SG1846/SG2846/SG3846

Current Mode PWM Controller

Description

Features

The SG1846 family of control ICs provides the required

features to implement Fixed Frequency, Current mode

control schemes while maintaining a minimum external

parts count.

The advanced performance of this

technique can be measured in improved line regulation,

enhanced load response characteristics, and a simpler,

easier-to-design control loop. Topological advantages

include, inherent pulse-by-pulse current limiting

capability, automatic symmetry correction for push-pull

converters, and the ability to parallel “power modules”

while maintaining equal current sharing.

Automatic Feed-forward Compensation

Programmable Pulse by Pulse Current Limiting

Automatic Symmetry Correction in Push-pull

Configuration

Enhanced Load Response Characteristics

Parallel Operation Capability for Modular Power

Systems

Differential Current Sense Amplifier with Wide

Common-mode Range

Double Pulse Suppression

200mA Totem-pole Outputs

± 1% Bandgap Reference

Under-voltage Lockout

Soft-start and Shutdown Capability

500kHz Operation

Protection circuitry includes built-in under-voltage

lockout and programmable current limit in addition to

soft start capability. A shutdown function is also

available which can initiate either a complete shutdown

with automatic restart, or latch the supply off.

Other features include fully latched operation, doublepulse suppression, dead-time adjust capability, and a

±1% trimmed bandgap reference.

High Reliability Features

Available To MIL-STD-883 – 883, ¶ 1.2.1

Available to DSCC

– Standard Microcircuit Drawing (SMD)

