Laboratory Report

advertisement

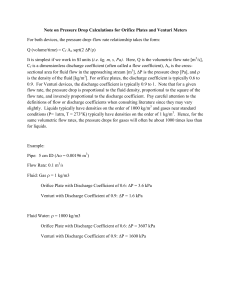

Introduction :

Bernoulli's law states that if a non-viscous fluid is flowing along a pipe of varying cross section,

then the pressure is lower at constrictions where the velocity is higher, and the pressure is

higher where the pipe opens out and the fluid stagnate. Many people find this situation

paradoxical when they first encounter it (higher velocity, lower pressure). This is expressed with

the following equation:

p

v2

z h * Constant

g 2g

(1.8)

Where,

p

= Fluid static pressure at the cross section

ρ

= Density of the flowing fluid

g

= Acceleration due to gravity

v

= Mean velocity of fluid flow at the cross section

z

= Elevation head of the center at the cross section with respect to a datum

h* =Total (stagnation) head

The venturi meter consists of a venturi tube and differential pressure gauge. The venturi tube

has a converging portion, a throat and a diverging portion as shown in the figure below. The

function of the converging portion is to increase the velocity of the fluid and lower its static

pressure.

A pressure difference between inlet and throat is thus developed, which pressure

difference is correlated with the rate of discharge. The diverging cone serves to change the

area of the stream back to the entrance area and convert velocity head into pressure head.

In metering practice, this non-ideality is accounted by insertion of an experimentally determined

discharge coefficient, Cd that is termed as the coefficient of discharge. With Z 1 = Z2 in this

apparatus, the discharge coefficient is determined as follow:

Cd

Qa

Qi

Discharge coefficient, Cd usually lies in the range between 0.9 and 0.99.

Objectives :

1.

To determine the discharge coefficient of the venturi meter

(1.20)

2.

To measure flow rate with venturi meter

3.

To demonstrate Bernoulli’s Theorem

Procedure :

Part 1: Discharge Coefficient Determination

1. The General Start-up Procedures was performed.

2. The hypodermic tube from the test section was withdrawed.

3. Discharge valve to the maximum measurable flow rate of the venturi was adjusted.

4. After the level stabilizes, the water flow rate using volumetric method was measured and

the manometers reading was record.

5. Step 4 with at least three decreasing flow rates was repeated by regulating the venturi

discharge valve.

6. The actual flow rate, Qa from the volumetric flow measurement method was obtained.

7. The ideal flow rate, Qi from the head difference between h1 and h3 using Equation 1.18

was calculated.

The chart of “Qa vs Qi” was plotted and finally obtain the discharge coefficient was obtained,

Cd which is the slope (c)

Part 2: Flow Rate Measurement with Venturi Meter

1. The General Start-up Procedures were performed.

2. The hypodermic tube from the test section was withdrawed.

3. Discharge valve to the maximum measurable flow rate of the venturi was adjusted.

4. After the level stabilizes, the water flow rate using volumetric method was measured and

the manometers reading was record.

5. Step 4 with at least three decreasing flow rates was repeated by regulating the venturi

discharge valve.

6. The venturi meter flow rate of each data were calculated by applying the discharge

coefficient obtained.

7. The volumetric flow rate with venturi meter flow rate were compared.

8. Data Analysis:

Throat Diameter, D3 (mm)

16.0

Inlet Diameter, D3 (mm)

26.0

Throat Area, At (m2)

2.011 x 10-4

Inlet Area, Ai (m2)

5.309 x 10-4

g (m/s2)

9.81

ρ (kg/m3)

1000

Part 3: Bernoulli’s Theorem Demonstration

1. The General Start-up Procedures were performed.

2. All manometer tubings are properly connected to the corresponding pressure taps and are

air-bubble free were checked.

3. Discharge valve to the maximum measurable flow rate of the venturi was adjusted.

4. After the level stabilizes, the water flow rate using volumetric method was measured.

5. The hypodermic tube (total head measuring) connected to manometer #G was slided gently,

so that its end reaches the cross section of the Venturi tube at #A. Wait for some time and

the readings from manometer #G and #A were noted down. The reading shown by

manometer #G is the sum of the static head and velocity heads, i.e. the total (or stagnation)

head (h*), because the hypodermic tube is held against the flow of fluid forcing it to a stop

(zero velocity). The reading in manometer #A measures just the pressure head (hi)

because it is connected to the Venturi tube pressure tap, which does not obstruct the flow,

thus measuring the flow static pressure.

