Peanut Oil Extraction Lab Report

advertisement

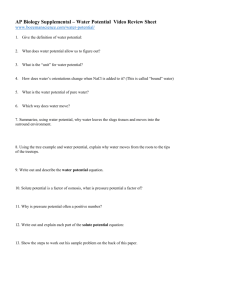

RESULT AND CALCULATION Mass of solids = 0.5 kg Solvent flow rate = 0.102 L/min Solvent feed temperature = 30 °C 20 min 30 min Filling Effluent Amount of Volume Volume Density Solute (mL) (mL) (g/mL) composition solute (g) Batch Contact time Solvent time 1 37 3000 5.5 0.764 0.80 3.178 2 37 3000 7.5 0.772 0.86 3.604 (min) During the experiment, we taking out some of the effluent volume to determine its density and amount of solute at different contact time. By applying density formula as below: Let take the volume of effluent at 20min is 5.5ml and the weight is 4.2g Density P = Mass /Volume P= 4.2g/5.5ml =0.764g/ml By referring calibration curve, the solute composition of density 0.764g/ml is approximately 0.80. Thus, we are able to calculate the amount of solute generate. Since, 5.2ml x 0.764 = 3.973g of total mixture. Amount Solute = Total Mixture X Solute Composition = 3.973g x 0.80 = 3.178g TABLE FOR CALIBRATION OF SOLUTE COMPOSITION Solute composition Mass of PO Mass off n-Hex (g) (g) 0.00 1.00 0.000 0.653 4.86 48.54 0.100 0.668 6.13 30.66 0.200 0.682 16.86 56.77 0.297 0.696 23.41 58.67 0.399 0.715 32.17 64.33 0.500 0.725 46.53 77.55 0.600 0.744 67.18 96.11 0.699 0.754 54.19 67.99 0.797 0.762 79.9 88.65 0.900 0.783 100.23 100.82 1.00 0.795 (g oil / g (g oil / g solvent) solution) Density (g/mL) Density Against Solute Compostion 0,9 DENSITY g/ml 0,85 0,783 0,8 0,744 0,75 0,715 0,7 0,653 0,668 0,682 0,754 0,795 0,762 0,725 0,696 0,65 0,6 0 0,2 0,4 0,6 0,8 1 1,2 Solute Compostion Figure 1: Calibration Curve of Peanut Oil with Isopropanol DATA ANALYSIS The experiment conducted is to determine the properties of peanut oil (lipids) extracted using 0.5 kg of peanut as a soluble material with concentrated solution of isopropanol as solvent using batch mode. For this experiment, 500 g of crushed peanut is measured, packaged and placed in an extraction vessel which then is fed with 2500 ml of solvent isopropanol. Purpose of isopropanol is to dissolve non-polar compounds which satisfies the criteria of dissolving oil from solid compounds. From the calibration curve of solute composition, we can analyze that the density is increase approximate linearly when the solute composition is getting higher. The solute composition is zero when only 100ml of isopropanol (solvent) is added and the density is 0.653g/ml. When the amount of solute which is peanut oil is added accordingly, the solute composition started. When 100g of solute is added to 100ml of isopropanol, the density becomes 0.668g/ml and the solute composition is 1.00. The density at 20min is less dense compared to 30min. The differences density between 20 and 30 min is 0.008g/ml. This probably due to the longer time of solvent-solute extraction will result higher density of effluent being produced. This probably due to the longer time of solvent-solute extraction will result higher density of effluent being produced. As we know, the effluent is the peanut oil which extracted from the peanut. Besides, the amount of solute produced will become higher when the time taken for extraction is longer. For example, the amount of solute at 30 min is 3.604g while 20min would only generate 3.178g. Furthermore, the volume at 20min is 5.5ml while 30min is 7.5ml which the difference is 2ml. Other than volume, the solute composition is also increase from 0.80 to 0.86.