Strategic Capacity Management Presentation

advertisement

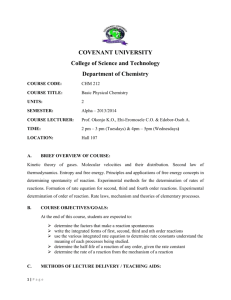

Strategic Capacity Management Learning Objectives Capacity and how to “manage” it. Impact of economies of scale on the capacity. 3. Decision trees to analyze alternatives of adding capacity. 4. Planning capacity for service firms. 1. 2. S. Bahl 2 Capacity Management in Operations Capacity can be defined as the ability to hold, receive, store, or accommodate Strategic capacity planning is an approach for determining the level of resources required over a time horizon Long range: greater than one year Intermediate range: six to 18 months Short range: less than one month S. Bahl 3 Capacity Planning Concepts Capacity: an attainable rate of output Best operating level: capacity for which the process was designed Capacity utilization rate reveals how close a firm is to its best operating level Capacity used Capacity utilization rate Best operating level S. Bahl 4 Economies and Diseconomies of Scale Economies of scale: as a plant gets larger, the average cost per unit drops Lower operating and capital costs Per unit cost of equipment drops More specialization of labor At some point, the plant becomes too large Diseconomies of scale becomes a problem S. Bahl 5 Capacity Flexibility Capacity flexibility: the ability to rapidly increase or decrease production levels or to shift production capacity quickly from one product or service to another Flexible plants: low changeover times Flexible processes: easily set up equipment Flexible workers: workers have multiple skills S. Bahl 6 Considerations in Changing Capacity 1. Maintaining system balance 2. Frequency of capacity additions 3. Want similar capacities at each operation Deal with bottlenecks Cost of upgrading too frequently Cost of upgrading too infrequently External sources of capacity Outsourcing 2. Sharing capacity 1. S. Bahl 7 Frequent Versus Infrequent Capacity Expansions S. Bahl 8 Determining Capacity Requirements Use forecasting techniques to predict sales for individual products 2. Calculate equipment and labor requirements to meet forecasts 3. Project labor and equipment availability over the planning horizon 1. S. Bahl 9 Example: Determining Capacity Requirements Steward Company produces two flavors of salad dressing Paul’s 2. Newman’s 1. S. Bahl Each is available in bottles and single-serving bags Management would like to determine equipment and labor requirements for the next five years 10 Step 1: Forecasting to Predict Sales for Individual Products S. Bahl 11 Step 2: Calculate Equipment and Labor Requirements S. Bahl 12 Example: Equipment and Labor Requirements 450,000 bottling capacity with 3 machines and 2 operators per machine – total 6 operators available 1,250,000 bagging capacity with 5 machines and 3 operators per machine – total 15 operators needed; 20 operators are available Year 1 135 /450 = 0.3 or 30% for bottling; .3x3 = .9 machines 300 /1,250 = 0.24 or 24% for bagging; .24x5=1.2 machines 0.9 bottle machines x 2 operators = 1.8 operators 1.2 bag machines x 3 operators = 3.6 operators S. Bahl 13 Example Step 3: Project Equipment and Labor Availabilities S. Bahl 14 Using Decision Trees to Evaluate Capacity Alternatives Decision tree: a schematic model of the sequence of steps in a problem and the conditions and consequences of each step Decision tree helps understand problem and helps find solution Decision trees are composed of decision nodes with branches Squares represent decision points Circles represent chance events S. Bahl 15 Example: Decision Trees 1. 2. 3. 4. 5. 6. 7. 8. S. Bahl Strong growth, 55 percent probability New site and strong growth=$195,000, weak=$115,000 Expansion and strong growth=$190,000, weak=$100,000 Exist and no change strong=$170,000, weak=$100,000 Expansion costs $87,000 Move costs $210,000 Expansion in second year costs $87,000 Operating costs equal 16 Calculating Values S. Bahl 17 Diagramming Problem Decision Chance S. Bahl Decision 18 Decision Tree Analysis Value of this decision S. Bahl Value of this decision Expected value Value of this branch 19 Decision Tree Analysis: NPV S. Bahl 20 Planning Service Capacity Time: goods can not be stored for later use and capacity must be available to provide a service when it is needed Location: service goods must be at the customer demand point and capacity must be located near the customer Volatility of demand: much greater than in manufacturing S. Bahl 21 Capacity Utilization and Service Quality Must consider the day-to-day relationship between service utilization and service quality Optimal utilization rate is very context specific Low rates are appropriate when both the degree of uncertainty and stakes are high Relatively predictable services or service facilities without customer contact can operate much nearer 100 percent utilization S. Bahl 22 Relationship Between the Rate of Service Utilization and Service Quality S. Bahl 23