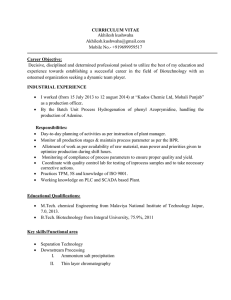

21 42 31 Omkar Kushwaha

advertisement

Subtheme: Energy and Climate Nanohybrid Materials For Enhanced CH4 Recovery and CO2 Sequestration: Countering Rapid Climate Change and Harnessing Clean Energy Omkar S. Kushwaha* and Rajnish Kumar Chemical Engineering Departement, Indian Institute of Technology-Madras, Chennai – 600036. Email: oskushwaha.csirncl@gmail.com Abstract With the ever-high levels of green house gases in the environment and rapid environment changes taking place globally, it is neccessary to cut down their emissions and find a sustainable process for sequestration [1-5]. Also, there is need to adopt clean energy pathways and the leading world economies need to become independent of the petroleum based technologies [6-8]. The natural gas hydrates are known as abundant source of clean energy having methane gas or guest gas molecule trapped at relatively elevated pressures and low temperatures in cage like structures (as shown in figure) known as clathrates [1, 8]. Gas hydrates also applicable in considerable projections in a range of applications such as capture/sequestration of various gases and their storage, seawater desalination, gas transport, and as an abundant source of clean fuel (methane gas) of the future [8-11]. In the present work, extensive experimental studies are conducted in 250 ml high pressure reactor in order to investigate the effect of foamless, environment friendly, and water soluble nanohybrid materials on the efficiency of methane gas recovery and carbon dioxide sequestration. Additionally, the effects of metal nanoparticles based core-shell nanohybrids on the dissociation kinetics and storage capacity are also investigated. The present study suggests that inexpensive, water-soluble, stable and foamless nanohybrids significantly affect the formation and dissociation kinetics, and can be potentially recycled and used as an alternative to the typically used expensive and harmful additives. REFERENCES [1]. Linga, P.; Matthew A. C.; Englezos P. J. Nat. Gas Sci. Eng 2016 35, 1353-1354. [2]. Kushwaha O. S.; Avadhani C. V.; Singh R. P. Carbohydr. Polym. 2015 23, 164–173. [3]. Singh R. P.; Kushwaha O. S. J. Mater. Educ. 2013 35, 79- 120. [4]. Kushwaha O. S.; Avadhani C. V.; Singh R. P. Adv. Mater. Lett. 2014 5, 272-279. [5]. Kushwaha O. S.; Avadhani C. V.; Singh R. P. Adv. Chem. Sci. 2014 3, 19-30. [6]. Lonkar S. P.; Kushwaha O. S.; Leuteritz A.; Heinrich G.; Singh R. P. RSC Advances 2012 2, 12255–12262. [7]. Singh R. P.; Kushwaha O. S. Macromol. Symp. 2013 327, 128–149. [8]. Kushwaha O. S. Int. J. Environment. Sci. Natur. Resources, 2017 2, 001. [9]. Kumar, A.; Kushwaha O. S.; Linga P.; Kumar R. Can. J. Chem. Eng. 2016 94, 2160-2167. [10]. Kumar, A.; Bhattacharjee G.; Barmecha V.; Kushwaha O. S. J. Environ. Chem. Eng. 2016 4, 1955-1961. [11]. Bhattacharjee G.; Barmecha V.; Kushwaha O. S.; Kumar R. J. Chem. Thermodyn. 2018 117, 248-255.