Effects of nanoscale porosity on thermoelectric

advertisement

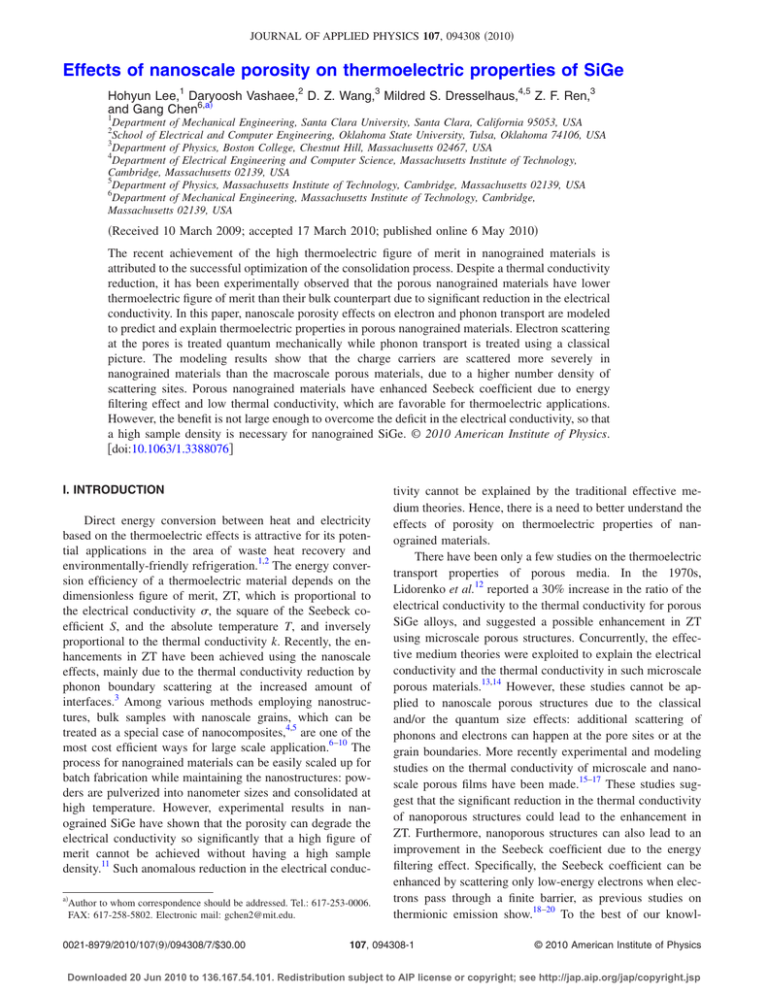

JOURNAL OF APPLIED PHYSICS 107, 094308 共2010兲 Effects of nanoscale porosity on thermoelectric properties of SiGe Hohyun Lee,1 Daryoosh Vashaee,2 D. Z. Wang,3 Mildred S. Dresselhaus,4,5 Z. F. Ren,3 and Gang Chen6,a兲 1 Department of Mechanical Engineering, Santa Clara University, Santa Clara, California 95053, USA School of Electrical and Computer Engineering, Oklahoma State University, Tulsa, Oklahoma 74106, USA 3 Department of Physics, Boston College, Chestnut Hill, Massachusetts 02467, USA 4 Department of Electrical Engineering and Computer Science, Massachusetts Institute of Technology, Cambridge, Massachusetts 02139, USA 5 Department of Physics, Massachusetts Institute of Technology, Cambridge, Massachusetts 02139, USA 6 Department of Mechanical Engineering, Massachusetts Institute of Technology, Cambridge, Massachusetts 02139, USA 2 共Received 10 March 2009; accepted 17 March 2010; published online 6 May 2010兲 The recent achievement of the high thermoelectric figure of merit in nanograined materials is attributed to the successful optimization of the consolidation process. Despite a thermal conductivity reduction, it has been experimentally observed that the porous nanograined materials have lower thermoelectric figure of merit than their bulk counterpart due to significant reduction in the electrical conductivity. In this paper, nanoscale porosity effects on electron and phonon transport are modeled to predict and explain thermoelectric properties in porous nanograined materials. Electron scattering at the pores is treated quantum mechanically while phonon transport is treated using a classical picture. The modeling results show that the charge carriers are scattered more severely in nanograined materials than the macroscale porous materials, due to a higher number density of scattering sites. Porous nanograined materials have enhanced Seebeck coefficient due to energy filtering effect and low thermal conductivity, which are favorable for thermoelectric applications. However, the benefit is not large enough to overcome the deficit in the electrical conductivity, so that a high sample density is necessary for nanograined SiGe. © 2010 American Institute of Physics. 关doi:10.1063/1.3388076兴 I. INTRODUCTION Direct energy conversion between heat and electricity based on the thermoelectric effects is attractive for its potential applications in the area of waste heat recovery and environmentally-friendly refrigeration.1,2 The energy conversion efficiency of a thermoelectric material depends on the dimensionless figure of merit, ZT, which is proportional to the electrical conductivity , the square of the Seebeck coefficient S, and the absolute temperature T, and inversely proportional to the thermal conductivity k. Recently, the enhancements in ZT have been achieved using the nanoscale effects, mainly due to the thermal conductivity reduction by phonon boundary scattering at the increased amount of interfaces.3 Among various methods employing nanostructures, bulk samples with nanoscale grains, which can be treated as a special case of nanocomposites,4,5 are one of the most cost efficient ways for large scale application.6–10 The process for nanograined materials can be easily scaled up for batch fabrication while maintaining the nanostructures: powders are pulverized into nanometer sizes and consolidated at high temperature. However, experimental results in nanograined SiGe have shown that the porosity can degrade the electrical conductivity so significantly that a high figure of merit cannot be achieved without having a high sample density.11 Such anomalous reduction in the electrical conduca兲 Author to whom correspondence should be addressed. Tel.: 617-253-0006. FAX: 617-258-5802. Electronic mail: gchen2@mit.edu. 0021-8979/2010/107共9兲/094308/7/$30.00 tivity cannot be explained by the traditional effective medium theories. Hence, there is a need to better understand the effects of porosity on thermoelectric properties of nanograined materials. There