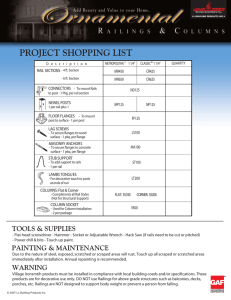

Linear Line

advertisement