power unit - PD Systems

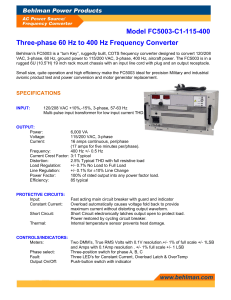

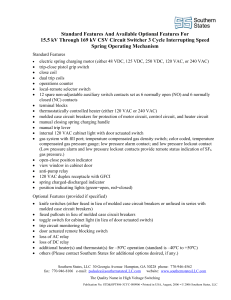

advertisement

PD SYSTEMS POWER PRODUCTS CATALOG 2016 V1 PD Systems, Inc. 5845 Richmond Highway Suite 405 Alexandria, VA 22303 703.778.7699 (P) 703.778.4781 (F) PD SYSTEMS is a Service Disabled Veteran Owned Small Business (SDVOSB) specializing in Engineering, Logistics, and Acquisition Support is an integrator and provider of power generation and power distribution equipment hardware and software, and is well versed at developing integrated power solutions for complex military customer requirements. PD Systems possesses all the capabilities required to successfully design, integrate, produce, and maintain power generation and distribution products. We possess personnel that comprise management, engineering, and manufacturing individual that are leaders, engineers, production managers, and logisticians experienced in the delivery of commercial and military power generation, power distribution as well as aircraft ground support equipment. PD Systems ISO Certified Quality Company and our use of lean technology will: Ensure accountability for quality performance and project control Provide a 24-month warranty and pass through of OEM warranties/ 24-hour call support Provide 24x7 “one stop shop” for all existing products as well newly developed requests PD Systems’ products include providing reliable and durable power in the form of power Generator sets ranging in size from 2.5KW to 6.7MW power plants, transportable and fully operational through both onboard and remote controls as well as extreme military environmental conditions. We provide products that generate prime power and provide through Primary Switching Centers (PSC) both Secondary (Secondary Distribution Centers) and tertiary distribution (15 kW, 25 kW, 30kW, 35kW, 60kW Power Distribution Panels) to support both 50 and 60-Hertz operations. Our products’ modular design and equipment facilities (user defined configurations) to meet specific electrical power generation and distribution needs ranging from as low as required in kW’s with additional “standby” fully integrated in the plant. In summary, PD Systems offers full service solutions. Our hardware developers and integrators have successful cradle-to-grave experience in hardware engineering, production, system integration, testing and Integrated Logistics Support (ILS). CONTACT US PD Systems can support your Power Generation and Distribution Requirements. Feel free to call or e-mail us, we’d be glad to help! MAZEN BADR Vice President, Power Systems Division 703.778.3518 (P) 703.623.6183 (M) mbadr@pd-sys.net DAVID HEYL Director, Power Programs 571.303.1895 (P) dheyl@pd-sys.net PowerSolutions@pd-sys.net www.pd-sys.net BILL MOLINO Vice President, Contracts 703.778.7694 (P) wmolino@pd-sys.net POWER DISTRIBUTION PANEL (PDP) 15KW The 15 KW PDP is designed to accept power at 120/208 VAC, 3-phase, utilizing 60-amp Power connectors. Power is then distributed at 120/208 VAC 3-phase and 120 VAC 1-phase. The PDPs are used to provide power to equipment requiring 120/208 VAC electrical power. GENERAL EQUIPMENT DATA Manufacturer PD SYSTEMS PD Systems’ Part Number PDSYS-PDP-15 NSN: 6110-01-236-3829 Operating Temperature range -25° F to +125° F Storage Temperature range -65° F to +150° F Weight 55 LB Overall Length 29 IN Overall Width 18 IN Overall Height 18 IN POWER RATINGS CHARACTERISTIC Power Input Power Output VALUE 1 @ 60-AMP, 120/208 VAC, 3-Phase 1 @ 60-AMP, 120/208 VAC, 3-Phase 12 @ 20-AMP, 120 VAC, 1-Phase Electrical power distribution consists of circuit breakers feeding an output connector and receptacles that permit connecting cable feeders for load centers. The circuit breakers protect the cables from excessive current flow. The