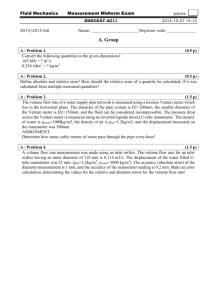

Chapter 4

advertisement

CHAPTER 4 • Introduction to Fluid Dynamics • Control Surface/Area/Volume • Flow Type • Streakline, Streamline & Pathline • CONTINUITY EQUATION • BERNOULLI EQUATION Introduction to fluid dynamics • Fluid dynamics is a study of fluid in motions. • It has several subdisciplines including aerodynamics (the study of air and other gases in motion) and hydrodynamics (the study of liquids in motion). • Fluid dynamics has a wide range of applications e.g : forces and moments calculation on aircraft, determining the mass flow rate of petroleum through pipelines, predicting weather patterns etc. • The solution to a fluid dynamics problem typically involves calculating various properties of the fluid, such as velocity, pressure and flow rate. Mean or Average Velocity • The velocity in the pipe normally is not constant across the cross section. • Crossing the centreline of the pipe, the velocity is zero at the walls increasing to a maximum at the centre then decreasing symmetrically to the other wall. • This variation across the section is known as the velocity profile or distribution. A typical one is shown in the figure below. FLOW TYPE Steady flow - A flow in which the fluid properties such as velocity, temperature and pressure at a point in the system do not change over time. Unsteady flow - A flow in which at least one variable at a fixed point in the flow changes with time . FLOW TYPE Uniform flow - The velocity of the fluid has the same magnitude and direction at any position in the fluid flow. Non-uniform flow – The velocity magnitude and direction are not equal at any position in the fluid flow. Compressible flow – ? Incompressible flow - ? Streakline, Streamline & Pathline Streamlines — A streamline is formed by tangents of the velocity field of the flow. Pathlines — A pathline can be formed from fluid particles of different colour originated from the same points, such as a line formed after the introduction of ink into a shallow water flow. Streaklines — A streakline represents a locus made by a miniature particles or tracers that passes at a same point. In a steady flow, fluid particle normally moves along a streamline…so streaklines, streamlines and pathlines are the same (coincide). Control Surface/Area/Volume In fluid mechanics, it is more convenient to work with control volume. Control volume = a specific region, space or area chosen for study. 1D analysis – although simple (almost not describe the actual situation) but it gives a useful engineering estimate. CONTINUITY EQUATION • Mass flow rate, m • Volume flow rate, Q • Continuity Equation • Derivation of the Continuity Equation Mass flow rate, m • The amount of mass flowing through a cross section per unit time is called the mass flow rate and is . The dot over a symbol is used to indicate denoted by m time rate of change. • If we want to measure the rate at which water is flowing along a pipe, a very simple way of doing this is to collect all the water coming out of the pipe in a bucket over a fixed time period. • Measuring the weight of the water in the bucket and dividing this by the time taken to collect this water gives a rate of accumulation of mass or the mass flow rate. cont… • For example an empty bucket weighs 2.0 kg. After 7 seconds of collecting water the bucket weighs 8.0 kg, so: cont… •Performing a similar calculation, if we know the mass flow is 1.7 kg/s, how long will it take to fill a container with 8 kg of fluid? Volume flow rate, Q • More commonly we need to know is the discharge or the volume flow rate (or simply called flow rate). • The volume flow rate, Q is defined as the volume of the fluid flowing through a cross-section per unit time or. Volume, Q or Q velocity area VA, Time, t • The SI unit for Q is m3/s. • However, in practice the unit commonly used is l/s (litre per second). • Multiplying this by the density of the fluid gives us the mass flow rate, or, m Q kg / s • Consequently, if the density of the fluid in the above example is 850 kg/m3 then: Example 1 A garden hose attached with a nozzle is used to fill a 10-gal bucket. The inner diameter of the hose is 2 cm, and it reduces to 0.8 cm at the nozzle exit. If it takes 50 s to fill the bucket with water, determine (a) the volume and mass flow rates of water through the hose, (b) the average