Hydraulic-LABManual

advertisement

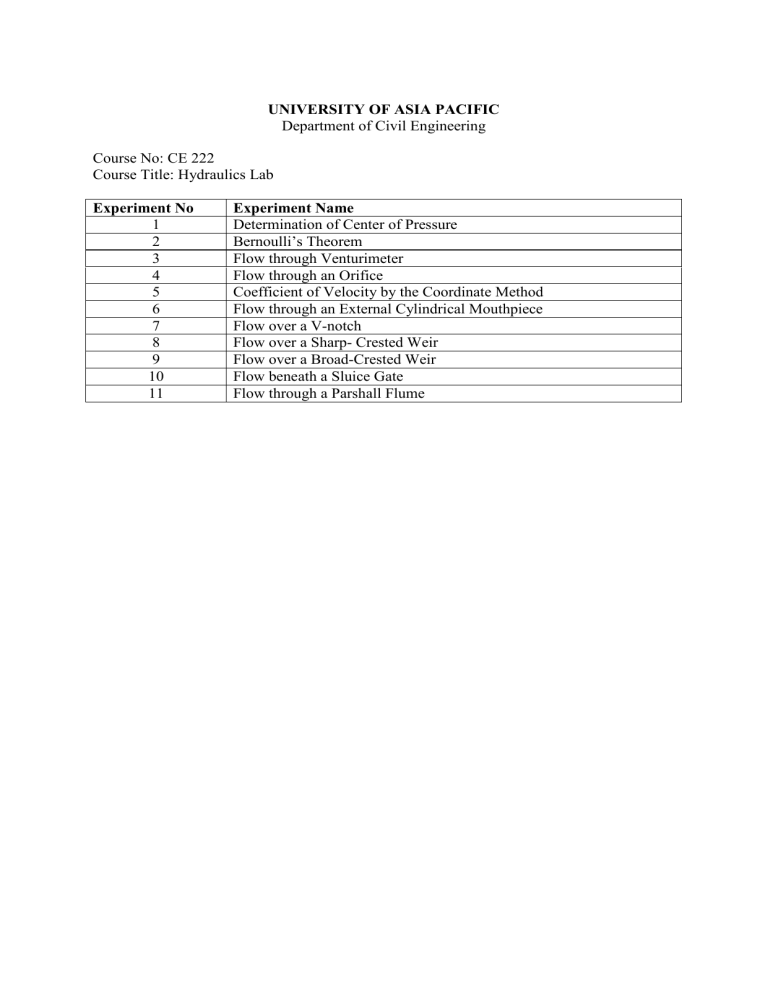

UNIVERSITY OF ASIA PACIFIC Department of Civil Engineering Course No: CE 222 Course Title: Hydraulics Lab Experiment No 1 2 3 4 5 6 7 8 9 10 11 Experiment Name Determination of Center of Pressure Bernoulli’s Theorem Flow through Venturimeter Flow through an Orifice Coefficient of Velocity by the Coordinate Method Flow through an External Cylindrical Mouthpiece Flow over a V-notch Flow over a Sharp- Crested Weir Flow over a Broad-Crested Weir Flow beneath a Sluice Gate Flow through a Parshall Flume UNIVERSITY OF ASIA PACIFIC Department of Civil Engineering CE 222: Hydraulics Sessional Experiment No. 1 CENTER OF PRESSURE Introduction The center of pressure is a point on the immersed surface at which the resultant of liquid pressure force acts. In the case of horizontal area the pressure is uniform and the resultant pressure force passes through the centroid of the area, but for an inclined surface this point lies towards the deeper end for the surface, as the intensity of pressure increases with depth. The objective of this experiment is to locate the centre of pressure of an immersed rectangular surface and to compare this position with that predicted by theory. Description of the Apparatus The apparatus is comprised basically of a rectangular transparent water tank, which supports a torroidal quadrant of rectangular section complete with an adjustable counter-balance and a water level measuring device. The clear perspex (acrylic resin) rectangular water tank has a drain tap at one end and a knurled leveling screw at each corner of the base. Centrally disposed at the top edge of the two long sides, are mounted on the brass knife-edge supports. Immersed within the tank and pivoted at its geometric centre of curvature on the knife-edge supports, is an accurate torroidal quadrant (ring segment). This is clamped and dowelled to an aluminium counter-balance arm which has a cast-iron main weight with a knurled head brass weight for fine adjustment at one end and a laboratory type weight pan at the other end. Two spirit levels are mounted on the upper surface of the arm. The water level is accurately indicated by a point gauge, which is at one end of the tank. Theory The magnitude of the total hydrostatic force F will be given by_ F = ρgyA Where, ρ = density of fluid g = acceleration due to gravity y = depth to centroid of immersed surface A = area of immersed surface This force will act through the centre of pressure (C.P) at a distance yp (measured vertically) from point O, where O is the intersection of the plane of the water surface and the plane of the rectangular surface. Theoretical Determination of yp: Theory shows that ICG yp = y + Ay Where, y ICG = distance from O to the centroid (CG) of the immersed surface = 2nd moment of area of the immersed surface about the horizontal axis through CG. Experimental Determination of yp: For equilibrium of the experimental apparatus, mements about the pivot P give where F.y = = W.z Mgz y M Z = = = distance from pivot to centre of pressure mass added to hanger distance from pivot to hanger Therefore MgZ y= F But and y y = = yp + r – y1 yp + r + y1 [ Fully Submerged ] [ Partially Submerged ] yp yp = = y – (r – y1) y – (r + y1) [ Fully Submerged ] [ Partially Submerged ] r y1 = = distance from pivot to top of rectangular surface depth of water surface from top of rectangular surface Therefore and where, Counter Balance Z p r y R y1 TORROID Water Level y W=Mg y p 2 L LL ρgy2 CENTRE OF PRESSURE Fig. 01 Partially submerged condition Counter Balance Z P r y R WATER LEVEL ρg(y2-L) y1 O W=Mg yp y2 L TORROID ρgy2 CENTRE OF PRESSURE Fig. 02 Fully submerged condition PROCEDURE The apparatus was placed in a splash tray and correctly levelled. The length ‘L’ and width ‘b’ of the rectangular surface, the distance r from the pivot to the top of the surface and the distance from the hanger to the pivot were recorded. The rectangular surface was positioned with the face vertical (θ = 0) and clamped. The position of the movable jockey weight was adjusted to give equilibrium, i.e. when the balance pin was removed there was no movement of the apparatus. The balance pin was replaced. Water was added to the storage chamber. This created an out of balance clockwise moment in the apparatus. A mass M was added to the hanger such that the system was brought almost to equilibrium, the clockwise moment still marginally greater. Water was slowly removed from the storage chamber via the drain hole until equilibrium was attained. At this condition the drain hole was closed and the balance pin again removed to check equilibrium. The balance pin was replaced and the values of y1, y2 and M were recorded. The above procedure was repeated for various combinations of depth. OBJECTIVE To plot the Mass on the pan (M) against y2 in plain graph paper. ASSIGNMENT i. ii. Discuss What are the practical applications of the centre of pressure? DISCUSSION Comments on the results, sources of error, nature of the curves etc. Experiment No. 1 CENTRE OF PRESSURE Experiment data Sheet Inner radius of curvature, r Outer radius of curvature, R Width of plane surface, b Height of plane surface, L Distance from pivot to hanger, Z No. of Obs 01 y1 y2 y A (cm) (cm) (cm) 2 (cm ) = = = = = 10 cm 20 cm 7.5 cm 10 cm 27.5 cm F ICG yp theo. M (gm) y (cm) yp exp. (cm) Submerged Condition Partially/Fully Partially 02 Partially 03 Partially 04 Fully 05 Fully 06 Fully Group No. : ____________ Date : ____________ Name : ____________ Roll No. : ____________ ___________________ Signature of the Teacher Comment UNIVERSITY OF ASIA PACIFIC Department of Civil Engineering CE 222: Hydraulics Sessional Experiment No. 2 BERNOULLI’S THEOREM INTRODUCTION Energy is the ability to do work. It manifests in various forms and can change from one form to another. The various forms of energy present in fluid flow are elevation, kinetic, pressure and internal energies. Daniel Bernoulli in the year 1938 stated that in a steady flow system of frictionless (or non-viscous) incompressible fluid, the sum of pressure, elevation and velocity heads remains constant at every section, provided no energy is added to or taken out by an external source. This statement of Daniel Bernoulli, known as the Bernoulli’s Energy Equation, can be applied in practice for the construction of flow measuring devices such as Venturimeter, Flow nozzle, Orificemeter and Pitot tube. Furthetmore, it can be applied to the problems of flow under a sluice gate, free liquid jet, radial flow and free vortex motion. DESCRIPTION OF THE APPARATUS The unit is constructed as a single Perspex fabrication. It consists of two cylindrical reservoirs interconnected by a Perspex Venturi of rectangular cross-section. The Venturi is provided with a number of Perspex piezometer tubes to indicate the static pressure at each cross-section. An engraved plastic backboard is fitted which is calibrated in British and Metric units. This board can be reversed and mounted on either side of the unit so that various laboratory configurations can be accommodated. The inlet vessel is provided with a dye injection system. Water is fed to the upstream tank through a radial diffuser from the laboratory main supply. For satisfactory results the mains water pressure must be nearly constant. After flowing through the Venturi, water is discharged through a flow regulating device. The rate of floe through the unit may be determined either volumetrically or gravimetrically. The equipment for this purpose is excluded from the manufacturer’s supply. The apparatus has been made so that the direction of flow through the Venturi can be reversed for demonstration purposes. To do this the positions of the dye injector and discharge fitting have to be interchanged. PROCEDURE The apparatus should be accurately leveled by means of screws provided at the base. Connect the water supply to the radial diffuser in the upstream tank. Adjust the level of the discharge pipe by means of the stand and clamp provided to a convenient position. Allow water to flow through the apparatus until all air has been expelled and steady flow conditions are achieved. This can be accomplished by varying the rate of inflow into the apparatus and adjusting the level of the discharge tube. Readings may then be taken from the piezometer tubes and the flow through the apparatus measured. A series of readings can be taken for various through flows. WORKING FORMULA Assuming frictionless flow, Bernoulli’s Theorem states that, for a horizontal conduit P1 γ + V12 P 2 V22 = + γ 2g 2g where, P1,P2 γ V1, V2 g = = = = (1) pressure of flowing fluid at sections 1 and 2 unit weight of fluid mean velocity of flow at sections 1 and 2 acceleration due to gravity. The equipment can be used to demonstrate the validity of this theory after an appropriate allowance has been made for friction losses. OBJECTIVE i. To plot the static head, velocity head and total head against the length of the passage in one plain graph paper. ii. To plot the total head loss, hL against the inlet kinematics head, V2/2g, for different inflow conditions in plain graph paper. ASSIGNMENT i. What are the assumptions underlying the Bernoulli’s energy equation? ii. Do you need any modification (s) of Eqn(1) when (a) the frictional head loss is to be considered, and (b) the conduit is not horizontal? DISCUSSION Comment on the results, sources of error, etc. Experiment No. 2 BERNOULLI’S THEOREM Experimental Data Sheet Cross-sectional area of the measuring tank = 45 x 30 = 1350 cm2 Initial point gage reading = _________________ cm Final point gage reading = _________________ cm Collection time = _________________ seconds Piezometer tube no. A (cm2) 1 2 3 4 5 6 7 8 9 6.45 5.48 3.55 2.39 2.39 3.48 4.65 5.81 6.45 V=Q/A (cm/s) V2/(2g) (cm) P/γ (cm) H=P/γ+V2/(2g) (cm) Gr. No. V /2g (cm) 1 2 3 4 5 6 2 1 hL (cm) Group No. : ____________ Date : ____________ Name : ____________ Roll No. : ____________ Signature of the Teacher UNIVERSITY OF ASIA PACIFIC Department of Civil Engineering CE 222: Hydraulics Sessional Experiment No. 3 FLOW TROUGH VENTURIMETER THEORY Fig. 1: Flow through a Venturimeter Consider the Venturimeter shown in the above figure. Applying the Bernoulli’s equation between Point 1 at the inlet and Point 2 at the throat, we obtain P1 γ + V12 P2 V22 = + 2g γ 2g (1) where P1 and V1 are the pressure and velocity at Point 1, P2 and V2 are the corresponding quantities at Point 2, γ is the specific weight of the fluid and g is the acceleration due to gravity. From continuity equation, we have (2) A1V1 = A2V2 Where A1 and A2 are the cross-sectional areas of the inlet and throat, respectively. Since π π A1= D12 ; A2 = D22 4 4 from Equns. (1) and (2), we have V1 = ( P1 − P2 ) 2g D ( 1 )4 − 1 γ D2 = K1H 1 / 2 (3) where, K1= 2g and, H = ( P1 − P2 ) D1 4 γ ( ) −1 D2 The head H is indicated by the piezometer tubes connected to the inlet and throat. The theoretical discharge, Qt is given by Qt =A1V1 =KH 1 / 2 (4) where, K = K1A1 (5) Now, if Cd is the coefficient