Manual Serviço ANTRON-IIs Ingles

advertisement

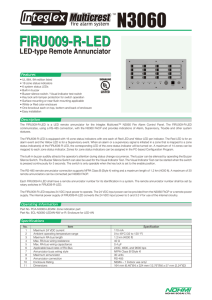

Alarm Annunciator ANTRON II-s Service Manual – ANTRON II-s Alarm Annunciator Historical Review Information about the documentation index, as well as revisions and corrections performed. Item Date Comments 01 16/08/04 Version 1.0 – Initial development of the ANTRON IIs version, based on version ANTRON II, including the new functions. ATEEI – Industrial Electroelectronics Author M. Spisila Reviewer L. Domingos 2 Service Manual – ANTRON II-s Alarm Annunciator TABLE OF CONTENTS Item 1 2 3 3.1 4 4.1 4.2 4.3 4.4 5 5.1 5.2 6 7 8 9 10 Description APPLICATION GENERAL CHARACTERÍSTICS DESCRIPTION OF WORKING PRINCIPLES ANTRON II-s BLOCK DIAGRAM FRONT PANEL VIEWING PANEL MEMBRANE PANEL LED AND BUZZER PANEL DIMENSIONS AND FRONT VIEW OF THE PANELS CONNECTION DIAGRAMS VCC CONNECTION DIAGRAM VCA CONNECTION DIAGRAM ANNOUNCEMENT SEQUENCES APPLICATION SOFTWARE TECHNICAL CHARACTERÍSTICS ORDERING SPECIFICATIONS LABELING PATTERN ATEEI – Industrial Electroelectronics Page 4 4 5 6 7 7 7 8 9 10 10 11 12 14 15 16 17 3 Service Manual – ANTRON II-s Alarm Annunciator 1 - APPLICATION The ANTRON II-s equipment belongs to a generation of signaling and alarm equipment, with control, supervision and remote operation resources. Its purpose is monitoring processes, supervising the state of equipment or signals. It is recommended for any type of installation in which one wishes to be advised by means of visual and audible indications. Because it is microprocessor-based equipment, ANTRON II-s is sufficiently adaptable to meet practically all configurations required for each type of application. 2 – GENERAL CHARACTERISTICS This equipment aims to meet the functional requirements of energy utilities and industries, offering a high degree of modularity, reliability and performance, associated with a low cost for supply, installation and maintenance. The main objective of this equipment is monitoring the conditions of processes, signaling the occurrence of abnormal situations. Signaling may obey a sequence established by a standard, with the following sequences available for the user to choose from: A(ISA 1), A-5 (ISA 1A), M (ISA 2C), M-5 (ISA 2D), R-8 (ISA 2A), R-10, F1A (ISA 4A), SYSTEM F, A5M, MM, R8S, A5MC e A5MP. The sequence that is chosen may be programmed at the factory or it may be field programmed, if the client has the available application software . Because it is a microprocessor-based device, it offers a communication function to the user. This function is essential for the automation of a process or substation. The ANTRON II-s employs memory with an internal battery, which prevents it from losing programming data even in the absence of external power. Thanks to this aspect, the ANTRON II-s can go for as long as 1 year without external power. However, a log of events will be lost because it is stored in RAM memory with no battery. As for the number of points, the client has various configurations available: 16, 24, 32, 48, 56, 64, 80, 88 or 96 points. 3 – DESCRIPTION OF WORKING PRINCIPLES Basically, the ANTRON II-s receives signals arising from the action of external electrical contacts, associated with equipment or systems that one wishes to supervise, through contacts (NO or NC) that initiate its logic, processing the specified sequence. As one can see on the block diagram on the next page, the monitored points feed into the ANTRON II-s through peripheral cards, with each of these cards able to receive signals from up to 8 external points (with the exception of peripheral card 1, for which the first point is for indicating the CC fault or “DC fault” and the remaining are alarm points). Therefore, if the ANTRON II-s has 23 active points + 1 CC fault this shows that it has 3 ATEEI – Industrial Electroelectronics 4 Service Manual – ANTRON II-s Alarm Annunciator peripheral cards, and if it has 95 active points + 1 CC fault point this shows that it has 12 peripheral cards, and so on. Any abnormal condition will give rise to the generation of local visual and audible alarms, as well as this information appearing on the computer screen, if the client has the application software and is connected to a PC. Each input point for the ANTRON II-s can have a retransmission contact for remote signaling or for initiating complementary operations. All of the peripheral cards are connected to an LED card. The reference voltages that come from the ANTRON II-s internal power supply are also connected to this same card, and so is the CPU card. The CPU card receives signals from all of the peripherals, processes the information and generates an algorithm that is stored in internal memory. This algorithm returns information to the peripherals with commands to be followed (close repeater contact, open repeater contact, flash the LED, switch on the LED, switch off the LED, etc). The CPU card also receives user commands, through the membrane keyboard or the remote inputs. It