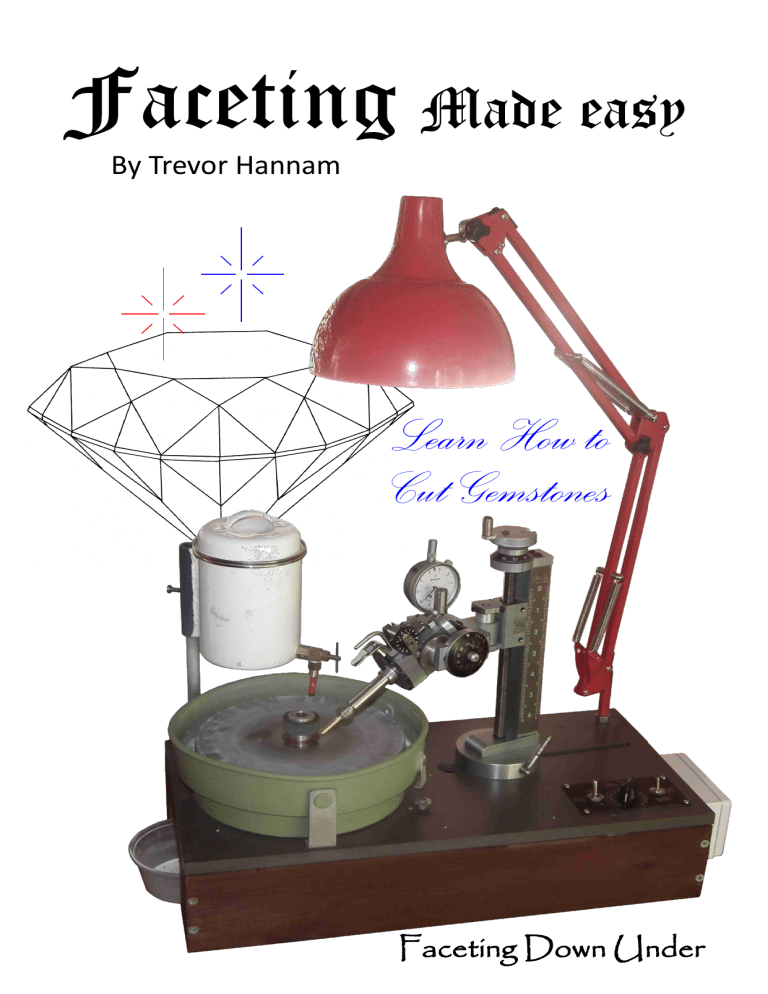

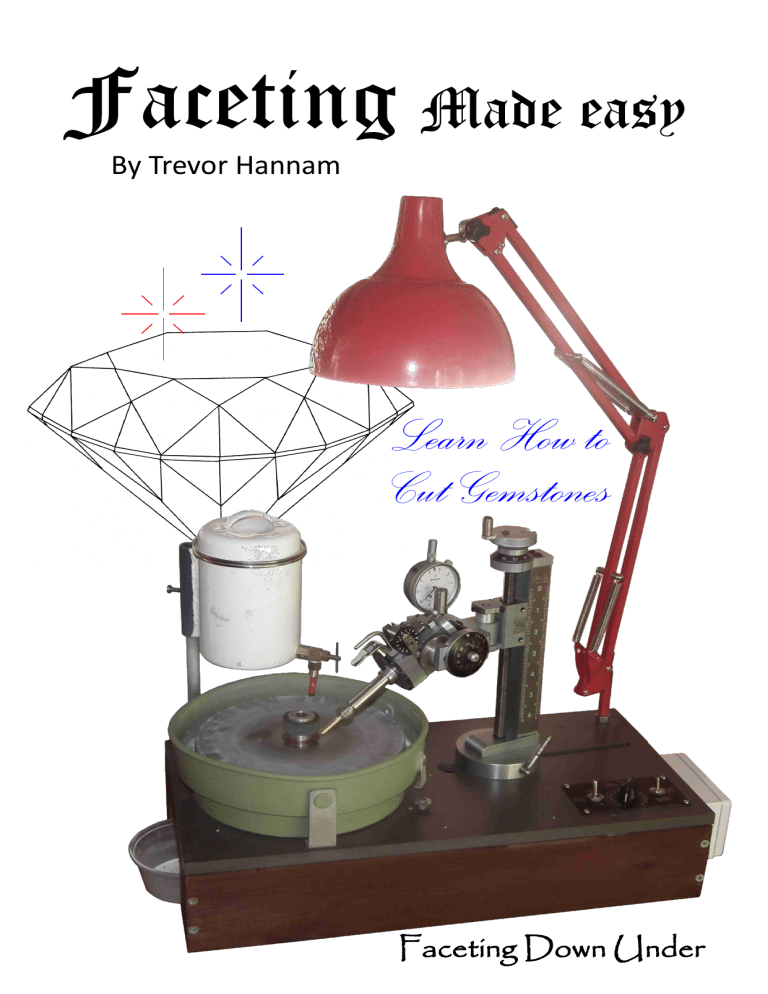

Faceting Made easy

By Trevor Hannam

Learn How to

Cut Gemstones

Faceting Down Under

The Beginners Guide

On

Faceting Gemstones

Copyright © 2000 Trevor G. Hannam

4th edition

All rights reserved - No part of this book or associated DVD

May be reproduced in any form, without the written permission from the author.

Trevor G. Hannam, 1 Glenwood Close., Atherton, QLD 4883

PH: 4091 1966

Should you require a copy of the book or the DVD

please contact the following:

Trevor G. Hannam, 1 Glenwood Close., Atherton, QLD 4883

PH: 4091 1966

Pages that are damaged through some mishap can be

re-supplied @ $3.00 per page

© Copyright 2000

Trevor G. Hannam

Page 2

H

INTRODUCTION

ave you ever read a book filled with so much technical jargon that it leaves you

more confused than when you started! I think we have all fallen into this category one time or another.

It is for this reason that this book has been written. I myself found learning from such a

book, if not properly illustrated or explained in everyday terms can be very frustrating and

discouraging. Unless you can get an instructor to help you, most beginners will just give it

up.

This book and associated DVD (if purchased) contains detailed instructions and illustrations

in concise patterns on cutting the Standard Brilliant, and gives the individual a working

knowledge of all parts of the Faceting Machine.

Books and teachers of faceting often vary in their technique and most still advocate cutting

the table first. Times change, and new ways are found to cutting the Standard Brilliant.

This book just presents faceting another way, starting with the pavilion and as you read

and learn, you will see the wisdom of this technique.

There is no hard and fast rule in faceting, just the basics and beginners are encouraged to

experiment once they have mastered the Standard Brilliant.

I feel this book has presented gem faceting in such a way that any average person can learn

quickly, and soon develop their own technique in the art of gem cutting.

Trevor Hannam

2000

ABOUT

the

AUTHOR

Trevor G. Hannam, born in Wudinna South Australia, moved to Cairns Queensland 1966. Introduced to faceting by Kay & Jimmy Gadd, where he

learned to facet with the help of Bob Johnson.

Furthered the study of gems by completing a diploma in ‘Earth Science’, and continued to study

the art of ‘Gemmology’ through kye Jewellers. Member of the 'Cairns

Mineral & Lapidary Club Inc.' where he use to teach the art of silver

smithing , Gemmology techniques and faceting. Currently Retired.

© Copyright 2000

Trevor G. Hannam

Page 3

CONTENTS

CHAPTER 1

Light and its Properties

Page 5

CHAPTER 2

Faceting Machine

Page 11

CHAPTER 3

Faceting Equipment

Page 16

CHAPTER 4

Preparing Polishing Laps

Page 20

CHAPTER 5

Selecting Rough

Page 21

CHAPTER 6

The Standard Brilliant

Page 23

CHAPTER 7

Dopping

Page 24

CHAPTER 8

Rounding

Page 26

CHAPTER 9

Cutting the Pavilion

Page 29

CHAPTER 10

Polishing

Page 32

CHAPTER 11

Transferring

Page 37

CHAPTER 12

Cutting the Crown

Page 42

CHAPTER 13

Cutting Angles for different Minerals

Page 49

DESIGN CUTS

Emerald Cut

Page 51

Spidery Cut

Page 52

Ollen Cut

Page 53

Champagne Glass

Page 54

Kaytre Cut

Page 56

Kaytre No5 Cut

Page 57

References

Page 58

© Copyright 2000

Trevor G. Hannam

Page 4

CHAPTER 1 - LIGHT & ITS PROPERTIES

S

peed of light Travels through air and space at 297,600 kilometres per second, but as it

passes through a solid object, such as a piece of glass, it does two things, slows down

and changes direction or bends.

Why does light slow down? Because it’s passing through a denser material than air.