6. Step 5 for other cross sections (#B, #C, #D, #E and #F) was repeated.

7. Step 3 to 6 with three other decreasing flow rates were repeated by regulating the venturi

discharge valve.

8. The velocity, ViB was calculated using the Bernoulli’s equation where;

Vi 2 g (h8 hi )

9. The velocity, ViC was calculated using the continuity equation where

Vi_Con

=

Qav / Ai

10. The difference between two calculated velocities were determined.

Result :

Part 1: Discharge Coefficient Determination

Qav

hA

hB

hC

hD

hE

hF

h A - hC

Qi

(LPM)

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

(m)

(LPM)

12.15

131

126

90

113

118

123

0.041

11.69

11.93

138

133

99

120

124

130

0.039

11.40

11.72

152

147

115

136

139

145

0.037

11.11

11.11

173

168

136

157

160

166

0.037

11.11

10.22

209

201

178

195

198

203

0.031

10.17

Part 2: Flow Rate Measurement with Venturi Meter

Qav

hA

hB

hC

hD

hE

hF

(LPM)

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

12.15

131

126

90

113

118

123

11.93

138

133

99

120

124

130

11.72

152

147

115

136

139

145

11.11

173

168

136

157

160

166

10.22

209

201

178

195

198

203

Qav(LPM)

hA - hC (m)

Qi(LPM)

Calculated Flow Rate (LPM)

Error(%)

12.15

0.0041

11.69

12.04

0.91

11.93

0.0039

11.40

11.75

1.51

11.72

0.0037

11.11

11.45

2.30

11.11

0.0037

11.11

11.45

3.06

10.22

0.0031

10.17

10.48

2.54

Part 3: Bernoulli’s Theorem Demonstration

Cross

Section

Using Continuity

Using Bernoulli equation

equation

Difference

h*=hG

hi

ViB =

Ai =

ViC =

ViB-ViC

(mm)

(mm)

√[2*g*(h* - hi )]

π Di2 / 4

Qav / Ai

(m/s)

(m/s)

(m2)

(m/s)

#

A

150

131

0.61

0.00053

0.38

0.23

B

159

126

0.80

0.00037

0.55

0.25

C

160

90

1.17

0.00020

1.01

0.16

D

160

113

0.96

0.00031

0.65

0.31

E

159

118

0.90

0.00038

0.53

0.37

F

155

123

0.79

0.00053

0.38

0.41

Calculation :

Part 1: Discharge Coefficient Determination

Qi (LPM)

A 2

Qi A2V2 A2 1 2

A1

1 / 2

p1 p 2

Z1 Z 2

2 g

1000*60*{0.0082 * π[1-(0.008/0.013) 4]-0.5(2*9.81*0.041) 0.5}=11.69

1000*60*{0.0082 * π[1-(0.008/0.013) 4]-0.5(2*9.81*0.039) 0.5}=11.40

1000*60*{0.0082 * π[1-(0.008/0.013) 4]-0.5(2*9.81*0.037) 0.5}=11.11

1000*60*{0.0082 * π[1-(0.008/0.013) 4]-0.5(2*9.81*0.037) 0.5}=11.11

1/ 2

1000*60*{0.0082 * π[1-(0.008/0.013) 4]-0.5(2*9.81*0.031) 0.5}=10.17

According to the graph,

Cd=1.0303

Part 2: Flow Rate Measurement with Venturi Meter

Calculated Flow Rate (LPM)

Error(%)

1.0303*11.69=12.04

| [(12.04-12.15)/12.15] |*100% =0.91

1.0303*11.40=11.75

| [(11.75-11.93)/11.93] |*100% =1.51

1.0303*11.11=11.45

| [(11.45-11.72)/11.72] |*100% =2.30

1.0303*11.11=11.45

| [(11.45-11.11)/11.11] |*100% =3.06

1.0303*10.17=10.48

| [(10.48-10.22)/10.22] |*100% =2.54

Part 3: Bernoulli’s Theorem Demonstration

ViB =

√[2*g*(h*

π

- hi )]

Ai =

ViC =

ViB-ViC

Di2

Qav / Ai

(m/s)

/4

(m2)

