BS-1414-1975

advertisement

BS 1414 : 1975

UDC 821.648.&: 888.14: (822.313+eI2.7&3+1II.I1

"

(

Specification for

Steel wedge gate valves

(flanged and butt-welding ends)

for the p.etroteum, petrochemical

and allied industries

NO COPYING

IN ANY FOR.\1 WlTIIOl'T

WRITTEN

PERMISSION

FROM

B.."l

STANDARDS

1lUs British standard. haviDa beat "IIIX0Wld by the Petroleum Equipment Industry SWJcIudI Committee. wu published

under the authority of the ExecuM Baud Oft30 April 1975.

C British StaadardaIDStitutioa.

1975

Fust published January 1949

FII'It RViIioDJune 1954

Second rcvisioa Man:b 1960

1bird rcviIioa April 1975

ISBN: 0 580 08991 6

Copyright

UICI'S or British Standards are remiDcledthat copyriabt subsists in aU ISI publications. No put 01 this pu•••••• inQ ~

be

reproduced in any form without the prior permissionin writiq of BSI. This does DOtpndude the •.••••• ia the CIOUI'Ie

or

ImplcmcmiDathe atandard. of DCICCa1UY ddaill such as symbols and size. type or pade dai~tioaI.

Enquiria IbouId be

addraIcd to the BSI Scaetariat.

Contract •.•••ul •.•ments

Attaation is drawn to the fact that this British Standard does DOtpurport to include aU the ~

pIO¥iIioosoIa CODtnId.

Revlalon of Brltlah Stsnclanla

III order to keep abreast of pr'OII'eSI in the indumieI C:Oncemcd,British SIaDdardsare IUbjectto periodic:aIN¥iew. !lIo_ ••••

(or improvaDeDti will be recorded and in due course broulht to the notice of the committees charpd with the IW¥iIioa01

the Itandards to which they refer.

British Standards are revised, when necessary,by the issue either or ameadmcnt IIipI or of miIed .utioaL B II' I e....t tIIIIt

__ elltdtWa SC:adudI •••• ac:saJa tIIIt die, 8ft •• pi I '""'q el tile 1ateIt· v ---~.•_ •••••••.FuB ioCClI'ID&IioD

aa

BSI public:atiooa,numbcriD&over 6000,wiDbe (ound in the lIrllbII SItIIrtIt1tvb y~.

1biI iaformatioDillUJlPIe;_4l.4 by

ddaiJs published each month in BSI Newsor new publications. revisioDIand amendmadI.

d

BSI Nnn is available to Sublcribiq Membcn 01 the IDStitutioa. AU other puhl~ta.- ilia)' be pun:baIed cIka:t from ••••

Department. EDquirieac:oncemiDilUblcn1liDcmembasbip. wIUcbbaa considerable advan•••• wiDbe weIcomecL&DdIhouId

be made to Sublc:riptionsDepartment. Both dcpanmcntl are located at:

III P•••••••••

LoIIIIaa

Nt tND (T•••••

01-131_1; T~

23211).

The rol1owiq BSI references !date to the wort on this atudard:

Committee reference PEElI Draft for COII1IDCDt

7J/37781 DC

Co-operating organizations

The Petroleum Equipment IDduItry Standards Committee. UDderwhole supervision this BritisltSIaDdanlwas prepaftld. COIIIiIta

o( repnlCDtaIiws from the (oIIowiDiCo...et.iu-d ~tI

ancllCicntificand iDdUlbial0llP'..n..v-:

au

British

Corporatioa

British ~.ft;""1

J!DIineerinI coaCcdcratioa

British R.1IIlIl«MaouCIlcturcn' Associatiaa Ltd.

·British Sted IDduICry

"CouDI:il 01 British MaDuC8chmn01 PctroIcum E!q11ipment

Deputment 01 Enav (Oil)

~ Compuica Matcriall AIIociaIion

Proc:as Plant AIIodaIioa

The orpftmdolw muted with an utaisIt in the above lilt. toaethcr' with the (o1IowiDt.•••

committee eatruated with the preparation or this British StancIarcI:

AaocifItioa 01 Hychaulic Equipment Ma~

British Cbcmical J;1\~

Contnctors' AIIOCiaJion

British IndUltrial McuuriDa and Control AppuatUI

Manufac:turcn' A.uciatioD

British PIutica FedaadoD

8002

directly repl'ClCDledaa the

British Ship RcIeIn:h ~don

British Valve ManuCactun:n'AlIOCiItion

~ •••.••• EquipmeGtUIas' AIIodatiaa

Steel CutiDp 04----..,..

AMD5837

Amendment No.1

published and effective from 30 June 1988

to BS 1414: 1975

Specification for steel wedge gate valves

(flanged and butt-welding ends) forthe

petroleum, petrochemical and allied industries

Revised text

AMD5837

Inside front cover

June 1988

In line 2 of the paragraph covering BSI references relating to work on the standard. delete

'PEEl I ' and substitute 'PSEl7 (formerly PEE/I)'.

AMD5837

Foreword

June 1988

Delete paragraph 3 (beginning 'British Standards for')

AMD5837

Clause 27. Yoke sleeve retaining nut

June 1988

Delete this clause and substitute the following new clause.

'27. Yoke sleeve retaining nut

The yoke sleeve retaining nut shall be ofa material having a melting point above 955 -c. Grey cast iron shall not be

used. If malleable cast iron is used it shall comply with the requirements ofBS 6681 for grade B 32-10 or grade

B 35-12. Ifspheroidal graphite cast iron is used it shall comply with the requirements ofBS 2789 grades 350/22,

400/18 or 420/12:

AMD5837

Clause 32.1

June 1988

In line I delete'BS 1506-621 grade A' and substitute 'BS 1506-630-860'.

AMD5837

June 1988

Table 2. Trim materials, hardness and acceptable specifications

Delete this table and substitute the new table 2 attached.

---------------------------------------------------

--------------------------------------------------AMD 5837

June 1988

aSI publications

referred to in this standard

Delete the entries for

as 310, BS 1501-6 and

BS 1503.

Delete tbe entries for as 1400. as 1503 and BS 2789 and substitute the following:

'SS 1400

Specification for copper alloy ingots and copper alloy and high conductivity copper castings .

SS S03

I

Specification for steel forgings (including semi-finished torged products) for pressure purposes

as 2789

Specification for spheroidal graphite or nodular graphite cast iron'.

Insert the following British Standards in numerical order:

IS04

SS IS06

'SS

SS 6681

SpecifIcation for steel castings for pressure purposes

Specification for carbon, low alloy and stainless steel bars and billets for bolting material to be used in pressure

retaining applications

SpecifIcation for malleable cast iron'.

2

-...

CD

CD

o

01

I

i-Cu N

Table 2. Trim materials. hardness and acceptable specifications

-a I--II

I--Cu-Ni

HF

1)"lDboi

-

200

3200

M

071

anufacturer's

B

NAI

ronze

A

182·F310

standard

30 % nickel

min.I400-""

3300'1

14Cr·Ni

nCr

50'1

75'1

3A3SI-CFBC

1II

076

503-316533

503-321531

276-317

Manaanesc

3I3Cr

5011

lurfac:et

Iil:lll

Cr-Ni-Nb

66-26-S

18-1

A

18-1

I12-F32

I standard

18-8

2174-CA101

BI24-642

SlelD

8584-865

2S0

13

A182-F6

A487-CA15

Cr

6BS

3

11

bronle

B2 hardnessnCr

Ni-Cu

Manuracturer'sltandard

Aluminium

Cr-Ni·Nb

SlelD

Back

Manufacturer's

2872-Cl114

8584-864

8138-675

standard14OO-HTBI

2SO

IISQ4-42OC29

S04-42OC29

2SO'l

18-10-2

Cr·Ni·Ti

Cr-Ni-Mo

Cr-Ni·Ti

A216-341

A182·f316

A487-CAI5

A3SI-CFBM

B584-90S

18-10-2

1503-347531

13Cr

I82-F347

standardIS04·341C17

standardIS04-316C16

standard

18·8

2872-CAI04

BI5O-642

Back

seal with

Bar

7

5Cr-Ni

1110)'

10

IS04-42OC29

13Cr

A182-F6

Cu·Ni

1S03-410521

B584-836

250

66-26-5

bronze

B148-9SSD

BI24-630

Ni·Cu

Ni-Cu

Cr-Ni·Mo

2S-20

25-20

18-12-3

18-12-3

Bronze

ASTM

BS

13

CrNAI3

Iuminium

A276-32I

A276·316

1506-321531

Seal

2874-Cl114

8138-615

Cr·Ni·Mo

1503-316531

1506-34

7531

1506·316533

13

Cult

A276-410

A487·CAIS

2174·CAI04

BISO-630

Manufacturer's

Manufaclurer's

standardIS04-317C16

IS

14OO·ABI,

Minimum

Brlaell

1506-316531

1S03-410521

IS04-347C

1506-410521

1503-410521

B148-9S2A,

"••

•.••

lIoy

Manpncsc

1400.01,

•.••

Acnplable

malerlallpeclf1callo

l\Ialerlall)'pe

Forpl

bushl •• 11

Seal

1503-316533

1503-3475SI

1503-3215SI

I,.)

