PART 1 GENERAL

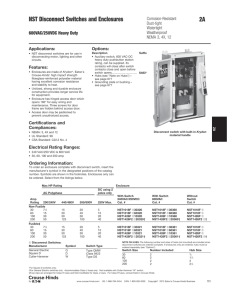

advertisement

SECTION 16410 DRAFT DISCONNECT SWITCHES PART 1 - GENERAL 1.1 DESCRIPTION A. The work required under this section of the specifications consists of the furnishing, installation, and connection of disconnect switches for electrical equipment, and the fuses mounted in the disconnect switches. B. Provide disconnect switches for any of the following conditions: 1. 2. 3. 4. 1.2 QUALITY ASSURANCE A. Industry Referenced Standards. The following specifications and standards are incorporated into and become a part of this Specification by reference. 1. 2. 3. 4. 5. B. Underwriters' Laboratories, Inc. (UL) Publications: a. Enclosed Switches b. 198C High Interrupting Capacity Fuses, Current Limiting Type c. 198E Class R Fuse d. Product Directory - Electrical Construction Materials National Electrical Manufacturers' Association (NEMA) Standards: a. KS-1 Enclosed Switches National Fire Protection Association (NFPA) Publications: a. National Electrical Code National Electrical Contractors' Association (NECA) Publication: a. ANSI/NECA-1 Standards of Installation and related family of standards American National Standards Institute (ANSI) Standards: a. C97.1 Low Voltage Cartridge Fuses 600 Volts or Less Acceptable Manufacturers. Products by the following manufacturers which conform to this specification are acceptable. 1. 2. 1.3 Where a motor is located out-of-sight of its motor controller. Where an electrical resistance heater is provided. Where required by the National Electrical Code. Where indicated on the drawings. Disconnect Switches: Eaton, General Electric, Siemens, Square-D Fuses: Cooper Bussman, General Electric, Ferraz Shawmut, Littelfuse COORDINATION A. Coordinate installation with architectural and structural features and equipment installed under other sections of the specifications to ensure disconnect switch accessibility and ensure that working clearance minimums are provided. Milton Court/Fire/Police A11-207/10-12 DISCONNECT SWITCHES 16410-1 DRAFT PART 2 - PRODUCTS 2.1 2.2 GENERAL MATERIALS REQUIREMENTS A. Provide all materials under this section of the specifications. B. All disconnect switches and fuses shall be UL listed and bear a UL label. MATERIALS DESCRIPTION A. Switches 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. B. Provide 600 volt rated switches for use on 480Y/277V systems and 250 volt rated switches for use on 240V or 208Y/120V systems. Switches shall be heavy duty rated and shall be horsepower rated when used on circuits serving motor loads. Provide switches with number of poles as required to disconnect all ungrounded conductors. Provide with a solid neutral where installed in a circuit which contains a neutral conductor. Provide an equipment grounding conductor termination lug bonded to the enclosure. This lug shall be dedicated to equipment grounding and shall be used for no other purpose. Switching mechanism shall be quick-make, quick-break type, with arc chutes for each pole. Provide line terminal shields in all switches. Provide means for padlocking of switches. Provide door interlocks to prevent door from being opened when energized. Provide inconspicuous means to defeat door interlock. Provide permanent nameplate indicating switch rating in volts, amperes, and horsepower. Provide plastic laminated nameplate with machine stenciled lettering 1/4" in height indicating equipment being served and the circuit designation. Enclosures shall be NEMA 1 in all interior dry locations and NEMA 3R in all damp, wet, or exterior locations, unless otherwise indicated on the drawings. Switches shall be non-fusible unless fusible type is indicated on the drawings. Where fusible type is indicated, provide with rejection clips for Class RK1 or RK5 fuses, for sizes up to 600 amps. Larger switches shall accept Class L fuses only. Provide a complete set of fuses for each fusible disconnect switch. Fuses 1. 2. 3. 4. 5. 6. Milton Court/Fire/Police A11-207/10-12 Fuses shall be heavy duty, horsepower rated for the motor load served. Fuses shall be current-limiting, with an interrupting rating of 200,000 RMS symmetrical amperes. Provide fuses of types, sizes, ratings, and average time-current and peak let-through current characteristics indicated, which comply with manufacturers' standard design, and are constructed in accordance with published product information and with industry standards and configurations. All fuses shall be from one manufacturer, and shall have a 200,000 ampere RMS symmetrical interrupting rating, unless otherwise noted. Fuses for sizes up to and including 600 amperes shall be UL Class RK-1. Fuses for sizes above 600 amperes shall be UL Class L time-delay. Except for control power applications, or where the service voltage(s) to the project is less than 250 volts, all fuses shall be 600 volt rated. For control power circuits/transformers, fuses shall be dual element, time delay, 250 volt rated, with a 10,000 ampere RMS symmetrical interrupting rating. DISCONNECT SWITCHES 16410-2 DRAFT PART 3 - EXECUTION 3.1 3.2 INSTALLATION A. Install switches to maintain line of sight from item served and to maintain working clearances and accessibility required by the National Electrical Code. Refer to the National Electrical Code for requirements for “accessible” non-fused disconnect switches and “readily accessible” fusible disconnect switches. Locate switches adjacent to equipment served unless otherwise indicated. B. Mounting: Secure enclosure to structure with four fastening devices. Provide round washer (1.5" diameter minimum) between fastening device and enclosure. Attach directly to wood, masonry, or concrete surfaces. Where enclosure is attached to sheet rock walls, steel structure, or sheet metal, mount on galvanized steel channel system mounted to structure. Where indicated as free-standing, mount enclosure to galvanized steel channel structure secured to floor, pad, or other appropriate building component. Mount such that operating handle is between 42" and 60" above floor or grade, unless otherwise indicated. C. Only one conductor shall be installed under each terminal. Uninsulated conductor shall not extend more than 1/8" inch from terminal lug. Train conductors neatly inside enclosure, parallel and at right angles to box. Do not splice conductors in enclosure. If required, install junction box or wireway adjacent to disconnect switch and splice within box. Conductors not terminated on switch shall not enter disconnect enclosure. D. Provide push-in plugs to close any unused knockout openings. E. Install fuses in fusible switches. Provide to Owner three spare fuses of each type/voltage/ampere size. Verify from nameplate data the recommended fuse sizes for all project equipment requiring fusible disconnects. FIELD QUALITY CONTROL A. Upon completion of installation of switches, and after circuitry has been energized with power source, operate each switch and verify that each are functioning properly. Correct malfunctioning units at site, then retest to demonstrate compliance. B. After completion, clean the enclosure interior and exterior of dirt, dust, paint overspray, and construction debris. Any scratched or marred surfaces shall be touched up with factory-supplied paint to match the original finish. END OF SECTION 16410 Milton Court/Fire/Police A11-207/10-12 DISCONNECT SWITCHES 16410-3