alkylate HF DESC

advertisement

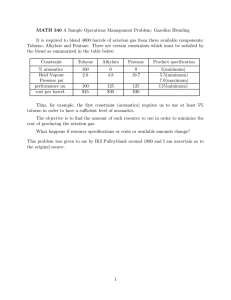

1.1 ALKYLATION PROCESS SUMMARY TABLE Table 1.1: Hydrofluoric Acid (HF) Alkylation process summary table PARAMETERS Objective DESCRIPTION To form long chain highly branched isoparaffin by reacting alkyl group with olefin Operating 20-40°C temperature Operating pressure 7.8 bar Catalyst Liquid Hydrofluoric acid (82% to 90%) Feedstock Isoparaffin & Olefin Feedstock ratio 5:1 (Isoparaffin to Olefin ) Product Alkylate, n-Butane, Propane By-product Acid soluble oils Major equipment Impeller Reactor, Depropanizer, Deisobutanizer, Defluorinator, HF Stripper, HF Rerun column, Drier 1.2 ALKYLATION PROCESS DESCRIPTION 1. The feed mixture (Olefin & Isoparaffin) from stream, S1 are first subjected to caustic wash to remove any Sulphur compound 2. The feed mixture from S2 enters into drier, R-102 to remove any water content followed by precooling in cooler C-103 to reduce the feedstock temperature before enters into reactor 3. Then, the mixture from S4 enters into impeller reactor, R-104 which consist of cooling tubes to absorb the heat generated 4. The reaction takes place at temperature of 20 to 40°C & pressure of 7.8 bar with incoming stream of acid catalyst from S18 5. The alkylate product produced from the reactor will be fed into phase separator S-105 via S5 where propane, recycled iso-butane, normal butane, and alkylate will be separated from HF 6. The alkylate rich stream, S6 from the separator will send to HF stripper S-107 to remove any HF in lower quantities and recycled back into the reactor via S8. 7. The HF removed from the bottom of separator via S7 will be transported to HF Rerun column R-106 to remove traces of oils from HF 8. The top product from the unit R-106 which is purified HF will be recycled back to the impeller reactor through S16 whereas the bottom product generated from S17 will be acid soluble oils 9. The alkylate rich stream from bottom of unit S-107 is fed into the deisobutanizer, D-108 to produce isobutane and propane mixture in S10 as top product and alkylate with n-butane in S11 as bottom product. 10. Then the top product from S10 will be transported to depropanizer D-110 to separate the propane as top product from stream S13 and isobutene as bottom product which will be recycled to the feed via S14 11. The bottom product from S11 will fed into defluorinator D-109 to remove any excess fluorines via caustic wash or adsorption to produce pure alkylate & n-butane as bottom product