Data Sheet

Ovation™ OPC

Connectivity

Features

Supports the transfer of multiple data items

per request

Communicates with third-party office and

process control applications

Executes reads and writes of process data

Provides data quality code with values and

time stamping

Utilizes Microsoft®’s OLE / COM structure

(OPC classic) or vendor-independent

structures (OPC unified architecture)

Introduction

Emerson’s Ovation™ OPC connectivity bridges the

gap between third-party Microsoft® Windows® based

applications and process control systems.

Dynamic process information is easily and

automatically accessed using the latest standard in

process data exchange, Open Platform

Communications (OPC), which integrates third-party

applications with the Ovation system.

The OPC standard enables users to easily integrate

plant data with plant analysis applications,

independent of the type and source of data. OPC

connectivity does not require a custom interface or

driver in order for an external application to access a

plant’s process control device.

OPC is a real-time data interchange protocol that is

based on an open standard and a consistent method

of obtaining data from plant devices.

OPC software is developed once and then reused by

business, SCADA, workstation or custom software

packages. New customized OPC client applications

can be easily created because many development

languages such as Visual Basic for Applications (VBA),

C++ and Basic already have OPC interface routines.

OPC was designed by an open foundation to meet

the general needs of industry. Predefined standards

allow any OPC client software to communicate with

any OPC server, regardless of the device type.

The OPC specification provides for future

developments in technology and functionality, allowing

OPC components to meet the emerging needs of

industry.

Page - 1

PWS_002797 [6]

