product catalog

advertisement

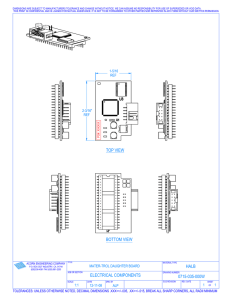

PRODUCT CATALOG B&B DENTAL implant company GENERAL INDEX - B&B DENTAL IMPLANT COMPANY..............................................4-5 - surgical kit.................................................................................. 44 - SURFACE TREATMENT..................................................................6-7 - 3P surgical kit........................................................................ 45 - IMPLANT PACKAGING...................................................................... 8 - Wide surgical kit................................................................... 46 - IMPLANT LABELING.......................................................................... 9 - Ø 3 surgical kit ..................................................................... 47 - CONEXA THE REVOLUTIONARY CONECTION.....................10-11 - SURGICAL components............................................................. 48 - DURAVIT-INN 3P IMPLANT........................................................12-13 - Surgical facilities / initial drills - Intended use......................................................................... 14 - Conical drills......................................................................... 49 - Implant site preparation..................................................... 15 - Compactor expander........................................................... 50 - Drilling technique - Counterbore......................................................................... 51 - Bone Compactor-Expander................................................. 16 - Characteristics - Duravit-Inn WIDE......................................................................... 17 - Wide conical drills................................................................ 52 - Characteristics........................................................... 18-19-20 - Metal stoppers / Wide metal stoppers.............................. 53 - surgical COMPONENTS............................................................. 21 - Implants drivers 3P / Wide and ø3...................................... 54 - surgical components / healing screws................................ 22 - Prosthetic drivers.................................................................. 55 - IMPRESSION COMPONENTS........................................................ 23 - Ratchet & manual key - Mini Duravit Implant................................................................. 56 - Closed tray transfer / Open tray transfer - PROSTHETIC COMPONENTS........................................................ 24 - Characteristics...................................................................... 57 - Try-Inn kit abutments............................................................ 25 - Surgical Protocol.................................................................. 58 - Titanium Abutments (cement-retained restoration).....26-27 - Surgical kit................................................................................. - Temporary Abutments (cement-retained restoration)....... 28 - Prostetic components.......................................................... 59 - Multi-scan abutment (cement-retained restoration)......... 29 - MATERIAL FOR BONE REGENERATION...................................... 60 - Zirconium abutments (cement-retained restoration)........ 30 - Novocor plus........................................................................ 61 - Multi-use abutment (screw-retained restoration).............. 31 - T-barrier membranes............................................................ 62 - Surgical components........................................................... 32 - KDURAVIT CRESTAL SINUS LIFT.................................................... 63 - Prostetic abutment (screw-retained restoration)............... 33 - OSTEOTOMES................................................................................. 64 - Attachment -retained restorations...................................... 34 - PHYSIO DISPENSER 3000................................................................ 65 - Equator anchor system........................................................ 35 - MARKETING & TRAINING MATERIALS....................................66-67 - Spherical anchor system...................................................... 36 - Bar system............................................................................. 37 - DURAVIT IMPLANT-3P Ø 3.........................................................38-39 2 - Characteristics - Intended use / implant site preparation............................. 40 - Surgical and impression components................................ 41 - Titanium abutments (cement-retained restoration).......... 42 - Spherical anchor system...................................................... 43 3 B&B DENTAL implant company B & B Dental s.r.l. is an Italian leading company in oral implantology, established in Quality and control 1991, specialized in the development of products such as dental implants and materials All production stages are constantly monitored by sophisticated management systems for bone regeneration. The experience gained over the years let us to develop high which intervene automatically during running processes in case of deviations from the quality prosthetic implant technologies and innovative materials with affordable prices. set parameters. Production controls are based on defined protocols called SPC (Statistic Process From more than 20 years B & B Dental Technologies Ltd. is conceived by dental surgeons Control) in which the amount and frequency of controls and the criteria for acceptability for dental surgeons assisted by engineers expert in implantology. are fixed (depending on the type of product). It is all started from a Dr. Claudio Banzi’s idea who became in 1982 one of the early Dimensional checks are made on the last-generation three-dimensional measuring pioneers of implantology by investing his savings in one of the first patent for dental machines, capable to ensure an accuracy of ± 0.0005 mm (0.5 microns). implants “DURAVIT SYSTEM” and material for bone regeneration “Novocor PLUS” he The quality of production complies with EN ISO 13485:2003 / AC: 207 and 93/42/EEC did not know that he was founding one of the first implant companies. on medical devices. In 2007 his team of engineers developed a new connection CONEXA which aims to reduce the uscrewing of the prosthetic screws and avoids the bacteria colonization at Warehouse the base of implants. That is how the second generation of implants “DURAVIT INN” Finished and semi-finished products are stocked and organized by vertical lift automatic was born. cabinets allowing a rationalization of the space and a fully computer based processing Dr. Claudio Banzi has an experience of more than 20 000 implants placed, millions of of the orders. Standard orders are shipped within 48 hours in Italy and 7 working days surgeons trained and hundreds of lectures gave around the world, he has spread B & B in the foreign countries. Dental Ltd. values which are: integrity, knowledge sharing and innovation. Customer service Research and development B & B Dental s.r.l. works to satisfy the customer’s expectations and is represented with We are constantly improving our products and techniques by listening to customer dealers in 60 countries. A careful pre-sale and postsale customer assistance is provided needs and their issues. Taking also advantage of support higher education structures by qualified technical and commercial staff works to meet any requirement or question and institutions that enable us to verify the validity of our products according to the latest in order to give detailed information and help the client to choose the product and in technologies and best-established techniques. Experience also allows us to evaluate, its application and use . design and innovate by producing materials designed and tested in our structures and certify they in different countries. Training and update Courses are held to illustrate a wide variety of prosthetic solutions in line with the 4 Production “philosophy” of the company, which consists in apply new techniques to get reliable Our staff is composed by qualified engineers, mechanical experts. and valid results, providing an alternative to well known traditional techniques which we use last generation CNC lathes bar, which are high precision machines, with dynamic have been used for years. correction of the tools that enable compliance with tolerances of ± 0.001 mm (1 micron) The experience of dentists and dental technicians who actively collaborate with us, to produce our components. joined to the research of our department technical planning and micro-mechanics, All the innovations in the production stages and characteristics of our pieces are the have enabled us to achieve excellent results and to develop courses that interest all the result of continuous intensive studies as well as of significant and constant investments. operators. 