Design Lab - Manual

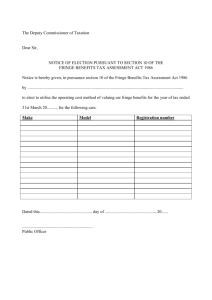

advertisement

PHOTOELASTICITY -1 Aim: To determine the material fringe value of a circular disc specimen subjected to compression. Fig – Photoelasticity Apparatus Theory: Photoelasticity: It is an experimental method of stress analysis employing transparent plastic models of a prototype and a field of polarized light produced by an instrument known as "polariscope". The interaction of polarized light with stressed models produce characteristic patterns, known as "Stress Patterns" from which the complete distribution of the principal stresses in two dimensional as well as three dimensional problems can be determined. Polarizer: A filter for converting randomly polarized light into plane polarized light; and which is located immediately in front of the light source. Analyzer: A Filter at the viewing end of the polariscope. The polarizer and analyzer are optically identical, and are thus named to distinguish their respective functions. Quarter wave plates: An optical element for inducing ¼ of a wavelength of relative retardation between two spatially perpendicular component light rays. The transmission polarizer contains two-quarter wave plates – one in conjunction with the polarizer, and one in conjunction with the analyzer. Plane polarized light: Light characterized by having the transverse vibrations limited to a single plane for a ray; or to parallel planes for a beam. Circularly polarized light: Light in which the plane of polarization rotates continuously with propagation of the light ray. Circularly polarized is produced when the vibration of two component rays of equal amplitude are perpendicular to each other on space and 1/4 of a wavelength out of phase. Fringe: Generically, colored or black lines, bands, or areas forming the photoelastic pattern, and representing loci of constant difference in principal stresses. Specifically, in the case of isochromatic fringes, the tint-of-passage in white light, or the centers of the dark bands in monochromatic light. Fringe order (N): ordinal numerical designation assigned to an isochromatic fringe. N equals the magnitude of the birefringence at a point (expressed in fringes), and is proportional to the difference in principal stresses at that point. Isochromatic: A fringe (single-colored in white light, essentially black in monochromatic light) representing a locus of constant difference in principal stresses (x - y) as the locus of constant maximum stress, max. Isoclinic: A black line representing a locus of constant directions of principal stresses, or in other words, constant inclinations of the principal axes with respect to an arbitrary reference axis. Monochromatic light: Light of only one wavelength. Principal Stresses: The algebraically maximum and minimum normal stresses at a point. The principal stresses coincide in direction with the principal strains in isotropic materials having the same elastic properties in all directions. Description of Apparatus: Polariscope is a precision optical instrument for performing quantitative stress measurements. The basic model consists of a polarizing assembly, analyzing assembly, mechanical drive coupling system for control of all four filters. All components are mounted on a common base frame. The polarizer, analyzer, and quarter wave plates are glass-laminated construction. They are mounted in Aluminum rings, and rotate on ball bearings. The rotation is indicated on a precision engraved dial. In use, a photoelastic model is placed in the polariscope and when forces are applied, a colorful fringe pattern results. This pattern reveals a visible picture of the stress distribution over the whole area of the model. The basic polariscope provides the capability for the following types of analysis and measurement. Overall assessment of nominal stress magnitude and gradients. The directions of the principal stresses The magnitude of sign of the tangential stresses along free (unloading) boundaries and in regions where the state of stress is uniaxial. The magnitude of the difference in principal stresses in a biaxial stress state. Procedure: (i) Switch 'ON' the monochromatic source and allow it to attain full intensity. (ii) Align the axis of the 'Polarizer' 'Analyzer' and 'Quarter wave plates' to obtain either a dark or bright field. (iii) Fix the specimen in the loading frame and bring the horizontal arm in position by means of balancing weights. (iv) Load the specimen suitably and determine the fringe order by Tardy's* method of compensation. (v) Increase the load in equal steps and note the corresponding fringe order. (vi) Plot a graph of load vs. fringe order (F Vs. n) Diagram: Observations: 1. 