warning - Ad.A. KLEIN

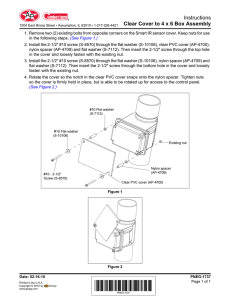

advertisement