velocity of water at the nozzle exit. CONTINUITY EQUATION •Matter cannot be created or destroyed but it is simply changed into a different form of matter. •This principle is know as the conservation of mass and it is used in the analysis of flowing fluids to derive the continuity equation. • Generally; Mass entering per unit time = Mass leaving per unit time + Increase of mass in the control volume per unit time • For steady flow there is no increase in the mass within the control volume , Mass entering per unit time = Mass leaving per unit time Derivation of the Continuity Equation • Consider a streamtube such as shown at the figure in the left side. • A liquid is flowing from left to right and the pipe is narrowing in the same direction. No fluid flows across the boundary so mass only enters and leaves through the two ends of this streamtube section. • By the continuity principle, the mass flow rate must be the same at each section - the mass going into the pipe is equal to the mass going out of the pipe. • So we can write: 1A1V1 = 2A2V2 Or for steady flow, 1A1V1 = 2A2V2 = constant This equation is called as continuity equation. When the fluid is considered as incompressible (i.e. the density does not change or ρ1 = ρ2 = ρ), therefore, A1V1= A2V2= Q This is the form of the continuity equation most often used. BERNOULLI EQUATION • Introduction to Bernoulli Equation • Limitations on the Use of the Bernoulli Eqn. • Derivation of the Bernoulli Equation • Other forms of Bernoulli Equation • Stagnation pressure • Bernoulli Equation’s Applications - orifice in reservoir - orifice in pipes - pitot tube - venturi meter - weirs Introduction to Bernoulli Equation • Bernoulli Equation is the most popular equation in fluid mechanics. • The Bernoulli equation is an approximate relation between pressure, velocity, and elevation, and is valid in regions of steady, incompressible flow where net frictional forces are negligible. • It is derived from Euler equation (Leonhard Euler – the greatest Swiss mathematician). • The Bernoulli equation is one of the most frequently used and misused equations in fluid mechanics. Its versatility, simplicity, and ease of use make it a very valuable tool for use in analysis, but the same attributes also make it very tempting to misuse. Therefore, it is important to understand the restrictions on its applicability and observe the limitations on its use. Limitations on the Use of the Bernoulli Eqn. 1.Steady flow - applicable to steady flow. 2. Frictionless flow - Every flow involves some friction, no matter how small, and frictional effects may or may not be negligible. The situation is complicated. But in general, frictional effects are negligible for short flow sections with large cross sections, especially at low flow velocities. (viscousity assumed as constant or no fiction losses occur). 3. Incompressible flow - One of the assumptions used in the derivation of the Bernoulli equation is that ρ = constant and thus the flow is incompressible. This condition is satisfied by liquids and also by gases at Mach numbers less than about 0.3 since compressibility effects and thus density variations of gases are negligible at such relatively low velocities. 4. Flow along a streamline -The Bernoulli equation is applicable along a streamline, and the value of the constant C, in general, is different for different streamlines. Others : no shaft work like pump/turbine, etc. (Refer cengel) Derivation of the Bernoulli Equation • Consider the motion of a fluid particle in a flow field in steady flow. Other forms of Bernoulli Equation 2. Total head - by dividing each term of the Bernoulli equation (1) by g. ** pressure head + velocity head + elevation head = C 3. Total pressure - by multiplying each term of the Bernoulli equation (1) by density ρ. 1. Total energy static pressure + dynamic pressure + hydrostatic pres. = C ** commonly used The Bernoulli equation between two points can be written as : Or in the form of total head eqn. : ? Stagnation pressure • The stagnation pressure represents the pressure at a stagnation point, where the fluid is brought to a complete stop isentropically ( or fluid particle velocity equal to zero). • Eg. of stagnation point : The stagnation pressure is the sum of the static and dynamic pressures and it is expressed as When static and stagnation pressures are measured