Presentation Lifts and Exclators Electrical Safety by JMV

advertisement

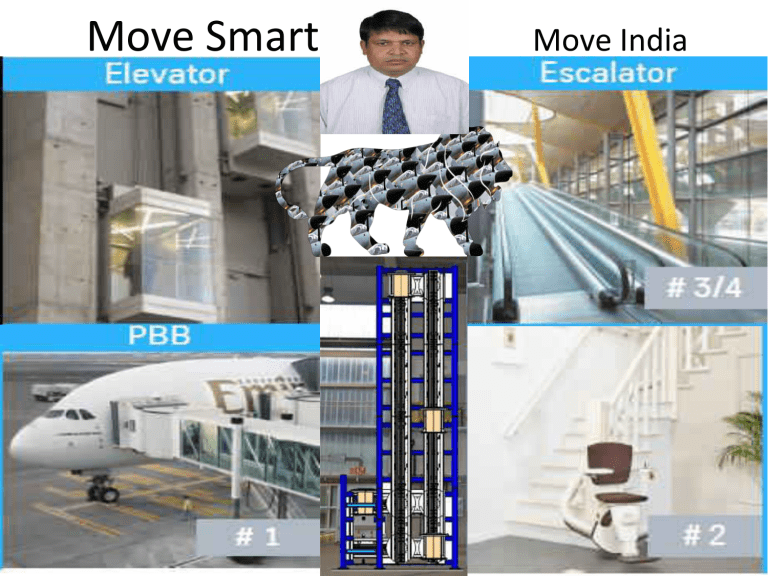

Move Smart Move India Mendatry Lifts Move by Govt Smart India • Indian Railways Faciliates with Lifts&Exclators. • All Airports with Lifts ,Exclators and Walkaways • Smart Buildings Lifts ,Exclators and Walkaways Lifts ,Exclators and Walkaways • Road & Bridges Lifts ,Exclators and Walkaways • Hospital ,Hotels,School,ShoppingComplex Lifts ,Exclators and Walkaways • Carparking Managements • Material Lifting • Sea Ports Lifts ,Exclators and Walkaways • Tunnel and Elevated Bridges Lifts ,Exclators and Walkaways Make In India become World Leader National Manufacturing Policy (NMP): NMP Objectives: • Promote investments in the manufacturing sector • Make India a hub for both domestic and international markets • Increase the share of manufacturing in GDP to 25% by 2022 • To enhance global competitiveness of India’s manufacturing sector • NMP proposes setting up of National Investment and Manufacturing Zones (NIMZs) which are located in areas with contiguous land of 5,000 hectares. • NIMZs would be a combination of production units, public utilities, logistics, environmental protection mechanism, residential areas and administrative services. Faciliate your Life and Lift Calculate your Lift with Bussiness Dream India Grow Building Eligant Living Style in Process Efficient Way Safety Must Sikhana to Padega Hi Follow NBC2016 Corporate Presentation Merging with Technologies Smart and Safe Lift India National Mission Make in India Project (2017) External/Internal Surge Source Equipotential bonding for lightning protection according IEC 610241 and IEC 61312-1; IEC62305 The 100% of lightning energy breaks down as follows: a) 50% of the lightning current will flow through the ground b) 50% of the lightning current will flow over the connected metal parts out of the building: In India & Sri Lanka Only Chance is Power Line • about 10% to the water pipe (metal) Approximately 50 % of Total Lightning Current has •to about 10% to the gas pipe (metal) be diverted to Power lines 50 % • about 10% to the oil pipe (metal tank) • about 10% to the sewage pipe • a out % to the power supplier’s i o i g feed • max. 5% or 5 kA shared across all data lines 50 % Earthing Design and Require Result • For substation Large Power below 1.00Ohm • For substation Small Power below 2.00Ohm • SCADA/TELECOM and AutomationFor substation Large Power below 0.50Ohm • Tower and Other Structure between 8-15Ohm • Lightning Surge Protection 50KA below 5Ohm or 100KA between 8-15Ohm • Follow Standard IEC /IEEE • Recommended use of Hybrid Metal to Protect from Theft Copper Clad Steel/Alumineum Clad Copper • Exothermeic weld IEEE 837 Surge in Systems and Result Surge in DC Application Surge Protection use Recommendation v JMV LPS Products Copper Cladded Conductor For Electrical Installation The Copper Clad Steel Grounding Conductor is made up of steel with the coating of 99.99% pure copper. These conductors/ wires or strands are equipped with the strength of steel with the conductivity and copper with the better corrosion resistance property. The concentric copper cladding is metallurgic ally bonded to a steel core through a continuous, solid cladding process using pressure rolling for primary bonding. The copper cladding thickness remains constant surrounding steel. We use different steel grades for the steel core result in Dead Soft Annealed, High strength and Extra High Strength Characteristics. The Copper Clad Steel Wire yields a composite conductivity of 21%, 30% and 40% IACS, and available in Annealed and Hard drawn. We are delivering products with varied conductivity and tensile strength as per the customer need. Further, the wire can be processed to be silver plated or tinned copper clad steel wire. Most Efficient JointProcess It is efficient and superior to all existing surface –to-surface mechanical retention connectors. What is Exothermic Welding System? Copper to Bi-Metal and Alumenium Types of Exothermic Joints: Possible to join any bi metal except aluminum Exothermic welding is a process of making maintain free highly molecular bonding process is superior in performance connection to any known mechanical or compression-type surface-to-surface contact connector. Exothermic weld connections provide current carrying (fusing) capacity equal to that of the conductor and will not deteriorate with age. It offers Electrical connections between two or more copper to copper and copper to steel conductors. Highly portable method as it does not require any external power source or heat source, so it can be done almost anywhere. It provides strong permanent molecular bond among metallic conductors that cannot loosen and further will not deteriorate with age. Connection does not corrode with time and it offers permanent conductivity. Copper Clad Steel Solid ROD and Conductor Thimble Joint all phase wire/ cable with the help of crimping tools and lugs Step – 1 Separation Sheet Fixed the separation sheet between all wires/ cables Step – 2 Gel / Silicon Close the filled Silicon enclosure from top and bottom , complete installation is done. Step – 3 Features : Provides cable with cable connections and jointing wires in switchboard / electric boxes Being a jelly it can be easily fit into molds of any shape and size. Helps in safeguarding electrical connections and also protects electrical connection joints from catching fire, sparking and leakage current. Eradicates all the possibilities of fire, electric shocks and sparks, etc. causes due to improper electrical connection joints and safeguards structure, equipment and person. Offers safety to your electrical joints from ageing, corrosion, moisture and also observes leakage current. Advantages : Nontoxic Insulating Highly reliable operation Maintenance Free Repairable Cost Effective High repeat value Elasticity Shape retention JMV’s Clients Neeraj Saini – 9910398538 Rahul Verma – 9910398535 Manav Chandra - 9910398999 manav@jmv.co.in