- See BS 240 : Pan I.

t CutinlS not applicable to stem materials; see 29.4.

thard

For facinl.

austenitic: trims

I

);:c

o

U1(X

~S

the backseat may altemalively be a weld deposit oftbe lime nominal material composition as the trim or a welded·on hard racinl. For hard rac:cd(HF) trim the back scat may alternatively be a welded-on

Body and wedae scat surfaces 250 HB min., with SOHB min. differential between body and wedle scat surraces.

II Differential hardness belween body and wedlle seat surfaces is not required .

• Differential hardness between body and wedae scat surfaces~hall be the manufacturer's standard.

(

AMD8582

Amendment No.2

published and effective from 31 August 1990

to BS 1414 : 1976

Specification for steel wedge gate valves

(flanged and butt-welding ends) for the petroleum,

petrochemical and allied industries

Revised text

Contents

Delete the entries for section five and clause 43 and substitute the fonowing.

'Section five. T&Sting

43. Production pressure testing'

Under the heading 'Tables' , after the entry for table 2 insert the following.

'2a. Test durations'

Delete the entry for table 11 and substitute the following.

'11. Table deleted'

Foreword (as amended by Amendment No.1)

In line 10, delete'BS 5146 'Inspection and test of steel valves for the petroleum,

petrochemical and allied industries" and substitute the following.

'BS 6755 'Testing of valves' Part 1 'Specification for production pressure testing

requirements"

After line 10, insert the following note.

'NOTE. Requirements for final inspection and supplementary inspection at all stages of manufacture.

previously specified in BS 5416 : Pan 1 : 1974 (now withdrawn) should be stated by the purchaser in his

enquiry or order.'

Section five. Inspection and test

Delete the title and substitute

'Section five. Testing'

AMD868Z

Auguat 1110

Clause 43. Inspection and test requirements

Delete the existing clause and substitute the following.

'43. Production pressure testing

All valves shall be pressure tested by the manufacturer

accordance with BS 6755 : Part 1 as follows:

before despatch in

(a) hydrostatic shell and backseat tests;

(b) hydrostatic seattest (see note);

(c) pneumatic seat test (see note).

The test durations shall be as given in table 2a.

NOTE. Attention is drawn to DOte1 of D.8.3.2 of BS 6755 : Part 1 : 1986 regudina the seqUCIICCof

operations when the seat test procedure is carried out. Valves tested to BS 1414 should hPe the sequeace

ofiteml (b) and (e) in D.8.3.2 ofBS 6755: Part 1: 1986 reversed. SeattOit leakqeme A ahOuJdaPPly.

For the baclaeat test there should be DOYiaualleakqe for the duration of tho test tD.

----------------------------------------------------

N 1S0

DN

300

."

.

Newtable2a

Insert the following new table 2a after clause 43.

Table 2a. Test durations

MIDlm

1S ••

S

S 60

BlICkseat

Sat

test

NomiDaI YlIIftIbe

120

1S

1S test

15

S

120

60

300

testdaratloD

Shell test

AMD 1I&1Z

AUIUIt 1810

AMD6&1Z

August 1810

AMD lIS62

August 1990

Clause B.5lnspection and testing

Delete the clause entirely and substitute 'B.S Tat deleted'.

Table 11. Hydrostatic test pressures

Delete the table entirely and substitute 'Table 11. Table deleted'.

BSI publications referred to in this standard

Amendment No.1)

(as amended by

Delete the existing reference to BS 5146 and substitute the follo~g.

BS 6755

Testing of valves

Pan 1 Specification for production pressure testing requirements'

----------------------------------------------------

8008-1

2

PSEI7

as 1414 : 1975

UDC 821.648.5: 689.14: (822.313

+ 882.7153 + ee&.8)

,.

(

.Specification for

Steel wedge gate valves ...

(flanged and butt-welding ends)

for the petroleum, petrochemical

and allied industries

Amendments issued since publication

Amd. No.

I Date of issue

British Standards Institution

Telephone 01-829 9000

T•••• 288833

I Text

.

affected

2 Park Street

.

london W1 A 2BS

yp the

!BS 1414 : 1975

t_ nIIl'II

40. Nameplate markiDp

.39.

Body materials.

aDd boDDCtmarkiDp

2. Preparation

Trim

hudncss and

Pa,e

4S.

for despatch

4.

Dimensions

Oass

400

300

valves

8.

DimcDsions

ofsize

Class

1500

valves

S.

6.Pacbging

2SOO

600

ISO

valwa

9.

3.

7.

900

10.

Nominal

and

nominal

pressure

range

andcast

class

ratiDp

acc:cptablcspecifications

Appendlcea

11.

Hydrostatic

test

pressures

17

22

2S

46.

23

IS

IS

414

13

10

21

682216

20

812

24

IS

16

934

Tabl_

18

20

19

13

Section

five.

In.peatlon

and

Inside

front

cover

ofva1ve

Section

four.

Marking

A.

Particu1u

dimensions

for

each

class

2.

Butt-welding

endI

42.

Omission

of

mukinp

and

rising

stem,

or

foqed

IteeI

lICI'eW

1. Location

Solid

wedge

pte

valve,

outside

3.

of

tappings

BS yoke

4504

ftangcs

B.

Application

to test

piping

systems

with

SectIon

alx.

Shipping

43.

Inspection

aDd

requirements

37.

Required

markiDp

Flgu,.

purchaser

44.

1. PrcIin1inary

Stufling box bore and packing width

Contents

2

r,

851414 : 1975

(

Foreword

This British Standard is one of a series" for valves prepared under the authority of the Petroleum Industry

Standards Committee. It was first published in 1949 when the materials rd'em:d to were described by

reference to ASTM specifications. It is a metricated revision except that class designations and body to

bonnet bolting sizes have not been converted into metric units. Imperial units are also Jiven for some

dimensions in order to comply with established international petroleum practice. The previous sections

dealing with face--to-face and end-~d

dimensions, inspection and tests ha'WeDOW been omitted as these

subjeds have their own separate standards:

BS 2080"' Face-to-face, centre-to-face, end-to-end and centre-to-end dimensions of flanged and buttwelding end steel valves for the petroleum, petrochemical and allied industries'.

BS 5146 • Inspection and test of steel valves for the petroleum, petrochemical and allied industries '.

The end flanges for valves of 600 mm (24 in) size and below are required to be in accordaJH:C with BS 1560

• Steel pipe flanges and flanged fittings (nominal sizes

in to 24 in) for the petroleum industry': Part 2

'Metric dimensions' (corresponding to ANSI B 16.5) and butt-welding ends are generally in accordance

with ANSI B 16.15. For valves larger than 600 DUD (24 in) size, end flanges are Rquired to be in accordance

with BS 3293 'Carbon steel pipe flanges (over 24 in nominal size) for the petroleum industry'

or API

Standard 60S.

i

NOTE. User requiranaltl

for valva acaaaJ1y in accordance with this standard but suitable for use in pipina aystemI with

ftaa8es in accordance with BS 4504' FJ.anaa and boltil1l for pipes, valves and fittinp. Metric scria' are dealt with in &pJJeDdixB.

British Standards for steel (BS 1501-6 • Steels for use in the chemical, petroleum and allied industries ')

comparable with ASTM specifications were first published in 19.50 and a revision of BS 1414 incorporatina

them was published in 1954.

"It is intended that valves complying with the requirements of this standard should be interchangeable as

units with those of similar type specified in API 600. The present revision ofBS 1414 is generally in accordance

with the seventh edition of API 600 (November 1973) except that it has been extended to cover carbon steel

valves in sizes up to 10.50 mm (42 in) in aass ISO and aass 300.

Acknowledgment is made to the American Petroleum Institute and to the American National Standards

Institute for data used.

