Literature Review of High Performance Thermal Insulation

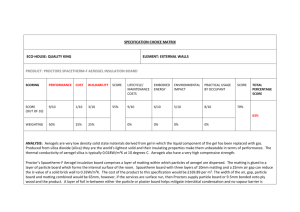

advertisement