©2013 Orbital Sciences Corporation

All Rights Reserved.

July 2013

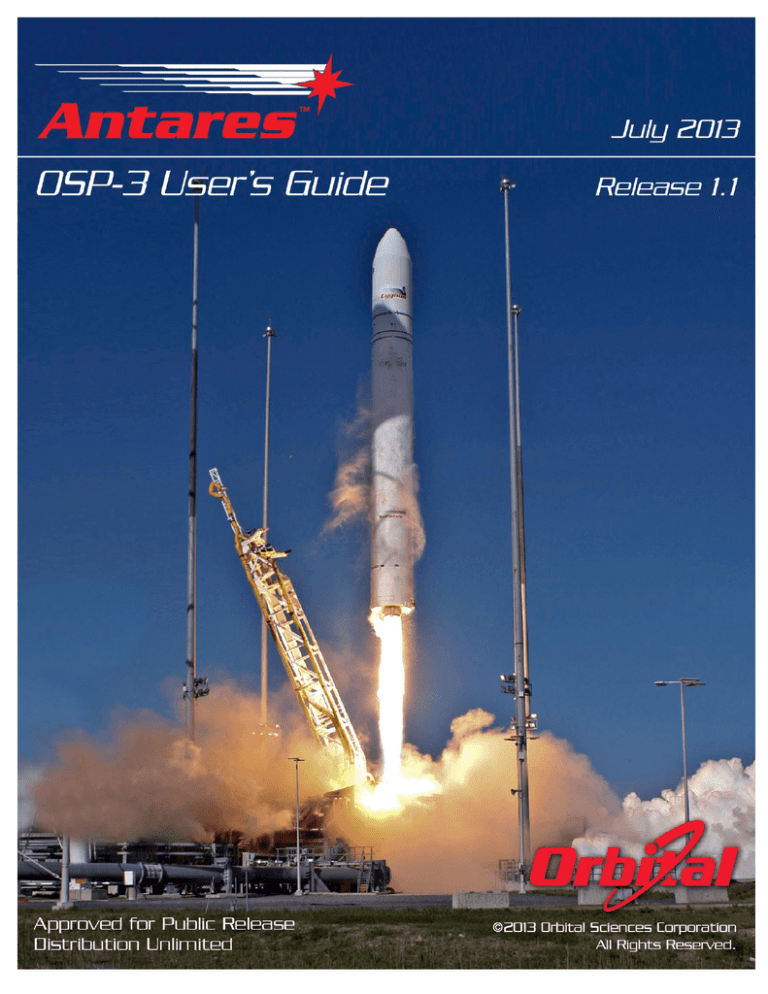

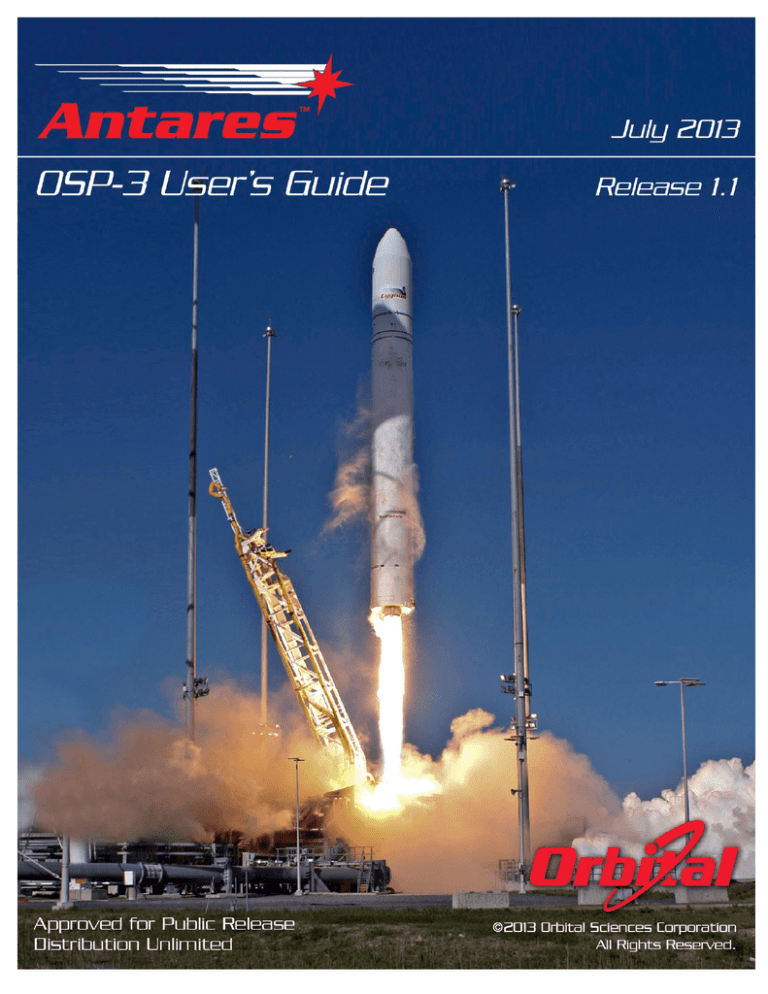

Antares® OSP-3 User’s Guide

Release 1.1

Approved for Public Release

Distribution Unlimited

©2013 Orbital Sciences Corporation

All Rights Reserved.

Antares® OSP-3 User’s Guide

Revision Summary

REVISION SUMMARY

VERSION

DATE

1.0

May 2013

1.1

June 2013 Changes Throughout

Release 1.1

CHANGE

Approved Original Release

July 2013

PAGE

N/A

All

iii

Antares® OSP-3 User’s Guide

Preface

MEDIUM-CLASS LAUNCH SERVICES FOR THE 21

ST

CENTURY

®

Orbital Sciences Corporation’s (Orbital’s) Antares is a flight proven two stage launch vehicle designed

to provide responsive, cost effective, and reliable access to orbit for Medium-Class payloads. While the

initial Antares missions will demonstrate the capability to perform commercial resupply of the International

Space Station (ISS) under NASA’s Commercial Orbital Transportation Services (COTS) and Commercial

Resupply Services (CRS) contracts, the Antares launch system also meets the needs and mission success standards of Medium-Class defense, science, and commercial missions. The Antares development,

internally funded by Orbital, includes the following features:

Low-Risk Design: Antares incorporates flight

proven components from leading global suppliers,

and largely utilizes subsystem designs successfully

employed on other Orbital launch vehicles.

Leveraging Flight Proven Technologies: The

Antares first stage is powered by dual AJ26 engines. Aerojet has modernized these engines with

updated avionics and control systems. The Antares

®

second stage relies on proven ATK CASTOR solid

rocket motors and Orbital’s Modular Avionics Control Hardware (MACH) electronics technology.

Fills Medium-Class Launch Services Gap:

Antares fills the service gap between Orbital’s Medium-Light Minotaur IV launch vehicle and larger,

Intermediate-Class vehicles on the market.

This Antares OSP-3 User's Guide describes the

basic elements of the Antares system as well as

available optional services under the Orbital Suborbital Program-3 (OSP-3) Launch Services Contract.

In addition, this document provides general vehicle

performance, defines payload accommodations and

environments, and outlines the Antares mission

integration process. The descriptions contained in

this Antares OSP-3 User’s Guide will familiarize

potential customers with the Antares launch system, its capabilities and its associated services.

The data presented provides the current capabilities

and interfaces of the Antares launch system, with

the goal of enabling potential customers to perform

mission feasibility trade studies and complete preliminary mission designs. Detailed analyses are

performed by Orbital based on the requirements

and characteristics of each specific mission.

Release 1.1

July 2013

iv

Antares® OSP-3 User’s Guide

Preface

The information provided in this Antares OSP-3 user’s guide is for initial planning purposes for OSP-3

payloads only. Information for development/design is determined through mission specific engineering

analyses. The results of these analyses are documented in a mission-specific Interface Control Document (ICD) for the spacecraft organization to use in their development/design process. This document

provides an overview of the Antares system design and a description of the services provided to our customers.

Technical Information and additional copies of this User's Guide may be requested from Orbital at:

Antares@orbital.com

www.orbital.com/Antares-Cygnus/

(703) 429-7200

Orbital Sciences Corporation

Launch Systems Group

45101 Warp Drive

Dulles, VA 20166

Additional information can be obtained from the USAF OSP Office at:

USAF SMC Space Development and Test Directorate (SMC/SD)

Launch Systems Division (SMC/SDL)

3548 Aberdeen Ave SE

Kirtland AFB, NM 87117-5778

(505) 853-5533

(505) 853-0507

Release 1.1

July 2013

v

Antares® OSP-3 User’s Guide

Table of Contents

PAGE

PREFACE .....................................................................................................................................................iv

GLOSSARY .................................................................................................................................................. x

1. INTRODUCTION ...................................................................................................................................... 1

1.1.