have been only a few studies on the thermoelectric transport properties of porous media. In the 1970s, Lidorenko et al.12 reported a 30% increase in the ratio of the electrical conductivity to the thermal conductivity for porous SiGe alloys, and suggested a possible enhancement in ZT using microscale porous structures. Concurrently, the effective medium theories were exploited to explain the electrical conductivity and the thermal conductivity in such microscale porous materials.13,14 However, these studies cannot be applied to nanoscale porous structures due to the classical and/or the quantum size effects: additional scattering of phonons and electrons can happen at the pore sites or at the grain boundaries. More recently experimental and modeling studies on the thermal conductivity of microscale and nanoscale porous films have been made.15–17 These studies suggest that the significant reduction in the thermal conductivity of nanoporous structures could lead to the enhancement in ZT. Furthermore, nanoporous structures can also lead to an improvement in the Seebeck coefficient due to the energy filtering effect. Specifically, the Seebeck coefficient can be enhanced by scattering only low-energy electrons when electrons pass through a finite barrier, as previous studies on thermionic emission show.18–20 To the best of our knowl- 107, 094308-1 © 2010 American Institute of Physics Downloaded 20 Jun 2010 to 136.167.54.101. Redistribution subject to AIP license or copyright; see http://jap.aip.org/jap/copyright.jsp 094308-2 J. Appl. Phys. 107, 094308 共2010兲 Lee et al. edge, however, there has been no systematic modeling on how nanoscale porosity affects thermoelectric figure of merit. This paper presents a modeling study on the effect of nanoscale pores on the thermoelectric properties. First, we investigate why the electrical conductivity of nanoporous materials is degraded more severely than the prediction by the effective medium theories. Second, we explore if the nanoscale porosity effect can lead to the enhancement in ZT. We developed a charge scattering model caused by spherical pore sites to calculate electron transport. For phonon transport, a modified effective medium theory is exploited to consider the classical size effect.21 Although this model can be applied to various material systems, the result is presented for SiGe, which is widely used as a thermoelectric material for high temperature power generation. The present authors also reported the experimental studies on the nanograined SiGe, which are in line with this modeling study.22,23 The modeling results show that the electrical conductivity degradation in nanoporous materials is due to the strong charge carrier scattering at the large number of pore sites. Furthermore, the enhancement in the Seebeck coefficient and the reduction in the phonon thermal conductivity are not large enough to overcome electrical conductivity deterioration in nanoporous SiGe. Hence, this model suggests that a high sample density is essential for the nanograin approach to enhance the ZT of SiGe. II. MODEL FOR THERMOELECTRIC TRANSPORT IN NANOPOROUS MATERIALS A. Electron modeling The electrical conductivity 共兲 and the Seebeck coefficient 共S兲 of bulk materials can be derived from the standard formulation based on the Boltzmann transport equation under the relaxation time approximation:24 =− 1 3 冕 1 3 冕 q S= q2共E兲v共E兲2 f共EF,E兲 D共E兲dE, E E − EF f共EF,E兲 D共E兲dE/ , 共E兲v共E兲2 T E 共1兲 共2兲 where E is the electron energy, EF is the Fermi level, q is the charge of electrical carriers, is the energy dependent momentum relaxation time, v is the group velocity of the charge carriers, f is the Fermi–Dirac distribution function, and D is the density of electronic states. The validity of this approach relies on the accurate consideration of the momentum relaxation time, or inverse of the scattering rate. In crystalline SiGe, the major scattering mechanisms for electrons are ionized impurity scattering and acoustic phonon scattering. According to the Matthiessen’s rule, when a scattering event happens independently