of discharge (also known as the meter coefficient) and Qa is the actual discharge, then Cd = Qa Qt (6) OBJECTIVE i. ii. iii. iv. v. To find Cd for the Venturimeter To plot Qa against H in plain graph paper To plot Qa against H in log-log paper and to find (a) the exponent of H, and (b) Cd To calibrate the Venturimeter To plot Cd against corresponding Reynolds number (Re) at throat. ASSIGNMENT i. Why is the diverging angle smaller than the converging angle for a Venturimeter? ii. What are the uses of a Venturimeter? iii. On what factors does the meter co-efficient depend? iv. What is cavitation? Discuss its effect on flow through a Venturimeter. How can you avoid cavitation in a Venturimeter? DISCUSSION Comment on the results, sources of error, etc. Experiment No. 3 FLOW THROUGH A VENTURIMETER Experimental Data and Calculation Sheet: Cross-sectional area of the measuring tank, A= 45 x 45 = 2025 cm2 Pipe diameter, D1 = 3.175 cm Area of the pipe, A1= Area of the throat, A2= Throat diameter, D2 = 1.58 cm 0 Temperature of water t = 20 c Kinematic viscosity of water = Initial point gage reading = ____________cm Final point gage reading = No. of Obs. Volume of water V(cm3) Collection time T (seconds) Actual Discharge Qa (cm3/s) Piezometer reading Left h1 Right h2 K1 Diff H K Theoretical discharge Qt (cm3/s) 1 2 3 4 5 6 Group No. : ____________ Date : ____________ Name : ____________ Roll No. : ____________ ___________________ Signature of the Teacher __________cm2 __________ cm2 1 x 10-6 m2/s __________cm Cd= Qa Qt V 2= Qa A2 Reynolds number Re UNIVERSITY OF ASIA PACIFIC Department of Civil Engineering CE 222, Hydraulics Sessional Experiment No. 4 FLOW TROUGH AN ORIFICE THEORY: Fig. 1 Flow Through an Orifice An orifice is an opening with a closed perimeter in the wall of a tank or in a plate normal to the axis of the pipe through fluid can flow. Consider a small orifice having a cross-sectional area A and discharging water under a constant head H as shown in the above figure. Then the theoretical discharge, Qt is given by Qt = A 2 gH (1) Where, g is the acceleration due to gravity. Let Qa be the actual discharge. Then the coefficient of discharge, Cd, is given by Q Cd = a (2) Qt Coefficient of velocity, Cv is defined as the actual velocity at vena contracta to the theoretical velocity. Thus, Cv = Va = Vt Va 2 gH (3) Coefficient of contraction, Cc is defined as the area of jet at vena contracta to the area of orifice. Thus, A Cc = a (4) A It follows from (1), (2), (3) and (4) that Cd = CcxCv (5) Note: Reference Value of Cd (0.59 – 0.68) OBJECTIVE i. ii. iii. iv. To find the value of Cd for the orifice. To plot a graph for Qa vs. Qt in plain graph paper. To plot a graph for Qa vs. H in plain graph paper. To plot Qa vs. H in log-log paper and to find the value of (a) the exponent of H and (b) Cd. ASSIGNMENT i. ii. iii. iv. v. What is an orifice? Why is it used? What are the coefficient of velocity, coefficient of contraction and coefficient of discharge for an orifice? On what factors do these coefficients depend? What are the average values of these coefficients for a sharp-crested orifice? What is the effect of rounding the edge of an orifice? What is a submerged orifice? What are the average values of the coefficient of velocity, coefficient of contraction and coefficient of discharge for a submerged orifice? Why is the actual discharge through an orifice less than the theoretical discharge? DISCUSSION Comment on the results obtained, sources of error, etc. Experiment No. 4 FLOW THROUGH AN ORIFICE Observation and Calculation Sheet Cross-Sectional area of the measuring tank = 2025 cm2 Diameter of the orifice, D = 1.3 cm Area of the orifice = 1.33 cm2 Head correction, h′ = 23 cm No. of Obs Observed head h (cm) Initial Final Mean Point gage reading (cm) Initial Collection time T (seconds) Vol. Of water V (cm3) Actual head H=h- h′ =cm Final Diff. Group No. : ____________ Date : ____________ Name : ____________ Roll No. : ____________ ___________________ Signature of the Teacher Actual discharge Qa (cm3/s) Theo. Discharge Qt (cm3/s) Coeff. of discharge Cd Mean Cd UNIVERSITY OF ASIA PACIFIC Department of Civil Engineering CE 222, Hydraulics Sessional Experiment No. 5 COEFFICIENT OF VELOCITY BY THE COORDINAE METHOD THEORY Fig. 1 Coefficient of Velocity by the Coordinate Method Let H be the total head causing flow and section-c-c conditions the vena contracta as shown in the figure. The jet of water has a horizontal velocity but is acted upon by gravity with a downward acceleration of g. Let us consider a particle of water in the jet at P and let the time taken for this particle to move from 0 to P be t. Let x and y be the horizontal and vertical co-ordinates of P from 0, respectively. Then, x = Va t and 1 y = 2 gt2 (1) (2) Equating the values of t2 from these two equations, one obtains x2 2y = g Va2 Va = gx 2 2y (3) But, the theoretical velocity, Vt = 2 gH Hence, the coefficient of velocity, Cv is given by Va x2 = 4 yH Vt And the head loss is given by HL =(1-Cv2)H Cv = (4) (5) Reference Value: 0.95 – 0.99 OBJECTIVE i. ii. iii. iv. To find Cv for the orifice. To find the head loss, HL. To plot Va vs. Vt in plain graph paper and find Cv. To plot Va vs. H in log-log paper and to find (a) Cv and (b) the exponent of H. ASSIGNMENT i. ii. iii. iv. Define vena contracta. Why does it form? Explain the inversion of jet with the help of sketches. How can you determine the coefficient of contraction Cc for an orifice? Will the value of Cv be different for sharp-edged and rounded