Master`s Thesis:

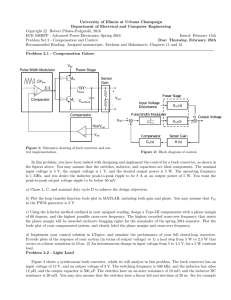

advertisement