For example, try driving a car through water. The water is more dense than the air, so we

are slowed down by it.

Why does light bend? As light tries to pass through the glass it is pulled due to the

sudden reduction of speed, because of the higher density. Lets take for example, that we

are driving on a sealed road and up ahead there is a small amount of water on the left hand

side of the road. As we hit this water at normal speed, the vehicle is immediately slowed

down and pulled to the left. This is exactly what happens when light passes through glass.

This phenomenon is known as Refraction and is constant in all gem stones.

REFRACTIVE INDEX

Is the speed of light divided by the speed of light in the mineral concerned

SINGLE REFRACTIVE

Light Path

Light Path

Refraction

297,600 Km/Sec

177,600 Km/Sec

297,600 Km/Sec

Light Path

In Calcite Crystals and some other

minerals light has the tendency to

split into two paths. This is known as

Double Refraction.

DOUBLE REFRACTIVE

Light Path

Refraction

Light Path

© Copyright 2000

Trevor G. Hannam

Page 5

When a gem is cut properly with angles that are designed for it, the gem will cause

light to be internally reflected many times and thence returned through the table to your

eyes. It is the internal reflection and refraction which produces the little explosions of colour. The facets actually acting as tiny prisms.

White light breaks down readily if passed through a prism into the colours of a rainbow. As a kid I was taught this as a name; ‘Roy G. Biv’ - Red, Orange, Yellow, Green, Blue,

Indigo and Violet.

Red

Orange

Refraction

Yellow

Green

Blue

Indigo

Violet

Light Ray

Glass Prism

THIS PHENOMENA IS KNOWN AS DISPERSION

DOUBLE REFRACTION

Light can be affected in other ways in a crystal. Minerals can either be single refractive or

double refractive. In normal single refractive minerals, light behaves in its normal manner,

that is, it slows down, refracts and is internally reflected. In double refractive minerals, this

however is altered. Light is split up into two paths. This is due to the minerals atomic structure and its having one or two axis's of different lengths..

Calcite is a very good example of double refraction. If you place a piece of clear calcite

over some small print, you will clearly see the print doubled, as if you have gone cross eyed.

Original print shows

Up as two sentences.

Calcite Crystal

Diagram showing Double Refraction

In a Calcite Crystal

© Copyright 2000

Trevor G. Hannam

Page 6

POLARISCOPE

Double refractive minerals can easily be identified by using a Polariscope, which is definitely required by the amateur faceter if he or she is looking for the best optical benefits.

A Polariscope consists of two discs of polarized plastic (or a cheap pair of Polaroid sunglasses) that are separated by a mechanical support. A light source is produced

underneath one of the discs. The gem rough is then placed atop of this disc, whilst

your eyes are looking through the top disc. The top disc is then turned until it reaches

it darkest point. The stone is then turned or rotated in a 360 Degrees revolution in all

directions until you see the best position of refraction. What you see as the gem is

turned is a lightness and darkness of the polarized light. Will be either 2 times for a

double refractive stone (known as uniaxial) or 4 times for a stone with a double axis of

double refractive stone (Known as biaxial). The axis of the stone or gem rough is the

part where the gem turns the least amount of light and dark.

Below is the principal of a Polariscope.

General Diagram of use of a Polariscope

Polarized disc when 90 Degrees

out of phase. Produces the darkest area. This is the correct position for viewing. The Polariscope

is a must for double refractive

stones, such as, Zircon and Peridot.

Blue Zircon

Direction of

Double Refraction

Light Source

© Copyright 2000

Trevor G. Hannam

Page 7

THE CRITICAL ANGLE

As the angle of light from a source increases to the surface of a gem stone, the angle of refraction will also increase until a point is reached where it will run parallel with the surface

of the gem stone. The angle of incidence which causes the light to become parallel to the

surface is known as the Critical Angle.

If the angle of light exceeds the critical angle, the light source will become totally reflected. The minerals with a small critical angle will loose less light than ones that have a

larger critical angle. This means that gem stones with a smaller critical angle can prolong

the internal reflection of light thus producing more sparkle and colour.

WHAT LIGHT DOES WHEN THE ANGLE OF INCIDENCE IS INCREASED

Partial Refraction

Partial Refraction

Increasing Angle

Light runs parallel

with the surface

Critical

Angle

Critical Angle

Exceeded causing

Total reflection

Total Reflection

Partial Refraction

Partial Refraction

© Copyright 2000

Trevor G. Hannam

Page 8

CUTTING OF CORRECT ANGLES AND WHAT CAN HAPPEN

IF THE ANGLES ARE NOT CORRECT FOR THE MINERAL

CONCERNED

TOPAZ CRITICAL ANGLE 37º

Cut from 39 to 42º

Angle 42º

This gem stone has been cut correctly

The angles are correct for the mineral

Topaz and has full total reflection

which produces those little explosions

of colour.

This gemstone has a dark centre and is

caused by excessive leakage of light

through the pavilion because it has

been cut at an excessive angle of 50

Degrees.

Angle 35º

© Copyright 2000

Trevor G. Hannam

Angle 50º

This gemstone has what is known as a ‘Fish

eye’ effect, and is indicated by seeing

straight through the centre of the gem stone

producing a halo appearance around the perimeter. This is caused by cutting the gem

stone far to shallow, 35 Degrees.

Page 9

PLEOCHROISM

Certain minerals have a colour change which is caused by absorption of light when it passes

through different directions in the mineral.

If you turn a gem and see different colours from different directions, the mineral is

referred to as being Dichroic. A good example of this would be a sapphire. If looked straight

down upon the crystal, that is its ‘C’ axis, the gem will appear to be blue, but if looked at 90

Degrees or side on the crystal will appear green.

The gem Iolite also shows this phenomenon, but has three colour changes. Blue,

clear, and yellowish.

An instrument used for viewing this effect (dichroism), is called a Dichroscope, and is

made from a piece of clear calcite and a lens situated in a small tube.

SAPPHIRE CRYSTAL SHOWING PLEOCHROISM

Blue

Green

‘C’ Axis

© Copyright 2000

Trevor G. Hannam

Page 10

CHAPTER 2 - HALLS MKII FACETING MACHINE

Light 40W

Coarse Height

Adjuster

Adjustable

Micro Height

Adjuster

Angle Cheater

Stop Indicator

Post

Dial Gauge

Speed Control

Water Reservoir

Control Box

Coarse Angle

Adjuster

Protractor

Angle Stop

Index Cheater

Index Wheel

Quill - Dop Arm

Water Spiggit

Valve

Chuck

Master Lap

Dop Stick

Nut

Swarf Tray

Remember, with any machine, no matter how good it is, will not be as good

as your eyes. The old saying “CUT A LITTLE LOOK A LOT” always apply.

© Copyright 2000

Trevor G. Hannam

Page 11

ULTRA TECH FACETING MACHINE

40 Watt Lamp

Water Reservoir

& Valve

Coarse/Micro Height

Adjuster

Dial Gauge

Angle Cheater

Index Changer

& Free Wheel

Index Cheater

Nut

Protractor

Post Lock

Post

Speed Control

Diamond Lap

Swarf Tray

Index Wheel

Quill - Dop Stick

Swarf Waste

Tray

Set of Dop Sticks

&

Transfer Jig

© Copyright 2000

Trevor G. Hannam

Page 12

Dial Gauge

Index Free Wheel

Lever & Lock

Angle Cheater

and Stop

Protractor

Index Cheater

Master Lap

Speed Controller

Set - 0

Rounding

Post

12VDC

Motor

Micro Height

Adjuster

Swivel Joint

Index

Wheel

Course Height Adjust

Quill - Dop Stick

Swarf Tray

Index

Cheater

CAMPER SERIES FACETING MACHINE

Post

Index Release Protractor

Lever & Lock

Angle

Stop Lock

Micro

Height Adjust

Water

Vessel

Coarse

Height Adjust

Index

Wheel

Post

Quill

Master Lap

Motor

Speed

Control

Nut

Swarf Tray

Post Lock

Transfer Jig

GEM MASTER G1

Indicator Stop Lamp

© Copyright 2000

Trevor G. Hannam

Page 13

TERMINOLOGY

Quill & Alignment Tool

The quill or dop arm as it is sometimes called, houses the

mounted dop stick, and is attached to the toothed gear known as

Small Set Screw

the index wheel. This quill has either a self centre chuck or a small

set screw to lock the dop stick in position.

Some machines do not have alignment notches built into the quill

or transfer Jig, and alignment tools makes life easier for aligning

facets between the Crown and Pavilion. A good machine should

Quill with Dop Stick

have at least one of these. The alignment tool allows for perfect

realignment, should you have to remove or replace the dop stick at any stage whilst cutting

or polishing.