also houses the internal buzzer, which will be activated whenever an abnormal condition occurs at any of the supervised points. Whenever the internal buzzer is activated, the buzzer repeater relay also changes state, allowing the activation of another signal such as: external lamp or buzzer, etc. If there is a DC power supply failure, the CC fault (DC fault) repeater relay changes state, allowing the activation of another signal such as an external lamp or buzzer, etc., at the same time as the visual signal for channel 1 is switched on. This LED for channel 1 will be supplied by an AC voltage that is applied to pins 8 and 9 on the CPU. The ANTRON II-s has a self-diagnosis function, that is, it tests itself internally, and if an internal fault takes place (the microcontroller failing, for example) the ANTRON II-s warns externally by means of a repeater contact and an Active CPU LED (if the LED remains on or off the CPU is malfunctioning and if the LED is blinking the CPU is normal). The ANTRON II-s can communicate with a PC through an available RS232 or RS485 interface. There is detailed application software described in the software manual ANT2V2. By means of inputs available on the CPU card it is possible to operate the ANTRON II-s remotely. ATEEI – Industrial Electroelectronics 5 Service Manual – ANTRON II-s Alarm Annunciator 3.1 – ANTRON II-s BLOCK DIAGRAM ATEEI – Industrial Electroelectronics 6 Service Manual – ANTRON II-s Alarm Annunciator 4 – FRONT PANEL The front panel of the ANTRON II-s is composed of the following parts: 4.1- Viewing Panel: this module allows local viewing of the alarm points. 4.2- Membrane Panel: • Lamp Test Key: LT – pressing this key once turns on all of the LEDs, with the exception of the LED for channel 1 which is exclusively for a CC fault (or “DC fault”); • Input Test Key: IT – panel key that allows checking circuit conditions. When pressed, it simulates an alarm at all active points in the circuit; • Acknowledge Key: A – panel key to be pressed by the operator whenever an abnormal condition occurs at one of the supervised points, indicating to the ANTRON II-s that he acknowledges the problem. When the acknowledge key is pressed the buzzer will become silent or not, depending on the sequence that has been programmed; • Reset Key: R – panel key that the operator will press whenever the point that caused the abnormal condition returns to normal. This key is used only in sequences that do not include automatic reset; • Reset Buzzer Key: RB – When pressed, it interrupts the sound from the buzzer. ATEEI – Industrial Electroelectronics 7 Service Manual – ANTRON II-s Alarm Annunciator 4.3- LED and Buzzer Panel: • Aux. V. LED: indicates that the annunciator is being supplied with the corresponding auxiliary voltage; • Active CPU LED: when blinking, indicates that the annunciator’s CPU is working, if it stays on or off it signals a CPU malfunction; • Buzzer: indicates annunciator audible signal; • Buzzer switch: turns the buzzer on/off. ATEEI – Industrial Electroelectronics 8 Service Manual – ANTRON II-s Alarm Annunciator 4.4 - DIMENSIONS AND FRONT VIEW OF THE PANELS ATEEI – Industrial Electroelectronics 9 Service Manual – ANTRON II-s Alarm Annunciator 5 – CONNECTION DIAGRAMS 5.1 - Vcc Connection Diagram KEY TO ABBREVIATIONS: IT – Input Channels Test A – Acknowledgment R – Reset RB – Reset Buzzer LT – Lamps Test ATEEI – Industrial Electroelectronics 10 Service Manual – ANTRON II-s Alarm Annunciator 5.2 – Vac connection Diagram KEY TO ABBREVIATIONS: IT – Input Channels Test A – Acknowledgment R – Reset RB – Reset Buzzer LT – Lamps Test ATEEI – Industrial Electroelectronics 11 Service Manual – ANTRON II-s Alarm Annunciator 6 – ANNUNCIATOR SEQUENCES The sequences are programmed by means of a PC. They are standards that indicate changes in process conditions, through different visual signaling states and operation functions. The ANTRON II-s is prepared to follow any of the sequences shown in the drawing below, and each active point can follow a sequence determined by the client. NOTE: In addition to the sequences shown to the left, there are others available on demand. ATEEI – Industrial Electroelectronics 12 Service Manual – ANTRON II-s Alarm Annunciator Key to Symbols: Each sequence has its specific application. Thus, for example, if the client wishes to know which was the first alarm giving rise to a failure, we see from the table that he will choose sequence F1A, since in this sequence only the first alarm will blink, while the others will remain continuously on. In this manner, each application has a sequence that is most appropriate for usage. Below we see an example of usage of sequence A (ISA 1): ATEEI – Industrial Electroelectronics 13 Service Manual – ANTRON II-s Alarm Annunciator 7 – APPLICATION SOFTWARE If the client so desires, he may acquire the ANTRON II-s application software in order to remotely follow the ANTRON II-s activity on-line, as well as operate the equipment or alter