orifices? Why? DISCUSSION Comment on the results obtained, sources of error, etc. Experiment No. 5 COEFFICIENT OF VELOCITY BY THE COORDINATE METHOD Observation and Calculation Sheet Diameter of the orifice, D = 1.3 cm Head correction, No. of Obs Observe d head h (cm) h′ = 23 cm Actual head H (cm) Actual Theoretical Hor. Vertical velocity y Coordinate Coordinate velocity y Vt (cm/s) X (cm) Y (cm) Va (cm/s) Coeff. Of velocity y Head Loss HL Cv Group No. : ____________ Date Mean Cv = : ____________ Name : ____________ Roll No. : ____________ ___________________ Signature of the Teacher UNIVERSITY OF ASIA PACIFIC Department of Civil Engineering CEE 222, Hydraulics Sessional Experiment No. 6 FLOW THROUGH AN EXTERNAL CYLINDRICAL MOUTHPIECE THEORY If a small tube is attached to an orifice, it is called mouthpiece. The standard length of a mouthpiece is 3d, where d is the diameter of the orifice. If the length is less than 3d, jet after passing the vena contracta does not occupy the tube fully and thus acts as orifice. If the length is greater than 3d, it acts as pipe. The effect of adding a mouthpiece to an orifice is to increase the discharge. The pressure at vena contracta is less than atmospheric, so a mouthpiece decreases the pressure vena contracta and increases the effective head causing the flow, hence, discharged is increased. Fig. Flow Through an External Cylindrical Mouthpiece Consider an external cylindrical mouthpiece of area A discharging water under a constant head H as shown in the figure. Applying Bernoullis equation at point 1 and 3. V2 H= 2g or, V = 2 gH Then the theoretical discharge, Qt, is given by Qt = A 2 gH Where A is the area of the mouthpiece. Let Qa be the actual discharge. Then the coefficient of discharge, Cd, is given by Q Cd = a Qt (1) (2) (3) (4) APPARATUS i. ii. iii. iv. v. Constant head water tank Mouth piece Discharge measuring tank Stop watch Point gauge PROCEDURE Measure the diameter of the mouthpiece. Attach the mouthpiece to the orifice of the constant head water tank. Supply water to the tank. When the head at the tank (measured by a manometer attached to the tank) is steady, record the reading of the manometer. Measure the flow rate. Repeat the procedure for a different combinations of discharge. OBJECTIVE i. ii. To find Cd for the mouthpiece. To plot Qa vs. H in log-log paper, and to find (a) Cd and (b) the exponent of H. ASIGNMENT i. ii. iii. iv. v. Explain why the discharge through an orifice is increased by fitting a standard short tube to it. What will happen to the coefficient of discharge if the tube is shorter than the length or the head causing the flow is relatively high? What is the effect of rounding the entrance of the mouthpiece? Why the coefficient of contraction for an internal mouthpiece is less than that of an orifice? What is a submerged tube? Does the coefficient of the tube change due to submergence? DISCUSSION Comment on the results obtained, sources of error, etc. Experiment 6 FLOW THROUGH AN EXTERNAL CYLINDRICAL MOUTHPIECE Calculation Sheet Diameter of the mouthpiece, D = __________________ Area of the mouthpiece, A = ________________ Cross-sectional area of the measuring tank = _________________ Head correction, h′ = _________________ Initial point gauge reading = __________________ Final point gauge reading = __________________ Difference in gauge reading = ________________ Observed head, h = ________________ No. of Obs. Actual head H=h-h′ Level/Term Student No. Group No. Volume of water V : _____________ : _____________ : _____________ Collection Actual Time discharge T Qa Theoretical Co-eff. of Discharge discharge Qt Cd Mean Cd Dept. : _____________ Section : _____________ Date : ______________ Signature of the Teacher UNIVERSITY OF ASIA PACIFIC Department of Civil Engineering CE 222. Hydraulics Sessional Experiment No. 7 FLOW OVER A V-NOTCH THEORY The measure of flow rate in flumes or channels is of obvious importance to the practicing engineer in the fields of irrigation, water conservation and flood alleviation. Hydraulic structures used for flow measurement can be listed as follows: 1. Sharp-crested thin plate weirs; 2. Solid long base weirs; 3. Throated flumes; Sharp crested weirs are overflow structures whose length of crest in the direction of flow is equal to or less than 2 mm. The use of sharp crested weirs is generally limited to laboratories, small channels, and streams which do not carry debris and sediment. The most common types of sharp-crested weir are the rectangular weir and the V-notch weir. The upstream face must be installed vertically and the edge of the weir plate must be accurately shaped. The V-notch weir is preferred when small discharges are involved, because the triangular cross-section of the flow ‘nappe’ leads to a relatively greater variation in head. The wetted perimeter is dependent on head and co-efficient of discharge remains fairly constant. Fig. Flow Over a V- Notch Consider the V-notch shown in the figure. Let H be the height of water surface and θ be the angle of notch. Then, width of the notch at the water surface θ L = 2H tan (1) 2 Consider a horizontal strip of the notch of thickness dh under a head h. Then, Width of the strip, W = 2(H-h)tan θ 2 Hence, the theoretical discharge through the strip dQt = area of the strip x velocity = 2(H-h) tan θ 2 dh 2 gh (2) (3) Integrating between the limits 0 and H and simplifying, the total theoretical discharge over the notch is given by θ 8 2 g tan H sup 5 / 2 15 2 (4) = KH5/2 Qt = (5) where, θ 8 2 g tan 15 2 Let Qa be the actual