The titles of the American standards referred to in this standard and the foreword are as follows:

ANSI

B16.s

B 16.15

API

Std 5b

Std 600

Std 60S

ASTM

A 182

A

A

B

B

276

351

124

138

B·I48

B ISO

BS84

Steel pipe flanges and flanged fittings (including supplements)

Buttwelding ends

Specification

threads

for threading,

gaging, and thread

Steel gate valves (ftanged or butt-welding

Large-diameter carbon steel ftanses

inspection

of casing, tubing

and line pipe

ends)

Forged or rolled alloy-steel pipe flanges, forged fittings and valves and parts for high temperature service

Stainless and heat resisting steel bars and shapes

Fcrritic and austenitic steel castings for high temperature

Copper and copper alloy forging rod, bar and shapes

Manganese bronze rod, bar and shapes

Aluminium bronze sand castings

Aluminium bronze rod, bar and shapes

Copper alloy sand Qlstinp for SCoeral applicatiops

3

service

as 1414 : 1975

British Standard Specification for

Steel wedge gate valves (flanged and

butt-welding ends) for the petroleum,

petrochemical and allied industries

Section one. General

1. Scope

·This British Standard speci1ies Rquimnents for cast or forged carbon and alloy steel outside scmr and

. yoke, solid wedge (plain or flexible) rising stem gate valves, with or without soft seals, with ftanpd or buttwelding ends, in nominal sizes within the range of 2S mm to 600 mm (1 in to 24 in) and Class ISO to ClasS

2500. It also covers carbon steel valves in nominal sizes 6SO mm to 10SO·mm(26 in to 42 in) in Class ISO

and Class 300 only. This standard can also be used as a general guide where valves ofmateria1 compositioa

outside the scope of section three of this standard are required as, for example, for use in highly corr~

servic:es or environments or for low temperatures (see clause 36).

2. References

'lbe titles of the British Standards referred to in this standard are listed oa the inside bade cover.

3. Nomencleture

For the purposes of this British Standard the nomenclature for valve parts shan be as shown in

which is also illustrative of some acceptable MtiI1lR,

fi&uze

1

4. Pressure cla•• ificatlon

This standard applies to valves of the fonowing pressure class desigaatiolll:

Class ISO, Class 300, Class 400, Oass 600, Class 900, Class 1500 and Class 2SOO.

The numerals in these class designations represent the primary service pmsure ratinp of the valves in

pounds-force per square inch•..

6. Pressure/tempereture ratinp

The pressure/temperature ratings applicable to valves specified in this staDdatd shall be in accordance with

tables PE-I to PB-I2 of appendix A of BS 1560: Part 2: 1970 for the pIItic:uJar shell material specificcL

There is, however, a temperature restriction on soft seals and on certain trim materials (see 11.3 and :19.5).

Wbcre valves in accordance with this standard are to be used at service temperatures below ~30 "C,

referenc:e should be made to BS 3351. Service temperature refers to the temperature of the fluid in the liDo

at the valve.

e. Nomlnalsiz ••

This standard covers valves of the fonowing nominal sm:

Dun

em)

mm

25

(1)

ISO

200

2SO

300

32-

(Ii>-

«)

(11)

50

65-

(2)

(2,)-

80

100

em)

(6)

mm.

em)

SOO

(20)

600

(24)

(26).

(28)

(30)

3SO

(8)

(lot

(12)

(14)

(3)

400

(16)

900

(36)

(4)

4SO

(18)

10SO

(42)

.6SO

700·

TSO

Por each valve class the applicable sizes are shown in appendix A.

• Thae Iizca have been maiJIaI ooIy for the purpoIO or replKiq cxiluna valva. Their

.,...

••

lIS l5tiO : rwrt ~ cad ftaDIra sboulcl be avoidecl.

4

'*

ror new ClOIIIItr'lIetioD

in pipia,

"

(

Page 5 (bIanIc)

as 1414 :.1975

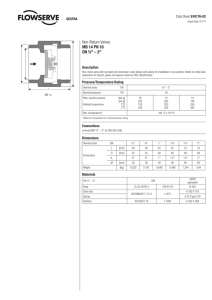

Half sections and sketches show "terneti¥e typic" dnlgns

26

18

17

16

20

19

21

14

Soft Mal ¥8I¥e••••

in wedge

13

Butt-weldingends

Typical flexible wedge

figure 1. Solid wedge gate wive, outIidescrew end yoke rising stem, cast or forged steel .

8

BS 1414 : 1975

(

15

39

•--

View showing yoke with actuator mounting flange

a.-

-l'

It

BonDCt

Handwbeel

Yokellee¥e

Handwhed

nut

Yoke

11

23

2tand2.9

25

Dand2.9

Z4

Mand2.9

Rin,joint

Bonnet

End

Bodyboaes

Flexible

Plain

ftanac

wedae

ftanae

wedac

cap

Butt-we1dina

Bonnet

Bearina

psket

lubricator

end

Yoke

sleeve

rollina

beariDi

Body

Actuator

mountiq

ftan&e

Bottom

seated

ring

Bodyfbonnet

ftanae

Shoulder

seated

riDJflttiq

NIaDe

f1I

JIII't

Relenace

28

2S

40

38

39

26

22

24

41

42

31

33

29

3S

36

37

32

30

34

27

23

MdIdIl

•••

-n

21

Gland

bolt

and

nutand

29

followcr

Back

seat

30

2.9

31

Stem

rt

33

35

34

nlenace

35nuts

BonDct

stud-bolts

Yoke

NamepIato

Back-seat

seal

boluna

rc:tainiq

riq

rin&

ICICWS

ftanae

Wiper

Stuffin.

Soft

Lantern

pIcltins

rin

lua

box

rin,

mainin,

••bushing

bolt

plu,

and

rinI

nut

sleeve

retainiqnut

Wedge

One

piece

facinl

8Iand

rin.

Na.f1I

JIII't

Mat.w

NOTE. These aketcltes are composite for the purpose of showina some typical variations in indiviclual details and part nameL

A product utilisin. any combination of thcee dcIaiJs (except when such combination may be specifically prohibited in the tat)

01' simiJar construction will be acceptable provided it complies with this standard in all other raped&.

• See appendix A.

See flaure 2-

t

Figure 1. (continued)

7

as 1414 : 1975

7. Information to be supplied by the purchaser

Certain clauses of this standard permit alternatives and the purchaser may require features which depart

from the requirements of this standard. The purchaser should state in the enquiry and order the following

(the items marked with an asterisk are mandatory).

(a)- Class and nominal size (see clauses 4 and 6 and &7).

(b) - If soft seals are required and. if so, whether these are required to be in the wed~ seats or body

seats (see clauses 5 and 18).'

(c)- Whether flanged or butt-weldiIig ends "arerequired.

(1) If flanged ends are required, whether welded-on flanges are acceptable (see 8.5); the type of

facing (see 8.6); for sizes above" 600 nun (24 in), whether flanges are to be in accordance with

BS 3293 or API Std 605.

(2) If butt-welding ends are required, the pipe schedule number or wall thickness and outside

diameter (see 8.8 (b».

(d)

If allowance is to be made for the passage of a pipe scraper (see 8.8 (c».

(e)

If shell tappings are required and, if so, the location and the type of thread if other than API Std SB

(see 8.9 and 9.8).

(f)

If a particular form of wedge is required (see 10.2).

(g)

If the yoke is to be fitted with a flange for actuator or gearbox mounting (see clause 11).

(h)

Details of type of operation required if other than dircct-handwheel operated (see clauses 11and 16).

(i)

If a lantern ring is to be provided for Class 300 to Class 2500 valves (see 14.4).

(j) If a bypass is required, give the fuU specification of the bypass valve, piping and connections (see

clause 17).

(k)- The shell material (see clause 19).

0)

If a special bonnet gasket is required (see clause %1).

(m)- The nominal trim material symbol (see %9.2).

(n)

If any special stem packing is required, or specify packing design temperature jf above 400 °C (see

clause 31).

(0)

Material(s) for bonnet, gland, and yoke bolting if required for operation at process design temperatures below -30 DCor above 480 DC,or for other special operating conditions (see clause 3%).

(p)

Material requirements for valves in highly corrosive services or environment, or for low temperature

service (see clause 36).

(q)

Test and inspection requirements in accordance with BS 5146.

(r)

Requirements for tropical or special packaging (see clause 46).

Section two. Design

8. Body

8.1 For the body the design criteria specified in 8.2 to 8.11 shall be observed.

8.% The body shall be designed to minimize pressure loss as well as corrosive and crosivc·cffects. The body

cnd ports shall be circuJar.

8.3 The wall thickness of the body shall conform to the shcll thickness given in appendix A. Drilling of, or

pinning to, the wall of a pressure-containing part, e.g. for nameplate fixing, is not permissible where it

would reduce the cffectivc thickness below the minimum permitted valuc.

8.4 Face-ta-face dimensions for raised face flanged end valves and end-to-end dimensions for butt-wclding

end and ring joint flanged end valves shall conform to the dimensions specified in BS 2080.

s.s End ftanges shall be cast or forged integral with the body except that flanges may be attached by welding

if so specified in the order. The welds of end flanges attached by butt-wclding shall comply with the require-.

ments of BS 3351 and shall have any necessary heat treatment as required by BS 3351 to cnsure that they are

suitable for service temperatures down to -30 DC. Flange attachment by other welding processes shall be

thc subject of agreement between the manufacturer and the purchaser.