Orbital History ............................................................................................................................... 1

1.2.

Antares Launch Vehicle ................................................................................................................ 1

2. ANTARES LAUNCH SYSTEM OVERVIEW ............................................................................................ 2

2.1.

Antares Launch Service ................................................................................................................ 2

2.2.

Antares Launch Vehicle ................................................................................................................ 2

2.3.

Launch Operations ........................................................................................................................ 7

3. PERFORMANCE ..................................................................................................................................... 8

3.1.

Mission Design .............................................................................................................................. 8

3.2.

Mission Profile ............................................................................................................................... 8

3.3.

General Performance from WFF................................................................................................. 11

3.4.

General Performance from KLC ................................................................................................. 15

3.5.

Orbit Insertion Accuracy.............................................................................................................. 18

3.6.

Payload Deployment ................................................................................................................... 19

4. PAYLOAD ENVIRONMENTS ................................................................................................................ 21

4.1.

Design Limit Load Factors .......................................................................................................... 21

4.2.

Payload Vibration Environment................................................................................................... 26

4.3.

Payload Shock Environment ....................................................................................................... 28

4.4.

Contamination and Environmental Control ................................................................................. 29

4.5.

Thermal Environments ................................................................................................................ 30

4.6.

Pressurization Profile .................................................................................................................. 30

4.7.

Payload RF Environment ............................................................................................................ 31

5. PAYLOAD INTERFACES ...................................................................................................................... 32

5.1.

3.9 Meter Payload Fairing ........................................................................................................... 32

5.2.

Payload Mechanical Interface and Separation System .............................................................. 34

5.3.

Electrical Payload Accommodation Requirements ..................................................................... 36

5.4.

Payload Design Constraints........................................................................................................ 37

6. MISSION INTEGRATION ...................................................................................................................... 40

6.1.

Mission Management Approach ................................................................................................. 40

6.2.

Mission Planning and Development ........................................................................................... 43

6.3.

Mission Integration Process ........................................................................................................ 45

7. GROUND AND LAUNCH OPERATIONS .............................................................................................. 51

7.1.

Antares Launch Processing and Integration Overview ............................................................... 51

7.2.

Antares Processing and Launch Facilities at WFF ..................................................................... 52

7.3.

Launch Vehicle Processing ......................................................................................................... 56

Release 1.1

July 2013

vi

Antares® OSP-3 User’s Guide

Table of Contents

7.4.

Payload Processing/Integration .................................................................................................. 57

7.5.

Pre-Launch and Launch Operations ........................................................................................... 58

8. ENHANCEMENTS ................................................................................................................................. 60

8.1.

Separation Systems .................................................................................................................... 60

8.2.

Conditioned Air ........................................................................................................................... 66

8.3.

Nitrogen Purge ............................................................................................................................ 66

8.4.

Additional Access Panel ............................................................................................................. 66

8.5.

Enhanced Telemetry ................................................................................................................... 66

8.6.

Enhanced Contamination Control ............................................................................................... 67

8.7.

Secure FTS ................................................................................................................................. 68

8.8.

Over the Horizon Telemetry ........................................................................................................ 69

8.9.

Increased Insertion Accuracy...................................................................................................... 70

8.10.

Payload Isolation System ............................................................................................................ 70

8.11.

Debris Mitigation System ............................................................................................................ 71

8.12.

Dual/Multi-Payload Adapter ........................................................................................................ 71

8.13.

Enhanced Performance .............................................................................................................. 71

8.14.

Lengthened Payload Envelope ................................................................................................... 73

8.15.

Hydrazine Servicing .................................................................................................................... 73

8.16.

Nitrogen Tetroxide (NTO) Servicing ........................................................................................... 73

8.17.

Poly-Pico Orbital Deployer (P-POD) ........................................................................................... 74

8.18.

Suborbital Performance .............................................................................................................. 74

8.19.

Alternate Launch Locations ........................................................................................................ 74

LIST OF FIGURES

PAGE

Figure 2.2-1. Baseline Antares Launch Vehicle Configuration .................................................................... 2

Figure 2.2-2. Antares 120 and 130 Configurations ...................................................................................... 3

Figure 2.2.1-1. Antares Main Engine System .............................................................................................. 4

Figure 2.2.2-1. CASTOR 30B Motor ............................................................................................................ 5

Figure 2.2.3.1-1. Antares 3.9 m Fairing Assembly ...................................................................................... 6

Figure 3.1.1-1. U.S. Launch Ranges Compatible with Antares ................................................................... 9

Figure 3.2-1. Antares 120 Typical Mission Profile to LEO ......................................................................... 10

Figure 3.3-1. Antares Fleet Launch Capabilities from WFF....................................................................... 11

Figure 3.3-2. Antares 120 Launch Capabilities from WFF ......................................................................... 12

Figure 3.3-3. Antares 121 Launch Capabilities from WFF ......................................................................... 12

Figure 3.3-4. Antares 130 Launch Capabilities from WFF ......................................................................... 13

Figure 3.3-5. Antares 131 Launch Capabilities from WFF ......................................................................... 13

Release 1.1

July 2013

vii

Antares® OSP-3 User’s Guide

Table of Contents

Figure 3.3-6. Antares 122 and 132 High Energy Performance from WFF ................................................ 14

Figure 3.4-1. Antares Fleet Launch Capabilities from KLC ....................................................................... 15

Figure 3.4-2. Antares 120 Launch Capabilities from KLC ......................................................................... 16

Figure 3.4-3. Antares 121 Launch Capabilities from KLC ......................................................................... 16

Figure 3.4-4. Antares 130 Launch Capabilities from KLC ......................................................................... 17

Figure 3.4-5. Antares 131 Launch Capabilities from KLC ......................................................................... 17

Figure 3.4-6. Antares 122 and 132 Critically Inclined Elliptical Launch Capabilities ................................. 18

Figure 4.1.2-1. Nominal Payload Acceleration as a Function of Mass (Antares 120) ............................... 23

Figure 4.1.2-2. Nominal Payload Acceleration as a Function of Mass (Antares 121) ............................... 23

Figure 4.1.2-3. Nominal Payload Acceleration as a Function of Mass (Antares 122) ............................... 24

Figure 4.1.2-4. Nominal Payload Acceleration as a Function of Mass (Antares 130) ............................... 24

Figure 4.1.2-5. Nominal Payload Acceleration as a Function of Mass (Antares 131) ............................... 25

Figure 4.2-1. Antares Fairing Internal Maximum Flight Level Payload Acoustic Environment .................. 26

Figure 4.2.2-1. Antares Payload Interface Sine Vibration Levels .............................................................. 27

Figure 4.3-1. Antares Payload Maximum Flight Level Shock at the Base of the Payload ........................ 28

Figure 4.6-1. Antares Fairing Internal Pressure Profile ............................................................................. 30

Figure 5.1.1-1. Antares Fairing Dynamic Payload Envelope with 1575 mm Mechanical Interface ........... 33

Figure 5.1.2-1. Antares Fairing Standard Access Door Location .............................................................. 34

Figure 5.2.1-1. Antares 1575 mm (62 in.) Non-Separating Payload Mechanical Interface ....................... 35

Figure 5.3-1. Antares Electrical Interface Block Diagram .......................................................................... 36

Figure 6.1-1. Mission Integration Team ..................................................................................................... 40

Figure 6.1-2. Antares Program Structure ................................................................................................... 41

Figure 6.1.2-1. Orbital Mission Responsibilities ......................................................................................... 42

Figure 6.2-1. Antares Mission Cycle .......................................................................................................... 44

Figure 7.2-1. Antares HIF at WFF .............................................................................................................. 52

Figure 7.2.1.1-1. Transporter-Erector-Launcher (TEL) .............................................................................. 52

Figure 7.2.1.2-1. Portable Environmental Control System (PECS) .......................................................... 53

Figure 7.2.2.1-1. WFF Launch Pad 0A ...................................................................................................... 54

Figure 7.2.2.2-1. WFF Launch Control Center........................................................................................... 54