SGR1846 Rad-Tolerant Version Available

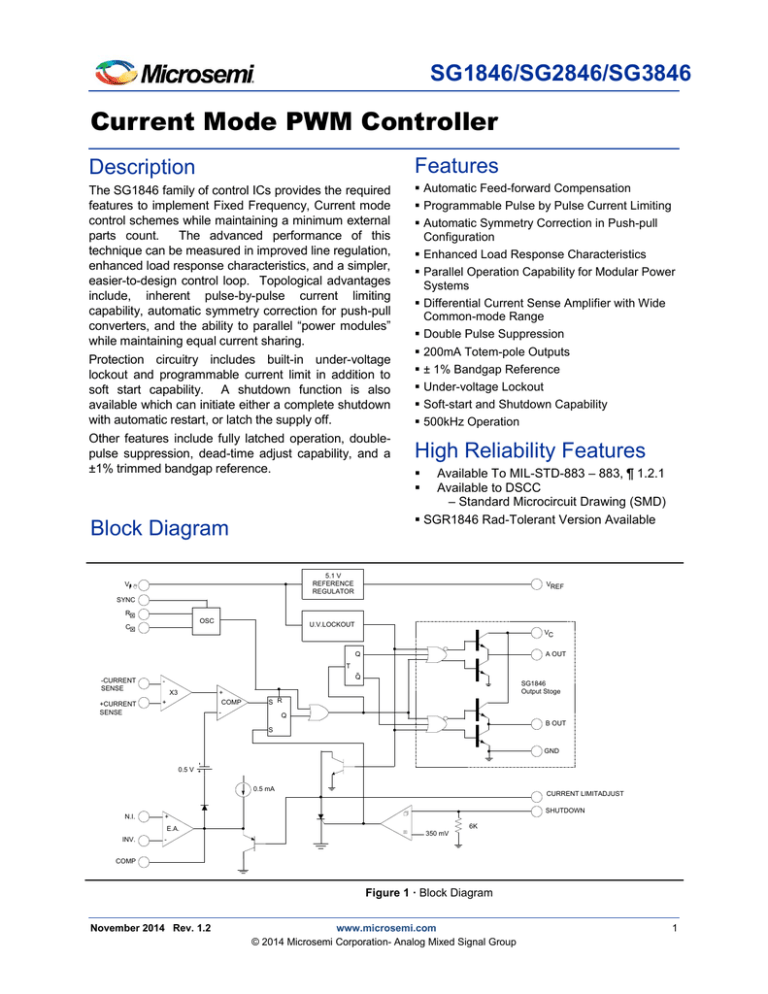

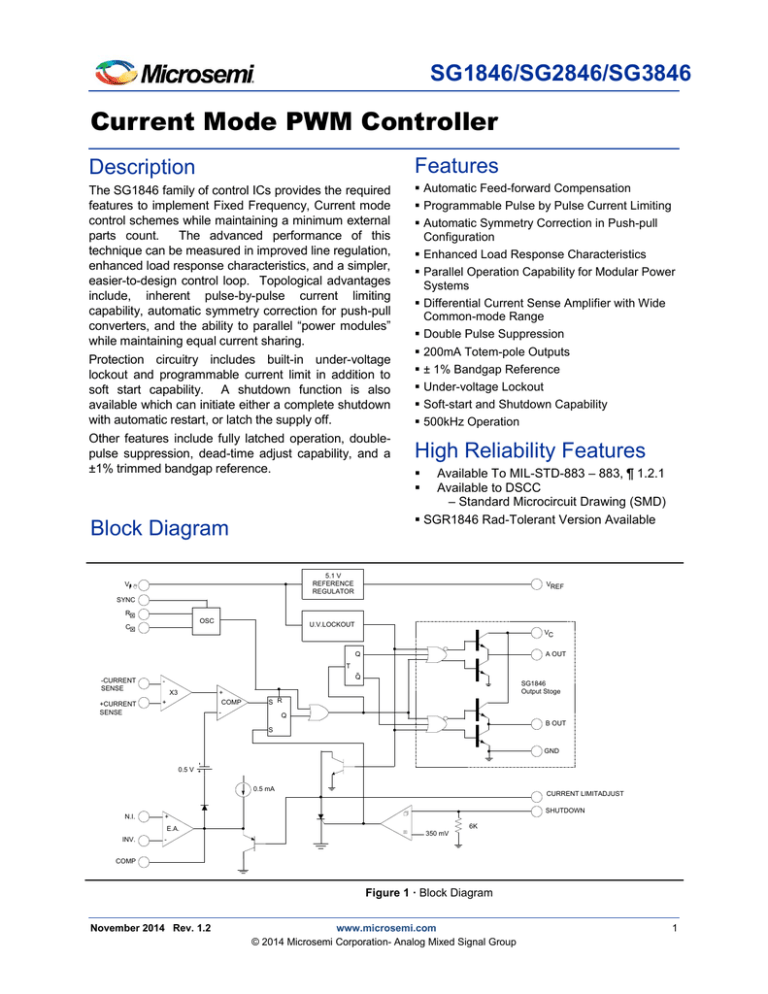

Block Diagram

5.1 V

REFERENCE

REGULATOR

VIN

VREF

SYNC

RT

OSC

CT

U.V.LOCKOUT

VC

Q

A OUT

T

-CURRENT

SENSE

-

+CURRENT

SENSE

+

Q

SG1846

Output Stoge

+

X3

COMP

S R

-

Q

B OUT

S

GND

0.5 V

0.5 mA

N.I.

+

E.A.

INV.

CURRENT LIMITADJUST

SHUTDOWN

+

-

6K

350 mV

-

COMP

Figure 1 · Block Diagram

November 2014 Rev. 1.2

www.microsemi.com

© 2014 Microsemi Corporation- Analog Mixed Signal Group

1

Current Mode PWM Controller

Connection Diagrams and Ordering Information

Ambient

Temperature

-55°C to 125°C

Type

Package

Part Number

SG1846J-883B

J

16-PIN

CERAMIC

DUAL INLINE

PACKAGE

-25°C to 85°C

N

0°C to 70°C

DW

SG2846N

PACKAGE

SG3846N

0°C to 70°C

PLASTIC

SOIC

PACKAGE

C.L./SOFTSTART

VREF

CERDIP

C.L./SOFTSTART

VREF

(-) C.S.

(+) C.S.

SG2846DW

FLAT PACK

PACKAGE

-55°C to 125°C

L

20-PIN

CERAMIC

LLC

3

PACKAGE

SG1846L

CLCC

12

11

10

9

GROUND

OUTPUT A

SYNC

RT

7

8

SHUTDOWN

+VIN

OUTPUT B

VC

16

15

14

13

1

2

3

4

1

2

3

4

5

6

7

8

(-) C.S.

(+) C.S.

(+) ERROR AMP

(-) ERROR AMP

COMPENSATION

CT

SG1846L-DESC

5

6

OUTPUT B

VC

12

GROUND

OUTPUT A

11

SYNC

10

7

RT

8

9

DW Package: RoHS Complaint / Pb-free Transition DC: 0516

DW Package: RoHS / Pb-free 100% Matte Tin Lead Finish

FLATPAK

SG1846L-883B

SHUTDOWN

+VIN

5

6

(+) ERROR AMP

(-) ERROR AMP

C.L./SOFTSTART

VREF

3

16

15

14

13

COMPENSATION

CT

SG3846DW

SG1846F-DESC

1

2

3

4

N Package: RoHS Complaint / Pb-free Transition DC: 0503

N Package: RoHS / Pb-free 100% Matte Tin Lead Finish

PDIP

16-PIN

CERAMIC

F

(-) C.S.

(+) C.S.

(+) ERROR AMP

(-) ERROR AMP

COMPENSATION

CT

SOWB

4

Connection Diagram

SG1846J

16-PIN

PLASTIC DIP

16-PIN

WIDEBODY

-25°C to 85°C

SG1846J-DESC

Packaging

Type

1. N.C.

2. C.L./SOFTSTART

3. V REF

4. (-) C.S.