discharge. Then the coefficient of discharge, Cd, is given by K= Cd = Q actual − disch arg e = a theoretical − disch arg e Qt Qa = K CdH5/2 (6) (7) (8) The co-efficient of discharge depends on relative head (H/P), relative height (P/B) and angle of the notch ( θ ). From hydraulic point of view a weir may be fully contracted at low heads while at increasing head it becomes partially contracted. The flow regime in a weir is said to be partially contracted when the contractions along the sides of the V-notch are not fully developed due to proximity of the walls and / or bed of approach channel. Where as a weir which has an approach channel and whose bed and sides of the notch are sufficient remote from the edges of the V-notch to allow for a sufficiently great approach velocity component parallel to the weir face so that the contraction is fully contracted weir. In case of a fully contracted weir Cd is fairly constant for a particular angle of notch. APPRATUS 1. 2. 3. 4. 5. A constant steady water supply with a means of varying the flow rate. An approach channel A V-notch weir plate A flow rate measuring facility A point gauge for measuring H. PROCEDURE Position the weir plate at the end of the approach channel, in a vertical plane, with the sharp edge on the upstream side. Admit water to channel until the water discharges over the weir plate. Close the flow control valve and allow water to stop flowing over weir. Set the point gauge to datum reading. Position the gauge abut half way between the notch plate and stilling baffle. Admit water to the channel and adjust flow control valve to obtain heads, H, increasing in steps of 1 cm. For each flow rate, stabilize conditions, measure and record H. Take readings of volume and time using the volumetric tank to determine the flow rate. OBJECTIVE i. ii. iii. To find for the V-notch To plot Qt vs. Qa in a plain graph paper. To plot Qa vs. H in a log-log paper and to find (a) the exponent of H and (b) Cd. ASSIGNMENT i. ii. iii. iv. v. Why does the V-notch give more accurate flow measurement than any other weirs and orifices when the flow is slightly fluctuating? On which factor does the value of Cd depend? What is the average value of Cd for a 90o V-notch? Does it depend on floe condition (partially or fully contracted)? Why should the tail water level remain below the vertex of the notch? What minimum ventilation below the flow over the notch at downstream side should be maintained? Why the water head measurement is made at some distance upstream from the notch? What is this minimum distance in case of a V-notch? DISCUSSION Comment on the results obtained, sources of error, etc. Experiment No. 7 FLOW OVER A V-NOTCH Observation and Calculation Sheet Angle of the notch, θ = __________________ K = ________________ Cross-sectional area of the measuring tank = ______________ Initial point gauge reading = _____________ Final point gauge reading = _____________ Difference in reading = ________________ Datum water level reading = _____________ Water level above vertex = ______________ Final water level reading =_______________ No. of Obs. Level/Term Student No. Group No. Vol. Of water V Collection time T : ___________ : ___________ : ____________ Actual discharge Qa Effective head H Theoretical discharge Qt Co-eff. of discharge Cd Dept. : ____________ Section: ____________ Date : ____________ Signature of the Teacher Mean Cd UNIVERSITY OF ASIA PACIFIC Department of Civil Engineering CE 222 Hydraulics Sessional Experiment No. 8 FLOW OVER A SHARP-CRESTED WEIR THEORY The relationship between discharge and head over the weir can be developed by making the flowing assumptions as to the flow behaviour: 1. Upstream of the weir, the flow is uniform and the pressure varies with depth according to the hydrostatic equation P = pgh. 2. The free surface remains horizontal as far as the plane of the weir, and all particles passing over the weir move horizontally. (In fact, the free surface drops as it approaches the weir). 3. The pressure through out the sheet of liquid or nappe, which passes over the crest of the weir, is atmospheric. 4. The effects of viscosity and surface tension are negligible. 5. The upstream approach velocity head is neglected. Fig. Flow Over a Sharp-Crested Weir Now consider the Sharp-crested weir in the figure. Let H be the working head and B is the length of the weir. Let us consider a small horizontal string of thickness dh under a head h. The strip can be considered as an orifice. Therefore, the theoretical discharge through the strip dQt = area of the strip x velocity (1) = (Bdh) 2 gh (2) Integrating between the limits 0 and H, the total theoretical discharge over the weir is given by 2 Qt = (3) 2 g BH 3 / 2 3 Let Qa be the actual discharge. Then the co-efficient of discharge, Cd is given by Qa Qt Therefore, Cd = (4) 2 Qa = C d 2 g BH 3 / 2 3 = KCdH3/2 (5) (6) where, K= 2 2g B 3 (7) A suppressed rectangular weir is one which extends across the full width of the approach channel. It the length of the weir crest (B) is less than the width of the channel, the end contraction occurs. In that case, B is equation (5) should be replaced by effective length (B′) which is given by B′ = B-0.1 nH Where n is the number of end contraction. It is important to notice that the nappe should be ventilated or fully aerated otherwise the pressure below the nappe will not be atmospheric. APPARATUS: 1. 2. 3. 4. 