5 SURFACE TREATMENT The clean surfaces of equipment is a slightly complex task. Even if the solvents used for cleaning are very pure can leave traces on the below surface. The few impurities or the solvent molecules can be combined with the constituents of implants surface, especially in the case of reactive materials such as metals. The perfect tool for cleaning should be unable to react chemically with the material Evaluation of surface topography of DURAVIT implants treated with Speed-Bone method device and at the same time be very efficient the remove contaminants. It is possible to exploit this ideal principle by cleaning with plasma. From this point of view B & B Dental Ldt. is among the few companies in Italy which uses technological high-level quality The aim of this work was the evaluation of the surface treatment, decontamination procedures . using the Sandblasted and doubly acid etched on “DURAVIT”implants. METHODS AND MATERIALS Sandblasting surface etching The surface topography of the implants was evaluated by scanning electron microscope (SEM). B & B Dental Ldt.’s team of international researchers with proven experience in Roughness was evaluated quantitatively using dedicated software to convert treatment processes for implant surfaces has developed the company’s exclusive conventional SEM images into three-dimensional data (Mex 4.2, Alicona Imaging). Speed-Bone treatment, which guarantees a controlled surface profile characterised by In particular, in this case, the images are increasing magnifications (shown in each strong osteoinductive power, better bone anchorage and shorter healing times. Component surfaces are sandblasted with alumina oxide by using a dedicated image) of the treated implants. Fig. 1 appliance. The surface is treated with a double etching by using mineral acids. This treatment aims RESULTS to obtain, by subtraction an implant surface with a controlled micro-roughness. The main results of SEM observation are reported in the micrographs below: The initial roughness level favours the initial osteoblast cells anchor and the integration First of all, (Fig. 1) shows a low magnification (200 x) image of the sample. It is possible to with the bone tissue, reducing the osseointegration time. All processes are performed in appreciate the nice machining work, together with a homogeneous surface finish without machines that guarantee the homogeneity of the surface and therefore the maintenance particles or blasting residuals. of the characteristics along all the implant surface. Fig. 2 Fig. 3 Fig.4 (Fig. 2) Increasing the magnification, we observe the typical topography induced by this treatment, where it can be appreciated larger craters due to blasting and internally it can be noticed a more short-ranged roughness. Argon plasma treatment (Fig. 3 and 4) (2500 and 5000 x) show the typical structure of micro-roughness surfaces treated with double acid attack. As known and as reported in the scientific literature on The ideal cleaning tool, argon plasma cleans component surfaces by bombarding them the subject, this particular micro-topography enables the surface to act as a “sponge”, with accelerated ions ARGON gases are opportunely used inside a reactor in order interacting strongly with the clot and stimulating bone re generation. these images to form a plasma constituted by the gas heavy ions that reacts with the surface of show better the absence of contaminants or foreign deposits, as shown below in the the implant removing all the contaminants. This means that they do not come into contact with solvents and organic contaminants are removed by exploiting the impact of plasma particles. The plasma treatment reactor used to clean implant screws is housed in a class 10000 clean room, to guarantee the absence of environmental contamination. As a last process efficacy test, component surfaces undergo sophisticated, dedicated assays. Specifically, each batch of implant screw undergoes x-ray photoelectron spectroscopy (XPS or ESCA), a widely-used rough surface analysis technique as well as surface analysis section. Fig.5 Campione Ra Rq B&B Dental 3.19 ± 1.06 4.78±1.15 SLA* 3.93 ±0.93 4.69±1.19 Rt 11.41±1.06 12.76±4.10 (Fig. 5) EDX analysis confirms that the only elements detected are Ti, Al and V, as expected from the nature of the sample. *Da: Park JY, Gemmell CH, Davies JE, Platelet interactions with titanium: modulation of platelet activity by surface topography, Biomaterials, 2002; 22:2671-2682 (Fig. 6) To quantify the roughness a stereo SEM analysis three-dimensional Fig.6 reconstruction of the surface has been used to provide the following data, reported in accordance with ISO 4287: (the table contains, for comparison, the values of the SLA its chemical composition composed 95% by titanium. from the literature): This type of analysis provides information on the qualitative and quantitative chemical composition of the first few nanometres of the material, the layers that come into the (Fig. 7) show the typical topography expected. The values observed on DURAVIT most direct contact with the bone tissue. implants treated with the Speed-Bone method are derived from the analysis of two points for each sample, a statistical point of view they are not significantly different than the parameters reported in the literature. Therefore in general the data are in good agreement with expectations for this type of treatment. Fig.7 6 7 Implant Packaging IMPLANT LABELING Innovative packaging for “Duravit 3P”, over the past few years, have been based on customer input to make our implant systems more efficient and easier to use. The label on the package of any medical device set on the market will show the symbols in compliance with the harmonized standards, based on the ISO 21531, ISO 15223-1, EN 980 European Standard and on the 93/42EEC Directive. Simplified retrieval The packaging provides an easy access to the implant and cover screw. Implant can be easily lifted once the Plastc Mount has been engaged by the implant driver. Cover screw is located in the upper portion of the Plastc Mount . Simplified delivery B&B DENTAL implant company Touchless delivery system allows the implant, upon retrieval, to be carried directly to patient’s mouth without any intermediate steps. Description: IMPLANT 3P Diameter:........ ø 4 mm Rev00 del 21/06/2010 Length:......... L. 10 mm 3P-4010 Packaging Components 2016-06 2811 Implant 3P 3P-4010 ø 4 mm L. 10 mm 2811 2016-06 B.&B. Dental srl - S. Pietro in Casale (BO) ITALY B.&B. Dental srl V. San Benedetto, 1837 40010 S. Pietro in Casale (BO) ITALY Rev00 del 21/06/2010 Mat. Ti Gr 4 Cover screw (Titanium) Implant passport Each implant is accompanied by an “implant Passport” issued by the implantology to the patient after surgery. It’s a guarantee of the quality of the implants and components used and contains traceability information useful for a more careful management, particularly in patients from other dentists. C % MAX. Cons. Fe.30 M 0.35 C.10 Y CM N.05 MY H.0125 CY CMY REST Ti C K M Certificato per il paziente MATERIALE USATO Titanio Commercialmente Puro Via San Benedetto, 1837 40018 San Pietro in Casale (BO) Italy Tel. +39 (0) 51 81.13.75 - Fax +39 (0) 51 666.94.00 info@bebdental.it - www.bebdental.it DURAVIT IMPLANT KIT 0123 MY CY CMY K Implant line Product code Lot number Sterilization with gamma rays Read the instruction sheet The device must be use exclusively by the physician Monouse UPPER SUPERIORI Dentist’s name: Studio Dott.: Customer certified USED MATERIAL Commercially Pure Titanium CM Implant 3P Patient’s name: Nome del paziente: IMPLANT COMPANY KIT IMPIANTO DURAVIT Y known about the symbols DX Expire date Producer SX Date: Data: LOWER INFERIORI Lot: ø L. COLOUR CODED ø 3,5 mm ø 4 mm ø 4,5 mm ø 5 mm 8 9 CONEXA the revolutionary connection CHARACTERISTICS CHARACTERISTICS: INTERNAL EXAGON “MORSE” TAPER - Easy and safe transfer of the abutment’s position and The CONEXA is a revolutionary connection between im- The hexagon enhances the resistance to torsional loads The Morse taper ensures a very high mechanical stability as impression taking plant and abutment, results from the combination of two and allows an easy transfer of the abutment’s position from well as an absence of micro movements, a perfect bacterial geometries: the laboratory to the dental office seal and an optimal distribution of the masticatory load. ADVANTAGES - Absence of micro movements, The “Morse” effect (Fig. 1) - Optimal distribution of the masticatory load Inserting with pressure an element with a tapered external - Perfect bacterial seal PLATFORM SWITCHING surface in a corresponding female element that has a hole The concept of the platform switching is aimed to minimize with an identical tapered design, the friction between the the vertical bone loss by providing different diameters of two tapered surfaces, combined with the push created by the platform and the abutment. The clinical advantages of the insertion force that presses them together, locks the this concept are as follows. male cone in the female one. - To obtain a good long-term prognosis through increasing This locking remains and keeps itself efficient also when the the degree of bond between implant and bone by mini- insertion force applied ceases. This is the “Morse” effect. mizing the bone loss of crestal area. PLATFORM SWITCHING “MORSE” TAPER - To make it