at a specified location, the fluid velocity at that location can be calculated from : Bernoulli Equation’s Applications • The Bernoulli equation can be applied to a great many situations. • In the following sections we will see some examples of its application in flow measurement from tanks, within pipes as well as in open channels. Bernoulli Equation’s Applications Its include •the pitot tube •and also the devices to measure flowrate in pipes and conduits such as orifice and venturi meters. The operation of each is based on the same physical principles - an increase in velocity causes a decrease in pressure. The difference between them normally is a matter of cost and accuracy. Bernoulli Equation’s Applications Flow Through Orifice at Reservoir • Orifice = small opening. • E.g of application : drain outlet at tank/vessel. • Purpose : to calculate the rate/discharge at which a fluid will flow from a tank so that the time it takes to drain can be calculated. •Consider a flow of liquid from a tank through a hole in the wall side close to the tank base. The general arrangement and a close up of the hole and streamlines are shown in the figure below. •At the streamlines, we can see the flow contract after the orifice to a minimum value. •This convergence is called the vena contracta (the point in a fluid stream where the diameter of the stream is the least ). •At this point, the velocity and pressure are uniform across the jet and it is necessary to know the amount of contraction to allow us to calculate the actual flow. •This can be done by using a coefficient of contraction, Cc to calculate the actual area and this will be shown later. • We can predict the velocity at the orifice using the Bernoulli equation. • Apply it along the streamline joining point 1 on the surface to point 2 at the centre of the vena contracta. • We take point 1 to be at the free surface of water so that P1=Patm (at the atmosphere), also P2=Patm (water discharges into the atmosphere). V1≈0 (the tank is large relative to the outlet), and z1=h and z2=0 (we take the reference level at the center of the outlet). • Then the Bernoulli equation simplifies to • Leaving • This is the theoretical value of velocity. It will be over estimate of the real velocity because friction losses have not been taken into account. • To incorporate friction, we use the coefficient of velocity, Cv to correct the theoretical velocity. Vactual = CvVtheoretical • Each orifice has its own coefficient of velocity, they usually lie in the range of 0.97 - 0.99. • To calculate the discharge through the orifice we multiply the area of the jet by the velocity. The actual area of the jet is the area of the vena contracta not the area of the orifice. • We obtain this area by using a coefficient of contraction for the orifice Aactual= Cc Aorifice So the discharge through the orifice is given by Q AV AactualVactual Cc AorificeCvVtheoretical Cc Cv AorificeVtheoretical Cd AorificeVtheoretical Cd Aorifice 2 gh Where coefficient of discharge, Cd is given by Cc multiply by Cv. Cd=CcCv The discharge coefficient Cd depends on the configuration of the outlet. General steps to solve problem involving Bernoulli Eqn. Normally the Bernoulli equation is used to determine the flowrate, pressure or velocity at a given point. The following steps might be useful to solve the problems involving Bernoulli equation. i. Consider the figure and identify point 1 and 2. ii. Write the Bernoulli eqn between the two points. iii. List out and substitute all known information in Bernoulli eqn. iv. Use continuity eqn if needed. v. Solve the equation to determine the required value. Example 1 A large tank open to the atmosphere is filled with water to the height of 5 m from the outlet tap. A tap near the bottom of the tank is now opened, and water flows out from the smooth and rounded outlet. Determine the water velocity at the outlet. Example 2 An orifice 50 mm in diameter is discharging water under a head of 10 m. If Cd = 0.6 and Cv = 0.97, find actual velocity and actual discharge of the jet at vena contracta. Example/Exercise 3 Orifice Meter Orifice plate • A plate which has an opening in it, smaller than the internal diameter of the pipeline. • Installed in a pipe which equipped with pressure measuring devices. Advantages : • Simple design • Low cost (compared to venturi meter) Disadvantage : • Low Cd/larger energy losses • A typical value for a sharp edged orifice being 0.65. • The orifice plate produces a constriction of the flow as shown, the cross sectional area A2 of the flow immediately downstream of the plate being approximately the same as that of the orifice. • The theoretical discharge can be calculated from Bernoulli and Continuity equation but the actual discharge may be as little as two-third of this value. A coefficient of discharge also must be introduced. Fig 6.2: Orifice meter eqquiped with U-tube manometer Example 1 For figure below, find the flowrate in pipe. Example 2 An orifice meter having an inside diameter of 2.5 cm is located in a 8 cm pipe. Water is flowing through the pipe and the mercury manometer measures the differential pressure over the pipe. When the manometer reading is 35 cm, what is the flow rate of water per minute? Exercise 1 (from tutorial) An orifice plate is used to measure the rate of air flow through a 2 m diameter duct. The mean velocity in the duct will not exceed 15 m/s and the water tube manometer, having a maximum difference between water levels of 150 mm, is to be used. Assuming the coefficient of discharge to be 0.64, determine a suitable orifice diameter to make full use of the manometer range. Take the density of air as 1.2 kg/m3. Exercise 2 • What diameter orifice hole, d, is needed if under ideal conditions the flowrate through the orifice meter is to be 113L/min of seawater with p1 – p2 = 16.34 kPa. The contraction coefficient is assumed to be 0.63. Pitot tube The pitot tube is a simple and inexpensive way used to measure the velocity of a fluid stream. Consists of a simple L- shaped tube with opened end,facing into the oncoming flow. Use the principle of stagnation point - a particle is brought to rest at stagnation point result a greater pressure at this point. pitot tube - Attached with piezometer – to measure static pressure while pitot tube is to measure dynamic pressure. pitot tube static • In the Pitot-static tube, the inner tube is used to measure the impact/dynamic pressure when the outer sheath has holes in its surface to measure the static pressure. Example 1 A piezometer and a pitot tube are tapped into a horizontal water pipe to measure static and stagnation pressures. For the water column heights, determine the velocity at the center of the pipe. Ans : 1.53 m/s Example 2 The specific gravity for manometric fluid as shown in figure below is 1.07. Calculate the flow rate, Q if the fluid flowing in the pipe are; i. water ii. air Exercise 1 An airplane flies 44.7 m/s at an elevation of 3048 m in a standard atmosphere. Determine the pressure at point (1) far ahead of the airplane, the pressure at the stagnation point on the nose of the airplane (point 2), and the pressure difference indicated by a pitot-static probe attached the the fuselage. Air flows through a pipe at a rate of 200 L/s. The pipe consists of two sections of diameters 20 cm and 10 cm with a smooth reducing section that connects them. The pressure difference between the two pipe sections is measured by a water manometer. Neglecting frictional effects, determine the differential height of water between the two pipe sections. Take the air density to be 1.20 kg/m3. Ans 3.7cm Air at 110 kPa and 50°C flows upward through a 6-cmdiameter inclined duct at a rate of 45 L/s. The duct diameter is then reduced to 4 cm through a reducer. The pressure change across the reducer is measured by a water manometer. The elevation difference between the two points on the pipe where the two arms of the manometer are attached is 0.20 m. Determine the differential height between the fluid levels of the two arms of the manometer. Venturi Meter Advantages : • Higher Cd/small energy losses Disadvantages : • Difficult to manufacture • expensive • Venturi meter consists of a short converging conical tube leading to a cylindrical portion, called the throat, of smaller diameter than that of the pipeline, which is followed by a diverging section in which the diameter increases again to that of the main pipeline. • Normally is made from bronze – or cast iron (for huge size) with bronze lining in inner section for a smooth surface. • Equipped with pressure measurement devices such as piezometer, manometer or pressure gauge. Orientation of venturi in pipeline system Horizontal with