Figure 7.2.2.3-1. WFF Mission/Range Control Center .............................................................................. 55

Figure 7.3-1. Flow of Antares Hardware to the Launch Site ...................................................................... 56

Figure 7.5.3-1. Antares Launch from WFF ................................................................................................ 59

Figure 8.1.1-1. 937S Separation System ................................................................................................... 60

Figure 8.1.1-2. Antares 937S Payload Dynamic Envelope ........................................................................ 61

Figure 8.1.2-1. 1194VS Separation System .............................................................................................. 62

Figure 8.1.3-1. 1666VS Separation System .............................................................................................. 64

Figure 8.1.3-2. Antares 1666VS Payload Dynamic Envelope ................................................................... 65

Release 1.1

July 2013

viii

Antares® OSP-3 User’s Guide

Table of Contents

Figure 8.6-1. The Orbital Team Has Extensive Experience in a Payload Processing Clean Room

Environment ................................................................................................................................................ 67

Figure 8.7-1. Antares Secure FTS System Block Diagram ....................................................................... 68

Figure 8.8-1. TDRSS 20W LCT2 Transmitter and UB S-Band Antenna ................................................... 69

Figure 8.8-2. TDRSS Notional Telemetry Flow.......................................................................................... 69

Figure 8.9-1. Antares Bi-Propellant Third Stage ........................................................................................ 70

Figure 8.10-1. Omni-Flex Isolators Are Easily Integrated Between the Payload and the Payload

Separation System (Minotaur I Installation Shown) ................................................................................... 70

Figure 8.10-2. Use of Soft Ride Significantly Attenuates Peak LV Dynamic Environments ...................... 71

Figure 8.13-1. Antares LV Enhanced Performance Options ..................................................................... 72

Figure 8.14-1. Antares 120 Enhanced Fairing Dynamic Envelope ............................................................ 73

Figure 8.15-1. Typical Propellant Loading Schematic ............................................................................... 74

Figure 8.19-1. Layout of the Antares Facilities at KLC .............................................................................. 75

LIST OF TABLES

PAGE

Table 2.2-1. Antares Numbering Conventions ............................................................................................. 3

Table 3.6-1. Antares Payload Deployment Pointing and Rate Accuracies ................................................ 19

Table 4.1-1. Design Limited Load Factors ................................................................................................. 21

Table 4.1.1-1. Typical Antares 120 Ground and Flight Acceleration Loads at the Payload Interface ....... 21

Table 4.1.1-2. Phasing of Dynamic Loading Events .................................................................................. 22

Table 4.7-1. Launch Vehicle RF Emitters and Receivers .......................................................................... 31

Table 5.4.2-1. Payload Mass Properties Measurement Tolerance ........................................................... 38

Table 6.3.1-1. Overview of Typical Mission Integration Working Group Flow .......................................... 45

LIST OF APPENDICES

PAGE

APPENDIX A. PAYLOAD QUESTIONNAIRE...........................................................................................A-1

Release 1.1

July 2013

ix

Antares® OSP-3 User’s Guide

Glossary

GLOSSARY

6DOF

AAC

ACS

ADS

AIM

ait

ATK

ATP

BTS

C

C&C

C/No

CBOD

CCAM

CDR

CG

CLA

cm

CONOPS

COTS

CRD

CRS

CVCM

dB

deg

DIACAP

ECS

EED

EELV

EGSE

EICD

EMC

EME

EMI

F

FAA

FAB

FMA

Release 1.1

Six Degrees of Freedom

Alaska Aerospace Corporation

Attitude Control System

Automatic Destruct System

Analog Input Module

atmospheric interceptor technology

Alliant Tech Systems, Inc.

Authority To Proceed

Bi-Propellant Third Stage

Celsius

Command and Control

Carrier to Receiver Noise Density

Clamp Band Opening Device

(CBOD)

Collision/Contamination Avoidance

Maneuver

Critical Design Review

Center of Gravity

Coupled Loads Analysis

centimeter

Concept of Operations

Commercial Orbital Transportation

Services

Command Receiver Decoder

Commercial Resupply Services

Collected Volatile Condensable

Materials

decibels

degrees

DoD Information Assurance

Certification and Accreditation

Environmental Control System

Electro-Explosive Device

Evolved Expendable Launch

Vehicle

Electrical Ground Support

Equipment

Electrical Interface Control Drawing

Electromagnetic Compatibility

Electromagnetic Environment

Electromagnetic Interference

Fahrenheit

Federal Aviation Administration

Fabrication

Final Mission Analysis

ft

FTLU

FTS

g

GEO

GFE

GN&C

GN2

GSE

He

HEPA

HIF

HTPB

Hz

I/O

ICD

ILC

in.

IPA

Isp

ISS

kbps

kg

KLC

km

lb

lbf

lbm

LC

LCC

LEO

LEV

LFF

LOX

LRR

LV

m

m/s

mA

MACH

MARS

Max Q

MCC

MCD

MDR

July 2013

feet

Flight Termination Logic Unit

Flight Termination System

gravitational force

Geosynchronous

Government Furnished Equipment

Guidance, Navigation, and Control

Gaseous Nitrogen

Ground Support Equipment

Helium

High Efficiency Particulate Air

Horizontal Integration Facility

Hydroxyl Terminated Polybutadiene

Hertz

Input/Output

Interface Control Document

Initial Launch Capability

inch

Isopropyl Alcohol

Specific Impulse

International Space Station

kilobits per second

kilogram(s)

Kodiak Launch Complex

kilometer

pound

pound(s) of force

pound(s) of mass

Launch Conductor

Launch Control Center

Low Earth Orbit

Launch Equipment Vault

Launch Fueling Facility

Liquid Oxygen

Launch Readiness Review

Launch Vehicle

meters

meters per second

milli-Amps

Modular Avionics Control Hardware

Mid-Atlantic Regional Spaceport

Maximum Dynamic Pressure

Mission Control Center

Mission Constraints Document

Mission Design Review

x

Antares® OSP-3 User’s Guide

MDR

MECO

MES

MGSE

MHz

MICD

MIL-STD

MIWG

mm

MRR

ms

MSPSP

mV

N2

N

NASA

NiCd

nmi

NTO

OBV

OD

ODM

OR

Orbital

OSP-3

P/L

PCM

PDR

PECS

PFF

PMA

PMF

POC

PPF

ppm

P-POD

PRD

Release 1.1

Glossary

Mission Dress Rehearsal

Main Engine Cut-Off

Main Engine System

Mechanical Ground Support

Equipment

Mega-Hertz

Mechanical Interface Control

Drawing

Military Standard

Mission Integration Working Group

millimeter

Mission Readiness Review

millisecond

Missile System Pre-Launch Safety

Package

milli-Volt

Nitrogen

Newton

National Aeronautics and Space

Administration

Nickel Cadmium

nautical mile

Nitrogen Tetroxide

Orbital Boost Vehicle

Operations Directive

Ordnance Driver Module

Operations Requirement

Orbital Sciences Corporation

Orbital Suborbital-3

Payload

Pressurized Cargo Module

Preliminary Design Review

Portable Environment Control

System

Payload Processing Facility

Preliminary Mission Analysis

Payload Mate Fixture

Point of Contact

Payload Processing Facility

parts per million

Poly-Pico Orbital Deployer

Program Requirements Document

psf

PSRR

PSS

RAAN

RCC

RF

RH

RP

rpm

RWG

S.L.

S/A

SCAPE

scfm

SD

SDL

sec

SRM

SV

TDRSS

TEL

TIM

TLM

TML

TVA

TVC

UDS

UHF

Ultraviolet

UPC

USAF

V/m

VAC

Vdc

Vp-p

WDR

WFF

WP

July 2013

per square foot

Pre-Ship Readiness Review

Premature Separation Switch

Right Ascension of Ascending

Node

Range Control Center

Radio Frequency

Relative Humidity

Rocket Propellant

revolutions per minute

Range Working Group

Sea Level

Safe and Arm

Self-Contained Atmospheric

Protective Ensemble

standard cubic feet per minute

Space Development and Test

Directorate

Launch Systems Division

second(s)

Solid Rocket Motor

Space Vehicle

Telemetry Data Relay Satellite

System

Transporter Erector/Launcher

Technical Interchange Meeting

Telemetry

Total Mass Loss

Thrust Vector Actuator

Thrust Vector Control

Universal Documentation System

Ultra High Frequency

UV

United Paradyne Co.