equipment is designed for safe operation and conforms to the NEC for outdoor use. INPUT - The 15 kW PDP has one 60-amp, 4-pole, 5-wire connector. The input connector is labeled J1 on the enclosure. The PDP is protected by an appropriately sized main circuit breaker. OUTPUT - The 15 kW PDP has one 60-amp, 4-pole, 5-wire connector and twelve 20-amp (NEMA L5-20R) receptacles. The output connector and receptacles are protected by appropriately sized circuit breakers. The 60-amp connector is labeled J2 on the panel. The 20-amp receptacles are labeled J3, through J14 on the enclosure. CIRCUIT BREAKERS - The circuit breakers are thermal magnetic type. The 3-phase circuit breakers are three pole, molded-case, common trip with a single operating toggle. The 1-phase circuit breakers are single pole, molded-case, with a single operating toggle. The operating mechanism for all circuit breakers is over center, trip free operation, providing quick-make and quick-break operation. When the circuit breaker is tripped, the operating toggle takes a position between ON and OFF. All 1-phase circuit breakers are GFCI rated and provide a PUSH TO TEST function. For more information, contact Mazen Badr, Vice President and General Manager of Power Systems at PD Systems, Inc. Email: mbadr@pd-sys.net l Phone: 703.778.3518 l Fax: 703.960.4050 l Web: www.pd-sys.net POWER DISTRIBUTION PANEL (PDP) 25KW The 25 KW PDP is designed to accept power at 120/208 VAC, 3-phase, utilizing 60 amp Power connectors. Power is then distributed at 120/208 VAC 3-phase and 120 VAC 1-phase. The PDPs are used to provide power to equipment requiring 120/208 VAC electrical power. GENERAL EQUIPMENT DATA Manufacturer PD SYSTEMS PD Systems’ Part Number NSN PDSYS-PDP-25 6110-01-244-3209 GSA Schedule Contract No. GS-07F-0543W Operating Temperature range -25° F to +125° F Storage Temperature range -65° F to +150° F Weight 38 IN Overall Length 23 IN Overall Width 18 IN Overall Height 18 IN POWER RATINGS CHARACTERISTIC Power Input VALUE 1 @ 60 Amp, 120/208 VAC, 3-Phase 1 @ 60 amp, 120/208 VAC, 3-Phase Power Output 4 @ 20 amp, 120 VAC, 1-Phase 1 @ 15 amp, 120 VAC, 1-Phase Electrical power distribution consists of circuit breakers feeding an output connector and receptacles that permit connecting cable feeders for load centers. The circuit breakers protect the cables from excessive current flow. The equipment is designed for safe operation and conforms to the NEC for outdoor use. INPUT - The 25 kW PDP has one 60amp, 4-pole, 5-wire connector. The input connector is labeled J1 on the enclosure. The PDP is protected by an appropriately sized main circuit breaker. OUTPUT - The 25 kW PDP has one 60-amp, 4-pole, 5-wire, output connector, one 15-amp (NEMA 5-15R), and four 20-amp (NEMA L5-20R) receptacles. The output connector and receptacles are protected by appropriately sized circuit breakers. The 60-amp output connector is labeled J2 on the enclosure. The 15amp receptacle is labeled J3 on the enclosure. The 20-amp receptacles are labeled J4 through J7 on the enclosure. CIRCUIT BREAKERS- The circuit breakers are thermal magnetic type. The 3-phase circuit breakers are three pole, molded-case, common trip with a single operating toggle. The 1-phase circuit breakers are single pole, molded case with a single operating toggle. The operating mechanism for all circuit breakers is over center, trip free operation, providing quick-make and quick-break operation. When the circuit breaker is tripped, the operating toggle takes a position between ON and OFF. All 1-phase circuit breakers are GFCI rated and provide a PUSH TO TEST function. For more information, contact Mazen Badr, Vice President and General Manager of Power Systems at PD Systems, Inc. Email: mbadr@pd-sys.net l Phone: 703.778.3518 l Fax: 703.960.4050 