5. (+) C.S.

6. N.C.

7. (+) ERROR AMP

8. (-) ERROR AMP

9. COMPENSATION

10. C T

3 2

16

15

14

13

SHUTDOWN

+VIN

12

11

10

9

GROUND

OUTPUT A

SYNC

RT

OUTPUT B

VC

1 20 19

4

18

5

17

6

16

7

8

15

14

9 10 11 12 13

Notes:

1.

2.

3.

4.

5.

Contact factory for DESC part availability.

All parts are viewed from the top.

Consult factory for product availability.

The SG2846 & SG3846 is available shipped as tape & reel with the addition of a –TR suffix.

Hermetic Packages J, F, & L use Pb37/Sn63 hot solder lead finish, contact factory for availability of RoHS versions.

Absolute Maximum Ratings

Parameter

Supply Voltage (+VIN)

Collector Supply Voltage(VC)

Analog Inputs (Pins 3, 4, 5, 6, and 16)

Logic Input

Source/Sink Load current (continuous)

Source/Sink Load Current (peak, 200 ns)

Reference Load Current

Soft Start Sink Current

Sync Output Current

Error Amplifier Output Current

Oscillator Charging current (Pin 9)

2

Value

40

40

Units

V

V

-0.3V to +VIN

-0.3V to 5.5V

200

500

30

50

5

5

5

V

V

mA

mA

mA

mA

mA

mA

mA

11. N.C.

12. R T

13. SYNC

14. OUTPUT A

15. GROUND

16. N.C.

17. V C

18. OUTPUT B

19. V IN

20. SHUTDOWN

Thermal Data

Parameter

Operating Junction Temperature Hermetic (J, L, F Packages)

Operating Junction Temperature Plastic (N, DW Package)

Storage Temperature Range

Lead Temperature (Soldering, 10 Seconds)

RoHS Peak Package Solder Reflow Temp. (40 sec. max. exp.)

Values beyond which damage may occur.

1.

Pin numbers refer to ceramic J package.

2.

Value

150

150

-65 to 150

300

260 (+0, -5)

Units

°C

°C

°C

°C

°C

Value

Units

30

80

°C/W

°C/W

40

65

°C/W

°C/W

Thermal Data

Parameter

J Package:

Thermal Resistance-Junction to Case, θJC

Thermal Resistance-Junction to Ambient, θJA

N Package:

Thermal Resistance-Junction to Case, θJC

Thermal Resistance-Junction to Ambient, θJA

DW Package:

°C/W

Thermal Resistance-Junction to Case, θJC

40

°C/W

Thermal Resistance-Junction to Ambient, θJA

95

F Package:

°C/W

Thermal Resistance-Junction to Case, θJC

70

°C/W

Thermal Resistance-Junction to Ambient, θJA

115

L Package:

°C/W

Thermal Resistance-Junction to Case, θJC

35

°C/W

Thermal Resistance-Junction to Ambient, θJA

120

Notes:

Junction Temperature Calculation: TJ = TA + (PD x θJA).

1.

The above numbers for θJC are maximums for the limiting thermal resistance of the package in a standard mounting

2.

configuration. The θJA numbers are meant to be guidelines for the thermal performance of the device/PCBoard system. All of

the above assume no ambient airflow.

Recommended Operating Conditions

Parameter

Supply Voltage Range

Collector Supply Voltage Range

Source/Sink Output Current (continuous)

Source/Sink Output Current (peak 200ns)

Reference Load Current

Oscillator Frequency Range

Oscillator Timing Resistor (RT)

Oscillator Timing Capacitor (CT)

Value

8 to 40

4.5 to 40

100

200

0 to 10

1 to 500

2 to 100

1 to 100

Units

V

V

mA

mA

mA

kHz

kΩ

nF

Operating Ambient Temperature Range

SG1846

SG2846

55 to 125

25 to 85

°C

°C

°C

SG3846

Note: Range over which the device is functional.

0 to 70

3

Current Mode PWM Controller

Electrical Characteristics

Unless otherwise specified, these specifications apply over the operating ambient temperatures for SG1846

with -55°C ≤ TA ≤ 125°C, SG2846 with -25°C ≤ TA ≤ 85°C, SG3846 with 0°C ≤ TA ≤ 70°C, +VIN = 15V. Low

duty cycle pulse testing techniques are used which maintains junction and case temperatures equal to the

ambient temperature.

