dlscrib.com engine-design-report-for-formula-student-competiton

advertisement

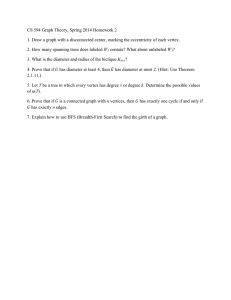

Hyperion Racing Engine Design Report For Formula Student India The making of the Engine system of the HRT-01 was split into the following phases: Selection of the Engine Designing of the intake and Exhaust systems Manufacturing of the intake and Exhaust systems Engine Assembly Initial Testing Cooling System Design Powertronic ECU tuning Final Testing Technical Specifications Royal Enfield 500 EFI KTM Duke 390 Engine Displacement (cc) 499 cc 373.2 cc Engine Type 4 stroke 4 stroke Number of cylinders 1 1 Gross weight 62 kg 90 kg Max Power 27.2 bhp @ 5250 RPM 43.5 bhp @ 9000 RPM Max Torque 41.3 Nm @ 4000 RPM 35 Nm @ 7250 RPM Fuel type Petrol Petrol Compression Ratio 8.5 : 1 12.9 : 1 Engine Cooling System Air cooling system Liquid cooling system, continuous circulation of cooling liquid with water pump Cost 85,000 INR 1,90,000 INR Engine Selection Two Engines were taken into consideration, Royal Enfield 500 EFI and KTM Duke 390. Being a first year team we opted Single Cylinder Engine for simple package of the engine: Reasons for choosing the Royal Enfield 500 EFI 1. Lighter in weight compared to oil and water cooled engines 2. Single Cylinder Air cooled engines, for a first year team, less complicated compared to multi cylinder water/oil cooled engines. 3. More torque available in the lower RPM range. 4. Service centers and spare parts abundantly available. 5. Experienced engine tuners, which was the main reason in going for engine boring. Engine Specification Sheet Ignition System Digital Electronic Ignition Clutch Wet, multi-plate Gearbox 5 Speed Constant Mesh Lubrication Wet sump Engine Oil 15 W 50 API, SL Grade JASO MA Engine oil currently used Motul 3000 4T Plus 15W50 with API SM, JASO MA2. Engine oil capacity 2.5 litres Fuel Supply Keihin Electronic Fuel Injection Engine Start Electric/Kick Engine modification process The engine cylinder diameter was increased from 84mm to 90mm, thus increasing the engine cubic capacity from 500cc to 572.6cc. The cylinder head was also ground to ensure the piston would not strike the head. Hence the combustion chamber volume comes to roughly 576cc. Engine components: The new piston used the engine is manufactured by the company JE pistons, and is used in the Yamaha XT 500 engines. Piston specifications Weight 0.340 kg Diameter 90mm Gudgeon pin diameter 20mm INTAKE SYSTEM System Goals 1. To design and fabricate an intake and exhaust systems for a modified Royal Enfield EFI engine, displacement of 576cc. 2. Must be light in weight but should withstand engine vibrations. 3. Using the 20mm restrictor as a venturi and to increase air flow to the engine. 4. Manufacture the intake system under 185 Euros (INR 15,000). 5. Obtain peak torque at 2000 RPM for acceleration. Software tools used: Solid Works Student Edition 2014, Ansys 14, Ricardo Wave, Lotus Engine Simulation. Software Selection of intake components: Selection of air filter The air filters considered were K&N, cosworth and Piper cross due to availability of models and the air filter chosen is the Piper Cross PK-186 model. Specifications: Filter area 78mm diameter x95mm length. Filter material volume π x (78-75)2 x 95mm = 2686.06 mm3 Selection of throttle body The throttle body used is the stock Royal Enfield 500 EFI throttle body, manufactured by Keihin, Japan. Butterfly valve with cable actuation. Butterfly valve diameter 32mm. Throttle body length 75mm. Throttle body options: The other option considered for the throttle body was that of the Hyundai Santro. Cable actuated with double return spring. The butterfly valve diameter is 42mm. However, it was not chosen because 1. It had considerably higher weight. 2. The stock wiring harness, ECU and sensor system of the Enfield 500 EFI was being used. 3. All necessary sensors for the intake system are available at the required location on the stock throttle body. Royal Enfield 500 EFI throttle body specifications Inlet diameter 42mm Butterfly Valve diameter 33mm Total length 75mm Sensors Throttle Position Sensor, Manifold Air Pressure Sensor Sleeving the throttle body To match the diameter of the air filter and throttle body, a sleeve has been attached on the throttle body of ID 48mm and OD 50mm. The operation was carried out as air filters with an inner diameter of 48 mm was not available. Design of Restrictor Objectives: 1. Subsonic flow through restrictor. 2. Minimum back pressure through the restrictor. 