l Web: www.pd-sys.net POWER DISTRIBUTION PANEL (PDP) 60KW The 60 KW PDP is designed to accept power at 120/208 VAC, 3-phase, utilizing 200 amp Power connectors. Power is then distributed at 120/208 VAC 3-phase and 120 VAC 1-phase. The PDPs are used to provide power to equipment requiring 120/208 VAC electrical power. GENERAL EQUIPMENT DATA Manufacturer PD SYSTEMS PD Systems’ Part Number PDSYS-PDP-60 NSN 6110-01-237-4637 Operating Temperature range -25° F to +125° F Storage Temperature range -65° F to +150° F Weight 38 LB Overall Length 23 IN Overall Width 18 IN Overall Height 18 IN POWER RATINGS CHARACTERISTIC Power Input Power Output VALUE 1 @ 200 Amp, 120/208 VAC, 3-Phase 4 @ 60 amp, 120/208 VAC, 3-Phase Electrical power distribution consists of circuit breakers feeding an output connector and receptacles that permit connecting cable feeders for load centers. The circuit breakers protect the cables from excessive current flow. The equipment is designed for safe operation and conforms to the NEC for outdoor use. INPUT - The 60 kW PDP has one 200-amp, 4-pole, 5-wire connector. The input connector is labeled J1 on the enclosure. The PDP is protected by an appropriately sized main circuit breaker. OUTPUT - The 60 kW PDP has four (4) @ 60 amp, 120/208 VAC, 3-Phase receptacles. The output connector and receptacles are protected by appropriately sized circuit breakers. CIRCUIT BREAKERS - The circuit breakers are thermal magnetic type. The 3-phase circuit breakers are three pole, molded-case, common trip with a single operating toggle. The 1-phase circuit breakers are single pole, molded-case, with a single operating toggle. The operating mechanism for all circuit breakers is over center, trip free operation, providing quick-make and quick-break operation. When the circuit breaker is tripped, the operating toggle takes a position between ON and OFF. All 1-phase circuit breakers are GFCI rated and provide a PUSH TO TEST function. For more information, contact Mazen Badr, Vice President and General Manager of Power Systems at PD Systems, Inc. Email: mbadr@pd-sys.net l Phone: 703.778.3518 l Fax: 703.960.4050 l Web: www.pd-sys.net PRIMARY SWITCHING CENTERS (PSC) The Primary Switching Center (PSC) provides the connection interface between multiple medium voltage inputs and multiple outputs. GENERAL EQUIPMENT DATA Manufacturer PD SYSTEMS PD Systems’ Part Number PDSYS-PSC Model Number The PSC is based upon a standard industrial underground Vista switch that has been ruggedized for mobile applications. The PSC provides a safe method of distributing medium voltage using IEEE-386 200A loadbreaks and 600A deadbreaks. The PSC allows rapid connection and disconnection of medium voltage sources and loads without requiring the use of hotsticks. PSC624-1 Operating Temperature range -25° F to +125° F Storage Temperature range -65° F to +150° F Weight 3,300 LB Overall Length 104 IN Overall Width 72 IN Overall Height 48 IN RATINGS FOR FAULT AND LOAD INTERRUPTERS CATEGORY Short Circuit Fault Interrupters RMS Symetric VALUE 16,000 Continuous 600 Load Dropping 600 Interrupting, RMS Sym. 16,000 The PSC is based on the Vista-624 switch with its six (6) switches (Ways). Four (4) of the switches are fault interrupters, two (2) are load interrupters. Each Way connection point may be configured as a 600A dead break or a 200A loadbreak. The four fault interrupters have individually programmable overcurrent protection relays. The PSC is rated for 600A distribution. The PSC is fully transportable and includes provisions to be doubleLoad Interrupters Load Dropping 600 stacked for transport, if necessary. All the necessary hardware for stacking Interrupting, RMS Sym. 16,000 two PSCs for shipment is included between both PSCs. Operation of the PSC Ways does not require access