2. 3. 4. Diameter of the circular disc d = _____ mm Thickness of the circular disc h = _____ mm Length of fulcrum to centre of loading pan l1 = _____mm Length of fulcrum to centre of specimen l2 = _____ mm Tabular column: Load (FL) Sl. No. Kg N Load on Model ‘F’, N Fringe order (n) 1. 2. 3. 4. Calculations: 1. Load Ratio r = l1/l2 2. Load on model: F = FL * r 3. Slope = F / n 4. 5. N/fringe (from Graph) Material fringe value: (f) f = 8/D (F / n) N/mm-fringe Model fringe value: (fm) fm = 8P/Dh N/mm2 -fringe Slope (F/n) Material Fringe Value f Model Fringe Value Fm PHOTOELASTICITY -2 Aim: To determine the material fringe value of a photoelastic material using a simply supported beam specimen subjected to pure bending. Theory: In photoelastic analysis the stress distribution in a complex model is sought for applied load. To obtain the stress distribution we should first know the material fringe value. The material fringe values of photoelastic materials vary with the supplier, the batch of resin, the temperature and the age. For this reason it is always necessary to calibrate each sheet of photoelastic material at the time of test. Accurate determination of material fringe value can be obtained by using 1. Tensile specimen 2. Disc specimen The circular polariscope setup is used in this experiment. supported beam loaded as shown in figure. 3. Beam specimen The test specimen is a simply Description of Apparatus: Polariscope is a precision optical instrument for performing quantitative stress measurements. The basic model consists of a polarizing assembly, analyzing assembly, mechanical drive coupling system for control of all four filters. All components are mounted on a common base frame. The polarizer, analyzer, and quarter wave plates are glass-laminated construction. They are mounted in Aluminum rings, and rotate on ball bearings. The rotation is indicated on a precision engraved dial. In use, a photoelastic model is placed in the polariscope and when forces are applied, a colorful fringe pattern results. This pattern reveals a visible picture of the stress distribution over the whole area of the model. The basic polariscope provides the capability for the following types of analysis and measurement. Overall assessment of nominal stress magnitude and gradients. The directions of the principal stresses The magnitude of sign of the tangential stresses along free (unloading) boundaries and in regions where the state of stress is uniaxial. The magnitude of the difference in principal stresses in a biaxial stress state. Procedure: (vii) Switch 'ON' the monochromatic source and allow it to attain full intensity. (viii) Align the axis of the 'Polarizer' 'Analyzer' and 'Quarter wave plates' to obtain either a dark or bright field. (ix) Fix the specimen in the loading frame and bring the horizontal arm in position by means of balancing weights. (x) Load the specimen suitably and determine the fringe order at the extreme fibres by adopting Tardy’s method of compensation. (xi) Increase the load in equal steps of 20 N and note the corresponding fringe order. (xii) After completing the experiments the specimen is removed from the corresponding value of and the light source is switched off. (xiii) Plot a graph of load vs. fringe order (P Vs n) (xiv) The fringe order is given by the equation n = 1 ± (/180) Where is the angle through which the analyser must be rotated to obtain extinction at the edge of the specimen. Fringe order for the different loads applied is noted. The results are obtained and ‘P’ v/s ‘n’ curve is plotted and the slope is obtained. Diagram : Observations : Length l1 Length l2 Distance X1 Distance X2 Depth of the specimen Thickness of the specimen Load on the specimen Feff = ____ mm = ____ mm = ____ mm = ____ mm = ____ mm = ____ mm = F * (l1/l2), N Tabular column : Sl. No. 1. 2. 3. 4. 