Building thick photoresist structures from the bottom up

advertisement

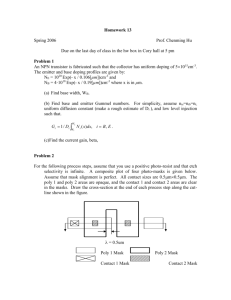

INSTITUTE OF PHYSICS PUBLISHING JOURNAL OF MICROMECHANICS AND MICROENGINEERING J. Micromech. Microeng. 13 (2003) 380–382 PII: S0960-1317(03)55287-1 Building thick photoresist structures from the bottom up Mark C Peterman1, Philip Huie2, D M Bloom3 and Harvey A Fishman2 1 Department of Applied Physics, E L Ginzton Laboratory, Stanford University, Stanford, CA 94305-4090, USA 2 Department of Ophthalmology, Stanford University School of Medicine, Stanford, CA 94305-5308, USA 3 Department of Electrical Engineering, E L Ginzton Laboratory, Stanford University, Stanford, CA 94305-4085, USA E-mail: hfishman@stanford.edu Received 28 October 2002, in final form 23 January 2003 Published 28 February 2003 Online at stacks.iop.org/JMM/13/380 Abstract Micromachining has pushed the limits of photolithography in the vertical direction. We demonstrate a new technique for producing structures in thick photoresists, with excellent contact alignment and high aspect ratios using a standard UV source. In this technique, we exposed the resist from the bottom by defining the mask as part of the substrate. By doing so, we successfully created high aspect ratio and multiple-layer structures. Additionally, the structures have a slight inward taper, a very useful feature for molding. This technique is a new way of thinking about photolithography, allowing novel structures and simplified processing. 1. Introduction While much of photolithography drives to produce smaller lateral dimensions, microelectromechanical systems (MEMS) push large vertical dimensions and aspect ratios. One of the more popular thick photoresists in MEMS, SU-8, has yielded aspect ratios of greater than 15:1 with conventional UV photolithography [1–3]. Here, we demonstrate a technique to expose this photoresist from the bottom, providing excellent contact alignment, high aspect ratio structures with small features, and a new tool for producing three-dimensional structures. There are multiple challenges in photolithography, especially with thick photoresists. First, underexposure is a common problem. With thick photoresists, getting enough energy to the base of the resist can be difficult or timeconsuming. If there is not enough energy to drive the crosslinking reaction at the base, the photoresist will remain unexposed and subsequent development will lift the entire structure from the substrate. Second, aligning a mask to an underlying feature can be challenging with thick photoresists. During alignment, the mask is brought into close proximity with the substrate, allowing features on both the mask and substrate to be co-focal. If the photoresist is thick, it may not 0960-1317/03/030380+03$30.00 be possible to focus on the mask and substrate simultaneously. Additionally, an uneven photoresist surface provides uneven contact during exposure. Sections of the substrate not in contact with the mask will not resolve small features. Uneven surfaces are especially a problem with thick films (>100 µm), where the photoresist may flow during baking steps. When the photoresist is thick, a small percentage variation in the surface becomes very significant. One solution to these problems is to expose the photoresist through the substrate. By spinning the thick photoresist directly on the mask, perfect contact alignment is achieved. By exposing from the base of the structure, the structure will not lift off during development due to underexposure. Since using a chrome mask directly as the substrate would be an expensive R glass wafers upon which option, we chose Schott Borofloat amorphous silicon was deposited. The glass passes the light necessary to crosslink the photoresist, while the silicon acts as the mask. This technique will work with any opaque material that can be deposited and patterned. The objective of our project was not only to produce tall structures, but also to produce a structure useful for molding. For a mold to be useful, the molded material must be removable, preferably without damaging the master. This typically requires at least vertical sidewalls, if not an inward © 2003 IOP Publishing Ltd Printed in the UK 380 Building thick photoresist structures from the bottom up Figure 1. (a) Process schematic for generating pillars. (i) Start with 1500 Å of amorphous silicon on a glass wafer. (ii) Pattern and etch the amorphous silicon. (iii) Spin on a thick layer of SU-8 photoresist. (iv) Develop SU-8. (b) Scanning electron micrograph of pillars. The pillars are 9 µm across at the top and 220 µm tall. (c) Higher magnification micrograph of the pillar base. taper from the base to the top. Exposure through photoresist often causes a taper to occur, narrowing away from the source, due to the loss of energy as the photoresist absorbs the light. By exposing from the base, the taper narrows to the top, a desirable feature for molding. 2. Fabrication A schematic of the fabrication is shown in figure 1. Four-inch R wafers, 700 µm thick, were obtained with Schott Borofloat 1500 Å of amorphous silicon already in place. The amorphous silicon was patterned lithographically using 1 µm AZ3612 photoresist. Reactive ion etching (SF6/F-115) transferred the pattern to the amorphous silicon, after which the AZ3612 was stripped in acetone. SU-8 2100 (MicroChem Corp.) was spun on the wafer (100–300 µm) and baked according to the manufacturer’s specifications. The wafer was inserted into an aligner upside down, with the SU-8 toward the vacuum chuck (figure 1(a)). The exposure time was chosen to yield a dosage 150% higher than the recommended dosage, to ensure that the structures were as tall as possible. The exposures were pulsed, typically 10 s on followed by 5 s off, to allow the resist to relax between doses. Development was performed in either PGMEA (SU-8 developer) or in ethyl lactate (SU-8 thinner) as supplied by MicroChem Corporation. For structures with multiple layers, the processing progressed similarly (figure 2(a)). After the mask was defined in the amorphous silicon and the photoresist stripped, a layer of SU-8 2050 (25–50 µm) was spun on the wafer. This layer was exposed from the top, just as in standard topside lithography, with alignment to the features etched in the silicon. After development, a second layer of thick photoresist (100– 300 µm) was spun onto the wafer, and exposed from the backside of the wafer. Figure 2. (a) Process schematic showing how multi-layer structures are generated. (b) Scanning electron micrograph of single-layer and two-layer SU-8 pillars. Note the smoothness of the sidewalls on the alignment cross. (c) Higher magnification micrograph at the base of the two-layer pillars. 