from other scattering events, the total scattering rate is obtained by taking the sum of each scattering rate corresponding to different scattering mechanisms. Functional forms of the momentum relaxation time for various scattering mechanisms can be found in typical device physics textbooks and are summarized in Table I.25,26 The approach used in this work is similar to that of Vining,24 but more details are considered. In particular, we consider the nonparabolicity of the conduction band due to a high carrier concentration.27 The change in band structure with varying temperature and doping concentrations is also considered.28 The coefficients associated with band structure are taken from the literature as summarized in Table I.24,29,30 The validity of our model for dense bulk samples was verified with the experimental results on bulk SiGe alloy by Dismukes et al.31 While the Fermi level is used as a fitting parameter in Vining’s work, we derived the Fermi level directly from the measured carrier concentration by Dismukes et al.31 Without using any fitting parameter, our model can fit the experimental data for bulk SiGe alloy for the temperature range of 300 to 1300 K and for the various composition ratios 共Fig. 1兲. We develop a new scattering model to consider the effect of nanoscale pores on the charge carriers transport properties. Figure 2 shows a schematic of charge carrier scattering caused by a pore site. Pores are regarded as spherical sites with a potential difference. When a charge carrier passes near a spherical pore, it is scattered to a different wave vector due to the potential perturbation. In order to evaluate scattering rate caused by spherical potential, we exploit the Fermi Golden rule as in the other scattering studies.25 In the scattering rate calculation, it is generally assumed that the band structure is not affected by the potential perturbation. Hence, we neglect any modification in atomic structure caused by the pore sites. The amount of potential perturbation U0 is the difference between the electron energy levels in the pore site and in the environment, and is equivalent to the electron affinity of SiGe. The mathematical form of the spherical scattering potential with a radius a can be expressed as U共rជ兲 = U0H共a − 兩rជ兩兲, 共3兲 where r is the distance from the center of pore and H is the Heaviside step function. Using the Fermi’s Golden Rule, we can obtain the transition rate SR from the original eigenstate with the wave vector kជ to another with a wave vector kជ ⬘ SR共kជ ,kជ ⬘兲 = 2 兩M kជ kជ ⬘兩2␦共E⬘ − E兲, ប 共4兲 where ប is Plank’s Constant, E and E⬘ are the energy of charge carriers before and after scattering, and ␦ is the delta function. M kជ kជ ⬘ is the matrix element of the scattering potential U between the eigenstates kជ and kជ ⬘ M kជ kជ ⬘ = 冕冕冕 ជ ជ eik·r̄U共rជ兲e−ik⬘·rជdrxdrydrz . 共5兲 As the scattering rate measures how often a charge carrier is scattered into a different eigenstate, we need to integrate Eq. 共4兲 over all possible eigenstates kជ ⬘ that result from a scattering event. Since we assume that the scattering is elastic, Eq. 共4兲 will have nonzero value only when the energy of charge carriers is conserved. The scattering rate or the inverse of relaxation time, for pore sites is Downloaded 20 Jun 2010 to 136.167.54.101. Redistribution subject to AIP license or copyright; see http://jap.aip.org/jap/copyright.jsp 094308-3 J. Appl. Phys. 107, 094308 共2010兲 Lee et al. TABLE I. Electron modeling parameters. Majority carrier concentration Effective mass of electrons of Si1−xGex at X pointa Effective mass of electrons of Si1−xGex at L pointa Effective mass of holes of Si1−xGex at ⌫ pointa Si energy gap at X pointa Si energy gap at L pointa Ge energy gap at L pointa Ge energy gap at X pointa Si1−xGex energy gap at each pointa Nonparabolicityb Electron density of states at X pointc Electron density of states at L pointc Hole density of states at ⌫ pointc Dielectric constant of Si1−xGex a Screening lengthd Ionized impurity scattering rated Electron-phonon scattering potentiald Bulk moduli of Si1−xGex a Electron-phonon