GSM BASED HOME AUTOMATION edited by manju

advertisement

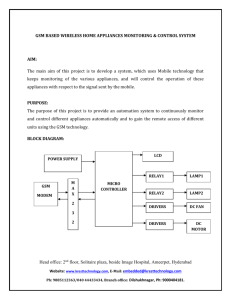

THE USE OF GSM NETWORK TO MONITOR AND CONTROL HOME APPLIANCES THROUGH SMS GOVINDARAJU.M.P1, BASAVARAJ.U.K,2 CHANDRIKA.M.K3 ,VINAYAK.S.K4, MANJUNATH.S.C5, 1 U.G STUDENT, EEE DEPT, SJMIT, CHITRADURGA, KARNATAKA, INDIA U.G STUDENT, EEE DEPT, SJMIT, CHITRADURGA, KARNATAKA, INDIA 3 U.G STUDENT, EEE DEPT, SJMIT, CHITRADURGA, KARNATAKA, INDIA 4 U.G STUDENT, EEE DEPT, SJMIT, CHITRADURGA, KARNATAKA, INDIA 5 ASSISTANT PROF, DEPARTMENT OF EEE, SJMIT, CHITRADURGA, KARNATAKA, INDIA 2 1 Manjusc69@gmail.com, Abstract This Paper represents the emerging application of the GSM technology. Using the public GSM network a home/industrial automation system has been proposed and designed. A standalone embedded system is been designed in such a way that it can monitor and control the home /industrial appliances. This system uses the built in input and output peripherals that allow the owner to monitor and control the home appliances from mobile phone set by sending command in the form of sms messages and receiving the status of the appliances. The GSM modem provides the communication between the owner and the embedded system by means of a sms. Keywords:GSM,Automationcontrol,mobile phone,sms. I.INTRODUCTION A GSM based embedded System which implements the emerging applications of the GSM technology. Using GSM network, an embedded system has been proposed that will act as a system which can monitor and control home/industrial appliances and other devices remotely using built-in input and output peripherals. Remotely the system allows the user to effectively monitor and control the home/industrial appliances and equipment’s through the mobile phone set by sending commands in the form of SMS messages and receiving the appliances status. The main concept behind this paper is receiving the sent SMS and processing it further as required to perform several operations. The necessary operation to be performed depends on the nature of the SMS sent. The principle on which the system works is very simple. First, the sent SMS is stored and polled from the receiver mobile station and then the required control signal is generated and sent to the intermediate hardware that we have designed. According to the command received in form of the sent message, these messages are sent from the mobile set that contain commands in written form which are then processed accordingly to perform the required task. II.SYSTEM MODEL III THE SYSTEM DESCRIPTION AND METHODOLOGY The figure shown is the simple block diagram. It is a simple illustration of how we have implemented the proposed design and the various parts involved in it. From the above representation, first mobile station is used as a transmitting section from which the subscriber sends text messages that contain commands and instructions to the second mobile station which is based on a specific area where our control system is located. The received SMS message is stored in the SIM memory of the phone and then extracted by the microcontroller and processed accordingly to carry out specific operations. The LCD is used to indicate the status of the operation performed by the microcontroller and also its inclusion makes the overall system userfriendly. The input from different sensors are feed to micro-controller and processed to operate respective task semi autonomously and autonomously. The system has a gsm interface to send and receive sms message. The system is equipped with relays for controlling power to devices. When the operator sends a command to change the device status it reaches the system in the form of sms message the system then reads the sms message and device status setting. The message will then be deleted and the device status is changed accordingly. IV. PREVIOUS WORK [1] Mahesh N. Jivani et al author proposed paper on“GSM Based Home Automation System Using App-Inventor for Android Mobile Phone” with an idea the remote Home Automation turns out to be more and more significant and appealing. It improves the value of our lives by automating various electrical appliances or instruments. This paper describes GSM (Global System Messaging) based secured device control system using App Inventor for