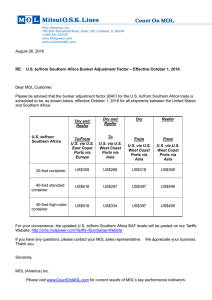

MOL LINER

advertisement

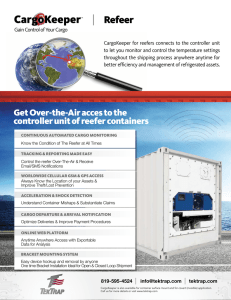

MOL GLOBAL REEFER SERVICES (v201104/LRM/AN) MOL LINER GLOBAL REEFER SERVICES 1 Disclaimer The MOL Global Reefer Services profile is provided as a general reference. While every effort has been made to ensure the accuracy and reliability of the information provided, MOL shall accept no liability for technical or editorial errors or omissions in the contents contained in this section; nor for any damage, including but not limited to direct, incidental or consequential damages resulting from or arising out of the use of the information contained herein. MOL GLOBAL REEFER SERVICES (v201104/LRM/AN) 1. MOL Liner Reefer Services MOL Liner reefer services have continued to expand in scope and capability to support MOL’s customers’ growing needs in seaborne container transportation of perishable and atmosphere-sensitive cargoes. MOL’s dedicated global reefer management team, backed by a worldwide network of experts in sales and operations, is committed to support the valued customers who significantly contribute to global commerce. Whenever and wherever it is needed, MOL Liner’s worldwide network is there to support you with incomparable quality services. For general information, please contact your local MOL office. For specific technical questions, please contact the MOL Reefer Help Desk through email: reeferhelpdesk@mol-liner.com. We are committed to respond back to you within 2 business days (Saturday, Sunday, and National Holidays in Hong Kong excluded). 2 Disclaimer The MOL Global Reefer Services profile is provided as a general reference. While every effort has been made to ensure the accuracy and reliability of the information provided, MOL shall accept no liability for technical or editorial errors or omissions in the contents contained in this section; nor for any damage, including but not limited to direct, incidental or consequential damages resulting from or arising out of the use of the information contained herein. MOL GLOBAL REEFER SERVICES (v201104/LRM/AN) 2. Our Reefer Equipment All MOL equipment is built in collaboration with the manufacturers to meet our strict quality control standards, and conforms to standards set by the International Organization for Standardization (ISO). It is also TIR certified to comply with international transportation requirements and relevant national laws and regulations. A reefer container consists of a container shell, with a heat-insulated foam layer, and a refrigeration unit. The temperature setting is typically adjusted between -30oC and +30oC, although more extreme temperatures can be accommodated depending on equipment model and specification of the refrigeration unit. Reefer containers are used for transporting temperature-sensitive cargoes. These mainly consist of foodstuffs such as meat, seafood, dairy products, beverages, fruits and vegetables. Non-food items, like live plants, photographic film, chemical and pharmaceutical products are also commonly transported in reefer containers. MOL’s reefer container fleet comprises two sizes: 20’ and 40’ High Cube. The chart below gives details of the dimensions and weights of our reefer containers. *Photos: MOL Reefer Container 3 Disclaimer The MOL Global Reefer Services profile is provided as a general reference. While every effort has been made to ensure the accuracy and reliability of the information provided, MOL shall accept no liability for technical or editorial errors or omissions in the contents contained in this section; nor for any damage, including but not limited to direct, incidental or consequential damages resulting from or arising out of the use of the information contained herein. MOL GLOBAL REEFER SERVICES (v201104/LRM/AN) 20' (8'6"high) Type 40' (9'6"high) R20201S Z40201S (L) 6,058mm(19'10"1/2) 12,192mm(40'0") (W) 2,438mm(8'0") 2,438mm(8'0") (H) 2,591mm(8'6") 2,896mm(9'6") (L) 5,460mm(17'10"61/64) 11,581mm(37'11"15/16) (W) 2,284mm(7'5"59/64) 2,290mm(7'6"3/16) (H) 2,263mm(7'5"3/32) 2,542mm(8'4"1/16) 28.2m3(996cft) 67.4m3(2,380cft) (W) 2,290mm(7'6"5/32) 2,290mm(7'6"5/32) (H) 2,224mm(7'3"9/16) 2,506mm(8'2"11/16) Tare Weight 3,090kg(6,810lbs) 4,700kg(10,360lbs) Max Payload 27,390kg(60,390lbs) 29,300kg(64,600lbs) Max Gross Weight 30,480kg(67,200lbs) 