Gas Dehydration Regeneration Options for Natural Gas

advertisement

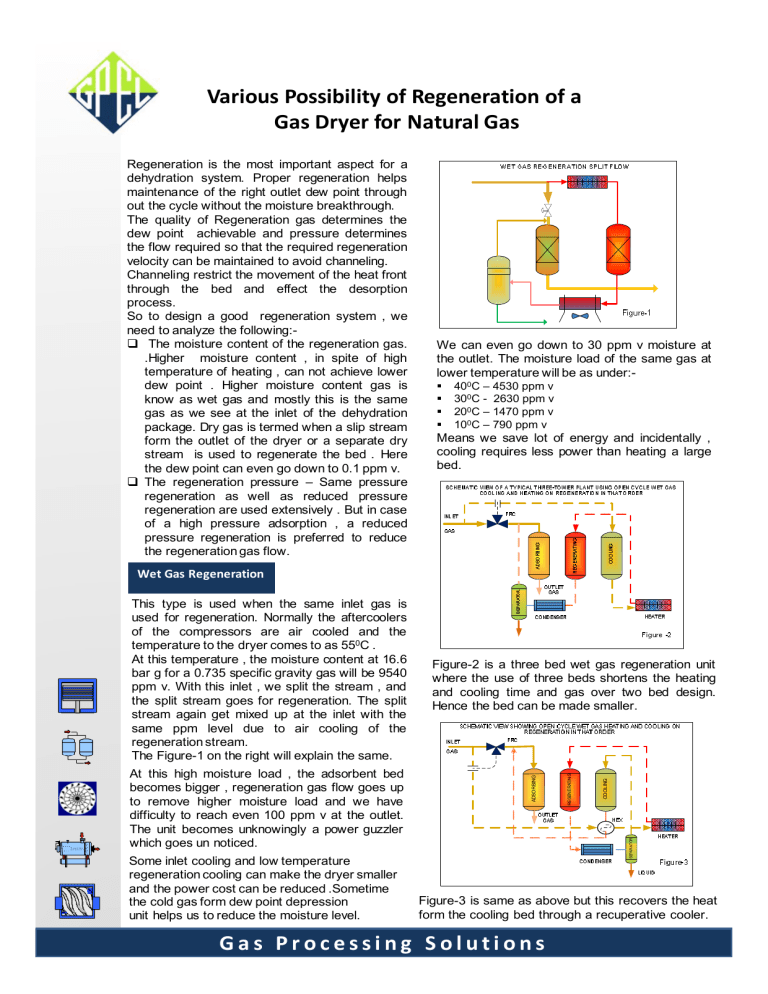

Various Possibility of Regeneration of a Gas Dryer for Natural Gas Regeneration is the most important aspect for a dehydration system. Proper regeneration helps maintenance of the right outlet dew point through out the cycle without the moisture breakthrough. The quality of Regeneration gas determines the dew point achievable and pressure determines the flow required so that the required regeneration velocity can be maintained to avoid channeling. Channeling restrict the movement of the heat front through the bed and effect the desorption process. So to design a good regeneration system , we need to analyze the following: The moisture content of the regeneration gas. .Higher moisture content , in spite of high temperature of heating , can not achieve lower dew point . Higher moisture content gas is know as wet gas and mostly this is the same gas as we see at the inlet of the dehydration package. Dry gas is termed when a slip stream form the outlet of the dryer or a separate dry stream is used to regenerate the bed . Here the dew point can even go down to 0.1 ppm v. The regeneration pressure – Same pressure regeneration as well as reduced pressure regeneration are used extensively . But in case of a high pressure adsorption , a reduced pressure regeneration is preferred to reduce the regeneration gas flow. We can even go down to 30 ppm v moisture at the outlet. The moisture load of the same gas at lower temperature will be as under: 400C – 4530 ppm v 300C - 2630 ppm v 200C – 1470 ppm v 100C – 790 ppm v Means we save lot of energy and incidentally , cooling requires less power than heating a large bed. Wet Gas Regeneration SEPARATOR COOLING REGENERATING At this high moisture load , the adsorbent bed becomes bigger , regeneration gas flow goes up to remove higher moisture load and we have difficulty to reach even 100 ppm v at the outlet. The unit becomes unknowingly a power guzzler which goes un noticed. Some inlet cooling and low temperature regeneration cooling can make the dryer smaller and the power cost can be reduced .Sometime the cold gas form dew point depression unit helps us to reduce the moisture level. Figure-2 is a three bed wet gas regeneration unit where the use of three beds shortens the heating and cooling time and gas over two bed design. Hence the bed can be made smaller. ADSORBING This type is used when the same inlet gas is used for regeneration. Normally the aftercoolers of the compressors are air cooled and the temperature to the dryer comes to as 550C . At this temperature , the moisture content at 16.6 bar g for a 0.735 specific gravity gas will be 9540 ppm v. With this inlet , we split the stream , and the split stream goes for regeneration. The split stream again get mixed up at the inlet with the same ppm level due to air cooling of the regeneration stream. The Figure-1 on the right will explain the same. Figure-3 is same as above but this recovers the heat form the cooling bed through a recuperative cooler. Gas Processing Solutions Wet Gas Heating & Dry Gas Cooling Figure-4 uses wet gas heating and dry gas cooling. This is a better method to obtain deeper dew point than the schematics shown earlier but needs three adsorber. Cooling heat recovery can be part of this wit a recuperative exchanger.. Figure-7 shows the pipe line gas is boosted and the dry gas used for regeneration is pumped back to mail pipe line Dry Gas Heating & Cooling This is a must for lower dew point but even for higher dew point , this approach will also reduce the power cost Figure-6 above is used when residual gas is not available. A slip stream assisted by a booster recycles the dry gas for heating and cooling. REGEN ERATING S EP ARAT OR The Figure-5 uses dry residual gas for regeneration at lower pressure than the adsorption pressure . The common application is feed gas drying in LPG extraction plants. COOLING ADSORBING Sometimes we use the last stage of the feed gas compressor to help the recycle and dry gas does the regeneration. Figure-8 depicts the same. Sometimes we use the last stage of the feed gas compressor to help the recycle and dry gas does the regeneration. Figure-8 depicts the same. Figure-9 depicts a combined unit for moisture removal and dew point depression. By shifting the gas to gas exchanger in the front of the dryer , we can reduce the moisture load means smaller dryer. Gas Processing Solutions