Model 5050LL-PTD Liquid Level Pressure Transducer Instruction

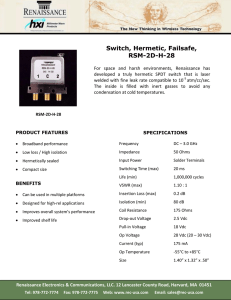

advertisement

HydroLynx Systems, Inc. Model 5050LL-PTD Liquid Level Pressure Transducer Instruction Manual Document No: A102741 Document Revision Date: December, 2004 HydroLynx Systems, Inc. Model 5050LL-PTD Liquid Level Pressure Transducer Receiving and Unpacking Carefully unpack all components and compare to the packing list. Notify HydroLynx Systems immediately concerning any discrepancy. Inspect equipment to detect any damage that may have occurred during shipment. In the event of damage, any claim for loss must be filed immediately with the carrier by the consignee. If the equipment was shipped via Parcel Post or UPS, contact HydroLynx Systems for instructions. Returns If equipment is to be returned to the factory for any reason, call HydroLynx between 8:00 a.m. and 4:00 p.m. Pacific Time to request a Return Authorization Number (RA#). Include with the returned equipment a description of the problem and the name, address, and daytime phone number of the sender. Carefully pack the equipment to prevent damage during the return shipment. Call HydroLynx for packing instructions in the case of delicate or sensitive items. If packing facilities are not available, take the equipment to the nearest Post Office, UPS, or other freight service and obtain assistance with packaging. Please write the RA# on the outside of the box. Warranty HydroLynx Systems warrants that its products are free from defects in material and workmanship under normal use and service for a period of one year from the date of shipment from the factory. HydroLynx Systems' obligations under this warranty are limited to, at HydroLynx's option: (i) replacing; or (ii) repairing; any product determined to be defective. In no case shall HydroLynx Systems' liability exceed product's original purchase price. This warranty does not apply to any equipment that has been repaired or altered, except by HydroLynx Systems, or that has been subjected to misuse, negligence, or accident. It is expressly agreed that this warranty will be in lieu of all warranties of fitness and in lieu of the warranty of merchantability. Address HydroLynx Systems, Inc. 950 Riverside Pkwy., Suite 10 West Sacramento, CA 95605 Phone: (916) 374-1800 Fax: (916) 374-1877 E-mail: hydro@hydrolynx.com Copyright © 2004 by HydroLynx Systems, Inc. Page 2 A102741 Model 5050LL-PTD Liquid Level Pressure Transducer HydroLynx Systems, Inc. TABLE OF CONTENTS SECTION NO. PAGE NO. 1.0 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 1.1 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 1.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 2.0 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.1 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.1.1 Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.1.2 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2 Cable Strain Reliefs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.3 Transmitter Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 6 6 6 6 6 3.0 THEORY OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.1 Pressure Transducer (PT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.1.1 Gage Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.1.2 Strain Gage Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.2 Signal Conditioning Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.2.1 Regulated Excitation Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.2.2 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.2.3 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.3 Desiccant Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.3.1 Vent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.3.2 Desiccant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.3.3 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 7 7 7 7 7 7 8 8 8 8 8 4.0 TESTING, CALIBRATION, AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . 8 4.1 Field Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 4.1.1 Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 4.1.2 Function Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 4.1.3 Calibration Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 4.2 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 4.2.1 Calibration Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 4.2.2 Zero Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 4.2.3 Span Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 4.3 Central Site Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 4.3.1 Divisor = 1 / Increment Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 4.3.2 Base Value - ZDP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 4.4 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 4.4.1 