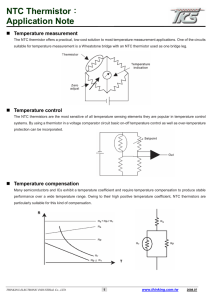

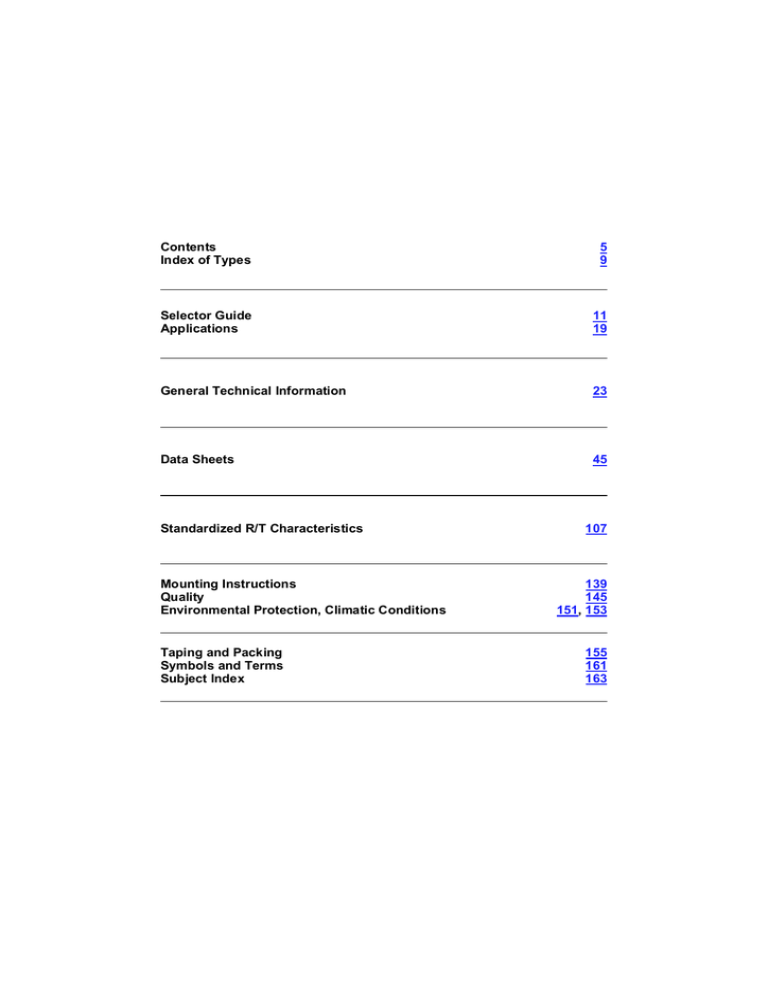

Selector Guide 11 Applications 19 General Technical Information 23

advertisement