pressure gauge Horizontal with manometer Inclined with manometer and piezometer • The pressure difference from which the volume rate of flow can be determined is measured between the entry section 1 and the throat section 2, often by means of a U-tube manometer (as shown). • The axis of the meter may be inclined at any angle. Fig 6.1: Inclined venturi meter and U tube • Assuming that there is no loss of energy, and applying Bernoulli’s equation to section 1 and 2, P1 V12 P2 V22 + + z1 = + + z2 ρg 2g ρg 2g V22 - V12 = 2g [(P1 - P2 )/ ρg + (z1 - z2 )] • For continuous flow, A1V1 = A2V2 or V2 = (A1 / A2 )V1 • Substituting in equation 6.1 V12 [(A1 /A2 ) - 1] = 2g [(P1 - P2 )/ ρg + (z1 - z2 )] 2 V1 = A2 (A 2 1 -A 1 2 2 2 ) 2g[(P1 - P2 )/ρg + (z1 - z 2 )] • Volume rate of flow Q A1V1 A1 A2 /(A1 - A2 ) 2 2 1 2 (2gH ) where H (P1 - P2 )/g + (z1 - z 2 )or m Area ratio A1 /A2 Q A1 /(m - 1) 2 1 2 (2gH ) (eq 6.2) • In practice some loss of energy will occur between section 1 and 2. The value of Q given by the equation 6.2 is a theoretical value which will be slightly greater than the actual value. • A coefficient of discharge, Cd is therefore introduced. Actual discharge, Qactual = Cd x Qtheoretical • The value of H in the equation can be found from the reading of the U-tube gauge (Fig6.1). • Assuming that the connections to the gauge are filled with the fluid flowing in the pipeline, which has density ρ, and that the density of the manometric liquid in the bottom of the U-tube is ρman. • Then, since pressure at the same level XX must be the same in both limbs, Px P1 g ( z1 z) P2 g ( z2 z h) manhg • Expanding and rearranging, H ( P1 P2 ) / g ( z1 z2 ) h( man / 1) • Equation 6.2 can be written Q A1 /(m - 1) 2 1 2 ρman 2gh 1 ρ eq 6.3 Note that eq 6.3 is independent of z1 and z2, so that the manometer reading h for a given rate of flow Q is not affected by the inclination of the meter, If however, the actual pressure difference (p1-p2) is measured and equation 6.1 and 6.2 used, the values of z1 and z2 and, therefore, the slope of the meter must be taken into account. Exercise A pipe inclined at 45° to the horizontal converges over a length l of 2 m from a diameter d1 of 200mm to a diameter d2 of 100mm at the upper end. Oil of relative density 0.9 flows through the pipe at a mean velocity v1 at the lower end of 2 m/s. find the pressure difference across the 2 m length, ignoring any loss of energy, and the difference in level that would be shown on a mercury manometer connected across this length. The relative density of mercury is 13.6 and leads to the manometer are filled with the oil. Air is flowing through a venturi meter whose diameter is 6.6 cm at the entrance part (location 1) and 4.6 cm at the throat (location 2). The gage pressure is measured to be 84 kPa at the entrance and 81 kPa at the throat. Neglecting frictional effects, show that the volume flow rate can be expressed as and determine the flow rate of air. Take the air density to be 1.2 kg/m3 Example 1 A venturi meter having a throat diameter d2 of 100 mm is fitted into a pipeline which has an diameter d1 of 250 mm through which oil of specific gravity 0.9 is flowing. The pressure difference between the entry and the throat tappings is measured by a U-tube manometer, containing mercury. If the difference of level indicated by the mercury in the U-tube is 0.63 m, calculate the theoretical volume rate of flow through the meter. Example 2 Water flows through a pipe reducer as is shown in figure. The static pressure at point (1) and (2) are measured by the differential manometer containing oil of specific gravity, SG which less than one. For this manometer, show that the manometer reading, h is given by Exercise 1 • A venturi meter with an entrance diameter of 0.3 m and a throat diameter of 0.2 m is used to measure the volume of gas flowing through a pipe. Assuming the specific weight of the gas to be constant at 19.62 N/m3, calculate the volume flowing when the pressure difference between the entrance and the throat is measured as 0.06 m on U-tube manometer. Given the discharge coefficient Cd is 0.96. Exercise 2 JP-4 fuel with SG=0.77 flows through the venturi meter with velocity of 4.57 m/s in the 15 cm pipe. If viscous rffects are negligible, determine the elevation h, of the fuel in the open tube connected to the throat of the venturi meter. THANK YOU !