Ovation™ OPC Connectivity

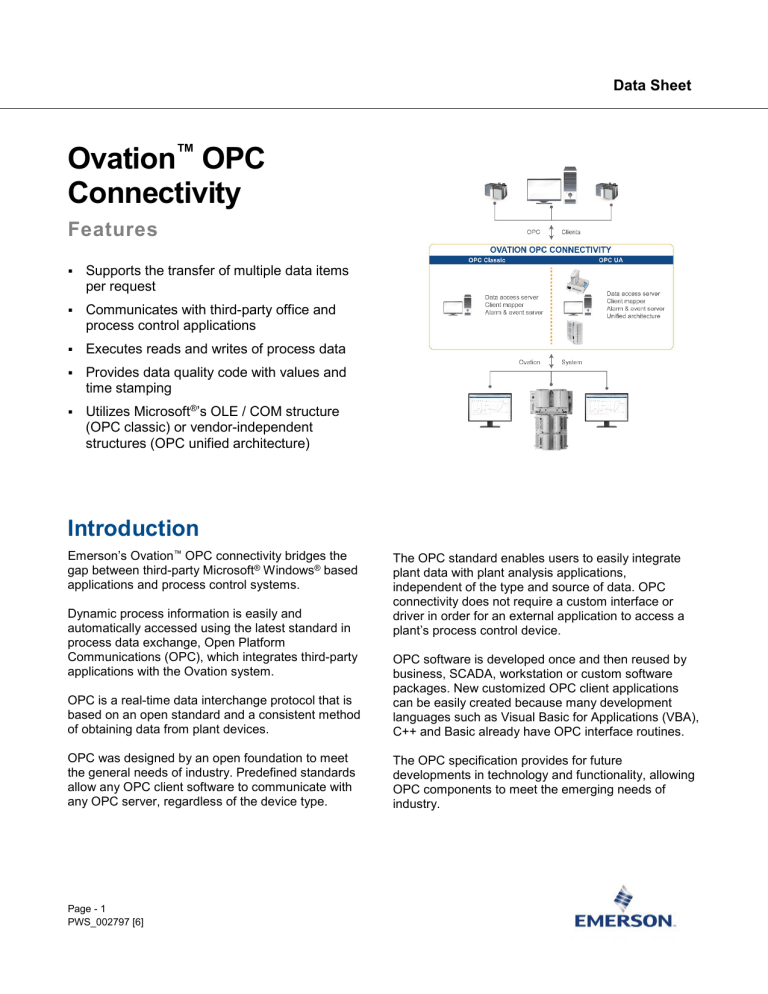

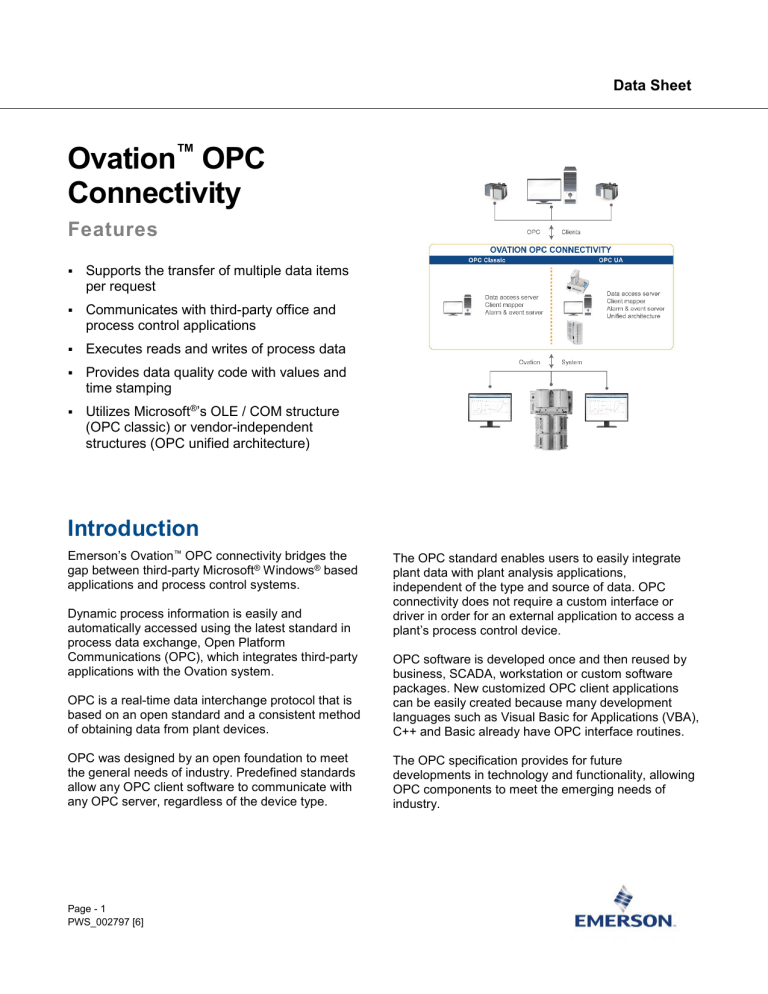

Ovation OPC Connectivity

Architecture

OPC exchanges information between an OPC server

application and OPC-compliant software applications

called “clients”. An OPC server collects data from a

field device via the plant network and delivers it to the

OPC client software. Ovation OPC connectivity can

be comprised of a combination of the following

software applications:

Data access server (DA)

Alarm and event server (AE)

Client mapper (CM)

Unified architecture (UA)

Ovation OPC client/server software can be loaded

onto an existing Ovation drop that has been

configured to function as an OPC communicator. The

software can also be loaded onto a standalone

workstation depending upon the communication

requirements.

Ovation’s OPC software organizes process points in

a tree-like structure, allowing easy access to all point

information from both the client application and the

end user.

Data Sheet

Multiple clients can connect to a single OPC data

access server application. Each client interfaces with

a separate instance of an OPC server object within

the OPC data access server. This means each client

has its own set of OPC groups and items.

A dedicated graphic provides indication of

communication status and other important

characteristics of the Ovation OPC data access

server such as security, item updates and read/write

statistics.

Ovation OPC Unified

Architecture Server

An Ovation OPC unified architecture server is a

software program that runs on a Windows-based

workstation or select Ovation hardware and supports

OPC unified architecture standard version 1.03.