scattering rated Hole-phonon scattering rated Lattice constanta Alloy scattering potentialb Alloy scattering rate 共electrons兲e Alloy scattering rate 共holes兲e N 共cm−3兲 mX = 关1.08共1 − x兲 + 1.41x − 0.183x共1 − x兲兴me 共kg兲 mL = 关1.08共1 − x兲 + 0.71x − 0.183x共1 − x兲兴me 共kg兲 m⌫ = 共0.81− 0.47x兲me 共kg兲 EgSi_X = 1.17– 4.73⫻ 10−4T2 / 共T + 636兲 共eV兲 EgSi_L = 1.65– 4.73⫻ 10−4T2 / 共T + 636兲 共eV兲 EgGe_L = 0.74– 4.80⫻ 10−4T2 / 共T + 235兲 共eV兲 EgGe_X = 0.85EgGe_L / 0.66 共eV兲 ⴱ Eg = EgSi共1 − x兲 + EgGe x − 0.4x共1 − x兲 − 0.009 ln共N / 1017兲 + 兵关ln共N / 1017兲兴2 + 0.5其1/2 共eV兲 A = 2 共eV兲 DX = 8冑2E共1 + 共E / ␣兲兲冑共共mX / h2兲兲3共1 + 共2E / ␣兲兲 DL = 8冑2E共1 + 共E / ␣兲兲冑共共mL / h2兲兲3共1 + 共2E / ␣兲兲 D⌫ = 共8冑2E共m⌫兲3 / h3兲 = 11.7+ 4.5x LD = 冑40kT / q2N 1 / i = 22N / h共q2LD2 / 40兲2DX DA = −9.5 共electron兲, 5.0 共holes兲 共eV兲 Cl = 98− 23x 共GPa兲 共1 / e−p兲 = 共22kT / hcl兲共DX / 6兲DA2 共s−1兲 共1 / h−p兲 = 共22kT / hcl兲D⌫DA2 共s−1兲 a = 0.002 733x2 + 0.019 92x + 0.5431 共nm兲 UA = 0.7 共eV兲 共1 / a兲 = x共1 − x兲共3a34U2A / 32h兲共DX / 6兲 共s−1兲 共1 / a兲 = x共1 − x兲共3a34U2A / 32h兲D⌫ 共s−1兲 a Reference 28. Reference 30. c Reference 27. d Reference 25. e Reference 26. b s−1 = N 共2兲3 冕冕冕 SRkជ kជ ⬘共1 − cos 兲dkx⬘dk⬘y dz⬘ , 共6兲 where s is the momentum relaxation time, N is the number density of the spherical pores, and is the angle between the original and scattered wave vectors. Here we have simply multiplied the scattering rate by the number density of pores since it is assumed that each pore affects electron transport independently and that pores are uniformly distributed. This assumption is reasonable for the case of a high carrier concentration 共⬎1020 / cm3兲, where the electron screening length is around 1 nm. With mathematical manipulation, Eq. 共6兲 can be arranged as following: s−1 = N3U20D共E兲 兵兩2akជ 兩2关CI共兩2akជ 兩兲 − 1兴 2ប兩kជ 兩6 + 兩2akជ 兩sin共兩2akជ 兩兲 + sin2共兩2akជ 兩兲其, 共7兲 where D共E兲 is the electron density of states and CI is an integral function defined as CI共x兲 ⬅ 冕 The size and the number density of the pores need to be evaluated to calculate the scattering rate in Eq. 共7兲. Once the pore size is known, the number density N can be derived from the definition of the porosity ⌽, which is the ratio of the pore volume to the total sample volume N= 0 1 − cos t dt. t 共8兲 The momentum relaxation time calculated from Eq. 共7兲 can be combined with the other scattering mechanisms using Mathiessen’s Rule, and the electrical transport properties can be calculated using Eqs. 共1兲 and 共2兲. 共9兲 where a is the radius of a spherical pore. In the following paragraph, we will discuss how the pore size is determined. The pore is regarded as a vacant space among grains. As the grain size becomes smaller, the size of the pore also becomes smaller. To derive the relation between the size of grains and pores, we assume that the grains are closely packed hard spheres with diameter L as shown in Fig. 3. In this case, a space exists inside the four spheres that touch each other. We model the pore site as the sphere that can fit in this space. The pore radius a is derived from the geometry of a tetrahedron as a= x 3⌽ , 4a3 冉冑 冊 3 1 − L. 8 2 共10兲 The actual pore radius can be smaller than Eq. 共9兲 due to adhesion forces between grains and the nonspherical geometry of grains. While additional scattering of charge carriers by pore sites can be determined from Eq. 共7兲, the finite volume of the pores should not be neglected, especially when the porosity Downloaded 20 Jun 2010 to 136.167.54.101. Redistribution subject to AIP license or copyright; see http://jap.aip.org/jap/copyright.jsp 094308-4 J. Appl. Phys. 107, 094308 共2010兲 Lee et al. FIG. 2. 共Color online兲 Schematic of electron scattering by a spherical potential. Pores are assumed to be a spherical site that has scattering potential. As an electron passes by the spherical potential, it will change its momentum from the original eigenstate kជ to another kជ ⬘. coefficient S, Eq. 共12兲 is solved by numerical iteration. The thermal conductivity used in Eq. 共13兲 includes both the electron and phonon contributions. The electron contribution to the thermal conductivity ke can be evaluated from ke = − 1 3 冕 共E − EF兲2 f共EF,E兲 D共E兲dE − S2T . 