Desiccant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 4.4.2 Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 4.4.3 Maintenance Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 5.0 FORMS AND DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 A102741 Page 3 HydroLynx Systems, Inc. Page 4 Model 5050LL-PTD Liquid Level Pressure Transducer A102741 Model 5050LL-PTD Liquid Level Pressure Transducer HydroLynx Systems, Inc. 1.0 INTRODUCTION 1.1 General Description Refer to drawing AC107998 for a view of the Model 5050LL-PTD Sensor Assembly. The 5050LL-PTD Liquid Level Pressure Transducer combines a rugged submersible pressure transducer (PT) with a signal conditioning circuit conveniently mounted in the desiccant box. 1.2 Specifications Sensor Range: Over pressure: PT output voltage: Accuracy: Zero offset: Span setting: Operating temperature range: Compensated temperature range: Temperature effects: PT cable length: Maximum cable length: Pressure connection: Size: Weight: 5 to 50 psig (other ranges are available) 4X 10 mV/V (per excitation Voltage) ± 0.1% BSL for all ranges ±3 mV max ±10 mV max -20 to +80°C -2 to +30°C ±0.3% total error band (-2 to +30°C) 40' vented 500' (consult factory for longer lengths) M14 x 1.5 with radial inlet holes 0.7" x 4.5" (dia x length) 3.5 oz, nominal (excluding cable) Signal Conditioning and Unit Output: Operating temperature range: Signal cable: Connector: Weight: 0-5 Vdc -20 to +80°C 20' MS 4-pin, rotated 3 lbs 2.0 INSTALLATION The 5050LL-PTD is most often installed as part of the 5090 Packaged Station. Refer to the 5090 manual for site selection considerations and site installation. Other installations include well sites and snow pillow monitoring; consult factory for information on these or other installations. A102741 Page 5 HydroLynx Systems, Inc. Model 5050LL-PTD Liquid Level Pressure Transducer 2.1 Wiring 2.1.1 Wiring Diagram Most installations will require the removal of the PT cable from the desiccant box. Loosen the strain relief, then unscrew terminals on J1 and remove the cable. Once the installation of the PT is complete, re-attach the cable to the signal conditioning board. Refer to wiring diagram AC107985. Caution: Never apply power when the PT is disconnected. 2.1.2 Grounding A path to earth ground is required for the input over-voltage protection and for proper shielding of the signal cables. Both cable shields are terminated on the signal conditioning ground plane. One green wire attaches the ground plane to the ground screw inside the desiccant box. Another green wire attaches the ground screw, outside the desiccant box, to the mounting flange. The path to earth ground is complete when the desiccant box is installed to the mounting racket inside the standpipe. Important note: For installations which do not include a standpipe, another path to earth ground must be provided. 2.2 Cable Strain Reliefs Both cables enter the desiccant box through cable strain reliefs; ½" for the PT cable and ¼" for the signal cable. The strain reliefs reduce the physical strain on the electrical connection as well as provide liquid tight entry into the desiccant box. 2.3 Transmitter Connection The PT signal cable connects to the ANALOG port which is a 4-pin rotated MS connector. Refer to wiring diagram AC107985. The ANALOG port is "AN-3". When installed with a 5096N station the PT signal cable may be connected to any analog input desired. Refer to wiring diagram AC107867. Multiple PTs may be attached to a single 5096, consult the factory for wiring diagrams. 3.0 THEORY OF OPERATION The 5050LL-PTD "measures" the column of water over it's position and outputs a proportional analog signal. While there are various measured ranges possible the most common in ALERT applications is 25.5 ft. This is due to the 8-bit Analog to Digital Converter (ADC) used in the first ALERT data transmitters. An 8-bit ADC converts an analog signal to a digital range of 0-255 increments; thus increment size for the 25.5 ft measured range is 0.1 ft. Page 6 A102741 Model 5050LL-PTD Liquid Level Pressure Transducer HydroLynx Systems, Inc. 3.1 Pressure Transducer (PT) The PT is constructed of Titanium to ensure long-term reliability and incorporates a miniature silicon piezoresistive sensor that has excellent resistance against shock and vibration. The small size of the sensor is an important installation advantage in many applications. A tough polyurethane cable is molded to the PT to provide a high integrity, waterproof assembly. Kelvar is used to prevent cable elongation when the cable is used to suspend the PT, such as installations using PTs to monitor deep wells, eliminating the need for an external suspension wire. 3.1.1 Gage Pressure Differential pressure is measured between two pressure sources; Gage Pressure is when one of those sources is ambient pressure. The sensor element measures gage pressure which necessitates venting the reference side of the element to ambient air pressure. 