EXPERT LABVIEW CONSULTING SERVICES

Controlling Zinc-flow Batteries and Switch-Mode

Power Regulation for Megawatt-scale Energy Storage

By François Normandin, Javier Ruiz, Tomi Maila, Jim Kring, and Ryan Talbot

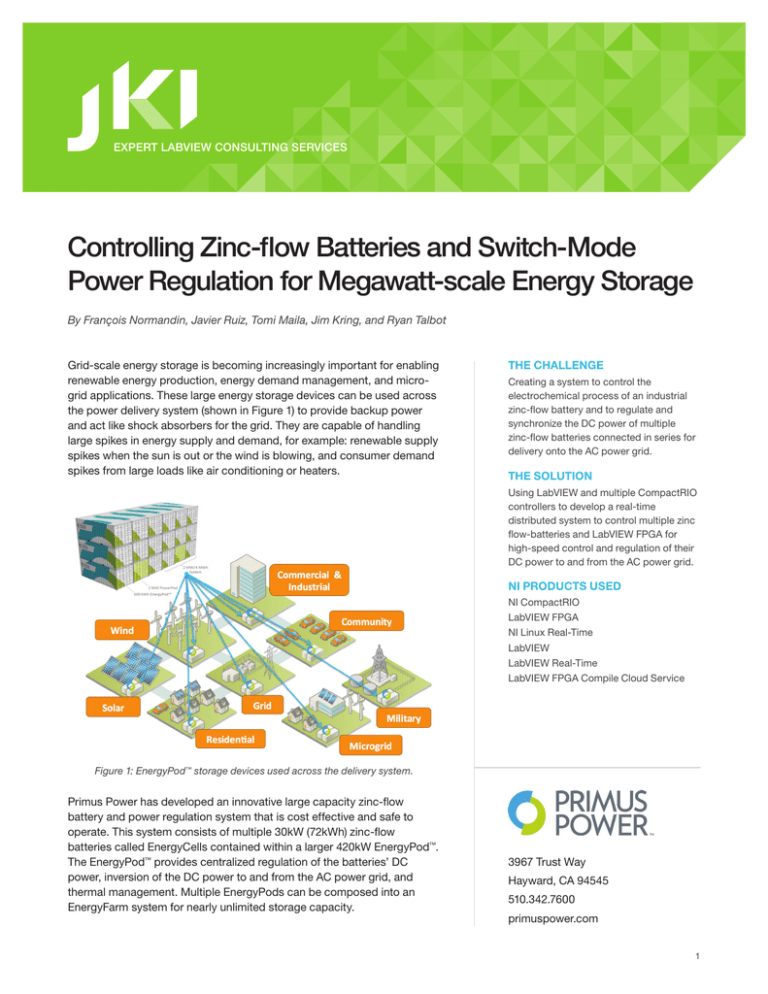

Grid-scale energy storage is becoming increasingly important for enabling

renewable energy production, energy demand management, and microgrid applications. These large energy storage devices can be used across

the power delivery system (shown in Figure 1) to provide backup power

and act like shock absorbers for the grid. They are capable of handling

large spikes in energy supply and demand, for example: renewable supply

spikes when the sun is out or the wind is blowing, and consumer demand

spikes from large loads like air conditioning or heaters.

THE CHALLENGE

Creating a system to control the

electrochemical process of an industrial

zinc-flow battery and to regulate and

synchronize the DC power of multiple

zinc-flow batteries connected in series for

delivery onto the AC power grid.

THE SOLUTION

Using LabVIEW and multiple CompactRIO

controllers to develop a real-time

distributed system to control multiple zinc

flow-batteries and LabVIEW FPGA for

high-speed control and regulation of their

DC power to and from the AC power grid.

NI PRODUCTS USED

NI CompactRIO

LabVIEW FPGA

NI Linux Real-Time

LabVIEW

LabVIEW Real-Time

LabVIEW FPGA Compile Cloud Service

Figure 1: EnergyPod™ storage devices used across the delivery system.

Primus Power has developed an innovative large capacity zinc-flow

battery and power regulation system that is cost effective and safe to

operate. This system consists of multiple 30kW (72kWh) zinc-flow

batteries called EnergyCells contained within a larger 420kW EnergyPod™.

The EnergyPod™ provides centralized regulation of the batteries’ DC

power, inversion of the DC power to and from the AC power grid, and

thermal management. Multiple EnergyPods can be composed into an

EnergyFarm system for nearly unlimited storage capacity.

3967 Trust Way

Hayward, CA 94545

510.342.7600

primuspower.com

1

The system had the following requirements:

• Real-time control and monitoring of the electrochemical processes

of each zinc-flow battery

• Real-time control of battery power distribution and inversion to allow

charging/discharging from/to the power grid

• Deterministic high-speed fault monitoring and protection to ensure

system performance and reliability

• High-speed communication to support real-time control across

multiple embedded controllers

• Flexible communication via multiple industrial protocols to support

third-party energy management systems

• Modular and expandable system architecture to support multiple

possible deployment scenarios

• Professional-grade human machine interfaces (HMI) to allow

operator control and monitoring of the high-level system, low-level

subsystems, and individual components

Primus Power had developed lab prototype systems using LabVIEW for

test and validation. When it came time to develop commercial systems for

shipment to customers, Primus Power partnered with JKI, a Silver NI

Alliance Partner specializing in commercial-quality LabVIEW development

and helping high-tech companies get their innovative products to market

with speed and impact.