共E兲v共E兲2 T E 共14兲 FIG. 1. 共Color online兲 The model validity with SiGe for different concentrations of Ge at various temperature ranges. Lines are from the modeling, and points are from the experimental work reported by Dismukes et al. 共Ref. 31兲. Composition ratio and carrier concentration of circle, square, triangle, and diamond are Si73Ge27 and 1.5⫻ 1020, Si70Ge30 and 6.7⫻ 1019, Si67Ge33 and 2.3⫻ 1019, and Si74Ge26 and 2.2⫻ 1018, respectively. becomes large. To account for the finite volume of the pores, we treat nanoporous materials as media where one phase is the host material and the other is vacuum. We employ the effective medium theories to calculate the transport properties of the nanoporous media.13,14 The effective electrical conductivity and Seebeck coefficient of porous media can be described as 2 − 3⌽ , 2 共11兲 ␥effh , ␥heff 共12兲 eff = h Seff = Sh Besides electronic thermal conductivity, phonon contribution to the heat conduction in thermoelectric materials is significant. The transport analysis will not be complete without careful consideration of the change in phonon thermal conductivity of porous nanograined structures. In the following section, the effect of nanosized pores and nanograins on the phonon thermal conductivity is discussed. B. Phonon modeling While the Seebeck coefficient and the electrical conductivity are derived by integrating the energy flux and charge flux over all energy levels of electrons, the lattice thermal conductivity is derived by integrating phonon energy flux over all phonon frequencies. The simplified expression of lattice thermal conductivity is k= 1 3 冕 C共兲v共兲⌳共兲d , 共15兲 where is the phonon frequency, C is the lattice heat capacity, v is the sound velocity, and ⌳ is the phonon mean-free path. The phonon mean-free path is given by the group ve- and ␥ is defined as ␥ ⬅ k + TS2 , 共13兲 where k is the total thermal conductivity. The subscript h stands for the properties of the host material, which can be calculated from Eqs. 共1兲 and 共2兲 after incorporating the scattering by the pores. Since ␥ is also dependent on the Seebeck FIG. 3. 共Color online兲 Schematic of closely packed hard spheres. Pore site can exist in the middle of four spheres. Downloaded 20 Jun 2010 to 136.167.54.101. Redistribution subject to AIP license or copyright; see http://jap.aip.org/jap/copyright.jsp 094308-5 J. Appl. Phys. 107, 094308 共2010兲 Lee et al. TABLE II. Phonon modeling parameters. N = h / 2kTD TD = 630− 266x 共K兲 M = 28.09共1 − x兲 + 72.61x 共g / mol兲 crv = 兵关12.1共1 − x兲 + 13.6x兴 / NA其1/3 = 2329+ 3493x − 499x2 共kg/ m3兲 v = 共2kTD / h兲共 / 6兲1/3共crv / 100兲 共m / s兲 ␥ = 0.91 1 / U = 3.264⫻ 10−219␥2N2 T / 27 Mcrv2TD 共s−1兲 1 / N = 2 / U 共s−1兲 1 / PD = 兵共 28.09– 72.61 / M 兲2 + 39关 共 12.1 / NA 兲1/3 – 共 13.6 / NA 兲1/3 / crv 兴2其 ⫻ 6.17 ⫻ 1011TDN4 共s−1兲 2 1 / p−e = 4DA v共m兲3 / h4 共 2kT / mv2 兲 ⫻ 兵N TD / T − ln1 + exp关共mv2 − 2EF兲 / 2kT + N2 TD2 / 8mv2kT3 + NTD / 2T兴 / 1 + exp关共mv2 − 2EF兲 / 2kT + N2 TD2 / 8mv2kT3 − NTD / T兴 其 共s−1兲 1 / B = v / grain 1 / C = 1 / U + 1 / N + 1 / PD + 1 / p−e + 1 / B 兰10CN2 共共NTD / T兲2eNTD/T / 共eNTD/T − 1兲2兲dN 1 2兰0共C / U兲N2 共共NTD / T兲2eNTD/T / 共eNTD/T − 1兲2兲dN 2兰10共1 / U兲共1 − 共2C / U兲兲N2 共共NTD / T兲2eNTD/T / 共eNTD/T − 1兲2兲dN −2 4.67⫻ 10 共I1 + I22 / I3兲TD2 / crv Normalized phonon frequency Debye temperature of Si1−xGex a Atomic mass of Si1−xGex a Cube root volume of Si1−xGex a Density of Si1−xGex a Sound velocitya Anharmonicity parameterb 3 phonon Umklapp scattering rateb 3 phonon Normal scattering rateb Point defect 共alloy兲 scattering rateb Phonon-electron scattering rateb Boundary scattering ratec Combined scattering rate I1 b I2 b I3 b Lattice thermal conductivityb a Reference 28. Reference 33. c Reference 6. b locity of acoustic phonon, i.e., sound velocity, divided by phonon scattering rate. As in the electron transport properties calculation, we consider the various scattering mechanisms to determine the phonon scattering rate. Three-phonon scattering, point defect scattering, and phonon-electron scattering are the major scattering mechanisms for phonons in the bulk SiGe