5. A constant steady water supply with a means of varying the flow rate. An approach channel A rectangular weir plate A flow rate measuring facility A point gauge for measuring H. PROCEDURE: Measure the height and length of the weir. Position the weir plate at end side of the approach channel, in a vertical plane, with sharp edge on the upstream side. Allow water to the channel so that water flows over the weir. Measure the head H and rate of discharge at a steady condition. Vary the discharge and record a series of readings of Q and H. OBJECTIVE i. Observation of the nappe for ventilated and non-ventilated conditions. ii. To find Qd for the weir iii. To plot Qa vs. H in a plain graph paper iv. To plot Qa vs. H in a log-log graph paper and to find (1) the exponent of H and (2) Cd . ASSIGNMENT i. Derive Equation (5). What are the assumptions made in deriving this equation? What is the extent of their validity? ii. Why the pressure distribution over the weir-crest is less than hydrostatic? iii. What is the effect of rounding the weir edge? iv. Why it is necessary to ventilate the space below the nappe? v. Discuss the effects of lateral contraction, in case of contracted weir, on the flow over the weir. DISCUSSION Comment on the results obtained, sources or error, etc. Experiment No. 8 FLOW OVER A SHARP-CRESTED WEIR Experimental Data Sheet Width of the weir, B Height of the weir, P Elevation of bed level Final water level Difference in water level, H No. of Obs. Vol. of Water V Level/Term Student No. Group No. = _____________________ = _____________________ = _____________________ = _____________________ = _____________________ Time T : ____________ : ____________ : ____________ Signature of the Teacher Actual discharge Qa Ventilated Condition Head H Dept. : ____________ Name : ____________ Date : ____________ Theoretical discharge Qt Co-eff. of discharge Cd Mean Cd UNIVERSITY OF ASIA PACIFIC Department of Civil Engineering CE 222, Hydraulics Sessional Experiment No. 9 FLOW BENEATH A SLUICE GATE SLUICE GATE Fig. Flow beneath a sluice gate THEORY The Bernoulli energy equation may be applied in those cases where there is a negligible loss of total head from one section to another, or where the magnitude of the head loss is already known. Flow under a sluice gate is an example of converging flow where the correct form of the equation for discharge may be obtained by equating at Sections 1 and 2 as shown in the figure 4.1. As the energy loss between the section is negligible, H1 = H2 (1) V2 V12 = y2 + 2 2g 2g (2) And therefore, y1 + Expressing the velocities in terms of Q, the above equation becomes Q2 Q2 y1 + = + y 2 2 gb 2 y12 2 gb 2 y 22 where b is the width of the sluice gate. (3) Simplifying and re-arranging the terms, one obtains Q = by1 2 gy 2 ( y1 / y 2 + 1) (4) Q = by 2 2 gy1 ( y 2 / y1 + 1) (5) Or alternatively, The small reduction in flow velocity due to viscous resistance between Sections 1 and 2 may be allowed for by a coefficient Cv. Then Q = C v by 2 2 gy1 ( y 2 / y1 + 1) (6) The coefficient of velocity, Cv varies in the range 0.95<Cv<1.0, depending on the geometry of the flow pattern (expressed by the ratio yg/y1) and friction. The downstream depth y2 may be expressed as a function of the gate opening, yg, i.e. Y2 = Ccyg (7) Where, Cc is the coefficient of contraction whose commonly accepted value of 0.61 is nearly independent of the ratio yg/y1. The maximum contraction of the jet occurs approximately at a distance equal to the gate opening. Thus equation (6) becomes Q = C c C v by g 2 gy1 (C c y g / y1 + 1) (8) The above equation can also be written as Q = C d by g 2gy1 (9) Where Cd is the coefficient of discharge and is a function of Cv, Cc, b, yg and y1. Therefore, Cd = Cc Cv C c y g / y1 + 1 (10) Equation (9) may also be written as Qa = CdQt (11) Qt = by g 2gy1 (12) So that Where Qt and Qa are the theoretical and actual discharges, respectively. The momentum equation may be applied to the fluid within any control volume where the external forces are known or can be estimated to a sufficient degree of accuracy. The horizontal components of these forces acting on the fluid within the control volume shown in fig. 4.1 are the resultants of the hydrostatic pressure distributions at Sections 1 and 2, the viscous shear force on the bed and the thrust of the gate. It should be noted that the equation permits the resultant gate thrust (Fg) to be determined even though the pressure distribution along its surface is not hydrostatic. Over a short length of smooth bed the contribution of the shear force may be neglected. The resultant force applied to the fluid within the control volume in the downstream direction is given by Fx = [(1 / 2) ρgy12 − (1 / 2) ρgy 22 − Fg ]b (13) The effect of this force is to accelerate the fluid within the control volume in the downstream direction. Hence, Fx = ρQaV2 − ρQaV1 (14) Substituting for Fx and gathering terms, one obtains Fg = ρQ 2 y 1 ρgy 22 [( y1 / y 2 ) 2 − 1] − 2 a [1 − 2 ] 2 b y2 y1 (15) Simplifying and eliminating Qa, We get Fg = ( y − y2 )3 1 ρg 1 2 y1 + y 2 (16) The pressure distribution on the gate cannot be hydrostatic, as the pressure must be atmospheric at both the upstream water level and at the point where the jet springs clear of the gate. Note that the thrust on the gate, FH, for a hydrostatic pressure distribution is given by 1 FH =Error! Bookmark not defined. ρg(y1-yg) 2 2 (17) OBJECTIVE 1. 2. 3. 4. 