5. Load Kg N Effective Load, Feff, N Fringe Order, n Material Fringe value ‘f’ Model Fringe value, fm Calculations: Section Modulus Z = td2/6, mm3 Bending moment on the specimen Mb = [F/2] * [(X1-X2)/2] N-mm Bending stress b = Mb/Z MPa Maximum Bending Stress b max = M/Z = n*f / t F = n slope Slope (from the graph F Vs n) 3( X 1 X 2 ) F n 2d 2 slope Material Fringe value f Model fringe value fm 3( X 1 X 2 ) F n 2d 2t slope PHOTOELASTICITY -3 Aim: To determine the stress concentration factor for a flat plate with a circular hole, subjected to a tensile load. Theory: In photoelastic analysis the stress distribution in a complex model is sought for applied load. To obtain the stress distribution we should first know the material fringe value. The material fringe values of photoelastic materials vary with the supplier, the batch of resin, the temperature and the age. For this reason it is always necessary to calibrate each sheet of photoelastic material at the time of test. Accurate determination of material fringe value can be obtained by using the circular polariscope setup is used in this experiment. The test specimen is a flat plate with a circular hole made of photoelastic material. Definitions: Photoelasticity: It is an experimental method of stress analysis employing transparent plastic models of a prototype and a field of polarized light produced by an instrument known as "polariscope". The interaction of polarized light with stressed models produce characteristic patterns, known as "Stress Patterns" from which the complete distribution of the principal stresses in two dimensional as well as three dimensional problems can be determined. Polarizer: A filter for converting randomly polarized light into plane polarized light; and which is located immediately in front of the light source. Analyzer: A Filter at the viewing end of the polariscope. The polarizer and analyzer are optically identical, and are thus named to distinguish their respective functions. Quarter wave plates: An optical element for inducing ¼ of a wavelength of relative retardation between two spatially perpendicular component light rays. The transmission polarizer contains two-quarter wave plates – one in conjunction with the polarizer, and one in conjunction with the analyzer. Plane polarized light: Light characterized by having the transverse vibrations limited to a single plane for a ray; or to parallel planes for a beam. Circularly polarized light: Light in which the plane of polarization rotates continuously with propagation of the light ray. Circularly polarized is produced when the vibration of two component rays of equal amplitude are perpendicular to each other on space and 1/4 of a wavelength out of phase. Fringe: Generically, colored or black lines, bands, or areas forming the photoelastic pattern, and representing loci of constant difference in principal stresses. Specifically, in the case of isochromatic fringes, the tint-of-passage in white light, or the centers of the dark bands in monochromatic light. Fringe order (N): ordinal numerical designation assigned to an isochromatic fringe. N equals the magnitude of the birefringence at a point (expressed in fringes), and is proportional to the difference in principal stresses at that point. Isochromatic: A fringe (single-colored in white light, essentially black in monochromatic light) representing a locus of constant difference in principal stresses (x - y) as the locus of constant maximum stress, max. Isoclinic: A black line representing a locus of constant directions of principal stresses, or in other words, constant inclinations of the principal axes with respect to an arbitrary reference axis. Monochromatic light: Light of only one wavelength. Principal Stresses: The algebraically maximum and minimum normal stresses at a point. The principal stresses coincide in direction with the principal strains in isotropic materials having the same elastic properties in all directions. Stress concentration: A stress concentration (often called stress raisers or stress risers) is a location in an object where stress is concentrated. An object is strongest when force is evenly distributed over its area, so a reduction in area, e.g. caused by a crack, results in a localized increase in stress. A material can fail, via a propagating crack, when a concentrated stress exceeds the material's