8.6 End flanges shall comply with the requiremcnts of BS 1560:Part 2 for valves up to and including 600mm

(24 in) nominal size and BS 3293 or API Std 605 (as specified by the purchaser) for valves over 600 mm

(24 in) nominal size. End flangc facings shall be one of the types shown in figures 1 and 2 of BS 2080. The

purchaser shall specify the type of facing required.

Valves generally in accordance with this standard but suitablc for use in piping systems with BS 4504

flanges shall comply with the requirements of appendix B.

8

BS 1414 : 1975

a.7 Butt-welding ends sball comply with the details shown in figure 2NOTE. When weId.iaa butt-wddiq

with the requiremalta of BS 3351.

eocl valva into pipiq

systems the welds and any necessary heat trcatmcnI shaD comply

'\

-',--~ .

•..

•..

.....•.

i

I....-_.~.:.~_

.. I

1.6

! 0.8

(a) Welding end for connection

pipe of wall thlc:lu1•• , of

6 mm to 22 mm incIuaiw

A

B

t

==

==

==

(i

"'"'

to

(b) Welding end for connection

pipe of wall thicknea t

greater than 22 mm

to

Dominal outside diameter of welding end (see table below)

Dominal inside diameter of pipe (for tolerance on B, see table below)

nominal wall thickness of pipe.

NOTE 1. The inside and outside surfaces of valve weldina ends shall be machine finished overall. Wddina-ead bores sbaIl be

nw:hined paralld for a distance of I.St and then run out as shown in the figures without abrupt cbaoge of sectioa. The outsiclca

of wddiDI ends may be run out in any manner indicated in the fiJUres, provided that sharp angles and abrupt chaDp::s of slopes

are avoided.

NOTE 2. For nominal outside d.iameten and wall thicku

nUl

of standard steel pipes see BS 1600 : Part 2.

±

2.S. shaD DOt apply

NOTE 3. For valves required to CODDeCt with pipe of less than 4.8 rom walt thickness the angle 37 oS

and weldiDa ends sbaIl be finished to a alight clwnfer or be square, at the option of the manufaeturer.

NOTE 4. ReprdIesa of tolerauc:es specified for dimcnsioDl •••aad B, the thic:bess of the weldiq end sbaIl DCYeI'be lea tbm

87.5" of the DOIIlioa1 thickDcaa of the pipe.

.

NOTE 5. For end-lP-eDd dimeasioua of butt-wcldioa end wlva

Valve

50 I 6S

IIOIIIiDa1

I(4) I(6)

Tolerance

I 50 I 62 I15-1 91

1117 1172

(2)

Tolerance

B

+0

OD

(mm)

B5

-0.'44

(mID)

I ±o..

OD

• A IbaD be 78

mID wbeo UIed with BS

I

1100 1150

(21)1 (3)

size

•••.

A

I 80

lee BS 2010.

±u

36iOO

·1teeJ pipe.

figure 2. Butt-welding ends

9

+3.2

-1.6

BS 1414 : 1975

8.8 For flanged valves the minimum iDside diameter of the body end port shall be IS specified in appendix A.

For butt-welding end valves the miDimum inside diameter of the body end port sbaU comply with the

details given in figure 2. Pipe schedule number or pipe wall thickness and outside diameter of the pipe shall

be specified by the purchaser ..

If it is required to pass a pipe scraper through the valve, this shan be specified by the purchaser.

8.9 Valves of nominal sizes 80 mm (3 in) and above shall have provision for tappings at the ~en positions

A to G shown in figure 3. When the metal thickness of the body is insufficient to provide thCe1fective lenJth

of the thread for body tapping, or the body presents an uneven surface, bosses shall be prcmded.

Provision should be made for the body tappings as follows:

NcIaIr.I_

I•••••••

it

44

3854

70

1 ••••••••diameter vi ••

in

Imm

Pfpe

Ii

Holes shall not be drilled or tapped unless specified in the order, which should then state the thread

required (if other than API Std SB) and the location (see figure 3). Tapped holes shall be provided with plugs.

On valves of nominal sizes below 80 mm (3 in), provision for tapping shall be IS specified by the purchaser

and shall comply with figure 3 as regards location.

Where a bypass is to be provided see clause 17.

A

c

c

o

G 0

Third angle projection.

NOTE. For vaJvcs below 80 mm the boaacc tappinl may ~ positioned to suit the manuf'.aurer.

Figure 3. Location of tappings

8.10 Separate seat rings in the body sball be employed except as indicated in <a) and (b) of this subclause.

<a) Austenitic steel valves, in which case these may have integral seats.

(b) Austenitic or hard-facing (body) scat materials which may be deposited directly on the valve body

and the minimum finished thickness of the deposit shall then be 1.6 mm. Direct deposition of 13"

chromium seat material on to the body is not permissible.

10

as 1414 : 1975

Separate seat rings may have directly deposited seati11l material in ac::cordance with any of the S~tiODS

indicated in table 2, in which case the minimum thickness of the deposit shall be 1.6 mID.

Seat rings may be shoulder-seated or bottom-seated at the option of the manufacturer and may be -..",.....,d

in, rolled in or welded in unless one particular method is specified by the purchaser. Threaded seat rinp

shall be provided with lugs or slots to facilitate removal Shoulder-seated rings shall be designed 10 that

any clearance between the back of the ring and the bottom of the ring recess shall be not greater than 1.6 mm for

sizes 300 mm (12 in) and smaller, and 3.2 mm for sizes 350 mm (14 in) and larger (see figure I). Tack weldin,

may be employed to prevent loosening (see BS 33S1). The faces of the rings shall be smooth finished with the

sharp comers at the inner and outer edges removed to prevent scoring of the wedge faces.

The use of a sealing medium on the threads is not permissible.

The use of soft seals in body seats is dealt with in clause II.

8.11 Wedge guides shall be provided in the bodies of an valves to cover for the full travel of the wedge 10

that the seating surfaces of the wedge do not touch the body seats until near the point of closure. 1'beso

guides shall be of the male or female type, so p1ac:ed as to engage with the guide slots or lugs of the wedge.

Valve guides shall be integral with the body except that for valves of nominal sizes 6SO mm (26 in) and larger

the guides may be separate components welded into position.

9. Bonnet

'.1 For

boaDets the design criteria specified in ,.2 to , •• shall be observed.

,.2 Wall thickness of the bonnet shall conform with sheU thickness as shown in appendix A. DriJIiD, of, or

pinning to, the wall of a pressure containing part, e.g. for nameplate fixing, is not permissible where it

would reduce the effective thickness below the minimum permitted value.

,.3 The

body to bonnet connection shall be ftanged and the flange facings shall be male-and-female. tongueand-groove, or ring joint type,except for Class ISO which may be a plain (ftat) faCc~

Where possible, bodyJbonnet flange facings anti ~

.shall be of standard di~"!I'ons

in ICCOrd8DCe

with BS IS60 : Part 2, BS 3293 or API sid 6057-.- .

'A

Bonnet flanges and bodY/bonDet ftanses shan be of circular form in all cases, except that:

(a) for Class ISO valves they may be oval;

(b) for all valves below nominal size 80 mID (3 in) they may be square or rectangular.

Flanges shall be spot-faced or back-faced as specified in BS 1560 : Part 2-

,.5 The body to bonnet joint shall have at least four stud-bolts of the following minimum

for nominal sizes below SO mm (2 in) studs may be used (see also 15.2).

mm

to SO

80 to 200

2S

2SO and larger

.

size c:xcept that

in

I1

t

9.' To permit repacking of a valve in the open position while in scrvic:e, a machined conical or spberica1

back seat shall be provided in the bonnet to contact a corresponding seating surface on the vahe stem.

Bonnet back seats shan be in a busliing, exc::ept that for a valve with either an austenitic or hard faced trim

the seating surface may be a welded deposit. On an austenitic steel valve the back seat may be on eilber an

integral surface or welded-on hardfacing. Welded deposita shall have a minimum finished thic:kness of

1.6 rom.

9.7 The hole at the back seat shall be designed to provide adequate gui~

packing extrusion.

for the stem and to prevent

1

9•• Valves of nominal size 80 mm (3 in) and larger shall have provision for a in tapping at the location H

showll in figure 3. Provision for a in tapping shall also be made on valves smaller than nominal sizIe 80 mm

(3 in) at a position convenient to the manufacturer. The thread shall be stated if ot~r th~" API Std ,8.

1

11

.

85·'.414.: 1975

10. Wedge

10.1 FOI' wedgesthc design criteria specified in 10.2 to 10.5 shaD be observed.

10.2 A solid wedge. which may be fabricated by welding, shall be provided. It may be either a plaiD wedge.

baving essentially a trapezoidal (or an I)aoss section, or a flexible wedge bavina a tapered H or inverted U

cross sect,iOD.It shaD be free from pockets which could form,liquid traps when the valve is mounted with

the stem vertical. Unless the order specifies a plain wedge or a flexible wedge, either may be supplied.