United States Air Force

Volts per meter

Vacuum

Volts direct current

Volts peak-to-peak

Wet Dress Rehearsal

Wallops Flight Facility

Work Package

xi

Antares® OSP-3 User’s Guide

Section 1.0 – Introduction

1. INTRODUCTION

The objective of the Antares OSP-3 User’s Guide is to familiarize payload mission planners with Orbital’s

Antares launch service as available through the OSP-3 contract. This document provides an overview of

the Antares system design and a description of the standard launch services provided to our customers.

Orbital also offers a variety of enhanced services to allow maximum flexibility in satisfying customer requirements.

1.1. Orbital History

Orbital is a leading developer and manufacturer of small and medium class space systems. Orbital has

three decades of demonstrated reliable, rapid and affordable development and production experience,

serving customers in the commercial, defense and civil government markets. Orbital has delivered or is

under contract for over 1,000 space products, including satellites and space systems, space and strategic

launch vehicles, and sub-orbital target vehicles and sounding rockets.

Orbital is a domestic launch service provider and an ISO-9001/2008 certified company. Founded in 1982,

Orbital has pioneered new classes of rockets, satellites, and other space-based technologies that help

make the benefits of space more affordable and accessible.

1.2. Antares Launch Vehicle

The Antares is a flight proven two stage, ground launched vehicle. Conservative design margins, stateof-the-art structural systems, a modular avionics architecture, and a simplified integration and test approach yield a robust, highly reliable launch vehicle design. In addition, Antares payload accommodations and interfaces are flexible and satisfy a wide range of potential customer requirements. Each element of the Antares launch system is developed to maximize payload mass to orbit, streamline the mission design and payload integration process, and to provide safe, reliable space launch services.

The baseline launch site for the Antares launch service is on the NASA Wallops Flight Facility (WFF) and

supported by the Mid-Atlantic Regional Spaceport (MARS). A cornerstone of the Antares program is the

simplified integration and test capabilities that include horizontal integration of the vehicle stages and the

payload. This horizontal integration process and mobile Ground Support Equipment (GSE) implemented

at WFF would be replicated at Orbital’s high inclination launch site – the Kodiak Launch Complex (KLC) in

Kodiak, Alaska.

Release 1.1

July 2013

1

Antares® OSP-3 User’s Guide

Section 2.0 – Overview

2. ANTARES LAUNCH SYSTEM OVERVIEW

Orbital developed the Antares launch vehicle to serve the Medium-Class space launch market, and to

provide a cost effective, reliable and flexible means of placing Medium-Class satellites into orbital and

Earth-escape trajectories. The Antares design focuses on system reliability, transportability, and minimum on-pad time.

2.1. Antares Launch Service

Orbital provides all of the necessary hardware, software and services to integrate, test and launch a

payload into its prescribed orbit. The Antares mission integration process completely identifies,

documents, and verifies all spacecraft and mission requirements. In addition, as part of the standard

launch services, Orbital will complete all required agreements, licenses, and documentation to

successfully conduct Antares launch operations.

2.2. Antares Launch Vehicle

The baseline Antares vehicle, shown in Figure 2.2-1, is a two stage, ground launched vehicle. Antares

features a low-risk design approach by incorporating flight proven components from leading global suppliers, and by utilizing subsystem designs successfully flown on many Orbital launch vehicles.

Figure 2.2-1. Baseline Antares Launch Vehicle Configuration

To simplify description of the Antares configurations offered, Orbital has created a configuration numbering convention detailed in Table 2.2-1. Each configuration varies in the selection of second or third stages depending on the unique requirements of the specific mission. All configurations rely on a common

Liquid Oxygen/Rocket Propellant (LOX/RP) Stage 1 booster powered by dual Aerojet AJ26 engines. All

Antares configurations also utilize a standard 3.9 m payload fairing, as well as common electrical, mechanical, and reaction control systems, ordnance devices, and flight instrumentation.

Release 1.1

July 2013

2

Antares® OSP-3 User’s Guide

Section 2.0 – Overview

The Antares 120 configuration rocket is the baseline for OSP-3. The 130 is an enhancement off that

baseline. The Antares 120 and 130 configurations (Figure 2.2-2) utilize the CASTOR 30B and CASTOR

30XL SRM second stage, respectively, to provide

Table 2.2-1. Antares Numbering Conventions

increased performance to Low Earth Orbit (LEO).

Vehicle

Stage 2

Stage 1

Stage 3

Identifier

(CASTOR)

Both the CASTOR 30B and CASTOR 30XL second

120 (Baseline)

LOX/RP, AJ26

30B

None

stage motors, built by Alliant Techsystems, Inc.

121 (Enhanced) LOX/RP, AJ26

30B

BTS

(ATK), are based on the CASTOR 30 SRM. The

122 (Enhanced) LOX/RP, AJ26

30B

STAR 48BV

Antares 130 also includes a second 1860 mm (73.3 130 (Enhanced) LOX/RP, AJ26

30XL

None

in) tall fairing adapter to accommodate the addition- 131 (Enhanced) LOX/RP, AJ26

30XL

BTS

al length of the CASTOR 30XL SRM. This adapter 132 (Enhanced) LOX/RP, AJ26

30XL

STAR 48BV

allows Orbital to offer the same payload fairing dynamic and static envelopes for both the Antares 120

and 130 configurations.

For missions with stringent orbit insertion requirements, improved insertion accuracy is provided with

Orbital’s optional Bi-Propellant Third Stage (BTS) on

Antares 121 and 131 configurations. The accuracy

achievable by the BTS is limited only by any accumulated navigation errors during flight, which are

dependent on the mission timeline and trajectory

chosen. An optional 3-axis stabilized STAR™ 48BV

third stage is also available on Antares 122 and 132

configurations, which provides a significant performance increase for payloads with high-energy orbit

requirements. These optional third stages are described in greater detail in Section 8 of this guide.

2.2.1. Stage 1 Assembly

The Stage 1 Assembly consists of the Stage 1 propellant tanks and the Main Engine System (MES). It

also incorporates the Range-required Flight Termination System (FTS). Stage 1 establishes the 3.90

m (154 in) diameter of the Antares launch vehicle

and is 27.6 m (90.6 ft) long.

The Stage 1 core facilitates the storage, management, and delivery of propellants (LOX and kerosene RP) to the MES at required conditions and

flow rates. The Stage 1 core includes propellant

tanks, pressurization tanks, valves, sensors, FTS,

feedlines, tubing, wiring and other associated hardware. The Stage 1 core structures and associated

propellant systems are manufactured by the Yuzhmash State Enterprise under the design authority of

State Design Office Yuzhnoye, both in the Ukraine.

The Stage 1 systems, while specifically designed for

Release 1.1

July 2013

Figure 2.2-2. Antares 120 and 130

Configurations

3

Antares® OSP-3 User’s Guide

Section 2.0 – Overview

the Antares vehicle, are largely derived from structures and systems used on the Zenit series of launch

vehicles, which have extensive flight heritage including more than 60 successful launches.

The Stage 1 aft bay contains the MES and is the primary interface between the launch vehicle and

ground systems. Many of the mechanical, fluid, and electrical interfaces connect through the aft bay

structure. These connectors mate with a launch ring that mounts to the vehicle in the integration building

while the launch vehicle is horizontal. This permits all flight separation connections to be mated and verified inside the integration facility prior to transporting to the pad.

The MES, shown in Figure 2.2.1-1, generates thrust for launch vehicle motion and control during Stage 1

ascent. The MES consists of two AJ26 LOX/RP rocket engines that supply approximately 3,630 kN

(816,000 lbf) total vacuum thrust mounted on a thrust frame. The two Aerojet AJ26 engines are modified

Russian NK-33 engines originally designed and produced for use on the Russian N-1 launch vehicle.

The engines use an oxygen-rich, staged combustion cycle that can throttle from 58% to 108%, and has a

variable mixture ratio valve for controlling relative flow rates of oxidizer and fuel. These engines are operational, well characterized, and have an extensive test history. Each of the AJ26 engines, refurbished

with modern components, undergoes hot-fire acceptance testing at the test stand at the NASA Stennis

Space Center prior to integration onto the vehicle.