The OPC unified architecture includes all OPC data

access server functionality with added features such

as security through encryption, user control and

authorization. The unified architecture software is

platform agnostic which allows for the drivers to be

embedded within the Ethernet link controller module

and the Ovation compact controller (Model OCC100).

The Ovation OPC data access server application

reads control system data by creating groups of

specific process points.

Ovation OPC Alarm and

Event Server

The OPC client mapper software determines how

often the data access server checks the Ovation

system for new point information and sends a

message when a group point value has changed.

Alarms and events are indications that something

within the process requires immediate operator

attention. The Ovation OPC alarm and event server

is a software application which exports Ovation alarm

and event information to a compatible OPC alarm

and event client.

Ovation OPC Data Access

Server

Ovation’s OPC data access server is a software

program that runs on a Windows-based workstation

and supports the OPC data access standards

versions 3, 2 and 1.

The OPC data access server receives data access

requests from third-party OPC clients, providing a

continuous stream of live process data.

Page - 2

PWS_002797 [6]

Ovation’s OPC alarm and event server software also

has the optional ability to generate sequence-ofevents (SOE) and operator event messages. Status

of the Ovation OPC alarm and event server can be

viewed in the OPC monitoring tool which provides

server and client connection information.

The Ovation OPC alarm and event server supports

the OPC alarm and event 1.10 standard.

Ovation™ OPC Connectivity

Data Sheet

Ethernet link controller module or Ovation

compact controller

OPC Client Mapper

The Ovation OPC client mapper interfaces an

Ovation system to any OPC server which enables

reading and writing of information between the

systems. OPC’s client mapper supports OPC data

access versions 1.0 and 2.0 standard specifications

and can communicate to multiple third-party OPC

servers.

Requires license manager server software

(included)

The minimum Ovation software version for the

OPC alarm event server is 2.4 and later

Ovation OPC connectivity redundancy is achieved by

installing two workstations equipped with Ovation

OPC client mapper software. In the redundant

configuration, one OPC client mapper workstation

performs control while the other acts as a backup. If

the workstation in control fails, shuts down or has

some problem where it no longer functions as an

Ovation client mapper workstation, the backup

workstation will detect the issue and take control.

Additionally, if the OPC client mapper software

forcibly fails one of the workstations, the backup will

take control.

Technical Requirements

Licenses

OPC Data Access, Alarm & Event or

Unified Architecture

Ovation OPC applications use a license manager to

limit the number of concurrent connections for process

data transfer. The following OPC applications require

licenses to operate:

Ovation systems - A dedicated or existing

Windows workstation on an Ovation network

connection via driver or appropriate network

interface card

The operating system of the OPC server

workstation must be Windows 7, 2008 server and

newer

The OPC unified architecture software can

operate on a Windows workstation, Ovation

OPC Client Workstation

The operating system of the OPC client

workstation must be Windows 2008 server or

Windows 7 and newer

Connected to the Ovation network via driver and

appropriate network interface card

Security

Process security between the control system and an

enterprise-wide LAN/WAN connection is controlled by

a Cisco firewall for network/highway level security

and Microsoft Windows for workstation level security.

Ovation OPC data access server (based on the

number of client connections)

Ovation OPC unified architecture (based on the

number of installations)

Ovation OPC alarm and event server with license

options for sequence of events and operator

events

©2017-2018 Emerson. All rights reserved. The Emerson logo is a trademark and service mark of Emerson Electric Co. Ovation™ is a mark of one of the Emerson Automation Solutions

family of business units. All other marks are the property of their respective owners. The contents of this publication are presented for information purposes only, and while effort has been

made to ensure their accuracy, they are not to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or

applicability. All sales are governed by our terms and conditions, which are available on request. We reserve the right to modify or improve the designs or specifications of our products at

any time without notice.

Page - 3

PWS_002797 [6]