to the medium voltage connection area. The necessary load break and dead break connectors are included in each PSC as is pre-terminated cabling for connecting two PSCs together. Continuous 600 This new generation of PSC has been updated to include attached “feet” to raise the PSC off the ground and allow placing the PSC directly on the ground. This updates eliminates the requirement of dunnage to allow power cable access to the PSC. Additionally, the new PSC includes external access ports to the overcurrent relays, removing the requirement to open the cover to access the relays. For more information, contact Mazen Badr, Vice President and General Manager of Power Systems at PD Systems, Inc. Email: mbadr@pd-sys.net l Phone: 703.778.3518 l Fax: 703.960.4050 l Web: www.pd-sys.net PRIMARY SWITCHING CENTER (PSC) FOR ARMY/AIR FORCE The Primary Switching Center (PSC) provides for distribution and safe isolation of the power output of 5kV medium voltage generators. GENERAL EQUIPMENT DATA Manufacturer PD SYSTEMS PD Systems’ Part Number PDS-PSC-AR/AF NSN 6110-01-493-3391 GSA Schedule Contract No. GS-07F-0543W 60HZ Rating 15,500V AC 600A 50HZ Rating 12,000 VAC 630A Weight 1,800 LB Overall Length 96IN Overall Width 48 IN Overall Height 48 IN The main component of the Primary Switching Center (PSC) is the internal S&C Vista Switch. The Vista Switch is enclosed within a housing that provides environmental protection and operator safety. Additionally, the design of the enclosure permits two PSCs to be stacked within a shipping frame for transportation and/or storage. The PSC uses load-interrupter switches and vacuum fault interrupters for switching 600 amp IEEE-386 Deadbreak connections. Four of the six connections are protected using a microprocessor based overcurrent controller which is reconfigurable and resettable. The load-interrupter switches are three-position (closed-open-grounded), manually operated disconnect switches, each providing three-pole switching to isolate associated 600A Deadbreak connection points. The fault interrupters are the same style load interrupters (closed-open-grounded) with the addition of vacuum interrupters connected in series. A built-in voltage indicator is located under the viewing window for each disconnect. The indicator is isolated from the main 5kV voltage and uses a solar powered source to indicate the presence of voltage. The PSC features six (6) individual 3-phase disconnects. Each connection point, referred to as Ways, is rated for 600 amps and all are bussed together on one side. Each 600A connection point is an IEEE-38 Deadbreak. All power connections in or out of the PSC are thorugh either 600A Deadbreak or 200A load-break connections. For more information, contact Mazen Badr, Vice President and General Manager of Power Systems at PD Systems, Inc. Email: mbadr@pd-sys.net l Phone: 703.778.3518 l Fax: 703.960.4050 l Web: www.pd-sys.net SECONDARY DISTRIBUTION CENTER SMART MODULE (SDC-SM) The Secondary Distribution Center Smart Module (SDC-SM) connects to the individual SDC outputs. GENERAL EQUIPMENT DATA Manufacturer PD SYSTEMS PD Systems’ Part Number PDSYS-SDC-SM/16X60 Model Number SDC-SM Operating Temperature range -25° F to +125° F Storage Temperature range -65° F to +150° F Weight 600 LB (est.) Overall Length 60.00 IN Overall Width 48.00 IN Overall Height 48.00 IN (52.28 with lifting rings) CONNECTIONS PARAMETER SDC-SM Power Rating RATING/CONNECTION 150KVA Input Receptacles (60 Amp) 16 Output Receptacles(60 Amp) 16 MEP Input Connectors (200 Amp) 1 MEP Output Connectors (200 Amp) 1 The outputs are then routed through individually controlled contactors before being made available to loads. The SDC-SM in positioned next to the SDC, interconnection done with the included connector cables. The SDC-SM is