34,000kg(74,960lbs) MOL Spec. No. (example) External Dim. Internal Dim. Interior Capacity Door Open In the structural design for the bottom air circulation system, reefer containers have corrugated interior walls and a T-floor to facilitate air passage throughout the container. For effective temperature control, careful cargo stacking is necessary to avoid blocking or impeding air flow, which is critical in achieving optimal air circulation around or through the cargo. *Air flow illustration example, adapted from Carrier Transicold Adjustable ventilation ports are available to help avoiding fresh fruits from excessive ripening during transportation. Most MOL reefer containers also contain a dehumidification function, which not only keeps fresh fruits in desired condition during voyages, but also protects other humidity-sensitive commodities such as live plants, flower bulbs, vegetables, and so forth. Reefer containers are equipped with automatic defrosters to prevent the loss of refrigeration resulting from frost generated by moisture in the condenser coils or the ventilation ports. Additional components and devices for Cold Treatment or Atmosphere Control can also be installed onto the reefer containers, depending on the regulatory requirements or specific optimal cargo carriage conditions of particular commodities. 4 Disclaimer The MOL Global Reefer Services profile is provided as a general reference. While every effort has been made to ensure the accuracy and reliability of the information provided, MOL shall accept no liability for technical or editorial errors or omissions in the contents contained in this section; nor for any damage, including but not limited to direct, incidental or consequential damages resulting from or arising out of the use of the information contained herein. MOL GLOBAL REEFER SERVICES (v201104/LRM/AN) 3. Our Reefer Service Features Reefer transportation services are mainly used to handle perishable cargoes like meat, fruits and vegetables, with the advantage of minimizing decay, controlling ripening, and retaining food quality to the best possible condition for consumers, even after being transported long distances. Some chemical and pharmaceutical products are moved by reefer services to avoid decomposition or deterioration of the products which can take place during allweather-exposed transportation. For many cargoes, maintaining an appropriate ambient condition through proper operational handling is indispensable for every step of the supply chain – from packing, storing, loading, transporting, and unpacking, to delivery to the end consumer. Ocean reefer transportation is a key part of this supply chain, and modern technology allows us to control the temperature, humidity and even the air composition inside our containers for the entire voyage, ensuring safe and optimal transportation conditions for the products. Ventilation Our reefer containers enable adjustment of the fresh air ventilation level for the purpose of diluting or removing undesirable gases (for example, ethylene and CO2) generated by the cargo inside the container during the transportation period. This can reduce or eliminate negative effects such as the acceleration of the ripening process or flavor loss of some commodities. The necessity and quantity of air exchange depends on commodity type and condition at the time of loading. Temperature Control Temperature control is the most critical function of any reefer services. Temperature has the largest effect on the respiration of produce and bacterial growth. A temperature increase of 10°C will result in an approximate doubling of the respiration rate of fruit; while lowering the temperature will substantially reduce the growth rate of micro-organisms. However, an optimal temperature set point, which is commodity-specific, is needed as too low a temperature may also cause adverse effects like chill injury of fruits, meat texture changes, or crystallization of some chemical products. It should be noted that reefer equipment is designed to regulate temperature inside the container in relation to the cargo pre-loading condition, rather than removing heat absorbed by cargo before or during its loading. Hence, proper pre-treatment and precooling of cargo, as well as proper handling in the appropriate ambient conditions