possible to produce an aesthetic prosthesis Avoid of breakings and unscrewing of the prosthetic screws with the reproduction of papilla through minimizing the A suitable tapering of the cones guarantees the “locking” bone loss between implants and protecting the recession that will be a safe and natural anti unscrewing system for of papilla. the prosthetic screws that connects the abutment to the im- - To protect the concentration of force on the crestal area. INTERNAL EXAGON plant. These screws bring to the perfect engaging between the surfaces to avoid the strengths that could bring to its breaking Extractor Screw The "Morse" effect is created by such push that, combined with the friction existing between the two surfaces of the cones, locks the 2 parts (implant-abutment) that can be dismounted only inserting an “Extractor screw” (ref. INN-6050) 10 11 DURAVIT-INN 3P IMPLANT CHARACTERISTICS CONE MORSE & HEXAGON MICROGROOWING COLLAR CONE MORSE & HEXAGON COLLAR MICROGROOWING The internal tapering and hexagonal connection shows an The specific micro-architecture of the implant collar incre- increased contact area between the fixture and the abut- ases the primary stability and facilitates the introducion of ment, ensuring a prolonged durability in time, a superior the implant. It promotes hence soft tissue’s healing process stability and unscrewing of the dental abutment. and reduces the risk of bone resorption at collar level. The hexagonal connection shape ensures precise positioning of prosthetic components and allows optimal choices TRIPLE THREAD BODY PERFECT ANATOMICAL DESIGN LIKE A RADICULAR STRUCTURE for the respect of parallelism. PERFECT ANATOMICAL DESIGN LIKE A RADICULAR STRUCTURE TRIPLE THREAD BODY The innovative macromorphological facility of Duravit-INN 3P implant line, with a variable degree of tapering, more The revolutionary triple threads, unique in its nature, allows pronounced near the apical region, has been designed to the full insertion of the implant body more easily than using make easier implant’s insertion and to achieve an high pri- other common implants. mary stability even in cases in which the bone is being un- This advantage simplifies extremely the work of the oral dermined, ensuring therby the full integrity of all proximal surgeon and reduce considerably the time of insertion. structures. The thread has a particular 60° degrees beveled profile: which shape, angle and depth are specificaly conceived to increase contact surface with the bone. It reduces the invasive process and improves at the same SELF-TAPPERING SYSTEM time the osseointegration. “BONE FRIENDLY” APEX The implant apex shape help to avaluate the floor at the maxillary sinus, avoiding th risk of perforeting in SELF-TAPPERING SYSTEM The triple apical groove of Duravit-INN 3P implants has APICE “BONE FRIENDLY” been designed with a special sharp skewed section and in order to promote bone tappering during the insertion and preventing at the same time any trauma resulted from pressure. 12 13 DURAVIT-3P IMPLANT IMPLANT SITE PREPARATION INTENDED USE Drilling technique Suitable for Hard bone. (D. I , II) ø4 ø4 L2mm L3mm Cover screw (Titanium) Implant sites are prepared in a step-by- L (A)* mm - All the implants are supplied with step procedure using drills of different Implant 3P ø 3,5 Implant 3P ø 4 diameters to ensure an efficient and - Progressive taperd implant atraumatic widening of the implant site. - Achives hight primary stability All drilling of the bone tissue should - Easy, fast and stable implant be carried out under profuse external insertion irrigation with saline solution and with ø 2,6 - Beter control during implant placement - Sutable for all procedures - Sutable for all bone types ø 3,2 Ref. ø 3.5 an intermittent drilling technique to prevent heating of the bone and to Ref. ø 4 L. (08) 3P-3508 L. 06 3P-4006 * L. (10) 3P-3510 L. 08 3P-4008 L. (12) 3P-3512 L. 10 3P-4010 L. (14) 3P-3514 L. 12 3P-4012 create a pumping effect for efficient removal of bone tissue. Ø 2,2 Bone density D1/D2 Ø3 Ø 3,5 Final Drill - Ref. 3P-35CUT Ø 2,2 Ø3 Ø 3,5 Ø4 Bone density D1/D2 Final Drill - Ref. 3P-40CUT DRILLING SPEED Hard bone: 500/800 Rpm. L. 14 3P-4014 Implant 3P ø 4,5 Soft bone: 200/300 Rpm IMPLANT PLACEMENT ø 4,5 Nota: If you feel strong resistance at the ø5 time of placing the implant, rotate Lenght 6 mm Implante ø 4 and ø 5 include a shorter prosthetic screw that has to be used for final setting of the abutment L2mm L2mm back (counter-clockwise) 2-3 turns then continue to screw clockwise. The implant will drill and tap itself. Ref. INN-6055 L (A)* mm Blue color screw Ø 2,2 Ø3 Ø 3,5 Ø4 Ø 4,5 Bone density D1/D2 Final Drill - Ref. 3P-45CUT Implant 3P ø 5 ø 3,7 Ref. ø 4.5 ø 4,3 Ref. ø 5 legend L. 08 3P-4508 L. 06 3P-5006 * ø 3 mm L. 10 3P-4510 L. 08 3P-5008 L. 12 3P-4512 L. 10 3P-5010 ø 3,5 mm L. 14 3P-4514 L. 12 3P-5012 L. 14 3P-5014 ø 4 mm ø 4,5 mm ø 5 mm 14 Ø 2,2 Bone density D1/D2 Ø3 Ø 3,5 Ø4 Ø 4,5 Ø5 Final Drill - Ref. 3P-50CUT 15 IMPLANT SITE PREPARATION Duravit-inn Wide Bone Compactor-Expander Suitable for spongy bone. (D. III , VI) AN ALTERNATIVE TO OSTEOTOMES Implant 3P ø 3,5 Implant 3P ø 4 Duravit bone Compactor-Expander are an alternative to osteotomes for the expansion and condensing of the atrophic mandible and maxilla in preparation for dental implant insertions. Compactor-Expander are also an alternative to the maxillary sinus elevation technique. SURGICAL TRAUMA DECREASED Ø 2,2 Ø3 Ø 3,5 Bone density D3/D4 Final Compactor - Ref. 331-3P Ø 2,2 Ø3 Ø 3,5 Ø4 Bone density D3/D4 Final Compactor - Ref. 381-3P Implant 3P ø 4,5 Duravit bone Compactor-Expanders are driven into the bone manually with a surgical driver or with torque ratchet. This decreases the surgical trauma of osteotomes. Bone compactor-expanders improve the clinical success by improving stability, maintaining bone density and increasing fixation. IMPLANT PLACEMENT Ø 2,2 Bone density D3/D4 Ø3 Ø 3,5 Ø4 Ø 4,5 Final Compactor - Ref. 431-3P Implant 3P ø 5 If you feel strong resistance at the time of placing the implant, rotate back (counter-clockwise) 2-3 turns then continue to screw clockwise. The implant will drill and tap itself. Ø 2,2 Bone density D3/D4 16 Ø3 Ø 3,5 Ø4 Ø 4,5 Ø5 Final Compactor - Ref. 481-3P 17 DURAVIT-3P Wide IMPLANT CHARACTERISTICS CONE MORSE & HEXAGON DURAVIT-INN WIDE MICROGROOWING COLLAR TRIPLE THREAD BODY PERFECT ANATOMICAL DESIGN LIKE A RADICULAR STRUCTURE Innovation “Duravit-inn Wide” dental implant systems feature a body The “Duravit-inn Wide” dental implant system is the first to with a larger-than-conventional diameter to fill the molar allow for immediate placement into a multi-rooted molar site, ultimately achieving primary stability from engage- extraction site. ment with the perimeter bony wall. intended use: With tapered dental implant bodies and an enhanced sur- A conventional implant is not suited for immediate place- face, the “Duravit-inn Wide” dental implant is designed to ment in the molar extraction socket. As a result, waiting fit the natural shape of the molar socket. The end result is periods of three to four months are necessary to allow for an optimal implant fit in the multi-rooted immediate ex- healing of the socket prior to implant placement. Often, traction site that minimizes bone loss and reduces treat- the healed extraction site presents reduced bone height, ment time. inadequate for implant placement without a bone augmentation procedure. SELF-TAPPERING SYSTEM APICE “BONE FRIENDLY” 18 19 DURAVIT-INN Wide IMPLANT Surgical and Prosthetic Benefits: surgical COMPONENTS ø 5,5 ø6 -Fits multi-rooted molar socket and allows for L2mm immediate placement following extraction L2mm -Minimizes need for bone grafting -Increases patient acceptance - Reduces treatment time L (A)* mm -Maximizes bone preservation -Ability to use standard surgical protocol and instrumentation with minimal additions ø 0,0 Note 1: ø 0,0 Ref. ø 5.5 Ref. ø 6 L. (06) WIDE-5506 L. 06 WIDE-6006 The implant “Duravit inn-Wide “ use L. (08) WIDE-5508 L. 08 WIDE-6008 the same prosthetic accessories and prostetics L. (10) WIDE-5510 L. 10 WIDE-6010 driver of “Duravit 3P “ L. (12) WIDE-5512 L. 12 WIDE-6012 L. (14) WIDE-5514 L. 14 WIDE-6014 ø 6,5 Note 2: ø7 L2mm L2mm shorter prosthetic screw that has to be used for final setting of the L (A)* mm Lenght 6 mm Implante includes a abutment ø 3,7 Ref. ø 6.5 ø 4,3 Ref. ø 7 Healing Screw Transfer L. 06 WIDE-6506 * L. 06 WIDE-7006 Blue color Screw Healing Screw is a solid, one-piece component, designed to Impressions taken at the implant level can offer several L. 08 WIDE-6508 L. 08 WIDE-7008 Ref. INN-6055 support optimal aesthetic results. The Screw is used for soft advantages: L. 10 WIDE-6510 L. 10 WIDE-7010 tissue contouring during the healing phase and can be used for - The quality of prosthetic planning and treatment can be L. 12 WIDE-6512 L. 12 WIDE-7012 both one- and two-stage surgery. Healing Abutments can be L. 14 WIDE-6514 L. 14 WIDE-7014 used in combination with a removable temporization. Prezzo: � 130,00 (iva 4%) enhanced - Implant angulations can be compensated for at an early stage - Individual anatomic designs can be performed through Implant WIDE ø 5,5 Implant WIDE ø 6 Implant WIDE ø 6,5 Implant WIDE ø 7 One-stage surgery Place a Healing Abutment at time of implant installation. After abutment selection and preparation - The Implant Transfer (Pull-off impression technique) or healing, replace the healing abutment with a temporary or Implant Pick-up (open-tray technique) ensures precise and permanent abutment. easy impression procedures. Implant Transfers and Implant Pick-ups are two-piece Two-stage surgery components and available for different clinical situations. Place a Cover Screw at time of implant installation and suture In order to achieve optimal results, the impression should the soft tissue. After appropriate healing period the healing be carried out with a rigid impression tray and a suitable abutment is placed at a second surgical procedure. From here impression material. on continue as for One-stage surgery. 