Environmental Management at Operating Outdoor Small Arms Firing

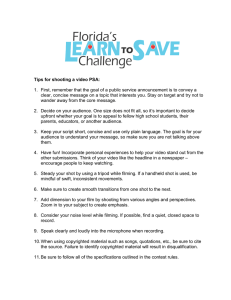

advertisement