3.1.2 Strain Gage Output The sensor element is a resistance bridge in which one component changes its resistance, in a predictable and repeatable way, when a strain is applied. When a voltage is applied to the bridge the output across the strain gage will be proportional to the strain (pressure) applied. The strain gage output is the difference between the strained and non-strained branches of the resistance bridge. The output is also proportional to the applied voltage; the proportionality is 10 mV/V, e.g. the full scale output is 83 mV if 8.3 Vdc is applied to the bridge. 3.2 Signal Conditioning Circuit Signal conditioning external from the PT housing allows each PT to be calibrated to a 0-5Vdc signal. This eliminates the large zero offset associated with enclosed signal conditioning and eliminates the requirement to have separate calibration factors for each unit in the central site computer. The field technician can perform field calibrations to correct for Zero and Span drifts, which occur over time. Refer to schematic AC107983 and assembly AC107982 drawings. 3.2.1 Regulated Excitation Voltage The excitation voltage is regulated, by U1, R1 and R2, to approximately 8 Vdc. This allows the PT to continue to operate during low battery periods. 3.2.2 Input The differential mV input from the sensor element is converted to a single ended signal, with the same magnitude, by U2. The input lines are over-voltage protected by CR6 and CR7. A102741 Page 7 HydroLynx Systems, Inc. Model 5050LL-PTD Liquid Level Pressure Transducer 3.2.3 Output The single ended signal from U2 is amplified by U3 to a 0-5 Vdc signal. Potentiometers R4 and R7 adjust the Zero and Span respectively. R5 and R6 control the gain and are chosen at the factory during calibration. Most PTs will be interchangeable with most circuit boards. Consult factory for further information on the interchange of PTs and circuit boards. 3.3 Desiccant Box The desiccant box serves three functions: 1) terminates vent to ambient pressure, 2) desiccates (removes moisture from) ambient air, and 3) houses signal conditioning. 3.3.1 Vent Previous desiccant boxes were vented to ambient pressure through a 1/8" diameter hole drilled in the enclosure. Testing has shown that the signal cable provides effective venting which eliminates the need for the vent hole. 3.3.2 Desiccant Desiccant removes moisture from the ambient air which prevents moisture from traveling down the vent tube and adversely affecting PT performance. 3.3.3 Mounting The signal conditioning circuit board is mounted to a plate with snap-on standoffs. The housing itself is supplied with a flange which slips on a mounting bracket supplied with the 5090 standpipe assembly. 4.0 TESTING, CALIBRATION, AND MAINTENANCE 4.1 Field Testing Field testing includes function test and calibration check. Due to the constraints of the PT installations, calibration is also most often performed in the field. 4.1.1 Test Setup The test setup may vary but three items must be supplied: 1) power; 2) a method for reading the voltage output; and 3) a method for applying and reading pressure. Power may be supplied from the data transmitter, through a test box (5050PTBP), or a 12Vdc battery. Read the output with a volt meter or by using the 5096 "read-an" command. The pressure can be applied in-situ and read from a staff gage or may be simulated by a water column or air pressure gage. Page 8 A102741 Model 5050LL-PTD Liquid Level Pressure Transducer HydroLynx Systems, Inc. 4.1.2 Function Test To check functionality, read the 5050LL-PTD output while a known pressure is being applied. Note: When using the "read-an 3" command it is not necessary to use the "ad-on" command. ! ! ! ! Apply power (ad-on). Read output voltage with VOM (read-an 3). Compare output to applied pressure. Limit : Output is representative of pressure applied. Refer to Calibration Curve. 4.1.3 Calibration Check To check calibration, the applied pressure must be variable and is best when zero and full scale pressures are included. ! ! ! ! ! ! ! ! Determine expected output and fill out test results sheet. Apply power. Apply low pressure (zero or ambient). Limit: # 25 mV Apply high pressure (full scale). Limit: Expected output ±25 mV (5.000 Vdc) Apply mid pressure (mid scale). Limit: Expected output ±25 mV ( 2.500 Vdc) 4.2 Calibration Besides the equipment required for a function test, calibration also requires an accurate adjustable pressure source and an accurate VOM (4½ digit accuracy). 4.2.1 Calibration Setup ! ! ! ! Fill out test results sheet; determine expected outputs. Attach pressure source to the sensor, the fitting is M14 x 1.5 with radial inlet holes. Connect VOM to signal output. Connect power - only while reading output. 