20 21 IMPRESSION COMPONENTS Cover screw (Titanium grade 5) Pull-off impression transfer (closed tray technique) Place the plastic transfer by pressure-fitted Provided in the implant package. Use when you want to completely cover the implant after it has been inserted. into the implant hexagon and make some little The implant is reopened 3-6 months, followed by the use of healing screws. moments to check the correct position of the PULL-OF TRANSFER Each pack contains 3 pcs Ref. INN-00306 13,3 mm SURGICAL COMPONENTS transfer (Fig. 1). Prepare a standard impression tray and Inject Fig. 1 ANALOGUE Ref. INN-00585 elastomeric impression material around the Implant Transfer and into the impression tray (Fig. 2). Fig. 3 Once the material is solid, remove the impression and pressure-fitted the Analogue into the impresion model (Fig. 3). Fig. 2 TIGHTENING: Ref. 016013 NOTE: It is important to use a tear resistant material. PLASTIC CUP Each pack contains 2 pcs Ref. INN-00507 Insert the Cover Screw into the implant and tighten with only light finger force FACILITY transfer (closed tray technique) Place the transfer impression inside the implant Healing screws (Titanium grade 5) and make sure the internal hex is correctly Each package contains 1 piece. driver using light finger force. After that place engaged before tightening with Hexagon screw These components are used to rehabilitate soft tissue on the implant in order to insert the final prosthetic abutment later on. COMPLEATE SET - plastic cup - screw - metal trasfer Ref. INN-00506 Fig. 1 correctly the plastic cap on the transfer (Fig. 1). Prepare a standard impression tray and Inject elastomeric impression material around the They are available in different heights and Implant Transfer and into the impression tray in 2 different diameters profile: (Fig. 2). - Ø 5 indicated for anterior area Once the material is solid, remove the impression - Ø 6 indicated for posterior area and take out the impression copings to attach ø5 the analogue and correctly reposition into the ø5 ø5 ø5 impression model (Fig. 3). ø5 H. 7 Ref. INN-6010 H. 3 H. 2 H. 1 Ref. INN-6011 ANALOGUE Ref. INN-00585 Ref. INN-6012 Fig. 2 H. 5 Ref. INN-6014 Ref. INN-6015 Open tray transfer (open tray technique) and make sure the internal hex is correctly ø6 engaged before tightening the screw using light ø6 H. 2 COMPLEATE SET - post screw - metal trasfer Ref. INN-00600 10 mm Place the transfer impression inside the implant ø6 Fig. 3 Fig. 1 finger force. (Fig. 1). Prepare a customized impression tray and Inject H. 3 elastomeric impression material around the H. 1 Implant Transfer and into the impression tray. ANALOGUE Ref. INN-00585 (fig 2) Ref. INN-6020 22 Ref. INN-6021 Ref. INN-6022 TIGHTENING: Tighten the Implant Transfer securely into the Insert the Healing Screw into the implant and tighten with only light finger force Implant Analogue using light finger force (fig. 3). Fig. 2 Fig. 3 23 PROSTHETIC COMPONENTS Try-INN Kit Abutments CEMENT-RETEINED AND SCREW-RETEINED RESTORATIONS (Plastic product) Try-INN Kit Abutments Helps the dental technician select the most suitable abutment, based on the inclination and laser mark the transmucosal height of the implant that has been inserted. Characteristics - Simple; - Color-coded and well-marked on the holder and easily readable TRY-INN abutments; color coded - Comprehensive TRY-INN set containing all TRY-INN abutments arranged clearly; Turn the plastic kit up side down tho read the corrisponding ø5 titanium abutment - Easy handling thanks to the plastic holder; - Proper seating of TRY-INN abutments verified through the clear-cut response from, the prosthetic connection; - TRY-INN abutments fabricated of sterilizable polymer material. Cement-retained Restoration Screw-Retained Restoration Note The cemented implant is defined The prosthesis is screwed on implants abutments following intra-oral use. The bonevolume available, occlusion, as an intermediate elements of defined as a prosthetic screw prosthetic needs and requests of the cementedprosthesis (false stumps) edintermediate elements (pillars), in turn, patient’s choices aesthetics of the screwed directly on the plants screwed directly on the plants advantages: advantages: - Improved aesthetics due to compliance - Easy disassembly of the prosthesis Analysis of pre-implant allows you to choose between the different prosthetic options. Be sure to clean and sterilize the planning TRY-INN KIT REF. 000.07 The box contains 3 pcs. of each code Do not sterilize the TRY-INN abutments cassette. prosthesis. with the profile of emergency phone - The concrete sealant facilitates the Anatonical STRAIGHT ABUTMENTS - Connecting with pillars anatomical - No use of sealants, cements ø5 ø5 ø5 15° ANGLED ABUTMENTS ø5 ø5 ø5 25° ANGLED ABUTMENTS ø5 ø5 ø5 passivation structure. - Easy balancing occlusal disadvantages - Profile emergency anatomical disadvantages - Difficulty in removal of the prosthesis - Risk that the concrete comes out below the gum line 24 sometimes difficult to achieve - Projection of the screws on the occlusal H. 1 H. 2 H. 3 H. 1 H. 2 H. 3 surface - Difficult to control the liability Ref. PC107.01/1 Ref. PC107.01/2 Ref. PC107.01/3 Ref. PC107.02/1 Ref. PC107.02/2 Ref. PC107.02/3 H. 1 Ref. PC107.03/1 H. 2 Ref. PC107.03/2 H. 3 Ref. PC107.03/3 25 Titanium Abutments (cement-retained restoration) Prosthetic abutments are titanium components that are fixed to the dental implant using prosthetic screws to create a prosthetic anchorage. STRAIGHT ABUTMENTS ANGLED ABUTMENTS ø5 Straight abutment is designed to meet the clinicians’ demands to meet more demanding implant for conventional crown and bridge angulations. procedures and restorative simplicity. They are available in 2 different They are available in 2 different diameters profile: diameters profile: - Ø 5 indicated for anterior area 11 mm - Ø 5 indicated for anterior area - Ø 6 indicated for posterior area - Ø 6 indicated for posterior area and 3 heights ( H. 1 , H. 2 H. 3 mm) and 3 heights ( H. 1 , H. 2 H. 3 mm) 11 mm according to the gingival , mimicking according to the gingival , mimicking optimal preparations of natural teeth, optimal preparations of natural teeth, PROSTETIC SCREW Ref. INN-6050 which provides the opportunity to create esthetics for all tooth which provides the opportunity to create PROSTETIC SCREW Ref. INN-6050 esthetics for all tooth TIGHTENING: TIGHTENING: the prostetic screw using the 1.25 Hex Screwdriver and Torque Wrench. Recommended torques for final seating 25 Ncm the prostetic screw using the 1.25 Hex Screwdriver and Torque Wrench. Recommended torques for final seating 25 Ncm 15° ANGLED ABUTMENTS Ø 5 25° ANGLED ABUTMENTS Ø 5 Complete with Prostetic Screw Complete with Prostetic Screw ø5 ø5 ø5 ø5 ø5 ø5 H. 1 H. 2 Ref. INN-2015 Ref. INN-2016 H. 3 Ref. INN-2017 H. 2 H. 1 Ref. INN-2025 Ref. INN-2026 H. 3 Ref. INN-2027 Ø 5 STRAIGHT ABUTMENTS Ø 6 STRAIGHT ABUTMENTS 15° ANGLED ABUTMENTS Ø 6 25° ANGLED ABUTMENTS Ø 6 Complete with Prostetic Screw Complete with Prostetic Screw Complete with Prostetic Screw Complete with Prostetic Screw ø5 ø5 ø5 Ref. INN-2000 H. 2 Ref. INN-2001 H. 3 Ref. INN-2002 ø6 ø6 ø6 H. 1 26 ø5 15° / 25° Angled abutment version H. 1 Ref. INN-2030 H. 2 Ref. INN-2031 ø6 H. 3 Ref. INN-2032 ø6 ø6 H. 1 Ref. INN-2065 H. 2 Ref. INN-2066 H. 3 Ref. INN-2067 ø6 ø6 ø6 H. 1 Ref. INN-2075 H. 2 Ref. INN-2076 H. 3 Ref. INN-2077 27 Temporary Abutments (cement-retained restoration) MULTI-SCAN ABUTMENT (cement-retained restoration) FIBRE-GLASS ABUTMENT designed as temporary abutment ø4 MULTI-SCAN ABUTMENTS laser mark are used to fabricate a fully patient- easily customized chairside by the clinician customized abutment through the or in the laboratory realization of a customized part to be by the dental technician. bonded on the central portion of the 4 mm The fibre-Glass Abutment has been abutment. Use NIMETIC CEM (3M Intended use Espe), PANAVIA 21 (Kuraray Medical Inc.) - Immediate loading in anterior area out adhesive materials for bonding. 