3. Results and discussion The result of this processing is shown in figure 1(b). The structures are 10 µm across at the base, 9 µm at the top, and 220 µm tall. A higher magnification image at the base of the pillars is shown in figure 1(c). These dimensions correspond to an aspect ratio of 22, but the process can be pushed further. Deep reactive ion etching can produce similar results in silicon, but is limited to the removal of a lesser area of silicon. Our process can remove any percentage of the surface desired. Additionally, the sidewalls of the SU-8 structures are smooth; there is no scalloping like that seen with the Bosch process. This is an advantage for molding, where the scalloped edge would tend to hold the molded material in place. Other techniques using x-ray or proton sources have shown excellent aspect ratios (100:1 in >150 µm of SU-8), but they require advanced sources and equipment [4–6]. If the amorphous silicon were wet etched (e.g. KOH), then our technique requires nothing other than a fume hood and UV source. The limits to structure size are two-fold. First, limitations in plasma etching and lithography on the amorphous silicon produce a lower limit on the lateral dimensions. The lateral dimensions are defined using standard photoresist and lithography, so this limitation is no different than any other lithographic technique. The use of electron beam lithography and reactive ion etching could yield features smaller than 100 nm. Second, the vertical resolution limit is due to the diffraction of light passing through the small mask features and the absorption of light passing through the photoresist. After 381 M C Peterman et al a certain distance, the light cannot provide enough energy to crosslink the film, for any exposure time. Because of the perfect contact between photoresist and mask, our technique eliminates loss of resolution due to the mask–photoresist gap. Beyond the advantages for photolithography in thick films, this technique also provides the ability to create novel, three-dimensional structures. Because the mask is part of the substrate, the mask is an integral part of the device. Some groups have deposited and patterned metal layers to create an embedded mask [7]. While our technique is advantageous in that it does not require metal deposition, a combination of these two techniques could be very useful. In either case, if wafers are to be bonded together, exposure can occur after assembly. Moreover, multi-layer structures can be generated, as shown in figure 2(b), with a high magnification image in figure 2(c). If all exposures were done from the top, the alignment between the thick top layer and the underlying layers would have been very difficult. In this case, alignment occurred during processing of the underlying thin layer. Problems with lack of co-focality were eliminated. Multi-layer structures such as those shown in figure 2(b) with a pillar on top of a pedestal have an additional advantage for molding. The SU-8/SU-8 interface is stronger than the SU-8/substrate interface. Although exposure from the top leads to a taper in the wrong direction, the larger contact area between the pedestal and substrate increases the strength of the contact, effectively increasing the strength of the narrow pillar. 4. Summary The concept of building a photoresist structure from the substrate up introduces a new way of thinking about 382 photolithography. While the methodology requires an additional processing step to etch the amorphous silicon mask, it provides a tool to make novel structures, with nothing other than a UV source and etchants. Additionally, the technique simplifies some of the more difficult processing steps encountered with thick photoresists: (1) alignment problems due to focus, surface unevenness, and sticking and (2) photoresist liftoff because of underexposure. This approach to photolithography is a powerful new tool for simplifying the current techniques and building new structures. References [1] Lorenz H, Despont M, Fahrni N, Brugger J, Vettiger P and Renaud P 1998 High-aspect-ratio, ultrathick, negative-tone near-UV photoresist and its applications for MEMS Sens. Actuators A Phys. 64 33–9 [2] Pan C T, Yang H, Shen S C, Chou M C and Chou H P 2002 A low-temperature wafer bonding technique using patternable materials J. Micromech. Microeng. 12 611–5 [3] Conradie E H and Moore D F 2002 SU-8 thick photoresist processing as a functional material for MEMS applications J. Micromech. Microeng. 12 368–74 [4] Bogdanov A L and Peredkov S S 2000 Use of SU-8 photoresist for very high aspect ratio x-ray lithography Microelectron. Eng. 53 493–6 [5] Osipowicz T, van Kan J A, Sum T C, Sanchez J L and Watt F 2000 Use of proton microbeams for the production of microcomponents Nucl. Instrum. Methods Phys. Res. B 161 83–9 [6] Tay F E H, van Kan J A, Watt F and Choong W O 2001 A novel micro-machining method for the fabrication of thick-film SU-8 embedded micro-channels J. Micromech. Microeng. 11 27–32 [7] Alderman B E J, Mann C M, Steenson D P and Chamberlain J M 2001 Microfabrication of channels using an embedded mask in negative resist J. Micromech. Microeng. 11 703–5