theoretical cohesive strength. The real fracture strength of a material is always lower than the theoretical value because most materials contain small cracks or contaminants (especially foreign particles) that concentrate stress. Stress concentration factor: A theoretical factor Kt expressing the ratio of the greatest stress in the region of stress concentration to the corresponding nominal stress. Description of Apparatus: Polariscope is a precision optical instrument for performing quantitative stress measurements. The basic model consists of a polarizing assembly, analyzing assembly, mechanical drive coupling system for control of all four filters. All components are mounted on a common base frame. The polarizer, analyzer, and quarter wave plates are glass-laminated construction. They are mounted in Aluminum rings, and rotate on ball bearings. The rotation is indicated on a precision engraved dial. In use, a photoelastic model is placed in the polariscope and when forces are applied, a colorful fringe pattern results. This pattern reveals a visible picture of the stress distribution over the whole area of the model. The basic polariscope provides the capability for the following types of analysis and measurement. Overall assessment of nominal stress magnitude and gradients. The directions of the principal stresses The magnitude of sign of the tangential stresses along free (unloading) boundaries and in regions where the state of stress is uniaxial. The magnitude of the difference in principal stresses in a biaxial stress state. Procedure: (xv) Switch 'ON' the monochromatic source and allow it to attain full intensity. (xvi) Align the axis of the 'Polarizer' 'Analyzer' and 'Quarter wave plates' to obtain either a dark or bright field. (xvii) Fix the specimen in the loading frame properly with the help of shackles and bring the horizontal arm into position (xviii) Load the specimen suitably and determine the fringe order at the extreme fibres by adopting Tardy’s method of compensation. (xix) Increase the load in equal steps of 5 Kg and note the corresponding fringe order. (xx) After completing the experiments the specimen is removed from the corresponding value of and the light source is switched off. (xxi) Plot a graph of load vs fringe order (P Vs N) (xxii) Determine the stress concentration factor Diagram: Observations: Width of the specimen w = ____mm Diameter of the circular hole d = ____mm Thickness of the specimen t = ____mm Length l1 = ____mm Length l2 = ____mm Tabular column: Sl. No. 1 2 3 4 5 Load FL Kg N Effective Load, F N Angle Fringe order x n Peak Stress p MPa Normal Stress n MPa SCF Kt = p /n Calculations: Effective load F = FL * (l1/l2) Fringe order n = x + ( / 180) Normal stress n = F / (w-d) t Peak Stress or Max. Stress p = (n f)/t Stress concentration factor Kt= p /n (10 to 12 N/mm/sec) Porter Governor Aim: To conduct experiment on Porter governor & to determine the frictional resistance at the sleeve, centrifugal forces on the governor balls & draw the controlling force diagram. Apparatus: Porter Governor, Tachometer, Measuring tape. Observations: 1. Mass of governor fly balls m=------ Kg 2. Mass of sleeve M= ---------- Kg 3. Length of upper links = Length of lower links L= ------ meters 4. Offset of links from axis of rotation y = -------- meters 5. Initial distance between top & bottom pivots H= --------meters h L C 2 mw r S H r L M Sleeve motion y Schematic diagram of Porter Governor Tabular Column: Trial Speed Sleeve Distance Distance No ‘N’ Lift 'c' 's' rpm ‘x’ meters meters meters Radius of rotation 'r' meters Angle Height of Friction governor al '' degrees 'h' meters Force 'f' Newton Centrifugal Effort force ‘E’ 'Fc' Newton Newton 1 2 3 4 5 Specimen calculations: H x 1. Distance c metres 2 2 2. Distance s L 2 c 2 meters 3. Radius of rotation r y s metres where y=offset of links c 4. Angle sin 1 L 5. Height of governor h r tan 6. Frictional force we know that the equilibrium speed of a porter governor with equal link lengths & equal offset of the upper & lower links is given by mg ( Mg f ) 895 N2 mg h N 2 mgh Hence f= (m M ) g 895 7. Effort of the governor is the mean force exerted at the sleeve for a fractional change in speed. E=0.01(Mg+mg+f) for 1% change in speed. 