during container loading and unloading, are crucial to maintain cargoes in the best possible condition. Reefer cargoes are generally classified according to the storage temperature as below: Type Frozen Partial-Frozen Chilled Light-Chilled Temp. Range -10oC and below -3oC to -10oC -3oC to +5oC +5oC to +25oC Typical Commodities Meat, Fish, butter Meat Fruits, Vegetables, Chilled Meat Fruits, Vegetables, Films Comment Completely frozen Partially frozen Lowest temp. above freezing Temp. to reduce deterioration 5 Disclaimer The MOL Global Reefer Services profile is provided as a general reference. While every effort has been made to ensure the accuracy and reliability of the information provided, MOL shall accept no liability for technical or editorial errors or omissions in the contents contained in this section; nor for any damage, including but not limited to direct, incidental or consequential damages resulting from or arising out of the use of the information contained herein. MOL GLOBAL REEFER SERVICES (v201104/LRM/AN) The optimal temperature set-point is commodity-specific. To fulfill certain regulatory requirements, upon request a temperature record during the transport service can be retrieved from the equipment after cargo delivery and equipment return. Dehumidification The reefer machine unit features a dehumidifier to lower the humidity level inside the container. Typical usage includes the transportation of flower bulbs and precision instruments. The humidity level can be reduced to a set percentage during voyage to provide the desirable environment for the cargo. The correct setting also serves the purpose of complying with some import regulatory requirements, for example, acquiring the ATODLO certification from the Netherlands Agricultural Ministry for the transportation of flower bulbs. Atmosphere Control Atmosphere control is the process by which the internal gas atmosphere of the reefer container is changed, regulated or enhanced in order to reduce the decay and ripening of fresh produce. Food quality is better maintained, enabling a longer transit time, wider geographical distribution, and extended shelf life. Perishables, especially climacteric fruits and vegetables, continue to live and breathe after harvesting and during transportation to the consumer. Various technical development and techniques have been developed to slow down the rate of respiration and extend the shelflife of perishables, including storage atmosphere control and treatment of foodstuffs prior to and during transportation. Normal air mainly comprises 21% oxygen (O2), 0.038% carbon dioxide (CO2) and 78% nitrogen (N2). During respiration, fruits and vegetables take in oxygen and emit carbon dioxide and ethylene. By altering the composition of oxygen and carbon dioxide in the atmosphere, the respiration rate of perishable products can be slowed down and the storage life is extended. Below are several atmosphere control technologies commonly employed in today’s reefer transportation: Modified Atmosphere (MA) refers to the technology which changes the composition or concentration of gases inside the reefer container. Typically, nitrogen is injected in the container from an external source during cargo loading to replace oxygen. With a low oxygen atmosphere, respiration and ethylene production of fruit and vegetables are significantly reduced, which in turn slows down ripening and decay. Controlled Atmosphere (CA) refers to the technology which actively regulates a modified atmosphere composition. The initial composition of gases is maintained for the duration of storage/transit by the addition or removal of undesirable gases controlled by a regulating device installed on the reefer container. Ozone Enhanced Atmosphere is the active introduction of ozone into the internal atmosphere of the container, which has the effect of preserving the cargo. Regulated amounts of ozone are released into the reefer container throughout its journey, which reduces microbial decay and slows ripening for commodities such as climacteric fruit and vegetables by decomposing the ethylene they generate. 