Saranraj87

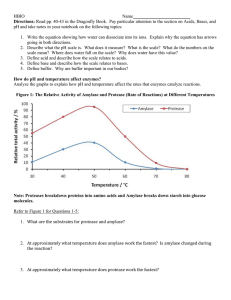

advertisement