designed to operate in conjunction with a standard SDC. The SDC-SM provides the SDC with the ability to control and monitor each individual output. Each SDC-SM contactor is tied into the controller for remote operations. Each contactor also has an associated multi-function transducer associated with it to display power quality for that output. The SDC-SM controller allows each output to be individually programmed with a priority setting for load shedding. The Operator’s Terminal provides the operator with total system power, warnings if an individual output is approaching its limit and if the total load is approaching maximum SDC capacity. The settings may be adjusted at any time from the on board operator’s terminal. The individual output monitoring allows operators to check individual phase balancing, quickly determine which output(s) are having loading issues, and take corrective action. The onboard controller has the ability to network with other SDC-SMs and back to an optional remote monitoring system. The SDC-SM has a transducer to monitor the connection point between the SDC-SM’s MEP input and it’s tiein back the SDC’s MEP input connector. Using the SDC-SM MEP pass through connection transducer, the SDC-SM can immediately recognize when an SDC is operating on the reduced capacity of the MEP input. Electrical power distribution consists of electronically controlled contactors sized to handle the outputs from the SDC. The contactors were chosen to be able to handle the extreme environments as an SDC. For more information, contact Mazen Badr, Vice President and General Manager of Power Systems at PD Systems, Inc. Email: mbadr@pd-sys.net l Phone: 703.778.3518 l Fax: 703.960.4050 l Web: www.pd-sys.net SECONDARY DISTRIBUTION CENTER (SDC) 150 KVA PDSYS-SDCL-150/16X60 The Secondary Distribution Center (SDC) accepts primary power and reduces the voltage for distribution. Manufacturer GENERAL EQUIPMENT DATA PD SYSTEMS PD Systems’ Part Number PDSYS-SDCL-150/16X60 Model Number 480 - 16 x 60 AMP GSA Schedule Contract No. GS-07F-0543W Operating Temperature range -25° F to +125° F Storage Temperature range -65° F to +150° F Weight 2,450 LB Overall Length 60.56 IN Overall Width 47.63 IN Overall Height 71.88 IN (76.16 with lifting rings) CONNECTIONS PARAMETER RATING/CONNECTION SDC Power Rating 150KVA Output Receptacles (60 Amp) 16 Output Convenience Receptacles 2 MEP Input Connectors (200 Amp) 1 Load Break Elbow Receptacles 9 Primary power can be either from a commercial power plant, engine driven prime power generator sets, or from another SDC. The SDC is designed to accept primary power at 480VAC, 50/60Hz from any source utilizing Loadbreak Elbows and reduce the voltage (by a 150kVA transformer) to 120/208VAC, 60 or 50Hz, 3-phase for distribution. The SDC is used to provide power for equipment requiring 120/208VAC electrical power. The SDC is also equipped with two (2) additional sets of Medium Voltage Output Loadbreak Elbow connections (bushing wells). These connections are used for parallel operations with additional SDCs, forming a common bus. The SDC can also accept secondary power from a Mission Essential Power (MEP) generator set. MEP generators feed through a circuit breaker to the secondary bus. The breaker is interlocked to prevent inadvertently feeding the secondary bus from two power sources. Electrical power distribution consists of circuit breakers feeding pin and sleeve type connectors which permit connecting the secondary cable feeders which in turn feed out to the load centers. The pin and sleeve connectors are designed to meet MIL-C-22992 or commercial equivalent specifications. SDC POWER REQUIREMENTS Input Voltage/Phase/Hertz Mission Essential Power Voltage/Phase/Hertz Output Total Power Rating Current 480 VAC/3-Phase/50/60Hz 