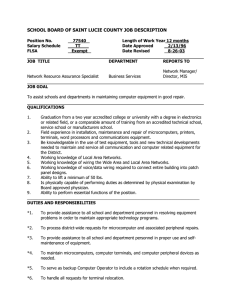

MR453X7917B000

advertisement