Index Wheel & Cheater

The index wheel is the large toothed gear and comes in a variety of indexes. Normally the

machine will come with a 96, and/or a 48 index wheel as standard equipment. These

indexes should be easily interchanged without

Index Wheel Release

difficulty. If not - be wary!

The index wheel can be released by pushing in the

arm of the spring retainer so the quill can be moved in

either direction (as with most machines). This arm can

be locked into position so the index wheel, and quill

can turn in a 360° for rounding.

A small amount of movement, either left or right of

96 Index Wheel

Index Cheater (showing No 2)

the main setting is available by using the index

cheater. The cheater will allow for small errors in cutting or polishing, and normally will

have a centre mark to help you show direction (left or right) when cheating.

Protractor, Stop & Cheater

The protractor is probably the most important part of the machine, and should have clear

engraved half degree divisions

Angle

Cheater

with a good marker, pointer or

face that can be seen, and read

from nearly all directions when in

normal operation.

The angle stop sets the quill to any

Stop

angle between 0 and 90° on the

Protractor (Set at 60º)

protractor, and should move

Angle Stop & Cheater

freely between the stop, and the

Angle Cheater

set angle. Most machines will incorporate a dial gauge and/or a

small indicator light to give the operator a warning when the stop

is reached. The stop should be solid, and held firm by a locking

device so the quill cannot past this point.

Located on the stop, may be an angle cheater, a small tapered

shaft that can be screwed in or out to adjust the angle by the 10th

degree, but be prepared, there are a lot of machines out there

Dial Gauge Fitted

that do not have an angle cheater, in fact most faceters will tell

you that the angle cheater is not necessary.

© Copyright 2000

Trevor G. Hannam

Page 14

The Post & Coarse Adjuster

The post is the main support for the head assembly and is

90° to the base plate. The post can be either fixed or

adjustable along a slide that is fixed by a locking nut. On this

post, to which the head assembly is fitted, is a coarse

adjuster. This is a large knurled knob which releases or

tightens the head assembly to the post so the quill can be

raised or lowered by hand (coarse adjustment).

The micro Height Adjuster

Fitted to the head assembly or in some cases to the main

post support. The micro height

Coarse & Micro Height

Base Assembly Lock

Adjuster 0.02mm Increments

Pull Handle Down to secure Post to Base

adjuster should be adjustable

within a span of approximately 25mm, and is normally marked

in graduated steps of 1 to 5 thou increments. Some machines

do have micrometers fitted as part of their standard

equipment.

Water Reservoir

A good reserve of water should be

Water Container

available to the faceter. Normally

Valve & Spout

all faceting machines will have a

reservoir fitted to the side of the

Master Lap

swarf tray, and have a capacity of

RH Lock Nut

Main Post

500 mils minimum. A stop valve

should be fitted to allow control over the water flow, and the

container should be able to be swung away from the lap when

required.

Speed Control & Motor

All faceting machines must be driven by an electric motor of

Ultratech Swarf Tray

sorts (or can be hand crank). This can be by either 240V or

12/24 Volt, and is normally belt driven by stepped pulleys or variable speed

control.

If a fixed 2 or 4 pole motor is used, then the faceting machine should be

fitted with a stepped pulley system so the speed can be changed manually. A

good speed for minimum is 100 rpm to around 1400 + for fast speed.

The best system is a variable speed system either in 240V, 12 or 24 Volt.

Ultratech Speed Control

12/24 Volt is preferable due to high torque and less noise.

As mentioned earlier, all machines today can be considered a marvel of modern

engineering. Some are better than others, and some offer more incentive by gimmicks, and

attachments, but all in all, the faceter has to make the decision that suits him best. The

main criteria for any faceter is Ease of Operation when facing the machine in the standard

cutting mode.

© Copyright 2000

Trevor G. Hannam

Page 15

CHAPTER 3

FACETING EQUIPMENT

FACETING MACHINE

Should include dop sticks, transfer jig, 45 degree angle dop and a flat dop. It seems that

quite a few faceting machine manufacturers don’t include flat dops in their kits. If you happen to be one of the unlucky ones, don’t despair, as a valve from an auto or bike shop will

suffice quite well. Just be sure that it has a 1/4” or 6 mm shank. Essential tools, such as

small spanners, screwdrivers and Allen keys are a must.

LAPS

A lap is a flat disc which is used to cut and polish gemstones. Today there is a multitude of

laps offered for sale, but non better than the good old copper lap. The copper lap has been

around for many decades, makes an excellent pre-polish lap and is still preferred by many

experienced faceters. These type of laps have to be charged with diamond powder, are

cheap and easy to maintain.

Metal bonded laps have diamond powder electroplated onto a thin copper disc which is

glued to a master lap made of aluminium. These type of laps are more expensive than the

copper laps, but cut flat and true with good clean facet edges. I have found from experience, that the pre-polish lap do have a tendency to become dull very quickly and therefore

is not recommended for the beginner until he or she has gained more experience. Coarse

laps on the other hand are a must for the faceter and will last an extremely long time and

are well worth the few extra dollars to buy.

Polishing laps also come in a variety of types, namely: Aluminium, brass, ceramic, Lucite,

cast iron, iron, tin lead, type metal, and even timber, but one can’t surpass the ever popular

tin lead lap for polishing as an all round general purpose type. Used with 50,000 mesh diamond powder, it will outperform all other laps due to the metal’s ability to polish most

gemstones.

LAPS REQUIRED

(1) Coarse 100 to 180 grit disc grit metal bonded type - Used for quick removal

(2) Coarse 220 to 300 grit metal bonded type

(3) Pre-polish 1200 and/or 3000 Copper Lap

(4) Polish Tin Lead lap - made from 60/40 solder or Type Metal

Once you have established yourself as a faceter, try experimenting with other laps. They all

work very well and you will find the aluminium lap extremely good for polishing sapphires.

The ceramic lap gives clean flat sharp facet edges, and is best suited to gemstones of 8+ in

hardness. Not to be considered as a general purpose lap, but if you are considering entering

faceting competitions, the laps superiority over soft laps must be well considered.

Cast iron and iron laps can be considered a second best to the tin lead lap. They give a

good crisp straight edge and are suitable for stones of 8+ (Topaz & Sapphire) that can only

be used with diamond powder and a good grade of olive oil. The laps coarseness or porosity of the metal makes it a good holder of polish powder. From experience, this lap can be

considered to be on par with the ceramic lap, giving precise clean flat facets and is worth

persevering with until the lap is worn in.

© Copyright 2000

Trevor G. Hannam

Page 16

The last one to mention is the Lucite lap. Made of plastic and is normally used with

cerium or tin oxide powders mixed with water. This type of lap is generally used for

polishing Quartz, and requires the lap to be kept extremely wet while in use to prevent

heat build up and rounding of the facet edges. Quartz being one of the hardest minerals I

have found to polish can be assisted by the use of a small amount of vinegar added to the

polish mixture. Using Lucite laps require a very slow speed.

DIAMOND POWDER

Diamond grit used for cutting and polishing of gems come in a variety of sizes, ranging from

0.1 to 100 micron. The diamond powder that we use today is mostly made by man, and is

more consistent in particle size than natural stones which have been sieved by a screen.

Grit sizes of 80 to 325 normally come in a powder form from 1 carat to 5 carat vials. Whilst

600 mesh size and over can come in a variety of containers, vials,

syringes and spray packs.

To start, we will need 1 carat of each size, 1,200 mesh, 3,000 mesh

and 50,000 mesh. The 1,200 and 3,000 mesh are both the pre-polish

grade. 1,200 mesh is the all rounder for pre-polishing, whilst the 3,000

mesh is recommended for doing sapphires as they suffer badly from

‘Orange Peel’ or over cutting due to planes of softness within the

mineral. The 50,000 mesh is used for the polishing stages and is a

good all round polish powder. You can however use 100,000 mesh for

Diamond Products

polishing, but polishing of the facets will take a little longer. It has

100 Thousand Spray Bottle

Syringes - 14,000 & 50,000

been my experience that there is virtually no difference between

220 & 50,000 Mesh in

1 carat & 5 carat vials

these polishing powders when it comes to viewing the finished

product.

ADHESIVES

5 minute/24 hour epoxies and super glues (cyanoacrylate) are an added advantage when it

comes to faceting and all faceters should have in their arsenal, Loctite 416 Super glue,

Epoxy adhesive such as ‘Tite On’/JB Weld and a small tube of 5 minute araldite.

© Copyright 2000

Trevor G. Hannam

Page 17

DOP HELP

A small container of dop help which you can buy direct from any good lapidaries supplier or

you can make your own.