Figure 2.2.1-1. Antares Main Engine System

Release 1.1

July 2013

4

Antares® OSP-3 User’s Guide

Section 2.0 – Overview

2.2.2. Stage 2 Assembly

Orbital uses the CASTOR 30 family of SRMs as the

second stage for the Antares vehicle (Figure 2.2.21). The CASTOR 30 product line is derived from the

heritage CASTOR 120 motor used on the Taurus

launch vehicle. The CASTOR 30 motors, manufactured by ATK, consist of a composite graphite/epoxy

wound case and a flexseal design at the throat to

allow for two-axis Thrust Vector Control (TVC) motion during flight. Orbital supplies a composite

sandwich structure motor adapter cone to provide a

structural load path from the Stage 1 forward skirt to

the CASTOR motor aft skirt.

Figure 2.2.2-1. CASTOR 30B Motor

Antares utilizes variants of the CASTOR 30 motor to

meet the requirements of specific missions. The baseline Antares service for OSP-3 will use the CASTOR 30B motor (Antares 120). An enhancement offered includes the CASTOR 30XL motor (Antares

130). Both the CASTOR 30B and CASTOR 30XL motors are derived from the CASTOR 30 but are modified for increased performance and to increase commonality with other ATK products.

2.2.2.1. Attitude Control System (ACS)

The Antares ACS provides three-axis attitude control throughout boosted flight and coast phases. The

MES provides yaw, pitch, and roll control during Stage 1 powered flight. Stage 1 flies a pre-programmed

attitude profile based on pre-flight trajectory design and optimization.

Stage 2 flight is controlled by the combination of the CASTOR 30 TVC and the onboard Attitude Control

System (ACS) discussed in the following paragraph. Stage 2 is guided by the Powered Explicit Guidance

algorithms that compute the trajectory based on the vehicle state just after Stage 1 separation and preprogrammed orbital targets. The algorithm first computes the required coast period between Stage 1 separation and Stage 2 ignition, and then computes the attitude profile to be used during the burn. An inplane or out-of-plane turning scheme is used to manage any excess energy to minimize insertion errors.

The Stage 2 ACS employs a cold gas nitrogen system with heritage from Orbital’s other space launch

vehicles. During the Stage 1/2 coast period and after Stage 2 burnout, the vehicle's attitude is controlled

by this ACS system. The cold-gas control system is also used during the Stage 2 burn to control roll attitude and rate, and to orient the payload for separation. Following payload separation, the cold-gas control system is used to orient Stage 2 for collision avoidance and prevent payload contamination from residual by-products of the Stage 2 motor.

Release 1.1

July 2013

5

Antares® OSP-3 User’s Guide

Section 2.0 – Overview

2.2.2.2. Stage 2 Avionics Module

The Antares avionics design incorporates Orbital’s latest MACH design technology to provide power

transfer, data acquisition, booster interfaces, and ordnance initiation. This advanced system supplies the

increased capability and flexibility required by the Antares to communicate with vehicle subsystems, GSE,

and the payload utilizing standard Ethernet links and discrete Input/Output (I/O).

2.2.3. Payload Accommodations

Antares payload accommodations include a fairing and the USAF standard non-separating mechanical

interface. The spacecraft interface can be enhanced with a variety of payload separation systems.

2.2.3.1. Payload Fairing

Antares employs a 3.9 m (155 in.) composite bi-sector fairing (Figure 2.2.3.1-1) consisting of two graphite

composite shell halves and associated separation systems. The two fairing halves are joined with a frangible rail joint, and the base of the fairing is attached

to Stage 2 using a similar ring-shaped frangible

joint. Severing the rail/ring frangible joints allows

each half of the fairing to rotate on hinges mounted

on the Stage 2 fairing cylinder. A cold gas system is

used to drive pistons that force the fairing halves

open. All fairing deployment systems are noncontaminating.

3

With a fairing volume greater than 57.5 m (2,031

3

ft ) available for users, Antares provides significantly

greater volume for accommodating payloads than

Figure 2.2.3.1-1. Antares 3.9 m Fairing

any other Medium-Class launch vehicle in producAssembly

tion. The payload design envelope for the Antares

fairing ensures adequate static and dynamic clearances to the payload assembly are maintained during

ground operations and ascent. The static and dynamic payload envelopes provided by Antares fairing

are detailed in Section 5.

2.2.3.2. Payload Interface

Under OSP-3, Orbital offers a non-separating interface for the customer as well as a variety of separation

systems as enhancements. The standard payload interface for Antares for OSP-3 missions is a 1575 mm

(62 in.) bolt circle common with the Evolved Expendable Launch Vehicle (EELV) interface standard. This

non-separating mechanical interface accommodates all Orbital-provided payload separation system enhancements and can accommodate customer-provided payload adaptors and separation systems. Details of the available non-separating mechanical interface and optional payload separation systems are

presented in Sections 5 and 8, respectively.

Release 1.1

July 2013

6

Antares® OSP-3 User’s Guide

Section 2.0 – Overview

2.3. Launch Operations

While initially based at the Wallops Flight Facility (WFF) in Virginia, The Antares Concept of Operations

(CONOPS) as well as all required GSE were developed to be adaptable. With the appropriate fueling

infrastructure and pad capability, the Antares launch vehicle and GSE are designed to be compatible with

any of the other major Ranges and commercial Spaceports in Alaska, California, and Florida. Brief descriptions of the Antares launch operations and fixed launch infrastructure are provided below, with a

more detailed discussion in Section 7.

2.3.1. Horizontal Integration

The Antares launch vehicle is designed for horizontal processing. Orbital performs Antares launch site

integration and test activities in a Horizontal Integration Facility (HIF) in preparation for roll-out to the pad

for erection, launch vehicle fueling, and launch. This HIF is used to assemble and test the Antares launch

vehicle, mate the payload to the launch vehicle, perform launch vehicle to payload checkout, and enclose

the payload in the fairing.

2.3.2. Payload Processing and Fueling

Orbital’s approach to payload processing places few requirements on the customer. Payload processing

is conducted near the launch vehicle integration facility in an environmentally controlled Payload

Processing Facility (PPF). If required, spacecraft fueling is conducted in an environmentally controlled

hazardous operations Payload Fueling Facility (PFF). Once the payload is fully assembled, checked out,

and fueled (if required), the payload is transported to the HIF for integration with the launch vehicle.

2.3.3. Mission and Launch Control

The Mission/Range Control Center (MCC/RCC) serves as the launch authority center for Antares

launches. The MCC houses the Antares and customer launch teams; hosts consoles for Orbital, Range

Safety, and customer personnel; and provides hardline and Radio Frequency (RF) telemetry consoles,

voice net communications and launch Pad 0A live video. Launch control is performed from the Launch

Control Center (LCC) which provides Antares vehicle Command and Control (C&C); Antares fueling control; payload control; Range Safety; and launch site control (i.e., propellant farm, Environmental Control

System (ECS), and telemetry, power, and network support equipment).

2.3.4. Launch Pad

The current launch pad for Antares, WFF Pad 0A, consists of the equipment necessary to support launch

vehicle erection, fueling, and launch. These fixed assets include a launch mount with a flame duct &

lightning towers, Launch Equipment Vaults (LEVs) to house the launch vehicle and payload Electrical

Ground Support Equipment (EGSE), cabling and fueling trenches, water storage, LOX and RP fueling

system and tanks, and N2 and He tank skids. Antares pad activities include erection, fueling, final checkout, and launch. These operations are streamlined to take less than 36 hours from roll-out to launch.

This responsive launch operations paradigm also minimizes launch pad infrastructure costs.

2.3.5. GSE

The primary GSE that supports Antares launch operations include the Transporter Erector/Launcher

(TEL), the Portable Environmental Control System (PECS), lifting slings, and launch vehicle handling

GSE. This mobile GSE is discussed further in Section 7.

Release 1.1

July 2013

7

Antares® OSP-3 User’s Guide

Section 3.0 – Performance

3. PERFORMANCE

This section describes the orbital performance capabilities of the Antares vehicle. Antares can deliver

payloads to a variety of altitudes and to a range of posigrade and retrograde inclinations. High Energy

missions can also be achieved through the addition of an optional STAR 48BV third stage (see Section

8).

3.1. Mission Design

Orbital will provide the USAF with a mission design for each payload optimized to meet critical requirements while satisfying payload, launch vehicle, and Range Safety constraints. Launch site selection, ascent trajectory design, and post-injection deployment design are developed and verified during the Antares mission design process.