3. The design calculations and flow simulation were done to achieve maximum mass flow into the combustion chamber for the working RPM range of 4500-5500. Analysis tools: Done on Fluent software. Design specifications: The restrictor profile was decided keeping in mind ease of manufacturing. Straight profile was chosen. Parabolic profile is difficult to manufacture and requires more precision in design. Since the intake design was completely changed, a parabolic profile was difficult to refine. Also Fused Deposition Modelling does not provide a good surface finish. Hence the straight profile was chosen. Selection of Nozzle and Diffuser diameters 1. Nozzle diameter: Same as the diameter of the throttle body, 33mm. 2. Diffuser diameter: Iterations were carried out on Fluent to decide the diffuser diameter to achieve minimum pressure drop across the restrictor geometry. 3. Nozzle and diffuser taper angles: The taper angles were iterated to achieve the best combination of least pressure drop, subsonic flow and less turbulence. Boundary Conditions 1. For choking condition at the restrictor, the Mach number will be 1. Hence, the mass flow rate under a choked flow condition would be defined by the following formula: Here, C = 0.62(assumed), A = 314.159mm2 (for d = 20mm), K = 1.4 (for air), ρ = 1.8768 kg/m3, P = 1.89 bar The mass flow rate is calculated to be 0.065 kg/s. 2. Calculation for maximum mass flow through the engine Using the equation m = density * cross sectional area of runner* velocity of air m = 1.2* 0.001089 * 340 = 0.35 kg/s 3. To find a suitable length of the nozzle and diameter of the diffuser end, iterations were carried out on Fluent for steady state conditions. The objective was to achieve minimum turbulence and overall pressure loss. Steady state analysis using Fluent Steady state analysis was carried out to gauge the effects of change of geometry on velocity, pressure and turbulence. Dimensions: Total length, 183mm Nozzle diameter: 33mm Nozzle taper angle: 8.2 degrees Restrictor diameter: 20mm Diffuser diameter: 27mm Diffuser taper angle: 1.8 degrees Analysis Results Pressure at inlet: 1.06 bar Pressure at outlet: 1.01 bar Inferences: Steady state iterations do not give accurate results. It is not possible to obtain proper velocity and pressure results. Hence the existing geometry was subjected to transient simulations using CFX to obtain realistic results. Calculation of runner length Selection of Length for the Intake Runners The calculation for the length of the tuned intake runners is based upon the duration between two events of the intake valve’s operation: the first being the closing of the intake valve, and the second being the re-opening of the intake valve on the next cycle. Therefore, considering the RPM and how an increasing RPM will suggest a reducing time period for the wave to reflect, a range of values is calculated for the lengths of runners required to achieve the effect of reflecting the higher-pressure air onto the intake valves as they open. The track is geared towards the low end powerful and nimble race car as can be depicted from the track description. With average speeds in the endurance race between 48 km/hr to 57 km/hr and top speeds of approximately 105 km/hr the engine spends most of its time in the lower region of its power band. As a result an RPM level of 4500 was chosen as the most suitable for intake tuning. The main design calculations were in relation to plenum volume, runner length and runner diameter. Governing Equation Considering the following notations: ECD = Effective Cam Duration L = Optimal Intake Runner Length RV = Reflective Value= 8th, 10th, 12th D = Runner Diameter (in Inches) = 1.299in = 33mm VPW = Pressure Wave Speed (1100-1300 for hot air intake) = 1100 ft/s (Assumed) CID = Cubic Inch Displacement of Engine = 35.1496 in 3 VE = Volumetric Efficiency = 80% (Assumed) V = Velocity (Mean piston speed) =51.673ft/s The following formulae are used to calculate required runner length and diameter: Here we have used the measured intake valve opening duration which is 30+180+60 = 270 degrees Calculations The runner diameter selected was based on the constraint that the intake runner diameter of the Enfield engine is 33mm. Hence the diameter obtained from the above formula has not been considered. Degrees Calculating length for the 10th reflective Similarly for the 8th reflective value the runner length is obtained to be 7.448in = 189.1mm and For the 12th reflective value it is 4.756in = 120.8mm Selection of runner length Due to availability of space, the 8 th reflective was chosen, with the runner length of 190mm Selection of Volume and Shape of the Plenum The main principle is to choose the right volume of the manifold as well as the resonator resonating