alloy. The functional forms of each scattering rate and the required constants are listed in Table II. Each scattering rates calculated by the different scattering mechanisms is superposed using Mathiessen’s Rule. In addition to these scattering mechanisms in bulk SiGe, phonons will be scattered diffusively at grain boundaries. When the grain size is smaller than the bulk phonon mean-free path, the grain boundary scattering becomes dominant. In this case, the effective phonon mean-free path will be limited by the small grain size L and given by6 1 ⌳effective = 1 ⌳bulk + 1 . L 共16兲 The actual functional forms for the lattice thermal conductivity are slightly more complicated than Eq. 共15兲 and are taken from studies in the 1960s 共Table II兲 共Refs. 32 and 33兲 For the lattice thermal conductivity in porous structures, we use the modified formulation of the effective medium theory.21 A simplified expression for the lattice thermal conductivity of porous media is described as follows: keff = kh 2 − 2⌽ , 2+⌽ 共17兲 where keff is the effective thermal conductivity, kh is the thermal conductivity of the host, and ⌽ is the porosity. The effect of small grain size is taken into consideration for the host thermal conductivity calculation, using Eqs. 共15兲 and 共16兲. By this way, the modified effective medium theory considers both the classical size effect and the porosity effect on the lattice thermal conductivity. III. RESULTS AND DISCUSSIONS Figure 4 shows our modeling results fitted on the experimental data reported by Lidorenko.12 Due to lack of information on grain size and carrier concentration, we take them as fitting parameters. We use a grain size of 10 m and concentration of 1020 / cm3, to match the trends of both the thermal conductivity and the electrical conductivity. For the 10 m pores, electrons are not significantly scattered by the pores due to the large separation between pores. Since the screening length of charge carriers in the solid portion is 1 nm order of magnitude, the sparse pore sites will not affect the charge carrier transport. Therefore, the reduction in the electrical conductivity is mainly attributed to the lack of medium. However, when the grain size is on the nanometer scale, the interpore spacing becomes shorter, and electron transport is severely limited by the scattering from the pores. Figure 5 shows the energy dependency of charge carrier scattering by the spherical potential model for 20 nm grain size with 1% porosity. The energy dependent scattering rate provides the logical bases for low electrical conductivity and enhanced Seebeck coefficient. At this pore size and porosity, the pore scattering dominates the total momentum relaxation time. Without the scattering by the pores, the momentum relaxation time is an order of magnitude higher, which indicates that the electrical conductivity decreases significantly by the nanosized pores. However, the pore scattering can provide us with an advantage of the enhanced Seebeck coefficient, which results from the more efficient scattering of low-energy electrons than high-energy electrons. Conse- Downloaded 20 Jun 2010 to 136.167.54.101. Redistribution subject to AIP license or copyright; see http://jap.aip.org/jap/copyright.jsp 094308-6 Lee et al. J. Appl. Phys. 107, 094308 共2010兲 FIG. 6. 共Color online兲 Transport properties of SiGe as a function of porosity for different grain sizes at 1300 K: 共a兲 electrical conductivity, 共b兲 Seebeck coefficient, 共c兲 thermal conductivity, and 共d兲 ZT. The properties are normalized to the uniform bulk values. Same symbols as in 共a兲 apply for all figures. FIG. 4. 共Color online兲 Comparison of our model with Lidorenko’s experimental results, grain size of 10 m and concentration of 1020/ cm3 are used to fit the results. quently, the Seebeck coefficient, which measures an average energy of electrons that contribute to electrical conductivity, is enhanced by reducing the contributions from low-energy electrons. Figures 6 and 7 show the thermoelectric properties for the porosity range between 0% and 15% and for grain sizes down to 20 nm. The 20 nm is the grain size that we observed for SiGe nanograined samples with a high ZT.22,23 In the calculations, we use a temperature of 1300 K and a doping concentration of 1.5⫻ 1020 / cm3 that is typical for high temperature SiGe thermoelectric power generation. As demon- FIG. 5. 