0,5 mm of occlusion The customized abutment portion can be - Individual soft tissue management for performed under the following options esthetic cases -Screw-or cement-retained temporary PROSTETIC SCREW Ref. INN-6050 crowns PROSTETIC SCREW Ref. INN-6050 TIGHTENING: - Cement-retained temporary bridges the prostetic screw using the 1.25 Hex Screwdriver and Torque Wrench. Recommended torques for final seating 25 Ncm Characteristics - Fibre-glass material allows for easy and Ref. INN-00652 quick chair-side modification - Easy-to-achieve aesthetics due to toothcolored and metal free - Available in 3 different angulations (0°, 15° and 25°) and 3 different With CAD/CAM heights (H.1, H.2 , H.3) for any different technology by taking a scan of the angulations, which minimize the need seated abutment on the dental cast and for abutment customized. modelling of the customized abutment portion with a specific software. The fabrication is performed in the FIBRE-GLASS KIT REF. 000.08 The box contains 1 pc. of each code. laboratory with a specific ComputerAssisted Machine or by a specialized production centre upon the receipt of the data file; fibre-glass STRAIGHT ABUTMENTS fibre-glass 15° ANGLED ABUTMENTS fibre-glass 25° ANGLED ABUTMENTS Complete with Prostetic Screw Complete with Prostetic Screw Complete with Prostetic Screw ø5 ø5 ø5 ø5 ø5 ø5 ø5 ø5 ø5 WITH THE TRADITIONAL METHOD by using a pre-fabricated burn-out coping placed on the abutment, adjustment and modelling with wax and/or acrylic and fabrication of the H. 1 FV107.04/1 28 H. 2 FV107.04/2 H. 3 FV107.04/3 H. 1 FV107.05/1 H. 2 FV107.05/2 H. 3 FV107.05/3 H. 1 FV107.06/1 H. 2 FV107.06/2 H. 3 customized abutment portion through casting. FV107.06/3 29 ZIRCONIUM ABUTMENTS (cement-retained restoration) MULTI-USE ABUTMENT (screw-retained restoration) The special two-part design of the INTENDED USE: zirconium abutment consists of a - Prosthesis hybrid prosthesis or bridges, titanium base and zirconium abutment - Toronto Bridge in various inclinations. And provides a - Bar-retained overdentures. natural looking base for an all ceramic, cemented-retained crown in the esthetic STRAIGHT MULTI-USE ABUTMENT zone. The Straight Multi-use abutment have a conical top with an external exagone, SPHERICAL SCREW DRIVERS that allows tightening it by means of a Muti-use driver (manual or ratchet connection) INTENDED USE Restorations in the esthetic zone. Zirconium Straight Abutment Ref. ZA-2000 STRAIGHT ABUTMENTS H (*) Made from White Zirconium oxide they RATCHET Ref. INN-00637 ø5 2,5 mm CHARACTERISTICS Muti-use driver Ref. 00440M provide a more natural color for the H. 1 abutment in esthetic the zone. H. 2 H. 3 3 mm Reliable. Ref. INN-4750/1 Esthetic - Light passage allows for Ref. INN-4750/2 Ref. INN-4750/3 natural tooth appearance. Strong - Interfaced base-abutment connection provides strength and stability. Precise - Hight precision connection ANGLED MULTI-USE ABUTMENTS between implant and titanium base. The 17 and 30 degrees Angled Multi-use abutments help achieve parallelism for Easy to use – Anatomical design non-parallel implants. They can be connected easily by means of its preassembled minimizes the need for abutment transporter. The package includes an angled abut, fixation screw and the tansporter. SCREW Ref. INN-5146 customized. Zirconium 15 Angled Abutment Ref. ZA-2015 2,5 m m H. 1 Ref. INN-1760/1 Fitting the abutment in the model. 30 Modelling of of the abutment. Placement of the restoration. ø5 H. 1 Ref. INN-1750/2 17° ANGLED ABUTMENTS H. 2 Ref. INN-3050/1 H. 2 Ref. INN-3050/2 30° ANGLED ABUTMENTS 31 SURGICAL COMPONENTS PROSTETIC ABUTMENT (screw-retained restoration) Closed tray impression for Multi-use Abutment 8 mm Place the impression copings on the Multi-use abutments (Fig. 1). impression (Fig. 2). Burn-out cylinder Complete of “connecting screw”, It is suitable for the realization of milled bars or screw-retained prosthesis (Fig. 1). Simplify the preparation of the definite metallic framework which can be obtained by a casting process (Fig. 2) using a metallic alloy at technician’s option (Fig. 3). Fig. 1 Multy-use analogue Ref. INN-00586 Once the material is solid, remove the impression and take out the impression copings to attach the replicas ø5 3,5 mm Inject impression material and take the Closed tray transfer Ref. INN-00611 CONNECTING SCREW Ref. INN-6051 and correctly reposition 12 mm 12 mm Fig. 3 into the cast (Fig. 3). Fig. 2 Fig. 1 Open tray impression for Multi-use Abutment 15 mm Place the impression copings on the Transfer Screw Ref. INN-00612 Multi-use abutments (Fig. 1). Castable Abutment Complete of cennecting screw Ref. INN-5145 Temporary abutment Complete of “connecting screw”, Ref. INN-5144 Multy-use analogue Ref. INN-00586 Inject impression material around the impression copings and inside the Position the tray in the mouth and ensure that you see all the guide screws of the Fig. 1 10,5 mm impression tray. Open tray transfer Ref. INN-00610 impression copings emerge (Fig. 2). Fig. 2 Once the material is solid, unscrew the Multy-use analogue The Multy-use analogue replicates the critical dimensions of the abutment. It allows for correct position and orientation of the abutment in the working model. guide screws to withdraw the impression copings along with the impression (Fig. 3). Multy-use analogue Ref. INN-00586 Fig. 3 Fig. 2 4,5 mm Healing Cap Screw Screw onto the abtments the healing cap screws so as to keep the soft tissue Healing Cap Screw Ref. INN-6030 Fig. 3 in place until the final prosthesis is completed (Fig. 1). Fig. 1 32 33 Attachment-retained restorations EQUATOR ANCHOR SYSTEM COMPLETE SET INCLUDES: 1 Anchor abutment (Ref. 130DIN1 / 2 / 3 / 4 / 5) 1 Stainless steel housings (Ref.141CAE) 1 Retentive caps - violet “strong” (Ref. 140CEV) H1 1 Retentive caps - white “standard” (Ref. 140CET) 1 Retentive caps - pink “soft” H2 130DIN1 130DIN2 141CAE 140CEV H3 130DIN3 H4 130DIN4 H5 130DIN5 (Ref. 140CER) 1 Retentive caps - yellow “extra-soft” (Ref. 140CEG) caps with metal housing 141CAE: 2 Stainless steel housings 140CEV: 4 Retentive caps violet “strong” (2.7kg) 140CET: 4 Retentive caps white “standard” (1.8kg) 140CER: 4 Retentive caps pink “soft” (1.2kg) 140CET 140CER 140CEG 140CEG: 4 Retentive caps ATTACHMENT-RETAINED RESTORATIONS There are several indications for overdenture treatment in Abutments designed for attachment-retained restorations connection with implant therapy. Functional, esthetic, phonetic Ball Abutment and hygienic requirements in certain clinical situations support the - Designed to accommodate the maximum denture-bearing area use of the overdenture as a treatment option - Eliminates wear on the implant ball abutment and minimizes the yellow “extra-soft” (0.6kg) laboratory accessories need for maintenance Indications for overdenture treatment 4 Processing Caps - black Ref. 140CEN - Available in multiple retention options and replaceable - An unfavorable jaw relation which makes treatment with a fixed bridge restoration difficult Equator Abutment - Esthetic problems, e.g. the need for lip support in the upper jaw - Designed to accommodate the maximum denture-baring area - Phonetic problems due to loss of alveolar bone in the upper jaw - Self-aligning design with exceptional durability - Patient dissatisfaction with removable denture due to oral - Available in multiple vertical height options starting as low as 2.0 mm irritations and/or loss of bone for denture fixation - A bridge option makes satisfactory oral hygiene impossible or - Available in multiple retention options and replaceable 2 Impression Coping Ref. 144MTE 2 Laboratory Analog Ref. 144AE Pull-off Impression Coping Ref. 044CAIN surgical instruments - Up to 40° angle correction extremely difficult to achieve - Edentulous patients with a cleft palate Bar System - Economic constraints The design offers flexibility in the clinical situation for implants placed in non-parallel situations by maintaining an axis of withdrawal for implants converging or diverging up to angles of 90° 34 1 Blue plastic “multiuse” insertion tool Ref. 124ICP 1 Metal insertion tool for caps Ref. 185IAC 1 Square driver connector for torque Ref. 760CE 1 OT-Equator square screw driver for implant abutment (square 1,25mm) Ref. 774CQ 35 O-ring anchors or o-ring titanium housing can be used for the ø 1.8 NOTA: The following components should be utilized with “Multy-use Abutment” 3,5 mm Bar System CONNECTING SCREW Ref. INN-6051 12 mm SPHERICAL ANCHOR SYSTEM Castable Abutment Ref. INN-5145 ø 4,5 ø 1,8 3,5 mm ø 1,8 ø 1,8 STEP 1 - Fix the castable abutment and make height adaptations according to the individual situation. H. 3 H. 2 H (*) H. 1 Fig. 1 STEP 2 - Use a residue-free burn-out plastic to fix the bar segments to the castable abutments. Ref. INN-1040 Ref. INN-1041 Ref. INN-1042 Fig. 1 STEP 3 - The yellow clips(027CRG) are fixed into the prosthesis. Fig. 2 METAL HOUSING The metal housings are available in three different retentions, achieved by using the appropriate silicon O-ring and metal OT BAR housing. It is a bar with two different shaped surfaces, one is flat and the other is rounded, 4,75 mm 4,3 mm 3,6 mm either side can be utilized, the choice will 4 mm 3,3 mm depend upon the situation. 