Syllabus MEC331

advertisement

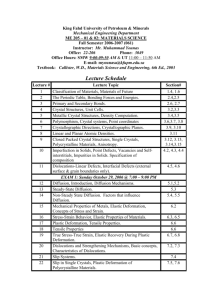

Al-Asala Colleges College of Engineering Mechanical Engineering Department Course Syllabus MEC 331 Material Science Course Description: Introduction to materials science; Atomic bonding; Structure and characteristics of metals; polymers and ceramics; Imperfections; Diffusion; Mechanical properties of metals, polymers, ceramics; Equilibrium-phase diagrams; Microstructures of alloys; Heat treatments. Course Book: Callister, W.D., Materials Science and Engineering, 9th Ed. 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Introduction and classification of materials. The periodic table, bonding forces and energies. Primary and secondary bonds. Crystal structures, unit cells. Metallic crystal structures, density computation. Polymorphism, crystal systems, crystallographic direction. Crystallographic planes. Linear and planar densities & Closed-packed crystal structures. Single crystals, polycrystalline materials, anisotropy. Imperfection in solids, point defects, vacancies and selfinterstitials, impurities in solids. Impurities in solids and specification of compositions Dislocations-linear defects, interfacial defects. Diffusion mechanisms, steady-state diffusion. Non-steady state diffusion. Factors that influence diffusion. Concepts of stress and strain Stress-strain behavior of materials. Elastic and plastic deformation, tensile properties. True stress-true strain, elastic recovery during plastic deformation. Dislocations and strengthening mechanisms, basic concepts Slip systems, slip in single crystals and polycrystalline materials Strengthening by grain size reduction, solid solution hardening. Strain hardening. Recovery, recrystallization and grain growth. Reading Assignments 1.1 - 1.6 2.1 – 2.5 2.6- 2.8 3.1 – 3.3 3.4 - 3.5 3.6 – 3.9 3.10 3.11 – 3.12 3.13 – 3.15 4.1 – 4.2 4.3 – 4.4 4.5 – 4.7 5.1 – 5.3 5.4 5.5 - 5.6 6.1 – 6.2 6.3 – 6.5 6.6 6.7 – 6.8 7.1 – 7.3 7.4 – 7.6 7.8 – 7.9 7.10 7.11 – 7.13 Exam 1st Major Exam 1 Topic 2nd Major Exam Lecture # 17 18 19 20 21 22 23 24 25 26 27 28 Phase diagram, solubility limit, microstructure, phase equilibrium. Binary isomorphous system. Interpretation of phase diagrams and Development of microstructure in isomorphous alloys Binary Eutectic Systems Development of microstructure in Eutectic alloys The iron-iron carbon phase diagram Development of microstructure in iron-carbon alloys 9.1 – 9.5 Phase transformation, Basic Concepts, Isothermal Transformation diagrams Bainite, Spheroidite, Martensite. Continuous Cooling Transformation diagrams Mechanical Behavior of iron-carbon alloys Tempered Materials, review Ferrous Alloy & Steel. Cast Irons Hydrocarbon molecules, polymer molecules Molecular weight, shape, and structure. Thermoplastic and thermosetting polymers. 10.1 – 10.5 9.6 – 9.7 9.8 – 9.9 9.11 9.12 9.18 9.19 – 9.20 10.5 10.6 10.7 10.8 – 10.9 11.2 11.2 14.1 – 14.4 14.5 – 14.7 14.9 Grading Policy 1st Major Exam 2nd Major Exam Final Exam Lab Exam Attendance Quiz Home-Work 15% 20% 40% 10% 5% 5% 5% Class Policy 1. Class participation is highly encouraged and will be considered in the final grade. 2. Always come to class with your calculator. 3. Come to class on time. Four lates will be considered as one absence Instructor Name: Abdul Aziz Afzal E-mail: abazizafzal@gmail.com Office: TBA Final Exam 16 Laboratory Outline Week # 2 3 4 5 6 7 8 9 10 11 12 13 14 Lab Title Introduction to the lab Introduction to experiment report writing Sample preparation for metallography Metallographic examination and quantitative measurements Hardness Measurements Tension Test- Ductile Materials Tension Test- Brittle materials Impact Test Heat Treatments-1 Heat Treatments-2 Cooling Curve Recovery and Recrystallization Final lab exam