10.3 Wedges 'may have integral faces or may have separate facing rings rolled in, welded on or directly

deposited. Directly deposited faciDp shall have a minimum finished thickness of 1.6 !DID.

The use of soft seals in wedge seats is dealt with in clause 18.

10.4 Guide slots or lugs to engage the body guides shall be provided on the wedges of all vaIves. The slots

or .lugs shall be of ample length and shall extend below the horizontal centre line of the wedae. Wedps

shaD be provided Viith a suitable slot at the top to receive the button or ~bead of the stem.

10.5 ·The desian shall provide adequate seatina width, both before and after wear of the seatina surfaces.

The minimum values of wear travel sbaII be as follows:

mm

25to

65

mm

SO

to ISO

2OOto

3SOto

SOOto

6SOto

300

4SO

600

1050

2

3

6

10

13

15

11. Yoke

The yoke may be integral with the bonnet or, if separate, self-locatina on the boaDct and attached by suitable

bolting. The yoke shall be machined where it comes in contact with the bonnet and the yob sleeve. WheD

specified in the order the yoke shall be provided with an actuator or gearbox mounting flange (see 16.4).

The yoke and the actuator or gearbox mounting shall be of adequate strength to support the actuator or

~~u~an~m~oomthew~

.

12. Handwheeland

handwheel nut

12.1 The handwheel shall be of the spoke-and-rim design, preferably with not more than six spokes. In the

smaller sizes, where the space between the spokes is 'limited, the provision of knobs or studs projcctina

beyond the outside diameter of the handwheel is desirable.

12.2 The valve shall be opened by turning the handwhcel in an anti-clockwise direction. The handwhcel

shall be suitably marked with an arrow and the word OPEN to indicate the direction of rotation to opeD

the valve.

12.3 The handwheel shall be retained on the yoke sleeve by a threaded handwheel nut.

13. Stem and yoka sleeve

13.1 The minimum stem d.iaIne= shall be as given in appendix A.

13.1 The stem shall be of one piece design and shall have a beveIlcd or spbaical seat Jl'acb\ned on it to

seat on the bonnet back seat when the valve is fully opened.

Ui3" The projection outside the yoke sleeve of the stem threads on a new doeed valve sball be

followa

UDJess a closer tolerance is requinld by the purchaser:

u

Ne.IMI" . (1

to

so

mm

em)

3(14

IS

621

to

20

2to

10

13

40

10

toto

3042)

.(8

18)

(26

to

2)

(20

to12)

24)

(15

6)

LIIIIIafI6•••• ,.;edJ.

12

BS 1414 :1975

1M The stem shall ha~

threads of Acme or other trapezoidal form and shall have an integral end of button

or tee-head form. fitting into a slot in the top of the wedge. to provide flexibility between the stem and the

wedge. The design shall prevent turning of the stem ·or disengagement of the stem from the wedge durinl

service. Threaded or pinned connections between the stem and the wedge shall not be used.

13.5 The yoke sleeve shall be internally threaded to suit the stem and shall be designed to permit ready

removal of the handwhee1 without allowing any axial movement of the stem.

13.6 AU surfaces of the yoke sleeve in contact with the yoke shall be machined. Rolling bearings shall be

fitted to the followinl nominal sizes of valve:

.

Cass 400

250 mm (10 in) and larger.

Class 600 and upwards

ISOmm (6 in) and larger.

Adequate provision for lubrication shall be made in all classes and nominal sizes.

14. Stuffing box. packing and lantern ring

14.1 The stuffing box bore shall conform to the dimensions given in table I and shan have a minimum

depth. based on square section packing of the nominal width shown in the table. as fonows.

equivalent to six rings of packing.

Class I SO

Class 300 and above

equivalent to a lantern ring length and seven rings of packing.

,.I

Table 1. Stuffing box bore and packing width·

I

.

31.0 (Ill)

••

5(I)

(in)

14.3

(in)

102.4

105.6

134.1

140.5

178.6

121.4

7.9

48.4

6J.J

64.3

67.5

73.8

77.0

83.3

96.0

32.5

35.7

38.9

57.9

886.5

9.7

mm

12.7

mm

127.8

146.8

9.5

6.4

29.4

45.2

51.6

(in)

19.0

11.1

25.4

(lK)

(6)

(5)

(11)

(2f)

(4)

(2H)

(11',)

(Iii)

(2ft)

(3~)

(lit)

(1)

(I)

(5ir)

(5H)

(7ft)

(~)

(iI)

(l)

(I)

(n

(-A)

(I)

(3)

(If)

(Ii)

(2f)

(31)

(ll)

(lit)

h\)

0)

(/,)

(ft)

(f)

(2)

H)

H)

(JH)

(311)

(2~)

(2/.>

(2

(3/r)

(3ft)

(5

(4ft)

(4~)

(51r)

(21)

(31)

(11.)

(A)

(41.)

(II)

3(41)

2

NGBIiIIII

fIlltIdIIaI

wWda

NcaI8aI ••.•pKkiDa

ba

• For intermediate sizes or stan one of tho ICUldard pl!dtilll widths lilted IbaII be used,

13

as 1414.: 1975

14.2 Packing glands shall be of one piece, one piece bushed, or two piece self-aligning design. Vertically

split glands shall not be used. The gland proper of a two piece gland shall have a shoulder on its outer end

to prevent complete entry of the gland into the stuffing box.

14.3 The packing width shall be as spccificd in table 1. The packing may be of square, rectangular or

chevron section.

14.4 Class ISO valves shall not have lantern rings. Class 300 to Class 2500 valves shall be supplied with a

lantern ring when specified in the order. Lantern rings shall have two holes, spaced at 180 0, provided at

each end for removal. These holes shall either be through-holes for hooks or tapped 5-40 UNC. When a

lantern ring is provided it shall be positioned such that with square section packing there will be Ave rings

of packing above the lantern ring and two below. The stuffing box shall then be tapped opposite the centre

of the instaUed lantern ring and fitted with a round head pipe plug in accordance with BS 3799 of not less

than nominal size. A boss shall be 'provided if necessary to ensure minimum thread eqagCMcnt.

1

16. Bolting

15.1 This clause is concerned only with that bolting which forms part of the valve and is not concerned

with bolting for fiangcd connections between the valve and a pipeline or pipe fitting.

15.2 The allowable working stress in bolting material for bonnet fianges at the primary service pressures

Jiven in clause 4 shall not exceed 62 MPa assuming that the pressure acts upon an area circumscribed by

the outside periphery of the gasket or, for a ring joint, that the pressure acts through the pitch circle of the

ring joint.

Bonnet fiange bolting shall be by stud-bolts with a nut at each end of the stud-bolt except that for valve

sizes below SO mm (2 in) studs in accordance with BS 2693 : Part 1 may be used. Stud-bolts and nuts shall

comply with the requirements of BS 4882: 1973, sections and 3.

15.3 Gland bolting may be of one of the fonowing types.

(a) Hinged bolt secured by either a headed bolt passed through the eye and secured by a Jlut or a pin

passed through the eye and effectively secured. Cotter pins are not acceptable as the sole securing dcvic:es.

(b) Stud-bolt passed through a plain hole in the Bange on the bonnet neck and secured to the ftanF by

two nuts.

(c) Stud-bolt screwed into a tapped hole in the Bange on the bonnet neck and secured by a lock nut.

(d) Headed bolt passed through a plain hole in the flange on the bonnet neck.

Headed bolts in slotted brackets on the bonnet neck shall not be used. Bolts, stud-bolts and nuts shall be

threaded metric or UNC and dimensioned in accordance with BS 4882, BS 1768 (below in nominal size),

BS 1769, BS 3692 or BS 4190 except that square head, side head and tee head bolts are acceptable. Studs

are not permissible.

15.4 Yoke bolting shall be threaded metric or UNC and dimensioned in accordance with BS 4882, BS 1769,

BS ~

or BS 4190. Studs are not permissible.

1

1

18. Operation

16.1 Valves shan be direct-handwheel operated unless otherwise specified in the order.

16.2 If chainwheel operation is required. the type of chainwheel shall be specified in the order which shall

also specify any chain to be supplied.

1'-3 If gear operation is required, the type of gearing and its arrangement and the design maximum differential pressure across the valve sbal1 be specified in the order.

16.4 If actuator operation is required, the details of the actuator and its power supply together with the

·design muimum pressure differential across the valve shall be specified in the order.

For multi-turn actuators the attachment dimensions shall be as specified in BS .••• • Flange attachment

dimensions of actuators to general purpose valves' (in course of preparation).