3.1.1. Mission Integration

Mission requirements are detailed in the specific mission Interface Control Document (ICD) that is developed as part of the payload/launch vehicle mission integration process. The Antares Mission Manager

works with the USAF and their customer to optimize requirements parameters to best suit both spacecraft

and Antares launch vehicle capabilities. Special mission requirements (e.g. argument of perigee, pointing, etc.) are addressed on a mission-specific basis. Mission requirements drive elements of the trajectory design, including maximum dynamic pressure, launch azimuth constraints, free molecular heating at

fairing separation, etc. When applicable, the launch site is selected based on orbit inclination requirements, as shown in Figure 3.1.1-1.

3.1.2. Launch Sites

The baseline Antares launch operations are from WFF. WFF supports easterly launch azimuths, some

high inclination missions, and high energy launches. For missions requiring greater performance to high

inclination polar or sun-synchronous orbits, Orbital offers KLC located on Kodiak Island, Alaska as an enhancement. A discussion of this capability and performance from KLC is provided in Section 3.4.

3.2. Mission Profile

A typical mission profile for an Antares 120 vehicle with the CASTOR 30B second stage from WFF to

LEO is shown in Figure 3.2-1. The Antares lifts off the pad 2 seconds after Stage 1 ignition. Stage 1

burns for 234 seconds, and separates after a brief post-burn coast. The upper stage stack continues to

coast for approximately 85 seconds before the fairing is jettisoned. After fairing jettison, Stage 2 is ignited. Stage 2 burnout occurs approximately 488 seconds into the flight, and the upper stack continues to

coast for another 120 seconds before the payload is separated. Once the payload has separated, the

Stage 2 performs a Collision/Contamination Avoidance Maneuver (CCAM) to ensure no potential exists

for recontact with the payload.

Release 1.1

July 2013

8

Antares® OSP-3 User’s Guide

Section 3.0 – Performance

Figure 3.1.1-1. U.S. Launch Ranges Compatible with Antares

Release 1.1

July 2013

9

Antares® OSP-3 User’s Guide

Section 3.0 – Performance

Figure 3.2-1. Antares 120 Typical Mission Profile to LEO

Release 1.1

July 2013

10

Antares® OSP-3 User’s Guide

Section 3.0 – Performance

3.3. General Performance from WFF

Antares general performance for circular orbits of various configurations, altitudes, and inclinations is provided in Figures 3.3-1 through 3.3-5 for launches from WFF.

Figure 3.3-1. Antares Fleet Launch Capabilities from WFF

Release 1.1

July 2013

11

Antares® OSP-3 User’s Guide

Section 3.0 – Performance

Figure 3.3-2. Antares 120 Launch Capabilities from WFF

Figure 3.3-3. Antares 121 Launch Capabilities from WFF

Release 1.1

July 2013

12

Antares® OSP-3 User’s Guide

Section 3.0 – Performance

Figure 3.3-4. Antares 130 Launch Capabilities from WFF

Figure 3.3-5. Antares 131 Launch Capabilities from WFF

Release 1.1

July 2013

13

Antares® OSP-3 User’s Guide

Section 3.0 – Performance

Antares performance for high energy orbits for various configurations utilizing the STAR 48BV enhancement from WFF is provided in Figure 3.3-6.

Figure 3.3-6. Antares 122 and 132 High Energy Performance from WFF

Release 1.1

July 2013

14

Antares® OSP-3 User’s Guide

Section 3.0 – Performance

3.4. General Performance from KLC

For missions requiring greater performance to high inclination polar or sun-synchronous orbits, Antares

will launch from KLC located on Kodiak Island, Alaska. Antares estimated performance from KLC for circular orbits of various configurations, altitudes and inclinations is provided in Figures 3.4-1 through 3.4-6.

The Antares launch system has been designed for and can be made compatible with the KLC launch site.

The basic Antares operations approach consists of horizontal vehicle integration, mobile transport to the

launch pad, and austere ―clean pad‖ launch processing. Orbital has verified that this approach can be

replicated at KLC. The Antares integration and launch operations will remain largely the same as those

implemented at WFF.

Figure 3.4-1. Antares Fleet Launch Capabilities from KLC

Release 1.1

July 2013

15

Antares® OSP-3 User’s Guide

Section 3.0 – Performance

Figure 3.4-2. Antares 120 Launch Capabilities from KLC

Figure 3.4-3. Antares 121 Launch Capabilities from KLC

Release 1.1

July 2013

16

Antares® OSP-3 User’s Guide

Section 3.0 – Performance

Figure 3.4-4. Antares 130 Launch Capabilities from KLC

Figure 3.4-5. Antares 131 Launch Capabilities from KLC

Release 1.1

July 2013

17

Antares® OSP-3 User’s Guide

Section 3.0 – Performance

Figure 3.4-6. Antares 122 and 132 Critically Inclined Elliptical Launch Capabilities

3.5. Orbit Insertion Accuracy

Orbit insertion errors for any launch vehicle are primarily driven by impulse errors from terminal stage

propulsion, payload mass, guidance scheme used, and navigational errors. Orbital characterizes apse

errors in terms of altitude errors at the insertion and non-insertion apses. The insertion apse is less dependent on impulse errors and payload mass and typically has a tighter dispersion than the non-insertion

apse. Errors in the non-insertion apse are caused by velocity errors at insertion, and, as a result, are driven more strongly by impulse errors and payload mass. The distribution of errors between the two apses,

as well as to other orbital parameters, can be greatly affected by the guidance scheme, which can be adjusted to place more or less priority on any one of the insertion parameters.

3.5.1. Insertion Accuracies for Antares Configurations 120 and 130

Orbit injection errors for Antares configurations 120 and 130 are strongly driven by total impulse errors

from the CASTOR 30B and 30XL motors, respectively. The actual insertion errors are dependent on the

payload mass and the guidance algorithm. However, insertion apse errors are within ±18 km (10 nmi) and

non-insertion apse errors are within 92.6 km (50 nmi). Lighter payloads going to high altitudes will

experience greater dispersions, particularly on the non-insertion apse.

Inclination dispersions are less than 0.2 degrees. When made a targeting priority, Right Ascension of

Ascending Node (RAAN) dispersions are also less 0.2 degrees.

3.5.2. Insertion Accuracies for Antares Configurations 121 and 131

The enhanced Antares configurations 121 and 131 include a restartable bipropellant third stage. This

stage has sufficient propulsive capability to both improve performance to higher altitude LEO missions as

well as significantly reduce apse altitude errors to within ±15 km (8 nmi) on both apses. Inclination errors

Release 1.1

July 2013

18

Antares® OSP-3 User’s Guide

Section 3.0 – Performance

are also improved to within ±0.08 degrees. When made a targeting priority, RAAN errors are similar to

the other configurations at less than 0.2 degrees. Furthermore, this stage allows the explicit targeting of

argument of perigee to within ±0.5 degrees.

3.5.3. Insertion Accuracies for Antares Configurations 122 and 132

The Antares enhanced configurations with the ATK STAR 48BV as a third stage are used primarily for

missions where high energy is required such as high apogee altitude or escape missions. Payload insertion accuracies for these unique requirements will be provided on a mission-specific basis.

3.6. Payload Deployment

Following orbit insertion, the Antares avionics subsystem executes a series of ACS maneuvers to

provide the desired initial payload attitude prior to

separation. This capability may also be used to

incrementally reorient the upper stage for the deployment of multiple spacecraft with independent

attitude requirements. Antares is capable of orienting to a wide range of deployment attitudes including inertial, orbit track relative, and sun pointing. An

inertially-fixed or spin-stabilized attitude may be

specified by the customer. Typical accuracies are

shown in Table 3.6-1.

Table 3.6-1. Antares Payload Deployment

Pointing and Rate Accuracies

Error Type

Pitch

3-Axis

Yaw

Roll

Spin Axis

Spinning

Spin Rate

Angle

±1.0°

±1.0°

±1.0°

±1.0°

-

Rate

±0.5 °/sec

±0.5 °/sec

±0.5 °/sec

±3 °/sec

The maximum spin rate for a specific mission depends upon the spin axis moment of inertia of the payload and the ACS propellant budget but cannot nominally exceed 30 degrees per second. Greater spin

rates are possible as a mission unique service.

As part of the Standard Launch Service, Orbital performs a mission-specific payload separation tip-off

analysis to determine the expected maximum payload attitude rates immediately following payload separation. The post separation rates are a function of pre-deployment rates, separation system performance,

and payload mass properties.

3.6.1. Payload Separation

Payload separation dynamics are highly dependent on the mass properties of the payload and the particular separation system utilized. The primary parameters to be considered are payload tip-off and the

overall separation velocity.

