High Density EMI Filter Design in High Power Three-Phase

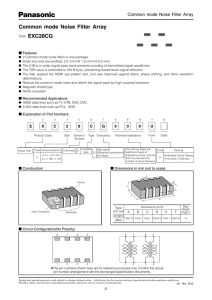

advertisement