8. Power =Effort x Sleeve lift=E x x=--------Nm 2N 9. Angular velocity w rad/sec 60 10. Centrifugal force or controlling force Fc=mwr Newton Power P, Nm centrifugal force Fc Radius of rotation r Controlling force curve Proell Governor Aim: To conduct experiment on Proell governor & to determine the frictional resistance at the sleeve, centrifugal forces on the governor balls & draw the controlling force diagram. Apparatus: Proell Governor, Tachometer, Measuring tape. Observations: 6. Mass of governor fly balls m=------ Kg 7. Mass of sleeve M= ---------- Kg 8. Length of upper links = L = ------ meters 9. Offset of links from axis of rotation y = -------- meters 10. Extension of links which carry rotating masses e = ----- meters 11. Initial distance between top & bottom pivots H= --------meters Pivot 2 mw r h L C e S r M Sleeve motion x Pivot y Schematic diagram of Proell Governor Tabular Column: Trial No Speed ‘N’ Rpm Sleeve Lift ‘x’ meters Distan Distance Radius ce 'c' 's' of meters meters rotation 'r' meters Angle Height of Frictional governor Force 'f' '' Newton degrees 'h' meters Centrifugal force 'Fc' Newton Effort ‘E’ Newton 1 2 3 4 5 Specimen calculations: H x 11. Distance c metres 2 2 12. Distance s L 2 c 2 meters 13. Radius of rotation r y s metres where y=offset of links c 14. Angle sin 1 L 15. Height of governor h r tan 16. Frictional force As equilibrium speed of a proell governor with equal offset of links is c mg ( Mg f ) 895 (c e) mg h where e=length of extension links N2 N 2 mgh c e (m M ) g 895 c 17. Effort of the governor is the mean force exerted at the sleeve for a fractional change in speed. E=0.01(Mg+mg+f) for 1% change in speed. Hence f= 18. Power =Effort x Sleeve lift=Ex=--------Nm 2N 19. Angular velocity w rad/sec 60 20. Centrifugal force or controlling force Fc=mwr Newton Power P, Nm centrifugal force Fc Radius of rotation r Controlling force curve Hartnell Governor Aim: To conduct experiment on Hartnell (Spring controlled) governor & to determine the frictional resistance at the sleeve, centrifugal forces on the governor balls & draw the controlling force diagram. Apparatus: Hartnell Governor, Tachometer, Measuring tape. It is a spring type governor and much more sensitive then porter and proell governor. In this governor the balls are controlled by spring which is mounted on the spindle axis. It consists of the casing in which the pre-compressed spring is housed so as to apply the force on the sleeve. There are two bell crank levers and each of it carries a ball at one of the end and the roller at another end, both are fitted on the frame of the casing. The casing along with spring and frame rotates about the spindle axis. When the speed of the governor increase then the balls fly out away from the axis, bell crank lever moves on the pivot and then the roller end lifts the sleeve against force. This movement is then transferred to the throttle of the engine. We can also adjust the force just by tightening it. In this a represents the vertical arm of the bell crank lever and b represents the horizontal arm of the bell crank lever, W is the weight of the sleeve, w is the weight of the ball and s is the spring force exerted on sleeve. For deriving the relation we take half of the combine weight exerted by sleeve and spring. Fly ball r1 r 2 F=m c w r a Ball arm a (S+f) 2 b x b Sleeve arm x =sleeve lift (or compression of spring) Fulcrum Taking moments about the fulcrum , (S f ) Fc a b, (i) where 2 Fc =centrifugal force on the rotating masses=mw 2 r Newton S= Spring force exerted on the sleeve S=stiffness of spring compression of spring (or sleeve lift)=k x Rearranging the terms in the equation (i), a frictional force at the sleeve f=2Fc ( S ) Newton b Observations: 12. Mass of governor fly balls m=------ Kg 13. Stiffness of the spring, k= 3 kg/cm= 2943N/m 14. Length of vertical (ball arm) link = a= ------ meters 15. Length of horizontal (sleeve arm) link = b= ---------meters 16. Initial radius of rotation r1=--------- meters Tabular Column: Tria l No Speed ‘N’ rpm Sleeve Lift ‘x’ meters Spring Radius of Centrifugal force ‘S’ rotation ‘r’ force Newton meters 'Fc' Newton Frictional Force 'f' Newton Effort ‘E’ Newton Power P, Nm 1 2 3 4 5 Specimen calculations: 2 N rad/sec 60 22. Spring force S=Stiffness x sleeve lift = k x N a 23. Radius of rotation r x r1 metres where r1=Initial distance between the governor b masses & the spindle axis (Stationary condition) 24. Centrifugal force Fc= mw 2 r Newton where m= mass of governor fly balls. a 25. frictional force at the sleeve f=2Fc ( S ) Newton b 26. Effort of the governor is the mean force exerted at the sleeve for a fractional change in speed. E=0.01(Mg+S+f) for 1% change in speed. 