208Y VAC/3-Phase/60Hz 208 Y / 120 VAC/3-Phase 60 or 50Hz 3-wire or 208 Y / 120 VAC/3-Phase 60 or 50Hz 4-wire 150 kVA 416 A The SDC is designed for safe operation and it conforms to the National Electric Code (NEC) for outdoor use. The phase rotation is A, B, C for the Secondary Output Circuit. See Appendix A for the schematic diagram of the electrical system for this SDC. For more information, contact Mazen Badr, Vice President and General Manager of Power Systems at PD Systems, Inc. Email: mbadr@pd-sys.net l Phone: 703.778.3518 l Fax: 703.960.4050 l Web: www.pd-sys.net SECONDARY DISTRIBUTION CENTER (SDC) 4160 VAC VERSION The Secondary Distribution Center (SDC) accepts primary power and reduces the voltage for distribution. Primary power can be either from a commercial power plant, engine driven prime power generator sets, or from another SDC. The SDC is designed to accept primary power at 4160VAC, 60Hz, or 3800VAC, 50 Hz, 3 phase from any source utilizing Loadbreak Elbows and reduce the voltage (by a 150kVA transformer) to 120/208VAC, 50/60Hz, 3-phase for distribution. The SDC is used to provide power for equipment, such as airfield lighting, shelters, hangers, remote area lighting systems and other related equipment requiring 120/208VAC electrical power. The SDC is also equipped with two (2) additional sets of Medium Voltage Output Loadbreak Elbow connections (bushing wells). These connections are used for parallel operations with additional SDCs, forming a common bus. In the event of loss of 4160 or 3800 volts primary power, the SDC can accept secondary power from an emergency power generator, called a Mission Essential Power (MEP) generator set. MEP generators feed through a circuit breaker to the secondary bus. The breaker is interlocked to prevent inadvertently feeding the secondary bus from two power sources. Input Output SDC POWER REQUIREMENTS 4160 VAC/3-Phase/60 Hz or 3800 VAC/3-Phase/50Hz or 208Y VAC/3-Phase/60 Hz 208Y/120 VAC/3-Phase 60/50Hz 3-wire or 208Y/120 VAC/3-Phase 60/50Hz 4-wire This SDC is Energy Star Compliant, using an ultra efficient transformer and convection cooling system with no parasitic loads. GENERAL EQUIPMENT DATA Manufacturer PD SYSTEMS PD Systems’ Part Number PDSYS-SDC-150 Model Number Operating Temperature range Storage Temperature range Weight Overall Length Overall Width Overall Height 6110-01-501-6980 -25° F to +125° F -65° F to +150° F 2,085 LB 60.56 IN 47.63 IN 71.88 IN (76.16 with lifting rings) CONNECTIONS RATING/CONNECTION 150 kVA; 416 Amps 16 @ 60 Amp Output Receptacles 2 @ 100 Amp Output Convenience Receptacles 2 @ 15 Amp MEP Input Connectors 1@ 200 Amp Load Break Elbow Receptacles 9 @ 200 Amp PARAMETER SDC Power Rating For more information, contact Mazen Badr, Vice President and General Manager of Power Systems at PD Systems, Inc. Email: mbadr@pd-sys.net l Phone: 703.778.3518 l Fax: 703.960.4050 l Web: www.pd-sys.net 500KW GENERATOR SET/ POWER UNIT (PU500) The PU500 is a trailer-mounted, diesel engine driven, prime power generator unit that produces 500 kilowatts, 480 volts line-to-line at 60 Hz with a 0.8 power factor, lagging. GENERAL EQUIPMENT DATA Manufacturer PD SYSTEMS PD Systems’ Part Number PDSYS-PU500 NSN TBD Operating Temperature range -25° F to +125° F Storage Temperature range -65° F to +150° F The PU500 is configured to operate alone or in parallel with other PU500 generators as prime power generators.. The PU500 is a diesel engine driven, prime power rated generator factory rated at 500KW, but environmental condition rated to produce 500 kilowatts at 480 VAC, 60 Hz with a 0.8 lagging power factor. The generator is rated to deliver 601 amps at rated output voltage. The engine is a Volvo TAD1642GA, EPA Tier II certified engine. The engine is a 16-liter, in-line, 6-cylinder, 4stroke