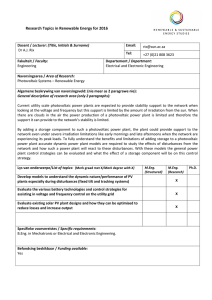

Master Thesis

advertisement