6 Disclaimer The MOL Global Reefer Services profile is provided as a general reference. While every effort has been made to ensure the accuracy and reliability of the information provided, MOL shall accept no liability for technical or editorial errors or omissions in the contents contained in this section; nor for any damage, including but not limited to direct, incidental or consequential damages resulting from or arising out of the use of the information contained herein. MOL GLOBAL REEFER SERVICES (v201104/LRM/AN) Selection and application of the atmosphere control technology is commodity-specific. MOL works closely with a number of atmosphere control technology providers in the market, (for example, Transfresh, MAXtend, Purfresh), enabling the company to offer customers a range of transportation solutions, whatever their requirements are. For specific information, please contact your local MOL office or email reeferhelpdesk@mol-liner.com. Cold Treatment Cold treatment (or sometimes called cold sterilization) is a common practice in containerized reefer services. In cold treatment, an uninterrupted and sufficiently low temperature is maintained for a predetermined duration in order to kill any insects and larvae that may be hidden in perishable cargo (for example, citrus, apples, grapes, lychees, and so forth). Temperature probes that measure and record the internal temperature of the cargo at specific locations inside the reefer container are installed and connected to the reefer unit controller for subsequent temperature record verification. This practice is usually applied to fulfill the quarantine exemption requirement as stipulated by the sanitary laws and regulations of the importing countries. Required treatment duration, the number of probes and their installed locations inside the container are specified in the protocol which is mutually agreed upon between the authorities of the export and import countries. 4. Reefer Handling Precaution and Booking Checklist The efficiency and effectiveness of reefer containers to perform their purpose in controlling the internal temperature and atmosphere is largely dependent on the pre-loading conditions of cargo and proper packing and stowage to enable the desirable air circulation around and through the cargo inside the container. Improper handling during the reefer loading operation not only affects the performance level of the reefer equipment, but also causes serious damage to both the reefer machine unit and the cargo itself. The following is a reference checklist used for loading operations: Before Loading - A (Pre-Trip Inspection) PTI of the reefer container should be done to ensure the equipment is in good operating condition. - Pre-cleaning the container to make sure there is no debris on or beneath the T-floor. - Check and clean the T-floor to ensure the air channel is clear all the way from the panel to the door and free from debris. - Pre-treat products appropriately and pack them with sufficient protection. - Pre-cool products to reach the desired carriage temperature range - Note: Stuffing hot products may damage both the equipment and cargo! Pre-cooling of container is not recommended. The exception is the case in which the cargo loading is performed at a cold facility with a temperature-conditioned loading bay connected to the container. The container may be pre-cooled to the appropriate loading temperature. 7 Disclaimer The MOL Global Reefer Services profile is provided as a general reference. While every effort has been made to ensure the accuracy and reliability of the information provided, MOL shall accept no liability for technical or editorial errors or omissions in the contents contained in this section; nor for any damage, including but not limited to direct, incidental or consequential damages resulting from or arising out of the use of the information contained herein. MOL GLOBAL REEFER SERVICES (v201104/LRM/AN) During Loading - Do not keep the reefer unit switched-on while the container doors are open, as this could allow condensation and moisture to develop, which in turn could induce cargo mold and decay. - Do not store cargo beyond the end of the T-floor, and ensure there is no blockage at the end of the T-floor channel. - Do not load above the loading red-line indicated on the container wall, as this will block the return air flow. - The total floor surface must be covered to avoid short-circuiting of cold air circulation. - Load cargo as quickly and efficiently as possible. Stowage