共Color online兲 Relaxation times due to various scattering mechanism. strated in Figs. 6共b兲 and 7共b兲, the enhancement in the Seebeck coefficient due to the nanoscale pores becomes larger for smaller grain size. However, the momentum relaxation time of the porous materials is much smaller than that of materials with high sample density 共Fig. 5兲, so that the electrical conductivity of the nanoscale porous media is severely degraded compared to their bulk counterparts 关Figs. 6共a兲 and 7共a兲兴. Figure 7共a兲 also shows that the electrical conductivity is degraded more as the grain size decreases with the porosity kept constant. While the scattering rate is roughly proportional to the square of the pore size as shown in Eq. 共7兲, the FIG. 7. 共Color online兲 Transport properties of SiGe as a function of the grain sizes for different porosity values: 共a兲 electrical conductivity, 共b兲 Seebeck coefficient, 共c兲 thermal conductivity, and 共d兲 ZT. The properties are normalized to the uniform bulk values. Same symbols as in 共a兲 apply for all figures. Downloaded 20 Jun 2010 to 136.167.54.101. Redistribution subject to AIP license or copyright; see http://jap.aip.org/jap/copyright.jsp 094308-7 J. Appl. Phys. 107, 094308 共2010兲 Lee et al. number density is inversely proportional to the third power of the pore size, so that the scattering rate is higher for smaller grain size. When the grain size gets as small as 20 nm and the porosity gets larger than 10%, the strong scattering due to porosity is not even favorable to the Seebeck coefficient 关Fig. 6共b兲兴. The thermal conductivity also decreases as the grain size is reduced 关Fig. 7共c兲兴. In the limit of no porosity, this trend can be explained by the classical size effect that reduces the phonon contribution to the thermal conductivity. When the porosity is not negligible, the electron contribution to the thermal conductivity is also reduced by strong scattering at the nanoscale pore sites. Although the electron contribution is often considered to be small in SiGe, it becomes comparable to that of phonons in nanograined SiGe due to significant reduction in the phonon contribution. As a consequence, the total thermal conductivity reduction is larger for smaller grain size and higher porosity 关Figs. 6共c兲 and 7共c兲兴. In spite of the reduction in the thermal conductivity and the enhancement in the Seebeck coefficient, the porous nanograined SiGe cannot lead to a high ZT because the electrical conductivity drops by orders of magnitude. There exist regions of porosity and grain size that can have a small enhancement in ZT 关Fig. 7共d兲兴. However, the enhancement in these regions is much less than the enhancement we can obtain for nanograined samples with no porosity and the amount of enhancement is not significant. Moreover, it is hard to control porosity and grain size in experiment. Therefore, the challenge is not trivial if we want to increase ZT by introducing porosity in nanograined SiGe. IV. CONCLUSIONS We have explored the effect of nanosized porosity on thermoelectric transport properties. An electron scattering model was developed to calculate the momentum relaxation time caused by the scattering potential at pore sites. The model is derived in a generic form and can be considered together with other scattering mechanisms by Mathiessen’s rule. Our modeling work shows good agreement with the previously reported experimental studies in the macroscale porosity effect on the thermoelectric properties. The model is applied to nanograined SiGe, and explains the significant reduction in the electrical conductivity when the number density of pore sites is large. Although nanosized pores are efficient in reducing the thermal conductivity and increasing the Seebeck coefficient, the electrical conductivity drops so significantly that the porosity degrades the thermoelectric