17.Bypua

17.1 A byppf I1W1 not be provided unless specifi.cdin the order.

14

as 1414 : 1975

"

(

17.2 Any bypass supplied shaI1be cxtcmal to the main valve and be of tile foIlowiDs

in

DUn

SO

m:

to 100

ISO to 200

2SOto300

3SO and larger

1

t

1

Ii

18. Soft seal rings

u

18.1 Soft seal rings may be fitted in either the body seats or in the wedge seats specified by the purdwer.

The rings shall be designed to compress down to the level of the metal seats to Jive a tight shut-off on both

sides of the wedge and thus provide a double block and bleed' facility. Tbey sball also Jive a tight metalto-metal seal through the valve if the soft seals are damaged or I'eIDO\'ed.

18.2 The seal rings shall be designed to withstand a minimum of 2000 cycles of operation in dry atmospheric

conditions and thcre shall then be no evidence of damage or cold flow, revealed by spreading over the

metal seats. The valves shall then meet the hydrostatic and air tests specified in BS 5146.

A in tapping fitted with a plug shall be provided in the bonnet for testing the double block and bleed

facility. This shall be located in position H (see figure 3) unless specified otherwise by the purdwer. The

type of thread shall be stated if other than API Std 9 ..

18.3 The cffective operating temperature range of soft seal valves will be limited by the service temperature

of the seal material

&

u

I

.Section three. Materl."

19. Shel'

The body and bonnet shall be of the material specified in the order, the selection being made from those

listed in BS 1560 : Part 2. AD pressure containing parts involved in welding operations shall have the carbon

content restricted as follows:

.

(a) 0.15 % maximum for carbon or carbon/molybdenum steels;

(b) 0.15% maximum for S% Cr 1% Mo steeL

20. Bodyseat rings

A body seat ring made of a material different from its seating surface shall be of a material not inferior to

that of the sheD.

21. Bonnet gasket

Bonnet flange gaskets shall be metallic spiral wound as specified in BS 3381, or steel or soft iron, except that,

for Class ISO valves only, compressed asbestos fibre complying with the requirements of BS 1832 is an

acceptable alternativc. They shall be suitable for the pressure/temperature rating of the valve. Any metallic

part of the gasket shall have at least the same corrosion resistaDce the abeD.

u

NOTE. Pree chlorides in compreaed ubcstoI fibre materials wbal UIIlClwith low ..,

or 8UItcDitic IIaiDleIa •••••

stras corrosion craddq in the ••••• UId the UIC or alternative pakct materials IbouId be coasidered.

IIIIl1

ca.-

22. Wedge

A wedge·fitted with separate facing rings, or on which seatinl surflUlClare deposited by weldin•• sball be of

a material equal to that of tile sbeIl.

23. Yoke

A )'oJte separate from the bonnet shall be of carbon steel or of the same material as that of the sbclL

15

85'1.414 : 1975

24. Handwheel or chainwheel

. The handwhecl or chainwheel shall be of steel, malleable iron or nodular iron.

25. Handwheel or chainwheel nut

The handwheel or chainwheel nut shall be of copper alloy, steel, malleable iron or nodular iron. If of carbon

steel it shall be suitably protected against corrosion.

26. Yoke sleeve

The yoke sleeve shall be of non-rusting metal having a suitable bearing quality and a melting point above

955°C.

27. Yoke sleeve retaining nut

The yoke sleeve retaining nut shall be of a material having a melting point above 955°C. Grey cast iron

shall not be used. If malleable iron is used it shall comply with the requirements ofBS 310 for grade B340/12

or grade B310/10. If spheroidal graphite cast iron is used it shall comply with the requirements of BS 2789

grade 370/17 or grade 420/12.

28. Gland

A pne piece gland or any gland ftange shall be of steel. The bushing of a one piece bushed gland or the

gland proper of a two piece gland shall be made of a material having a minimum melting point above 955°C.

29. Trim

%9.1 Trim comprises the following:

(a) stem;

(b) body scat surfaces;

(c) wedge scat surfaces;

(d) back seat bushing.

29.2 The trim materials shall be selected from those listed in table 2 and specified in. the order by quoting

the relevant nominal trim symbol.

%9.3 If a combination trim, e.g. CR 13 and eu-Ni, is specified, either material may be used for the body seat

surface. The other material of the combination shall be used for the wedge scat surface.

%9.4 Stems shall be of wrought material.

29.5 The temperature limitations of certain trim materials may restrict the pressure/temperature ratings of

the. valve to which they are fitted.

30. l.8ntern ring

A lantern ring, when supplied, shall be of a material not inferior to that of the shell.

31. Stem packing

The packing shall be of braided asbestos containing a suitable corrosion inhibitor. Unless the order specifies

other packing or a higher packing design temperature, it shall be suitable for use with steam or petroleum .

fluid at a minimum packing design temperature of 400 DC.

32. Bolting

32.1 Bonnet bolts shall comply with the requirements of BS 1506-621 grade A(BS 4882: 1973, section 3.

grade B7) and nuts shall comply with the requirements of BS 1506-162 (BS 4882: 1973,section 3, grade 21:1)

unless other bolting material is specified in the order.

32.2 Material for gland and yoke bolting shall be carbon steel of at least 392 N/mm2• tensile strength

unless other bolting material is specified in the order. Free cutting steels shall not be used.

• 1 N/mm1 - 1 MPa.

16

-

Table 2, Trim materials. hardn ••• and acceptable specifications

I

-

HP

Cu-NI

tria

NI-Qa

.

-•, -•I•••••••

-, 1

1

-

3M

071

B

NAI

5016NAI3

ronze

03-321540

200

A

1503-316541

276-311

IIZ-P310

1uCr

15'

anufacturer'l

31503-347540

M.n

SO'1

50U

•••••

JO"

nickel

min.

Seat

12

bronze

Bronze

11-1

25-20

2872-CZ114

BS

Manuf.cturer'1

ltaDdard

200

Ste.

1504-713

•2872-CAI04

MfueI

5313

II

•'11-12-3

2Cu-NI

200

11-10-2

1506-145

276-316

182-F316

351-CFlM

11-12-3

B

124-630

150-642

1400-AB2

A

A35I-CFIC

276-347

IU-P341

Back

NI-Cu

NI-Qa

Cr

200

BS

1504-7U

A250t

A

I•.••

Cr-NI

Manufacturer'1

IS

Cr-Ni-Mo

ASTM

C

10

1506-713

1503-410824

66-26-5

I•.••

25-20

Seat

uCr

182-P321

r-Ni

A

ASTM

182-P6

182-F6

138~75

584-164

3S1-CAIS

ltandard

1400-HTBI

1400-01

1503-410821

1506-113

216-410

I3.Cr

uCr

13Cr

250

1504-113

276-410

Cr-NI-Mo

1503-316541

11-10-2

11-12-3

Aluminium

2174-CAI04

1150-630

14I-9"D

Cr-NI-Nb

1506-121

NI-Cu

Cr-NI-n

Manufacturer's

Manufactunr'11t&DdanI

A35I-CA15

B

276-321

584-905

standard

••

Bar

t with

584-136

351-CA15

Manullcturer'lltandard

1504-146

Alumhuum

Maaulacturer'l

Aluminium

standard

Manuf.cturer'l

1504-821

Back

2874-CCZ114

1506-821

•• nNb

t ltandard

13Cr

1506-7U

lS04-I45

B•••••••

Muulac:Wnrr'l

Cutt

llo)'

M.n

•••••••

~

M~

HrIDeII...-..-.B 584-165

2812-CA103,

2874-CAI03,

1124-64214I-952A.

Allo)'

I400-AB

I,nNb

•••••••

p•.•••

AcceptaWe

lIfed8ca'"

B

13~75

-

1503-347550

1503-321550

..

...,

CD

en

••••

~

••••

~

..

• See 8S 240 : Part I,

For .Ultcnlde

triml the tobact

ma)' altcruallvcl)'

t Cutin

•• Dot applicable

ltamIMt

materlall;

- •••• '*, • wckl deposll

altcra.&1vc1,be a wcIdcd-on hard fldDI

.,'

of 11Msame nominal material composidOD U tbc &rimor • weIded-oalaarcl facia •. For hard faced (HF) trim &bebact _t

..

at

haidncu

bctwelll bod,

wed••

ICft

nol be

rIClwred.

DlfI'craadalhardneu

betweeD

bod,

andmlD.,

wed••

surf.ces

shaD

the

standard.

~ Dltrerendal

Bod)' aDd wed•.

scall~

250 Haad

•••scat

'SOlurtaca

min.II

d1f1'e

•.•

daImanullc:tunr'l

between bod, ••••••••••

'

seat eurr-.

'

...,

••••

to

...-...

'

.

01

as

1414 .: 1.975

33. Plugs

Material for shdl plugs shall be not inferior to that of the shell.

34. Nameplate

34.1 For valves of nominal size 150 mID (6 in) and larger the nameplate sbal1 be of 18-8 Cr-Ni steel or

nickel alloy attached to the valve by pins of similar material or by welding.