3 mm ø 1,8 Soft Retention MD-3004/1 Medium Retention MD-3004 Hard Retention MD-3004/2 lasting functionality to the retention CLIP. 36 CASTABLE BAR version B Ref. 0220BB (2 pcs.) The housing in the casting that holds tolerance at the opening that permits a SMALL O-ring MD-3005 (5 pcs) GINGIVAL CONNECTOR (OPTIONAL) PLASTIC CLIP the retention CLIP is calculated with a BIG O-ring MD-3005/1 (5 pcs) CASTABLE BAR version A Ref. 0220BB (2 pcs.) SPHERICAL SCREW DRIVERS SPHERICAL ANALOG Ref. INN-00621 MANUAL Ref. 00440M RATCHET Ref. INN-00637 POSITIONING clip A Ref: 023CPA (4 pcs.) POSITIONING CLIP B Ref: 02CPB (4 pcs.) CASTABLE BOX Ref: 025CPB (4 pcs.) MEDIUM RETENTION Ref. 027CRG (4 pcs.) SOFT RETENTION Ref. 027CRR (4 pcs.) INSTRUMENTS TOOL FOR INSERTING CLIP Ref: 029OIC KEY FOR PARALLELOMETER Ref: 028OCP 37 DURAVIT IMPLANT-3P Ø 3 CHARACTERISTICS CONE MORSE & HEXAGON SAFE CLINICAL SOLUTION MICROGROOWING COLAR Stable bone and soft tissue levels after three years Narrow diameter implants allow for safely and predictably treating situations where traditional diameter implants Duravit Ø 3 is the implant of choice for clinicians looking for would increase clinical risk, such as indications with minimal excellent esthetics, especially in challenging indications. hard tissue and with limited space. The clinical performan- Three-year data from an ongoing five-year study demon- ce of narrow implants has been validated in several pro- strates continued positive trends consistent with the one- spective and retrospective studies with follow-ups of up to and two-year results. Bone remodeling occurred during the 15 years. first three months of the study, followed by increasing or stable bone levels. Soft tissue variables have been stable throughout the study. Strong sealed conical connection TRIPLE THREAD BODY The internal conical connection was designed for compact PERFECT ANATOMICAL DESIGN LIKE A RADICULAR STRUCTURE size, high strength, and a very tight fit. The gap between implant and abutment, measured at various locations of the conical connection, is between 0.04 and 0.09 μm. This is an exceptionally tight fit, which may be beneficial in preventing inflammatory bacteria from propagating in Maximum material strength Duravit 3P ø3 is made of commercially pure Grade 5 Titanium. Together with the unique “BIO-Active” treatment, which increases, implant stability through faster bone formation, this results in maximum strength and stability. the interface between abutment and implant. In addition, it effectively eliminates any potential for micro-movement. SELF-TAPPE RING SYSTEM “BONE FRIENDLY ” APEX 38 39 DURAVIT IMPLANT-3P Ø 3 SURGICAL AND IMPRESSION COMPONENTS INTENDED USE Healing screws (Titanium grade 5) ø3 - All the implants are supplied with Each package contains 1 piece. Cover screw (Titanium) These components are used to rehabilitate soft tissue on the implant in order to insert the - Progressive taperd implant and hight final prosthetic abutment later on. - Easy, fast and stable implant insertion - Beter control during implant L (A)* mm primary stability ø4 ø4 ø4 H6 H4 H2 Ref. ø 3 L. (08) 3P-3008 L. (10) 3P-3010 placement L. (12) 3P-3012 - Sutable for all procedures L. (14) 3P-3014 00584 00584/4 00584/6 - Sutable for all bone types ø 2,6 Open tray transfer (open tray technique) 1 Place the transfer impression inside the implant and make sure the internal hex is IMPLANT SITE PREPARATION correctly engaged before tightening the screw using light finger force. (Fig. 1). Prepare a customized impression tray and Inject elastomeric impression material 2 around the Implant Transfer and into the Impianto 3P ø 3 impression tray. (fig 2) Tighten the Implant Transfer securely into the Implant Analogue using light finger Drilling technique force. Transfer + SCREW Ref. 00600TR Post screw Ref. 00600TR/V ANALOGUE Ref. 00097AN/1 Suitable for Hard bone. (D. I , II) FACILITY transfer ø3 (tecnica cucchiaio chiuso) Place the transfer impression inside the Ø 2,2 Ø3 Fresa finale - Ref. 00075CUT implant and make sure the internal hex is correctly engaged before tightening with Hexagon screw driver using light finger force. Impianto 3P ø 3 After that place correctly the plastic cap on INN-00507 Each pack conteins 2 pcs 1 COMPLET set - plastic cup - screw - metal transfer Ref. 00355 the transfer (Fig. 1). Prepare a standard impression tray and Inject 2 elastomeric impression material around the Bone Compactor-Expander Suitable for spongy bone. (D. II , VI) Implant Transfer and into the impression tray (Fig. 2). Once the material is solid, remove the impression and take out the impression copings to attach the analogue and correctly Ø 2,2 Ø3 ANALOGUE Ref. 00097AN/1 reposition into the impression model. Compattatore finale - Ref. 281-3P 40 41 Titanium Abutments (cement-retained restoration) SPHERICAL ANCHOR SYSTEM Prosthetic abutments are titanium components that are fixed to the dental implant using prosthetic screws to create a prosthetic O-ring anchors or o-ring titanium housing can be used for the ø 1.8 anchorage. ø 3,5 STRAIGHT ABUTMENTS ø4 ø 1,8 3,5 mm Straight abutment is designed to meet the clinicians’ demands for conventional crown and bridge ø 1,8 ø 1,8 procedures and restorative simplicity. They are available in Ø 4 diameter indicated for anterior area and 3 heights H. 2 H. 3 H. 1 ( H. 1 , H. 2 H. 3 mm) according to the H (*) gingival , mimicking 11 mm optimal preparations of natural teeth, which provides the opportunity to create Fig. 1 esthetics for all tooth Ref. 00589/1 PROSTETIC SCREW Ref. 00358/V Ref. 00589/2 Ref. 00589/3 TIGHTENING: the prostetic screw using the 1.25 Hex Screwdriver and Torque Wrench. Recommended torques for final seating 25 Ncm METAL HOUSING The metal housings are available in three different retentions, achieved by using the appropriate silicon O-ring and metal housing. 4,75 mm 4,3 mm 3,6 mm Ø 4 STRAIGHT ABUTMENTS 15° ANGLED ABUTMENTS Ø 4 Complete with Prostetic Screw Complete with Prostetic Screw ø4 42 ø4 ø4 ø4 H. 1 H. 2 H. 3 Ref. 00358/1 Ref. 00358/2 Ref. 00358/3 Ref. 00370/15 4 mm 3,3 mm 3 mm ø 1,8 Soft Retention MD-3004/1 BIG O-ring MD-3005/1 (5 pcs) Medium Retention MD-3004 Hard Retention MD-3004/2 SMALL O-ring MD-3005 (5 pcs) SPHERICAL ANALOGUE Ref. INN-00621 SHORT MANUAL DRIVER Ref. INN-00604 43 surgical kit 3P AND Ø3 surgical kit Ref. 3P-00092SC Surgical Instruments Use: Technical Specifications Rules For Use: Lance Drill Ref. 147-021 Neck Drill Ø 4.1 Ref. NECK-40 Rounded Drill Ref. 000100 Neck Drill Ø 4.6 Ref. NECK-45 Depth Drill Ø 2.1 Ref. 00074CUT Neck Drill Ø 5.1 Ref. NECK-50 Conical Drill Ø 3 Ref. 00075CUT Metal Stop L. 8 mm Ref. STOP01 Conical Drill Ø 3.5 Ref. 3P-35CUT Metal Stop L. 10 mm Ref. STOP02 Conical Drill Ø 4 Ref. 3P-40CUT Metal Stop L. 12 mm Ref. STOP03 Conical Drill Ø 4.5 Ref. 3P-45CUT Metal Stop L. 14 mm Ref. STOP04 Ref. 3P-50CUT Implant Driver SHORT Ref. INN-00590/1 These instruments are used to penetrate Dental drills and reamers are produced Use drills and tappers in a gradual se- Conical Drill Ø 5 the soft tissue, perforate the mandible in AISI 630 grade stainless steel to gua- quence of diameters. Compactor-Expander Ø 2.2 Ref. 201-3P Implant Driver LONG Ref. INN-00590/2 and maxillary bone to create the perfect rante e an excellent balance between Compactor-Expander Ø 3 Ref. 281-3P Implant Insertion Key (Contra-Angle) Ref. INN-00581 Compactor-Expander Ø 3.5 Ref. 331-3P Prosthetic Screw Driver LONG Ref. INN-61000L Compactor-Expander Ø 4 Ref. 381-3P Prosthetic Screw Driver SHORT Ref. INN-61000 Compactor-Expander Ø 4.5 Ref. 431-3P Universal Ratchet Ref. 00376 Compactor-Expander Ø 5 Ref. 481-3P Straight Manual Key Ref. 3P-00090CM Extender Ref. 00236N Direction Pin (2 Pcs) Ref. 00441T Tissue Punch Ø 4 Ref. 00091BM surgical site in which to place the implant. cutting power and stainlessness When preparing the implant site, light pressure should be applied with forward We recommend that cutting instruments and backward movements of the instru- (burs, pilot drills and reamers), under ment. Do not exceed 400 RPM while normal operating conditions, should preparing the implant site. not be used more than 30 times. It is always necessary to check the amount of wear and tear of the cutting edges of Do not exceed 60 RPM while inserting the implant in the implant site. the instruments 44 45 WIDE SURGICAL KIT Ø 3 SURGICAL KIT Ref. WIDE-00092SC Ref. 3-00092SC Wide drill Ø 5,5 Ref. WIDE-55CUT Implant driver (short) Ref. INN-00590/1 Lance Drill Ref. 147-021 Extender Ref. 00236N Wide drill Ø 6 Ref. WIDE-60CUT Implant driver (Long) Ref. INN-00590/2 Depth Drill Ø 2.1 Ref. 00074CUT Ø 3 Implant Driver (long) Ref. 00578/L Wide drill Ø 6,5 Ref. WIDE-65CUT Prsthetic driver (short) Ref. INN-61000L Conical Drill Ø 3 Ref. 00075CUT Ø 3 Implant Driver (short) Ref. 00578/S Wide drill Ø 7 Ref. WIDE-70CUT Prsthetic driver (short) Ref. INN-61000 Compactor-Expander Ø 3 Ref. 281-3P Prosthetic Screw Driver (long) Ref. INN-61000L Wide Metal stop L. 8 mm Ref. W-STOP08 Universal ratchet Ref. 00376 Metal Stop L. 8 mm Ref. STOP01 Prosthetic Screw Driver (short) Ref. INN-61000 Wide Metal stop L. 10 mm Ref. W-STOP10 Metal Stop L. 10 mm Ref. STOP02 Universal Ratchet Ref. 00376DIN Wide Metal stop L. 12 mm Ref. W-STOP12 Metal Stop L. 12 mm Ref. STOP03 Direction Pin (2 Pcs) Ref. 00441 Wide Metal stop L. 14 mm Ref. W-STOP14 Metal Stop L. 14 mm Ref. STOP04 46 47 surgical kit surgical kit SURGICAL FACILITIES CONICAL DRILLS Parallel Pin place parallel pin in the site to facilitate the direction of the subsequent drilling. Tissue Punch intended for use with a contra angle set at a low speed, it allows to punch the mucosa according to the selected implant diameter. Template the template helps the surgeon in selecting the right implant to be inserted. The whole range of “Duravit 3P implants” in two scales is illustrated: actual dimensions, and dimensions increased by 25%, it takes into account the distortions of the panoramic. - The surgical drills are available in sequential diameter. - The drills are made of surgical stainless steel and are to be used with external irrigation. ø 3,5 mm - All drills are coloured and laser marked the diameter for easy identification Parallel Pin TISSUE PUNCH TEMPLATE Ref. 3P-09 during the surgery. - Drills are grove marked for different laser mark length as shown below. - Two laser lines, 6 to 7 mm and 10 to 11 color code to help the surgeon while is preparing the lends of the implant’s site 15 mm 14 mm 13 mm grove marks 12 mm 11 mm 10 mm 9 mm 8 mm Ref. 00441T Ref. 00441 plastic Ref. 00091BM ø 4 mm Ref. 00092BM ø 4,5 mm 7 mm Ref. 00093BM ø 5 mm 6 mm * 0,5 mm *IMPORTANT: INITIAL DRILLS an additional 0.5 mm must be added to the length of the drill to account for the angled cutting tip. Extender drill Increases operating length of the drills ø 5 mm ø 4,5 mm ø 4 mm To mark out and create the insertion ø 3 mm ø 2,2 mm Lanche Drill ø 3,5 mm during the surgery. point penetrating cortex to evaluate bone quantity and quality. 