VACUUM GAUGE MEASUREMENT & CONTROL SYSTEM

W W W . M K S I N S T . C O M

Pressure Measurement

& Control

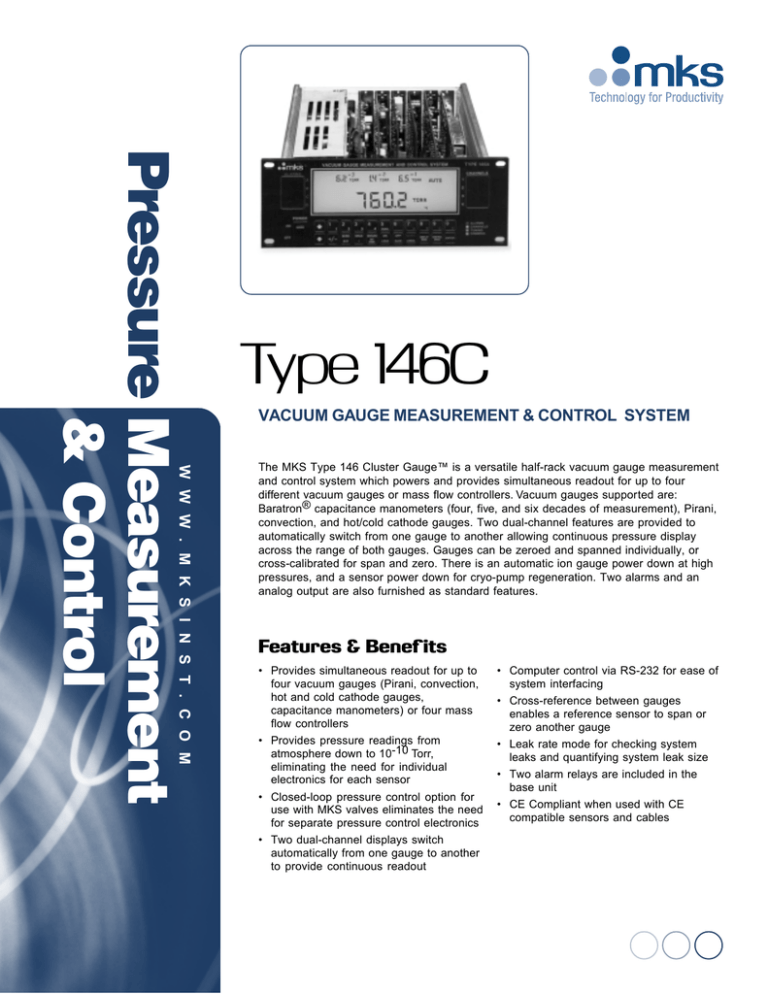

Type 146C

The MKS Type 146 Cluster Gauge™ is a versatile half-rack vacuum gauge measurement

and control system which powers and provides simultaneous readout for up to four

different vacuum gauges or mass flow controllers. Vacuum gauges supported are:

Baratron® capacitance manometers (four, five, and six decades of measurement), Pirani,

convection, and hot/cold cathode gauges. Two dual-channel features are provided to

automatically switch from one gauge to another allowing continuous pressure display

across the range of both gauges. Gauges can be zeroed and spanned individually, or

cross-calibrated for span and zero. There is an automatic ion gauge power down at high

pressures, and a sensor power down for cryo-pump regeneration. Two alarms and an

analog output are also furnished as standard features.

Features & Benefits

• Provides simultaneous readout for up to

four vacuum gauges (Pirani, convection,

hot and cold cathode gauges,

capacitance manometers) or four mass

flow controllers

• Computer control via RS-232 for ease of

system interfacing

• Cross-reference between gauges

enables a reference sensor to span or

zero another gauge

• Provides pressure readings from

atmosphere down to 10-10 Torr,

eliminating the need for individual

electronics for each sensor

• Leak rate mode for checking system

leaks and quantifying system leak size

• Closed-loop pressure control option for

use with MKS valves eliminates the need

for separate pressure control electronics

• Two dual-channel displays switch

automatically from one gauge to another

to provide continuous readout

• Two alarm relays are included in the

base unit

• CE Compliant when used with CE

compatible sensors and cables

Additional two alarm relays and two analog outputs are

available with an optional auxiliary output board. The

optional alarm relays can be configured as normally

actuated or de-actuated, and can be assigned to any of

the four sensor channels. The optional analog outputs

can be programmed as linearly scaled, logarithmically

scaled, or as set points, and, like the relays, can be

assigned to any of the four sensor channels.