at an engine speed at where the boost of the torque is desired; it is also necessary to experiment with the tuned pipe length to reach the optimum results. Hence various shapes were experimented with keeping in mind choked flow, turbulence and mass flow rate at the runner exit. The volume of the plenum was calculated based on the thumb rule of it being 1.5 times the cylinder volume. Taking into consideration manufacturing inaccuracies, the plenum volume was taken as 1.6 times the cylinder volume. Accordingly the plenum volume is 576cc x 1.6 = 922 cc The shape of the plenum was chosen after much iterations on Ansys Workbench. Various shapes were rejected due to insufficient mass flow rate, excess eddy generation, and energy loss. Two primary shapes were considered. One being the usual onion shaped air box commonly seen in FSAE events. The other one was a trial on a tapered air box so as to check for higher pressure generation. All flow analysis was done using Ansys Workbench 14.5 Analysis of plenum The earlier designs that were chosen for the plenum was the conventional onion shape. However these were rejected due to: 1. Not meeting the requirements of the surface envelope. 2. Insufficient mass flow through the plenum. 3. Improper restrictor design. Iterations of onion shaped plenum Iteration 1 Restrictor dimensions: Nozzle diameter 33mm Nozzle taper angle 16 degrees Diffuser diameter 37mm Diffuser taper angle 2.4 degrees Total length 350mm Plenum volume 880cc Runner diameter 33mm Iteration 2 Restrictor dimensions: Throttle diameter 33mm Nozzle taper angle 16 degrees Diffuser diameter 38mm Diffuser taper angle 2.4 degrees Total length 350mm Plenum volume 880cc Runner diameter 33mm Runner length 190mm Inferences: The onion shape design failed because 1. The plenum did not hold in enough air. 2. The restrictor geometry caused choked flow and generated supersonic velocities which was highly undesirable. Conclusion: Due to availability of space between the engine and the roll hoop bracing, and also due to obstruction from the head restraint it was decided to completely redesign the plenum as a side intake profile. Iterations of tapered cylinder plenum Iteration 1: Inwards taper Restrictor and plenum dimensions: Nozzle diameter 33mm Nozzle taper angle 8.7 degrees Diffuser diameter 29mm Diffuser taper angle 1.85 degrees Total length 167mm Plenum volume 901cc Runner diameter 33mm Runner length 190mm Results: Peak velocity at restrictor: 367.7 m/s Peak pressure at plenum entry: 1.309 bar Peak pressure at plenum exit: 0.8114 bar Inferences: 1. Incorrect orientation of restrictor with respect to runner preventing reduction of velocity in plenum. Causing turbulence and less flow into runner 2. Due to the orientation of the restrictor, the pressure generated at the plenum entrance is high. 3. Also due to the inwards taper of the plenum, the pressure gradient inside the plenum is uneven, hence air keeps swirling inside the plenum. This leads to loss of energy and mass flow rate in the runner was greatly reduced. Iteration 2: Outward tapered cylinder To eliminate the above issues, the taper angle was inverted so that the taper increased towards the runner. Restrictor and plenum dimensions: Nozzle diameter 33mm Nozzle taper angle 8.2 degrees Diffuser diameter 27mm Diffuser taper angle 1.8 degrees Total length 166.7mm Plenum volume 925cc Runner diameter 33mm Results: Peak velocity at restrictor: 432.7 m/s Peak pressure at plenum entry: 1.172 bar Peak pressure at plenum exit: 0.75 bar Inferences: 1. Pressure gradient and air flow inside the plenum has improved. 2. Mass flow into the runner has increased to 0.142 kg/s 3. Pressure at plenum exit reduced. Conclusions: 1. The above design is much easier to manufacture compared to the Onion shaped plenum design. 2. Reduced restrictor length means reduced bending stresses on the intake flanges. Hence chances of failure are reduced. Hence the above design was chosen for manufacturing. The final design is as follows: Manufacturing process options Material selection: MATERIAL DENSITY (kg/m3) Manufacturing process ALUMINUM 2.800 Molding or casting GLASS FIBRE LAMINATE 1.800 ABS PLASTIC (ACRYLONITRILEBUTADIENE) 1.050 Hand molding using glass fiber resins Rapid prototyping, using Fused Deposition Modelling. Selection Owing to the complete redesign of the intake system layout, and the expense of creating a mould, Rapid Prototyping method was chosen for manufacturing the intake system. Rapid Prototyping specifications: Rapid prototyping process Fused Deposition Modelling Material thickness 2.5mm Modelling material used: ABS plastic Support material used: ABS plastic Machining time: 22 hrs Manufacturing cost: 185 Euros (15000 INR) Coating applied: Yes, on outer surface, to eliminate porosity Adhesive used: Fevikwik 203 and Araldite for sealing flanges Exhaust System The exhaust system is built around rules and regulations formulated by FSAE organisation and quoted in FSAE rulebook which are as follows: 1. The exhaust must be routed so that the driver is not subjected to fumes at any speed considering the draft of the car. 2. The exhaust outlet(s) must not extend more than 45 cm (17.7 inches) behind the centreline of the rear axle, and shall be no more than 60 cm (23.6 inches) above the ground. 