electronic engine capable of producing 724 horsepower at 1800 RPM operating on DF-2 diesel fuel. To maintain a controlled working temperature in cylinders and combustion chambers, the engine is equipped with piston cooling. The engine is also fitted with replaceable cylinder liners and valve seats/guides to ensure maximum durability and service life of the engine. The alternator is a Marathon MagnaMaxÒ series alternator. The alternator meets NEMA MG1-22, BS500, CSA C22.2, IEC 34-1, and VDE 0530 requirements. Optimized widings provide low reactances and utilizing a 2/3 pitch, minimizes harmonic distortion and ficilitates parallel operation. Class H insulation is used along with unsaturated polyesxter varnish for optimal insualtion life and moisture protection. Output Breaker - The output breaker is a molded case circuit breaker with an electronic trip unit. The breaker is manually operated and has a shunt trip device installed for remote tripping. Generator Controller - The generator controller provides all the start/stop, monitoring and protection for the engine and generator. DC Control Power Switch - The DC Control Power switch is a maintained, 2-position toggle switch. The “Off” position removes all DC control power to the engine and controls, de-energizing the PU. The “On” position energizes the DC control power allowing the engine and generator to operate normally. Emergency Stop Pushbutton - The Emergency Stop button is a maintained position switch. It sends a stop command to the Generator Controller to turn off the engine. It also immediately sends a shunt trip command to trip the breaker. A shunt trip command places the breaker operator in the trip-free position, requiring the breaker be moved to the open position before it may be reclosed. For more information, contact Mazen Badr, Vice President and General Manager of Power Systems at PD Systems, Inc. Email: mbadr@pd-sys.net l Phone: 703.778.3518 l Fax: 703.960.4050 l Web: www.pd-sys.net REMOTE AREA LIGHTING SYSTEMS (RALS) The RALS container is designed to accept power at 120/208 VAC, 3-phase power from a secondary power source through secondary cable assemblies. GENERAL EQUIPMENT DATA Manufacturer PD SYSTEMS PD Systems’ Part Number PDSYS-RALS-09 NSN 6110-01-236-3829 GSA Schedule Contract No. GS-07F-0543W Operating Temperature range -25° F to +125° F Storage Temperature range -65° F to +150° F Weight 1,500 LB Overall Length 85 IN Overall Width 48 IN Overall Height 48 IN POWER RATNGS CHARACHTERISTIC Power Input VALUE 1 @ 60 amp, 120/208 VAC, 3-Phase 2 @ 20 amp, 120/208 VAC, 1-Phase Power Output 1 @ 15 amp, 120 VAC, 1-Phase 2 @ 15 amp, 120 VAC convenience receptacles Two loop cable assemblies, stored in bins in the RALS container, are laid out in the area to be lighted and connected to output receptacles on the RALS. The total length of each loop assembly is 750 feet. At 125 feet intervals along the loop cord, onefixture light assembly is mounted on 15 feet high support poles. One light assembly mounts directly to the RALS container. The fixtures are connected to receptacles on the loop cord assembly. A photoelectric cell on the RALS, or the manual bypass toggle switch, controls the application of power to the lights. The RALS is designed for safe operation and conforms to the NEC for outdoor use. INPUT - The 60 amp input connector is located on the front, lower right hand corner of the RALS container. The input connector is labeled J6. OUTPUT - The two 20 amp output connectors are labeled J4 and J5 and are located above the input connector. The 15 amp receptacle is labeled J1 and is located above the two 20 amp output connectors. The two 15 amp convenience receptacles are labeled J2 and J3 and are located above the 20 amp receptacle. CIRCUIT BREAKERS - The circuit breakers are