programming data. This software is composed of a main screen where the current states of the active points and buzzer are viewed. One also views the current state of the ANTRON II-s when there is communication between the ANTRON II-s and the PC. All commands effected by the operator (test, acknowledge, etc.), can be performed through the application software. On the main screen there are commands that access various menus. The first menu F1 (PROG) allows the operator to program all of the ANTRON II-s active points, each one separately (polarity NO/NC, existence and sequence). A password is required for accessing this menu, so that only authorized operators may access the programming. On the next menu F2 (INFO), one has the information for the commands listed on the main screen. On another menu F4, we can edit all of the text messages that appear on the front panel of the ANTRON II-s, so that, in the event of an alarm, a message will appear to the operator describing what happened. On another menu F7, the 2000 most recent events can be viewed, as well as the month, day, time, minute and second when they happened. For more information about the software, see the specific manual. If the user wants this software, it must be requested during the purchasing process. ATEEI – Industrial Electroelectronics 14 Service Manual – ANTRON II-s Alarm Annunciator 8 – TECHNICAL CHARACTERISTICS Auxiliary voltage for the ANTRON II-s (tolerance of –20/ +25%) Repeater contacts (1 NO per point) Maximum commuting current Maximum commuting voltage Maximum commuting power Buzzer repeater contact (1 NO) CC (DC) fault repeater contact (1 reversible) Maximum commuting current Maximum commuting voltage Maximum commuting power Power supply for activating the CC fault channel (DC fault) Minimum duration of the input signal Viewing Buzzer (intermittent sound) Buzzer sound intensity Working temperature range Degree of protection Lifetime of LEDs Communication Models Note: See ordering specifications Maximum power requirement: Antron 32 with Led Antron 64 with Led Antron 96 with Led Weight: Antron 32 Antron 64 Antron 96 Standards met: Insulation Resistance (500 Vcc) Applied voltage (0,5 kV, 60 Hz, 1 min) Radio-interference SWC ( 1 MHz) Impulse – 5 kV (peak value) for 1,2 / 50 microseconds ATEEI – Industrial Electroelectronics 12 Vcc 220 Vcc 24 Vcc 127 Vac 48 Vcc 220 Vac 125 Vcc Others on request 2A 220 Vac or 250 Vcc 120 W 2A 220 Vac or 250 Vcc 120W 100 ~240 Vac 10 ms LED 2800 Hz 90 dB at 30 cm from ANTRON II-s 0 to 55 degrees Celsius IP 50 30.000 hours RS 232 or RS 485 32, 64 and 96 points 30 W 45 W 60 W 4,5 kg 7,6 kg 9,6 kg Greater than 100 MOhms NBR 7116 NBR 7099 and IEC 255/4 IEC 255-22-3 NBR 7099 and IEC 255/4 NBR 7099 and IRC 255/4 15 Service Manual – ANTRON II-s Alarm Annunciator 9 – ORDERING SPECIFICATIONS ATEEI – Industrial Electroelectronics 16 Service Manual – ANTRON II-s Alarm Annunciator 10 – LABELING PATTERN ATEEI – Industrial Electroelectronics 17 Service Manual – ANTRON II-s Alarm Annunciator ATEEI – Industrial Electroelectronics 18 Service Manual – ANTRON II-s Alarm Annunciator ATEEI – Industrial Electroelectronics 19 Service Manual – ANTRON II-s Alarm Annunciator DEAR CLIENT, With the goal of perfecting the quality of our technical publications, we request suggestions and comments, by filling out the survey on this sheet. Please send it to the address listed below. We thank you in advance for your understanding and cooperation. ATEEI - Equipamentos Eletroeletrônicos Industriais Ltda Rua Ema Taner de Andrade, 512 - Ferrari CEP 81606-360 - Campo Largo - Paraná - BR Phone/Fax: +55 41 392-4346 E-mail: sac@ateei.com.br Representative: + 55 41 349-7077 01) Were any errors observed in this publication? If so, please indicate the pages, items, etc. 02) Is the publication easy to understand with the subjects well distributed? Are there any suggestions for improvements? 03) Is the information contained in this publication sufficient to meet your objective? If not, what was missing and could be included? Name: Date: Company: Telephone number: City: State: Country: E-mail: ATEEI – Industrial Electroelectronics 20 Service Manual – ANTRON II-s Alarm Annunciator Warning To avoid personal injury or damage to equipment, only qualified personnel should conduct the procedures described in this manual. Other publications about the product: q q Software Manual; Brochure. Because of continuing changes in standards and in materials, we reserve the right to alter the dimensions and characteristics. Only data and characteristics indicated on our order confirmation shall be maintained. For additional information contact our representative or write to the address below. ATEEI - Equipamentos Eletroeletrônicos Industriais Ltda Rua Ema Taner de Andrade, 512 - Ferrari CEP 83606-360 - Campo Largo - Paraná - BR Phone/Fax: +55 41 392-4346 Site: www.ateei.com.br E-mail: ateei@ateei.com.br Representative: + 55 41 349-7077 ATEEI – Industrial Electroelectronics 21