Made from shellac flakes and methylated spirits. The shellac flakes can be bought from

paint suppliers or any good hardware store. Using a small glass container that has a tight

fitting lid, such as a Promite container - half fill with shellac flakes and pour methylated spirits onto the top until the container is full. Shake this container vigorously for a few minutes

once every day for 3 days and then let settle for a couple of days. Pour of the top part of

the liquid into a small vial etc. This makes an excellent dopping media for faceters wax, inexpensive and will last you for years.

DOP STICK HOLDER

A must for beginners or any enthusiasts, 3 or 4 dop stick holders. Made from a 1” broom

handle. Don’t use the wife’s broom for this venture or you may very well end up in the dogs

house. Cut 3 or more pieces from your broom handle approximately 30mm long and drill a

1/4” hole in the centre to a depth of around 15mm. These essential pieces of equipment

will be required to hold your dop sticks in an upright position for gluing, fixing and handling

your gem stones especially when using hot wax.

FACETING WAX

Faceters dopping wax is made from a mixture of Shellac flakes and red Ceiling wax. Dopping

with wax has been around since ‘God was a little boy’, and is still regarded as the all purpose adhesives for gem faceting. Normally faceting wax comes in a bundle five to six sticks

per pack and is relatively cheap to purchase. Occasionally green wax can also be used but is

a lot softer and can cause shifting of the stone whilst polishing due to heat build up.

HEAD LOUPE

A small head loupe of 3 1/4 power and/or a 5 to 10 power eye piece, preferably one that is

corrected, so there is no distortion of the outer rim when viewing an object. A good lens

that can be purchased cheaply, is an eye piece from a pair of binoculars (7X50 or 10X50).

You can pick these up at second hand markets etc, and they work extremely well.

KNIFE

Any small knife will be fine to use. This will have to be dedicated to the job, as the blade will

be used for heating, scraping, mixing and applying adhesives.

OLIVE OIL & Polish Extender

Cooking grade olive oil will do fine. This oil is used as a coating to hold and distribute the

diamond powder onto your pre-polish and polish laps.

When mixed with Shellite (1 part of olive oil to 40 parts Shellite), you create an excellent

cutting oil extender for both the pre-polish and polish laps. Also, makes a very good cleaner

for the laps. Pour the extender into a small spray bottle (50 Mil), as it will give a better coverage.

Beware of Naked Flames & Use Common Sense

© Copyright 2000

Trevor G. Hannam

Page 18

OVEN

OVEN

A medium size jam tin that is cut out to suit your spirit lamp

to be used as a hot plate. Used for slowly heating your gem

rough to accept dopping wax to transfer onto the dop sticks

REFRACTOL

Available from any good lapidaries suppliers, and is a must

to the amateur faceter for seeing imperfections within a

piece of rough. This oil has a refractive index close to mid

range of most minerals, approximately 1.57. When this oil is

applied (with a small fine artist brush) to the gem rough, it

makes the surface extremely clear. Just like a piece of glass,

Spirit Burner

making it easier to view inclusions. You can also purchase

from a chemist some Clove and Cinnamon oil, as these have

refractive indexes 1.54 and 1.62 respectively and will help you view gem rough that have

lower and higher than 1.57.

SPIRIT LAMP

Almost any type of burner or even a candle will work as a flame heater for heating wax and

transferring, but you will find the alcohol lamp (as viewed above in a home made oven) will

be your best bet, namely because of its a clean flame and heating ability compared to some

other types.

VERNIERS & SCALES

A good pair of metric plastic vernier/callipers with dial

gauge to measure gem stones, a must if you consider going into competitions. Callipers can be expensive or cheap

- its best to get a good pair if possible, though I must admit in the end the pocket will decide the quality.

Not essential, but advantageous is a set of scales for

weighing your finished gem stones. The scales will need

to be able to weigh as low as .001 carat (there is 5 carats

to 1 gram).

1.

2.

3.

4.

MISCELLANEOUS

Soft tissues: The best to use here is soft Sorbent toilet

rolls, and it is a good idea to fix a toilet roll holder close

at hand when faceting.

Methylated Spirits and or Acetone make a good a cleaner

for dop sticks and cleaning of super glues etc.

Pen and Paper: Always keep at hand to write down information when faceting. Don’t try to rely on memory,

notes can always be referred to when required.

A small 4” trim saw would be a good investment, but can

be done without as most stones can be cut directly from

the rough. A small mandrel can be made by an engineer

to take a small blade on the faceting machine. This then is used to cut the mains of

the stone, thus saving the expensive laps.

© Copyright 2000

Trevor G. Hannam

Page 19

CHAPTER 4

PREPARING A PRE-POLISH LAP

PRE-POLISH LAP

Making up your pre-polish lap is very easy. Using a

new copper lap, clean the surface with a tissue

with the extender fluid. Place a couple of drops of

olive oil on your lap, and with a clean tissue wipe it

all over the lap until it is almost dry. You will need

the vial of 1200 mesh diamond powder (pre-polish

powder). Wipe a clean finger over the lap, this will

leave a smear of oil on it. Open the 1200 mesh diamond powder, place the index finger over the top

and invert. Invert back again and lift the finger off

the vial. You will now see a grey coating of powder

on your finger. Place your finger in different spots

over the lap, and then spread the powder as evenly as possible over the laps surface with your finger.

The lap is now prepared, and will last a long time before the lap will need resurfacing with

diamond powder.

Placing powder on the

lap using a clean finger

Preparing your Copper

lap for pre-polishing

Pre-polish

Copper lap

Spreading the mesh

Powder over the lap

© Copyright 2000

Trevor G. Hannam

Page 20

CHAPTER 5

SELECTING THE ROUGH

A

s we are a beginner, lets start with a piece of topaz. Topaz has a good relative hardness, has good refractive index, is nice and cheap and will produce a gemstone of

sparkling brilliance.

CLARITY - clearness

You have a piece of topaz that isn’t a piece of crystal, but has been water worn and is impossible to see through. Wetting this with water will help, but not enough to be able to see

the inclusions and flaws etc. This is due to the refractive index (RI) of the water (1.33) not

being high enough. To be able to view inside readily we need to use a liquid close to the RI

of topaz (1.63). The use of the refractol will do just that (or cinnamon oil). Paint this over

the stone with an artist brush and you will be able to see right through the stone as if it

were a piece of glass.

Look hard into the stone, use a five or ten power eye piece and see if there are any cracks,

inclusions of other minerals, cloud veils from ghost crystals or small bubbles that are probably filled with liquid. Obviously we are looking for a near flawless stone, but as nature will

have it ’Nigh Impossible’. The art of faceting is for you to be able to find the flaws and hide

them if they present a problem. By orientating a gem properly, flaws or inclusions can be

hidden under the girdle facets. Normally though, you wouldn’t bother unless special circumstances required it, like the piece of rough being regarded as a unique piece, sentimental value or having a high price. Usually the stone would be discarded for a better

piece. Also refer Chapter 3 section 3:8 on inclusions.

Now you have mapped out the interior of the rough for possible orientation and maximum

recovery of that stone.

COLOUR

‘C’ Axis

Does the stone you

Fracture

have selected have any

colour zoning in it, or is

Water Worn

Gem Orientated

Rough Topaz

5 to 6º off Axis

it all colour, maybe the

colour is lighter on one

side than the other!

Stones like amethyst,

citrine, sapphire and

blue topaz can have

Gem Orientation

one or more bands of

colour. If the colour is

Colour Zoning within

most important (and

The Gem Material

Cleavage

normally is), the rough

Crystal of

Plane

will have to be orienTOPAZ

tated in a position so

that the pavilion of the standard brilliant when cut is fully within the banding. Some care

however may be needed, so that the pavilion does not protrude past this point of colour

zone as the gem may loose the colour that we are looking for.

© Copyright 2000

Trevor G. Hannam

Page 21

Colour banding should not be confused with Pleochroism, such as in sapphires, which are

double refractive. Sapphires should be orientated along the ‘C’ axis for best colour,

especially corn flour blue, otherwise you may very well end up with a green sapphire. Also

refer Page 10 on Pleochroism.

CLEAVAGE

Topaz has a cleavage plane which may or may not cause you a problem when polishing. If

the piece you have selected is a crystal piece, or shows the cleavage plane easily, then you

have no worries as orientation will easy. If your selected stone is water worn, and there is

no indication of the cleavage plane, I suggest that you just go ahead and orientate the

stone as if there were no cleavage. The chance of placing a stone exactly on the cleavage

line is a thousand to one, and far to much emphasis has been placed on this subject. Even if

you have placed the cleavage on one of the facets to be polished there will be no real

problem as polishing can be done by the hand technique discussed later in the section

under ‘Polishing’.

So, if your piece shows the cleavage (which is 90 degrees from the ‘C’ axis), you would

orientate this piece of rough approximately 5 to 6 degrees away from the axis.