34.2 For smaller valves, the nameplate material and attachment shall be of corrosion resistant material in

accordance with the manufacturer's standard. Brass and aluminium are acceptable.

35. Soft seals

Soft seals shall be of tilt manufacturer's standard material for tilt duties specified. Any retaining ring in .

the wedge shall be of the same material as the stem but any fixing screws shall be of 18-8 Cr-Ni steel.

36. Special applications

When valves are specified for highly corrosive services or environment, or for low temperature service, the

material specification for all parts shall be subject to agreement between the purchaser and the manufacturer.

Section four. Marking

37. Required markings

Every valve in accordance with this standard shall be clearly marked as follows.

(a) Body and bonnet markings shall be integral.

(b) Every valve shall have a nameplate securely fastened to iL

38. ,Body and nameplate markings

Body and nameplate markings shall be as follows.

(a) Nominal size designation. The numeral(s) denoting the nominal size prefixed by the letters DN, e.g.

DN 100 (see clause 6).

(b) Class rating. The numerals denoting the class rating (see clause 4).

(c) Body material identification. Standard symbol from BS 1560 : Part 2: 1970, table 25.

(d) Manufacturer's name or tradc mark.

(e) The number of this British Standard, i.c. BS 1414.

39. Body and bonnet markings

r

39.1 Melt ideatiflcatloa. Melt identification is required on all pressure containing steel castings.

39.2 lUag joint 1UIIIIber.Pipe end flanges and bodyfbonnet ftanges grooved for ring joints and the rings to

be used with them shall be marked with the corresponding ring number (c.g. R2S). This identification shall

be placed on the rim of both pipe end flanges or the bonnct end ftange of tilt body as applicablc and on the

outside periphery of the ring. For ring numbers see appendix A. In thc case of non-standard ring joints

for bodyfbonnet flanges the flange and ring shall be marked R SpL.

40. Nameplate markings

<to.l Pressare/temperatuft

restrlcdous. Any pressure or temperature restrictions within· the appropriate

ratings given in BS 1560 : Part 2 that may be imposed by the manufacturer duc to limitations on materials

or design shall be shown on tilt nameplate.

Such special limiting pressure/temperature ratings shall also comply with the appropriate BS 1560 : Part 2

rating tabJe~

18

BS 1414 : 1975

40.2 VaiTCtrim hhDt •.••••• Trim materials shall be incticated in the following order, using the appropriate

symbol from table 2,

1. STEM

2. WEDGE

3. SEAT

as in the example below:

STEM CR 13

or CR 13 HF

WEDGEHF

SEAT

CR 13

CR13

CR. 13 or HF

CR 13

40.3 Ideatiftcatioa ••••••.• The manufacturer's figure or number identifying the valve in all respects shall

be shown. The same figure or number shall therefore only be used for valves which are identical in design,

detail, dimensions and material and which have interchangeable parts.

41. Additional

markings

Additional markings may be used at the option of the manufacturer provided they do not conflict with

any of the markings specified in this standard.

42. Omission of markings

41.1 Where the size or shape of the valve body precludes the inclusion of aU the required markings, they

may be omitted from the body only as found necessary subject to the approval ofthc purchaser. The sequence

of omission shall be as follows.

1. Nominal size

2. Manufacturer's name or trade mark

3. Class rating.

41.2 The number of this British Standard may be omitted from the body or the nameplate, but not from

both, at the manufacturer's option.

Section five. Inspection and test

43. Inspection and test requirements

Each valve in accordance with this standard shall be inspected and pressure tested in accordance with the

requirements of BS 5146.

Section six. Shipping

44. Preliminary

After inspection and before preparation for despatch all valves shall be thoroughly cleaned and dried.

46. Preparation for despatch

45.1 CoatiDg. Coating of valves shall be as follows.

(a) Unmachined cxtcmal surfaces of the valves shall be painted with aluminium finish paint, except for

austenitic steel vaMs which shall net be painted.

(b) Machinedorthreaded surfaces shall be coated with an easily removable rust protective (see BS 1133:

Section 6) except that this shall not be required for austenitic steel components.

45.2 EDd protectfoa. After complying with the requirements of 4S.1, body end ports. flange races and buttwelding ends shall be covered with suitable close fitting protectors to protect the machined ends and prevent

ingress of dirt and moisture.

45.3 Stem ,.,.)[ •••• The stem packing shall be fitted bet~re shipping.

45.4 Wedp. The walge shall Ue closed before shipping except in tl-e case of soft seal valves where the

wedge shall be baclrcd oft' to relieve the pressure on the seals..

48. Packaging.

Valves shall be so pldaged as to minimize the possibility of damage during storage or transit. Wbae

tropical or special pKkaging is necessary. the purchaser shan specify his requirements ..

f

19

BS 1414, : 1975

Appendix A. Particular dimensions for each cia •• of valve

Table 3. Dimensions of Class 150valv_

1

1

-

6mm

8~(-)

0.3

3.5

2.6

9.8

••

5622.2

St_

••••••••.

3mm

Iaside

dfaIIIeter

of mm·

RiDa

IIIIIIIber

R17

R22

R29

(mID.)

21.4

R19

R2S

R36

R48

19.0

Bedy

•••••••

bc8Iet "

32

R15

15.9

76

8.7

20.6

57.2

152

64

11.1

11.9

12.7

14.3

16.7

18.2

19.0

R72

R68

R64

R43

RS6

RS2

41.3

15.4

38.1

44.4

34.9

31.8

17.5

em)

r_

50.8

rial

22.2

23.0

28.6

635

R76

203

102

38

489

2S4

337

305

6.4

9.5

15.9

RS9

47.6

17.5

737

686

25.4

15

51

591

438

1020

. (3)

387

876

(12)

(10)

(lilt

(1

(16)

(4)

(6)

i) 10.3

(30)

(1)

(2)

(26)

(24)

(20)

(2i)t

(14)

(18)

(8)

(28)

(42)

(36)

• For details of wddiog ends includina inside diameters ice fiaurc 2-

t These

sizes have been retained for the PUIpOIe of replacilli existing valves. Their use for new construction in pipinl systems

using BS 1560 : Part 2 flanges should be a¥Oided

20

BS 1414 : 1975

Table 4. Dimensions of Class 300 valves

I

,sa.•••••.

88.9

1R45

76.2

82.6

01.6

69.8

nun

••

diuIeter

3mm

5fGr

2584

25

12.7

9.5

(in) 11.1

RiDI-..•.

)

~(

7.9

6.4

2S4

19.0

11.9

20.6

17.5

R49

64

R26

876

41.3

152

483

737

30.2

15.9

R20

•••••••••

25.4

51

32

R16

R18

44.4

102

R37

76

RS3

387

23.8

R65

305

337

22.2

R61

34.9

27.0

R77

R73

R23

38

19.0

riDe

joim

686

33.3

635

432

31.8

R69

1020

25.4

38.1

203

RS7

41.3

34.9

47.6

63.5

31.8

S4.0

44.4

(BodJ

..•.

)IIIIide

15.9

22.2

SO.8

(li).

(4)

R31t

(3)

(24)

(2)

(14)

(1)

(10)

(12)

(8)

(21)t

(28)

(36)

(20)

(18)"

(26)

(30)

(6)

(42)

(lUt

(16)

f1l

mm

• For dctllils of wcldiq ends indudin, inside diameters see fiaure 2.

These sizes have been retained only for the purpose of repJaciD, existin, valves. Their use for new construction in pipiq

systems usin, BS 1560 : Part 2 ftanges should be avoided.

"

For valves of 80 mm (3 in) nominal size. if intended to be used in conjunction with lapped flanges, tbe rin, number sball be

RJO.

t

t

Table 5. Dimensions of Class 400 valv ••

I

3432

2(20)

(in)

nun

381

333

102

2S4

479

575

. 203

305

152

(18)

(4)

(16)

(24)

(6)

(10)

(8)

(14)

(12)

diameter

f1l

Stem

diamet

•. )

tbickDeII

(•••••

R49

R53

R65

for

R37

BodJ

RJac-R73

n.

••• )oiIls

boaaet

38.1

34.9

R45

44.4

RS7

28.6

R61

69.8

36.5

SO.8

(12.7

...•..

)IDIide

28.6

63.5

57.2

33.3

R69

16.7

19.0

21.4

23.8

27.0

30.2

R77

I47.6

56

mm

••

• For details of weldina ends indudiq

mm

inside diametcn see ftaure 2.