21. Angular velocity of the governor spindle w 27. Power =Effort x Sleeve lift= E x =--------Nm centrifugal force Fc Radius of rotation r Controlling force curve GYROSCOPE Aim: To conduct an experiment on motorized gyroscope and to determine; (i) Gyroscopic couple (ii) Applied couple and (iii) To demonstrate the effect of gyroscopic couple using right hand screw rule Observations: 1. Mass of the spinning disc M= ------------ kg 2. Diameter of the disc D= ----------- meters 3. Distance of the weights added from the fulcrum of the motor x= -------meters Tabular column: Trial Weight No added, 'W' Newton RPM of the disc 'N' Angular Angle Time velocity '' taken t of spin deg (for precession 'w' of '') sec rad/sec Angular Gyroscopic Applied velocity of couple Cg, couple precession Nm Ca , Nm 'wp' rad/sec 1 2 3 4 Specimen calculations: 1. 2. 3. 4. 5. MD 2 = kg-m2 Mass moment of inertia of the disc I 8 2 N = rad/sec Angular velocity of spin w 60 w = rad/sec Angular velocity of precession p t 180 Nm Gyroscopic couple Cg = I w wp = Nm Applied couple Ca = W X = a' C g C Ca Ca O g a Characteristic curve Spin Vector diagram As the disc is spinning counterclockwise when viewed from the front, the applied couple acts so as to tilt the spin vector to oa'. The reactive couple tends to rotate the entire system clockwise when viewed from the top, which is evident from the Right hand screw rule. FULCRUM DISC WEIGHT W X DYNAMIC BALANCING Aim: To conduct an experiment on dynamic balancing machine and to determine; (iv) Unknown angular settings between unbalanced masses (v) Un known radius of rotation (vi) To demonstrate the effect of rotating unbalance before & after balancing Apparatus used: Dynamic balancing machine, Vernier caliper, Rotating masses, Allen key, Spanners, etc. Observations: 4. Rotating unbalance masses m=66 gms=0.066 kg 5. Diameter of the slotted disc D= 175mm 6. Diameter of the unbalance masses=30 mm 7. Radius of rotation of the masses in extreme position, X = (radius of slotted disc-radius of unbalance discs) = (175-30)/2= 72.5mm Problem 1 Determine the relative angular settings & the radius of mass A for complete dynamic balance, given the masses in the planes A,B, C & D are all equal to 66 gms. Radii of rotation of masses in planes B, C & D are 72.5 mm, 60 mm 50 mm respectively. The axial distance between the planes A-B, B-C, & C-D is 100 mm each. R.P A r B C D A 100mm 100mm 100mm Tabular column: (Problem 1) Plane Mass M, Radius of Centrifugal Distance Couple *A(Reference Plane) B C D kg rotation ‘r’ mm 0.066 rA force ‘Mr’ from ‘MrL’ kgkg-mm reference mm2 plane ‘L’, mm 0.066rA 0 0 0.066 0.066 0.066 72.5 60 50 4.785 3.96 3.3 100 200 300 478.5 792 990 D 2 Scale: 100 kg-mm=1cm Scale: 1 kg-mm =1 cm D =232 deg 990 792 3.3 C 478.5 B 0.066rA 3.96 C =81 deg 4.785 Couple Polygon From couple polygon find the relative angular settings between B, C & D Answers: A B =0 deg C =81 deg D =232 deg Force Polygon From couple polygon find the unknown radius of rotation & angle of mass in plane A Answers: A =201 r A =55 mm The masse may then be arranged as per the calculations and checked for complete dynamic balance. ANSWERS FOR PROBLEM 1 C 0 201 0 232 0 81 B A D Relative Angular Positions obtained from graphical solution Given Data: rB=72.5 mm, rC=60 mm, rD=50 mm Distance between planes =100 mm Answers: rA=55 mm, CD Problem 2: A rotating shaft carries four equal masses A, B, C & D of 66 gm each which are placed in planes as shown in fig. The radius of rotation of mass B is 70 mm and the angle between B & C is 900 and between B & D is 2400. Find the radii of rotation of masses A, C & D and also the angular position of mass A for complete dynamic balance. Check for balance graphically. R.P A B C C D 0 240 rA 0 90 B 100mm 50mm 100mm D Tabular column: Sl.No Plane Mass kg 1 2 3 4 A B C D 0.066 0.066 0.066 0.066 M, Radius of Centrifugal rotation ‘r’ force ‘Mr’ mm kg-mm rA 0.066rA 70 4.62 rC 0.066rc rD 0.066rD Distance from Couple