figure of merit in nanograined SiGe. Hence, a high sample density is required to achieve a net ZT enhancement in nanograined SiGe. However, an enhancement in ZT by the porosity effect may be observed in other material systems. For example, materials with small electron effective mass and a low relaxation time of charge carriers would exhibit a smaller reduction in the electrical conductivity than for SiGe. The present model can be used to find such materials and calls for further studies on such potential candidate materials. ACKNOWLEDGMENTS The authors would like to appreciate the funding from NASA under grant No. NNC06GA48G and NSF under grant No. CMMI 0833084. 1 G. S. Nolas, J. Sharp, and H. J. Goldsmid, Thermoelectrics: Basic Principles and New Materials Developments 共Springer, Berlin, 2001兲. 2 D. M. Rowe, CRC Handbook of Thermoelectrics 共CRC, Boca Raton, FL, 1995兲. 3 G. Chen, M. S. Dresselhaus, G. Dresselhaus, J. P. Fleurial, and T. Caillat, Int. Mater. Rev. 48, 45 共2003兲. 4 M. J. Mayo, Int. Mater. Rev. 41, 85 共1996兲. 5 S. Seal, S. C. Kuiry, P. Georgieva, and A. Agarwal, MRS Bull. 29, 16 共2004兲. 6 G. Chen, Recent Trends in Thermoelectric Materials Research III, 共Academic Press, San Diego, 2001兲, Vol. 71, pp. 203–259. 7 J. P. Heremans, C. M. Thrush, and D. T. Morelli, J. Appl. Phys. 98, 063703 共2005兲. 8 K. F. Hsu, S. Loo, F. Guo, W. Chen, J. S. Dyck, C. Uher, T. Hogan, E. K. Polychroniadis, and M. G. Kanatzidis, Science 303, 818 共2004兲. 9 W. Kim, J. Zide, A. Gossard, D. Klenov, S. Stemmer, A. Shakouri, and A. Majumdar, Phys. Rev. Lett. 96, 045901 共2006兲. 10 X. B. Zhao, X. H. Ji, Y. H. Zhang, T. J. Zhu, J. P. Tu, and X. B. Zhang, Appl. Phys. Lett. 86, 062111 共2005兲. 11 H. Lee, D. Z. Wang, M. Y. Tang, Z. F. Ren, P. Gogna, J.-P. Fleurial, M. S. Dresselhaus, and G. Chen, in International Conference on Thermoelectrics 共Clemson, SC, 2005兲. 12 N. S. Lidorenko, O. M. Narva, L. D. Dudkin, and R. S. Erofeev, Inorg. Mater. 6, 1853 共1970兲. 13 D. J. Bergman and O. Levy, J. Appl. Phys. 70, 6821 共1991兲. 14 R. Landauer, Electrical Transport and Optical Properties of Inhomogeneous Media, 共American Institute of Physics, New York, 1978兲, pp. 2–45. 15 D. W. Song, W. N. Shen, B. Dunn, C. D. Moore, M. S. Goorsky, T. Radetic, R. Gronsky, and G. Chen, Appl. Phys. Lett. 84, 1883 共2004兲. 16 D. Song and G. Chen, Appl. Phys. Lett. 84, 687 共2004兲. 17 R. G. Yang, G. Chen, and M. S. Dresselhaus, Nano Lett. 5, 1111 共2005兲. 18 A. Shakouri and J. E. Bowers, Appl. Phys. Lett. 71, 1234 共1997兲. 19 G. D. Mahan, Recent Trends in Thermoelectric Materials Research III, 共Academic Press, San Diego, 2001兲, Vol. 71, pp. 157–174. 20 G. D. Mahan, J. Appl. Phys. 76, 4362 共1994兲. 21 A. Minnich and G. Chen, Appl. Phys. Lett. 91, 073105 共2007兲. 22 X. Wang, H. Lee, Y. C. Lan, G. H. Zhu, G. Joshi, D. Z. Wnag, J. Yang, A. J. Muto, M. Y. Tang, J. Klatsky, S. Song, M. S. Dresselhaus, G. Chen, and Z. F. Ren, Appl. Phys. Lett. 93, 193121 共2008兲. 23 G. Joshi, H. Lee, Y. C. Lan, X. Wang, G. H. Zhu, D. Z. Wang, R. W. Giould, D. C. Cuff, M. Y. Tang, M. S. Dresselhaus, G. Chen, and Z. F. Ren, Nano Lett. 8, 4670 共2008兲. 24 C. B. Vining, J. Appl. Phys. 69, 331 共1991兲. 25 M. Lundstrom, Fundamentals of Carrier Transport, 2nd ed. 共Cambridge University Press, Cambridge, United Kingdom, 2000兲. 26 J. Singh, Physics of Semiconductors and Their Heterostructures 共McGraw Hill, New York, 1996兲. 27 Y. I. Ravich, B. A. Efimova, and V. I. Tamarchenko, Phys. Status Solidi B 43, 11 共1971兲. 28 V. Palankovsky, Thesis, Technische Universitat Wien, 2000. 29 F. Gamiz, J. B. Roldan, J. A. Lopez-Villanueva, P. Cartujo-Cassinello, and F. Jimenez-Molinos, Solid-State Electron. 46, 1715 共2002兲. 30 M. Fischetti, IEEE Trans. Electron Devices 38, 634 共1991兲. 31 J. P. Dismukes, L. Ekstrom, E. F. Steigmeieer, I. Kudman, and D. S. Beers, J. Appl. Phys. 35, 2899 共1964兲. 32 J. Callaway and H. C. von Baeyer, Phys. Rev. 120, 1149 共1960兲. 33 E. F. Steigmeier and B. Abeles, Phys. Rev. 136, A1149 共1964兲. Downloaded 20 Jun 2010 to 136.167.54.101. Redistribution subject to AIP license or copyright; see http://jap.aip.org/jap/copyright.jsp