© Copyright 2000

Trevor G. Hannam

Page 22

CHAPTER 6 - THE STANDARD BRILLIANT

T

he first faceted stones happened sometime in the late 14th and 15th century, and

since that time was to be held a secret that was passed from father to son. The nineteenth century found the art of faceting and lapidary clearly available to all amateur and

hobbyists. Today, numerous books are written on the subject, and many clubs are willing to

teach this art.

Cutting the standard brilliant starts with a piece of rough which is rounded. Then a combination of facets are placed in geometrical patterns around the stone to make use of the optical properties of that stone, thus producing a brilliance which is pleasing to the beholder.

TERMINOLOGY

There are 57 facets in the standard brilliant - The crown consists of 33 facets, 8 main facets,

16 girdle facets, 8 star facets and 1 table facet, totalling approximately ⅓ of the total height

of the brilliant. The pavilion consist of 24 facets, 8 main facets, 16 girdle facets, totalling

approximately ⅔ of the total height of the brilliant. In some circumstances the culet can be

cut as a small flat facet to prevent it from fracturing and at times is considered good practice. The maximum girdle width must not exceed 5% of the total height.

Table - Approximately

50 to 60%

1/3

CROWN

Star Facets

Main Facets

Main Facets

Girdle

Facets

Girdle

Facets

Girdle

Facets

Girdle

Facets

2/3

Girdle Width

Maximum 5%

Main

Facets

PAVILION

Main

Facets

Pavilion Point

Known as the Culet

STANDARD BRILLIANT TERMINOLOGY

© Copyright 2000

Trevor G. Hannam

Page 23

CHAPTER 9

DOPPING

O

ne of the most important parts of faceting - Dopping must be done correctly. There’s

nothing worse, especially to a beginner to have his or her gem stone full off at a crucial point because of improper dopping.

DOP STICK SIZE

Select the right dop stick for the stone, this would be approximately 50 to 60% of the size

of the finished article. This will come to you with trial and error, and after a while you will

be able to estimate with some accuracy the correct dop stick for the job.

Once you have orientated the stone correctly as per Chapter 8, you will have to grind a

small flat surface on the stone to accommodate the dop stick. This is done by placing the

coarse lap (220 Grit) onto the faceting machine’s master lap.

Turn the tap on the water container to the on position so a reasonable flow is running onto

the centre area of the lap surface. Set the machines speed to high.

Bring the stone to the surface of the spinning lap and using light pressure, proceed to cut a

small flat surface for dopping.

Using a piece of toilet tissue, wet it with methylated spirits and clean the ground area

(don’t forget to turn off the water and the machine, leave the lap on the machine for the

next phase of faceting). Paint this cleaned area with a very thin film of dop help (the one

you have made). The dop help will act as a binder for the transition of wax to metal

FIXING STONE TO DOP STICK

There are some stones that are quite heat sensitive, and it is best to use the modern day

epoxies, such as ‘Tite On’ and/or the super epoxy called “Weld It” which fully cures in 4

hours.

Set up the heater oven, and place the stone, painted side up onto the oven’s top. Place the

spirit lamp underneath the oven and light.

Gauging the right amount of heat will come to you only with experience, but as a guide line,

keep lifting the stone with your fingers until you find you can no longer hold it for more

than a couple of seconds, this is approximately the right temperature.

Whilst the stone is warming, place your selected dop stick in one of the dop stick holders

you have made.

Heat the end of the dop stick by placing the end into the flame. When reasonably hot bring

the faceters wax into the flame with the dop stick, and melt some of the wax onto the surface to form a small ball of melted wax. During this time you may have to keep the dop

stick moving around to retain the wax on the end. Continue to heat until the wax just catches fire (this is the right temperature for fixing).

Immediately place the waxed end of the dop stick onto the surface of the stones painted

side. Lift the combination from the oven and gently , before it cools, move the stone

around until it’s in the right position. BE VERY CAREFUL HERE AS THE STONE IS QUITE

WARM! - You can now see and appreciate the benefits of using dop stick holders

Put the dopped stone aside to cool down and prepare your faceting machine for the

next phase of your work.

© Copyright 2000

Trevor G. Hannam

Page 24

USING EPOXIES - Dopping

Epoxies offer the faceter a simpler alternative to that of using wax. Both epoxies and superglues (401 Cyanoacrylate) are very reliable and have the advantage of being able to be

worked at room temperatures. They also offer the faceter, superiority from premature failure due to heat build up causing the stone to shift while you are transferring from one dop

to another and save many a burnt finger to which I can readily relate too.

Epoxies and Cyanoacrylates can be troublesome however when trying to remove the adhesive from the stone. M.E.K. thinners and or Acetone will help release most epoxies and superglues. Heat still is the best option for prying the gem stone away from the dop stick, and

works very well; another method is to place into the freezer for 15 to 20 minutes and then

pry apart, however this may not always work.

Using Epoxies - make sure the ground flat area on your stone has been cleaned with methylated spirits. Clean the head of your dop stick thoroughly too. You may even have to use a

piece of wet and dry silicon carbide paper or similar to get it clean.

Using ‘Tite On’ or ‘Weld It’ epoxy, mix equal parts of base and hardener together. Mix

extremely well. Place a small amount onto the dop stick and press onto the flat area of your

stone. Set aside for at least 1/2 hour for best results.

Super glues are not really recommended for initial stone dopping, unless a stone has

fallen off the dop whilst cutting where it can easily be glued back on. I have found superglues are far better used in transferring of dopped stones, and it is here that the adhesive

works best.

In summary wax has the advantage over epoxy with quick drying times as does superglues,

which means you could be faceting in just a few minutes after dopping. If you can wait,

then I recommend you use epoxy - it’s up to you!

© Copyright 2000

Trevor G. Hannam

Page 25

CHAPTER 8 - ROUNDING

M

ost teachers of faceting begin with cutting the crown first, followed by the pavilion,

and has been taught this way for generations. Here we do the pavilion first, with the

crown and table facets being last. This technique allows for the amateur and professionals

to be able to estimate more accurately the depth of material left for the crown, have better

control of placing and hiding flaws under facets, easier transferring of the pavilion to crown

in the transfer jig and better control of placements of facets. The down side of this technique however is that the table facet (the last one to be cut) has to be ‘sat’ onto the star

facets and meet at every point. This can be considered good practice for when you venture

into the art of ‘MEET POINT FACETING’.

SETTING STONE TO QUILL - Rounding to form the ‘Girdle’

Set your index wheel of your faceting machine into free wheel, and protractor to 90°. Place

your coarse lap (220 Grit) onto the master lap and do the nut up firmly .

Now place the dop stick with the dopped stone on it into the chuck of the quill. Some machines, such as the Hall’s machine have specially shaped dop sticks that fit directly into the

quill. If your machine does not have this facility, just place the dop ⅔ of the way into the

chuck. Tighten up the chuck firmly.

Lift off the gate of the swarf tray, undo the coarse height adjusting wheel to free up the

head assembly and carefully lower the head so that the stone on the end of the dop stick

rest lightly on the edge of the coarse lap, re-tighten coarse adjuster - refer diagram below.

Wax

Swarf Tray

Dop Arm (Quill)

Locking screw

Gem Stone

Dop Stick

180 or 220 Grit Lap

Master lap

Gem Stone is Lowered so as to

Just Touch the Lap

Rounding the Gem Stone to form the ‘Girdle’

Now raise the stone slightly using the micro height adjuster to lift it off the lap. Start the

machine at fast speed, turn on the water at a reasonable rate so that it flows outward from

the centre of the lap. Slowly lower the quill with your micro height adjuster until you hear it

grinding against the lap.

Rotate the gem/quill assembly slowly in an anticlockwise direction or against the rotation

of the lap. Until you have gained experience in ‘rounding’, stick to the anticlockwise direction otherwise the gem may be grabbed by the lap and thrown off.

Keep turning until you hear a change in the grinding. This happens as you near the bottom

of the stop (the stop is where the cutting reaches its maximum depth, designed so that you

can’t cut any further than where you had the angle set).

© Copyright 2000

Trevor G. Hannam

Page 26

Lift the stone off the lap and have a look at what is happening. You will notice that some

parts of the stone have been ground, and maybe some parts have not, but at this time you

should be able to see some effect of the rounding.

Continue the technique of lowering and grinding until it begins to look reasonably round.

Always stop and have a look at what is happening until you feel comfortable with what you

are doing.

Continue with your rounding by lowering and cutting until you hear the action of the cutting

stop. Check your progress until you think its right, a small pair of plastic verniers are handy

for checking out of round.