Symbol

Parameter

SG1846

SG2846

Test Condition

Min Typ

SG3846

Units

Max

Min

Typ

Max

5.10

5.15

5.00

5.10

5.20

V

Reference Section

VREF

Output Voltage

TJ = 25°C, IO = 1mA

VREG

Line Regulation

VIN = 8V to 40V

5

20

5

20

mV

IREG

Load Regulation

IL = 1mA to 10mA

3

15

3

15

mV

Temperature Stability

1

Total Output Variation

Output Noise Voltage

Long Term Stability

VREFISC

4

1

1

1

0.4

Line, Load and Temperature

5.00

10Hz ≤ f ≤ 10kHz. TJ = 25°C

TJ = 125°C, 1000Hrs.

Short Circuit Output

Current

Oscillator Section

5.05

mV/°C

0.4

5.20

4.95

5.25

V

100

100

µV

5

5

mV

-10

-45

mA

39

43

47

kHz

1

2

%

VREF = 0V

-10

-45

39

43

47

2

6

OSC

Initial Accuracy

TJ = 25°C

OSCVS

Voltage Stability

VIN = 8V to 40V

1

OSCTS

Temperature Stability

Over Operating Range

1

VOH

Sync Output High Level

VOL

Sync Output Low Level

VIH

Sync Input High Level

Pin 8 = 0V

VIL

Sync Input Low Level

Pin 8 = 0V

IIL

Sync Input Current

Sync Voltage = 5.25V, Pin 8

= 0V

1

3.9

4.35

2.3

3.9

2.5

3.9

1

%

4.35

V

2.3

2.5

3.9

V

2.5

1.2

1.5

V

1.2

2.5

V

1.5

mA

Electrical Characteristics

Symbol

Parameter

SG1846

SG2846

Test Condition

Min

SG3846

Units

Typ Max Min

Typ

Max

Error AMP Section

EAVOS

Input Offset Voltage

0.5

5

0.5

10

mV

EAIIB

Input Bias Current

-0.6

-1

-0.6

-2

µA

EAIOS

Input Offset Current

40

250

40

250

nA

EACM

Common Mode Range

VIN-2V

V

EAAV

Open Loop Voltage Gain VO = 1.2V to 3V, VCM = 2V

1

VIN = 8V to 40V

VIN2V

0

0

80

105

80

105

dB

TJ = 25°C

0.7

1.0

0.7

1.0

MHz

EAUGB

Unity Gain Bandwidth

EACMRR

CMRR

VCM = 0V to 38V, VIN = 40V

75

100

75

100

dB

EAPSRR

PSRR

VIN = 8V to 40V

80

105

80

105

dB

EASNK

Output Sink Current

VID = - 15mV to -5V, VPIN 7 =

1.2V

2

6

2

6

mA

EASRC

Output Source Current

VID = 15mV to 5V, VPIN 7 =

2.5V

-0.4

-0.5

-0.4

-0.5

mA

EAVOH

High Level Output

Voltage

RL = 15kΩ (Pin 7)

4.3

4.6

4.3

4.6

V

EAVOL

Low Level Output Voltage RL = 15kΩ (Pin 7)

0.7

1

2.5

2.75

3.0

1.1

1.2

0.7

1

V

2.5

2.75

3.0

V

1.1

1.2

Current Sense Amplifier Section

CSAV

Amplifier Gain

2 &3

VPIN 3 = 0V, Pin 1 Open

3

Maximum Differential

2

Input Signal (VPIN 4 - VPIN Pin 1 Open RL = 15kΩ (Pin 7)

3)

Input Offset Voltage

2

5

VPIN 1 = 0.5V, Pin 7 Open

25

5

V

25

mV

CSCMRR

CMRR

VCM = 1V to 12V

60

83

60

83

dB

CSPSRR

PSRR

VIN = 8V to 40V

60

84

60

84

dB

CSIIB

Input Bias Current

CSIOC

Input Offset Current

CSCM

Input Common Mode

Range

Delay to Outputs

2

1

2

VPIN 1 = 0.5V, Pin 7 Open

-2.5

-10

-2.5

-10

µA

VPIN 1 = 0.5V, Pin 7 Open

0.08

1

0.08

1

µA

VIN -3

V

VIN 3

0

TJ = 25°C

0

200

500

200

500

ns

0.5

0.55 0.45

0.5

0.55

V

-10

-30

-10

-30

µA

Current Limit Adjust Section

CLIIB

Current Limit Offset

2

Voltage

VPIN 3 = 0, VPIN 4 = 0V, Pin 7

Open

Input Bias Current

VPIN 5 = VREF, VPIN 6 = 0V

0.45

5

Current Mode PWM Controller

Symbol

Parameter

SG1846

SG2846

Test Condition

SG3846

Units

Min

Typ

Max

Min

Typ

Max

250

350

400

250

350

400

mV

VIN

0

VIN

V

Shutdown Terminal Section

SD

Threshold Voltage

Input Voltage Range

SDLC

0

Minimum Latching

4

Current; (IPIN 1 )

