of Single Stream Collection Systems

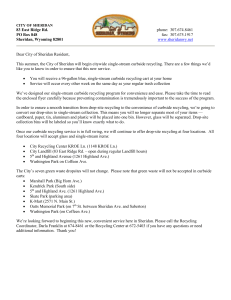

advertisement