5. To determine the discharge beneath the sluice gate. To determine Cv, Cc and Cd. To plot Cc and Cd Vs yg/y1 in plain graph paper. To plot y1 Vs Qa for different yg in plain graph paper. To plot Fg/FH Vs yg/y1 in plain graph paper. TYPICAL QUALITATIVE SHAPES OF GRAPHS Graph 2: y1 Vs Qa for different yg (Plain graph paper) Graph 3: Fg/FH Vs yg/y1 (Plain graph paper) ASSIGNMENTS i. ii. iii. iv. Explain why the pressure distribution along the surface of the gate is not hydrostatic. What happens when the gate opening is greater than the critical depth? Verify equations (9) and (16). When does the submergence occur and what is its effect on flow beneath a sluice gate? DISCUSSION Comment on the results obtain, sources of error, etc. Experiment No. 9 FLOW BENEATH A SLUICE GATE Experimental Data Sheet No. of Obs. 1 yg y1 y2 Volm of water 2 3 4 5 6 7 8 Level/Term: _______________ Roll No. : _______________ Group No. : _______________ Signature of the Teacher Dept : ______________ Section: ______________ Date : ______________ Time Qt Qa Cv Cc Cd Yg/y1 Fg/FH UNIVERSITY OF ASIA PACIFIC Department of Civil Engineering CE 222, Hydraulics Sessional Experiment No. 10 FLOW OVER BROAD CRESTED WEIR LABORATORY SET-UP Fig. 1.1 Flow over a broad-crested weir Fig. 1.2 Flow diagram DESCRIPTION A board-crested weir is on overflow structure with a truly level & horizontal crest above which the deviation from a hydrostatic pressure distribution because of centripetal acceleration may be neglected. In other words, the streamlines are practically straight & parallel. To obtain this situation the length of the weir crest in the direction of flow (L) should be related to the total energy head over the weir crest as 0.07 ≤H 1/L≤0.50. H1/L≥0.07 because otherwise the energy losses above the weir crest cannot be neglected & the undulations may occur on the crest; H1/L≤0.50, so that only slight curvature of stream occurs above the crest & a hydrostatic pressure distribution may be assumed. The upstream corner of the weir is rounded in such a manner that flow separation does not occur. Te minimum radius of the upstream rounded nose r is 0.11 H1 max, although for the economic design of field structures a value of r = 0.2 H1max is recommended. The length of the horizontal weir crest should not be less than 1.45 H1. To obtain a favorable (high) discharge coefficient (Cd) the crest length (L) should be close to the permissible minimum (L≥1.75H 1). The weir structure should be rigid & water tight & be at right angles to the direction of flow. THEORY Fig. 1.3 Flow over a broad-crested weir. If the structure is so designed that there is no significant energy losses in the zone of acceleration upstream of the control section, according to Bernoulli’s equation. H 1 = h1 + α v12 v2 = H = y +α 2g 2g ⇒ H1 = y + v2 [Assuming α = 1 for all sections] 2g v = 2 g ( H 1 − y) Discharge, Q = A * 2 g ( H 1 − y ) Provided that critical flow occurs at the control section (y = yc), then Q = Ac [2 g ( H 1 − y c )]0.5 For rectangular broad crested weir, Ac = Byc and yc can be computed from specific energy equation H = y+ v2 Q2 Q2 = y+ = + y 2g 2 gA 2 2 gB 2 y 2 dH Q2 v2 2 = 1− = − 1 . dy 2g y gB 2 y 3 For critical section H=constant. ∴ dH =0 dy y v2 2 v2 ∴1 − = c . =0⇒ 2 g yc 2g 2 ∴ H = yc + yc 2 ∴ yc = 2 2 H = H1 3 3 ∴ Q = By c [2 g ( H 1 − y c )]0.5 2 2 = B H 1 [2 g ( H 1 − H 1 )]0.5 3 3 2 2 = ( ) 0.5 Bg 0.5 H 11.5 3 3 2 Q = ( )1.5 Bg 0.5 H 11.5 3 (1) This formula is based on idealized assumptions such as: i. ii. iii. absence of centripetal forces in the upstream & downstream cross-sections bounding the considered zone of acceleration. Absence of viscous effects & increased turbulence. Uniform velocity distribution so that also the velocity distribution co-efficient can be omitted. In reality these effects do occur & they must therefore be accounted for by the introduction of a discharge co-efficient Cd. The Cd value depends on the shape & type of the measuring structure. 2 (2) Q = C d ( )1.5 Bg 0.5 H 11.5 3 Naturally in a field installation it is not possible to measure the energy head H1 directly & it is therefore common practice to relate the discharge to the upstream water level h1 over the crest in the following way. 2 Q = C d C v ( )1.5 Bg 0.5 h11.5 3 (3) Where Cv is a correction co-efficient for neglecting the velocity head in the approach channel, αv 2 / 2 g. Generally, the approach velocity co-efficient, Where, H 1 = h1 + Cv = [ H1 u ] h1 (4) v12 Q2 = h1 + 2g 2 gB 2 y12 Where u equals the power of h1 in the head discharge equation, being u=1.50 for a rectangular control section. Thus Cv is greater than unity & is related to the shape of the approach channel section & to the power of h1 in the head discharge equation. Generally affect of Cv is considered in Cd and head discharge equation becomes. 2 Q = C d ( )1.5 Bg 0.5 h11.5 3 (5) LIMITS OF APPLICATION: i. ii. iii. iv. The practical lower limit of h1 is related to the magnitude of the influence of fluid properties, to the boundary roughness, and to the accuracy with which h1 can be determined. The recommended lower limit is 0.06 m or 0.05 L, whichever is greater. The limitations on H1/P arise from difficulties experienced when the Froude number Fr1=v1/(gA1/B)0.5 in the approach channel exceeds 0.45. The limitations on H1/L arise from the necessity of ensuring a sensible hydrostatic pressure distribution at the critical section of the crest and of preventing the formation of undulations above the weir crest. Values of the ratio H1/L should therefore range between 0.08 and 0.7. The breadth (B) of the weir crest should not be less L/5. OBJECTIVE i. ii. iii. To find Cd for the weir. To plot Qa vs. h in plain graph paper. To plot Qa vs. h in log-log paper & hence find - exponent of h & - Cd iv. v. vi. vii. To