Compact Modeling of SOI-LDMOS Transistor including Impact

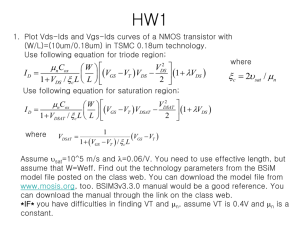

advertisement