3.0

Maximum Non-Latching

5

Current; (IPIN 1 )

SDDELAY

Delay to Outputs

1

TJ = 25°C

1.5

3.0

1.5

mA

1.5

0.8

1.5

0.8

mA

300

600

300

600

ns

Output Section

Collector Emitter

Voltage

40

40

Collector Leakage

Current

VC = 40V

Output Low Level

ISINK = 20mA

0.1

0.4

ISINK = 100mA

0.4

2.1

Output High Level

Rise Time

1

V

200

200

µA

0.1

0.4

V

0.4

2.1

V

ISOURCE = 20mA

13

13.5

13

13.5

V

ISOURCE = 100mA

12

13.5

12

13.5

V

CL = 1nF, TJ = 25°C

50

300

50

300

ns

CL = 1nF, TJ = 25°C

50

300

50

300

ns

Start-Up Threshold

7.7

8.0

7.7

8.0

V

Threshold Hysteresis

0.75

Fall Time

1

Under-Voltage Lockout Section

0.75

V

Total Standby Current

IQ

Supply Current

17

21

17

21

mA

Notes:

These parameters, although guaranteed over the recommended operating conditions, are not tested in the production.

1.

Parameter measured at trip point of latch with V PIN 5 = VREF , VPIN 6 = 0V.

2.

Amplifier gain defined as :

VPIN 4 = 0V to 1.0V

3.

Current into Pin 1 guaranteed to latch circuit in shutdown state.

4.

Current into Pin 1 guaranteed not to latch circuit in shutdown state.

5.

RT = 10kΩ, CT = 4.7nF

6.

6

Characteristic Curves

Characteristic Curves

VREF SHORT CIRCUIT CURRENT - (mA)

REFERENCE VOLTAGE - (V)

5.10

5.05

5.00

4.95

4.90

-55

-25

0

25

50

90

80

70

60

50

40

30

O

TJ = 125 C

O

TJ = 55 C

0.5

10

0

0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

-55

-25

0

50

25

100 125

75

ERROR AMPLIFIER OUTPUT VOLTAGE - (V)

JUNCTION TEMPERATURE - ( C)

O

JUNCTION TEMPERATURE - ( C)

Figure 2 · Reference Voltage Vs.

Temperature

Figure 3 · VREF Short Circuit

Current Vs. Temperature

2.82

2.80

2.78

2.76

2.74

2.72

2.70

1.50

Figure 4 · Current Sense Threshold

Vs. Error Amplifier Output

OSCILLATOR PEAK VOLTAGE - (V)

OSCILLATOR VALLEY VOLTAGE - (V)

2.84

CURRENT SENSE GAIN - (V/V)

1.0

20

O

1.40

1.30

1.20

3.20

3.10

3.00

2.90

1.10

2.68

-55

-25

0

50

25

2.80

100 125

75

-55

JUNCTION TEMPERATURE - (OC)

-25

0

50

25

100 125

75

-55

O

JUNCTION TEMPERATURE - ( C)

Figure 5 · Current Sense Gain Vs.

Temperature

-25

0

50

25

100 125

75

O

JUNCTION TEMPERATURE - ( C)

Figure 6 · Oscillator Valley Voltage

Vs. Temperature

Figure 7 · Oscillator Peak Voltage

Vs. Temperature

220

2.6

190

VIN = 15 V

(10% ABOVE THRESHOLD)

(10% ABOVE THRESHOLD)

2.2

2.0

1.8

1.6

1.4

1.2

200

SHUTDOWN DELAY - (ns)

2.4

CURRENT SENSE DELAY - (ns)

LATCH CURRENT THRESHOLD - (mA)

1.5

0

100 125

75

C.S. VOLTAGE DIFFENTIAL - (V)

100

5.15

180

170

160

180

160

140

150

1.0

120

-55

-25

0

25

50

100 125

75

O

JUNCTION TEMPERATURE - ( C)

Figure 8 · Minimum SCR Latch

Current

-55

-25

0

25

50

75

100

125

O

JUNCTION TEMPERATURE - ( C)

Figure 9 · Current Sense Delay Vs.

Temperature

-55

-25

0

25

50

75

100

125

O

JUNCTION TEMPERATURE - ( C)

Figure 10 · Shutdown Delay To

Output Vs. Temperature

7

Current Mode PWM Controller

1.60

1.50

1.40

1.30

11.0

4.0

SATURATION VOLTAGE - (V)

ERROR AMP SINK CURRENT - (mA)

INPUT OFFSET VOLTAGE - (mV)

5.0

12.0

10.0

9.0

8.0

7.0

6.0

5.0

3.0

C

TJ = -55°

°C

TJ = 25

2.0

TJ = 12

5°C

1.0

4.0

0

-55

-55

-25

0

25

50

75

100

125

-25

0

50

25

0

100 125

75

1900

°C

25

=1

TJ

°C

5

5

=C

TJ

25°

T J=

3.0

2.0

1.0

140

120

=

C T

100

00

0.