Rounding is an art, and will require a bit of practice, the old saying of ‘near enough is good

enough’ is not on here, and you must strive to get it perfect. Any variation, no matter how

small can cause errors in you facet sizes which progressively get worse. Even the best of us

have difficulties in getting it right, so don’t feel put off - PRACTICE MAKES PERFECT

If you are having difficulties with rounding, it will be because of using too much pressure at

parts causing over cutting. To solve this problem I suggest you recut the stone in steps using

1200 Grit Pre-polish Lap (Refer Chapter 4 & Next Page - Pre-polishing). We do this by using

the index gear set at 2 indexes every cut - using a 96 index wheel will produce the 48 facets

needed.

Leave the assembly in the same position, place your index gear on 96 and lower the quill

until cutting recommences, and cut to the stop, and then go to index 2, there should be no

need to lower the quill again as you now have established the depth,. Repeat for all other

indexes - 4,6,8,10,12, etc until you are back at index 96. Always try and use the same pressure, this will alleviate the problems over cutting somewhat (pushing past the stop).

When you have finished you should have 48 tiny parallel facets as shown in diagram below

(this now called the ‘girdle’).

Don’t forget to turn your water off when you have finished

Standard Round

Step Cutting Round

48 Tiny Parallel

Facets

Wax/Epoxy

Dop Stick

ROUNDING OF

THE GEMSTONE

Dop Stick

You have now formed the girdle of your gem stone, it was hard but we got there. Raise

your quill away from the machine, and remove the coarse lap and place it in its holder.

© Copyright 2000

Trevor G. Hannam

Page 27

Now it’s a good idea to check for flaws and inclusions that you could have missed when

viewing the rough. Paint a little refractol on the surface and do another check. If you see

some inclusions or flaws you must try and hide them under the girdle facets, or maybe they

will cut out when the pavilion is done. All this has to be decided here and now as to whether you should go on or not.

Clean everything up, including your gem stone still in the quill. Cleanliness is most important during these change over of laps. Make sure you pay close attention to cleaning

where your hand rests up against any part of the swarf tray. Any contamination from here

on can ruin all your work let alone the laps.

Next we put on the pre-polish lap (refer Chapter 4)

We Do Not Use Water Yet on This Newly Prepared Lap

PRE-POLISH - GIRDLE

Lower the quill until it just touches the lap as before. Lift the quill from the lap and start the

machine. Only use slow to moderate speed, we do not want to throw off all your diamond

powder.

Now! Depending whether you are doing it the’ round’ way or the faceted way for the girdle, it’s best to use very light pressure until you understand what is happening. If rounding

the girdle, the index wheel will be in free wheel and should be turned against the rotation,

which is normally anticlockwise. In the faceted girdle you will be starting on index 96 and

progressively indexing every 2 indexes until you have completed all facets.

Remember we are only trying to remove only the scratches from the last lap, and newly

prepared laps cut fast. There will be no need to remove much material. When the facet/s

look satiny all over the facet/s are done. If the lap seems too dry, add a couple of drops of

cleaner or polish extender to it and spread with a finger. This may get a bit messy with the

oil, but that’s what we have the toilet tissue for. Always clean the stone every time you

need to look at it. Check to make sure you have the girdle as round as you can get it. Ok

that done, lift the quill aside and put away your pre-polish lap.

You may have noticed that there was no need to use water at this time, this is because the

gem is being used to push diamond into the copper lap, just like when you rolled the coarse

lap. Later though, this wont be the case, as the diamond is pushed in, the oil becomes

fouled and forms a barrier making it more difficult to use, it’s here that the lap is washed

with hot soapy water until all of the swarf is gone, and from that stage on you will be using

water as the lubricant. By doing the lap this way, you are getting the most benefit from the

pre-polish powder, and will be able to do 3, 4 or more gem stones for a measly amount of

diamond powder.

Your next step is cutting the pavilion.

© Copyright 2000

Trevor G. Hannam

Page 28

CHAPTER 9 - CUTTING THE PAVILION

EIGHT MAINS COMPLEX

Set the new angle on the index head to 42° as this is the angle designed for the pavilion

mains of the gem topaz. Reset the index to 96 if you have not done so.

Place the coarse lap on the master lap (don’t forget to clean everything prior). Now you are

ready to cut what is known as the ‘Eight Complex’. That’s the first 8 facets, and it’s best to

cut them opposite to one another, this has the effect of reducing progressive error which

must be avoided.

Using your coarse adjuster, lower the head assembly so that the gem stone just touches the

lap as before, and lock into position. Turn on the machine, water at a moderate rate and

lower the quill by the height adjuster.

When cutting or polishing, always use a sweeping motion across the full surface of the lap,

by doing this you are preventing lap wear (forming a groove), and preventing harsh scratches and striations on the gems surface.

Cut the first facet to the stop and have a look. You will notice a small facet starting to cut

into the gemstone. Lower the quill a little more and again cut to the stop.

Now! Lift the quill and change the index to the complete opposite no, that is 48, and again

cut this facet to the stop.

see a large chisel point starting to form the pavilion. So far, so good. Go ahead and cut the

other six main facets in their opposite numbers - 24, 72, 60, 36 and 84.

Familiarise yourself to what is happening and you should be seeing the mains forming to a

perfect point . Continue with same sequence - lower a little, cut and look until the mains

come to a perfect point (check that you do not have any chisel points at the pavilion point

as these will cause errors when doing the girdle facets). This point of the pavilion is now

commonly called the culet.

You have just completed the roughing in of the first major facets of the gem stone - Well

Done! Now it’s time to change over to the pre-polish lap. Again lift the quill away from the

lap. Put away the coarse lap and clean the machine as before. Make sure that you also

clean the gem stone and quill with toilet tissue wetted with methylated spirits. It is very important that this is done to prevent cross contamination from coarser grits.

Chisel Point Facet, Does not meet to a point - All Facets Meet To a Point

ORDER OF CUTTING

96

84

8

72

8 Mains

42º

5

4

3

6

60

Pavilion

12

1

Culet

24

Topaz

THE 8

COMPLEX

7

2

Wax/Epoxy

36

48

Dop Stick

Index No’s

© Copyright 2000

Trevor G. Hannam

Page 29

Put on the pre-polish lap as before - you should be an old hand at this now.

Again readjust the quill so it just touches the lap, and repeat all the procedures as before. You may find when doing these larger facets that a couple more drops of extender will

be required Remember that the pre-polish cuts extremely fast when new, and requires only

a little pressure to achieve that satiny look. Make sure that all facets come to the exact

point (no chisel points) and that no scratches can been seen under a 25 or 40 watt lamp. You have now completed the 8 mains of the pavilion. All the other facets on the pavilion

will now be done on the pre-polish lap so it can be left on the master lap.

CUTTING GIRDLE FACETS

Cutting the girdle facets are a little harder than cutting the 8 mains and require “cut a little,

look a lot technique”. Set the index to 3 and the angle to 44°, this is the girdle facet angle

for topaz and is normally 2° more than the mains. These girdle facets extend to about half

to two thirds of the way to the culet, and meet adjoining facets in the centre on the main

facet, there being sixteen of them. Refer below:Relubricate the lap with cleaner/extender and start your machine, assuming you have

already made the necessary coarse adjustments for the new angle .

93

ORDER OF CUTTING

3

9

87

2

Pavilion

1

9

16

81

16 Girdle

44º

15

10

15

8

75

Culet

21

5

Topaz

6

7

69

27

11

14

33

63

13

12

4

Wax/Epoxy

3

Dop Stick

39

57

51

45

Index No’s

THE 8

COMPLEX

Again bring down the quill using the micro height adjuster until the gem stone just touches

the lap. Cut a little and then have a look to see what is happening.

You should start to see the beginnings of a small triangle. Now repeat this step on the index

number 93.

You now should have something like two triangles approaching one another as shown on

the diagram next page. Lower the quill a little more and repeat the exact same procedures

as above.

© Copyright 2000

Trevor G. Hannam

Page 30

You will definitely notice the two triangles

cutting higher up towards the culet and closer

together at the base line. If everything is OK,

just continue repeating the above until the

facets meet dead centre of the mains as

shown on the diagram lower right. You will

50% +

also notice the height has automatically

adjusted to about ½ - ⅔ way up to the culet.

Now what you have just done is establish the

correct adjustments for the rest of the girdle

facets, so don’t alter height or any other

adjustments. Again you will have to work the

opposite indexes as you did with the mains.

The next set to do will be indexes 45 - 51.

Use the same procedures as before, and you

then will have done another pair. From there

you go on to do indexes 21 - 27, 69 - 75, and

when these four pair have been done you can

Same Height

then go ahead and do the next four pair, but

these will be easier as all that has to be done is

to meet the points of the adjacent pairs. The

indexes are 9 - 15, 33 - 39, 57 - 63, and 81 - 87.