reference plane ‘MrL’ ‘L’, mm mm2 0 0 100 462 200 13.2rC 300 19.8rD kg- 240 deg 2 Scale: 100 kg-mm=1cm Scale: 1 kg-mm =1 cm 240 deg 13.2 r c 3.1 19.8rD 90° 462 B A 0.066rA C =90 deg 4.62 =0 deg Couple Polygon Force Polygon Fromcouple polygon find the unknown radius of rotation of masses C&D Answers: 4.026 From couple polygon find the relative angular settings betweenA &B rA =51 mm A =214 deg rC =61 mm r D =47 mm From the closure of the couple polygon, we get rc=61 mm rD=47 mm. Now, in the force table, 0.066rc=0.066x61=4.026 Kg-mm And 0.066rD=0.066x47=3.1 kg-mm. Substituting the above values & drawing the force polygon we obtain the direction of mass A & its radius of rotation. Ans: rA=51 mm, rC=61 mm rD=47 mmA=2140 ********* Critical Speed of Shafts Aim: To determine the critical speeds of a simply supported beam theoretically & to compare with the experimental values along with mode shapes. Apparatus: Steel rods of diameters 6mm & 8 mm, Photosensitive Tachometer, Critical speed test kit. Observations: 1. Elastic modulus of steel E= 207 GPa 2. Length of rod L=1.05 meters 3. Density of steel = 7800 kg/m3 4. Rod diameter 6mm and 8 mm Shaft Diameter ‘d’ meters Mass per unit length’m’ kg/m Mode Number 6 x10-3 8 x10-3 Theoretical Critical frequency (Hz) Experimental Frequency (Hz) I I Mode Number Theoretical Critical frequency (Hz) II II Specimen Calculations: 1. Mass per unit length of shaft =density x cross sectional area d 2 m= kg/m 4 2. Theoretical critical frequency = 3. Theoretical critical frequency = 2.45 EI mL4 7.95 for I mode EI for mode II mL4 Critical speed ( rpm ) 4. Experimental frequency = Hz 60 Mode Shapes I mode Node II mode Experimental Critical frequency (Hz) Spring Mass System (Undamped vibrations) Aim: To determine the natural frequency of vibrations experimentally & compare with the theoretical value. Apparatus: Spring, Weight, Scale, Graph sheet. Observations: 1. Free length of spring lo= -------meters 2. Mass attached with hanger = ------kg 3. final length after attaching the mass l = -------- meters 4. Diameter of recorder drum dr= ------mm 5. Rotational speed of the drum n= 6 rpm. Tabular column (Undamped Vibration) Sl.No Theoretical frequency fn (the) Hz Distance ‘H’ per cycle from graph, mm Experimental frequency fn (exp) Hz % Error Specimen calculations: 1. Static deflection of spring = (length of spring after attaching mass – free length of spring) = (l – l0) = ------- meters. 2. Stiffness of the spring k mg =-----------N/m where g =9.81m/sec2 k g =---------- radians/sec (OR w n rad/sec) m w 1 k 4. Frequency in Hertz fn= or n =-----------cycles per sec (CPS) or Hz 2 2 m 1 5. Experimental natural frequency f n (exp) = where T H T where H=distance measured on the graph per cycle, mm V dr n and V=linear velocity of the drum= , mm/sec 60 and n=rpm of the recorder drum =6 rpm. 3. Circular frequency wn= V Hence f n (exp) H f n (the ) f n (t exp) 100 f n ( the ) 6. % error = H Undamped Vibrations k k m k m x Undamped Free vibrations Spring Mass System (Damped vibrations) Aim: To determine the logarithmic decrement, damping ratio & damping coefficient for the spring mass system with viscous damping. Observations: 1. Free length of spring lo= -------meters 2. Mass attached with hanger = ------kg 3. final length after attaching the mass l = -------- meters x1 x2 x 3 Under damped vibrations (Viscous Damping) Tabular column (Damped Vibration) Sl.No Static deflection meters Ratio of Successive amplitudes Logarithmic decrement Damping ratio Damping coefficient C Frequency of Damped vibrations fd Specimen calculations: (1) Static deflection of spring = (length of spring after attaching mass – free length of spring) = (l – l0) = ------- meters. (2) Circular frequency w n (3) Frequency in Hertz fn= 1 2 g rad/sec w g or n =-----------cycles per sec (CPS) or Hz 2 (4) Ratio of successive amplitudes xn = xn 1 x x i.e 1 or 2 and so on from graph x2 x3 x (5) Logarthmic decrement ln n xn 1 2 Damping ratio = (6) But 2 2 1 2 4 (7)Frequency of damped vibration f d f n 1 2 = (8) Damping coefficent C 2mwn N / m / sec Hz k C m x Damped Free vibrations Torsional Pendulum (Torsional vibrations-Undamped) Aim: To determine the natural frequency of Torsional vibrations experimentally & compare with the theoretical value. Apparatus: Torsional pendulum, Scale, Graph