Android mobile phones. App Inventor is a latest visual programming platform for developing mobile applications for Android-based smart phones. The Android Mobile Phone Platform becomes more and more popular among software developers, because of its powerful capabilities and open architecture. It is a fantastic platform for the real world interface control, as it offers an ample of resources and already incorporates a lot of sensors. No need to write programming codes to develop apps in the App Inventor, instead it provides visual design interface as the way the apps looks and use blocks of interlocking components to control the app’s behaviour. The App Inventor aims to make programming enjoyable and accessible to novices. COMPONENTS USED 1. Microcontroller - P89V51RD2 – Phillips. 2. GSM Module 3. Alphanumeric Display 4. Relays 5. Power Supply MICROCONTROLLER- P89V51RD2 The P89V51RD2 is an 80C51 microcontroller with 64 kB Flash and 1024 bytes of data RAM. A key feature of the P89V51RD2 is its X2 mode option. The design engineer can choose to run the application with the conventional 80C51 clock rate (12 clocks per machine cycle) or select the X2 mode (6 clocks per machine cycle) to achieve twice the throughput at the same clock frequency. Another way to benefit from this feature is to keep the same performance by reducing the clock frequency by half, thus dramatically reducing the EMI. The Flash program memory supports both parallel programming and in serial In-System Programming (ISP). Parallel programming mode offers gang-programming at high speed, reducing programming costs and time to market. ISP allows a device to be reprogrammed in the end product under software control. The capability to field/update the application firmware makes a wide range of applications possible. The P89V51RD2 is also InApplication Programmable (IAP), allowing the Flash program memory to be reconfigured even while the application is running. FEATURES: 80C51 Central Processing Unit 5 V Operating voltage from 0 to 40 MHz 64 kB of on-chip Flash program memory with ISP (InSystem Programming) and IAP (In-Application Programming) Supports 12-clock (default) or 6-clock mode selection via software or ISP SPI (Serial Peripheral Interface) and enhanced UART Figure: Liquid crystal display PCA (Programmable Counter Array) with PWM and Capture/Compare functions Four 8-bit I/O ports with three high-current Port 1 pins (16 mA each) Three 16-bit timers/counters Programmable timer (WDT) Eight interrupt sources with four priority levels Second DPTR register Low EMI mode (ALE inhibit) TTL- and CMOS-compatible logic levels LCD (Liquid Cristal Display): Watchdog ESD Protection Exceeds JESD 22 – 2000-V Human-Body Model (A114-A) Applications o TIA/EIA-232-F o Battery-Powered Systems o Terminals o Modems o Computers A liquid crystal display (LCD) is a thin, flat display device made up of any number of color or monochrome pixels arrayed in front of a light source or reflector. Each pixel consists of a column of liquid crystal molecules suspended between two transparent electrodes, and two polarizing filters, the axes of polarity of which are perpendicular to each other. Without the liquid crystals between them, light passing through one would be blocked by the other. The liquid crystal twists the polarization of light entering one filter to allow it to pass through the other.A program must interact with the outside world using input and output devices that communicate directly with a human being. One of the most common devices attached to an controller is an LCD display. Some of the most common LCDs connected to the controllers are 16X1, 16x2 and 20x2 displays. This means 16 characters per line by 1 line 16 characters per line by 2 lines and 20 characters per line by 2 lines, respectively. Many microcontroller devices use 'smart LCD' displays to output visual information. LCD displays designed around LCD NT-C1611 module, are inexpensive, easy to use, and it is even possible to produce a readout using the 5X7 dots plus cursor of the display. They have a standard ASCII set of characters and mathematical symbols. For an 8-bit data bus, the display requires a +5V supply plus 10 I/O lines (RS RW D7 D6 D5 D4 D3 D2 D1 D0). For a 4-bit data bus it only requires