10 mm Rounded Drill Used to smooth out the ridges. 4 mm Extender Ref. 00236N 48 LANCE DRILL Ref. 147-021 ROUNDED DRILL Ref. 000100 Color Legend ø 2.2 ø3 ø 3,5 ø4 ø 4,5 ø5 Real Diameter ø 2.2 ø 2.6 ø 3,1 ø 3,6 ø 4,1 ø 4,6 Ref 00074CUT 00075CUT 3P-35CUT 3P-40CUT 3P-45CUT 3P-50CUT 49 surgical kit COMPACTOR EXPANDER Countersink Drill - The Compactor-Expander are available Use the countersink to create a shoulder in sequential diameter. area for the implant. color code Indicated expecialy in hard bone - The Compactor-Expander are made of condition to avoid compression around surgical stainless steel. the cortical bone. - All Compactor-Expander are coloured and laser marked the diameter for easy identification during the surgery. exagone ø 6 mm - Compactor-Expander are grove lasered ø 4 mm for different length as shown below. laser mark ø 3,5 laser marc CHARACTERISTICS - The surgical drills are in different color code Diameters (4.1, 4.6 and 5.1). 15 mm 13 mm 11 mm 14 mm - The drills are made of surgical stainless 12 mm steel and are to be used with external 10 mm irrigation. 9 mm 7 mm 8 mm - All drills are coloured and laser marked 6 mm the diameter for easy identification Color Legend 50 ø 2.2 ø3 ø 3,5 ø 3,5 ø4 ø4 ø 4,5 ø 4,5 ø5 ø5 Color Code Real Diameter ø 2.2 ø 2.8 ø 3,3 ø 3,8 ø 4,3 ø 4,8 Real diameter Ref 201-3P 281-3P 331-3P 381-3P 431-3P 481-3P Ref ø 3,5 ø4 ø 4,5 mm ø3 ø 3,5 mm ø 2,2 ø 4 mm during the surgery. ø 4,5 ø4 ø4 ø 4,5 NECK-35 NECK-40 NECK-45 51 WIDE CONICAL DRILL METAL STOPPER - The surgical drills are available in se- The Drill stoppers ensure to the surgeon quential diameter. ø 3,5 surgical kit simple and accurate depth control. - The drills are made of surgical stainless - Laser marked for immediate steel and are to be used with external identification of the length. irrigation. ø 3,5 - Clearly arranged matching depth from - All drills are coloured and laser marked 6 to 15 mm. the diameter for easy identification - Quick easy and easy assembling. during the surgery. ø 6 mm - Drills are grove marked for different length as shown below. - Two laser lines, 6 to 7 mm and 10 to 11 to help the surgeon while is preparing laser mark NOTE: Metal Stopper can NOT be mounted inside ø 5 Conical Drill and ø 5 Compactor - Expander the lends of the implant’s site - The drills are used with the appropriate 15 mm 14 mm 13 mm grove marks ø 5,3 color code Wide length stop 12 mm 11 mm 10 mm 9 mm STOP L.06 STOP L.07 STOP L.08 STOP L.09 STOP L.10 STOP L.11 STOP L.12 STOP L.13 STOP L.14 STOP L.15 Ref. STOP06* Ref. STOP11 Ref. STOP01 Ref. STOP07* Ref. STOP02 Ref. STOP08* Ref. STOP03 Ref. STOP09* Ref. STOP04 Ref. STOP10* 8 mm 7 mm 6 mm *IMPORTANT: * 0,5 mm an additional 0.5 mm must be added to the length of the drill to account for the WIDE METAL STOPPER angled cutting tip. The Drill stoppers ensure to the surgeon simple and accurate depth control. - Laser marked for immediate identification of the length. Color code 52 ø5,5 ø6 ø 6,5 ø 7 mm ø 6,5 mm ø 5,5 mm ø 6 mm - Quick easy and easy assembling. ø7 Real diameter ø 5.2 ø 5,7 ø 6,2 ø 6,7 STOP L.06 STOP L.08 STOP L.10 STOP L.12 Ref WIDE-55CUT WIDE-60CUT WIDE-65CUT WIDE-70CUT Ref. W-STOP06 Ref. W-STOP08 Ref. W-STOP10 Ref. W-STOP12 53 surgical kit IMPLANT DRIVERS PROSTHETIC HEX DRIVERS - Hex driver 1.27mm (stainless steel) - Insertion tools 2.6 mmd (stainless steel) - For all types of cover screws, healing - Used final for placing of the implants 3P and WIDE. abutments and prosthetic pieces ø 1,27 mm handpice driver ø 1,27 mm IMPLANT INSERTION KEY TORQUE RATCHET MOUNTER Contra-angle Ref. INN-00581 SHORT KEY Ref. INN-00590/1 ø1,27 mm ø 1,27 mm MANUAL DRIVERS PROSTHETIC SCREW DRIVER LONG Ref. INN - 00604 Ref. INN - 00602 SHORT Ref. INN - 00604/S exagone ø 6 mm Ø 3 IMPLANT DRIVERS implant connection exagone ø 2,4 mm screw connection exagone ø 1,27 mm Torque Ratchet allows the clinician to accurately apply the recommended preload torque for surgery and prosthetics. ø 6 mm ø 6 mm 22 mm 29 mm 27 mm LONG Ref. INN-61000L RATCHET & MANUAL KEY Used for final placing of the implant ø3 ø 1,6 mm ø 1,6 mm 54 SHORT Ref. INN-61000 LONG KEY Ref. INN-00590/2 torque wrench connection ø3 implant INSERTION Ref. 00578/DRILL 22 mm 29 mm 22 mm 27 mm ø 2,4 mm 29 mm 29 mm ø 2,4 mm 22 mm ø 6 mm 2,3 mm ø 6 mm ø 6 mm Ø3 TORQUE RATCHT MOUNTER KEY SHORT Ref. 00578/S KEY LONG Ref. 00578/L TORQUE RATCHET 50 N/cm Ref. 00376DIN ø 6 mm UNIVERSAL Ratchet Ref. 00376 STRAIGHT MANUAL KEY Ref. 3P-00090CM 55 MINI DURAVIT IMPLANT characteristics: - Made of 5g MEDICAL titanium; - Sandblasted and oxidised to increase the contact surface; - Self-threading spirals for better insertion and primary stability of the implant - Each implant is packed together with the implant carrier which enables manual positioning without contamination risks. - It is available in 2 diameters (2,0 – 2.4) and 3 lengths (10 - 13 – 15) ø 1,8 3,85 mm O-BALL MINI DURAVIT IMPLANT Mini Implant line is the solution for a removable prosthesis. 2,35 mm 2,35 mm immediate and long-term stabilization of 3,85 mm ø 1,8 This implant produces a high primary L* mm This device requires a simple surgical L* mm stability with immediate functionality. procedure. It is possible to create the site with or without creating a flap retention options as well as attachment designs that forgive up to 90-minute patented protocol, often completed without a flap and 30 degrees divergence between two implants with no need for an ABUTMENT MINI IMPLANT sometimes even using the patient’s existing denture. angle correction inventory. Original retention can be restored in This implant produces a high primary Mini Duravit Implants are designed for stability in soft and dense minutes by simply changing o-rings stability with immediate functionality. L. 10 MD/20/10 L. 10 MD/24/10 L. 13 MD/20/13 L. 13 MD/24/13 L. 15 MD/20/15 L. 15 MD/24/15 ø 1,8 It should be used in anterior sites to This implant produces a high primary 2,35 mm replace laterals, cuspids and bicuspids. ø 1,8 2,35 mm bone which is essential for immediate loading. Attachment Ref. ø 2,4 3,85 mm designs are available for custom retention for each case with three invasive and immediately stabilizes loose dentures using a 3,85 mm B. & B.Dental’s mini duravit dental implant system is minimally Ref. ø 2,0 stability with immediate functionality. This device requires a simple surgical with or without creating a flap. 56 Ref. ø 2,0 L* mm L* mm procedure. It is possible to create the site Ref. ø 2,4 L. 10 MA/20/10 L. 10 MA/24/10 L. 13 MA/20/13 L. 13 MA/24/13 L. 15 MA/20/15 L. 15 MA/24/15 57 Surgical Protocol PROSTETIC COMPONENTS Collared O-Ball 1 2 Mark each entry point on patient’s tissue and with Pilot Drill 1.1 pumped up and down until the cortical plate is penetrated. 