Payload tip-off refers to the angular velocity imparted to the payload upon separation due to payload center-of-gravity (CG) offsets and an uneven distribution of torques and forces. If an optional Orbitalsupplied Marmon Clamp-band separation system is used, payload tip-off rates are generally under 1°/sec

per axis. Separation system options are discussed further in Section 8.1. Orbital performs a missionspecific tip-off analysis for each payload.

Separation velocities are driven by the need to prevent recontact between the payload and the Antares

upper stage after separation. Typical separation velocities are 0.6 to 0.9 m/sec (2 to 3 ft/sec).

Release 1.1

July 2013

19

Antares® OSP-3 User’s Guide

Section 3.0 – Performance

3.6.2. Collision/Contamination Avoidance Maneuver (CCAM)

Following orbit insertion and payload separation, the Antares Upper Stage will perform a CCAM. The

CCAM minimizes both payload contamination and the potential for recontact between Antares hardware

and the separated payload. Orbital will perform a recontact analysis for post-separation events.

A typical CCAM begins soon after payload separation. The launch vehicle performs a 90° yaw maneuver

designed to direct any remaining Stage 2 motor impulse in a direction which will increase the separation

distance between the two bodies. After a delay to allow the distance between the spacecraft and Stage 2

to increase to a safe level, the launch vehicle begins a ―crab-walk‖ maneuver to impart a small amount of

delta velocity, increasing the separation between the payload and the final Antares stage.

Following the completion of the CCAM maneuver as described above and any remaining maneuvers,

such as downlinking of delayed telemetry data, the ACS valves are opened and the remaining ACS nitrogen propellant is expelled.

Release 1.1

July 2013

20

Antares® OSP-3 User’s Guide

Section 4.0 – Payload Environments

4. PAYLOAD ENVIRONMENTS

This section provides details of the predicted environmental conditions that the payload experiences

during Antares ground operations, powered flight, and post-boost operations. The environmental

conditions presented in this section are representative of a typical mission and are applicable to the

baseline Antares 120 unless specifically noted. Orbital performs mission-specific analyses as part of the

standard Antares launch service to determine payload environments for a specific mission. These results

are documented in compliance with the mission ICD.

4.1. Design Limit Load Factors

Design limit load factors due to the combined effects of steady state and low frequency transient

accelerations are defined in Table 4.1-1 for Antares

configurations 120, 121, 130, 131, and 132. These

values apply to the payload CG, account for maximum ground and flight loads, and include uncertainty margins.

Table 4.1-1. Design Limited Load Factors

Axis

Axial

Lateral

Maximum Acceleration (g)

-1.0/+6.5

±1.5

Notes:

1) Sign Convention: Positive Axial Acceleration Produces

Compression.

2) Axial and Lateral Accelerations Are Simultaneous.

Antares 122 is the single exception to the axial acceleration limit shown in Table 4.1-1. For this configuration, the axial design limit load factor of +8.0g may be reached during third stage operation.

In order to minimize loads and deflections as well as the potential for coupling with the launch vehicle

guidance system, the first bending frequency of the payload assuming a fixed base must be maintained

above 8 Hz. Dynamic response is largely governed by payload characteristics, so mission-specific

coupled loads analyses must be performed in order to provide precise load predictions. Results are

documented in the mission-specific ICD.

4.1.1. Time-Phased Acceleration Loads

Dynamic loading events that occur throughout various portions of the ground operations and flight include

steady state acceleration, transient low frequency acceleration, acoustic impingement, random vibration,

and pyroshock events. During ground and flight operations, the typical maximum steady state accelerations experienced at the payload interface are as shown in Table 4.1.1-1. Coupled Loads Analyses

(CLAs) are performed for each mission to define maximum predicted acceleration for a specific payload.

Table 4.1.1-1. Typical Antares 120 Ground and Flight Acceleration Loads at the Payload Interface

Ground

Ground

Flight

Flight

Flight

Load Case

Payload Vertical

Payload Horizontal

Liftoff

Transonic

Stage 1

Maximum

Flight

Main Engine Cut Off

Flight

Stage 2 Ignition

Flight

Stage 2

Maximum

Release 1.1

Static

-1.0

0.0

1.3

2.0

Axial

Transient

±0.5

±0.4

±0.5

±0.3

6.0

±0.5

4.8

0.8

0.0

0.9

±0.4

±1.3

-0.8/ +1.5

±0.3

3.7

±0.3

July 2013

Lateral

Static

Transient

0.0

±0.5

-1.0

±0.3

0.0

±0.5

0.2

±0.7

0.0

±0.5

0.0

±0.5

0.0

±0.3

0.0

±0.3

21

Antares® OSP-3 User’s Guide

Section 4.0 – Payload Environments

Table 4.1.1-2 provides the primary dynamic loading events and the time phasing of these events during

Antares flight. Pyroshock events are not indicated as they do not occur simultaneously with any other

significant dynamic loading events.

Table 4.1.1-2. Phasing of Dynamic Loading Events

Item

Typical Flight Time

Steady State Loads

Transient Loads

Acoustics

Random Vibration

Liftoff

Transonic

2 sec

Yes

Yes

Yes

Yes

79 sec

Yes

Yes

Yes

Yes

Supersonic/

Max Q

90 sec

Yes

Yes

Yes

Yes

S2 Ignition

S2 Burnout

~330 sec

No

Yes

No

No

~485 sec

Yes

No

No

No

As dynamic response is largely governed by payload characteristics, multiple mission-specific CLA are

performed, with customer-provided finite element models of the payload and different states of definition.

Flight events analyzed by the CLA include liftoff, the transonic portion of flight, supersonic flight, Maximum Dynamic Pressure (Max Q), MECO, and Stage 2 ignition. Results are documented in the missionspecific ICD.

Orbital performs two CLAs for each mission. The preliminary CLA is based on the analytical payload

models. The final CLA is based on the test-verified payload model.

4.1.2. Payload Acceleration as a Function of Mass

Payload mass affects the maximum axial quasi-static acceleration a specific payload experiences. Figures 4.1.2-1 through 4.1.2-6 provide the vehicle quasi-static acceleration as a function of payload mass

for all configurations.

Release 1.1

July 2013

22

Antares® OSP-3 User’s Guide

Section 4.0 – Payload Environments

Figure 4.1.2-1. Nominal Payload Acceleration as a Function of Mass (Antares 120)

Figure 4.1.2-2. Nominal Payload Acceleration as a Function of Mass (Antares 121)

Release 1.1

July 2013

23

Antares® OSP-3 User’s Guide

Section 4.0 – Payload Environments

Figure 4.1.2-3. Nominal Payload Acceleration as a Function of Mass (Antares 122)

Figure 4.1.2-4. Nominal Payload Acceleration as a Function of Mass (Antares 130)

Release 1.1

July 2013

24

Antares® OSP-3 User’s Guide

Section 4.0 – Payload Environments

Figure 4.1.2-5. Nominal Payload Acceleration as a Function of Mass (Antares 131)

Figure 4.1.2-6. Nominal Payload Acceleration as a Function of Mass (Antares 132)

Release 1.1

July 2013

25

Antares® OSP-3 User’s Guide

Section 4.0 – Payload Environments

4.2. Payload Vibration Environment

The random vibration environment at the payload interface is encompassed by acoustics and coupled

loads analysis results. Antares does not have a specific random vibration environment for the payload.

4.2.1. Payload Acoustic Environment

The maximum expected acoustic levels within the Antares fairing are shown in Figure 4.2-1. Antares

peak acoustic environments occur at lift-off and near the point of maximum dynamic pressure. Acoustic

levels are sensitive to spacecraft geometry (fill factor), so payload specific adjustments may be necessary.

Figure 4.2-1. Antares Fairing Internal Maximum Flight Level Payload Acoustic Environment

Release 1.1

July 2013

26

Antares® OSP-3 User’s Guide

Section 4.0 – Payload Environments

4.2.2. Sine Vibration

Figure 4.2.2-1 defines the maximum flight level payload interface sinusoidal vibration levels for a fixed

base payload test, which may be used for preliminary design. The spectrum defined in this figure is provided for reference only. Orbital develops a mission-specific sine spectrum for each mission using the

results from CLA.

Figure 4.2.2-1. Antares Payload Interface Sine Vibration Levels

Release 1.1

July 2013

27

Antares® OSP-3 User’s Guide

Section 4.0 – Payload Environments

4.3. Payload Shock Environment

The maximum shock response spectrum at the base of the payload from all launch vehicle events will not

exceed the flight limit levels provided in Figure 4.3-1. The flight limit levels are derived from ground separation test data and analytical predictions for the vehicle and payload separation systems. These levels

are applicable to a payload using the Antares optional payload separation system or attaching to the nonseparating interface.