Frozen Cargo Stowage - Stowage design is relatively straightforward. As the frozen cargo should have been appropriately pre-cooled to the desired temperature before loading, air circulation should be aimed at blocking and preventing heat penetrating from outside the container. - Ensure proper corner support of cartons or pallets, according to their weight and loading pressure. - The entire floor must be evenly loaded and covered. - Arrange cargo in a solid block, leaving no space between the packages/cartons and no space between the cargo and the walls of the container. - Stowage must not exceed the red-line to avoid air circulation blockage. The aim is to allow air circulation “around” the entire cargo load. - Ventilation and Dehumidification must be set to “Off”. Drain port must be “Closed”. Chilled Cargo Stowage - Stowage is designed to allow proper air circulation and flow-through of the entire cargo load so that heat, vapor, CO2, and other gases produced by the respiration process from chilled perishable products can be removed. - Proper air passages should be present on the packaging, with particular attention to the size, number, and position of vent holes on cartons, to allow refrigerated air to circulate through all the cargo in the container. - Proper packaging (for example, packaging style, package material, and so forth) must be used to support stacking weight and sustainability at various humidity levels. - Shrink-wrap, slip-sheet, foam trays, plastic bags, and so forth that block or obstruct air passage should not be used. - If cargo cannot cover entire floor, cardboard can be used to cover empty spaces to avoid short circuit of the refrigerated airflow. - There must be no stowage above the indicated red line on the container walls to avoid impeding return air flow. 8 Disclaimer The MOL Global Reefer Services profile is provided as a general reference. While every effort has been made to ensure the accuracy and reliability of the information provided, MOL shall accept no liability for technical or editorial errors or omissions in the contents contained in this section; nor for any damage, including but not limited to direct, incidental or consequential damages resulting from or arising out of the use of the information contained herein. MOL GLOBAL REEFER SERVICES (v201104/LRM/AN) Booking Information Checklist Customer should provide the following critical shipment information during booking: Specific Origin and Destination. A detailed description of the product(s) being shipped, e.g. commodity, quantity, weight, cubic measurement, and type of packaging (boxed, drums, pallets, hanging carcass, and so forth). Preferred equipment size (20’ or 40’HC). Preferred temperature set-point (specify in °F or °C). Fresh-air exchange requirements (specify in CFM or CMH). Modified or controlled atmosphere requirements. The date when the product is available at the point of origin and the required delivery date at the destination. Special handling requirements (e.g. dehumidification % level, Cold Treatment, and so forth). If container pre-cooling is required, the booking office should be informed. 9 Disclaimer The MOL Global Reefer Services profile is provided as a general reference. While every effort has been made to ensure the accuracy and reliability of the information provided, MOL shall accept no liability for technical or editorial errors or omissions in the contents contained in this section; nor for any damage, including but not limited to direct, incidental or consequential damages resulting from or arising out of the use of the information contained herein. MOL GLOBAL REEFER SERVICES (v201104/LRM/AN) 5. References Commodity Handling Reference Information regarding the proper handling and optimal storage conditions of commodities such as fruit, vegetables and meat is readily available from various industry sources and academic research institutes. For general reference and convenience of the reader, below are several examples of sources available in the public domain with comprehensive information: http://www.ppecb.com/images-1/PPECBExportDirectory2010Part3%20-%20PPECB%20Blue%20Book%202010.pdf - Procedural Manual on General Procedures, Loading and Carrying Temperature Requirements for the Export of Perishable Products, Perishable Products Export Control