4 Square Head 3 Carry the implant to the site with the plastic plug and scew it inside until noticeable bony resistance is encountered. Use the Butterfly Key to thread the implant into place until the wrench becomes difficult to turn. 5 6 MD-3007 Collared Analog Torque Wrench and implant diver will then finalize the insertion process MA-1007 Collared Square Head Analog Seat denture in patient’s mouth and have patient apply normal bite pressure in centric occlusion. Relieve denture to accommodate implants and metal housings, creating individual holes or a trough O-BALL CAPS STRAIGHT ABUTMENT SQUARE HEAD CAPS MD-3010 MD-3006 Castable Surgical COMPONENTS Complete plastic Box (sterilizzable) contains: MD-3013 Temp Cap 1 - BUTTERFLY KEY MD-3014 Transfer Cap Ref. MD-3002 2 - PREPARATION DRILL Ø1.1 4 Ref. MD-3001 CAPS 5 3 - PREPARATION DRILL Ø 1,5 4,75 mm Ref. MD-3001/20 PCV PROTECTION 4 - KEY FOR TORQUET RATCHET 1 long: MD-3003L short MD-3003S 5 - TORQUET RATCHET Ref. 00376DIN 6 - SURGICAL BOX Ref. 00075SC 6 COMPLETE BOX Ref. 00075SC 4,3 mm 3,6 mm Soft Retention MD-3004/1 2 3 3,3 mm 3 mm Medium Retention MD-3004 Hard Retention MD-3004/2 MD-3008 O-ring MD-3005/1 (5 pieces) 58 4 mm O-ring MD-3005 (5 pieces) 59 MATERIAL FOR BONE REGENERATION NOVOCOR PLUS The Novocor Plus medical device comprises grains of natural coral with a low surface/volume, ranging from 200 to 500 mm. The natural coral , also known as coralline hydroxyapatite, comprises 98% Aragonitic Calcium Carbonate (CaCO3) Properties - natural coral grafting material - slow resorption and directed integration by new bone formation - long-term dimensional stability - osteoconductive - 100% mineral - no foreign body or inflammatory reaction - hydrophilic surface, optimal cell adhesion and blood absorption - interconnective porosity - safe and sterile - easy handling Indications: Implantology, Periodontology & Oral Surgery - Sinus lift - Horizontal augmentation - Intraosseous defects - Peri-implant defects - Extraction sockets - Vertical augmentation - Furcation defects PACKAGING B&B Dental bone substitutes for dentistry represent a range of Flexible, cortical and spongy bone lamina are therefore available, products able to provide an efficient response to all demands for whose main use is in on-lay grafts. bone regeneration encountered in clinical practice on a daily basis: from small parodontal defects to large-scale reconstruction of In order to avoid invasion of the grafted site by soft tissues, B&B atrophic ridges. Dental provides dentistry with easily-handled re-absorbable Each box contains 4 capsules from 0,5 gr. Each. grain size: 0,2 - 0,5 mm collagen membranes, and the innovative Titanium membrane These options are very easy to apply, and extremely useful in filling that simplifies graft protection. This is particularly useful for minor parodontal defects and raising the sinus according to Summers. defects where the shape of the traditional collagen membrane To fill limited cavities, such as post-extraction alveoli, granule would take up a disproportionate amount of time. Ref. 00096N formulae are also available in malleable collagen paste, which also perform a useful haemostatic effect. A specific slow re-absorption membrane is also available in flexible cortical bone, which does not require removal and is particularly B&B Dental also proposes an exclusive range, unique worldwide, useful for protecting larger grafts (lateral or vertical on-lay). of flexible bone substitutes obtained by means of a partial demineralisation process. The advantage of the flexibility lies in the perfect contact obtained between graft and receiving bone bed. In this way, the probability of failure due to defective angiogenesis, is minimised. Implants in situ 60 Filling with Novocor Plus® granules Resorbable collagen membrane Flap suture 61 T-BARRIER MEMBRANES DURAVIT CRESTAL SINUS LIFT COLLAGENE MEMBRANE Lance Drill Ref. 147-021 Compactor-Expander Ø 2.2 Ref. 201-3p Compactor-Expander Ø 3 Ref. 281-3p Compactor-Expander Ø 3.5 Ref. 331-3p Compactor-Expander Ø 4 Ref. 381-3p Compactor-Expander Ø 4.5 Ref. 431-3p ADVANTAGES Compactor-Expander Ø 5 Ref. 481-3p - Perfect biocompatibility Metal Stop L. 4 Mm Ref. Stop12 - Complete resorption after 4/6 mouths Metal Stop L. 5 Mm Ref. Stop05 - Osteoconductive and osteoinductive Metal Stop L. 6 Mm Ref. Stop06 activity Metal Stop L. 7 Mm Ref. Stop11 - Anti-inflammatory, eutrophic and Metal Stop L. 8 Mm Ref. Stop01 cicatrizant properties Metal Stop L. 9 Mm Ref. Stop07 Push pin Ø 3.5 Ref. SL-PP35 Push pin Ø 4 Ref. SL-PP40 Push Screw Ø 3.5 Ref. SL-PS35 effect) for heterologous and autologous Push Screw Ø 4 Ref. SL-PS40 grafts; Straight Manual Key Ref. 3P-00090Cm T-Barrier Collagene is a type-1 native heterologous equine collagen indicated for use in guided tissue regeneration procedures to enhance wound healing. - Easy to apply on the defect area. CLINICAL APPLICATIONS Oral surgery: containment action (tent Paradontology: treatment of gum recessions; Implantology: protection of the sinus Ref. 00082C membrane prior to insertion of graft material. PACKAGING Ref. 3P-00093SC 2 Membranes each pack Size: 23 x 23 mm Thicknes 0,25 mm safety implant membranes TITANIUM MEMBRANES Ref. 00532 24 x 29 mm - ø 0,13 62 Ref. 00532/3 12 x 19 mm - ø 0,13 compleate with screw Ref. 00532/4 20 x 14 mm - ø 0,13 single compleate with screw Ref. 00532/5 17 x 20 mm - ø 0,13 single compleate with screw Ref. 00532/1 18 x 8 mm - ø 0,13 Ref. 00532/2 21 x 7 mm - ø 0,13 Blocking Screw 63 PhysioDispenser 3000 OSTEOTOMES PHYSIO DISPENSER 3000 is the result of 10 years’ experience in the design and development of electro-medical apparatus for implantology. High performance combined with extreme simplicity, and provided with a new-concept pedal that represents an absolute novelty. Ref. 00443-1 osteotome n.1 Ø3 Ø2 Ø1,5 CHARACTERISTICS - Motor speed from 3 to 125000 RPM Ref. 00443-2 osteotome n.2 Ø3,5 Ø2,5 Ø2 - N° 6 Reduction/Moltiplication of the contra angle (1:5, 1:1, 16:1, 20:1, 64:1, 70:1) Ref. 00443-3 osteotome n.3 Ø4 Ø3 Ø2,5 - N° 5 Memories - 24 torque values. MAX value indicates the maximum torque without limitation. Ref. 00443-4 osteotome n.4 Ø4,5 Ø3,5 - N° 3 defferent choises of cooling liquid Ø3 flows: 60, 80, 110 ml/min Ref. 00443-5 osteotome n.5 Ø5 Ø4 Ø3,5 5 mm 8 mm 10 mm 12 mm 14 mm 17 mm Ref. PD3000 COMPLETE WITH 1. Selects the program - Central unit - Multifunction Pedal , pump flow, HAMMER Ref. 1881 2. forward/reverse 1 - Peristaltic pump forward/reverse, program and motor 2 4 3 3. Turns on the motor with progressive action. 4. Sets the peristaltic pump flow action. - N° 2 irrigation tube - Reduction cotra-angle 20.1 Ref. S2772-1B (Empty Box) Ref. 00443-0 (Full Box) IMPLANT SITE PREPARATION ACCESSORIES carrying case - PD106 53 x 37 x 13 cm, weighs 750 g. Ref. PD106 64 IRAGATION tube Ref. PD107 Contra-angle 20.1 Ref. w0020/1CA 65 MARKETING & TRAINING MATERIALS Drilling Practice Model Sinus Lift Practice Model Ref. IMP-1003 Ref. P9-X.1032 - Mandibular jaw model for basic drilling practice - Jaw model for sinus lift practice - The model material duplicates type II - III hardness - The bone thickness of the posterior area is 3 mm on the left side Bone Material duplicates type II - III (1 layered construction) and 9 mm on the right side for lateral window and osteotome method practice - Schneiderian membrane is made of thin material Training Method Drilling DEMO IMPLANT SET implant insertion Bone Material duplicates type III (1 layered construction) Tooth model removable anatomic tooth model Other Schneiderian membrane Training Method Incision Lateral window tecnique Osteotome Full-thickness flap Drilling Immediate implant placement implant insertion Surgical guide plate 1a Duravit implant 3p and accessories 1b Implant ø3 and accessories Ref. DEMO KIT Ref. 3-DEMOKIT Complete of: Complete of: - Dental Implant 3P Ø 3.5 L. 10 mm ref. 3P-3510 - Dental Implant Ø 3 L. 10 mm ref. 00310IM - Dental Implant 3P Ø 4 L. 12 mm ref. 3P-4012 - Dental Implant Ø 3 L. 10 mm ref. 00312IM - Healing Screw H. 2 ref. INN-6010 - Healing Screw H. 2 ref. 00584 - Platic transfer ref. INN-00306 - Healing Screw H. 4 ref. 00585 - Transfer Abutment + plastic cap + screw ref. INN-00506 - Healing Screw H. 6 ref. 00586 - Metal Transfer INN-00600 - Metal Transfer+ screw Ref. 00600TR - Ø 5 Straight Abutment + Prosthetic screw ref. INN-2000 - Ø4 H. 1 Straight Abutment ref. 00358/1 - Analogue ref. INN-00585 - Ø4 H. 2 Straight Abutment ref. 00358/2 - Extractor screw ref. INN-6050 - Ø4 H. 3 Straight Abutment ref. 00358/3 - Prosthetic driver ref. INN-00604 - Analogue ref. 00097AN - Prosthetic driver ref. INN-00604 1a 2 3 1b IMPLANT TRANSPARENT MODEL MINI IMPLANT MODEL Ref. Model implant Ref. Model mini Features Features - Dental prosthesis on the lower and implants molar region - Dental removable prosthesis - Transparent jaw allows view of the anatomical roots - 4 mini implants placed on the anterior region complete of metal Purpose: housing -For explaining the dental prosthesis and implants Purpose: -For explaining the mini implants use with complete removable prosthesis. 2 Mini Duravit implant and accessories 3 Multi-Unit abutment Ref. MINI DEMO KIT Ref. M/U DEMO KIT Complete of: - Ø 5 H. 1 Straight Multi-use Abutment Ref. INN-4750/1 - Mini dental implant Ø 2.0 L. 15 Ref. MD/20/15 - Ø 5 H. 2 Straight Multi-use Abutment Ref. INN-4750/2 - Mini dental implant Ø 2.3 L. 13 Ref. MD/23/13 - Ø 5 H. 3 Straight Multi-use Abutment Ref. INN-4750/3 - Metal housing “soft retaintion” ref. MD-3004/1 - 17° H. 1 Angled Multi-use Abutment Ref. INN-1750/1 - Metal housing “medium retaintion” ref. MD-3004 - 17° H. 2 Angled Multi-use Abutment Ref. INN-1750/2 - Metal housing “hard retaintion” ref. MD-3004/2 - 30° H. 1 Straight Multi-use Abutment Ref. INN-3050/1 - Collared analogue ref. MD-3007 - 30° H. 2 Straight Multi-use Abutment Ref. INN-3050/2 - Temporary cap ref. MD-3013 - Healling cap Ref. INN-6030 - Transfer cap ref. MD-3014 - Open tray transfer + screw Ref. INN-00611 -Transfer/castable abut. ref. MD-3006 - Close tray transfer Ref. INN-00610 - Titanium abutment ref. MD-3010 - Castable abutment Ref. INN-5145 - Multy-use driver Ref. 00440M - Prosthetic driver ref. INN-00604 66 67 B&B DENTAL implant company Via San Benedetto, 1837 - 40018 San Pietro in Casale (BO) Italy Tel. +39 (0) 51.81.13.75 - Fax +39 (0) 51.666.94.00 info@bebdental.it - www.bebdental.it EN ISO 13485 Sistema Qualità Certificato Certified Quality System UNI EN ISO 13485 UNI EN ISO 13485