plot h/L vs. Cd on plain graph paper. To calibrate the weir. Observe the conditions when h/L <0.07 & h/L >0.50 and explain the situations. To plot h vs. Cd on plain graph paper. ASSIGNMENT i. ii. iii. iv. What is the difference between the working principles of a sharp-crested weir? When does a weir become in effect a sharp-crested weir or a broad-crested weir? Will the discharge per unit width be same for the same depth of flow over sharpcrested and broad-crested weirs? Why? Upon which parameter does the value of Cd depend? Derive equation (1) and state the conditions under which this equation is valid. DISCUSSION Comment on the results obtained, sources of error etc. Experiment No. 10 FLOW OVER BROAD CRESTED WEIR Experimental Data Sheet Length of weir, L =________________ Width of the weir, B = _______________ Height of the weir, P = ________________ No. of obs. Volume of water V (m3) Time T (Sec) Depth H (m) Actual discharge Qa=V/t (m3/Sec) Level/Term : ____________ Department : ____________ Roll No. : ____________ Section : ____________ Group No. : ____________ Date : ____________ (Signature of the Teacher) Theoretical discharge Qt=(2/3)1.5 g0.5Bh11.5 (m3/Sec) Coefficient of discharge Cd=Qa/Qt h1/L UNIVERSITY OF ASIA PACIFIC Department of Civil Engineering CEE 222, Hydraulics Sessional Experiment No. 11 FLOW THROUGH A PARSHALL FLUME PARSHALL FLUME Parshall flumes are calibrated devices for the measurement of water through open channel in which canal water flows over a broad flat converging section through a narrow downward sloping throat section and then diverges on an upward sloping floor. Fig. Plan and elevation of a parshall flume. Parshall flume dimensions (mm) 3″ 6″ W 76.2 152.4 A 467 621 a 311 414 B 457 610 C 178 394 D 259 397 E 457 610 L 152 305 G 305 610 K 25 76 1′ 304.8 914 845 914 610 914 76 609.6 914 1206 914 610 914 76 4′ 1219. 2 2438. 4 6096 1524 1937 914 610 914 76 2743 3397 914 610 914 76 7315 9144 15240 - 134 3 149 5 179 4 239 1 762 0 823 0 610 2′ 137 2 152 4 182 9 243 8 - 1727 2 1852 9 213 4 213 4 182 9 182 9 365 8 609 6 30 5 30 5 8′ 20 ′ 50 ′ 101 6 121 9 162 6 284 5 589 3 M 30 5 38 1 38 1 45 7 45 7 - N 57 11 4 22 9 22 9 22 9 22 9 68 6 68 6 P 902 149 2 185 4 271 1 417 2 - R 40 6 50 8 50 8 61 0 61 0 - - - X 25 51 Y 38 76 51 76 51 76 51 76 51 76 30 5 30 5 22 9 22 9 THEORY The discharge theory a parshall flume is given by Qt = kHan Where k = a dimensional factor which is a function of throat width (W) n = exponent which varies between 1.522 and 1.607 Ha = upstream depth measured at the location shown in fig Qt = theoretical discharge Table: Values of k, n and head range for different w W 3″ 6″ 1′ 2′ 4′ 8′ 20′ 50′ k 0.1771 0.3812 0.6909 1.428 2.953 6.112 14.45 35.41 n 1.55 1.58 1.522 1.55 1.578 1.607 1.6 1.6 Head range (m) 03-0.33 0.03-0.45 0.03-0.76 0.046-0.76 0.06-0.76 0.076-0.76 0.09-1.83 0.09-1.83 For free flow condition of a parshall flume of 3″ throat width as calibrated empirically (from Table) K = 0.1771, n = 1.55 ∴ Depth discharge relationship Qt = 0.1771 Ha1.55 Where Ha in m Qt in m3/s The relationship between the theoretical and the actual discharges is given by Qa = CdQt (2) Where, Qa = actual discharge Cd = co-efficient of discharge. The percentage of submergence for the Parshall flume is given by 100 Hb/Ha, where Hb is the downstream depth from the invert datum. When the percentage of submergence exceeds 0.6 for 3″, 6″, 9″ flumes the flume discharge is reduced. The discharge of Parshall flume then equals Where, Qs Qt QE = corrected discharge due to submergence = theoretical free flow discharge = correction of discharge as found from the attached figure. LIMITS OF APPLICATION a) It should be constructed exactly to the dimensions listed in Table b) It should be carefully leveled in both longitudinal and transverse directions. c) The practical range of heads Ha for each type as listed in Table 3.2 is recommended as a limit on ha d) The submergence ratio hb/ha should not exceed 0.90. OBJECTIVE i. ii. iii. iv. To observe the free flow discharge and the effect of submergence. To determine the value of co-efficient of discharge Cd. To plot Qa vs. Qt in plain graph paper. To plot Qa vs. Ha for free flow condition in a log-log paper and to find (a) Cd and (b) the exponent of Ha. TYPICAL QUALITATIVE SHAPES OF GRAPHS Graph 1: Qa vs Qt (Plain graph paper) Graph 2: Qa vs Ha for free flow condition (log-log paper) ASSIGNMENT i. ii. iii. iv. Draw the qualitative flow profiles showing free flow condition and submerged condition for the flow through Parshall flume. Do you find any reason for the sidewall convergence and sudden dip in the bed of the Parshall flume? Does the pressure of sediment in the stream affect the performance of the Parshall flume? Discuss. State the difference between the working principle and the performance of a weir and a flume. DISCUSSION Comment on the results obtained, sources of error, etc. Experiment No. 11 FLOW THROUGH A PARSHALL FLUME Experiment Data Sheet Throat width, w = _________________ No Volume Time Actual Free flow of of discharge Ha Theoretical obs water Qa discharge Qt Submerged flow Cd = Qa/ Qt Ha Hb Submerg Correctio ence in % n of 100Hb/Ha discharge QE (Fig.) 1 2 3 4 5 6 7 8 Level/Term : ______________ Dept. : ____________ Roll No. : ______________ Section: ____________ Group No. : ______________ Date : ____________ Signature of the Teacher Corrected discharge Qs=Qt-Qa UNIVERSITY OF ASIA PACIFIC Department of Civil Engineering Course No: CE 222 Course Title: Hydraulics Lab MANUAL Last Update: 17.04.2006