sheet & marker (sketch) pen. Observations: 6. Diameter of the wire or shaft d =--------meters 7. Length of wire L =---------meters 8. Rigidity modulus of wire material (Steel) G = 84 GPa= 84x109 N/m2 9. Mass of the disc M= -------- kg 10. Diameter of the disc D= ------ meters 11. Diameter of the recorder drum dr = --------- mm 12. Rotational Speed of the drum n=6 rpm. Tabular column (Undamped Vibration) Sl.No Theoretical frequency fn (the) Hz Distance ‘H’ per cycle from graph, mm Experimental frequency fn (exp) Hz % Error Specimen calculations: MD 2 kg-m2 = ----8 d4 7. Polar moment of inertia of the shaft J =-----------m4 32 6. Mass moment of inertia of the disc I 8. Natural frequency of Torsional vibration (Theoretical ) f n (the ) 9. Circular frequency w n 2 f n =---------- radians/sec 7. Experimental natural frequency f n (exp) 1 2 1 = where T H T where H=distance measured on the graph per cycle, mm V dr n and V=linear velocity of the drum= , mm/sec 60 and n=rpm of the recorder drum =6 rpm. V Hence f n (exp) H GJ = -------- Hz IL f n (the ) f n (t exp) 100 f n ( the ) 8. % error = Experimental Graph obtained for Undamped Torsional vibration H Undamped Vibrations d L I Undamped Torsional vibrations Torsional Pendulum (Damped vibrations) Aim: To determine the logarithmic decrement, damping ratio & damping coefficient for the Torsional pendulum with viscous damping. Observations: Diameter of the wire or shaft: d =--------meters 1. Length of wire L =---------meters 2. Rigidity modulus of wire material (Steel) G = 84 GPa= 84x109 N/m2 3. Mass of the disc M= -------- kg 4. Diameter of the disc D= ------ meters 5. Diameter of the recorder drum dr = --------- mm 6. Rotational Speed of the drum n=6 rpm. x1 x2 x 3 Under damped vibrations (Viscous Damping) Tabular column (Undamped Vibration) Sl.No Theoretical frequency fn Hz Ratio of Successive amplitudes Logarithmic decrement Damping ratio Damping coefficient C Frequency of Damped vibrations fd Specimen calculations: (4) Frequency in Hertz fn= 1 2 GJ IL = ----------cycles per sec (CPS) or Hz (4) Ratio of successive amplitudes xn = xn 1 x x i.e 1 or 2 and so on from graph x2 x3 x (5) Logarthmic decrement ln n xn 1 2 Damping ratio = (6) But 2 2 1 2 4 (7)Frequency of damped vibration f d f n 1 2 = (8) Damping coefficent C 2 I wn N / m / sec Hz d L Oil I Damped Torsional vibrations STRAIN ROSETTES Aim: To conduct experiment on a member subjected to combined bending and torsion using Rectangular & Delta Rosettes and to determine; (vii) Principal Strains & their orientations (viii) Principal stresses Apparatus required: Strain rosettes, Cantilever shaft with torsion arm, Weights, Wheat stone bridge circuit, and Strain indicator. Observations: 8. Elastic modulus of the material of the beam E=207 GPa 9. Poisson's ratio 10.Type of strain gauges: Electrical resistance type : Rectangular & Delta arrangement Tabular column: (Rectangular Rosette) Tria l No 1 2 3 Load, Newton Micro Strain '' x(10-6) Micro Strain '' x(10-6) Micro Strain 'C' x(10-6) Major Principal strain 1 Minor Principal strain 2 Major Principal stress 1 Minor Principa l stress 2 1 2 Specimen calculations: 6. Principal Strains; A C 2 1,2 1 2 A C 2 B A C 2 2 +ve sign for 1 (major principal strain) and – ve sign for 2 (Minor principal strain) (Note: if any of the individual strain values are negative, substitute them as it is) 2. Principal Stresses; 1 E 1 2 2 1 2 Mpa 2 E 2 1 1 2 2 Mpa Where, 1 and 2 are the major and minor principal stresses. 1 1 2 B A C tan = 3. Principal angle 2 A C deg and 1 2 Maximum shear stress max = --------------------Mpa 4. 2 Tabular column: (Delta Rosette) Tria l No Load, Newton Micro Strain '' x(10-6) Micro Strain '' x(10-6) Micro Strain 'C' x(10-6) Major Principal strain 1 Minor Principal strain 2 Major Principal stress 1 Minor Principa l stress 2 1 2 1 2 3 Specimen calculations: 1. Principal Strains; 1,2 1 2 A B C 3 3 A B B C C A 2 2 2 +ve sign for 1 (major principal strain) and – ve sign for 2 (Minor principal strain) (Note: if any of the individual strain values are negative, substitute them as it is) 2. Principal Stresses; 1 E 1 2 1 2 2 2 E 2 1 1 2 2 Where, 1 and 2 are the major and minor principal stresses. 1 1 3( C B ) 3. Principal angle 2 tan 2 A B C and = deg 1 2 Maximum shear stress max = --------------------MPa 4. 2