1µ

SYNC PULSEWIDTH - (ns)

4.0

F

80

60

40

0

0

100

300

200

1800

1700

1600

=0

CT

1500

µF

. 01

1400

1300

20

500

400

RT = 8 kΩ

RT = 8 kΩ

160

SYNC PULSEWIDTH - (ns)

SATURATION VOLTAGE - (V)

2000

180

5.0

500

400

Figure 13 · Output Transistor

Saturation Voltage Vs. Output

Current (Sink Transistor)

Figure 12 · Error AMP Sink Current

Vs. Temperature

6.0

300

200

OUTPUT CURRENT - (mA)

JUNCTION TEMPERATURE - ( C)

O

JUNCTION TEMPERATURE - ( C)

Figure 11 · Error Amplifier Input

Offset Voltage Vs. Temperature

100

O

1200

OUTPUT CURRENT - (mA)

-55

-25

0

25

50

75

100 125

-55

JUNCTION TEMPERATURE - (O C)

Figure 14 · Output Transistor

Saturation Voltage Vs. Output

Current (Source Transistor)

25

50

75

100 125

Figure 16 · Sync Pulsewidth Vs.

Temperature

RT = 8 kΩ

2.85

26.5

26.0

C = 0.01µF

T

25.5

46

C = 0.001µF RT = 8 kΩ

T

45

DUTY CYCLE - (%)

OSCILLATOR FREQUENCY - (kHz)

OSCILLATOR FREQUENCY - (kHz)

0

JUNCTION TEMPERATURE - ( °C)

Figure 15 · Sync Pulsewidth Vs.

Temperature

RT = 8 kΩ

2.75

C = 0.1µF

T

44

43

42

41

40

39

2.65

25.0

38

-55

-25

0

25

50

75

100

125

O

JUNCTION TEMPERATURE - ( C)

Figure 17 · Oscillator Frequency Vs.

Temperature

8

-25

-55

-25

0

25

50

75

100

125

O

JUNCTION TEMPERATURE - ( C)

-55

-25

0

25

50

75

100

O

JUNCTION TEMPERATURE - ( C)

Figure 18 · Oscillator Frequency

Vs. Temperature

Figure 19 · Duty Cycle Vs.

Temperature

125

Application Information

Application Information

100k

.1

µF

nF

C

T =

C

T =

20

50

nF

nF

C

T =

C

T =

5

10

nF

nF

C

T =

C

T =

C

T =

20k

R (Ω)

T

2

1

nF

50k

10k

5k

2k

1k

100µsec

10µsec

1000µsec

OSCILLATOR PERIOD (µs)

Figure 20 · Oscillator Frequency Curves

5V

3V

1.2 V

IR

IR

3.7 V

SAWTOOTH(Pin 8)

C

T

R

T

OSC(Pin 10)

Id

OUTPUT DEADTIME(T )

D

Oscillator frequency is approximated by the formula: f ~

T

2.2

R C

T T

Figure 21 · Oscillator Circuit

9

Current Mode PWM Controller

VREF

VREF

0.5 mA

5

+

6

Zs

-

7

COMP

Zf

If

< 0.5 mA

Figure 22 · Error Amp Output Configuration (Error amplifier can source up to 0.5 mA)

IS

R

RS

3

+

CURRENT

SENSE

C

4

-

Figure 23 · Current Sense AMP Connections

A small RC filter may be required in some applications to reduce switch transients. Differential input allows

remote noise free switching.