Figure 4.3-1. Antares Payload Maximum Flight Level Shock at the Base of the Payload

Release 1.1

July 2013

28

Antares® OSP-3 User’s Guide

Section 4.0 – Payload Environments

4.4. Contamination and Environmental Control

Orbital understands the importance of maintaining proper thermal and contamination control and is committed to providing environments that meet customer requirements. Orbital partners with each USAF

payload customer to ensure the required payload environments are identified and maintained at all times.

Orbital has developed a general environmental control plan for all Antares missions. This plan is tailored

for each mission to capture the unique environmental control requirements of each payload.

Prior to payload enclosure, payload thermal and humidity environments are maintained by the HIF facility

ECS. Once enclosed, payload environments are maintained by either the PECS or the Pad ECS. The

Pad ECS maintains the payload thermal and humidity environments through launch. Each of these systems control temperatures between 15.5 – 25.5 °C (60 – 80 °F) and humidity between 30 to 60%.

4.4.1. Ground Transportation Environments

Environmental control during Antares payload transport activities is maintained by the PECS. The PECS

is a trailerized, self-contained environmental control system. The system’s two independent refrigeration

circuits cool and dehumidify incoming air after which the air is reheated to maintain the desired temperature and Relative Humidity (RH) setpoints. A humidifier is available to add moisture, if needed. The

PECS continuously purges the fairing environment with clean filtered air providing a Class 8 (IAW ISO

14644) or better environment during all post-encapsulation operations. Orbital’s PECS incorporates both

a HEPA filter unit for particulate control and carbon filtration for hydrocarbon control. Conditioned air filtration removes 99.97% of all particles with a size greater than 0.3 microns and 95% of all hydrocarbons

of molecular weight greater than 70.

4.4.2. Launch Operations Fairing Environment

Once the TEL with the integrated Antares launch vehicle has been secured to the launch pad mount, the

fairing air supply is transitioned from the PECS to the pad ECS. During this transition, a short disruption

of airflow to the fairing occurs; however, no perceptible changes in the environment are anticipated. The

pad ECS then continues to maintain fairing environment control throughout the remainder of the launch

operations. Backup power is implemented at the launch site to ensure payload environment controls are

maintained at all times.

4.4.3. Contamination Control

Orbital’s Antares contamination control program is designed to minimize the payload’s exposure to contamination from the time the payload arrives at the payload processing facility through orbit insertion and

separation. The contamination control program, based on industry standard contamination control specifications, ensures that all personnel and processes strictly adhere to payload cleanliness requirements.

During all payload integration procedures in the HIF, the payload is maintained in a Class 8 or better

cleanliness environment at all times through the use of a clean tented area forward of the payload adapter. Once the payload is enclosed, the air entering the fairing is also maintained to Class 8 or better

cleanliness environment at all times through HEPA and carbon filtered air removing 99.97% off all particles with a size greater than 0.3 microns and 95% of all hydrocarbons of molecular weight greater than

70.

The internal surfaces of the Antares payload fairing and payload adapter are cleaned, certified, and maintained to visibly clean, Level II or better. The Antares avionics section, Stage 2 motor, and separation

Release 1.1

July 2013

29

Antares® OSP-3 User’s Guide

Section 4.0 – Payload Environments

system, all which are located within the payload fairing compartment downstream of the payload, are

cleaned to visibly clean.

4.4.4. Enhanced Thermal and Contamination Services

Orbital recognizes that some payloads may have more stringent cleanliness requirements than those

provided by the Standard Launch Service. Orbital offers a variety of enhancements to address these

needs. These options are discussed in more detail in Section 8:

4.5. Thermal Environments

During launch and ascent, the acoustic blanket inner surface temperature on the cylinder portion of the

fairing remains below 93 °C (200 °F).

4.6. Pressurization Profile

Typical Antares LEO mission ascents have peak pressure decay rates less than 0.3 psi/sec. The internal

pressure at fairing jettison is typically less than 0.2 psia. Typical fairing internal pressure is shown in Figure 4.6-1. The venting characteristics are sensitive to trajectory shape and payload unvented volume.

Figure 4.6-1. Antares Fairing Internal Pressure Profile

Release 1.1

July 2013

30

Antares® OSP-3 User’s Guide

Section 4.0 – Payload Environments

4.7. Payload RF Environment

As shown in Table 4.7-1, Antares has five RF sources: three S-Band transmitters at 2241.5, 2269.5, and

2288.5 MHz, respectively, and a C-Band Transponder that transmits at 5765 MHz. The fairing provides

attenuation for the payload RF environment produced by the external aft antennas until the fairing is deployed. Radiation inside the fairing, as a result of vehicle source radiation, is further limited through the

use of two sets of antennas. The aft antennas located on the vehicle interstage skin are used until fairing

separation. A second set of antennas, located inside the fairing, are used after fairing deployment. The

maximum field strength produced by these sources at the payload interface is 3.1 V/m in S-Band and

49.6 V/m in C-Band.

During ground and launch operations, the Range uses multiple radars to track the vehicle and a directional Ultra High Frequency (UHF) transmitter to capture the FTS receivers. Again, the payload fairing

provides some measure of attenuation of the RF fields from these sources. The maximum RF levels associated with range sources are actively managed to achieve less than 20 V/m at frequencies from

10 kHz to 1 GHz and 30 V/m from 1 to 40 GHz during launch and ascent. As lower levels are required to

protect the payload, Orbital will work to coordinate with the range to further limit RF power levels.

Table 4.7-1. Launch Vehicle RF Emitters and Receivers

SOURCE

Receive/Transmit

Band

Frequency (MHz)

Bandwidth (MHz)

Power Output

1

Command

Destruct

Receive

UHF

421

0.18

N/A

2

Tracking

Transponder

Transmit

C-Band

5765

14

400 W (peak)

3

Tracking

Transponder

Receive

C-Band

5690

14

N/A

Sensitivity

-107 dBm

N/A

-70 dBm

Function

Modulation

Tone

Pulse Code

Maximum Field Strength at

Fwd Edge of the Payload

N/A

49.6 V/m

Adapter Cone

* WFF Baseline KLC Values May Be Higher

Release 1.1

Pulse Code

N/A

July 2013

4

5

6

Launch

Launch

Launch

Vehicle

Vehicle

Vehicle

Transmit Transmit Transmit

S-Band

S-Band

S-Band

2241.5

2288.5

2269.5

3.56

3.56

3.56

5 W*

5 W*

5 W*

N/A

N/A

N/A

PCM/FM PCM/FM PCM/FM

3.1 V/m

0.1 V/m

0.4 V/m

7

Location

Receive

L-Band

1575.42

20.46

N/A

C/N0 =

35.4 dBHz

Phase

N/A

31

Antares® OSP-3 User’s Guide

Section 5.0 – Payload Interfaces

5. PAYLOAD INTERFACES

This section describes the available mechanical, electrical and GSE interfaces between the Antares

launch vehicle and the payload.

5.1. 3.9 Meter Payload Fairing

The Antares payload fairing encloses the payload and provides protection and contamination control during ground handling, integration and flight. The Antares payload fairing is a 3.9 m (155 in.) diameter

structure consisting of two shells constructed of graphite-epoxy facesheets with an aluminum honeycomb

core and associated separation systems.

While protecting the payload from environments on the ground and during flight, this composite metal matrix also provides a significant level of RF attenuation for the payload during periods of encapsulated

processing.

The two fairing halves are joined with a frangible rail joint along the bi-conic and cylinder sections, and the

base of the fairing is attached to Stage 2 using a ring-shaped frangible joint. The frangible rails and rings

are clean-separation systems employing sealed stainless steel tubes that fracture notched aluminum extrusions. Severing the rail/ring frangible joints allow each half of the fairing to rotate on hinges mounted

on the Stage 2 fairing cylinder. A cold gas generation system is used to drive pistons that force the fairing

halves open. All fairing deployment systems are non-contaminating.

5.1.1. Payload Fairing Static and Dynamic Envelopes

The Antares payload envelopes were developed to ensure that static and dynamic clearances to the

payload assembly are fully maintained during ground operations and ascent. The Antares dynamic

envelope is provided in Figure 5.1.1-1. The dynamic envelope is designed to accommodate the dynamic