Commands are activated through the front panel or via an

RS-232C interface, and all entry parameters are stored in

nonvolatile memory in case of power loss. A "displayless"

version of the Type 146 is also available as an option.

The 146 has the versatility to be re-configured as your

needs change. With the reassignment of channels and

the addition of cards, the Type 146 affords the flexibility

needed for future upgrades.

A leak rate mode is provided to measure the pressure

change over a user-defined time period, between an

initial pressure and a current pressure reading.

With the installation of a valve drive card, fast and

accurate closed-loop digital PID pressure control is

obtained with an MKS gas proportioning valve or

exhaust throttle valve. Alternately, upstream pressure

control can be accomplished with a mass flow controller

and an MFC card operating in ratio mode.

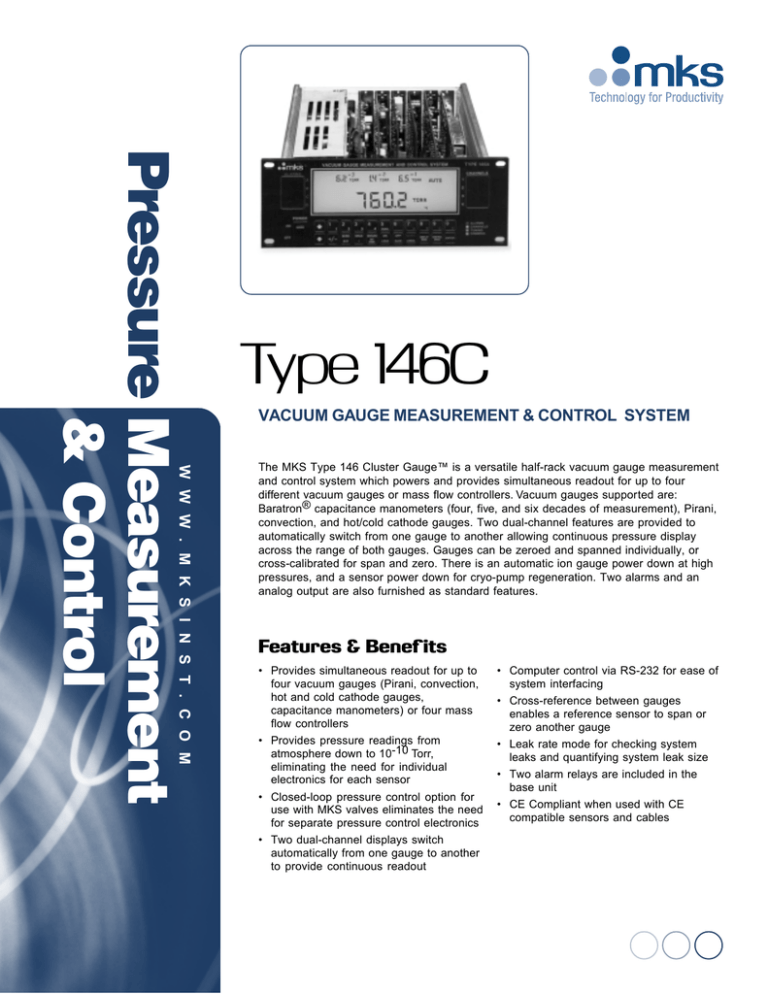

Channel 1 Display

Channel 2 Display

Channel 3 Display

Alarms

Trend Indicator

Main Display/Channel 4 Display

Type 146 Full LCD Display—

Upon power up, the Type 146 proceeds with its normal initialization and

provides a full LCD test display in the front panel window, as shown

above. When initialization is complete, the 146 defaults to Normal Mode

operation.

Pressure Control

and

Diagnostic Information

Specifications

Display

Backlit LCD, one channel with 4½ place readout plus exponent and three channels with 2½

place readout plus exponent

Optional displayless version

Compatible Sensors/Transducers*

MKS Baratron® Types 120, 122, 124, 127, 128, 220, 221, 223, 622, 623, 624, 625,

626, 627, 628, 722, or any capacitance manometer providing 0 to 10 VDC output

MKS' Vacuum Products Group Pirani sensors

MKS' Vacuum Products Group and Granville-Phillips convection/Pirani sensors

MKS' Vacuum Products Group cold cathode ionization sensors

Hot cathode ionization sensors (nude and glass envelope Bayard-Alpert types)

MKS Mass-Flo® mass flow controller Types 1179, 1559, 1679, or any MFC requiring

±15 VDC power and 0 to 5 VDC set point

Pressure Measurement Range

1000 Torr to 10-10 Torr (Dependent upon sensor type.)

Outputs

Digital

Analog

Standard

Optional

One 0 to 10 VDC on any channel; linear or log; may be assigned to dual channel

Two additional 0 to 10 VDC on any channel; linear or log

Relays

Standard

Optional

Two alarm relays (1 Amp @ 30 VDC) on any channel

Two additional alarm relays (2 Amps @ 120 VAC) on any channel

Output Power

±15 VDC @ 2 Amps (max.)