10

Application Information

15

+VIN

SG1846

10

9

8

VC

SYNC

RT

OSC

A OUT

NOR

F/F

13

VIN

11

CT

VOUT

PWM

LATCH

VREF

2

REF

B OUT

NOR

14

0.5 mA

7

-

0.5 V

INV

6

5

+ -

COMP

COMP

+

+ SENSE

+

EA

NI

I/A

- SENSE

SH/DN

I LIMIT

1

FEEDBACK

4

3

16

S/D

SFT/ST

350 mV

GND

12

Figure 24 · Single Ended Boost Configuration

15

+VIN

SG1846

10

9

8

2

VC

SYNC

RT

OSC

A OUT

NOR

F/F

13

VIN

11

CT

VREF

PWM

LATCH

REF

B OUT

NOR

14

0.5 mA

7

6

5

COMP

+ 0.5 V

INV

VOUT

COMP

+

NI

EA

+

I/A

+ SENSE

- SENSE

SH/DN

FEEDBACK

1

I LIMIT

SFT/ST

4

3

16

S/D

GND

12

350 mV

Figure 25 · Buck Converter with Current Sense Winding

11

Current Mode PWM Controller

15

+VIN

SG1846

10

9

8

VC

SYNC

RT

OSC

A OUT

NOR

F/F

13

11

CT

VREF

2

PWM

LATCH

VREF

REF

B OUT

NOR

14

0.5 mA

7

6

5

COMP

+ -

-

0.5 V

INV

COMP

+

+

EA

NI

I/A

+ SENSE

- SENSE

SH/DN

FEEDBACK

1

I LIMIT

S/D

350 mV

GND

12

SFT/ST

Figure 26 · Push/Pull Converter with Slope Compensation

IS

(+) 4

RS

x3

+ -

(-) 3 ISENSE

VREF

0.5 V

0.5 mA

R1

E/A

CURRENT

LIMIT 1

R2

COMP

7

COMP

R2VREF

Peak Current (IS) is determined by the formula: IS =

R1+R2

-0.5

3RS

Figure 27 · Pulse by Pulse Current Limiting

12

4

3

16

Application Information

VREF

ISENSE

R1

+ -

CURRENT

LIMIT 1

R2

+

ʃ

-

S

S

0.5

ISS

E/A

C

VREF

16

SHUT

DOWN

+

- +

-

350 mV

Figure 28 · Soft Start and Shutdown/Restart Functions

~

CURRENT LIMIT

(PIN 1)

~

0.5 V

0

ON

SHUTDOWN

(PIN 16)

~

OFF

~

PWM

VREF

< 0.8 mA

R1

Figure 29 · Shutdown with Auto-Restart

If

< 0.8 mA, the shutdown latch commutates.

when ISS < 0.8 mA, a restart cycle will be initiated.

~

~

~

~

V

REF

> 3 mA (LATCHED OFF)

R1

Figure 30 · Shutdown without Auto-Restart (Latched)

If

> 3 mA, the device will latch off until power is recycled.

13

Current Mode PWM Controller

Package Outline Dimensions

Controlling dimensions are in inches, metric equivalents are shown for general information.

Dim

D

16

9

H

E

8

1

e

L

A2

A

c

INCHES

MIN

MAX

A

2.06

2.65

0.081

0.104

A1

0.10

0.30

0.004

0.012

A2

2.03

2.55

0.080

0.100

B

0.25

0.51

0.010

0.020

c

0.23

0.32

0.009

0.013

D

-

10.67

-

0.420

E

7.40

7.75

0.291

0.305

e

B

MILLIMETERS

MIN

MAX

1.27 BSC

H

10.00

10.65

0.05 BSC

0.394

0.419

L

0.40

1.27

0.016

0.050

θ

0°

8°

*LC

-

0.10

0°

-

8°

0.004

*Lead co planarity

SEATING PLANE

A1

Note:

Dimensions do not include protrusions; these shall

not exceed 0.155mm (.006”) on any side. Lead

dimension shall not include solder coverage.

Figure 31 · DW 16-Pin SOWB Package Dimensions

Dim

D

1

b1

E

A

-

5.33

-

0.210

0.38

-

0.015

-

A

c

A1

L

e

SEATING PLANE

b

θ

3.30 Typ.

0.130 Typ.

b

0.36

0.56

0.014

0.022

b1

1.14

1.78

0.045

0.070

c

0.20

0.36

0.008

0.014

D

18.67

19.69

0.735

0.775

e

A2

INCHES

MIN

MAX

A1

A2

E1

MILLIMETERS

MIN

MAX

2.54 BSC

E

7.62

E1

L

θ

0.100 BSC

8.26

0.300

0.325

6.10

7.11

0.240

0.280

2.92

0.381

0.115

0.150

-

15°

-

15°

Note:

Dimensions do not include protrusions; these shall

not exceed 0.155mm (.006”) on any side. Lead

dimension shall not include solder coverage.

Figure 32 · N 16-Pin Plastic Dual Inline Package Dimensions

14

PACKAGE OUTLINE DIMENSIONS

PACKAGE OUTLINE DIMENSIONS

Dim

D

16

9

1

8

E

eA

b2

Seating Plane

L c

H

θ

b

e

INCHES

MIN

MAX

0.015

0.045

0.200

0.020

0.065

0.008

0.760

0.220

0.015

0.785

0.280

A

b

b2

0.38

1.04

5.08

0.51

1.65

c

D

E

0.20

19.30

5.59

0.38

19.94

7.11

e

Q A

MILLIMETERS

MIN

MAX

2.54 BSC

0.100 BSC

eA

H

7.37

0.63

7.87

1.78

0.290

0.025

0.310

0.070

L

α

Q

3.18

0.51

5.08

15°

1.02

0.125

0.020

0.200

15°

0.040

Note:

Dimensions do not include protrusions; these shall not

exceed 0.155mm (.006”) on any side. Lead dimension

shall not include solder coverage.