Board (PPECB) of South Africa http://postharvest.ucdavis.edu/Producefacts/index.shtml - Produce Facts, University of California Postharvest Technology Research and Information Center http://www.ba.ars.usda.gov/hb66/index.html - Draft version of USDA Agricultural Handbook Number 66, Agricultural Research Service, United States Department of Agriculture Reefer Set-Point Reference The tables below show the reefer set-point guidelines for various commodities. The recommended parameters shown are based on industry research with assumptions, and should be used purely as reference only. Optimal parameters are always dependent on variables like the specific commodity cultivars, post-harvest conditions, pre-loading conditions, origin of product, and so forth. Shippers are responsible for determining the optimal settings best suited for their cargo. Recommended Temperature (C) Fruits & Vegetables Apples Apricots Asparagus Avocados Bananas Blueberries Broccoli Cabbage Carrots Cauliflowers Celery Cherries Clementines Cucumbers Durians Figs Garlic Ginger Grapefruits Grapes Min -1 Recommended Temperature (F) Max +4 Min +30 +2 +13 +32 +38 0 +1 0 +31 +32 +28 0 0 +3 +32 +14 -1 0 -2 +32 +34 +32 +32 +32 +32 0 +4 +13 +4 +30 +32 +50 +38 0 0 +13 +10 -1 +36 +55 +57 0 0 0 -1 0 +10 +3 Max +40 +32 +39 +55 +40 +32 +32 +55 +16 0 +50 +31 +61 +32 Ventilation setting (CMH) 25 - 60 15 - 60 20 - 30 40 - 60 15 - 25 0 - 10 20 - 50 15 - 30 20 - 25 20 - 60 20 - 25 0 - 25 20 - 60 15 - 25 15 - 50 0 - 10 10 - 20 10 - 20 15 - 25 10 - 20 Storage Days 90 - 240 7 - 14 14 - 21 14 - 28 7 - 28 7 - 14 7 - 14 7 - 120 28 - 180 14 - 21 14 - 42 14 - 21 7 - 50 7 - 14 7 - 50 7 - 14 90 - 180 30 - 90 28 - 60 30 - 150 10 Disclaimer The MOL Global Reefer Services profile is provided as a general reference. While every effort has been made to ensure the accuracy and reliability of the information provided, MOL shall accept no liability for technical or editorial errors or omissions in the contents contained in this section; nor for any damage, including but not limited to direct, incidental or consequential damages resulting from or arising out of the use of the information contained herein. MOL GLOBAL REEFER SERVICES (v201104/LRM/AN) Fruits & Vegetables Kiwifruit Leeks Lemons Lettuce Limes Lychees Mangoes Melons (cantaloupe) Melons (honeydew) Onions (dry) Oranges Papayas Peaches/ Nectarines Pears Pineapples Plantains Plums Potatoes Potatoes (sweet) Pumpkins Strawberries Tomatoes Turnips Recommended Temperature (C) 0 0 +12 +14 0 +8 +13 +2 +6 +10 +14 +3 +5 +9 +13 0 +2 +2 +9 +7 +13 0 -1 0 +8 +13 +9 +15 0 +4 +8 +12 +16 +7 +13 0 +10 +15 0 +4 Recommended Temperature (F) +32 +32 +54 +57 +32 +46 +55 +36 +43 +50 +57 +37 +41 +48 +55 +32 +36 +36 +48 +45 +55 +32 +31 +32 +46 +55 +48 +59 +32 +39 +46 +54 +61 +45 +55 +32 +50 +59 +32 +39 Ventilation setting (CMH) 15 - 25 15 - 60 15 - 25 20 - 30 15 - 25 10 - 20 25 - 35 25 - 30 25 - 30 10 - 25 15 - 25 25 - 30 15 - 20 15 - 50 15 - 25 15 - 25 15 - 25 15 - 50 Close 0 - 15 10 - 25 15 - 25 Close Others (Dairy, Meat, Seafood, etc.) Butter Butter (frozen) Cheese Chocolate Eggs Fish (frozen) Ice Cream Juice and Concentrate (frozen) Meat (chilled) Meat (frozen) Milk & Dairy Products Poultry (frozen) Shellfish (frozen) Vegetables (frozen) Recommended Temperature (C) Min Max 0 +2 -30 -20 0 +4 +10 +18 -2 +1 -30 -20 -30 -26 -30 -20 -2 0 -30 -20 0 +1 -30 -20 -30 -20 -30 -20 Recommended Temperature (F) Min Max +32 +35 -22 -4 +32 +39 +50 65 +28 +34 -22 -4 -22 -15 -22 -4 +28 +32 -22 -4 +32 +34 -22 -4 -22 -4 -22 -4 Ventilation setting (CMH) Close Close Close Close Close Close Close Close Close Close Close Close Close Close Storage Days 60 - 90 30 - 90 30 - 120 7 - 21 14 - 56 21 - 35 14 - 21 7 - 14 16 - 20 30 - 180 14 - 90 14 - 21 14 - 28 14 - 180 14 - 21 7 - 28 7 - 35 30 - 180 30 - 180 60 - 90 5 - 10 14 - 21 7 - 28 Storage Days 14 - 65 11 Disclaimer The MOL Global Reefer Services profile is provided as a general reference. While every effort has been made to ensure the accuracy and reliability of the information provided, MOL shall accept no liability for technical or editorial errors or omissions in the contents contained in this section; nor for any damage, including but not limited to direct, incidental or consequential damages resulting from or arising out of the use of the information contained herein.