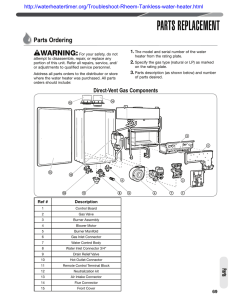

EB 80 Electro-Pneumatic System Catalogue

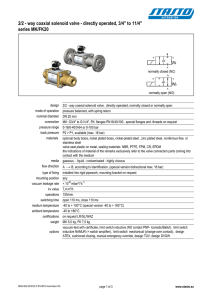

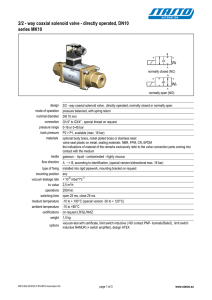

advertisement