the supply lines plus 6 extra lines(RS RW D7 D6 D5 D4). When the LCD display is not enabled, data lines are tri-state and they do not interfere with the operation of the microcontroller. av Lin len 8, 24 40 ch are sta in FEATURES: Interface with either 4-bit or 8-bit microprocessor. Display data RAM 80x8 bits (80 characters). Character generator ROM 160 different 57 dot-matrix character patterns. Character generator RAM 8 different user programmed 57 dotmatrix patterns. Display data RAM and character generator RAM may be Accessed by the microprocessor. Numerous instructions .Clear Display, Cursor Home, Display ON/OFF, Cursor ON/OFF, Blink Character, Cursor Shift, Display Shift. Built-in reset circuit is triggered at power ON. Built-in oscillator. RELAY relay satisfactorily. To enable this, a driver circuitry, which will act as a buffer circuit, is to be incorporated between them. The driver circuitry senses the presence of a “high” level at the input and drives the relay from another voltage source. Hence the relay is used to switch the electrical supply to the appliances. From the figure when we connect the rated voltage across the coil the back emf opposes the current flow but after the short time the supplied voltage will overcome the back emf and the current flow through the coil increase. When the current is equal to the activating current of relay the core is magnetized and it attracts the moving contacts. Now the moving contact leaves from its initial position denoted “(N/C)” normally closed terminal which is a fixed terminal. The common contact or moving contact establishes the connection with a new terminal which is indicated as a normally open terminal “(N/O)”.Whenever, the supply coil is withdrawn the magnetizing force is vanished. Now, the spring pulls the moving contact back to initial position, where it makes a connection makes with N/C terminal. However, it is also to be noted that at this time also a back emf is produced. The withdrawal time may be in microsecond, the back emf may be in the range of few kilovolts and in opposite polarity with the supplied terminals the voltage is known as surge voltage. It must be neutralized or else it may damage the system. RELAY DRIVER NC: - Normally Connected NO: - Normally Open COM: - Common Figure: Relay Switch Connections The relay driver is used to isolate both the controlling and the controlled device. The relay is an electromagnetic device, which consists of solenoid, moving contacts (switch)and restoring spring and consumes comparatively large amount of power. Hence it is possible for the interface IC to drive the A ULN2803 is an integrated circuit (IC) chip with a high voltage/high current Darlington Transistor Array. It allows you to interface TTL signals with higher voltage/higher current loads. The chip takes low level signals (TTL, CMOS, PMOS, NMOS-which operate at low voltages and low current) and acts as a relay of sorts itself, switching ON/OFF a higher level signal on the opposite side. A TTL signal operates from 0-5v, with everything between 0.0-0.8V considered “low” or OFF, and 2.25.0V being considered “high” or ON. The maximum power available on a TTL signal depends on the type, but generally does not exceed 25mW (~5mA at 5V), so it is not useful for providing power to something like a relay coil. Computers and other electronic devices frequently generate TTL signals. On the output side the ULN2803 is generally rated at 50V/500mA, so it can operate small loads directly. Alternatively it is frequently used to power the coil of one or more relays, which in turn allow even higher voltages/currents to be controlled by the low level signals. POWER SUPPLY CIRCUIT DIAGRAM V.CONCLUSION With the help of a simple cell phone, a user is able to control and monitor virtually any electrical devices. This makes it possible for users to rest assured that their belongings are secure and that the television and other electrical appliances was not left running when they left the house to just list a few of the many uses of this system. The end product will have a simplistic design making it easy for users to interact with. This will be essential because of the wide range of technical knowledge that homeowners have. VI. FUTURE SCOPE Figure : Power supply BRIDGE RECTIFIER A bridge rectifier can be made using four individual diodes, but it is also available in special packages containing the four diodes required. It is called a full-wave rectifier because it uses all the AC wave (both positive and negative sections). 