Installation Instructions

PT-0-3PSI-01, PT-0-5PSI-01, PT-0-10PSI-01, PT-0-50PSI-01, PT-0-100PSI-01, PT-0-300PSI-01,

PT-0-500PSI-01, PT-0-1000PSI-01, PT-0-3000PSI-01, and PT-0-5000PSI-01 Pressure Transducers

WARNING – Maretron pressure transducers are not approved for use with gasoline. If you wish to

use the FPM100 to monitor pressures or levels of gasoline, you must obtain a pressure transducer

that is approved for use with gasoline.

Instructions

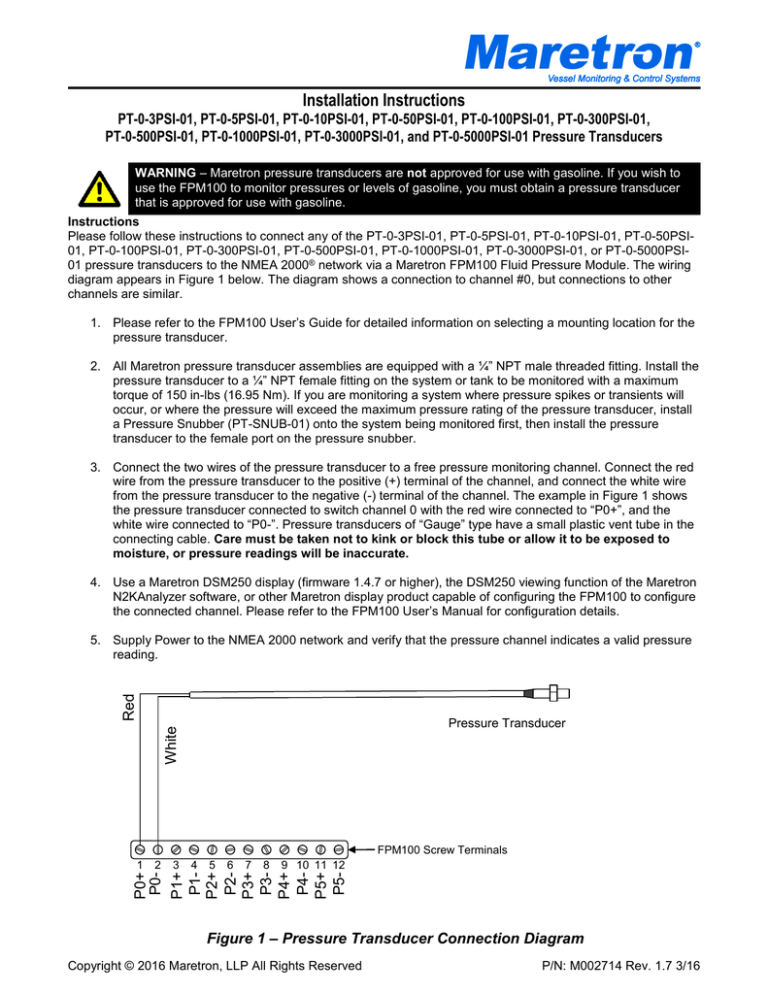

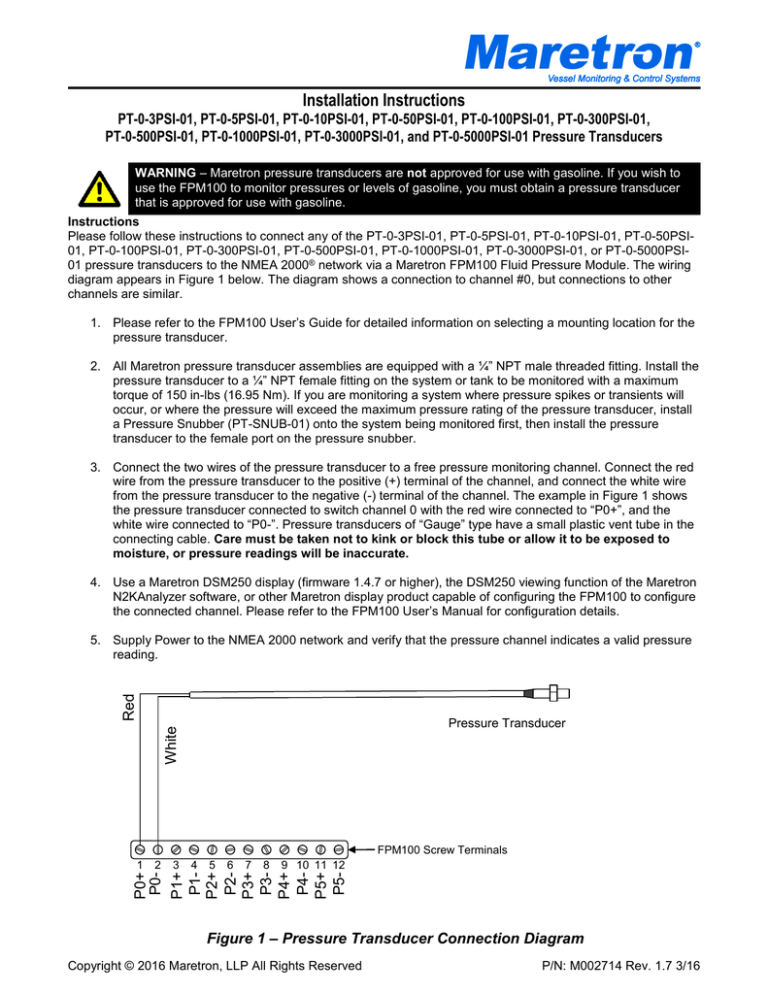

Please follow these instructions to connect any of the PT-0-3PSI-01, PT-0-5PSI-01, PT-0-10PSI-01, PT-0-50PSI01, PT-0-100PSI-01, PT-0-300PSI-01, PT-0-500PSI-01, PT-0-1000PSI-01, PT-0-3000PSI-01, or PT-0-5000PSI01 pressure transducers to the NMEA 2000® network via a Maretron FPM100 Fluid Pressure Module. The wiring

diagram appears in Figure 1 below. The diagram shows a connection to channel #0, but connections to other

channels are similar.