21

BS 1414·: 1975

Table 6. Dimensions of Class 600 valv ••

1

mm

5'_rial

4 IIIIide

diameter ~

3298

615.9

2(24)

Stea

•••••••

R16

R20

11.1

R23

25

mm

8.6

7.9

1lJIIa-R26

25.4

464

44.4

38

R77

9.3

thleh11-*

(in)

327

34.9

41.3

32

200

102

12.7

11.9

R37

RS3

R49

31.8

28.6

BodJ

••••• (••••)

559

R73

69.8

<-IL)

SO.8

51

76.2

19.0

419

375

R69

R65

60.3

152

76

64

R45

RS7

41.3

47.6

22.2

25.4

28.6

38.1

R61

63.5

248

57.2

(1)

(2)

(18)

(3)

(14)

(16)

(ll)

(12)

(10)

(4)

(8) R18

R31:

(20)

(2i)t

(6)

(li)t

mm

• For detaiJs of welding ends including inside diameters see flame 2.

t These

sizes have been n:tamed only for the purpose of repladnl cxistiq valves. Their use Cor new coDStnx:tion ia pipiDa

systems using BS 1560 : Part 2 flanges should be avoided.

: For valves of 80 mm (3 in) nominal size. if iatended to be UIed ia c:oojuDcdon with 1appecl ftan8es. the rial DUmber Iha1l

be RJO.

Table 7. Dimensions of Class 900 valv ••

1

3mm

2(12)

190

283

444

(in)

73

400

311

238

98

533

. 146

356

(10)

(8)

(3)

(20)

(16)

(6)

(14)

(18)

(4)

(24)

mm

631.8

St_

•••••

5R.74

4101.6

IIIIide

cUameter~

R49

RS3

47.6

41.3

R37

R.78

RS7

19.0

lUDI

(mIL)

••••••.

R70

63.5

R45

26.2

54.0

31.8

57.2

R31

28.6

R.66

R62

46.0

76.2

60.3

82.6

63.5

far

•101.r1rrial

(-.)

36.5

42.1

73.0

57.2

52.4

BodJ

•••••••

bo.et

21.4

mm

• For details of welding ends inc1udiDa inside diametcn

••

lain 2.

22

as 1414 : 1975

,

..

Tabla 8. Dimensions

-

1

--

of,CI ••• 1&00 vaIve8

-•..

..,......

•••••••

r._

mm

••

370

522.2

2(2i)t

IIIIiIIe~

3a.1

19.0

tWl~(IdI.)

12.7

114.3

416

R75

R71

95.2

88.9

19.4

137

R,46

R,63

47.6

44.4

69.a

66.7

57.2

R.39

R.35

28.6

23.a

48

R20

15.0

22.2

14.2

R.27

28.6

22

em)

19.0

R19

127.0

101.0

98.4

330

R67

82.6

178

222

289

264

R54

R.58

R50

$4.0

63.5

69.8

92

31.8

34.9

29

35

mm

(11II.)

2S.4

R,16

498

371

76.2

R,18

57

(2)

(20)

(16)

(6)

(1i)

(3)

(1)

(12)

(14)

(10)

(8) R.24

(4)

(24)

(1a)

(ll>t

• For details of wddiq

'" mm

c:o.daiDc:ludiDi iDlide diamctcn •• Ipre

t These

2-

sizes bave been m.ined oa1y for the purpoIe or rcpIIciDa exiatiq

aystemI usiq BS 1560 : Part ftaDpllbou1cl be awided.

1

,

Table 9. Dimensions

1

mm

--

3

2(in)

19

-146

111

29

73

IDJD

2S

48

38

57

219

184

(12)

(10)

(2)

(3)

(Ii)

(6)

(a)

(1)

(4)

(2i)t

(li)t

valva. Their \lie fOl' DCW COIIIInICtioDiD pipiaa

of Cia •• 2&OOvaIWe

•••••••

•••••••

..., ......

DUD

52S.4

••

60.3

22.2

73.0

B.S5

(IdI.)

47.6

R.21

28.6

31.8

34.9

1126

67.5

a2.6

86.5

30.2

17.5

19.0

R23

R.32

61.9

R.38

19.0

R2I

•••••••••••

35.7w.-..••••

(11II.)

Ria

R,60

22.2

2S.4

48.4

B.Sl

R47

15.1

'" mm

• For cletaiII of weldin, ends includ.lftl inIide diuneters lee ftpre 2These sizeI have been retained only ror the purpclIC or repIacina existilll valves. Their \lie rOC'new c:oostrudion

systems _III BS 1560 : Part 2 ftanaa shoukl be awided.

t

c

23

in pipiq

65··1414 : 1975

AppendixB

Application

to piping systems with BS 4504 flanges

B.l GeaeraL Valves in accordance with this British Standard. BS 1414. may be supplied for use in piping

systems with BS 4504 flanges when specified by the purchaser. When this is the case alJ the requirements of

this BritishStand~.

BS 1414. apply, with the qualifications specified in IU to 8.7 ..

B.2 Plaoun;Jtemperature ratings. The pressure/temperature ratings of valves with BS 4504 flanges shall be

in accordance with BS4504 : 1969,table AI. Pressure/temperature ratings for valves in materials other than

those listed in BS 4504: 1969, table Al shall be agreed between the purchaser and the manufacturer.

B.3 NomiDal prasare _ dus ratings IDd nomiDal size range. Valves in accordance with this appendix with

flanges of the nominal pressure ratings given in column I of table 10 shall have the same face-to-face

dimensions as valves with BS 1560 : Part 2 flanges of the corresponding class ratings in column 2. Column 3

gives the applicable nominal size range.

Table' O. Nominal pressure and class ratings and nominal size range

1

..300

4600

.to600·

CuI

(in)

2S

2SO

SOto

25

300

300

25

200

600

2S

to

25

600

300

2500

2SOO

ISO

1500

900

(1

8)

(l

10)

(2

to

24)

(I

12)

I~3

NODIIDal size

ruse

mm

B.4 Body tad

flaps

8.4.1 Dimensions. Body end flange dimensions s~1 comply with the requirements of BS.4504 except that

flange thicknesses may be the appropriate values from BS 1560 : Part 2. Flange thicknesses shalt be not less

than those specified in BS 4504. When flange thicknesses comply with those specified in BS 4504. the neck

dimensions shall also comply with the requirements of BS 4504.

. 8.4.2 Spot-facing or back-facing. The requirements of BS 1560 : Part 2 for spot-facing or back-facing shall

be complied with..

B.4.3 Finish of jow surface. The joint surface finish shall comply with the requirements of BS 4504.

B.S Iaspecdoa IDdtestfng. Va~ves shall be inspected and tested in accordance with BS 5146 except tbat

hydrostatic test pressures shall comply with the values given in table 11.

24

BS 1414 : 1975

Teble11. Hydroatlltlc teat pr••

1

•••

•••

310

400

2SO

160

2S

40

100

64

320

16

bar·

ura

TIIt..-..Iar

Z

600

24

375

ISO

60

240

480

15

96

37.5

bar·

W'--"

8.6

M'aItiDg. When supplied for use in piping systems with BS 4504 lanses valves shall be permaDCIltIy

marked with the appropriate nominal pressure rating (i.e. PN •• ). nus marking may replace or supplement

the n:quirements of clause 38(b) and shall appear on aU BS 4504 lanses used.

8.7 lDformadoa to be supplied by tile pardlaler.

The information to be suppliecl.by the purchaser shall be

as listed in clause 7 of this standard except that <a) shall be replaced by the following. .

<a) State that valves arc to comply with the n:quirements of this appendix and state nominal pressure

ratiDg and nominal size.

• I bar -

105 N/m2

-

100 kPa.

26

BSI publications referred to in this standard

('

•

This standard makes.aCI'CIICC 10 the rollowiDa British Standards:

BS2080

BS4882

BS

BS2874

BS SI46

3799

4504

••••

2172

3293

3692

1832

1133

1501-6

BS4190

BS3076

3071

33S1

1503

3600

1769

3381

1S60 'IS Z40

BS2693

BS2789

1400

1768 :

BS 310

BS

1600

Method rot BrincD hardness test

Part I Testial of meals

Blackheut

malleable iron c:astinp

~ainlcode

Section 6 Temporary protection or metal surfaces apinst

corrosion (durinl tranIpOI't aaclltOrqe)

Copper alloy inaots and copper and copper alloy c:astiDas

Steels ror UIe in the chemical, petroleum and allied industries

Steels ror finld and unfired pressUre veaeJs. Foqinp

l

Steel pipe ftaages and ftan&ed fittinp (nominalllizes

Part 2 Metric climensions

in 10 24 in) ror the petroleum iDdaIby

Dimeusions of steel pipe ror the petroleum iDdustry

Part 2 Metric units

Unified precision hexagon bolts. ICr'e'WIand DUts (UNC and UNF threads). Normal __

Unified black hcuaon

bolts, ICI'eM and nuts (UNC and UNF threads). Heavy IerieI

Oil resistant comprased asbestos fibre jointiDa

Face-to-face. c:entre-to-race, encl-to-end and ccntt.to-encl

ror the petroleum, petrochemical and allied industria

dimensions of ftanpd and butt-wddinl

eDd steel YaIftI