(m/s)

(m/s)

√[2*9.81*(150-131 )]=0.61

π

/ 4=0.00053

0.00020/0.00053=0.38

0.61-0.38=0.23

√[2*9.81*(159-126 )]=0.80

π 21.62/4=0.00037

0.00020/0.00037=0.54

0.80-0.54=0.26

√[2*9.81*(160-90 )]=1.17

262

π

162

/ 4=0.00020

0.00020/0.00020=1.00

1.17-1.00=0.17

√[2*9.81*(160-113 )]=0.96

π

202

/ 4=0.00031

0.00020/0.00031=0.65

0.96-0.65=0.31

√[2*9.81*(159-118 )]=0.90

π

222

/ 4=0.00038

0.00020/0.00038=0.53

0.90-0.53=0.37

√[2*9.81*(155-123 )]=0.79

π

262

/ 4=0.00053

0.00020/0.00053=0.38

0.79-0.38=0.41

Discussion :

Part 1 :

The Qi was calculated by the equation:

A 2

Qi A2V2 A2 1 2

A1

1 / 2

p1 p 2

Z1 Z 2

2 g

1/ 2

According to the Qav from the data, use Qav and Qi to plot the graph and then find the slope

which is the discharge coefficient, Cd. In Bernoulli's law, the pressure of pipe would become

smaller when the diameter decrease, which is shown good in the all data. According to the

theory, discharge coefficient, Cd usually lies in the range between 0.9 and 0.99. However, the

calculation of Cd in part 1, Cd=1.0303, which is larger than 0.99. Here are some reasons why

the error generated: 1. The error come from the leaking of the machine, in the experiment, not

only the tube, but also the pump was leaking. 2.The error of manometers reading and the

measure of flow rate Qav., according to the data of the result, there is a data that different Qav

have the same hA - hC. which is impossible in the real life.

3.There still had some bubbles in

the plastic transfer tube effect the manometers reading.

The way to reduce those error are : Check the function of device carefully before the experiment

and make sure the air bubbles are escape from the pipe. Testing five times of the time then use

the average time to measure the flow rate Qav.

Part 2 :

Use the Cd which we find in part 1 and the formula :

Cd

Qa

Qi

to calculate the calculated

flow rate. Then use the equation :error = | (Qa-Qav)/Qa |*100% to find the error. According to

the data, some of the calculated flow rate are larger than Qav. , but if the calculated flow rate

were calculated by using the ideally discharge coefficient, the Qav would become larger than

the calculated flow rate. So the error of the calculated flow rate was come form the error of the

Cd calculation.

Part 3 :

Use the Bernoulli equation : ViB =√[2*g*(h* - hi )] and the data we collect to calculate the flow

rate ViB. After that, use the Continuity equation : Ai = π Di2 / 4 and ViC = Qav / Ai to calculate

the flow rate ViC. Finally, compare two flow rate.In Bernoulli's law, the velocity of flow rate would

increase when the diameter decrease, which is shown well in the data in the part 3. The two

flow rate should be same with each theoretically. However, after the calculation, all of the ViB

were larger than ViC. In Bernoulli equation part, the error can only come from the manometers

reading of hi and h*. In Continuity equation part, the error is come from the calculation of Qav.

The error of Qav is due to the reading and the time measure. Use the average time to calculate

Qav can decrease the amount of error. Activity the error of the Continuity equation part should

be less than the Bernoulli equation part if the Qav is calculated by the average time, the Qav

would become almost same with the ideally flow rate. However there still have those error in

the manometers reading of hi and h*, which make the Bernoulli equation part more inaccurate.

Conclusion :

In Bernoulli's law, the pressure is lower at constrictions where the velocity is higher, and the

pressure is higher where the pipe opens out and the fluid stagnate. In the pipe, the velocity is

increasing when the diameter is decreasing, the velocity become higher when the diameter

become lower. According to the result, the Bernoulli equation is proven.

Reference :

Applied Fluid Mechanics 5th Edition, Robert L. Mott, Prentice-Hall

Elementary Fluid Mechanics 7th Edition, Robert L. Street, Gary Z. Watters, John

K. Vennard,

John Wiley & Sons Inc.

Fluid mechanics 4th Edition, Reynold C. Binder

Fluid Mechanics with applications, Anthony Esposito, Prentice-Hall International Inc.