1. Please refer to the FPM100 User’s Guide for detailed information on selecting a mounting location for the

pressure transducer.

2. All Maretron pressure transducer assemblies are equipped with a ¼” NPT male threaded fitting. Install the

pressure transducer to a ¼” NPT female fitting on the system or tank to be monitored with a maximum

torque of 150 in-lbs (16.95 Nm). If you are monitoring a system where pressure spikes or transients will

occur, or where the pressure will exceed the maximum pressure rating of the pressure transducer, install

a Pressure Snubber (PT-SNUB-01) onto the system being monitored first, then install the pressure

transducer to the female port on the pressure snubber.

3. Connect the two wires of the pressure transducer to a free pressure monitoring channel. Connect the red

wire from the pressure transducer to the positive (+) terminal of the channel, and connect the white wire

from the pressure transducer to the negative (-) terminal of the channel. The example in Figure 1 shows

the pressure transducer connected to switch channel 0 with the red wire connected to “P0+”, and the

white wire connected to “P0-”. Pressure transducers of “Gauge” type have a small plastic vent tube in the

connecting cable. Care must be taken not to kink or block this tube or allow it to be exposed to

moisture, or pressure readings will be inaccurate.

4. Use a Maretron DSM250 display (firmware 1.4.7 or higher), the DSM250 viewing function of the Maretron

N2KAnalyzer software, or other Maretron display product capable of configuring the FPM100 to configure

the connected channel. Please refer to the FPM100 User’s Manual for configuration details.

Red

5. Supply Power to the NMEA 2000 network and verify that the pressure channel indicates a valid pressure

reading.

White

Pressure Transducer

FPM100 Screw Terminals

2

3

4

5

6

7

8

9 10 11 12

P0+

P0P1+

P1P2+

P2P3+

P3P4+

P4P5+

P5-

1

Figure 1 – Pressure Transducer Connection Diagram

Copyright © 2016 Maretron, LLP All Rights Reserved

P/N: M002714 Rev. 1.7 3/16

Pressure Transducer Mechanical Drawing

Pressure Transducer Specifications

Part Number

Range

PT-0-3PSI-01

0 to 3 PSI (0.21 bar)

PT-0-5PSI-01

0 to 5 PSI (0.34 bar)

PT-0-10PSI-01

0 to 10 PSI (0.69 bar)

PT-0-50PSI-01

0 to 50 PSI (3.45 bar)

PT-0-100PSI-01

0 to 100 PSI (6.89 bar)

PT-0-300PSI-01

0 to 300 PSI (20.68 bar)

PT-0-500PSI-01

0 to 500 PSI (34.47 bar)

PT-0-1000PSI-01

0 to 1000 PSI (68.95 bar)

PT-0-3000PSI-01

0 to 3000 PSI (206.84

bar)

PT-0-5000PSI-01

0 to 5000 PSI (344.74

bar)

Specification

Compatible Fluids / Gases

Operating Temperature

Storage Temperature

Proof Pressure

Burst Pressure

Reverse Voltage Protection

Construction

Cable Length

Pressure/Temperature Cycles

Thermal Shock

Vibration

EMC Compatibility

Humidity

Weight

Accuracy

±2% Full Scale

±2% Full Scale

±2% Full Scale

±1% Full Scale

±0.5% Full Scale

±0.5% Full Scale

±0.5% Full Scale

±0.5% Full Scale

±0.5% Full Scale

Type

Gauge (Vent Tube)

Gauge (Vent Tube)

Gauge (Vent Tube)

Gauge (Vent Tube)

Gauge (Vent Tube)

Gauge (Vent Tube)

Absolute (No Vent Tube)

Absolute (No Vent Tube)

Absolute (No Vent Tube)

±0.5% Full Scale

Absolute (No Vent Tube)

Value

Refrigerant, Motor Oil, Diesel, Hydraulic Fluid, Brake Fluid, Water, Waste

Water, Hydrogen, Nitrogen, Air

-40°C to 105°C

-40°C to 105°C

2.4 × Full Scale

2.4 × Full Scale

± 16V over 5 Minutes

304L stainless steel

3 feet (0.91m)

0 to FS @ 8Hz; and –40°C to 105°C for > 1.8x106 cycles

105°C to –40°C, 0.5 hr soaks at Temp. (2s Transfer) for 300 cycles

100 to 2000 Hz, 20g Sinusoidal, 3 Axes for 144 hours

10 Volts/meter per EN 61000-4-3

85°C and 90% to 95% R. H. for 250 hours

85g

For installation support, please contact:

Maretron, LLP

9014 N. 23rd Ave #10

Phoenix, AZ 85021-7850

Telephone: (+1) 866-550-9100

E-mail: support@maretron.com

Web: http://www.maretron.com

Copyright © 2016 Maretron, LLP All Rights Reserved

P/N: M002714 Rev. 1.7 3/16