1D Barcode Verification Process Implementation Guideline

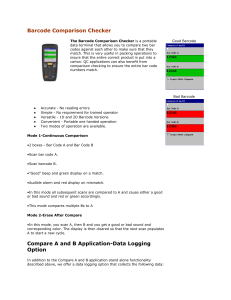

advertisement