3. Any exhaust components (headers, mufflers, etc.) that protrude from the side of the body in front of the main roll hoop must be shielded to prevent contact by persons approaching the car or a driver exiting the car. 4. The maximum permitted sound level is 110 dBA, fast weighting. DESIGN PROCEDURE: 1. Exhaust runner length Exhaust runner length is determined by maximum scavenging that can be attained at an rpm. Since our engine of Royal Enfield Motorcycles has rpm range up to 5500. Thus the exhaust runner is designed at 4000 rpm. The crank angle for which the exhaust valve remains closed is 430°. Thus it takes time for which the exhaust valve remains closed is 0.0179s. Temperature of exhaust gas as per Lotus simulation is 600 degree celsius. Speed of sound at that temperature is calculated as 590m/s. Hence runner length is L given by: L = (speed of sound × time for which exhaust valve remain closed) ÷ ( 2 × number of reflections) L= (590×0.0179) ÷ (2×5) L= 1.05 metres Thus the exhaust runner length is 105mm. Thus the noise pressure waves are reflected 5 times from the runner back to the valves. For longer stroke single cylinder engine, considerable scavenging can be obtained by 5 reflections at 4000rpm. 2. Muffler Design The Muffler Was designed following ASHRAE Technical Committee Rule 2.6 for Heat and Sound vibrations. Step-1: Unsilenced noise level (UNL) Modelling on Lotus was done to obtain unsilenced noise at the exhaust outlet as shown in the figure given below As per the above simulation in Lotus Engine simulation software, the unsilenced noise level obtained is 120dB. By actual running of engine without the muffler the exhaust noise was found to be 125dBA. Step-2: Calculate exhaust noise criteria ENC=RNC – 10 (dB) where, ENC = Exhaust Noise Criteria RNC = Required Noise Criteria = 110 dB as per rule no. IC3.3 ENC = 110 − 10 = 100 dB Step-3: Calculate Insertion Loss (IL) IL = UNL – ENC + 5 IL = 120 − 100 + 5 = 25 dB 25dB noise attenuation is required for muffler design. Step-4: Cylinder Firing Rate (CFR) CFR = RPM / 120 for a 4-stroke Engine at 5500rpm CFR=5500/120 CFR= 45.83 Step-5: Engine Firing Rate (EFR) EFR = n × CFR where, n = no. of cylinders. EFR = 1 × 45.83 = 45.83 Step-6: Chamber Length Selection using ASHRAE Technical Committee Rule No. 2.6 Since insertion loss was 25dB, Residential grade of mufflers was chosen Residential Grade: IL = 20 to 30 dB Body/Pipe = 2 to 2.5 Length/Pipe = 6 to 10 Silencer inlet pipe diameter (d) = 38mm ∴ Silencer Length (L) = (6 × 38) ≤L ≤ 10 × 38 = 228mm ≤ L ≤ 380mm ∴ Body Diameter(S) = 2 × 38 ≤ � ≤ 2.5 × 38 = 76mm ≤ � ≤ 95mm Thus higher values are taken, so L = 380mm and S = 95mm To allow for manufacturing and welding errors, etc body diameter is increased by 5mm and length to 10mm. Step-7: Selection of insulation material Glass wool of density 130kg/m was selected having maximum service temperature of 750° C. 3 3. Design of Perforated pipe For perforation, 60°staggered type is selected to obtain higher noise attenuation Transparency Index (TI): It is given by the following equation TI= (n×d)/ (t×a2) where, n = number of perforations per sq in; d = perforation diameter (in); t = sheet thickness (in); a = shortest distance between holes (in); a = b - d, where b = on-centre hole spacing (in); For attenuation of frequencies less than 2000Hz, TI should be less than 6000 Thus taking standard values as hole diameter (d) = 3.5mm, b = 10mm TI was obtained as 1.12, which is much lesser than 6000. SOLIDWORKS MODEL: Assembly of the exhaust Muffler: Intake, Exhaust Modelling in Ricardo Wave: Noise Test results on Ricardo Wave References: 1. Inclination on Intake Valve Flow Characteristics of a Single Cylinder Engine using ParticleImage Velocimetry”, World Academy of Science, Engineering and Technology 68 (2010). 2. Ceviz M.A and Akın M., “Design of a new SI engine intake manifold with variable length of plenum” ELSEVIER JOURNAL, (2009). 3. Design of a single cylinder intake system – Ladislav Adiamek, University of Brno 2011