Main Facet

3

93

Congratulations! and well done, you have just

successfully cut the whole pavilion.

Centre

Take off the pre-polish lap and put it away,

clean the gem stone and quill thoroughly with a tissue dampened with metho. These bits

will be covered with oil, copper oxide and some diamond powder that hasn’t been rubbed

in whilst cutting. While your at it clean around the swarf tray, especially paying attention to

the area where your hand touches. You cannot afford to get contamination on the polish

lap or you can considered it ‘Buggered’. The cost of re-lathing a lap today is not all that

cheap.

© Copyright 2000

Trevor G. Hannam

Page 31

CHAPTER 10 - POLISHING

P

olishing; an art in itself - Pro’s and amateurs alike will tell you that cutting a stone is

relatively easy compared to polishing, and can be considered to be the most important part of faceting, and so it is. Unless you get it right it just won’t do. Gems that have

microscopic scratches, grooves and lap striations (due to polishing in one spot on a turning

lap) will loose a lot of brilliance. Light reflection requires a good polished surface. If light

hits a good polished surface it is totally reflected, but if it strikes a poorly polished surface,

light will be sent in all direction, most of which will be lost outside of the gem thus producing a gem of less brilliance that looks hazy or fuzzy, so it stands to reason that a good polish

is essential for obtaining a gem with lots of brilliance and scintillation. You must always

strive for perfection in polishing, because in the end it will definitely pay off.

Today there is an arsenal of combinations that use different laps and agents for polishing, but non better than that of the old reliable tin lead (60/40 solder) and 50,000 diamond powder. True enough, there are times that it will not work on a gem that seems to

defy all combinations, and that is where at times hand lapping can come into its own. This

has saved my bacon many a time, and it is worth spending some time on it, so you too can

acquire a technique of your own (discussed later).

Ah!

Perfect

One of the main advantages of using diamond

powder compared to other

combinations such as Linde

A and tin lead is that diamond powder does not

have a tendency to ‘ball’

and cause scratching on

the polished surface of the

gem. Therefore, the lap

does not have to be scored

as required by other combinations. This lap is also a

dry lap as no water is used

during the polishing stages

and is one hell of a lot less

messy, and very economical to use.

IF AT FIRST YOU DONT SUCCEED - TRY, TRY AGAIN

A saying worth its weight in gold. Don’t give up, faceting is truly a wonderful hobby.

© Copyright 2000

Trevor G. Hannam

Page 32

Light Rays

TOPAZ

Not

Polished

Good Polish

Total Reflection

Lap Striations

Polish Scratches

Lap Contaminated

Deep Scratches

Olive oil (as used in the polish extender) is used for preparing the polish lap as diamond

powder has a great affinity for oil.

Polishing is done in the reverse order of cutting, that is girdle facets first followed by

the mains. The reason for this is that diamond powder is an abrasive polish, and therefore

cuts a little when polishing, which causes the facets to be over cut. When you come to do

the girdle facets, you will notice they ride up on each other due to this over cutting, so

when doing the main facets you will notice the facet cutting back towards the true girdle

line.

12:1 PREPARING POLISH LAP

Put on the tin/lead lap (polishing), and clean the surface with the extender thoroughly. Using a piece of toilet tissue, wipe the surface dry.

You may notice that the lap appears greasy looking, and you would be right. That thin film

of olive oil left on the lap is the base to which the diamond powder will adhere.

Now’s the time to get out the 50,000 mesh diamond powder. Unscrew the top off the

vial, wipe a clean finger across the lap (this will leave a small smear of oil on your finger),

© Copyright 2000

Trevor G. Hannam

Page 33

place the finger on top of the vial and invert. Invert back again and wipe this grey

powder which has adhered to your finger

over the surface of the lap as thoroughly as

you can. This process should theoretically

polish your whole stone, but in practice

doesn’t, this is mainly due to the oxides

from the tin and lead fouling the lap.

Inverting Vial For

Powder to Stick To

Finger

Placing Powder On

The Lap Using a

Clean Finger

Preparing Your

Tin/Lead Lap for

Polishing

Tin/Lead Polish Lap

Spreading Powder

Over The Lap

© Copyright 2000

Trevor G. Hannam

Page 34

POLISHING GIRDLE FACETS

Set the index wheel to index 3 if you have not already done so, and leave the angle as it was

(44°). Lower the quill with the coarse height adjuster as before so that it just touches the

lap and tighten into place. Lift the quill aside and turn the faceting machine on to low

speed. Using the micro height adjuster raise or lower the quill until you can just hear (or

feel) the gem stone touch the lap, and then lift off again. Now disconnect the stop by

setting the angle to around 25° or so. By doing this you have, relieved pressure from the

angle stop so the head assembly can’t be pushed, stressed or bent out of shape by pushing

past the stop when raising of the quill is required. We certainly cut to the stop, but never

polish on the stop. Until you are thoroughly conversed with cutting DON’T DO IT.

Put the gemstone against the lap gently, and work it across the surface for approx

two seconds. Lift the quill up, clean the facet with a piece of tissue, and check to see how

it’s polishing. The girdle facets depending on the size, should only take approximately 5 seconds to polish. Hmmm! It doesn’t look right, only the top appears to be polishing. WHAT TO

DO. By lowering a very small amount with the micro height adjuster, you will be altering the

contact area of the polishing so that the bottom half comes into better contact. A good

point to remember: If it’s high - lower height — if it’s low - increase height

Now try again for a second. Yes, that’s much better, we now have full

Lower Mast Assembly

contact of the surface.

Never polish longer

than several seconds at

a time as this causes a

heat build up in the

gem, and may cause

the stone to shift.

POLISHING & LIGHTING

Now! Is that facet really polished. Can you

‘SEE’ that facet clearly.

Lets look at that light

you are using. You’re Lowering the Mast Assembly pushes the gemstone forward which puts the unpolished facet into

better contact with the lap surface.

what? Using a 60 watt

globe. No! No! No ! You

may very well be ‘blinding yourself’ with the illumination.

40 Watt Bulb

A few pointers on using lighting before you go any furMaximum

ther:

The best lighting you can use is a single 40 Watt standard clear household globe or 12 Volt 21 Candle power.

Preferably with a dimmer control fitted. I have found

by experience all the fancy lights and high wattages

are a big mistake. A light that is too bright, actually

masks the scratches so that you cannot see them.

Eye Looks For

Polished Surface

© Copyright 2000

Trevor G. Hannam

Page 35

What you are looking for are shadows across the scratches. Not a brilliance that nearly

blinds you, and gives you severe eye strain. As you become more familiar with the lighting

you will understand the logic and reasoning behind using very low wattages. Try to get the

reflection of the filament on the facet, and as sure as you are reading this, the scratches if

there will jump out and grab you. Always try and go for perfection when polishing and you

will not be sorry afterwards

Wow! The first facet is polished and completed. Congratulations, but don’t get too cocky,

we've got a long way to go. Go ahead and do the rest of the facets as outlined (you do not

have to do opposites when polishing, as they are already cut and set). Indexes - 3, 9, 15, 21,

27, 33, 45, 51, 57, 63, 69, 75, 81, 87 and 93. Finished! Good now reset the machine to do

the main facets (that’s the eight large facets - 8 complex).

Using the angle 42°, set up and start polishing as you did for the girdle facets. Don’t forget

to disconnect the stop when set up is complete. We do not want to stress the quill.

You will notice as you are polishing the mains, the point will cut down to the girdle line to

meet as three points, and that the polishing of the facet will take longer as the facet is larger.

If you find the polish is loosing its ability to work well. Go ahead and redo the polish lap as

outline in Chapter 10

When you have completed the pavilion, clean the gemstone, and quill with toilet tissue and meths and then take out the dop stick from the quill.

NOTES:

© Copyright 2000

Trevor G. Hannam

Page 36

CHAPTER 11 - TRANSFERRING

Locking Screws

Wing Nut

Pressure Plate

Dop Stick Holders

Wing Nut

Dop Stick Transfer

Alignment Tool

Can be made cheaply

Tension Spring

Dop Stick Holders

TYPICAL TRANSFER BLOCK

‘V’ Slide

A

bove is a typical transfer jig, and is a must for transferring the pavilion of the gem

stone to face about so that the crown can be cut. It is an extremely efficient and accurate way to transfer from one dop stick to the other without losing alignment of facets. In

faceting you must have a good transfer block. These can be checked by putting in a couple

of the same size dop sticks in the holders, and bringing them together. Run a finger nail

across the join, and if your nail digs in at the junction at one point and not the other side,

you should have an engineer check out the alignment of the transfer block - or check the

dop sticks for bending.

A dop stick alignment tool and/or a transfer jig with adaptors makes life easier for aligning

the main facets up.