thermal magnetic type. The single-phase breakers are single pole molded-case, with a single operating toggle. The operating mechanism for all circuit breakers is over center, trip free operation, providing quick-make, and quick-break operation. When the circuit breaker is tripped, the operating toggles takes a position between ON and OFF. The circuit breaker for the convenience outlets is GFCI rated. For more information, contact Mazen Badr, Vice President and General Manager of Power Systems at PD Systems, Inc. Email: mbadr@pd-sys.net l Phone: 703.778.3518 l Fax: 703.960.4050 l Web: www.pd-sys.net WORLDWIDE RUGGEDIZED POWER SUPPLY (WRPS) PD Systems offers a portable 1800W general purpose power supply for the military. The Worldwide Ruggedized Power Supply (WRPS) is suited to serve our military in extreme environments. The power solution is ruggedized for outdoor use, including a robust waterproof housing. The superior reliability of WRPS makes it an ideal DC power source for use in shelters, armored vehicles, avionics, naval and open air applications. Global Parts Distribution and Support System Operational Conditions MIL-STD-810D, Method 502.2 Low Temperature MIL-STD-810D, Method 501.2 High Temperature Vibration MIL-STD-810D, Method 514.3 Mechanical Shock MIL-STD-810D, Method 516.3 Humidity 95% RH at +50 Degrees Celcius For more information, contact Mazen Badr, Vice President and General Manager of Power Systems at PD Systems, Inc. Email: mbadr@pd-sys.net l Phone: 703.778.3518 l Fax: 703.960.4050 l Web: www.pd-sys.net GROUND SUPPORT EQUIPMENT PD Systems offers a wide range of Ground Support Equipment for Commercial and Military applications. Pre-Conditioned Air Pre-Conditioned Air Unit - Central Air-Handler Units Pre-Conditioned Air Unit - 30, 60, and 90 Ton Diesel Air Conditioners Pre-Conditioned Air Unit - 15-20 Ton Diesel Air Conditioners Pre-Conditioned Air Unit - Ground Support PC Air DC Power Supplies DC Power Supplies—28 FDC Caster Mounted Frequency Converters Frequency Converters - Gate Box/Line Drop Compensator Frequency Converters - Line Drop Compensators Frequency Converters - 75 KVA - 180 KVA 400 Hz Frequency Converters - 30, 45 & 60 KVA 400 Hz Frequency Converters - Point-Of-Use System Frequency Converters - 312 KVA Central Power System Frequency Converters - 50, 60, 400 Hz Vertical Systems Combination Units Frequency Converters - 30, 45 & 60 KVA AC/DC Combination Unit Pre-Conditioned Air Unit - External APU Diesel Ground Power Units Diesel Ground Power Units - 28 VDC Diesel GPU Diesel Ground Power Units - 180 KVA Diesel 400 Hz GPU Diesel Ground Power Units - 90-120 Diesel 400 Hz GPU Diesel Ground Power Units - 60 KVA Diesel 400 Hz GPU For more information, contact Mazen Badr, Vice President and General Manager of Power Systems at PD Systems, Inc. Email: mbadr@pd-sys.net l Phone: 703.778.3518 l Fax: 703.960.4050 l Web: www.pd-sys.net MOBILE LOAD BANK (MLB) PD Systems offers load bank solutions that meet or exceed all Mission Capability requirements and has a significantly low Mission Capability risk rating. PD Systems Load Banks meet the transportability requirements without shoring on C-17 aircraft. PD Systems offers 1.0MW Trailer Mounted Load Banks, 2.5MW Trailer Mounted Load Banks, and 2.5MW Skid Based Mounted Load Banks. TRAINING PD Systems can support your training requirements. We have successfully conducted Field Training, Mobile Training Teams, New Equipment Training, and Classroom/ Platform instruction on Power Solutions equipment. We can provide assistance in equipment selection, set-up, operation and maintenance. For more information, contact Mazen Badr, Vice President and General Manager of Power Systems at PD Systems, Inc. Email: mbadr@pd-sys.net l Phone: 703.778.3518 l Fax: 703.960.4050 l Web: www.pd-sys.net