Figure 33 · J 16-Pin Ceramic Dual Inline Package Dimensions

E3

D

E

A

A1

L2

L

8

3

1

Dim

MILLIMETERS

MIN

MAX

INCHES

MIN

MAX

D/E

E3

e

8.64

9.14

8.128

1.270 BSC

0.340

0.360

0.320

0.050 BSC

B1

L

A

0.635 TYP

1.02

1.52

1.626

2.286

0.025 TYP

0.040

0.060

0.064

0.090

h

A1

A2

1.016 TYP

1.372

1.68

1.168

0.040 TYP

0.054

0.066

0.046

L2

B3

1.91

2.41

0.203R

0.075

0.95

0.008R

Note:

13

All exposed metalized area shall be gold plated 60

micro-inch minimum thickness over nickel plated

unless otherwise specified in purchase order.

h

A2

18

B1

e

B3

Figure 34 · L 20-Pin Ceramic Leadless Chip Carrier (LCC) Package Outline Dimensions

15

Current Mode PWM Controller

PACKAGE OUTLINE DIMENSIONS

Controlling dimensions are in inches, metric equivalents are shown for general information.

Dim

L

B

69

85

7

4

8

3

9

2

10

1

D

e

16

1

E

S1

S1

E1

L

L

A

Q

A

b

c

D

E

E1

e

L

Q

C

MILLIMETERS

MIN

MAX

INCHES

MIN

MAX

1.65

1.91

0.38

0.48

0.102

0.152

11.18

6.22

6.74

7.62

1.27 BSC

6.35

9.40

0.51

1.02

0.20

0.057

0.067

0.010

0.019

0.004

0.006

0.290

0.238

0.252

0.272

0.050 BSC

0.250

0.370

0.020

0.040

0.008

Note:

1. Lead No. 1 is identified by tab on lead or dot on cover.

2. Leads are within 0.13mm (.0005”) radius of the true

position (TP) at maximum material condition.

3. Dimension “e” determines a zone within which all body

and lead irregularities lie.

Figure 35 · F 16-Pin Ceramic Flatpack Package Dimensions

16

Microsemi Corporation (Nasdaq: MSCC) offers a comprehensive portfolio of semiconductor

and system solutions for communications, defense & security, aerospace and industrial

markets. Products include high-performance and radiation-hardened analog mixed-signal

integrated circuits, FPGAs, SoCs and ASICs; power management products; timing and

synchronization devices and precise time solutions, setting the world’s standard for time; voice

processing devices; RF solutions; discrete components; security technologies and scalable

anti-tamper products; Power-over-Ethernet ICs and midspans; as well as custom design

capabilities and services. Microsemi is headquartered in Aliso Viejo, Calif., and has

approximately 3,400 employees globally. Learn more at www.microsemi.com.

Microsemi Corporate Headquarters

One Enterprise, Aliso Viejo,

CA 92656 USA

Within the USA: +1 (800) 713-4113

Outside the USA: +1 (949) 380-6100

Sales: +1 (949) 380-6136

Fax: +1 (949) 215-4996

E-mail: sales.support@microsemi.com

© 2014 Microsemi Corporation. All

rights reserved. Microsemi and the

Microsemi logo are trademarks of

Microsemi Corporation. All other

trademarks and service marks are the

property of their respective owners.

Microsemi makes no warranty, representation, or guarantee regarding the information contained herein or

the suitability of its products and services for any particular purpose, nor does Microsemi assume any

liability whatsoever arising out of the application or use of any product or circuit. The products sold

hereunder and any other products sold by Microsemi have been subject to limited testing and should not

be used in conjunction with mission-critical equipment or applications. Any performance specifications are

believed to be reliable but are not verified, and Buyer must conduct and complete all performance and

other testing of the products, alone and together with, or installed in, any end-products. Buyer shall not

rely on any data and performance specifications or parameters provided by Microsemi. It is the Buyer’s

responsibility to independently determine suitability of any products and to test and verify the same. The

information provided by Microsemi hereunder is provided “as is, where is” and with all faults, and the

entire risk associated with such information is entirely with the Buyer. Microsemi does not grant, explicitly

or implicitly, to any party any patent rights, licenses, or any other IP rights, whether with regard to such

information itself or anything described by such information. Information provided in this document is

proprietary to Microsemi, and Microsemi reserves the right to make any changes to the information in this

document or to any products and services at any time without notice.

SG1846.1.2/11.14