Solution Details

Initially, a traditional PLC control system was considered for the

commercial systems. However, it quickly became clear that using NI

CompactRIO, powered by NI Linux Real-Time and LabVIEW FPGA, would

not only address the technical and performance requirements, but would

also reduce development time; this would enable us to get the product to

market much faster and generate considerable business value.

Each EnergyCell is controlled by an independent cRIO-9068 responsible

for managing the zinc-flow battery’s electrochemical process, state of

charge, and overall health by controlling and monitoring a variety of pumps,

valves, and sensors using NI 9375 and NI 9265 modules. Two NI 9205

modules are used to acquire 39 RSE voltage measurements for performing

real-time prediction of battery health and characterization of

electrochemical behaviors.

The EnergyCells are connected in series inside the EnergyPod to form a

high-power DC current loop called the “powertrain”. Each EnergyCell can

charge or discharge its zinc-flow battery by accepting or providing power

from or to the powertrain’s DC current loop. This is achieved with the

cRIO-9068’s FPGA plus NI 9474, NI 9401, and NI 9423 modules by

switching MOSFETs at high frequency to provide closed-loop current and

voltage regulation.

Figure 2: An Individual EnergyCell

2

The EnergyPod™ has a cRIO-9068 controller that it uses

to manage the powertrain DC current loop in order to

accept or provide power to or from the AC grid, as

requested by the EnergyFarm. The EnergyPod™

cRIO-9068’s FPGA acts as a switch-mode power

regulator that modulates IGBTs to achieve closed-loop

current and voltage control for the overall powertrain,

while individually modulating power and or bypassing

EnergyCells. Using high-speed NI 9401, NI 9423, and NI

9474 C Series modules, the powertrain system

synchronizes each EnergyCell to a common triggering

signal and distributes ON and OFF times with

microsecond accuracy. Additionally, the system is able

to detect and react to potentially catastrophic faults

within microseconds.

Figure 3: An EnergyPod containing 14 EnergyCells

The EnergyPod™ also uses its cRIO-9068 to run a

complex thermal management system (controlling pumps

and valves, and monitoring temperatures), to communicate with groundfault protection devices via Modbus, and to manage the fire suppression

and ventilation systems.

The EnergyFarm has a cRIO-9068 that controls and monitors multiple

EnergyPods, communicates with an external energy management system

(EMS) via OPC or DNP3, and controls inverters and other devices via

Modbus. When the EnergyFarm cRIO receives a request from the EMS to

accept/provide power from/to the grid, it determines the necessary steps

and commands all the EnergyPods to accept/provide the necessary power.

JKI designed and developed a modular and

distributed control software architecture that

allows for networked communication and

high scalability. Built upon the NI Actor

Framework for LabVIEW, the architecture

seamlessly runs on both embedded and PC

targets and can accommodate various

system configurations ranging from just a

couple of cRIOs to more than a hundred.

Switching between subsystem

implementations allows for fast prototyping

and rapid changes in requirements. Loosely

coupled distributed system components

make it possible to reuse elements in both

the lab and manufacturing environments. JKI

also developed commercial-grade human

machine interfaces (HMI) using LabVIEW to

provide intuitive operator control of the entire

system and individual components.

Figure 4: The control system consists of 15 cRIOs per EnergyPod™,

plus 1 cRIO for the EnergyFarm.

3

Project Conclusions

As with most high-tech product development efforts, we had an

aggressive project schedule and demanding requirements that continued

to evolve over the course of the project. NI CompactRIO, powered by NI

Linux Real-Time and LabVIEW FPGA, provided a fantastic platform for our

system, because of its performance, affordability, and ruggedness in

extreme environments where our EnergyFarm systems are deployed. We

saved thousands of dollars in custom board design and validation.

CompactRIOs were found to provide better performance and flexibility

than traditional PLCs and allowed for the reuse of existing LabVIEW code

originally written for testing and validation. Moreover, the NI Linux RealTime OS opens the door to augment the functionality of the system with

the ecosystem that Linux provides.

Using LabVIEW at all stages of the development cycle (from research to

proof-of-concept to product test and deployment) minimized the time to

market and facilitated code reusability. Moreover, LabVIEW allowed for

one programming language to be uniformly used all the way from low-level

FPGA control to high-level business logic and user interfaces.

Communication with external systems via OPC, Modbus, and DNP3 was

easily accomplished thanks to the extensive library of drivers for LabVIEW.

LabVIEW FPGA was used for running the complex high-speed control

algorithms and fault handling logic required for Primus Power’s powertrain

architecture. The LabVIEW FPGA-based solution allowed for extremely

short development iteration cycles, making it possible to go from prototype

to a shipping product in a fraction of the time compared to traditional FPGA

development. This accelerated development enabled Primus Power to

showcase its powertrain as part of an Advanced Microgrid Demonstration

at the National Renewable Energy Laboratory (NREL) in Golden, Colorado in

fall 2014, where the system was capable of islanded (off-grid) operation

using stored and high-penetration renewable energy.

Silver

Sil

Si

lver

lve

Alliance

Al

Alli

lilian

ance

an

ce

Partner

P

artner

t

JKI is a National Instruments

Certified Silver Alliance Partner.

By all measures, using NI CompactRIO, NI Linux Real-Time, and LabVIEW

FPGA significantly reduced development time, enabling our team to get

the product to market much faster than alternative approaches and make

a significant impact in the energy storage market.

3687 Mount Diablo Blvd, Suite 208

Lafayette, CA 94549

888.891.7821

jki.net

info@jki.net

jki.net/blog

facebook.com/JKISoftware

twitter.com/JKISoftware

© 2015 JKI. All rights reserved. Product and company names are trademarks or trade names of their respective companies.

4