Figure 19

IMPORTANT: Backhoe operating levers are numbered from left to right with the operator seated in the cab facing

rearward.

LEVER

LEVER

LEVER

LEVER

1

2

3

4

DIPSTICK

BOOM

BUCKET

SWING

LEVER 1

DIPSTICK CROWDS OUT

DIPSTICK CROWDS IN

LEVER 2

BOOM LOWERS

BOOM RAISES

LEVER 3

BUCKET CURLS IN

BUCKET CURLS OUT

LEVER 4

BOOM SWINGS LEFT

BOOM SWINGS RIGHT

FEATHERING CAPABILITY -Operating backhoe levers and the

H.E.D. foot pedal (where fitted)

together allows multiple feathering operations.

17

2--18

SECTION 2 -- CONTROLS AND OPERATION

1

2

3

4

18

2--19

SECTION 2 -- CONTROLS AND OPERATION

BACKHOE CONTROL LEVERS (OPTIONAL ISO

PATTERN), Figure 19

IMPORTANT: Ensure the sideshift carriage clamp switch (3) is ‘on’ before operating the backhoe.

RIGHT HAND -- Backhoe Operating Lever (1), is with the operator seated in the cab facing rearward.

INDIVIDUAL OPERATION -Straight line movement of the backhoe

lever (1) operates boom and bucket.

DUAL OPERATION -Diagonal movement of the backhoe

lever (1) allows dual operation of

boom and bucket.

BOOM LOWERS

BUCKET CURLS IN

BUCKET CURLS OUT

BOOM LIFTS

LEFT HAND -- Backhoe Operating Lever (2), is with the operator seated in the cab facing rearward.

DUAL OPERATION -Diagonal movement of the backhoe

lever (2) allows dual operation of

dipstick and boom.

INDIVIDUAL OPERATION -Straight line movement of the backhoe

lever (2) operates dipstick and boom.

DIPSTICK CROWDS OUT

BOOM SWINGS LEFT

BOOM SWINGS RIGHT

DIPSTICK CROWDS IN

1

FEATHERING CAPABILITY -Operating both backhoe Levers and the H.E.D foot pedal (1)

together (when fitted) allows multiple feathering operations.

2--20

SECTION 2 -- CONTROLS AND OPERATION

19

2--21

SECTION 2 -- CONTROLS AND OPERATION

HANDLES AND WINDOWS

Cab Door Handles, Figure 20

The cab is equipped with lockable external door

handles (1) and supplied with two keys. To operate

insert the door key into the lock and turn clockwise or

anti--clockwise to lock or unlock.

The internal door handles (2) are opened from inside

of the cab by lifting the dog leg lever.

20

Cab Door and Side Opening Windows,

Figure 21

Rear Side Window Catch (1)

Door Window Retainer with release button (2)

Rear Window (3)

Door Window (4)

Window Handle Movements, Figure 22

21

To partially open the window pull and lift the handle,

and push out sliding along the striker pin to the stop

then push down to lock into position.

To completely open the window, pull and lift the

handle and push out until the slot in the handle, aligns

with the striker pin. Push the handle through and over

the striker pin and lock the handle onto the rail.

Secure the fully open window in position by the using

the window retainer’s.

IMPORTANT: The door and side windows can only

be opened and secured individually.

Door window open -- secured to rear side window.

Rear side window open -- secured to door window.

To close and lock the window, release the assembly

then pull the window closed. Lift the handle and pass

the slot over the striker pin to engage with the stop

then push down in an arc to engage the lower latch.

IMPORTANT: Always keep hold of windows when

opening or closing until the window is latched.

2--22

22

SECTION 2 -- CONTROLS AND OPERATION

Rear Window, Figure 23

The rear window is mounted on a sliding rail and may

be opened and stowed above the operators head.

To open the window, release the two middle latches

(1) and the two lower latches (2) and swing the

window inwards and upwards. To retain the window

in the stowed position above your head twist the two

retaining latches (2) into the locked position.

To close the window, twist the two retaining latches to

release the window then pull downwards and

forwards. Lock the window in the closed position

using all four latches.

23

SEAT ADJUSTMENT (Standard Type),

Figure 24 & 25

Lift the upper lever (1) at the front of the seat to adjust

the seat height. Allow the spring assisted mechanism

to push against you until the seat has risen to the

required height. Release the lever to lock the seat at the

desired height.

The seat pad can also be inclined forward or

backward to suite personal comfort.

The lower lever (2) at the front of the seat controls the

seat travel. Pull the lever up and move the seat

assembly forward or rearward, as required. The seat

will lock in position when the lever is returned to

normal position.

To pivot the seat from loader operating position to

backhoe operating position, move the seat rearward

to the position that allows clear movement and pivot

the seat around to the desired position then adjust the

seat forward or rearward as required.

24

To adjust the suspension setting, variable to operator

weight, pull out and turn the knob (3) on the right hand

side of the seat and rotate to increase or decrease the

loading as required when the operator is seated.

A lever (4) to the rear of the left hand side armrest

allows the backrest to be tilted. Push the lever and tilt

the back rest forward or rearward to the desired

position.

IMPORTANT: Do not use solvents to clean the seat.

Use warm water with a little detergent added.

machines with cab that have cloth upholstered seats,

require care to avoid wetting the seat more than

necessary.

2--23

25

SECTION 2 -- CONTROLS AND OPERATION

SEAT BELT

WARNING

In some countries, machines may be equipped with

a Cab or Roll Over Protection Support. Always use

the seat belt when a ROPS or safety cab is

installed. Do not use the seat belt if the ROPS is

removed from the machine.

Retractable Seat Belt, Figure 26

Pull the seat belt (2) slowly around you from the left

and place the buckle into the anchor point (1) at the

right hand side of the seat (if the belt LOCKS during

this operation slowly return the belt to the rest position

and repeat the procedure). Once fitted as you release

the belt any slackness will be returned and the belt will

be a snug fit around your body. In the event of hard

breaking the seat belt will LOCK and restrain you from

excessive forward movement.

The belts may be sponged down with clean soapy

water. Do not use solvents, bleach or dye on the belt

as these chemicals will weaken the webbing.

26

Replace the seat belt when it shows signs of fraying,

damage or general wear.

SEAT ADJUSTMENT (De Luxe Type)

1. Arm rest adjustment can be set to a desired

position by rotation of the thumb wheel on the

underside of the arm rest.

2. Lumber support adjustment is by rotation of the

hand wheel on the left hand side and can be set for

5 positions to suit the operator.

3. Backrest angle adjustment is set by lifting the

handle up and with the backrest set to the desired

position release the handle to lock.

4. Seat belt anchorage point

5. Seat pad tilt adjustment at the rear of the pad is

achieved by lifting the lever and seat pad to correct

height and release of the lever to set position.

6. Seat pad tilt adjustment at the front of the pad is

achieved by lifting the lever and pad to correct height

and releasing of the lever to set position.

7. Seat travel adjuster: pull lever up and slide the seat

forward, rearward or rotate seat through 180° to the