© Copyright 2000

Trevor G. Hannam

Page 37

CLEANING & PREPARING DOPS FOR TRANSFER

Clean the pavilion with a little meths and toilet tissue. Brush a little dop help on the gem,

and I mean a little. If you use too much dop help, it takes a long time to dry effectively, and

this will cause the gem to shift due to the longer heating time required to dry it.

Place the dop stick into one of the transfer blocks (normally the left hand side) and then

select the opposite dop, which will be a cone shaped to fit the pavilion, and approximately

half to three quarters diameter of the gem stone. Melt a small amount of wax into the cone

of the dop stick, and when cool place it in the other side of the transfer block.

Pressure Plates

Retaining Nuts

Transfer Block

Gem Stone Pavilion

Melted Wax on

Cone of Dop Stick

TRANSFERRING the DOP STICKS

Transfer dopping - the idea is to heat the dop stick (not the one with the gem stone in it), to

The pressure plates are adjusted so that the dop sticks holders can slide in or out, but firmly.

melt the wax while slightly heating the gem stone on the other dop, yet not allowing the

gem stone to get too hot to soften the wax (which will cause the gemstone to shift). When

the heat is just right, you slide the heated dop stick into the other one holding the gem

stone, so the wax will grab and hold.

Sounds terrible! But not all that difficult once you have had a few goes. The best way to

learn, would be to practice transferring a piece of rough topaz from one dop stick to the

other.. OK! The real thing now - With spirit lamp lighted and flame settled, begin heating

the dop stick close to the end near the wax (remember not the one with the gem stone in

it). As it begins to melt.

Slightly apply the heat to the gem stone whilst not losing the heat from the melted wax. As

the wax starts to get very runny and catches fire, quickly press the heated dop up against

the gem stone. Speed here is critical, otherwise the transfer wont succeed. If the wax is allowed to cool by loosing its heat, it will not grab the stone (refer diagram next page).

© Copyright 2000

Trevor G. Hannam

Page 38

Melting Wax

Gem Stone

Pavilion Painted

With Dop Help

This Dop Stick

Is Normally Locked

Into Place

Spirit Lamp

Melted Wax is

Pushed into the Gem

Stone

This Dop Stick

Is Normally Locked

Into Place

Right Hand

Dop Stick

Slid Across

This may sound like you need a medical degree, or have eight hands to do the job, but it is

relatively easy, and will come to you with patience and practice.

Let the whole assembly cool down for ten to fifteen minutes (have a smoko break) and take

out the assembly from the transfer jig by releasing and removing the pressure plates, and

undoing any locking screws in the slides as above. Now test the join. The assembly must be

firm, don’t use too much pressure as waxes wont take it, and as sure as God was a little

boy, it will come apart.

SUPER GLUE - (Cyanoacrylates) Loctite 401 a one-part instant adhesive made for porous,

difficult to bond materials and has good gap filling abilities. High strength bonds wax to

brass, alloy or steel with very fast fixing times of 5 to 30 seconds. Full cure 10 to 12

minutes. Loctite 406 is another favourite that can be used but has no gap filling abilities, so

it is important if using 406 to get a close mated surface.

Set up the gem stone as per section 13:1, but do not apply any dop help onto the gem

stone. We do not want the wax to grab and hold in this application. Apply heat slowly to

the coned dop stick (not the one with the gem stone) until the wax softens and begins to

melt.

Remove the heat and push the dop stick into the gem stone. Lock up the wing nuts and

© Copyright 2000

Trevor G. Hannam

Page 39

let cool down. This will only take a couple of minutes.

Loosen the wing nut holding the cone dop only and pull away from the gem stone. A small

force may be required here, but will normally come away easily. You will see and impressed

version of the gem stone into the wax.

Apply a very small amount of superglue to the impression. Do not overdo the superglue as

too much will cause a weak joint. Press the dop stick hard against the gem stone and lock

the wing nut. After a few minutes it is completely cured and you can now follow the next

procedures, as removal etc applies to all forms of dopping.

TRANSFERRING WITH EPOXY

Today epoxies make life easier, as they alleviate the problems associated with melting wax

shifts. Prying dop sticks apart or away from the gem stone requires the same technique

used in wax transferring. The only disadvantage of using epoxies is there setting time. As

with wax and super glues, epoxies use exactly the same technique, except that heat is not

used for fixing of the gem stone or the dop stick.

SEPARATING DOP STICK FROM GEM STONE

‘Without alignment tool’ If the machine you have has dop stick locating areas built into the

transfer block and quill, there will be no need to use the alignment tool, as the alignment of

the dop sticks and transfer is done automatically.

Next heat up the dop stick (Geeze! Not the one you just transferred, THE OTHER ONE), until

the wax softens enough to remove. This also takes a little practice, as you are trying to heat

the one side to soften the wax just enough to remove it without transferring any heat at all

to the other side.

Twist and Push

Until Releases

Heat Until Wax

Softens

Hold Dop Stick Steady

Spirit Lamp

Very carefully scrape away the wax and clean the gem stone with toilet tissue moistened

with meths. Put the transferred dop stick into the quill, and locate the alignment notch and

tighten the quill nut or screw firmly.

© Copyright 2000

Trevor G. Hannam

Page 40

NOTES PAGE:

© Copyright 2000

Trevor G. Hannam

Page 41

CHAPTER 12 - CUTTING THE CROWN

P

ut your transferred dop into the quill and lock into place if you have not already done

so. Adjust the angle of the protractor to 39° (this is the angle for the crown mains),

and place the index gear onto 96.

Place the coarse lap (220 grit copper lap), onto the master lap and lock into place. Adjust

the coarse height adjuster as before, to lower the quill and gem stone so that the gem

stone just touches the lap, and lift off.

Again we are cutting the 8 complex, but there is a difference here, as the cutting will only

progress to a certain level to form what is known as the girdle facet. The girdle cannot exceed 5% of the total height of the stone.

THE GIRDLE

The girdle can be round or stepped cut as previously discussed in Chapter 8, under

‘Rounding’. The girdle can be no more than 5% of the total height of the finished gem

stone. Well now! You might be thinking, how the hell do I do this when all I’ve done is the

rounding and the pavilion? Good question, and it so happens that there is a simple formula

for working this out.

To arrive at the maximum total girdle width, multiply the diameter of the stone (this is after

rounding), by .034 Lets say for example that you have a 10 mm stone after rounding. Multiply this by .034 and you have 0.34 mm. This formula gives you an approximate girdle width

for a standard brilliant of 1/3 crown x 2/3 pavilion.

You may have noticed, the girdle wasn’t polished. In competition it’s a must, but I for one

like the frosted girdle look, it’s up to you. Polishing should be done prior to transferring.

THE MAINS

Switch on the machine, fast speed, and water at a moderate rate (just fast enough to keep

the lap wet when turning). Start cutting the mains as before, Chapter 9, using a sweeping

action across the lap. Keep lowering (using the micro height adjuster), and cutting until you

get to approximately 5%. The reason for stopping At 5% is that you still have to cut on the

pre-polish, and this will take up approx 1 to 2% of the width, leaving you around 3%. Once

you have cut this first facet to the set level, you

Maximum Girdle no longer have to re-adjust the machine for the

Width 5%

other seven facets.

Go ahead and proceed with the opposite index:

- 48, and then 24, 72, 12, 60, 36 and 84. You

may find that when you are cutting the eight

main facets, that the facets may or may not

reach to a point. Do not worry if the later is the

case, as the star facets, and the table have yet

to be done. Once the eight mains have been

completed, stop the machine, clean the area

thoroughly. Don’t forget the stone.

The 8 Mains

Take the pre-polish lap and give it a good clean

by scrubbing with detergent and water. The

1200 grit diamond powder has been pushed

into the copper lap after all that cutting,

© Copyright 2000

Trevor G. Hannam

Page 42

And is ready for using water only as the lubricant.

Place the pre-polish lap on the master lap, and lower the quill so that the gem stone just

touches the lap, lift off and start the machine (moderate speed only). You know the drill!

Repeat all the above steps for doing the mains, and pay particular attention to the facets

for that satiny finish.

You may also find that the pre-polish lap cuts extremely fast, so watch that you do not cut

too deep. The girdle thickness has to be even all way round, otherwise progressive error

will result. This may not be apparent until the girdle facets are done.

OK! You have finished the crown mains. Dammed good work! You have come a long way

since first putting on the stone to the dop stick. Now come those girdle facets, so lets go.

CUTTING THE CROWN GIRDLES

Leave the pre-polish lap on, as this is the lap that you will use, and be cutting the girdle facets. Reset the angle of the protractor to 44°. The angle for girdle facets is normally plus 5°

of that of the mains.

Readjust the machine height so that the gem stone just touches the lap. You should