Input Power

90 to 135 VAC or 200 to 270 VAC, 50/60 Hz, user-selectable

Optional Closed-Loop

Pressure Control

PID pressure control via either upstream using an MKS Type 148, 154, or 248

Proportioning Valve, or downstream using an MKS Type 153 Exhaust Throttle Valve in

sizes from 20 mm to 100 mm

CE Mark Compliance

Certain configurations are compliant to EMC Directive 89/336/EEC (when used with an

overall metal braided shielded cable properly grounded at both ends) and the Low Voltage

Directive 72/23/EEC. Consult Applications Engineering at 800-227-8766 for configurations

which are Fully CE Compliant.

Size

Half-rack cabinet: 9.45" W × 3.47" H × 12.59" D (240.0 mm × 88.1 mm × 319.8 mm)

RS-232C

*Note: For more information on the MKS products listed above, contact Applications Engineering at (800) 227-8766 for a product data sheet, or

download literature from the MKS web site at http://www.mksinst.com.

Ordering Information

Ordering Code Example: 146CAAAOM1

Type 146C Cluster Gauge Vacuum Gauge Measurement & Control System

Code

Type Number

146C

Channel and Function Cards (choice of up to 5 cards)

Channel:

Capacitance Manometer

A

Dual Pirani/Convecton Gauge

B

Cold Cathode Gauge

C

Hot Cathode Gauge

D

Dual Thermocouple Gauge

E

Mass Flow Controller

F

Function:

Control (occupies slot 5 only)

M

Optional Outputs (2 analog and 2 relays)

N

No Card (card slot covered)

O

8.00

(203.2)

Display

Standard: LCD readout

Optional: No display

1

2

Configuration

146C

AAAOM

1

Notes:

0.50

(12.7)

12.09 (307.1)

3.38

(85.7)

3.47

(88.1)

9.45 (240.0)

8.80 (223.5)

TYPE 146

VACUUM GAUGE MEASUREMENT AND CONTROL SYSTEM

ALARMS

CHANNELS

A

1

B

2

C

3

4

D

POWER

ON

OFF

1

2

1

+/-

3

4

2

3

ZERO

SPAN

EXP

5

4

DEGAS

SET

POINT

6

7

8

9

A

DUAL

ON

OFF

QUIET

LEAD

GAIN

CANCEL

B

0

C

DISPLAY

MODE

CONTROL

MODE

ALARMS

CHANNELS

TUNING

TUNING

D

ENTER

8.25 (209.6)

2.

All unused card slots must be specified as Code 0 (No Card) within the ordering code.

3.

There may be up to four measurement channels per instrument.

4.

There can be only one control card per instrument.

5.

There can be only one optional output card per instrument.

6.

There can be only one hot cathode card per instrument.

7.

Channel cards should be installed in lower number slots; function cards should be installed

in higher number slots. The ordering code establishes the order in which the cards will be

installed.

8.

For CE compliance, use CE compliant shielded cables and sensors. Glass tube hot

cathode gauges cannot be made CE compliant.

115V

9

6

5

Channel numbers are determined by sequence of channel card slots (For example, a

single channel card in slot 1 becomes channel 1; if a dual channel card is added to slot 2,

it becomes both channels 2 and 3. Dual channel cards may be changed to a single

channel by moving a jumper.)

0.38 (9.7)

4 PLACES

RS232

1

0.25 (6.4)

4 PLACES

1.

230V .63ASB

115V 1.25ASB

FUSES

13

1

14

25

Dimensional Drawing —

Note: Unless otherwise specified,

dimensions are nominal values in inches

(mm referenced).

Global Headquarters

90 Industrial Way

Wilmington, MA 01887-4610

Tel: 978.284.4000

Tel: 800.227.8766 within U.S. only

Web: www.mksinst.com

Bulletin 146C-6/04

© 2004 MKS Instruments, Inc.

All rights reserved.

Specifications are subject to change without notice.

Baratron® and Mass-Flo® are registered trademarks of MKS Instruments, Inc., Wilmington, MA.

Cluster Gauge™ is a trademark of MKS Instruments, Inc., Wilmington, MA.