4.2.2 Zero Adjustment ! Adjust pressure to zero (ambient). ! Adjust zero pot R4 to read zero volts. Note: The output will not read 0.000 Vdc as the amplifier output does not include the supply rails. ! Turn pot clockwise to lower the output voltage until it stops, usually 7 to 11 mVdc. ! Turn pot counter clockwise to raise the output voltage above this point, but below 25 mvdc. A102741 Page 9 HydroLynx Systems, Inc. Model 5050LL-PTD Liquid Level Pressure Transducer 4.2.3 Span Adjustment ! ! ! ! Adjust pressure to full scale. Adjust span pot R7 to read 5.000 Vdc. Note: Re-check the zero adjustment. Adjust pressure for mid scale. Limit: 2.500 Vdc (±0.025 Vdc) 4.3 Central Site Calibration Central site calibration includes converting raw data into engineering units with the divisor and base setting the sensor reading to the zero datum point (ZDP). 4.3.1 Divisor = 1 / Increment Size The increment size is found by dividing the measured range by the RAW increments (inc) the data transmitter uses to report that range: e.g. 25.5ft ÷ 255inc = 0.1ft/inc (RAW increments equal 255 for an 8-bit ADC and 1023 for a 10-bit ADC). The divisor is the inverse of the increment size: e.g. 255inc/25.5ft = 10 inc/ft 4.3.2 Base Value - ZDP The base value is an engineering unit value which correlates the PT zero reading to the ZDP. In most cases the ZDP is a local staff gage which is placed at a known elevation: e.g. a staff gage is at 84 ft above mean sea level, the staff gage reads 4.2 ft, the PT is reporting 2.0 ft with a ZERO Base Value; to correct the reported reading find a new Base Value = 84.0 + 4.2 - 2.0, = 86.2 ft. 4.4 Maintenance 4.4.1 Desiccant The desiccant box is vented to the ambient air and will require frequent replacement of the desiccant; how often depends upon the location. Indicating desiccant will change color, blue to pink, when it has become saturated with moisture. If the desiccant replacement frequency is uncertain, HydroLynx recommends a period of at least every three months. For sites with high humidity more than one package of desiccant may be used inside the enclosure. To dry out the desiccant, heat in a vented oven for about three hours at a temperature of 300°F. The desiccant that is in the small metal "Dri-Can" can be heated while it is inside the can without harming the can itself. Leave the desiccant in the oven until it attains a deep blue color. Remove the desiccant from the oven and place into an airtight container immediately to prevent absorption of moisture from the air. Page 10 A102741 Model 5050LL-PTD Liquid Level Pressure Transducer HydroLynx Systems, Inc. 4.4.2 Visual Inspection Visual inspection of equipment includes checking: ! ! ! ! ! ! ! PT orifice for damage, debris, and silting PT position to the local standard or ZDP All surfaces for accumulation of dust, dirt, and corrosive pollutants Cables for cuts, fraying, and other physical damage Connectors for corrosion Connectors for secure fit All mounting hardware for secure fittings 4.4.3 Maintenance Report HydroLynx recommends filling out a maintenance report during every visit to a site. Part of the maintenance report is comparing the sensor reading to the local standard. HydroLynx recommends performing the calibration check annually. 5.0 FORMS AND DRAWINGS AC107998 AC107985 AC107867 AC107982 AC100901 A100910 A104973 A102741 Outline - Sensor Wiring Diagram - Chassis Wiring Diagram - Sensors to 5096N Assembly - PCB, Signal Conditioning Curve - Voltage vs Feet of Water 5050LL-PTD Test Results Maintenance Report Page 11 5050LL-PTD TEST RESULTS Document Number A100910 Date: Serial number: Inspector: Range: Job number: PSI: Customer: Cable length: CALIBRATION DATA BY: Range DATE: inH20 Expected Vdc 100% 5.000 50% 2.500 0% 0.000 WATER TEST BY: Immersion test: Readings: Actual Vdc DATE: feet (3' minimum) DVOM: Vdc Calibration curve: NOTES HydroLynx Systems, Inc. ! 950 Riverside Pkwy., Suite 10 ! West Sacramento, CA 95605 Phone 916-374-1800 ! Fax 916-374-1877 ! Email hydro@hydrolynx.com Vdc Maintenance Report Document No. A104973 SITE INFORMATION Location: Gauge type: ID#: Purpose/Comments: Weather conditions: EQUIPMENT INFORMATION Equipment Model # Asset # Comments Data transmitter Antenna Battery Solar panel Sensors TEST DATA POWER Battery voltage w/o load: Vdc w/ load: Current Standby: :A w/ load: Solar panel w/o load: Vdc w/ load: Vdc Difference: Vdc A A Reverse: mA SIGNAL OUT - TX Power out: W Reverse power: W Freq error: Hz Dev: ± kHz SIGNAL IN - SENSOR Sensor Measured Reading Comments COMMENTS HydroLynx Systems, Inc. ! 950 Riverside Pkwy., Suite 10 ! West Sacramento, CA 95605 Phone 916-374-1800 ! Fax 916-374-1877 ! Email hydro@hydrolynx.com