1.4V is used up in the bridge rectifier because each diode uses 0.7V when conducting and there are always two diodes conducting, as shown in the diagram below. Bridge rectifiers are rated by the maximum current they can pass and the maximum reverse voltage they can withstand (this must be at least three times the supply RMS voltage so the rectifier can withstand the peak voltages). Please see the Diodes page for more details, including pictures of bridge rectifiers. After the bridge rectifier output we will get the DC output 5V and 12V by using the voltage regulator the required voltage for the microcontroller can be taken. The future implications of this paper are very great considering the amount of time and resources it saves. The design we have undertaken can be used as a reference or as a base for realizing a scheme to be implemented in other designs of greater level such as weather forecasting, Temperature updates, device synchronization, etc. The paper itself can be modified to achieve a complete Home Automation System which will then create a platform for the user to interface between himself and his household. The concept can be used in fields such as remote sensing, robotics, aeronautics, home automation and many other related fields where continuous monitoring and regulation is needed. REFERENCES 1. Mahesh N. Jivani Associate Professor, Department of Electronics, Saurashtra University, Rajkot, Gujarat, India “GSM Based Home Automation System Using App-Inventor for Android Mobile Phone” International Journal of Advanced Research in Electrical, Electronics and Instrumentation Engineering (An ISO 3297: 2007 Certified Organization) Vol. 3, Issue 9, September 2014 2. Morelli Ralph, Trishan de Lanerolle, Pauline Lake, Nina Limardo, Elizabeth Tamotsu, and Chinma Uche, "Can Android App Inventor BringComputational Thinking to K-12", In Proc., 42nd ACM technical symposium on Computer science education (SIGCSE'11), 2011. 3. R. Llamas, R Reith, M. Shiere, “Apple Cedes Market Share in Smartphone Operating System Market as Android Surges andWindows Phone Gains, According to IDC”, 7th August 2013, IDC Pressrelease. 4. Delgado, A. R., Picking, R., & Grout, V. Remotecontrolled home automation systems with different network technologies. Proceedings of the 6thInternational Network Conference (INC 2006), University of Plymouth, 11-14, pp. 357-366, July 2006 5. Ciubotaru-Petrescu, B., Chiciudean, D., Cioarga, R., & Stanescu, D.,Wireless Solutions for Telemetry in Civil Equipment and InfrastructureMonitoring. 3rd Romanian-Hungarian Joint Symposium on Applied Computational Intelligence (SACI) May 25-26, 2006. 6. Murthy, M. V. R., Mobile based primary health care system for rural India. W3C workshop on Role of Mobile Technologies in Fostering Social Development, Jun 2008 7. Jawarkar, N. P., Ahmed, V., Ladhake, S. A. & Thakare, R. D., Micro-controller based Remote Monitoring using Mobile through SpokenCommands. Journal of Networks, 3(2), 58-63, 2008 8. Malik, S. H. K., Aihab, K. and Erum, S., SMS Based Wireless Home Appliance Control System (HACS) for Automating Appliances andSecurity. Issues in Informing Science and Information Technology, 6, 887-894, 2009. 9. Ahmad, B. I., Yakubu, F., Bagiwa, M. A and Abdullahi, U. I., Remote Home Management: An alternative for working at home while away.World of Computer Science and Information Technology Journal (WCSIT), 1, 4, 144-147, 2011. 10. Mohamed Salman and Jayavrinda Vrindavanam, “Efficient Interactive Control System based on GSM”, International Journal of Latest Trendsin Engineering and Technology (IJLTET), Vol. 3 No. 2, pp. 50=56, November 2013 BIOGRAPHY [1] [2] [3] [4] U.G STUDENTS, EEE DEPT, SJMIT, CHITRADURGA, KARNATAKA, INDIA [5] Manjunath S C Working as Assistant Professor Dept of EEE, SJMIT, Chitradurga, Karnataka, India. He has completed B.E(EEE) in 2008 and M.tech (Power System & Power Electronics) in 2010. Areas of interest are power system, power Electronics Industrialdrives Electrical machines.